Mechanical Harvesting of Marginal Land and Agroforestry Field: New Insights from Safflower for Bio-Product Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Fields

- Location A: An agroforestry field of 0.54 ha originating from a 12-year-old Poplar plantation harvested in 2022.

- Location B: A field of 0.5 ha with marginality constraint caused by high waterlogging in the autumn–winter months. This type of field is usually cultivated with waterlogging-tolerant species, such as Poplar.

- Location C: A dedicated field with optimal cultivation characteristics, generally used for wheat production. The field has a total area of 11.15 ha.

2.2. Pre-Harvesting Sampling

2.3. Crop Yield, Harvesting Performances and Cost Analysis

2.4. Seed-Loss Assessment and Reduction in Cultivable Areas

- 50 m2 for the combine harvester of field A;

- 60 m2 for the combine harvester of field Cs and B.

2.5. Statistical Analysis

3. Results

3.1. Pre-Harvesting, Moisture Content, Crop Yield and Seed Losses

3.2. Work Performances and Cost Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and Climate Change Mitigation: An Assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef]

- Bernstein, S. The United Nations and the Governance of Sustainable Development Goals. In Governing through Goals: Sustainable Development Goals as Governance Innovation; MIT Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Rhodes, C.J. The 2015 Paris Climate Change Conference: COP21. Sci. Prog. 2016, 99, 97–104. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, Y.; Gu, B. COP26: Progress, Challenges, and Outlook 2022; Springer Nature: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Fetting, C. The European Green Deal. ESDN Report. December 2020. Available online: https://www.esdn.eu/fileadmin/ESDN_Reports/ESDN_Report_2_2020.pdf (accessed on 7 July 2024).

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Kiran, B.R.; Prasad, M.N.V.; Mohan, S.V. Farm to Fork: Sustainable Agrifood Systems. In Sustainable and Circular Management of Resources and Waste Towards a Green Deal; Elsevier: Amsterdam, The Netherlands, 2023; pp. 25–38. [Google Scholar] [CrossRef]

- Rates, O.E.C. Pricing Carbon Emissions through Taxes and Emissions Trading; Organisation for Economic Cooperation and Development: Paris, France, 2018. [Google Scholar]

- Pelkmans, L.M.; Van Dael, C.; Panoutsou, E. Alakangas S2BIOM Project Grant Agreement N°608622; D6.3 Policy Options to Mobilize Sustainable Non-Food Biomass Resources for the Biobased Economy; European Union: Maastricht, The Netherlands, 2016. [Google Scholar]

- Suardi, A.; Saia, S.; Stefanoni, W.; Gunnarsson, C.; Sundberg, M.; Pari, L. Admixing Chaff with Straw Increased the Residues Collected without Compromising Machinery Efficiencies. Energies 2020, 13, 1766. [Google Scholar] [CrossRef]

- Bergonzoli, S.; Suardi, A.; Rezaie, N.; Alfano, V.; Pari, L. An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection. Energies 2020, 13, 1265. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Pari, L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies 2020, 13, 1359. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713. [Google Scholar] [CrossRef]

- Cocco, D.; Deligios, P.; Ledda, L.; Sulas, L.; Virdis, A.; Carboni, G. LCA Study of Oleaginous Bioenergy Chains in a Mediterranean Environment. Energies 2014, 7, 6258–6281. [Google Scholar] [CrossRef]

- Dangol, N.; Shrestha, D.S.; Duffield, J.A. Life-Cycle Energy, GHG and Cost Comparison of Camelina-Based Biodiesel and Biojet Fuel. Biofuels 2020, 11, 399–407. [Google Scholar] [CrossRef]

- Graß, R.; Heuser, F.; Stülpnagel, R.; Piepho, H.-P.; Wachendorf, M. Energy Crop Production in Double-Cropping Systems: Results from an Experiment at Seven Sites. Eur. J. Agron. 2013, 51, 120–129. [Google Scholar] [CrossRef]

- Akbari, G.A.; Heshmati, S.; Soltani, E.; Amini Dehaghi, M. Influence of Seed Priming on Seed Yield, Oil Content and Fatty Acid Composition of Safflower (Carthamus tinctorius L.) Grown under Water Deficit. Int. J. Plant Prod. 2020, 14, 245–258. [Google Scholar] [CrossRef]

- Bowyer, J.L.; Stockmann, V.E. Agricultural Residues. For. Prod. J. 2001, 51, 10–21. [Google Scholar]

- FAO Statistical Year Book. Available online: https://www.fao.org/3/Cc2211en/Cc2211en.Pdf (accessed on 9 July 2024).

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef]

- Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability 2020, 12, 4936. [Google Scholar] [CrossRef]

- Carlsson, A.S. Plant Oils as Feedstock Alternatives to Petroleum—A Short Survey of Potential Oil Crop Platforms. Biochimie 2009, 91, 665–670. [Google Scholar] [CrossRef]

- Metzger, M.J.; Bunce, R.G.H.; Jongman, R.H.G.; Mücher, C.A.; Watkins, J.W. A Climatic Stratification of the Environment of Europe. Glob. Ecol. Biogeogr. 2005, 14, 549–563. [Google Scholar] [CrossRef]

- FAO. Global Agriculture towards 2050. Available online: http://www.fao.org/3/a-ap106e.pdf (accessed on 15 July 2024).

- Pandey, V.C. Suitability of Ricinus Communis L. Cultivation for Phytoremediation of Fly Ash Disposal Sites. Ecol. Eng. 2013, 57, 336–341. [Google Scholar] [CrossRef]

- Llugany, M.; Miralles, R.; Corrales, I.; Barceló, J.; Poschenrieder, C. Cynara Cardunculus a Potentially Useful Plant for Remediation of Soils Polluted with Cadmium or Arsenic. J. Geochem. Explor. 2012, 123, 122–127. [Google Scholar] [CrossRef]

- Mauromicale, G.; Sortino, O.; Pesce, G.R.; Agnello, M.; Mauro, R.P. Suitability of Cultivated and Wild Cardoon as a Sustainable Bioenergy Crop for Low Input Cultivation in Low Quality Mediterranean Soils. Ind. Crops Prod. 2014, 57, 82–89. [Google Scholar] [CrossRef]

- Pavlista, A.D.; Hergert, G.W.; Margheim, J.M.; Isbell, T.A. Growth of Spring Camelina (Camelina sativa) under Deficit Irrigation in Western Nebraska. Ind. Crops Prod. 2016, 83, 118–123. [Google Scholar] [CrossRef]

- Schillinger, W.F. Camelina: Long-Term Cropping Systems Research in a Dry Mediterranean Climate. Field Crops Res. 2019, 235, 87–94. [Google Scholar] [CrossRef]

- Christopher, L.P.; Kumar, H.; Zambare, V.P. Enzymatic Biodiesel: Challenges and Opportunities. Appl. Energy 2014, 119, 497–520. [Google Scholar] [CrossRef]

- Manvelian, J.; Weisany, W.; Tahir, N.A.; Jabbari, H.; Diyanat, M. Physiological and Biochemical Response of Safflower (Carthamus tinctorius L.) Cultivars to Zinc Application under Drought Stress. Ind. Crops Prod. 2021, 172, 114069. [Google Scholar] [CrossRef]

- Gengmao, Z.; Yu, H.; Xing, S.; Shihui, L.; Quanmei, S.; Changhai, W. Salinity Stress Increases Secondary Metabolites and Enzyme Activity in Safflower. Ind. Crops Prod. 2015, 64, 175–181. [Google Scholar] [CrossRef]

- Gongora, B.; Melegari de Souza, S.N.; Bassegio, D.; Santos, R.F.; Siqueira, J.A.C.; Bariccatti, R.A.; Gurgacz, F.; Secco, D.; Tokura, L.K.; Sequinel, R. Comparison of Emissions and Engine Performance of Safflower and Commercial Biodiesels. Ind. Crops Prod. 2022, 179, 114680. [Google Scholar] [CrossRef]

- Hashemi, S.S.; Mirmohamadsadeghi, S.; Karimi, K. Biorefinery Development Based on Whole Safflower Plant. Renew. Energy 2020, 152, 399–408. [Google Scholar] [CrossRef]

- Hashemi, S.S.; Karimi, K.; Mirmohamadsadeghi, S. Hydrothermal Pretreatment of Safflower Straw to Enhance Biogas Production. Energy 2019, 172, 545–554. [Google Scholar] [CrossRef]

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous Oil Crops, a Review on Mechanical Harvesting State of the Art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

- Berglund, D.; Riveland, N.; Bergman, J. Safflower Production. Fargo ND: North Dakota State University A-870. 2007. Available online: https://Library.Ndsu.Edu/Ir/Bitstream/Handle/10365/9154/A870_2007.Pdf?Sequence=1 (accessed on 15 July 2024).

- Pari, L.; Alfano, V.; Scarfone, A.; Toscano, G. Tecnologie Innovative per Un Utilizzo Efficiente Dei Co-Prodotti Agricoli; Compagnia delle Foreste: Arezzo, Italy, 2016. [Google Scholar]

- MIDAS EU PROJECT. Available online: https://www.Midas-Bioeconomy.Eu/ (accessed on 16 July 2024).

- Sleebos, J. Low Fertility Rates in OECD Countries: Facts and Policy Responses; OECD: Paris, France, 2003. [Google Scholar]

- Eliasson, Å. Review of Land Evaluation Methods for Quantifying Natural Constraints to Agriculture; The Institute for Environment and Sustainability, Joint Research Centre: Ispra, Italy, 2007; p. 22923. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC40316 (accessed on 20 July 2024).

- Pulighe, G.; Bonati, G.; Colangeli, M.; Morese, M.M.; Traverso, L.; Lupia, F.; Khawaja, C.; Janssen, R.; Fava, F. Ongoing and Emerging Issues for Sustainable Bioenergy Production on Marginal Lands in the Mediterranean Regions. Renew. Sustain. Energy Rev. 2019, 103, 58–70. [Google Scholar] [CrossRef]

- Dale, V.H.; Kline, K.L.; Wiens, J.; Fargione, J. Biofuels: Implications for Land Use and Biodiversity; Ecological Society of America: Washington, DC, USA, 2010. [Google Scholar]

- James, L. Theory and Identification of Marginal Land and Factors Determining Land Use Change; Michigan State University, Department of Agricultural, Food, and Resource Economics: East Lansing, MI, USA, 2010. [Google Scholar]

- Von Cossel, M.; Lewandowski, I.; Elbersen, B.; Staritsky, I.; Van Eupen, M.; Iqbal, Y.; Mantel, S.; Scordia, D.; Testa, G.; Cosentino, S.L. Marginal Agricultural Land Low-Input Systems for Biomass Production. Energies 2019, 12, 3123. [Google Scholar] [CrossRef]

- European Environment Agency EEA Report No 4/2019; Climate Change Adaptation in the Agriculture Sector in Europe; European Environment Agency: Copenhagen, Denmark, 2019.

- MAGIC. Marginal Lands for Growing Industrial Crops [www Document]. 2022. Available online: https://Magic-H2020.Eu/ (accessed on 20 July 2024).

- Kang, S.; Post, W.M.; Nichols, J.A.; Wang, D.; West, T.O.; Bandaru, V.; Izaurralde, R.C. Marginal Lands: Concept, Assessment and Management. J. Agric. Sci. 2013, 5, 129. [Google Scholar] [CrossRef]

- Smith, J. The History of Temperate Agroforestry; The Organic Research Centre: Cirencester, UK, 2010. [Google Scholar]

- Smith, J. Agroforestry: Reconciling Production with Protection of the Environment a Synopsis of Research Literature; The Organic Research Centre: Cirencester, UK, 2010. [Google Scholar]

- USDA 2017: Agroforestry Strategic Framework, Fiscal Year 2011–2016; U.S. Department of Agriculture: Washington, DC, USA, 2017.

- Pardon, P.; Reubens, B.; Mertens, J.; Verheyen, K.; De Frenne, P.; De Smet, G.; Van Waes, C.; Reheul, D. Effects of Temperate Agroforestry on Yield and Quality of Different Arable Intercrops. Agric. Syst. 2018, 166, 135–151. [Google Scholar] [CrossRef]

- Ramachandran Nair, P.K.; Mohan Kumar, B.; Nair, V.D. Agroforestry as a Strategy for Carbon Sequestration. J. Plant Nutr. Soil Sci. 2009, 172, 10–23. [Google Scholar] [CrossRef]

- Kay, S.; Graves, A.; Palma, J.H.N.; Moreno, G.; Roces-Díaz, J.V.; Aviron, S.; Chouvardas, D.; Crous-Duran, J.; Ferreiro-Domínguez, N.; de Jalón, S.G. Agroforestry Is Paying off–Economic Evaluation of Ecosystem Services in European Landscapes with and without Agroforestry Systems. Ecosyst. Serv. 2019, 36, 100896. [Google Scholar] [CrossRef]

- Fagerholm, N.; Torralba, M.; Burgess, P.J.; Plieninger, T. A Systematic Map of Ecosystem Services Assessments around European Agroforestry. Ecol. Indic. 2016, 62, 47–65. [Google Scholar] [CrossRef]

- Zeng, C.; Zhu, A.-X.; Liu, F.; Yang, L.; Rossiter, D.G.; Liu, J.; Wang, D. The Impact of Rainfall Magnitude on the Performance of Digital Soil Mapping over Low-Relief Areas Using a Land Surface Dynamic Feedback Method. Ecol. Indic. 2017, 72, 297–309. [Google Scholar] [CrossRef]

- Elbersen, B.S.; van Eupen, M.; Boogaard, H.L.; Mantel, S.; Verzandvoort, S.J.E.; Mücher, C.A.; Ceccarelli, T.; Elbersen, H.W.; Bai, Z.; Iqbal, Y. Deliverable 2.6 Methodological Approaches to Identify and Map Marginal Land Suitable for Industrial Crops in Europe; Wageningen University & Research: Wageningen, The Netherlands, 2018. [Google Scholar]

- Lohmann, U.; Sausen, R.; Bengtsson, L.; Cubasch, U.; Perlwitz, J.; Roeckner, E. The Köppen Climate Classification as a Diagnostic Tool for General Circulation Models. Clim. Res. 1993, 177–193. [Google Scholar] [CrossRef]

- Cui, D.; Liang, S.; Wang, D. Observed and Projected Changes in Global Climate Zones Based on Köppen Climate Classification. Wiley Interdiscip. Rev. Clim. Chang. 2021, 12, e701. [Google Scholar] [CrossRef]

- ISO 18134-2:2017; Solid Biobuels Determination of Moisture Content—Oven Dry Method—Part 2 Total Moisture—Simplified Method. ISO: Geneva, Switzerland, 2017.

- Reith, S.; Frisch, J.; Winkler, B. Revision of the Working Time Classification to Optimize Work Processes in Modern Agriculture. Chem. Eng. Trans. 2017, 58, 121–126. [Google Scholar] [CrossRef]

- Assirelli, A.; Pignedoli, S. Costo Di Esercizio Delle Macchine Agricole. Cent. Ric. Prod. Anim. 2005, 5, 1–10. [Google Scholar]

- ASAE ASAE D497_4 FEB2003.Pdf. 2003. Available online: https://elibrary.asabe.org/ (accessed on 7 July 2024).

- Banca d’Italia Banca d’Italia Lending Rate. Available online: www.bancaditalia.it/pubblicazioni/moneta-banche (accessed on 7 July 2024).

- Pari, L.; Cozzolino, L.; Marsac, S.; Hermet, L.; Bergonzoli, S. Effect of Swathing or Direct Combining on Yield, Seed Losses and Costs of Camelina. Agronomy 2024, 14, 325. [Google Scholar] [CrossRef]

- Stefanoni, W.; Latterini, F.; Ruiz, J.; Bergonzoli, S.; Attolico, C.; Pari, L. Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation. Energies 2020, 13, 5329. [Google Scholar] [CrossRef]

- Stefanoni, W.; Latterini, F.; Ruiz, J.P.; Bergonzoli, S.; Palmieri, N.; Pari, L. Assessing the Camelina (Camelina sativa (L.) Crantz) Seed Harvesting Using a Combine Harvester: A Case-Study on the Assessment of Work Performance and Seed Loss. Sustainability 2020, 13, 195. [Google Scholar] [CrossRef]

- R Core Team, R. R Core Team R: A Language and Environment for Statistical Computing; R Core Team: Vienna, Austria, 2020. [Google Scholar]

- Shahid, M.; Jaradat, A.; Rao, N.K. Safflower: A Multipurpose Crop for the Marginal Lands. In Emerging Research in Alternative Crops; Springer: Berlin/Heidelberg, Germany, 2020; pp. 279–294. [Google Scholar] [CrossRef]

- Singh, S.; Angadi, S.V.; Grover, K.K.; Hilaire, R.S.; Begna, S. Effect of Growth Stage Based Irrigation on Soil Water Extraction and Water Use Efficiency of Spring Safflower Cultivars. Agric. Water Manag. 2016, 177, 432–439. [Google Scholar] [CrossRef]

- Steberl, K.; Hartung, J.; Graeff-Hönninger, S. Impact of Cultivar, Harvest Date and Threshing Parameter Settings on Floret and Carthamidin Yield of Safflower. Agronomy 2020, 10, 1272. [Google Scholar] [CrossRef]

- Bateman, B.; Warner, J.O.; Hutchinson, E.; Dean, T.; Rowlandson, P.; Gant, C.; Grundy, J.; Fitzgerald, C.; Stevenson, J. The Effects of a Double Blind, Placebo Controlled, Artificial Food Colourings and Benzoate Preservative Challenge on Hyperactivity in a General Population Sample of Preschool Children. Arch. Dis. Child. 2004, 89, 506–511. [Google Scholar] [CrossRef]

- Křížová, H. Natural Dyes: Their Past, Present, Future and Sustainability. In Recent Developments in Fibrous Material Science; OPS: Kanina, Czechia, 2015; pp. 59–71. [Google Scholar]

- Gama, G.F.; da Silva, G.Z.; Rocha, D.I.; Machado, M.; Kuster, V.C.; Machado, C.G.; de Castro Dias, R.; Menezes, J.F.S. Safflower (Carthamus tinctorius L., Asteraceae) Is an Oilseed Species with Fast Seed Resource Mobilization. Obs. de la Econ. Latinoam. 2023, 21, 7217–7237. [Google Scholar] [CrossRef]

- Dajue, L.; Mündel, H. Safflower, Carthamus tinctorius L.; IPGRI: Rome, Italy, 1996; ISBN 9290432977. [Google Scholar]

- Schillaci, C.; Perego, A.; Acutis, M.; Botta, M.; Tadiello, T.; Gabbrielli, M.; Barsali, T.; Tozzi, F.; Chiaramonti, D.; Jones, A. Assessing Marginality of Camelina (C. Sativa L. Crantz) in Rotation with Barley Production in Southern Europe: A Modelling Approach. Agric. Ecosyst. Environ. 2023, 357, 108677. [Google Scholar] [CrossRef]

- Zanetti, F.; Alberghini, B.; Marjanović Jeromela, A.; Grahovac, N.; Rajković, D.; Kiprovski, B.; Monti, A. Camelina, an Ancient Oilseed Crop Actively Contributing to the Rural Renaissance in Europe. A Review. Agron. Sustain. Dev. 2021, 41, 2. [Google Scholar] [CrossRef]

- Chun, C.V.; Uribe, G.D.J.P.; Santos, A.L.; Jiménez, A.d.J.M. An Index of Environmental and Cultural Suitability for the Cultivation of Climate-Resilient Castor Bean in Rainfed Low-Productivity Common Lands in Mexico. Ital. J. Agron. 2023, 18, 1. [Google Scholar] [CrossRef]

- Ebrahimian, E.; Seyyedi, S.M.; Bybordi, A.; Damalas, C.A. Seed Yield and Oil Quality of Sunflower, Safflower, and Sesame under Different Levels of Irrigation Water Availability. Agric. Water Manag. 2019, 218, 149–157. [Google Scholar] [CrossRef]

- Ciaramella, B.R.; Corinzia, S.A.; Cosentino, S.L.; Testa, G. Phytoremediation of Heavy Metal Contaminated Soils Using Safflower. Agronomy 2022, 12, 2302. [Google Scholar] [CrossRef]

- Angelova, V.R.; Perifanova-Nemska, M.N.; Uzunova, G.P.; Kolentsova, E.N. Accumulation of Heavy Metals in Safflower (Carthamus tinctorius L.). Int. J. Agric. Biosyst. Eng. 2016, 10, 410–415. [Google Scholar]

| Parameters | Agroforestry (A) | Marginal (B) | Dedicated (C) |

|---|---|---|---|

| Clay (%) | 58 | 48 | 31 |

| Sand (%) | 22 | 16 | 48 |

| Silt (%) | 20 | 36 | 21 |

| Organic matter (%) | 2.1 | 1.7 | 1.8 |

| N (%) | 0.13 | 0.09 | 0.11 |

| pH (water) | 6.1 | 7.9 | 6.7 |

| P2O5 Olsen (mg kg−1) | 7 | 6 | 21 |

| K2O (mg kg−1) | 317 | 304 | 992 |

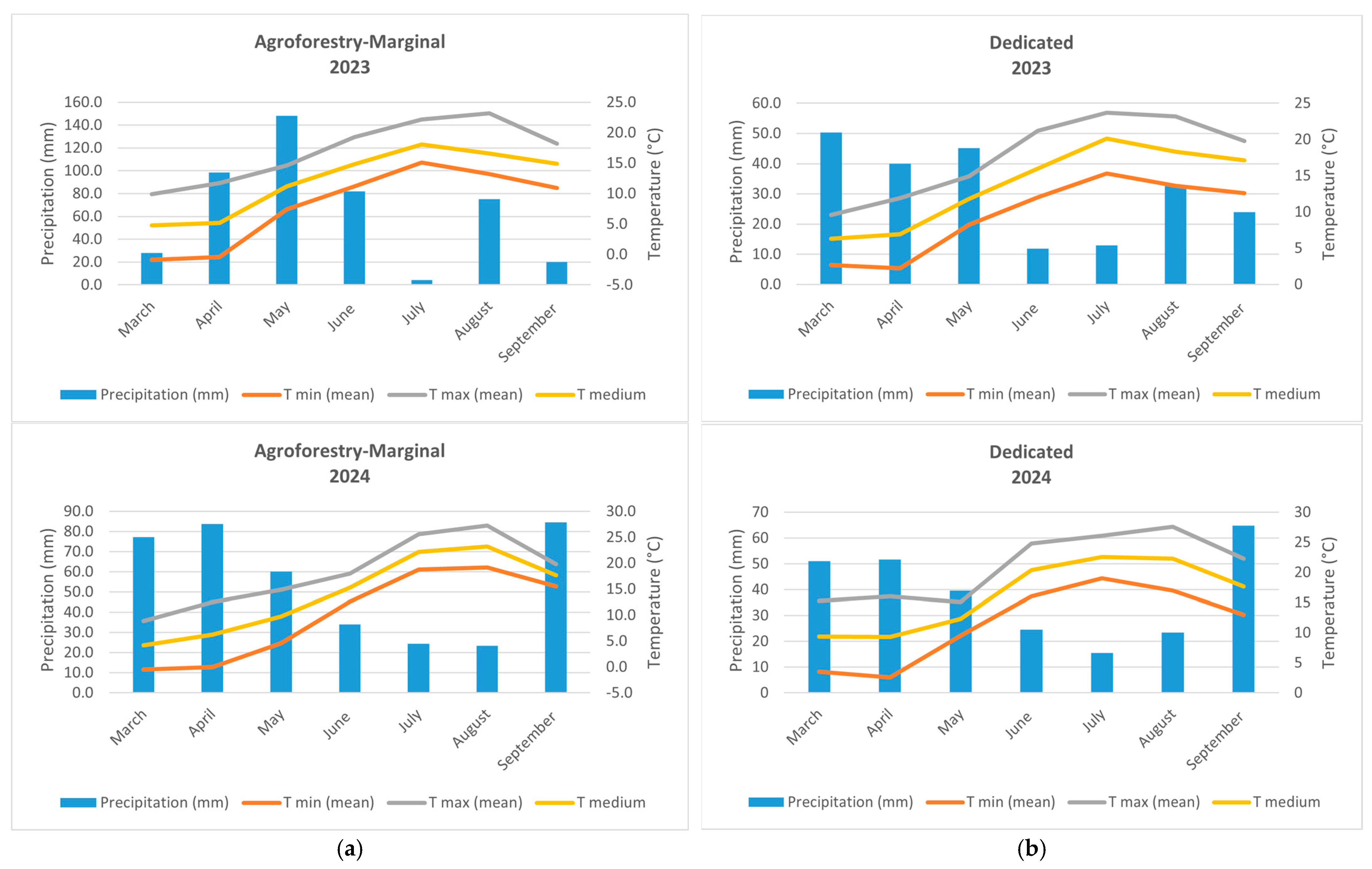

| Type | Location | Region | Latitude/ Longitude | Years | Climate Type 1 | PrS 2 2023 (mm) | PrS 2 2024 (mm) |

|---|---|---|---|---|---|---|---|

| Agroforestry (A) | Monterotondo (RM) | Lazio | 42°06′09″ N 12°37′43″ E | 2023–24 | Csa | 456.2 | 387.6 |

| Marginal (B) | Monterotondo (RM) | Lazio | 42°06′09″ N 12°37′43″ E | 2023–24 | Csa | 456.2 | 387.6 |

| Dedicated (C) | Cesano (RM) | Lazio | 42°05′06″ N 12°33′04″ E | 2023–24 | Csa | 217.0 | 271.0 |

| 2023 | |||

| Parameter | Agroforestry (A) | Marginal (B) | Dedicated (C) |

| Potential seed yield (DM Mg ha−1) | 1.06 ± 0.3 a | 1.15 ± 0.2 a | 1.29 ± 0.1 b |

| Total biomass (DM Mg ha−1) | 6.32 ± 2.7 a | 6.78 ± 0.6 a | 8.47 ± 3.2 b |

| Harvested seed yield (DM Mg ha−1) | 1.0 * | 1.07 * | 1.27 * |

| Plant density (n m−2) | 52.60 ± 5.5 a | 56.01 ± 6.1 a | 46.27 ± 8.7 a |

| Seed losses tarpaulin (%) | 8.51 ± 0.001 a | 9.13 ± 0.004 a | 3.32 ± 0.002 b |

| Seed losses (%) | 6 * | 7 * | 2 * |

| Reduction in cultivated area (%) | 14.85 | 11.64 | / |

| 2024 | |||

| Parameter | Agroforestry (A) | Marginal (B) | Dedicated (C) |

| Potential Seed Yield (DM Mg ha−1) | 1.14 ± 0.5 a | 1.2 ± 0.3 a | 1.44 ± 0.1 b |

| Total biomass (DM Mg ha−1) | 6.73 ± 2.2 a | 7.09 ± 0.6 a | 9.17 ± 2.8 b |

| Harvested seed yield (DM Mg ha−1) | 1.09 * | 1.16 * | 1.42 * |

| Plant density (n m−2) | 55.30 ± 5.4 a | 57.05 ± 6.4 a | 49.77 ± 9.1 a |

| Seed losses tarpaulin (%) | 7.7 ± 0.004 a | 8.1 ± 0.006 a | 2.76 ± 0.005 b |

| Seed losses (%) | 5 * | 4 * | 2 * |

| Reduction in cultivated area (%) | 13.22 | 10.84 | / |

| 2023 | ||||||

| Dry Matter (g) | Moisture Content (%) | |||||

| Agroforestry (A) | Marginal (B) | Dedicated (C) | Agroforestry (A) | Marginal (B) | Dedicated (C) | |

| Straw | 152.08 ± 4.53 a | 157.12 ± 3.65 a | 170.34 ± 3.34 b | 33.20 ± 0.09 a | 22.17 ± 0.96 a | 19.23 ± 0.08 b |

| Seeds | 72.16 ± 3.87 a | 78.97 ± 4.63 a | 86.77 ± 1.89 b | 25.19 ± 0.47 a | 19.49 ± 0.05 a | 9.33 ± 0.05 b |

| 2024 | ||||||

| Dry Matter (g) | Moisture Content (%) | |||||

| Agroforestry (A) | Marginal (B) | Dedicated (C) | Agroforestry (A) | Marginal (B) | Dedicated (C) | |

| Straw | 161.81 ± 5.53 a | 190.89 ± 2.52 a | 208.91 ± 4.22 b | 34.09 ± 0.32 a | 16.16 ± 0.06 a | 13.78 ± 0.02 b |

| Seeds | 81.13 ± 4.30 a | 99.12 ± 3.25 a | 114.41 ± 3.11 b | 26.85 ± 0.01 a | 19.77 0.02 a | 11.65 ± 0.03 b |

| 2023 | |||

| Parameter | Agroforestry (A) | Marginal (B) | Dedicated (C) |

| Theoretical Field Capacity (TFC ha h−1) | 1.21 | 1.41 | 2.35 |

| Effective Field Capacity (EFC ha h−1) | 0.95 | 1.12 | 1.98 |

| Field efficiency (FE%) | 78 | 79 | 84 |

| Total cost (EUR ha−1) | 205.80 | 174.56 | 114.59 |

| 2024 | |||

| Parameter | Agroforestry (A) | Marginal (B) | Dedicated (C) |

| Theoretical Field Capacity (TFC ha h−1) | 1.20 | 1.41 | 2.32 |

| Effective Field Capacity (EFC ha h−1) | 0.93 | 1.15 | 1.93 |

| Field efficiency (FE%) | 77 | 82 | 83 |

| Total cost (EUR ha−1) | 210.23 | 169.62 | 117.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pari, L.; Bergonzoli, S.; Cozzolino, L.; Baldi, G.M.; Falce, M.; Alexopoulou, E. Mechanical Harvesting of Marginal Land and Agroforestry Field: New Insights from Safflower for Bio-Product Production. Agronomy 2024, 14, 2268. https://doi.org/10.3390/agronomy14102268

Pari L, Bergonzoli S, Cozzolino L, Baldi GM, Falce M, Alexopoulou E. Mechanical Harvesting of Marginal Land and Agroforestry Field: New Insights from Safflower for Bio-Product Production. Agronomy. 2024; 14(10):2268. https://doi.org/10.3390/agronomy14102268

Chicago/Turabian StylePari, Luigi, Simone Bergonzoli, Luca Cozzolino, Gian Maria Baldi, Michele Falce, and Efthymia Alexopoulou. 2024. "Mechanical Harvesting of Marginal Land and Agroforestry Field: New Insights from Safflower for Bio-Product Production" Agronomy 14, no. 10: 2268. https://doi.org/10.3390/agronomy14102268

APA StylePari, L., Bergonzoli, S., Cozzolino, L., Baldi, G. M., Falce, M., & Alexopoulou, E. (2024). Mechanical Harvesting of Marginal Land and Agroforestry Field: New Insights from Safflower for Bio-Product Production. Agronomy, 14(10), 2268. https://doi.org/10.3390/agronomy14102268