Research and Experiment on the Ditching Performance of a Ditching and Film-Covering Machine in the Yellow Sand Cultivation Mode of Solar Greenhouses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Agronomic Requirements

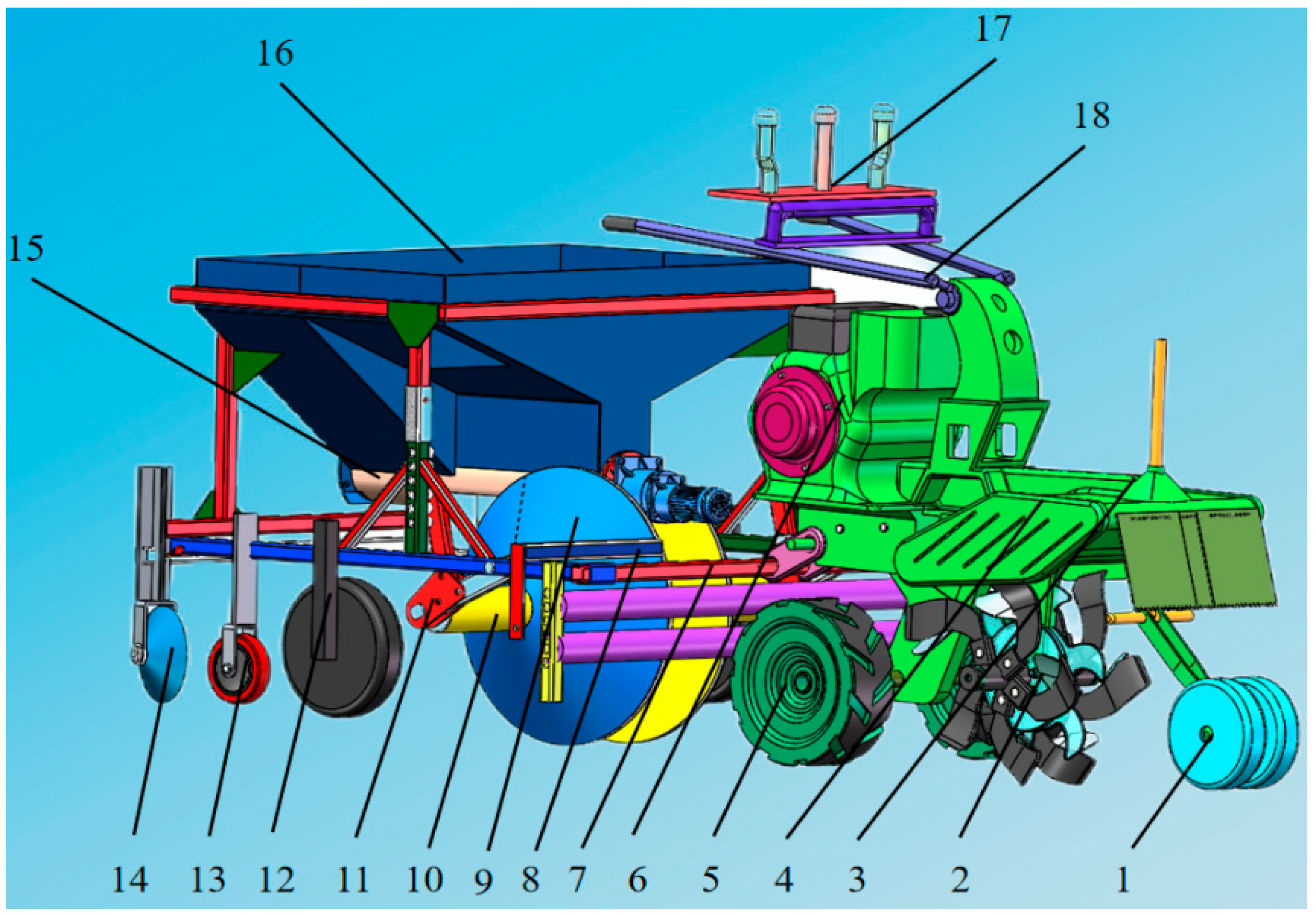

2.2. The Overall Structure of the Equipment

2.3. Working Principle

2.4. Design of Key Components

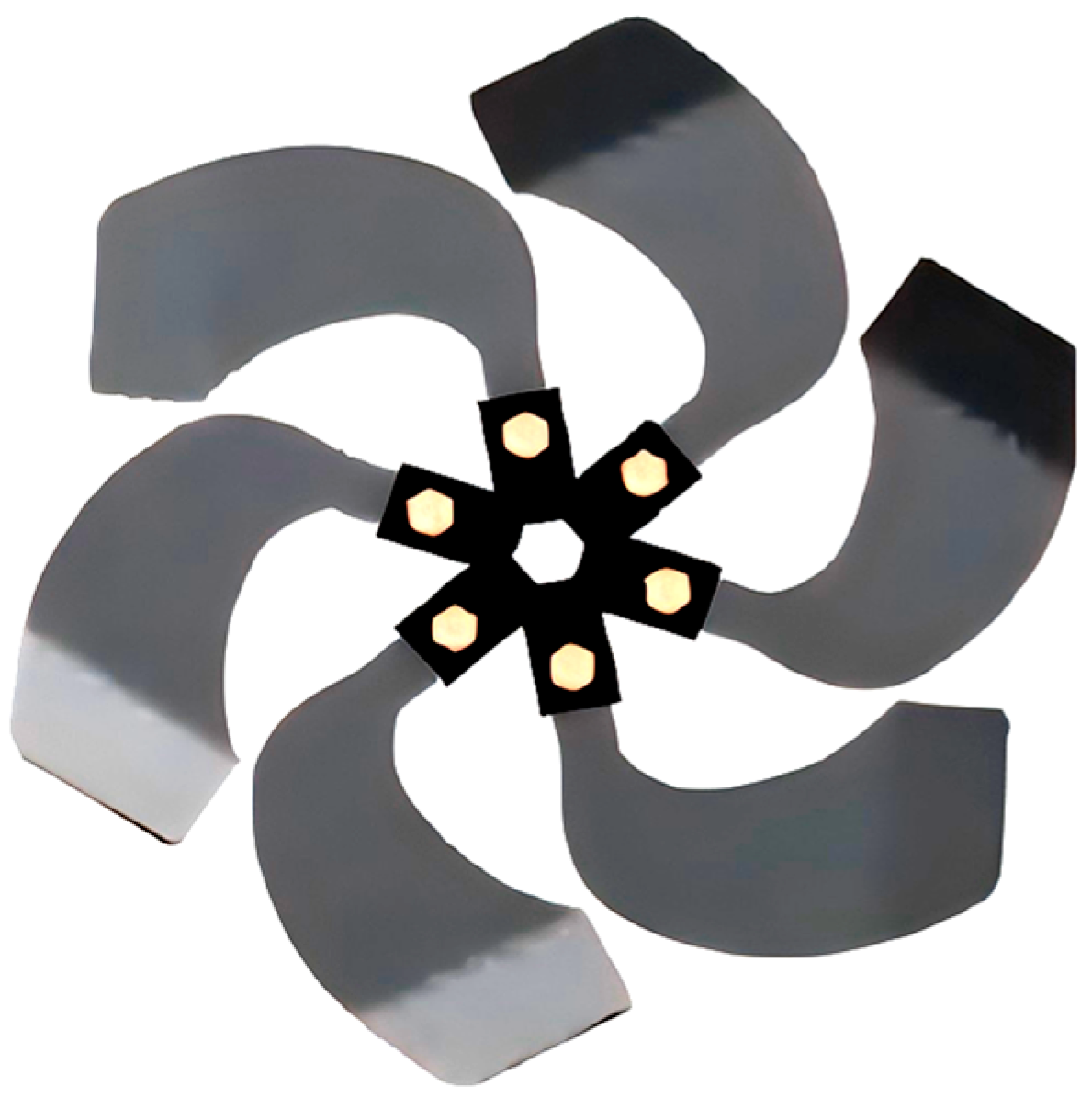

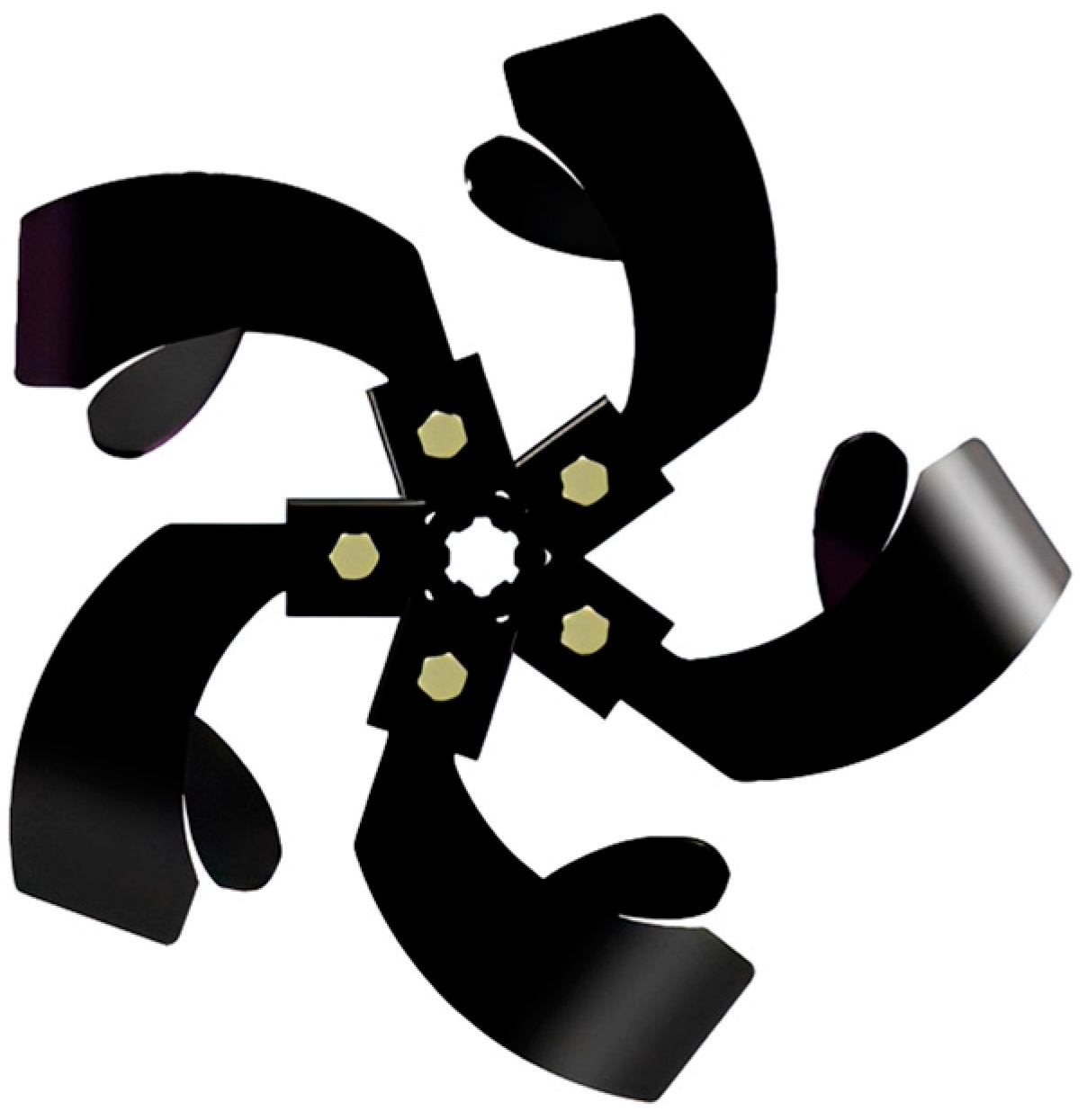

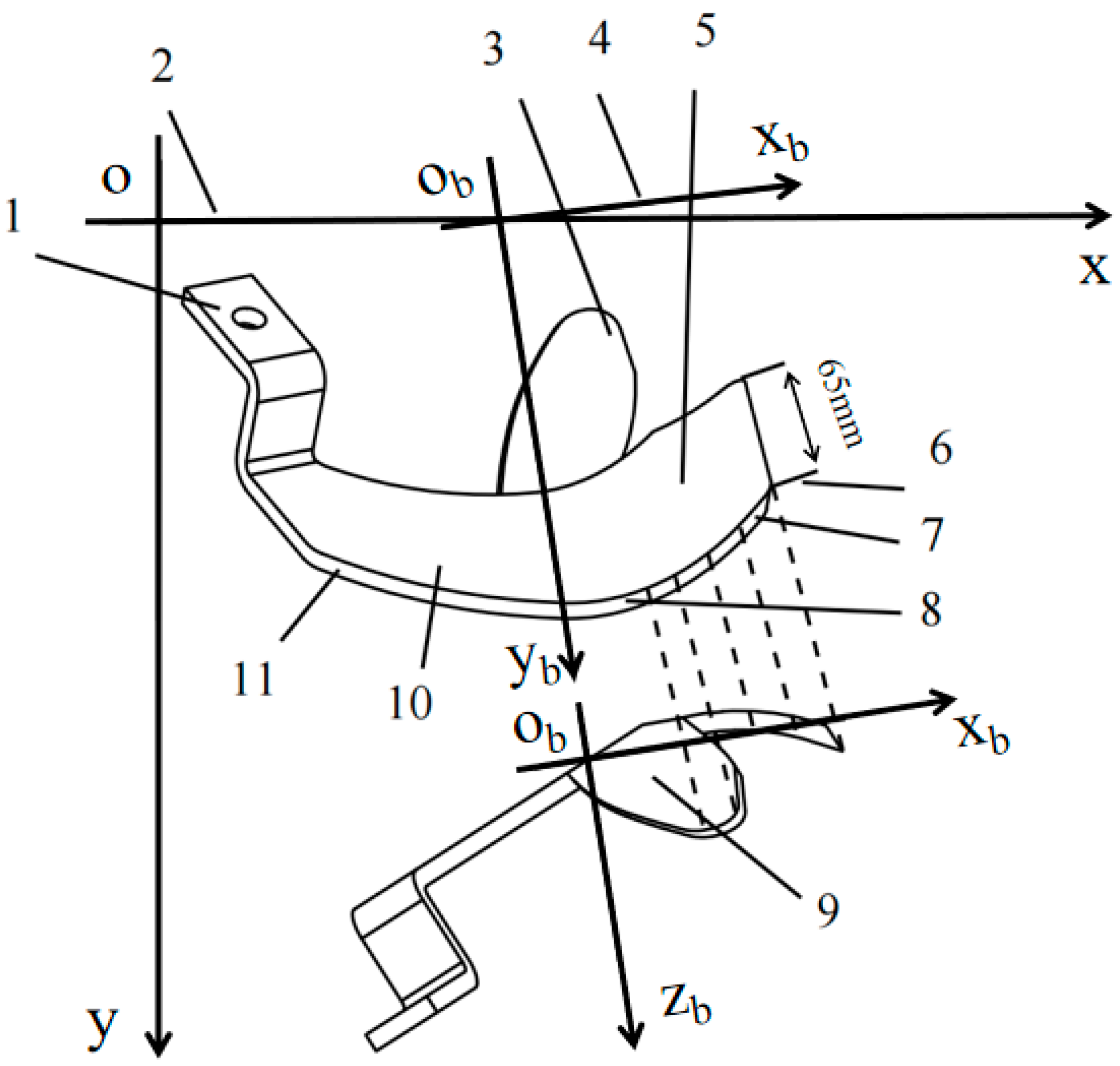

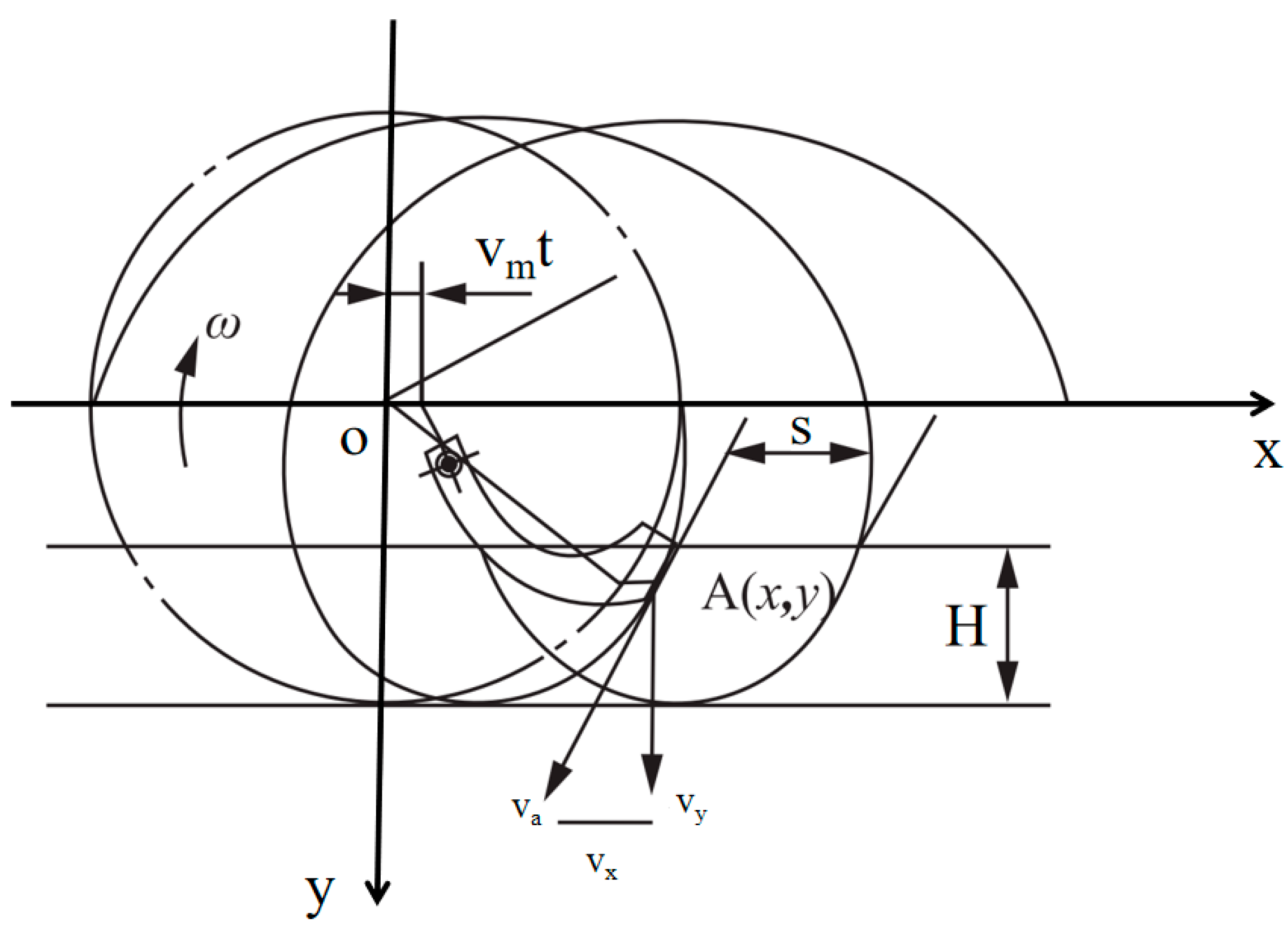

2.4.1. Design of Throw-Cut Combined Ditching Knife

2.4.2. Key Parameter Optimization

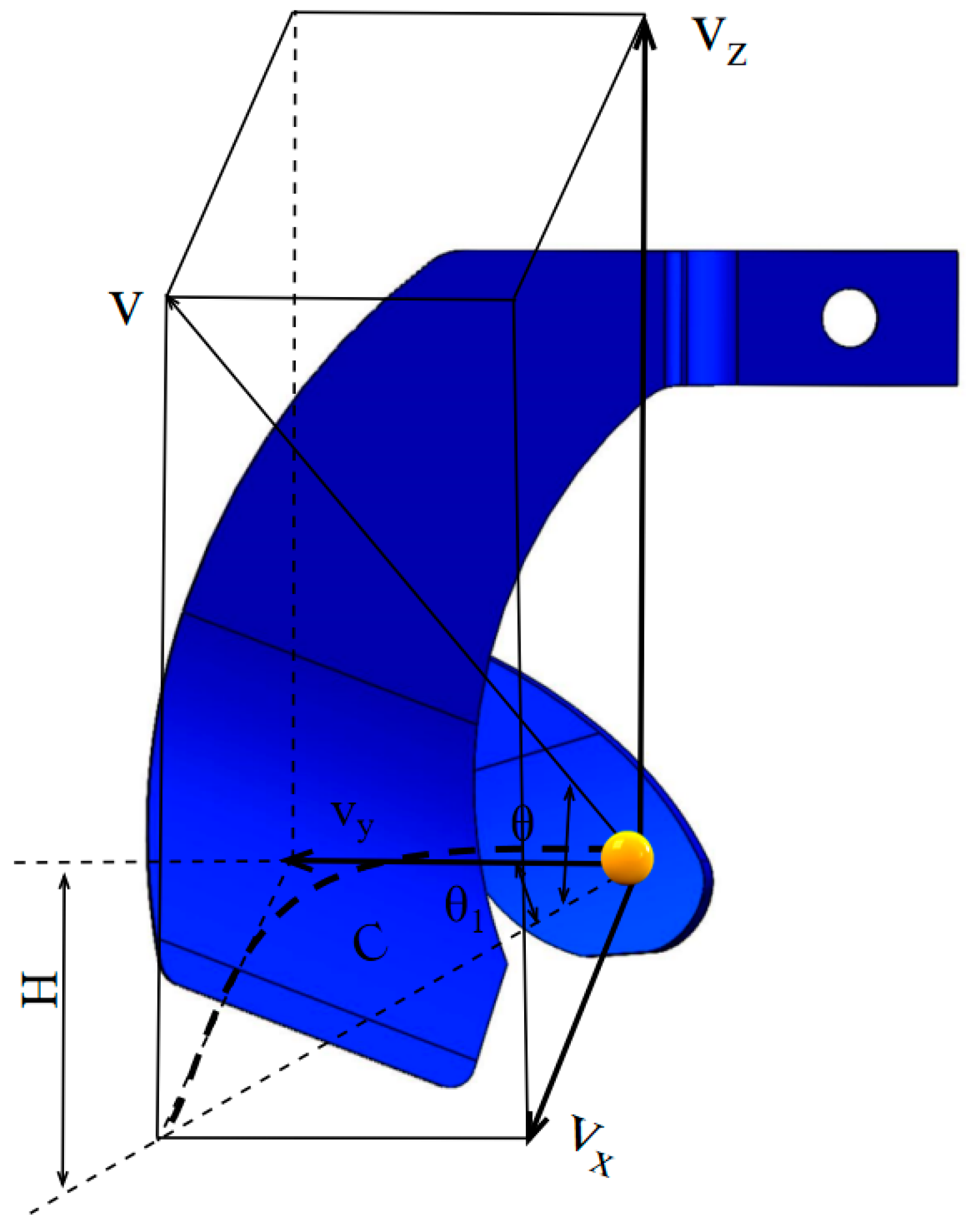

2.4.3. Analysis of the Soil-Throwing Process

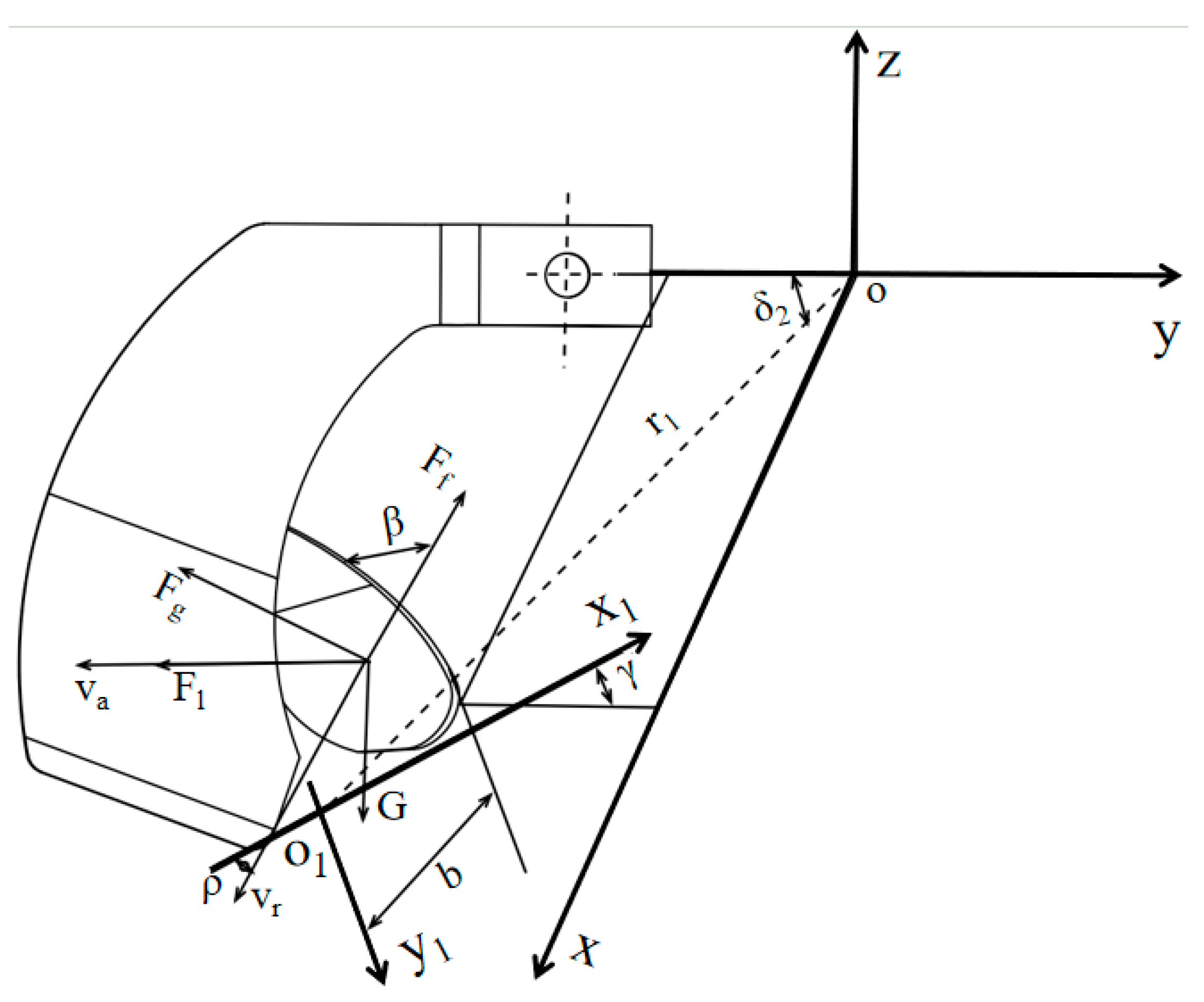

2.4.4. Force Analysis of Soil-Throwing Piece

2.5. Quantitative Formulas for Key Performance Parameters

2.5.1. Formulas for Calculating Trench Stability and Trench Width Consistency Coefficient

2.5.2. Formula for Calculating Total Power Consumption

2.5.3. Formula for Calculating Trench Depth Stability

2.6. Simulation Test Model

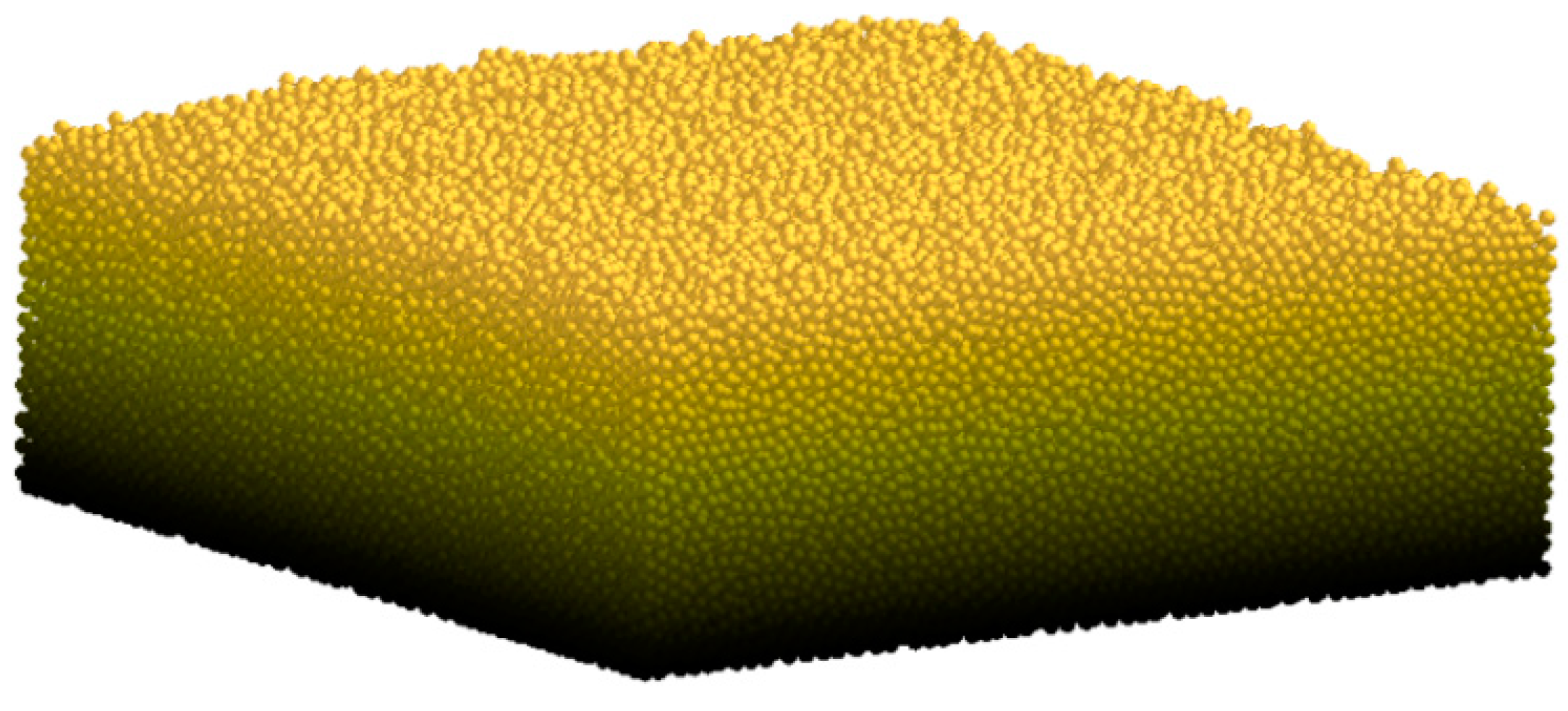

2.6.1. Simulation Model Parameter Design

2.6.2. Soil Particle Model Construction

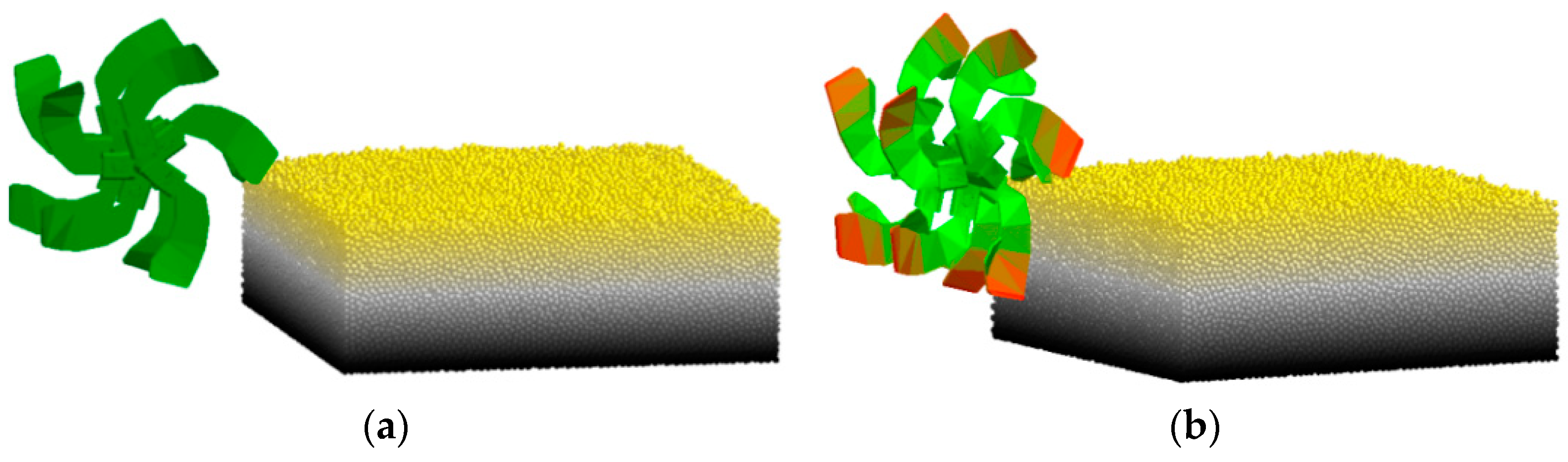

2.6.3. Ditching Knife Model Construction

2.6.4. Simulation Experiment Design

2.7. Field Trial Design

2.7.1. Experimental Conditions and Materials

2.7.2. Ditching Power Consumption Test

3. Results and Discussion

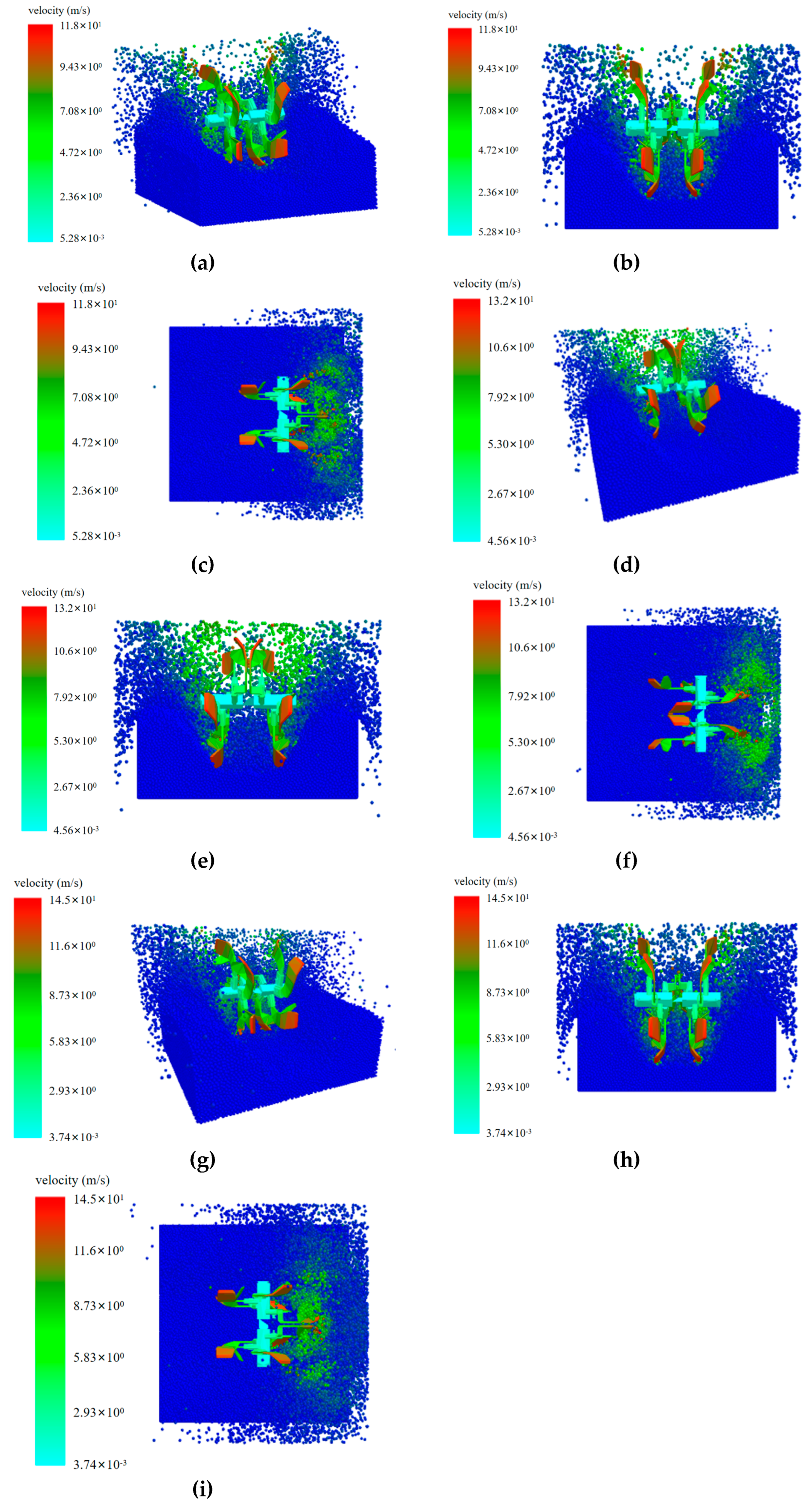

3.1. Simulation Test Results and Analysis

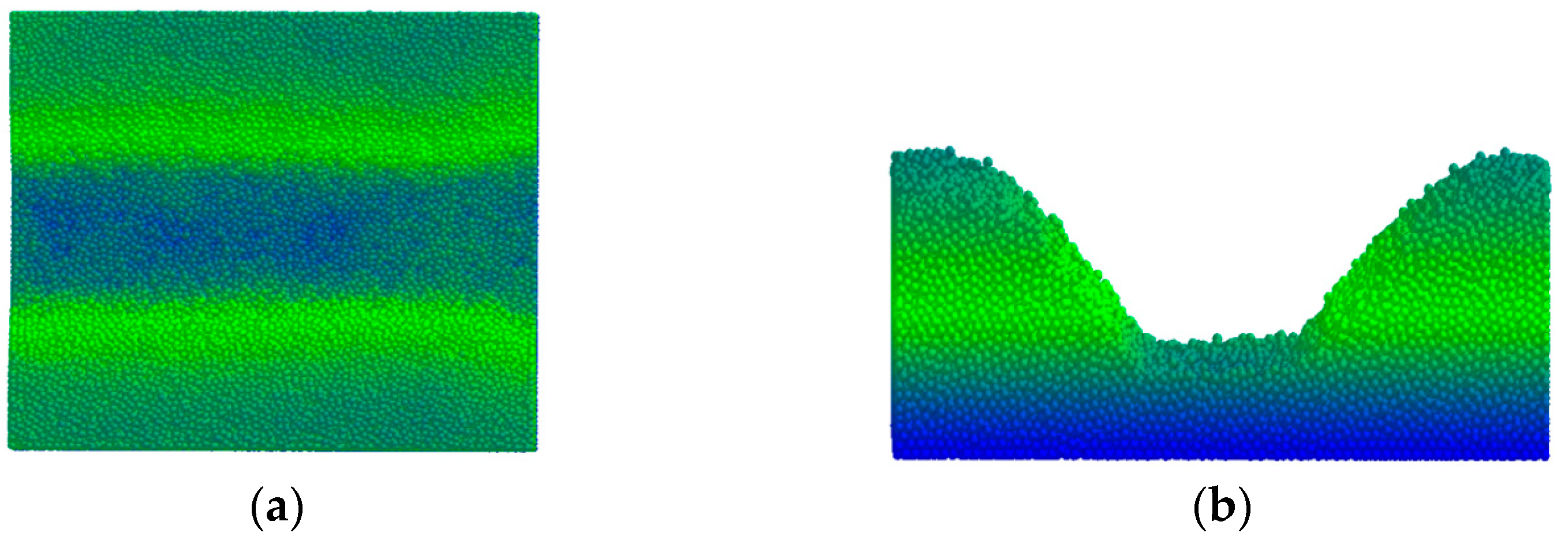

3.1.1. Simulation Groove Section Results and Analysis

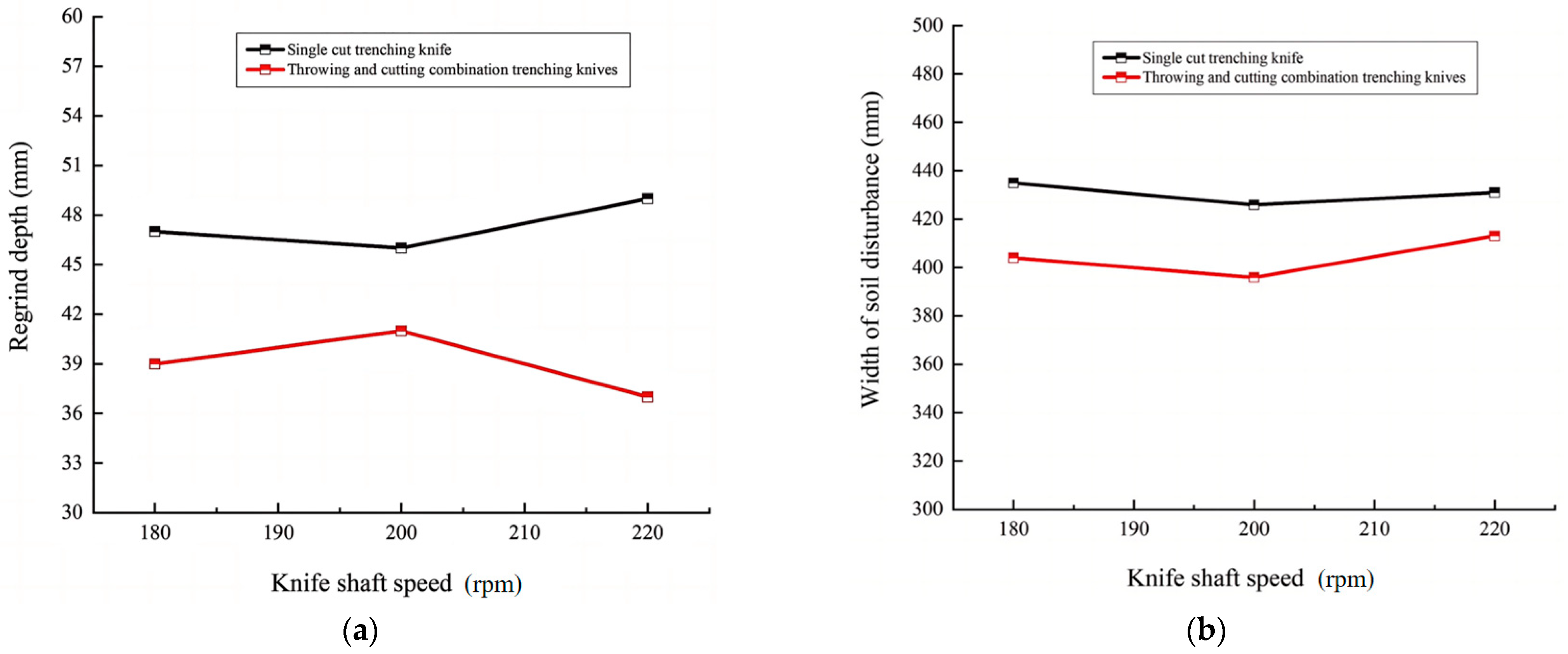

3.1.2. Analysis of Backfill Depth and Soil Disturbance

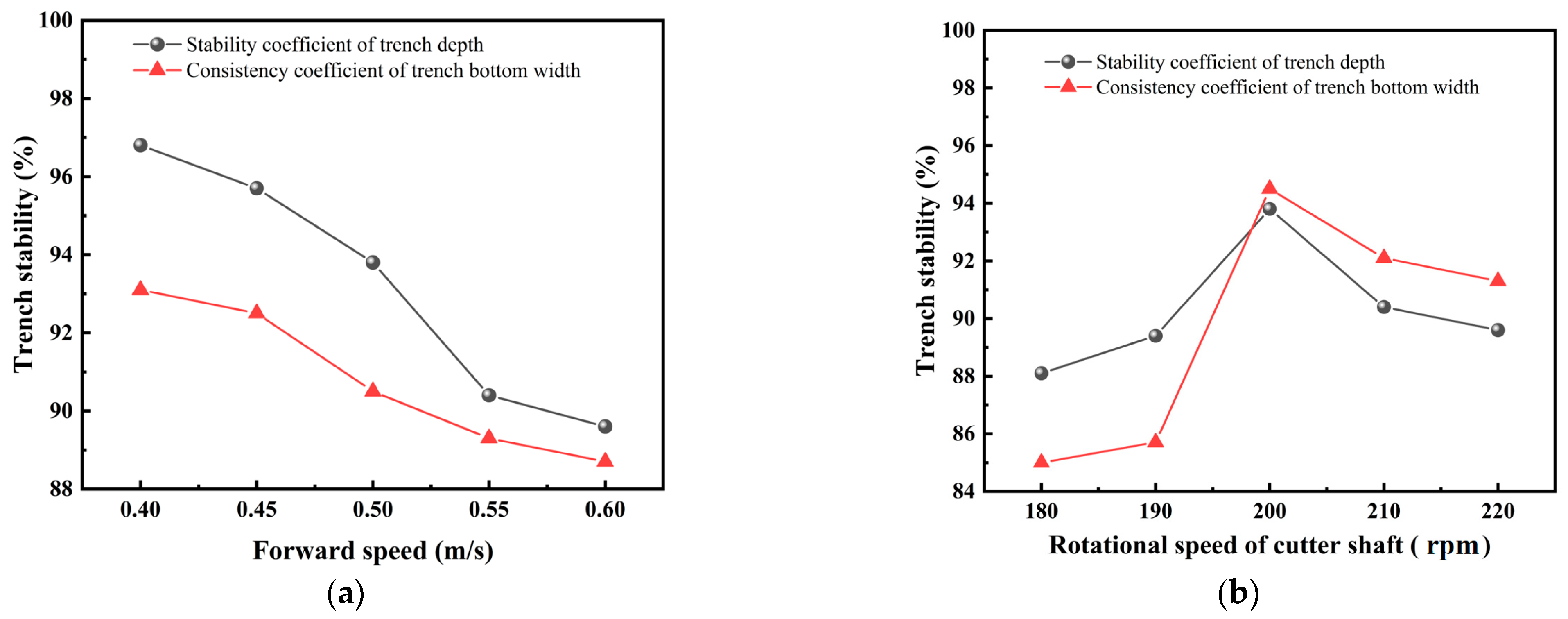

3.1.3. Analysis of Ditching Stability and Ditching Width Consistency Coefficient

3.1.4. Results and Analysis of Orthogonal Simulation Experiment on Ditching Knife

3.2. Field Trial Results and Analysis

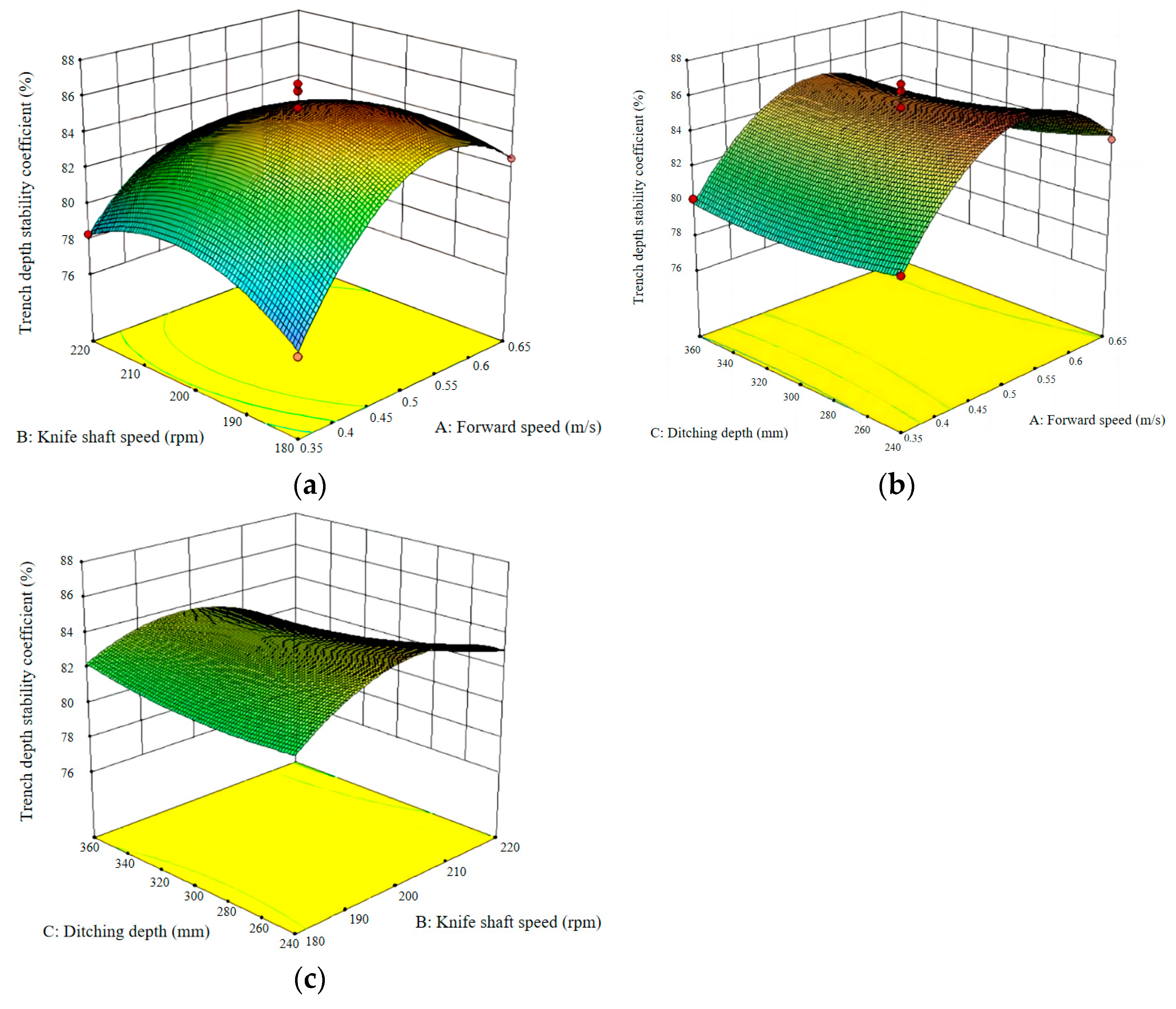

3.2.1. Response Surface Analysis

3.2.2. Ditching Performance Test and Results

4. Conclusions

- The overall design of the ditching and film-covering machine and the optimization of its crucial component—the ditching knife—have enhanced the uniformity of soil-throwing and the stability of ditching depth. The optimized key dimensions of the ditching knife include an end height of the tangent surface at 65 mm, an inclination angle of 30°, a soil-throwing piece width of 120 mm, and a lateral width of soil throwing reaching 300 mm.

- The improved structure of the ditching knife was validated by EDEM 2020 simulation analysis, demonstrating enhanced control over soil disturbance and reduced soil return depth in sandy soils, showcasing robust anti-disturbance capabilities. The optimal operating parameters for the ditching knife were set as: operating speed of 0.5 m/s, knife shaft speed of 200 rpm, ditching depth of 300 mm, ditching power consumption of 0.668 kW, and trench depth stability of 86.7%.

- Field test results confirmed the accuracy of the simulation model and the machine’s operational performance. The tests revealed an average ditching depth of 310 mm, a trench surface width of 413 mm, a trench bottom width of 304 mm, and a post-ditching soil crushing rate of 92.4%, all meeting or surpassing national agricultural mechanization standards.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, Z.; Gui, D.; Murtaza, G.; Liu, Y.; Ali, S. An Overview of Smart Irrigation Management for Improving Water Productivity under Climate Change in Drylands. Agronomy 2023, 13, 2113. [Google Scholar] [CrossRef]

- Li, W.R. Analysis on agricultural ecological environment protection and agricultural sustainable development in Northwest China. Hebei Agric. 2024, 6, 41–42. [Google Scholar]

- Jiang, W.; Liu, J.; Zhao, X. Effects of saline drip irrigation on greenhouse tomato growth and yield under yellow sand cultivation mode. Acta Agric. Univ. Jiangxiensis 2024, 46, 356–366. [Google Scholar]

- Chen, Y.Y.; Luo, Y.J.; Shi, Z.X. Research on the development trend of soilless cultivation. Chin. Veg. 2023, 36, 139–148. [Google Scholar] [CrossRef]

- Savvas, D.; Giannothanasis, E.; Ntanasi, T.; Karavidas, I.; Ntatsi, G. State of the Art and New Technologies to Recycle the Fertigation Effluents in Closed Soilless Cropping Systems Aiming to Maximise Water and Nutrient Use Efficiency in Greenhouse Crops. Agronomy 2024, 14, 61. [Google Scholar] [CrossRef]

- Li, B.S.; Li, H.; Wang, Q.; Li, W.K.; Zhao, M.J.; Zhou, C.B. Effects of film covering on root zone temperature and growth of sweet pepper seedlings in ridge-embedded and furrow-embedded substrate cultivation in solar greenhouse. Shandong Agric. Sci. 2021, 6, 33–38. [Google Scholar] [CrossRef]

- Tan, Z.M.; Zheng, Y.; Shu, S.; Xiong, C.R.; Du, J.G.; Li, C.Y. Yellow sand soilless cultivation model of greenhouse tomatoes in southern Xinjiang. North. Hortic. 2020, 22, 166–169. [Google Scholar]

- Jiang, N.; Yang, Z.; Zhang, H.; Xu, J.; Li, C. Effect of Low Temperature on Photosynthetic Physiological Activity of Different Photoperiod Types of Strawberry Seedlings and Stress Diagnosis. Agronomy 2023, 13, 1321. [Google Scholar] [CrossRef]

- Guo, H.; Yao, L. Problems and countermeasures of high-quality development of Xinjiang vegetable industry under the background of rural revitalization. North. Hortic. 2024, 4, 129–136. [Google Scholar]

- Chen, Y.M.; Li, Z.G.; Zhang, W.B. Research progress and development strategies of mechanization of facility agriculture. Agric. Eng. 2022, 12, 22–24. [Google Scholar] [CrossRef]

- Sun, Z.Y. Analysis on the advantages of east-west planting of vegetables in solar greenhouse. Jiangsu Agric. Mech. 2021, 2, 14–16. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Chen, Y.; Lin, P.; Zhang, Q.; Cheng, Y.; Yang, Z.; Huang, G. Research on Ditching Mechanism of Self-Excited Vibration Ditching Machine. Agronomy 2023, 13, 905. [Google Scholar] [CrossRef]

- Chai, M.H. Comparative experiment report on mechanized trenching and fertilization for grape production management and maintenance in Yaodu District. Agric. Dev. Equip. 2024, 5, 145–147. [Google Scholar]

- Yang, X.; Wang, J.; Yang, J. Design and experiment of furrow opener for orchard furrow fertilization machine. J. Chin. Agric. Mech. 2023, 9, 36–42. [Google Scholar] [CrossRef]

- Liu, D.; Gong, Y.; Wang, G. Design and experiment of a compound operation machine for trenching, fertilization, mulching and soil covering in dry pond melon. Agric. Res. Arid Areas 2020, 5, 243–251. [Google Scholar]

- Liu, S.X.; Xu, C.B.; Zhang, H.J. Transactions of the Chinese Society for Agricultural Machinery Research status and development analysis of orchard basal fertilizer fertilization equipment. Trans. Chin. Soc. Agric. Mach. 2020, 2, 99–108. [Google Scholar]

- Nie, Y. Research status and development trend of orchard furrow fertilization machine. Agric. Sci. Technol. Equip. 2020, 5, 55–56. [Google Scholar] [CrossRef]

- Hamroqul, R. Parameters of the furrow cutter with levellers of the combined machine. E3S Web Conf. 2023, 390, 6–7. [Google Scholar] [CrossRef]

- Sukhbir, S.; Ashok, T.; Singh, A.K. Effect of Furrow Opener Design, Furrow Depth, Operating Speed on Soil Characteristics, Draft and Germination of Sugarcane. Sugar Tech 2016, 19, 476–484. [Google Scholar] [CrossRef]

- James, B.; Jack, D.; Mustafa, U.; John, M.F. Bentleg furrow opener performance analysis using the discrete element method. Biosyst. Eng. 2020, 189, 99–115. [Google Scholar] [CrossRef]

- Ravshanov, K.; Fayzullaev, K.; Ismoilov, I.; Irgashev, D.; Mamatov, S.; Mardonov, S. The machine for the preparation of the soil in sowing of plow crops under film. IOP Conf. Ser. Mater. Sci. Eng. 2020, 883, 23–25. [Google Scholar] [CrossRef]

- Neil, B.; Allan, J.; Gordon, O. Performance of hoe and triple disc furrow openers on no-till grain drills in a fine sandy loam soil. Soil Tillage Res. 2019, 195, 104–106. [Google Scholar] [CrossRef]

- Liu, P.Z.; Zhang, T.; Zhang, F.G.; Ren, X.L.; Chen, X.L.; Zhao, X.N. Ridge and furrow configuration improved grain yield by optimizing the soil hydrothermal environment and maize canopy traits in Northwest China. Plant Soil 2022, 499, 23–36. [Google Scholar] [CrossRef]

- Lei, X.; Yuan, Q.; Xu, T.; Qi, Y.; Zeng, J.; Huang, K.; Sun, Y.; Herbst, A.; Lyu, X. Technologies and Equipment of Mechanized Blossom Thinning in Orchards: A Review. Agronomy 2023, 13, 2753. [Google Scholar] [CrossRef]

- Aili, H.; Ying, C. Soil disturbance and draft force of selected seed openers. Soil Tillage Res. 2014, 140, 48–54. [Google Scholar] [CrossRef]

- Chen, X.G.; Zhang, Z.Q. Construction of agricultural production conditions, capital inflow to rural areas and modernization of agricultural production methods. Contemp. Econ. Res. 2024, 6, 86–94. [Google Scholar]

- Zeng, Y.; Jiang, X.; Wu, M. Development of a stratified cutting and throwing trenching cutter set for oil tea forest based on DEM-MBD. Trans. Chin. Soc. Agric. Eng. 2024, 8, 30–42. [Google Scholar]

- Liu, M.Z.; Xie, F.P.; Liu, D. Analysis and experiment on power consumption of reverse rotary trenching machine roller based on particle size effect. Trans. Chin. Soc. Agric. Eng. 2024, 7, 83–92. [Google Scholar]

- Chen, Y.F.; Liao, K.; Chen, F. Optimization design and experiment of forest trencher cutter. J. Chin. Agric. Mech. 2024, 3, 38–43. [Google Scholar] [CrossRef]

- Zhang, M.W.; Liu, H.Y. Design and research of a new rotary tillage, furrowing and fertilizing seeder. Agric. Mech. Res. 2024, 8, 120–124. [Google Scholar] [CrossRef]

- Cai, Y.C.; Gao, Q.M.; Luo, Y.Y. Design and experiment of self-propelled vegetable garden ditch fertilization machine. China Agric. Mach. Equip. 2023, 8, 70–73. [Google Scholar]

- Xu, C.B.; Wang, J.X.; Zhang, J.H.; Liu, S.X.; Quan, Z.; Zhang, C.F. Finite element simulation analysis of key structures of orchard double-row ditch fertilization machine. J. Agric. Mech. Res. 2022, 9, 12–13. [Google Scholar] [CrossRef]

- Shi, Y.L.; Chen, X.Y.; Chen, D.M.; Wang, D.W.; Shang, S.Q. Design and experiment of plowshare furrowing and ridging device for sweet potato ridging and shaping machine. Trans. Chin. Soc. Agric. Mach. 2022, 10, 16–25. [Google Scholar]

- Zhang, H.P.; Lin, C.; Chen, L.X.; Zhang, P.K.; Zheng, S.H. Design and experiment of a machine for trenching, fertilizing and covering soil in tea garden. J. Chin. Agric. Mech. 2022, 3, 28–35. [Google Scholar] [CrossRef]

- Wang, C.W.; Zou, K.; Xiao, H. Design and experiment of tobacco furrowing and soil-raising machine. China Agric. Mach. Equip. 2024, 1, 2–8. [Google Scholar]

- Li, X.J.; Li, L.H. Design and experiment of combined stubble-killing and seedling-strip rotary tillage machine. J. Chin. Agric. Mech. 2020, 8, 13–19. [Google Scholar] [CrossRef]

- Qin, K.; Liang, X.L.; Cao, M.C.; Ding, W.M.; Wu, Z.M.; Fang, L.F. Design and experiment of combined trenching knife for cutting and throwing in tea garden. Trans. Chin. Soc. Agric. Mach. 2021, 5, 74–82. [Google Scholar]

- Guo, H.; Sun, B.H.; Bi, Z.B. Design and experiment of hanging grape vine burying machine. Agric. Mech. Res. 2018, 12, 86–90. [Google Scholar] [CrossRef]

- Jia, Y.; Hu, J.; Li, Q.D. Simulation and experimental study of deep tillage shovel based on EDEM discrete element method. Chin. Agric. Mech. 2016, 4, 14–18. [Google Scholar] [CrossRef]

- Chen, H.X.; Qi, W.; Wang, J. Design of furrow opener based on discrete element method and response surface method. Mech. Des. 2023, 1, 65–71. [Google Scholar] [CrossRef]

- Yang, W.M.; Wu, B.; Peng, Z.; Tan, S.W. Evaluation of trenching quality of vertical spiral trencher based on discrete element method. J. Southwest Univ. 2019, 12, 1–7. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Soil trough L × W × H | mm | 2000 × 600 × 400 |

| Forward speed | m/s | 0.4–0.6 |

| Rotational speed of cutter shaft | rpm | 180–220 |

| Soil density | kg/m3 | 1600 |

| Poisson’s ratio for soil | 0.35 | |

| Soil shear modulus | Pa | 1 × 106 |

| Iron density | kg/m3 | 7860 |

| Fe Poisson’s ratio | 0.4 | |

| Shear modulus of Fe | Pa | 8 × 1010 |

| Soil–soil recovery factor | 0.6 | |

| Soil–Fe coefficient of recovery | 0.5 | |

| Soil–soil static friction factor | 0.4 | |

| Soil–Fe static friction factor | 0.7 | |

| Soil–soil rolling friction factor | 0.55 | |

| Soil–Fe rolling friction factor | 0.05 | |

| Normal contact stiffness factor | N·m−3 | 19,000 |

| Tangential contact stiffness factor | N·m−3 | 14,000 |

| Critical normal stress | KPa | 50 |

| Critical tangential stress | KPa | 30 |

| Cutter Shaft Speed (rpm) | Soil Disturbance Width (mm) | Backfill Depth (mm) |

|---|---|---|

| 180 | 435 | 47 |

| 200 | 426 | 46 |

| 220 | 431 | 49 |

| Cutter Shaft Speed (rpm) | Soil Disturbance Width (mm) | Backfill Depth (mm) |

|---|---|---|

| 180 | 404 | 39 |

| 200 | 396 | 41 |

| 220 | 413 | 37 |

| Test Number | Forward Speed A (m/s) | Knife Shaft Speed B (rpm) | Ditching Depth C (mm) | Trench Depth Pass Rate Y1 (%) | Total Power Y2 (W) |

|---|---|---|---|---|---|

| 1 | 1 (0.4) | 1 (180) | 1 (250) | 97.6 | 655 |

| 2 | 1 | 2 (200) | 2 (300) | 99.2 | 515 |

| 3 | 1 | 3 (220) | 3 (350) | 97.8 | 867 |

| 4 | 2 (0.5) | 1 | 2 | 98.2 | 972 |

| 5 | 2 | 2 | 3 | 97.7 | 1008 |

| 6 | 2 | 3 | 1 | 98.4 | 892 |

| 7 | 3 (0.6) | 1 | 3 | 96.3 | 1513 |

| 8 | 3 | 2 | 1 | 97.3 | 1032 |

| 9 | 3 | 3 | 2 | 98.1 | 1347 |

| K1 | 294.60 | 292.10 | 293.30 | ||

| K2 | 294.30 | 294.20 | 295.50 | ||

| K3 | 291.70 | 294.30 | 291.80 | ||

| k1 | 98.20 | 97.37 | 97.77 | ||

| k2 | 98.10 | 98.07 | 98.50 | ||

| k3 | 97.23 | 98.10 | 97.27 | ||

| Extremely poor R | 0.97 | 0.73 | 1.23 | ||

| Optimum level | A1 | B3 | C2 | ||

| Major and minor factors | B > A > C | ||||

| Best combination | A1B2C1 | ||||

| Norm | Source of Variation | Square Sum | Degrees of Freedom | Mean Square | F-Value | Significance |

|---|---|---|---|---|---|---|

| Trench depth pass rate (Y1) | A | 2.069 | 2 | 1.035 | 129.313 | 0.007 |

| B | 1.029 | 2 | 0.514 | 64.306 | 0.015 | |

| C | 2.309 | 2 | 1.154 | 144.306 | 0.008 | |

| Errors | 0.016 | 2 | 0.008 | |||

| Aggregate | 5.423 | 8 | ||||

| Power wastage (Y2) | A | 573,889.8 | 2 | 286,944.9 | 168.103 | 0.06 |

| B | 72,673.88 | 2 | 36,336.94 | 24.414 | 0.045 | |

| C | 114,297.9 | 2 | 57,148.95 | 33.679 | 0.029 | |

| Errors | 3393.736 | 2 | 1696.868 | |||

| Aggregate | 764,255.3 | 8 |

| Test Number | Forward Speed (m/s) | Knife Shaft Speed (rpm) | Ditching Depth (mm) | Total Power (KW) | Trench Depth Pass Rate (%) |

|---|---|---|---|---|---|

| 1 | 0.6 | 220 | 300 | 0.751 | 78.6 |

| 2 | 0.5 | 200 | 300 | 0.668 | 84.3 |

| 3 | 0.4 | 200 | 350 | 0.751 | 80.2 |

| 4 | 0.5 | 180 | 250 | 0.614 | 84.3 |

| 5 | 0.5 | 180 | 350 | 0.657 | 84.6 |

| 6 | 0.5 | 220 | 350 | 0.692 | 81.4 |

| 7 | 0.6 | 180 | 300 | 0.716 | 82.6 |

| 8 | 0.4 | 180 | 300 | 0.716 | 76.4 |

| 9 | 0.5 | 200 | 300 | 0.677 | 85.4 |

| 10 | 0.5 | 200 | 300 | 0.653 | 83.6 |

| 11 | 0.6 | 200 | 350 | 0.742 | 82.4 |

| 12 | 0.4 | 200 | 250 | 0.647 | 80.4 |

| 13 | 0.4 | 220 | 300 | 0.726 | 78.3 |

| 14 | 0.5 | 200 | 300 | 0.662 | 86.3 |

| 15 | 0.5 | 200 | 300 | 0.674 | 86.7 |

| 16 | 0.5 | 220 | 250 | 0.638 | 84.1 |

| Operational Performance Indicators | Unit | Standard | Experimental Measurements |

|---|---|---|---|

| Ditching depth | mm | ≥300 | 310 |

| Ditching depth stability | % | ≥80.0 | 87.1 |

| Trench width | mm | 400 | 413 |

| Width of the trench bottom | mm | 300 | 304 |

| Rate of soil fragmentation after furrowing | % | ≥55 | 92.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Xu, J.; Xing, J.; Wang, X.; Hu, C.; Wang, L.; Li, W. Research and Experiment on the Ditching Performance of a Ditching and Film-Covering Machine in the Yellow Sand Cultivation Mode of Solar Greenhouses. Agronomy 2024, 14, 1704. https://doi.org/10.3390/agronomy14081704

Song Y, Xu J, Xing J, Wang X, Hu C, Wang L, Li W. Research and Experiment on the Ditching Performance of a Ditching and Film-Covering Machine in the Yellow Sand Cultivation Mode of Solar Greenhouses. Agronomy. 2024; 14(8):1704. https://doi.org/10.3390/agronomy14081704

Chicago/Turabian StyleSong, Yalong, Jiahui Xu, Jianfei Xing, Xufeng Wang, Can Hu, Long Wang, and Wentao Li. 2024. "Research and Experiment on the Ditching Performance of a Ditching and Film-Covering Machine in the Yellow Sand Cultivation Mode of Solar Greenhouses" Agronomy 14, no. 8: 1704. https://doi.org/10.3390/agronomy14081704