Leveraging Digital Technologies for Carbon Footprint Tracking in Perennial Cultivations: A Case Study of Walnut Orchard Establishment in Central Greece

Abstract

:1. Introduction

2. Materials and Methods

2.1. Emission Estimation

- Scope 1: All direct sources;

- Scope 2: Consumption of purchased heat, steam, and electricity (indirect source);

- Scope 3: All other indirect sources;

- Biogenic carbon: Sources related to land use and soil management.

| Emission Source | Scope | Mechanical/Non-mechanical | Emission Factor Source |

|---|---|---|---|

| Fuel | Scope 1 | Mechanical | [24] |

| Fertilizer use (direct and indirect) | Scope 1 | Non-mechanical | [20] |

| Crop residue management | Scope 1 | Non-mechanical | [20] |

| Land use change | Scope 1 | Non-mechanical | [20] |

| Irrigation energy | Scope 2 | - | [24] |

| Lubricant production | Scope 3 | - | [25] |

| Tractor manufacturing | Scope 3 | - | [26] |

| Implement manufacturing | Scope 3 | - | [25] |

| Tractor maintenance | Scope 3 | - | [26] |

| Implement maintenance | Scope 3 | - | [26] |

| Tractor housing | Scope 3 | - | [27] |

| Implement housing | Scope 3 | - | [27] |

| Fertilizer production | Scope 3 | - | [25] |

| Plant protection substance production | Scope 3 | - | [25] |

| Seed production | Scope 3 | - | [25] |

| Seedling production | Scope 3 | - | [25] |

| Irrigation system construction | Scope 3 | - | [28] |

| Soil management and land use change | Biogenic carbon | Non-mechanical | [20] |

| Soil organic carbon mineralization | Biogenic carbon | Non-mechanical | [20] |

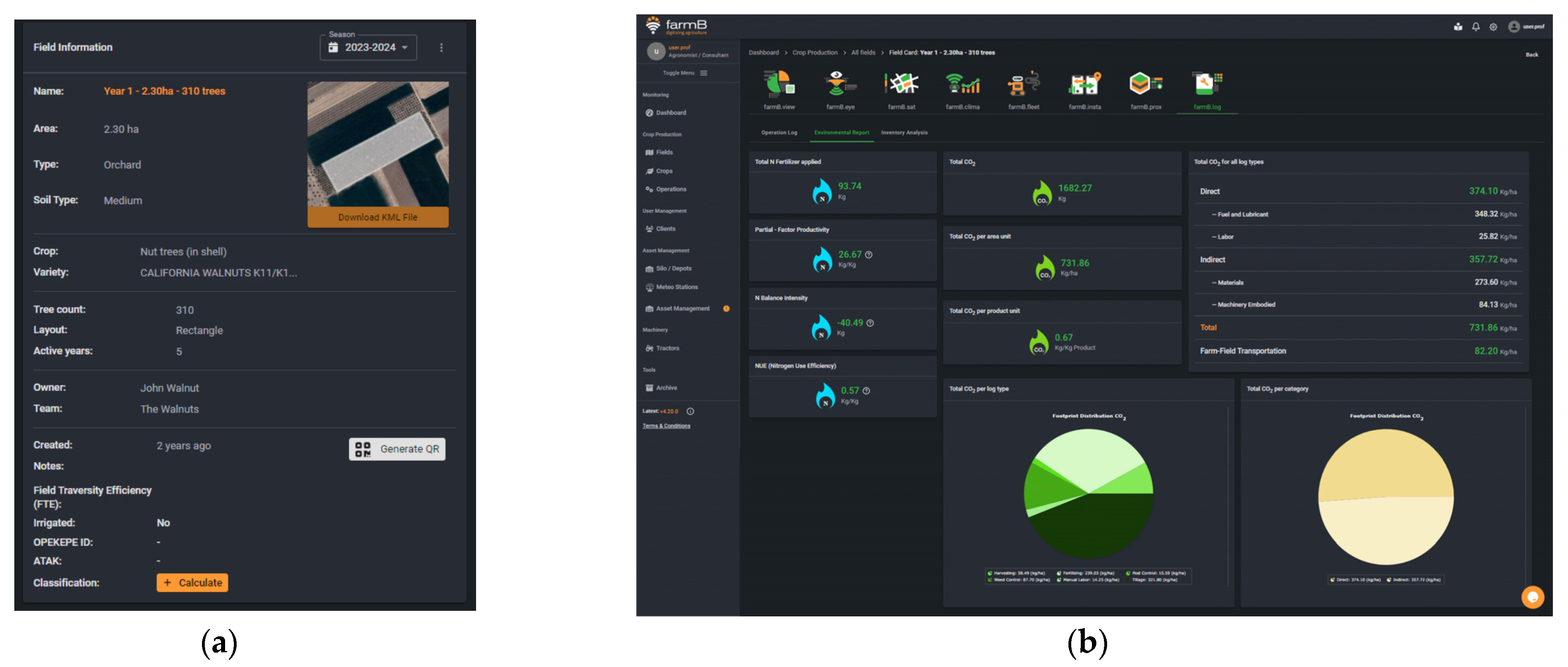

2.2. Data Collection

3. Case Study Description

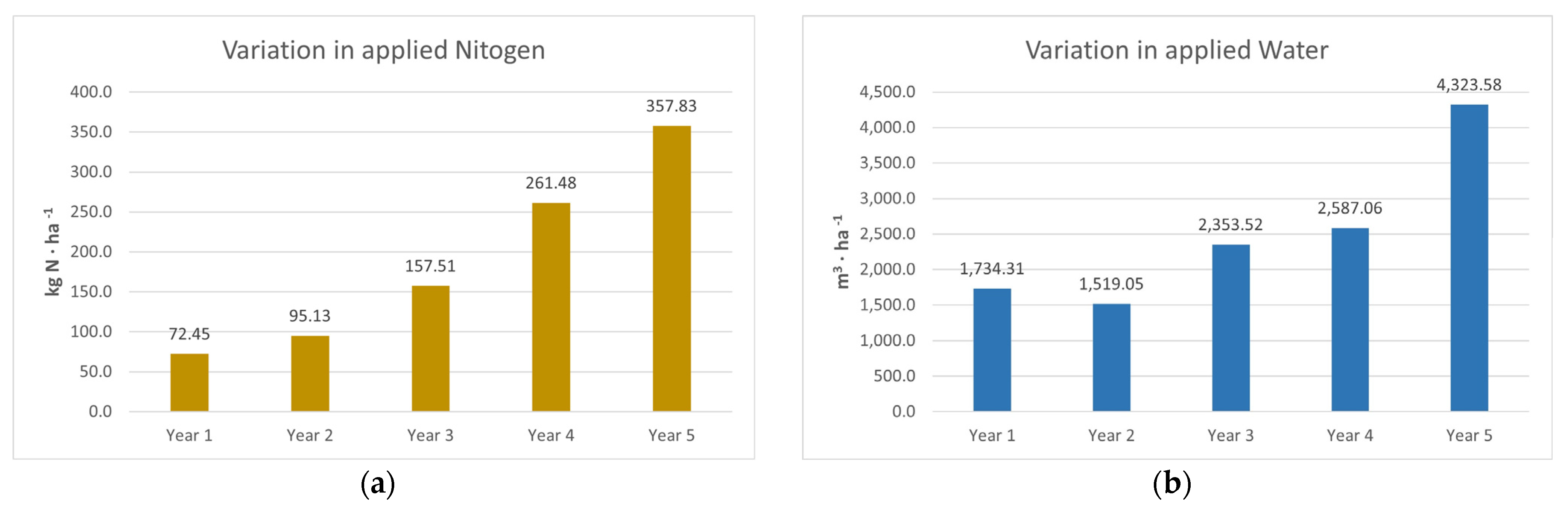

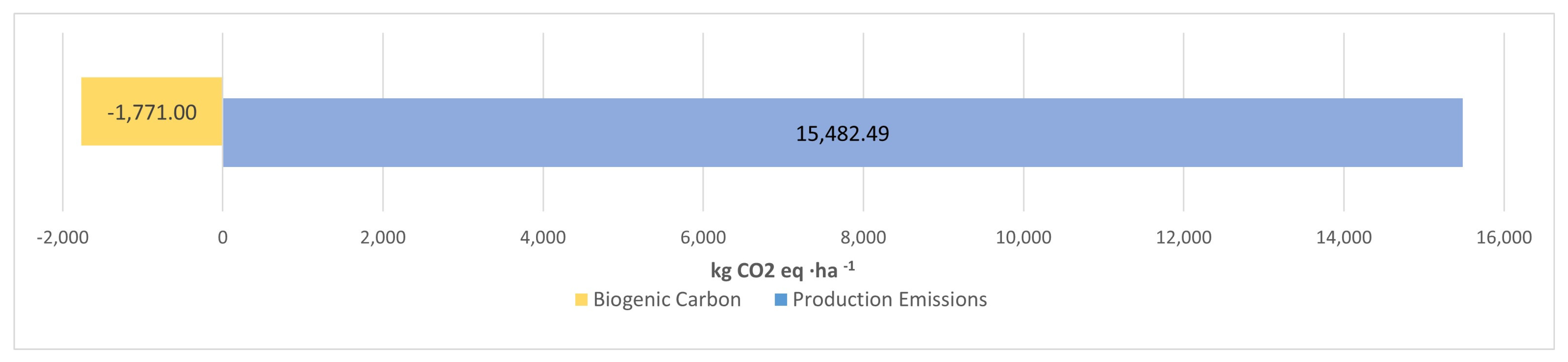

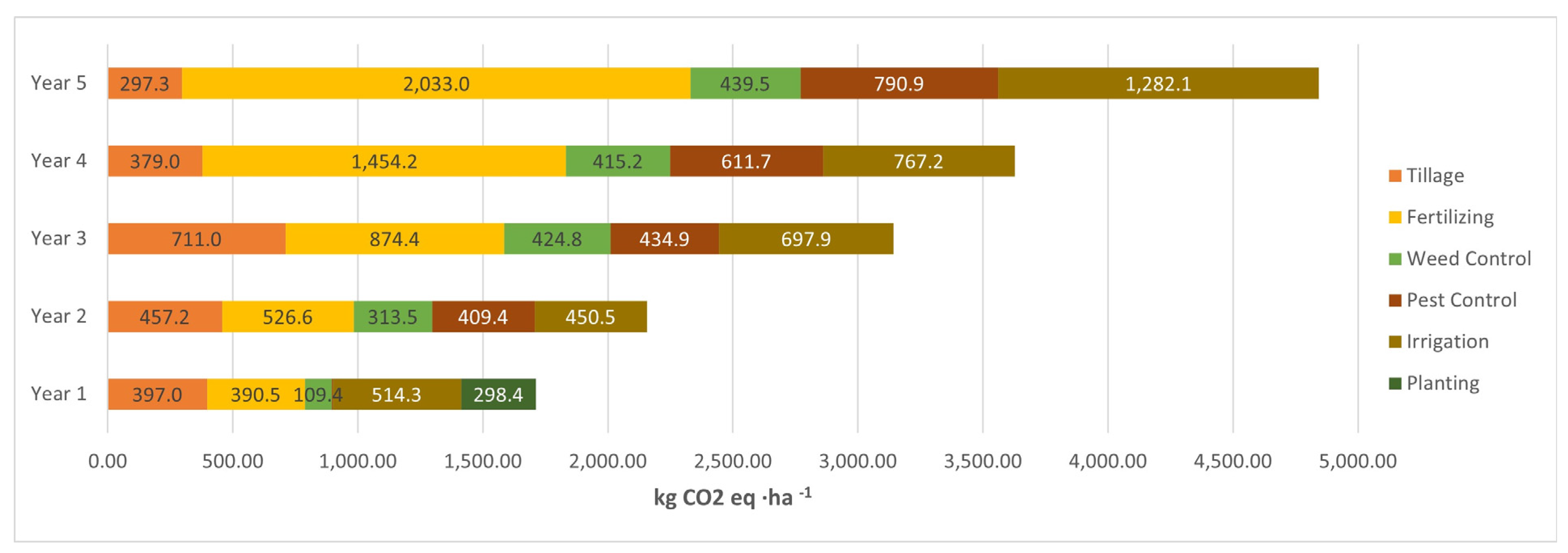

4. Results

4.1. Total Emissions

4.2. Emissions Per Year and Agricultural Tasks

4.3. Tool Usability and Lessons Learned

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kyriakarakos, G.; Petropoulos, T.; Marinoudi, V.; Berruto, R.; Bochtis, D. Carbon Farming: Bridging Technology Development with Policy Goals. Sustainability 2024, 16, 1903. [Google Scholar] [CrossRef]

- Mukhamedova, K.R.; Cherepkova, N.P.; Korotkov, A.V.; Dagasheva, Z.B.; Tvaronavičienė, M. Digitalisation of Agricultural Production for Precision Farming: A Case Study. Sustainability 2022, 14, 14802. [Google Scholar] [CrossRef]

- Papadopoulos, G.; Arduini, S.; Uyar, H.; Psiroukis, V.; Kasimati, A.; Fountas, S. Economic and Environmental Benefits of Digital Agricultural Technologies in Crop Production: A Review. Smart Agric. Technol. 2024, 8, 100441. [Google Scholar] [CrossRef]

- Gabriel, A.; Gandorfer, M. Adoption of Digital Technologies in Agriculture—An Inventory in a European Small-Scale Farming Region. Precis. Agric. 2023, 24, 68–91. [Google Scholar] [CrossRef]

- Cool Farm Tool. Available online: https://coolfarmtool.org (accessed on 17 September 2024).

- The Ex-Act Tool. Available online: https://www.fao.org/in-action/epic/ex-act-tool/suite-of-tools/ex-act/en/ (accessed on 17 September 2024).

- The Carbon Benefits Tool. Available online: https://cbp.nrel.colostate.edu/ (accessed on 17 September 2024).

- Brown, R.M.; Dillon, C.R.; Schieffer, J.; Shockley, J.M. The Carbon Footprint and Economic Impact of Precision Agriculture Technology on a Corn and Soybean Farm. J. Environ. Econ. Policy 2016, 5, 335–348. [Google Scholar] [CrossRef]

- Lampridi, M.G.; Sørensen, C.G.; Bochtis, D.D. Agricultural Sustainability: A Review of Concepts and Methods. Sustainability 2019, 11, 5120. [Google Scholar] [CrossRef]

- Popa, D.C.; Laurent, Y.; Popa, R.A.; Pasat, A.; Bălănescu, M.; Svertoka, E.; Pogurschi, E.N.; Vidu, L.; Marin, M.P. A Platform for GHG Emissions Management in Mixed Farms. Agriculture 2024, 14, 78. [Google Scholar] [CrossRef]

- Carlson, B.R.; Carpenter-Boggs, L.A.; Higgins, S.S.; Nelson, R.; Stöckle, C.O.; Weddell, J. Development of a Web Application for Estimating Carbon Footprints of Organic Farms. Comput. Electron. Agric. 2017, 142, 211–223. [Google Scholar] [CrossRef]

- Lal, R. Soil Carbon Sequestration Impacts on Global Climate Change and Food Security. Science 2004, 304, 1623–1627. [Google Scholar] [CrossRef]

- Laganière, J.; Angers, D.A.; Paré, D. Carbon Accumulation in Agricultural Soils after Afforestation: A Meta-Analysis. Glob. Chang. Biol. 2010, 16, 439–453. [Google Scholar] [CrossRef]

- Glover, J.D.; Reganold, J.P.; Bell, L.W.; Borevitz, J.; Brummer, E.C.; Buckler, E.S.; Cox, C.M.; Cox, T.S.; Crews, T.E.; Culman, S.W.; et al. Increased Food and Ecosystem Security via Perennial Grains. Science 2010, 328, 1638–1639. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.Y.; Xu, Y.; Xiang, K.; Wang, X.L. Review of Walnut Breeding Research at the Shandong Institute of Pomology. Acta Hortic. 2014, 1050, 55–60. [Google Scholar] [CrossRef]

- Chettri, V.; Ghosh, C. Tea Gardens, A Potential Carbon-Sink for Climate Change Mitigation. Curr. Agric. Res. J. 2024, 11, 695–704. [Google Scholar] [CrossRef]

- World Resources Institute and World Business Council for Sustainable Development. GHG Protocol Agricultural Guidance: Interpreting the Corporate Accounting and Reporting Standard for the Agricultural Sector; World Resources Institute: Washington, DC, USA, 2014; pp. 1–150. Available online: https://ghgprotocol.org (accessed on 10 October 2023).

- ASABE. ASAE D497.5 FEB 2006 Agricultural Machinery Management Data; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- Lampridi, M.; Kateris, D.; Sørensen, C.G.; Bochtis, D. Energy Footprint of Mechanized Agricultural Operations. Energies 2020, 13, 769. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- IPCC. IPCC 2021; IPCC: Geneva, Switzerland, 2021. [Google Scholar]

- Calvo Buendia, E.; Tanabe, K.; Kranjc, A.; Baasansuren, J.; Fukuda, M.; S., N.; Osako, A.; Pyrozhenko, Y.; Shermanau, P.; Federici, S. 2019 Refinement to the 2006 IPCC Guidlines for National Greenhouse Gas Inventories; Volume 2: Energy. Chapter 2: Stationary Combustion; 2019 Refinement to 2006 IPCC Guidel. Natl. Greenh. Gas Invent; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Handa, D.; Frazier, R.S.; Taghvaeian, S.; Warren, J.G. The Efficiencies, Environmental Impacts and Economics of Energy Consumption for Groundwater-Based Irrigation in Oklahoma. Agriculture 2019, 9, 27. [Google Scholar] [CrossRef]

- Ministry of Environment and Energy. National Inventory Report of Greece For Greenhouse and Other Gases for the Years 1990–2022; Ministry of Environment and Energy: Athens, Greece, 2024. [Google Scholar]

- Saunders, C.; Barber, A.; Taylor, G. Food Miles—Comparative Energy/Emissions Performance of New Zealand’s Agriculture Industry; Agribusiness & Economics Research Unit, Lincoln University: Canterbury, New Zealand, 2006; ISBN 0909042713. [Google Scholar]

- Mantoam, E.J.; Romanelli, T.L.; Gimenez, L.M. Energy Demand and Greenhouse Gases Emissions in the Life Cycle of Tractors. Biosyst. Eng. 2016, 151, 158–170. [Google Scholar] [CrossRef]

- Wells, C. Total Energy Indicators of Agricultural Sustainability: Dairy Farming Case Study; MAF: Wellington, New Zealand, 2001. [Google Scholar]

- Alsabri, A.; Al-Ghamdi, S.G. Carbon Footprint and Embodied Energy of PVC, PE, and PP Piping: Perspective on Environmental Performance. Energy Rep. 2020, 6, 364–370. [Google Scholar] [CrossRef]

- Lee, J.; Cho, H.J.; Choi, B.; Sung, J.; Lee, S.; Shin, M. Life Cycle Assessment of Tractors. Int. J. Life Cycle Assess. 2000, 5, 205–208. [Google Scholar] [CrossRef]

- Aguilera, E.; Guzmán, G.I.; Infante-amate, J.; García-ruiz, R.; Herrera, A.; Villa, I.; Soto, D.; Torremocha, E.; Carranza, G.; de Molina, M.G. Embodied Energy in Agricultural Inputs. Incorporating a Historical Perspective. Available online: https://econpapers.repec.org/paper/sehwpaper/1507.htm (accessed on 10 June 2022).

- Audsley, E.; Stacey, K.; Parsons, D.J.; Williams, A.G. Estimation of the Greenhouse Gas Emissions from Agricultural Pesticide Manufacture and Use. Available online: https://dspace.lib.cranfield.ac.uk/bitstream/handle/1826/3913/Estimation_of_the_greenhouse_gas_emissions_from_agricultural_pesticide_manufacture_and_use-2009.pdf;jsessionid=DC4D51F03A8C73E065940B464D68BDBD?sequence=1 (accessed on 5 December 2019).

- Mantoam, E.J.; Mekonnen, M.M.; Romanelli, T.L. Energy, water and material footprints of agricultural machinery industry. Agric. Eng. Int. CIGR J. 2018, 20, 132–140. [Google Scholar]

- Kitani, O. CIGR Handbook of Agricultural Engineering, Volume 5: Energy and Biomass Engineering. Am. Soc. Agric. Eng. 1999, 6–11. [Google Scholar]

- Walnut Cultivation with California Varieties. Available online: https://blog.farmacon.gr/katigories/texniki-arthrografia/pollaplasiastiko-yliko/item/800-i-kalliergeia-tis-karydias-me-poikilies-kalifornias (accessed on 17 September 2024).

- Lampridi, M.; Kougioumtzidis, G.; Tousi, M.A.; Kalognomou, E.-A.; Bochtis, D. Towards the Sustainability Assessment of Walnut Production in Greece. In Proceedings of the International Conference on Green Supply Chain-GSC’ 2018, Thessaloniki, Greece, 2–4 July 2018. [Google Scholar]

- Wikifarmer. Planting Walnut Trees. Available online: https://wikifarmer.com/planting-walnut-trees/ (accessed on 15 December 2023).

- Eren, O.; Baran, M.F.; Gokdogan, O. Determination of Greenhouse Gas Emissions (GHG) in the Production of Different Fruits in Turkey. Fresenius Environ. Bull. 2019, 28, 464–472. [Google Scholar]

- Marvinney, E.; Kendall, A.; Brodt, S. A Comparative Assessment of Greenhouse Gas Emissions in California Almond, Pistachio, and Walnut Production. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, CA, USA, 8–10 October 2014; Volume 1, p. 11. [Google Scholar]

- Proietti, P.; Sdringola, P.; Brunori, A.; Ilarioni, L.; Nasini, L.; Regni, L.; Pelleri, F.; Desideri, U.; Proietti, S. Assessment of Carbon Balance in Intensive and Extensive Tree Cultivation Systems for Oak, Olive, Poplar and Walnut Plantation. J. Clean. Prod. 2016, 112, 2613–2624. [Google Scholar] [CrossRef]

| Parameter | Unit | Parameter | Unit | Parameter | Unit |

|---|---|---|---|---|---|

| Field area | m2 | Fertilizer mass | kg·lt−1 | Irrigation water volume | m2 |

| Operation type | - | Nitrogen (N) content in fertilizer | % | Fuel type | - |

| Farm–field distance | m | Phosphorus content (Ρ) in fertilizer | % | Irrigation tube material | - |

| Farm–field transportation speed | km·h−1 | Potassium content (Κ) in fertilizer | % | Irrigation tube length | m |

| Tractor power | hp | Seed quantity | - | Pipe inner diameter | cm |

| Transmission type | - | Seedling quantity | kg | Pipe wall thickness | cm |

| Implement type | - | Plant protection substance quantity | kg·lt−1 | Irrigation duration | h |

| Operation width | m | Percentage of active substance | % | Manual labor | h |

| Operation depth | cm | Yield | kg | Residue management method | - |

| Implement mass | kg | Water pumping height | m |

| Area (ha) | Number of Trees | Farm–Field Distance (km) | |

|---|---|---|---|

| Field 1 | 2.3 | 310 | 7 |

| Field 2 | 1.7 | 289 | 6.6 |

| Field 3 | 1.26 | 466 | 7.7 |

| Field 4 | 0.91 | 123 | 8.3 |

| Field 5 | 1.31 | 177 | 6.4 |

| Field 6 | 2.04 | 276 | 6.8 |

| Field 7 | 1.54 | 208 | 2 |

| Field 8 | 0.71 | 121 | 2.5 |

| Field 9 | 1.4 | 238 | 8.5 |

| Field 10 | 3.1 | 527 | 4 |

| Field 11 | 1.75 | 298 | 10.1 |

| Field 12 | 1.73 | 640 | 7.5 |

| Field 13 | 2.96 | 1096 | 5.9 |

| Field 14 | 1.37 | 507 | 2.3 |

| Field 15 | 3.53 | 1307 | 11.1 |

| Tillage | Plant Protection | |||||||

|---|---|---|---|---|---|---|---|---|

| Year | Field Cultivator | Disk-harrow | Manual Weed Control | Weed Control | Pest Control | Planting | Fertilization (manual) | Irrigation |

| 1 | 1 | 6 | 5 | 1 | 9 | 1 | 7 | 10 |

| 2 | 3 | 6 | 6 | 3 | 8 | - | 7 | 9 |

| 3 | 3 | 10 | 6 | 4 | 8 | - | 6 | 13 |

| 4 | 4 | 6 | 4 | 4 | 11 | - | 5 | 12 |

| 5 | 4 | 5 | 7 | 4 | 12 | - | 6 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lampridi, M.; Kateris, D.; Myresiotis, C.; Berruto, R.; Fragos, V.; Kotsopoulos, T.; Bochtis, D. Leveraging Digital Technologies for Carbon Footprint Tracking in Perennial Cultivations: A Case Study of Walnut Orchard Establishment in Central Greece. Agronomy 2024, 14, 2241. https://doi.org/10.3390/agronomy14102241

Lampridi M, Kateris D, Myresiotis C, Berruto R, Fragos V, Kotsopoulos T, Bochtis D. Leveraging Digital Technologies for Carbon Footprint Tracking in Perennial Cultivations: A Case Study of Walnut Orchard Establishment in Central Greece. Agronomy. 2024; 14(10):2241. https://doi.org/10.3390/agronomy14102241

Chicago/Turabian StyleLampridi, Maria, Dimitrios Kateris, Charalampos Myresiotis, Remigio Berruto, Vassilios Fragos, Thomas Kotsopoulos, and Dionysis Bochtis. 2024. "Leveraging Digital Technologies for Carbon Footprint Tracking in Perennial Cultivations: A Case Study of Walnut Orchard Establishment in Central Greece" Agronomy 14, no. 10: 2241. https://doi.org/10.3390/agronomy14102241