Abstract

This study investigates the geometrical and mechanical properties of two cassava varieties: ‘Newly Elected No. 48’ and ‘Jin Yue HRMUS’. We analyzed various properties, including width, length, geometric diameter, thickness, compression firmness, shape ratio, surface area, shear strength, rupture force, and shear rupture force (SRF), at different moisture content (MC) levels ranging from 35.0 to 80.0% wet basis. Our findings indicate that all mechanical properties of cassava (MPC) were significantly influenced by moisture content within this range. Specifically, as moisture content decreases, the compression rupture force (CRF) increases linearly in the vertical direction, while a quadratic relationship is observed in the horizontal direction, characterized by an initial increase followed by a decrease. Additionally, a quadratic relationship was established between moisture content and firmness. In contrast, shear fracture force and strength exhibited a quadratic relationship that decreased initially and then increased with rising moisture content. Furthermore, both compression and shear fracture forces were significantly higher in the vertical loading direction compared to the horizontal direction. Notably, the ‘Jin Yue HRMUS’ variety demonstrated greater mechanical strength than the ‘Newly Elected No. 48’. These findings provide valuable insights for developing, optimizing, and evaluating cassava harvesting and processing machinery.

1. Introduction

Cassava (Manihot esculenta Crantz), or tapioca, is a shrubby plant with upright stems reaching 2–5 m. It has massive roots underneath the stems and is rich in fiber and starch [1,2]. Cassava is propagated using stems cut into 13–17 cm long seed stems. These seed stems are then planted horizontally, obliquely, or directly after trenching. Tuber stems and cassava leaves are both utilized to process over 2000 product varieties, such as starch, alcohol, and organic chemicals [3,4,5]. This versatile crop has applications in the food, medicine, and light industries [6,7]. Cassava is a significant renewable biomass energy crop and a crucial raw material for producing fuel ethanol [8]. Cassava cultivation holds practical and strategic importance in ensuring food security and addressing the energy supply–demand imbalance [9]. Cassava is predominantly grown in the Guangxi, Guangdong, and Hainan provinces in China, Yunnan, and Fujian. Cassava is mainly concentrated in Guangxi, accounting for approximately 60% of the country’s total output. China has now emerged as a significant cassava importer, with Guangxi alone importing around 5.5 million tons of fresh cassava raw materials from ASEAN countries annually, leading to a 50% dependence on foreign trade [10].

Numerous studies have focused on cassava’s chemical and nutritional compositions [11,12,13,14]; however, more research is needed on its geometrical and mechanical properties. Cassava serves as a crucial provider of vitamins, carbohydrates, and minerals and is used in diverse sectors, including food, pharmaceuticals, textiles, animal feed, and biomass energy [15,16]. Cassava is rich in mineral elements and contains calcium, iron, zinc, potassium, magnesium, and manganese in quantities comparable with many legumes, excluding soybeans. Notably, its calcium content ranges from 19 to 176 mg/100 g, while its potassium content is 271 mg/100 g, significantly surpassing that of other cereals and rhizome crops. The carotene content in fresh root tubers ranges from 0.454 to 1.069 mg/100 g, with the color intensity corresponding to carotene levels [17]. Brazilian red meat cassava varieties exhibit the highest carotene contents, followed by the yellow and white varieties [18]. Changlin’s research delved into the structural aspects of cassava seeds, investigating its seed dormancy mechanisms. The mechanical barriers or inhibitors of its seed coat have been identified as critical factors that induce seed dormancy. Changlin also proposed effective methods to break seed dormancy and determined the optimal germination temperature for cassava seeds [19].

The MPC are the basis for designing various cassava harvesting and processing machinery, conducting dynamic simulation studies, and establishing mathematical models. However, few theories and test methods exist on the MPC, both at home and abroad, and the scientific nature of the design of related harvesting and processing machinery needs to be improved. Yang Wang et al. studied the geometrical and MPC tubers and measured the bending, tensile, and shear mechanical properties of South China No. 205 cassava tubers but did not discuss the influencing factors of the MPC or their relationship [20]. Zhong studied the MPC stalks; designed relevant mechanical property test methods; and measured the compression, shear, bending force, loading direction, and diameter of the stalks [21,22]. Yan Mei studied the MPC, such as cutting and compression, and came up with the influencing factors, such as variety, cutting speed, cutting angle, and MC [23]. Dong Dong Ying designed and tested a tester for the MPC stems cut at multiple angles [24].

Although scholars have conducted some research on the MPC at the macro level, they have not considered the linkage between the mechanical and geometrical properties of cassava, and studies on the effects of a single factor are not in-depth enough; thus, further research on these parameters and influencing factors is needed. In addition, few studies have been conducted on cassava moisture content and the mechanical properties of cassava, and no studies on cassava moisture content as well as the geometrical properties of cassava have emerged. In addition, no studies have been published on the relationship between MC and the effect of the geometric and MPC. Based on this, the present study focused on measuring the variation in the geometric and mechanical properties of two cassava varieties, the traditional variety “HRMUS KIMUYU” and the new cultivar “Sinsen 48”, which has not yet been studied, at different MCs, including their three-dimensional dimensions; geometrical characteristics; surface area; and various mechanical properties such as firmness and shear strength. The objective of this study was to investigate the relationship between cassava moisture content and the geometric properties as well as the mechanical properties of cassava. The findings of this research can be utilized to design, optimize, and assess cassava harvesting and processing equipment.

2. Materials and Methods

The test materials ‘Newly elected No. 48’ (starting now, referred to as A) and ‘Jin Yue HRMUS’ (now referred to as B) were cultivated in Guilin City during the 2022 growing season. This experiment used a randomized complete block design at the Mechanical Engineering Laboratory of Guangxi Normal University. In October of the same year, cassava was harvested using mechanical equipment. After harvesting, the cassava was cleaned and dried, with uniformly sized tubers free of damage or wormholes selected as test samples. In order to guarantee that the two types of cassava have some similarity, we tested their chemical composition (starch, reducing sugar, anthocyanin, protein, dietary fiber, and vitamin C), and the results of the test were as follows: the content of starch in cassava of class A is about 688 mg/kg, the content of reduced sugar is about 36.47 mg/kg, the content of anthocyanin is about 159.41 mg/kg, the content of protein is about 8.13 g/kg, the content of dietary fiber is about 15.3 g/kg, and the content of vitamin C is about 403.6 mg/kg. The starch content in cassava of class B is about 672 mg/kg, reduced sugar content is about 36.02 mg/kg, anthocyanin content is about 177.34 mg/kg, protein content is about 8.44 g/kg, dietary fiber content is about 13.4 g/kg, and vitamin C content is about 432.7 mg/100 g (all of the above contents are homogeneous); the two types of cassava are not very different in chemical composition, and they have a certain degree of similarity.

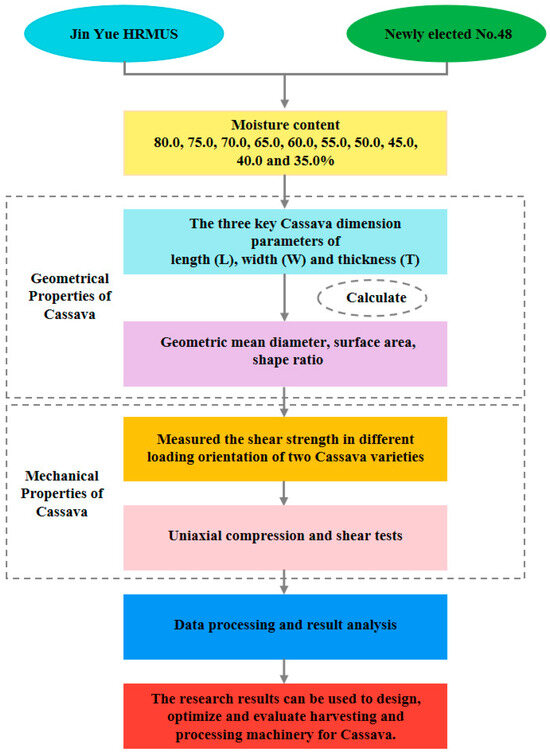

Freshly harvested cassava had an initial moisture content of about 65%. Subsequently, we dried the cassava to maintain its moisture content at ten moisture content levels, as applied to the two varieties, namely 80, 75, 70, 65, 60, 55, 50, 45, 40, and 35% (w.b.); uniaxial compression and shear tests were conducted in both loading directions, as shown in Figure 1.

Figure 1.

Methodological framework.

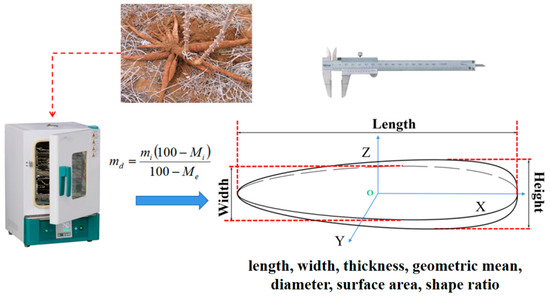

Using oven-drying for each variety at 110 ± 5 °C for twenty-four hours, the initial MC was measured. For various MC statuses, the samples were dried in a drying box at 85 °C (DHG-9051A electric thermostatic blast drying oven, Shanghai Yiheng Scientific Instrument Co., Ltd., Shanghai, China, with the relevant parameters detailed in Table 1). Weight measurements were conducted every two hours until the target MC was attained. Before each drying session, approximately 50 kg of cassava was used for the experiment, and the MC was measured using Equation (1), described by Huimin et al. [25], as illustrated in Figure 2.

where and are the initial mass and dried mass of the samples (g), respectively, and and are the required MCs (%w.b.), respectively.

Table 1.

Relevant parameters of the DHG-9051A drying box.

Figure 2.

The determination of the cassava MC and size parameters.

Three key cassava parameters, its dimension—width (W, mm), length (L, mm), and thickness (T, mm)—were assessed using a General Vernier caliper NT13-20 (Tuofeng Measuring Instrument Co., Ltd., Hangzhou, China), with an accuracy of 0.02 mm, as illustrated in Figure 2. The geometric average diameter, shape ratio, and surface area were evaluated, employing the subsequent equations:

where is the geometric average diameter (mm), is the shape ratio (%), and is the surface area (mm2).

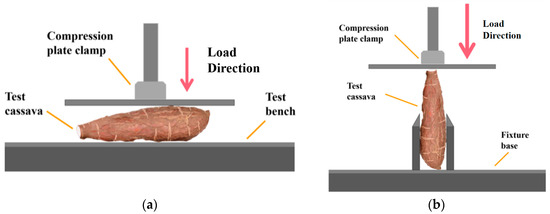

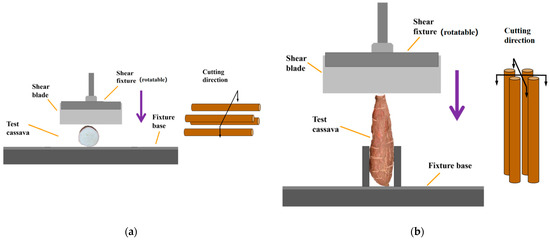

Uniaxial compression and shear assessments were conducted using a CTX texture analyzer manufactured by Brookfield Company in the New York, NY, USA, with specific parameters delineated in Table 2. The instrument boasted a mechanical sensor range extending to 1000 N, offering a precision resolution of 0.1 N. Testing protocols were applied in both vertical and horizontal orientations, positioning the specimen between two plates and subjecting it to a controlled compression and shear rate of 10 mm/min. Initial force measurements commenced at 0.5 N, with each trial meticulously repeated 20 times under ambient room conditions, as depicted in Figure 3 and Figure 4.

Table 2.

The relevant parameters of the texture analyzer.

Figure 3.

The uniaxial compression test of cassava under various loading axes: (a) the vertical orientation of cassava aligned with the loading direction; (b) the horizontal orientation of cassava aligned with the loading direction.

Figure 4.

The shear tests conducted on cassava under different loading orientations: (a) the vertical axis of cassava aligned with the loading direction; (b) the horizontal axis of cassava aligned with the loading direction.

Uniaxial compression tests were conducted to assess the compressive firmness of cassava. The upper compression plate’s diameter was 175 mm (Figure 3). Firmness was determined by dividing the compression force by the deformation value at the point of fracture.

where is the firmness (N/mm), is the compression force at the rupture point (N), and is the deformation at the rupture point (mm).

Shear tests were conducted to assess the shear strength of cassava under shear stress [26]. The upper shear plate used in the experiments had a thickness of 1 mm (Figure 4). Shear strength is defined as the ratio of the force to the area at the splitting point.

where is the shear strength (MPa), is the shear force at the fracture point (N), and is the stress area (mm2).

This study examined how varying moisture levels and two cassava varieties influence cassava’s geometric properties. It explored the impact of ten moisture levels and two stress orientations and varieties on mechanical attributes, including fracture force, fracture displacement, firmness, and shear strength. Duncan’s multiple range test was employed to compare mean parameter values. Additionally, polynomial regression analysis was conducted using MC as the independent variable and fracture force as the dependent variable. Data analysis was performed using SPSS Statistics 20 (IBM, Armonk, NY, USA), with visualization and plotting executed using Origin 8.6 (Origin Lab, Northampton, MA, USA).

3. Results and Analysis

3.1. Linkages between the Geometrical Properties and Moisture Content of Cassava

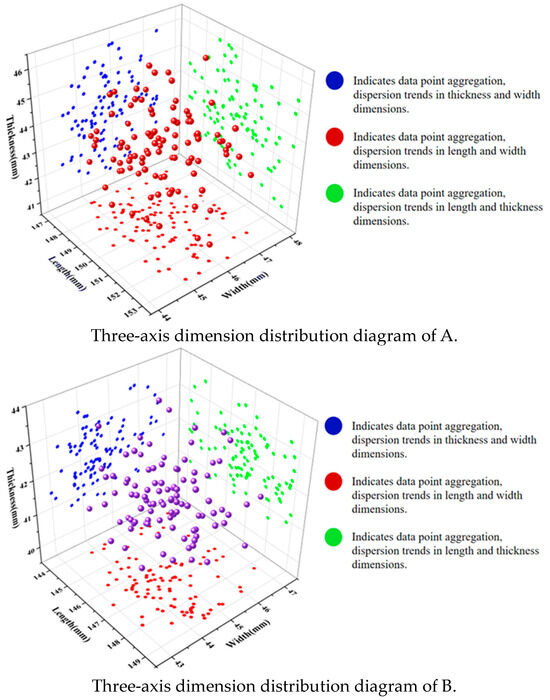

The mean values and standard deviations of the geometrical property parameters of the two cassava varieties are summarized in Table 3. A linear regression analysis (with a generic form of a + b × (MC)) is presented in Table 4 and Table 5, demonstrating that changes in its geometrical properties are related to its MC. This study found that the effect of MC on the geometrical properties of both cassava varieties was significant for length, width, thickness, geometric mean diameter, surface area, and shape ratio (p < 0.01). Additionally, the probability distribution of each size segment for the two cassava varieties is summarized in 3D scatter plots, as shown in Figure 5.

Table 3.

Cassava geometrical properties (mean ± standard deviation) determined from experiments.

Table 4.

The parameters of the linear regression analysis (a + b × (MC)) with their respective coefficients of determination (R2) and RMSEs for the geometrical properties of the ‘Newly elected No. 48’ cassava versus its dimensionless MC.

Table 5.

The parameters of the linear regression analysis (a + b × (MC)) with their respective coefficients of determination (R2) and RMSEs for the geometrical properties of the traditional ‘Jin Yue HRMUS’ cassava versus its dimensionless MC.

Figure 5.

Three-axis dimension distribution diagram.

The axial dimensions—the length (L), width (W), and thickness (T)—of cassava measured at five MCs ranging from 35 to 80% (w.b.) are detailed in Table 3. The slope of the regression equation for the axial dimensions of cassava is positive (Table 4 and Table 5). Specifically, the lengths, widths, and thicknesses of varieties A and B were reduced, with a decrease in moisture content of 2.46%, 5.49%, and 6.26% and of 2.30%, 6.91%, and 7.04%, respectively, with the most significant reduction observed in both thicknesses. A statistical analysis also indicated that the MC had a significant effect (p < 0.01) on all axial dimensions (Table 4 and Table 5). This increase may be attributed to water penetrating the intercellular space, which causes the sample to protrude. Furthermore, as MC decreased, the geometric mean diameter of the cassava decreased by 4.75% and 5.45%, respectively.

The changes in the surface area with MC are presented in Table 3, whereas Table 4 and Table 5 depict the changes in the slope of the trend lines. The surface area, which represents the shape characteristics of the material, decreased by 9.27% and 10.59%, respectively, with decreasing moisture content. The coefficient of the equation indicates a significant rate of change in the surface area with the MC.

The shape ratio, which indicates the shape characteristics of the material, decreased by 0.4% and 1.3%, respectively, with increasing MC. The regression equations depicting the relationship between the shape ratio and MC can be found in Table 4 and Table 5. The findings indicate a linear decrease in shape ratio as MC decreases. In the statistical analysis, the use of the same letters within a column indicates that the means are not significantly different at a 0.01 significance level, as determined by Duncan’s multiple range test Table 6.

Table 6.

The parameter test results of the geometrical properties.

3.2. Linkages between the Mechanical Properties and MC of Cassava

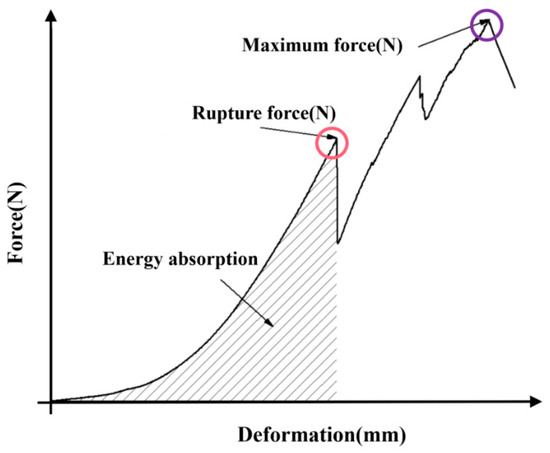

Figure 6 shows a typical cassava force–displacement curve, with the shaded portion indicating the energy absorbed during rupture. The curve initially has a parabolic shape before reaching the rupture point, after which it rapidly decreases, rises again, and finally ruptures at the maximum value. The compression rupture force (CRF), fracture point deformation, and hardness of different cassava varieties at different moisture contents were analyzed, as shown in Table 7. Both cassava varieties exhibited comparable trends: the CRF in the vertical loading direction increased as moisture content decreased. In contrast, in the horizontal direction, it initially increased with decreasing MC before subsequently decreasing. In the vertical loading direction, the CRF was higher than that in the horizontal direction. In addition, the stress area in the horizontal loading direction was larger than that in the vertical direction.

Figure 6.

Typical cassava force–displacement curve.

Table 7.

Compression characteristic results.

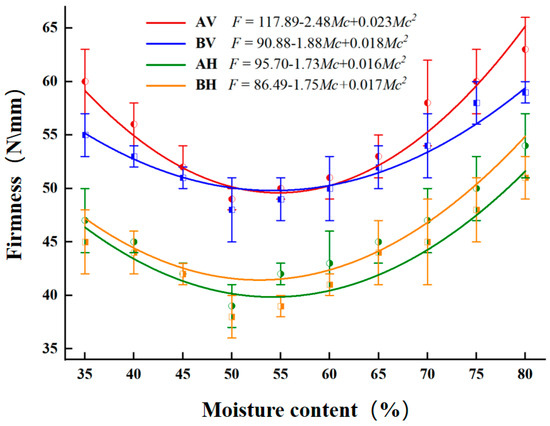

A further analysis (Table 7) revealed that the hardness of cassava decreased initially with decreasing MC and then increased with decreasing MC. In the vertical loading direction, the hardness of cassava variety A ranged between 48.68 N/mm and 63.31 N/mm, while that of variety B ranged between 47.81 N/mm and 59.19 N/mm; in the horizontal loading direction, the hardness of cassava variety A ranged between 38.55 N/mm and 54.16 N/mm, while that of variety B ranged between 37.87 N/mm and 51.17 N/mm. This study also emphasized a significant effect of loading direction on the firmness of cassava at the 1% probability level.

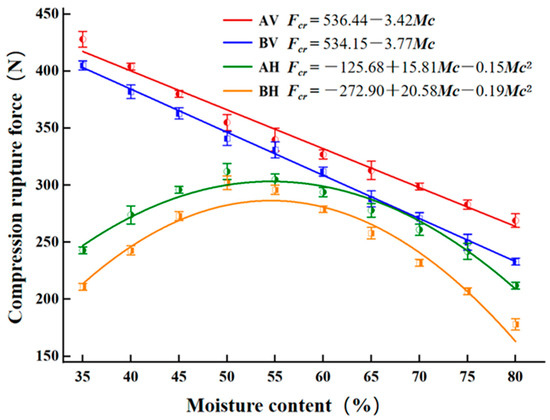

Figure 7 and Table 8 shows the CRF of the two cassava varieties at different MCs. As MC decreased, the CRF of both varieties showed a significant linear decrease in the vertical direction and a trend of increasing and then decreasing in the horizontal direction. The CRF in the vertical loading direction (mean values of 339.98 N and 317.49 N for the two varieties) was significantly higher than that in the horizontal loading direction (mean values of 271.60 N and 247.93 N for the two varieties) (p < 0.01). This difference could be attributed to the fact that the stress area in the horizontal direction was larger than that in the vertical direction and the distribution of fibers within cassava. According to the results of Duncan’s multiple range test, MC, cassava variety, and loading direction significantly impacted CRF (p < 0.01).

Figure 7.

The effect of MC on cassava compression rupture force (CRF).

Table 8.

Compressive rupture force.

Figure 8 and Table 9 shows the calculated firmness (F) values for the two cassava varieties at different MCs. The firmness values at the point of rupture of cassava decreased non-linearly with decreasing MC due to the significant increase in the deformation of cassava at a low MC. Based on the results of the Duncan’s multiple difference range test, the difference in firmness between the two varieties was significant (p < 0.05). Notably, the value of firmness in the horizontal loading direction was about 1.1 times that of the vertical loading direction, which was statistically significant (p < 0.01). In addition, the effect of MC on firmness was also statistically significant (p < 0.01).

Figure 8.

The effect of MC on the firmness (F, N/mm) of cassava.

Table 9.

Firmness analysis.

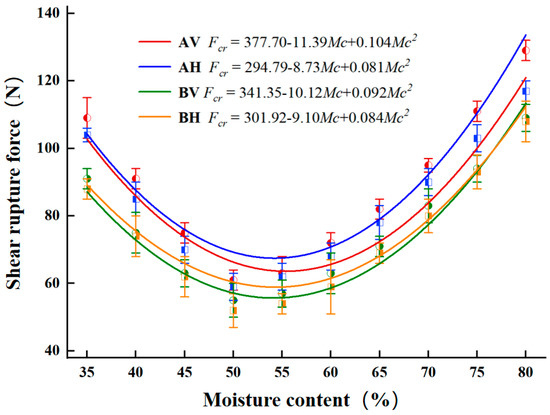

The results in Table 10 show the shear rupture force (SRF), deformation at the point of rupture, and shear strength of the various cassava varieties at different MCs. The two cassava varieties showed a similar trend, with higher shear fracture forces in the vertical loading direction than in the horizontal direction. The shear fracture forces in the vertical and horizontal directions ranged from 60.5 N to 128.56 N and from 54.56 N to 108.54 N, respectively, for variety A, and from 59.22 N to 116.58 N and from 51.91 N to 107.79 N, respectively, for variety B. The effect of loading direction on shear fracture force was observed at the 1% probability level. The effect of loading direction on shear fracture force was statistically significant at the 1% probability level. At the 1% probability level, the cassava variety’s influence on shear fracture point deformation was significant. For variety A, shear fracture point deformation ranged from 11.13 mm to 12.26 mm in the vertical loading direction and from 10.08 mm to 11.71 mm in the horizontal direction. For variety B, the corresponding values were 7.95 mm to 10.68 mm and 7.43 mm to 10.68 mm, respectively.

Table 10.

Shear property results.

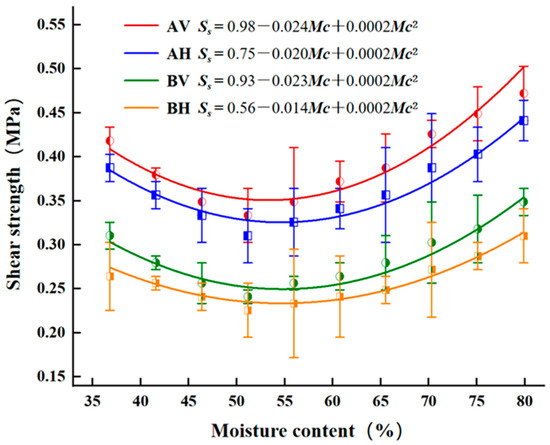

The shear strength of cassava initially decreased and then increased with decreasing MC, with a consistent trend in both loading directions for both varieties. The values of the shear strength of cassava varieties A and B ranged from 0.322 to 0.497 MPa and from 0.290 to 0.457 MPa in the vertical loading direction, respectively, and from 0.203 to 0.341 MPa and from 0.177 to 0.288 MPa in the horizontal loading direction, respectively. Duncan’s multiple range test revealed significant variations in the shear strength of cassava based on the loading direction and MC of the varieties.

Figure 9 and Table 11 shows the SRF of two cassava varieties at different MCs. The SRF for both varieties and loading directions first decreased and then increased with decreasing MC. This force transformation can be attributed to the difference in moisture content early on; with the decrease in water content, the internal fiber strength of the cassava root mass decreased, resulting in a decrease in SRF, and then, with a further decrease in MC, the volume of the experimental cassava tubers decreased rapidly, and the density of the internal fibrous tissue of the tubers increased dramatically, increasing SRF. Further studies found that the key MC that caused the change in cassava SRF transitions was between about 45% and 55%.

Figure 9.

The effect of MC on the shear rupture force (SRF) of cassava.

Table 11.

Analysis of SRF data.

Figure 10 and Table 12 shows the shear strength (Ss) of cassava at different MCs. The trend in shear strength with MC is like that of SRF, with both decreasing and then increasing with decreasing MC. In addition, shear strength was significantly higher (p < 0.01) in the vertical loading direction compared with the horizontal direction, with an overall range of 0.177 to 0.341 MPa and 0.290 to 0.497 MPa, respectively. The test results showed that the shear strength varied significantly (p < 0.05) between the different species.

Figure 10.

The effect of MC on the cassava shear strength (Ss, MPa).

Table 12.

Analysis of shear strength data.

4. Discussion

4.1. Moisture Content

In terms of moisture content, this study controlled the relative moisture content of cassava, specifically relative to the initial post-harvest moisture content of approximately 65%. This approach represents an advancement over previous cassava studies that determined moisture content based on air-drying time [23,27]. The moisture content of cassava directly influences its starch extraction efficiency; a higher moisture content enhances starch solubilization and separation during extraction, thereby increasing overall efficiency [27,28,29]. Consequently, in cassava processing, it is essential to focus on the effects of moisture content while comprehensively considering its geometric and mechanical properties. Selecting the appropriate processing stage based on these factors can significantly improve production efficiency.

4.2. Geometric Properties

The results of this study suggest that changes in cassava’s moisture content affect its geometric properties, which has not been indicated in any current research. As the moisture content decreased, parameters such as the length, width, thickness, geometric mean diameter, and surface area of cassava decreased. This was observed in the experiments as the length, width, and thickness of class A cassava decreased by 2.46%, 5.49%, and 6.26%, respectively, when the relative moisture content of cassava went from 80% to 35%. The changes in class B cassava differed from those in class A, with a reduction in the length, width, and thickness of 2.30%, 6.91%, and 7.04%, respectively. The radial change was more significant than for class A cassava, while the axial change was gentler. This also suggests that different cassava varieties may exhibit varying changes in geometric dimensions due to moisture content reduction. Further investigation revealed that the dimensional changes in cassava caused by moisture content fluctuations may be attributed to the shrinkage of cell walls and cell interstitial spaces due to water loss. When cassava loses water, the amount of water in the cells decreases, and the cell wall and interstitial space volume decreases. This shrinkage accumulates throughout the cassava tissues and eventually results in a reduction in cassava’s overall size. This finding is crucial for the transportation and processing of cassava. To avoid size reduction due to excessive water loss, appropriate moisturizing treatment should be carried out to maintain the moisture content of cassava at an optimal level [30,31], thereby improving the efficiency and quality of cassava processing.

4.3. Mechanical Properties

4.3.1. Moisture Content and Mechanical Properties of Cassava

Regarding the effect of cassava moisture content on its mechanical properties, the conclusions drawn in this study align with existing findings [20,21,22,23,32,33]. Specifically, cassava hardness, shear breaking force, and shear strength exhibit a pattern of decreasing and then increasing in response to reductions in moisture content. In contrast, the compression breaking force demonstrates an overall trend of increasing as moisture content decreases. Building on previous studies, this research investigates the functional relationship between cassava moisture content and its mechanical properties. It was found that different cassava species exhibit similar trends in mechanical properties as moisture content changes; however, the magnitude of these changes varies among species. The observed effects of moisture content on the mechanical properties of cassava can be attributed to several factors. Initially, as moisture content decreases, the hardness of cassava declines, followed by an increase. This phenomenon may occur because the initial reduction in moisture leads to a loss of elasticity in the cell walls, causing cassava to become softer and less robust overall.

As moisture content decreases, the cell walls and fibers become more compact and tightly arranged due to ongoing water evaporation. This compact structure enhances the fiber strength of cassava, resulting in an increase in hardness after reaching a certain threshold. Additionally, both shear force and shear strength exhibit a pattern of decreasing followed by increasing as moisture content declines. This behavior can be explained by the gradual evaporation of water from within the cells, which increases the gaps between cell walls and fibers. This change reduces friction between these structures, lowering shear force and strength. As moisture content decreases, the cell walls and fibers become dry and brittle, making them more susceptible to fracture under shear forces. Furthermore, as water evaporates, the connections between cell walls and fibers become tighter and stronger, increasing their shear strength. These changes reflect the complex physiological and geometrical responses of cassava to variations in moisture content.

The most immediate implication of this study is that physical damage resulting from reduced hardness in cassava can be mitigated by selecting appropriate packaging materials and methods during transportation. For instance, when cassava has a higher moisture content and lower hardness, using softer packaging materials or additional cushioning layers can help minimize collision and extrusion damage during transport. Furthermore, controlling environmental conditions during transport, such as temperature and humidity, can slow the rate of moisture loss in cassava. This helps maintain optimal hardness and shear strength, ensuring the cassava retains excellent quality upon reaching its destination. Understanding the relationship between shear breaking force, shear strength, and moisture content is critical for adjusting processing equipment parameters—such as cutting speed and cutting angle—to enhance efficiency and product quality in cassava processing. For example, when cassava has a moderate moisture content, its lower shear fracture force and shear strength allow for faster and smoother cutting.

Additionally, modifying the raw material treatment processes—such as drying and soaking—based on changes in moisture content can help control the hardness and shear characteristics of cassava, making it more suitable for subsequent processing needs. Specifically, during the drying process, managing drying temperature and time can prevent excessive hardness and shearing difficulties caused by over-drying. In designing cassava harvesting and processing machinery, considering the changing characteristics of cassava’s hardness, shear fracture force, and shear strength allows for developing more adaptable and efficient equipment. For instance, harvesting machinery could be equipped with devices that automatically adjust cutting strength based on the moisture content of cassava to minimize mechanical damage and enhance harvesting efficiency. Additionally, optimizing the material selection and structural design of equipment based on understanding changes in cassava’s mechanical properties can reduce wear and tear and the failure rate of machinery due to fluctuations in cassava hardness.

4.3.2. Direction of Force and Mechanical Properties of Cassava

This study investigated the relationship between force direction and the mechanical properties of cassava, yielding results that are generally consistent with previous studies [34,35]. The compression breaking force, hardness, shear breaking force, and shear strength of cassava exhibited significant correlations with the direction of applied force, with all parameters showing smaller values in the horizontal direction than in the vertical direction. Notably, except for the compression-breaking force, the direction of force had minimal impact on the overall trends in cassava’s mechanical properties. As moisture content decreases, the compression breaking force in cassava shows a significant linear decrease in the vertical direction, whereas, in the horizontal direction, it initially increases before subsequently decreasing. This behavior may be attributed to the more ordered and compact arrangement of cassava’s cell wall and fiber structure in the vertical direction.

As the moisture content decreases, the cell walls and fibers gradually lose moisture, becoming dry and fragile. This dry state makes them more susceptible to rupture when compressed vertically, resulting in a significant linear decrease in compression breaking force. In contrast, during initial moisture loss in the horizontal direction, voids between cell walls and fibers may decrease due to water evaporation, leading to an increased contact area between these structures. This enhanced contact area may strengthen the interaction forces between the cell walls and fibers, causing an initial increase in compression breaking force. However, as moisture content declines, the cell walls and fibers become increasingly dry and fragile. This condition renders them more prone to rupture under horizontal compression, reflected in a subsequent decrease in compression breaking force. Additionally, most of the other mechanical properties of cassava that exhibit different values under varying directions of applied force are also related to the orientation of fiber arrangement within cassava.

In practical production scenarios, utilizing cassava in the horizontal direction presents a greater risk of breakage. Therefore, designing more efficient cutting tools and crushing equipment for this characteristic can significantly reduce energy consumption and damage during processing, improving efficiency and product quality. When designing cassava harvesting machinery, it is critical to consider cassava’s mechanical properties under different force directions. This allows for the optimization of the structure and materials used in components such as digging shovels and cutters, ultimately enhancing harvesting efficiency while minimizing breakage. For instance, adjusting the angle and shape of digging shovels can better accommodate the breakage characteristics of cassava in the vertical direction.

As society increasingly recognizes the importance of optimizing natural resource use while minimizing the occupational risks, costs, and environmental impacts associated with construction projects and industrial processes, it becomes imperative to ensure that cassava transportation, processing, and related machinery are designed to be both efficient and economical [3,11,13,14]. Numerous studies have highlighted the significance of moisture content, and the geometric and mechanical properties of cassava examined in this research. These properties are critical for cassava transportation, processing, and mechanical design. By fully leveraging these characteristics, it is possible to optimize transportation conditions, enhance processing efficiency, design more adaptable machinery and equipment, and ultimately improve the overall efficiency of the cassava industry.

5. Conclusions

Our study underscores the significant effects of moisture content (MC), cassava variety, and loading orientation on the mechanical properties of cassava (MPC). We found that the MC of cassava, controlled by the drying process, ranged from 35% to 80% wet basis with increments of 5%. This range allowed us to evaluate the influence of humidity on key geometrical parameters, including length, width, and thickness, through a comprehensive correlation analysis. Notably, our results indicate that as MC increases, the compression rupture force (CRF) demonstrates a linear increase, while shear breaking force and shear strength exhibit a decrease with rising MC. These findings highlight the complex interplay between moisture levels and mechanical performance, emphasizing the need for the careful consideration of these factors in the design of harvesting machinery and food processing equipment. In the process of cassava processing, one can refer to the relationship between cassava moisture content and shear force, to explore the efficient processing time period after harvesting cassava. The evaluation of cassava properties presented in this study provides valuable reference data for establishing optimal conditions for harvesting, storage, and handling. However, it is important to acknowledge that our research focused on a limited set of geometrical and mechanical properties. Future investigations should expand upon these findings by exploring cassava contact parameters with various materials and examining the influence of roots and stems under real-world working conditions. Such research will further enhance our understanding of cassava behavior and improve the efficiency of processing technologies.

Author Contributions

Conceptualization, L.C., K.L. and E.M.A.; methodology, L.C., X.M., M.M., J.P. and E.M.A.; software, L.C., K.L. and Z.L.; investigation, X.M. and E.M.A.; resources, H.J.; data curation, Z.L.; writing—original draft, L.C., K.L. and E.M.A.; writing—review and editing, X.M., H.J., M.M., J.P. and E.M.A.; visualization, L.C. and E.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Guangxi Key R&D Program Project, grant number 2021AB38023, and the Guilin Major Special Plan Project, grant number 20220102-3.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yang, X.; Li, K.; Chen, S. Phenotypic comprehensive evaluation of agronomic and quality characteristics of 30 cassava germplasm resources. Mol. Plant Breed. 2022, 20, 6136–6144. [Google Scholar] [CrossRef]

- Chen, L.; Chen, R.; Atwa, E.M.; Mabrouk, M.; Jiang, H.; Mou, X.; Ma, X. Nutritional Quality Assessment of Miscellaneous Cassava Tubers Using Principal Component Analysis and Cluster Analysis. Foods 2024, 13, 1861. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Lu, B.; Li, K. New progress in cassava quality safety, nutritional quality, and processing and utilization. Chin. J. Food 2019, 19, 284–292. [Google Scholar] [CrossRef]

- Li, H.; Luo, X.; Liu, Y.; Mo, F. The impact of cassava stalk crushing and returning to the field on soil fertility. Guangxi Agric. Sci. 2009, 40, 705–709. [Google Scholar] [CrossRef]

- Nwaliowe, G.N.; Alamu, E.O.; Sanusi, R.A.; Maziya-Dixon, B. Evaluation of improved cassava (ManihotesculentaCrantz) varieties and associated products for proximate, cyanogenic potential and glycemic indices. CyTA-J. Food 2022, 21, 20–30. [Google Scholar] [CrossRef]

- Fang, J.; Pu, W.; Zhang, H. The development status of cassava industry at home and abroad. Chin. Agric. Sci. Bull. 2010, 26, 353–361. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, L.; Liu, H.; Zhou, Q. Study on the characteristics of acid production by anaerobic fermentation of cassava alcohol wastewater at room temperature. J. Chem. Eng. Coll. Univ. 2015, 29, 1279–1284. [Google Scholar] [CrossRef]

- Jansson, C.; Westerbergh, A.; Zhang, J.; Hu, X.; Sun, C. Cassava, a potential biofuel crop in (the) People’s Republic of China. Appl. Energy 2009, 86 (Suppl. S1), S95–S99. [Google Scholar] [CrossRef]

- Adebayo, W.G. Cassava production in africa: A panel analysis of the drivers and trends. Heliyon 2023, 9, e19939. [Google Scholar] [CrossRef]

- Babajide, K.; Irondi, E.A.; Alamu, E.O.; Ajani, E.O.; Abass, A.; Adesokan, M.; Parkes, E.; Maziya Dixon, B. Influence of traditional processing and genotypes on the antioxidant and antihyperglycaemic activities of yellow-fleshed cassava. Front. Nutr. 2022, 9, 894843. [Google Scholar] [CrossRef]

- Bayata, A. Review on nutritional value of cassava for use as a staple food. Sci. J. Anal. Chem. 2019, 7, 83–91. [Google Scholar] [CrossRef]

- Charles, A.L.; Sriroth, K.; Huang, T.C. Proximate composition, mineral contents, hydrogen cyanide and phytic acid of 5 cassava genotypes. Food Chem. 2005, 92, 615–620. [Google Scholar] [CrossRef]

- Leyva-Guerrero, E.; Narayanan, N.N.; Ihemere, U. RT Sayre Iron and protein biofortification of cassava: Lessons learned. Curr. Opin. Biotechnol. 2012, 23, 257–264. [Google Scholar] [CrossRef]

- Morgan, N.K.; Choct, M. Cassava: Nutrient composition and nutritive value in poultry diets. Anim. Nutr. 2016, 2, 253–261. [Google Scholar] [CrossRef]

- Tang, J.; Li, M.; Zhang, Y.; Hong, Y.; Zhang, Y.; Wang, Y.; You, X.; Zhou, K.; Wei, P. Processing Status and Development Prospects of Edible Cassava. Food Ind. Sci. Technol. 2023, 44, 469–476. [Google Scholar] [CrossRef]

- Carvalho, L.J.; Oliveira, A.G.; Godoy, R.O.; Pacheco, S.; Nutti, M.; de Carvalho, J.V.; Pereira, E.; Fukuda, W. Retention of total carotenoid and β-carotene in yellow sweet cassava (Manihot esculenta Crantz) after domestic cooking. Food Nutr. Res. 2012, 56, 15788. [Google Scholar] [CrossRef] [PubMed]

- An, F.; Luo, X.; Xue, J.; Chen, S.; Cai, J. Analysis of metabolites and related gene expression in white and yellow heart sugar cassava. J. Jiangxi Agric. Univ. 2022, 44, 1092–1100. [Google Scholar] [CrossRef]

- Guo, C.; Song, J.; Luo, K.; Tang, L.; Fu, X.; Chen, Y.; Zhang, R. Research on the characteristics of cassava seed dormancy and methods of breaking it. J. Trop. Crops 2023, 44, 1624–1634. [Google Scholar] [CrossRef]

- Qin, S.; Li, M. Review on the development of cassava planting machinery at home and abroad. J. Anhui Agri. 2011, 39, 5016–5018. [Google Scholar] [CrossRef]

- Yang, W.; Yang, J.; Zheng, X.; Wang, Q.; Jia, F.; Zhao, J. Mechanical properties testing of cassava. J. Agric. Eng. 2011, 27, 50–54. [Google Scholar]

- Xue, Z.; Huang, Z.; Guo, X.; Li, L.; Huang, X.; Wang, G.; Song, D.; Zhang, J.; Deng, G. Experimental Study on the Stem Mechanical Properties of Cassava Stem. Agric. Mech. Res. 2014, 36, 186–189. [Google Scholar] [CrossRef]

- Xue, Z.; Guo, X.; Huang, Z.; Wang, S.; Deng, G.; Zhang, J. Experimental study on mechanical properties of cassava stems. China J. Agric. Mach. Chem. 2014, 35, 83–87. [Google Scholar] [CrossRef]

- Yan, M.; Wang, T.; Li, M.; Li, Y. Mechanical characterization of cassava tuber cutting. Food Mach. 2013, 29, 88–91. [Google Scholar]

- Dong, D.; Wang, T.; Liao, Y.; Li, Y.; Zhang, X. Design and test of multi-angle cutting mechanical property tester for cassava stem. China J. Agric. Mach. Chem. 2015, 36, 59–62. [Google Scholar] [CrossRef]

- Yin, H.; Wu, W.; Dou, J.; Cheng, R.; Chen, J. Effect of hot air drying conditions on the gelatinization quality of potato flour. J. Agric. Eng. 2017, 33, 293–300. [Google Scholar] [CrossRef]

- Puran, B.; Onell, S. Effect of initial stem nodal cutting strength on dry matter production and accumulation in cassava (Manihot esculenta Crantz). J. Plant Breed. Crop Sci. 2014, 6, 64–72. [Google Scholar] [CrossRef][Green Version]

- Zhang, D. Enzymatic extraction of starch from cassava residue. Shandong Chem. Ind. 2015, 44, 43–45+52. [Google Scholar] [CrossRef]

- LI, M.; Wei, L.; Zhang, Y.; You, X.; Zhou, K.; Wang, Y.; Wei, P. Effects of different drying techniques on the quality characteristics and particle structure of tapioca acid starch. J. Food Sci. Technol. 2024, 1–16. Available online: http://kns.cnki.net/kcms/detail/10.1151.TS.20240909.1739.004.html (accessed on 25 September 2024).

- Wang, Y.; Lu, L.; Cao, S.; Shang, X.; Chen, Y.; Xiao, L.; Yan, H. Study on the suitability of different edible cassava varieties (lines) for potato chip processing. Food Res. Dev. 2021, 42, 15–20. [Google Scholar] [CrossRef]

- Deng, F.; Gao, Z.; Sun, M.; Yu, S.; An, F.; Cai, J.; Lu, X.; Ou, W. Effect of waxing treatment on quality of fresh cassava tuber roots stored at ambient temperature. Food Ferment. Ind. 2023, 49, 187–193+201. [Google Scholar] [CrossRef]

- Lin, L.; Luo, X.; Yu, H.; Wang, Q.; Zhang, Z.; Li, K. Corrigendum to “the effect of postharvest water migration on metabolism of cassava root by hypobaric storage”. Innov. Food Sci. Emerg. Technol. 2024, 93, 103609. [Google Scholar] [CrossRef]

- Lomchangkum, C.; Junsiri, C.; Sudajan, S.; Laloon, K. A Study on the Mechanical Characteristics of Cassava Tuber Cutter. Int. J. Agric. Technol. 2020, 16, 63–76. Available online: http://www.ijat-aatsea.com (accessed on 25 September 2024).

- Oguntunde, P.E.; Adejumo, O.A.; Odetunmibi, O.A.; Okagbue, H.I.; Adejumo, A.O. Data analysis on physical and mechanical properties of cassava pellets. Data Brief 2018, 16, 286–302. [Google Scholar] [CrossRef] [PubMed]

- Plett, S. Corn kernel breakage as a function of grain moisture at harvest in a prairie environment. Can. J. Plant Sci. 1994, 74, 543–544. [Google Scholar] [CrossRef]

- Ogunnigbo, O.C.; Dare, A.; Tunde, M.; Olusola, O.; Joshua, O. A study on the influence of the loading rate and orientation on some mechanical properties of cassava tubers of different ages. Res. Agric. Eng. 2021, 67, 34–44. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).