Subsoiling Operations Concurrent to the Distribution of Acidity Amendments in the Soil Profile: The Response from Soybeans

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of the Experimental Area

2.2. Experimental Design and Treatments

2.3. Field Study Setup and Conduction

2.3.1. Soybean: 2019/2020 Agricultural Year Summer Harvest

2.3.2. Soybean 2020/2021 Agricultural Year Summer Harvest

2.4. Data Statistical Analyses

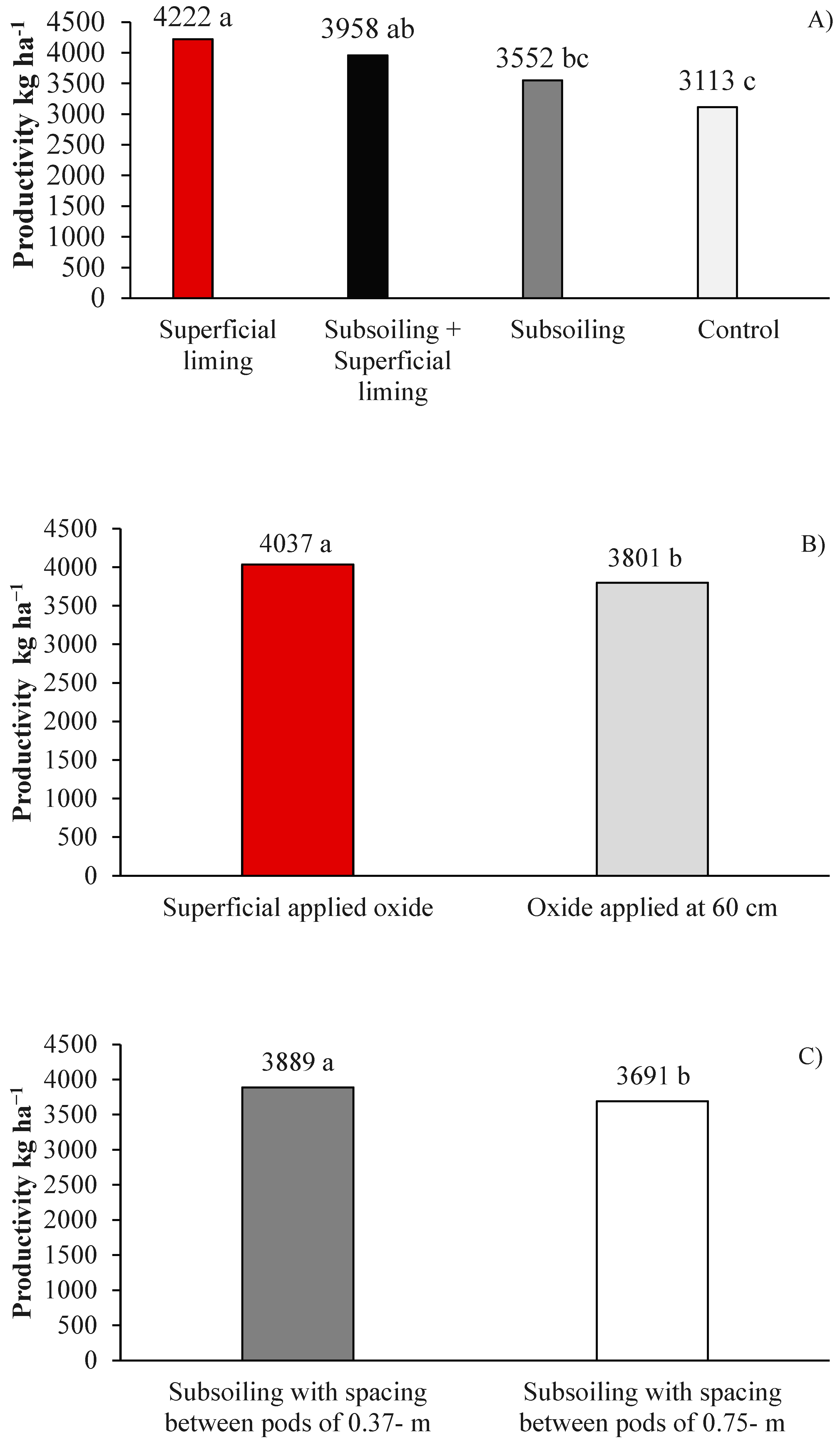

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United States Department of Agriculture (USDA). Grain: World Markets and Trade. 2022. Available online: https://apps.fas.usda.gov/psdonline/app/index.html#/app/home (accessed on 23 January 2023).

- Companhia Nacional de Abastecimento (CONAB). Acompanhamento da safra brasileira de grãos, safra 2021/22. Conab 2022, 9, 1–88. Available online: https://www.conab.gov.br/info-agro/safras/graos (accessed on 1 January 2022).

- Diniz, J.F.; Roque, C.G.; Ratke, R.F.; Vaez, R.N.; Teodoro, P.E.; Aguilera, J.G.; Campos, C.N.S.; Martínez, L.A.; Oliveira, J.T. Soybean grain yield as a function of surface and residual lime application. Res. Soc. Dev. 2022, 11, e16911225569. [Google Scholar] [CrossRef]

- Silva, T.A.; Silva, P.B.; Silva, E.A.A.; Nakagawa, J.; Cavariani, C. Condicionamento fisiológico de sementes de soja, componentes de produção e produtividade. Ciênc. Rural 2016, 46, 228–232. [Google Scholar] [CrossRef]

- Debarba, L.; Amado, T.J.C. Desenvolvimento de sistemas de produção de milho no sul do Brasil com características de sustentabilidade. Rev. Bras. Ciênc. Solo 1997, 21, 473–480. [Google Scholar] [CrossRef]

- Oliveira, M.; Barré, P.; Trindade, H.; Virto, I. Different efficiencies of grain legumes in crop rotations to improve soil aggregation and organic carbon in the short-term in a sandy Cambisol. Soil Tillage Res. 2019, 186, 23–35. [Google Scholar] [CrossRef]

- Liu, K.; Bandara, M.; Hamel, C.; Knightd, J.D.; Gana, Y. Intensifying crop rotations with pulse crops enhances system productivity and soil organic carbon in semi-arid environments. Field Crops Res. 2020, 248, 2–10. [Google Scholar] [CrossRef]

- Klein, V.A.; Dallmeyer, A.U.; Escosteguy, P.A.V.; Boller, W.; Fioreze, I.; Vieira, M.L.; Durigon, F.F.; Fávero, F. Adaptação de um equipamento para incorporação de calcário em solos sob plantio direto. Rev. Ciênc. Agrovet. 2007, 6, 95–103. [Google Scholar]

- Caires, E.F.; Joris, H.A.W.; Churka, S. Long-term effects of lime and gypsum additions on no-till corn and soybean yield and soil chemical properties in Southern Brazil. Soil Use Manag. 2011, 27, 45–53. [Google Scholar] [CrossRef]

- Dalla Nora, D.; Amado, T.J.C. Improvement in chemical attributes of Oxisol subsoil and crop yields under no-till. Agron. J. 2013, 105, 1393–1403. [Google Scholar] [CrossRef]

- Bortoluzzi, E.C.; Parize, G.L.; Korchagin, J.; Silva, V.R.; Rheinheimer, D.S.; Kaminski, J. Crescimento radicular da soja e produtividade da cultura em resposta à calagem no início do sistema plantio direto. Rev. Bras. Ciênc. Solo 2014, 38, 262–271. [Google Scholar] [CrossRef]

- Davies, S.L.; Armstrong, R.; Macdonald, L.; Condon, J.; Petersen, E. Soil constraints: A role for strategic deep tillage. Agron. Aust. 2019, 1, 117–135. [Google Scholar]

- Scanlan, C.; Brennan, R.; Sarre, G. Shifting Investment from Nutrients to Lime and Cultivation on Acid Soils: Is an Immediate Payback Possible? GRDC Updates Papers. 2014. Available online: https://grdc.com.au (accessed on 10 July 2024).

- Moraes, E.R.; Mageste, J.G.; Lana, R.M.Q.; Torres, J.L.R.; Domingues, L.A.S.; Lemes, E.M.; Lima, L.C. Sugarcane root development and yield under different soil tillage practices. Rev. Bras. Ciênc. Solo 2019, 43, e0180090. [Google Scholar] [CrossRef]

- Khorami, S.S.; Kazemeini, S.A.; Afzalinia, S.; Gathala, M.K. Changes in soil properties and productivity under different tillage practices and wheat genotypes: A short-term study in Iran. Sustainability 2018, 10, 3273. [Google Scholar] [CrossRef]

- Issaka, F.; Zhang, Z.; Zhao, Z.; Asenso, E.; Li, J.H.; Li, Y.T.; Wang, J.J. Sustainable conservation tillage improves soil nutrients and reduces nitrogen and phosphorus losses in maize farmland in southern China. Sustainability 2019, 11, 2397. [Google Scholar] [CrossRef]

- Dalla Nora, D.; Amado, T.J.C.; Nicoloso, R.S.; Mazuco, A.C.B.; Piccin, M. Mitigation of the Gradient of Chemical Properties in the Rooting Zone of Dystrophic Oxisols by Gypsum and Lime Inputs under a No-Till System. Rev. Bras. Ciênc. Solo 2017, 41, e0150541. [Google Scholar] [CrossRef]

- Falleiro, R.M.; Souza, C.M.; Silva, C.S.W.; Sediyama, C.S.; Silva, A.A.; Fagundes, J.L. Influência dos sistemas de preparo nas propriedades químicas e físicas do solo. Rev. Bras. Ciênc. Solo 2003, 27, 1097–1104. [Google Scholar] [CrossRef][Green Version]

- Alonço, A.S.; Ferreira, O.O. Incorporação profunda de fertilizantes e calcário: Sua influência na produção de milho (Zea mays L.) sob estresse hídrico e sobre algumas propriedades físicas e químicas de um solo de cerrado. Congr. Bras. Eng. Agríc. 1992, 20, 1206–1225. [Google Scholar]

- Azam, G.; Gazey, C. Slow movement of alkali from surface-applied lime warrants the introduction of strategic tillage for rapid amelioration of subsurface acidity in south-western Australia. Soil Res. 2021, 59, 97–106. [Google Scholar] [CrossRef]

- Cortez, J.W.; Alves, A.D.S.; Moura, R.D.; Olszevski, N.; Nagahama, H.J. Atributos físicos do Argissolo amarelo do semiárido nordestino sob sistemas de preparo. Rev. Bras. Ciênc. Solo 2011, 35, 207–216. [Google Scholar] [CrossRef]

- Nagahama, H.J.; Granja, G.P.; Cortez, J.W.; Ramos, R.L.; Arcoverde, S.N.S. Efeitos da escarificação mecânica nos atributos físicos do solo e agronômicos do capim elefante. Rev. Ceres 2016, 63, 741–746. [Google Scholar] [CrossRef]

- Santos, C.C.; Rosa, D.P.; Pagnussat, L.; Pesini, F.; Fincatto, D. Subsolador com disco de corte de palha x subsolador convencional: Manutenção da palhada e condições físicas de um solo sob plantio direto. Ramvi 2014, 1, 1–11. Available online: https://www.passofundo.ideau.com.br/wp-content/files_mf/9559c71d6151c056100d3c25cc004681193_1.pdf (accessed on 5 February 2023).

- Peixoto, D.S.; Silva, B.M.; Oliveira, G.C.; Moreira, S.G.; Silva, F.; Curi, N. A soil compaction diagnosis method for occasional tillage recommendation under continuous no tillage system in Brazil. Soil Tillage Res. 2019, 194, 104307. [Google Scholar] [CrossRef]

- Silva, R.F.; Severiano, E.C.; Oliveira, G.C.; Barbosa, S.M.; Peixoto, D.S.; Tassinari, D.; Silva, B.M.; Silva, S.H.G.; Dias Júnior, M.S.; Figueiredo, T.A.F. Changes in soil profile hydraulic properties and porosity as affected by deep tillage soil preparation and Brachiaria grass intercropping in a recent coffee plantation on a naturally dense Inceptisol. Soil Tillage Res. 2021, 213, 105127. [Google Scholar] [CrossRef]

- Santos, H.G.d.; Jacomine, P.K.T.; Anjos, L.H.C.d.; Oliveira, V.A.d.; Lumbreras, J.F.; Coelho, M.R.; Almeida, J.A.d.; Araujo Filho, J.C.d.; Oliveira, J.B.d.; Cunha, T.J.F. Brazilian Soil Classification System, 5th ed.; Embrapa: Brasília, Brazil, 2018. [Google Scholar]

- Teixeira, P.C.; Donagemma, G.K.; Fontana, A.; Teixeira, W.G. Manual de Métodos de Análises de Solo, 3rd ed.; Embrapa Solos: Brasília, Brazil, 2017. [Google Scholar]

- Silva, F.C.d. Avaliação da Disponibilidade de Fósforo por Diversos Extratores em Solos Cultivados com Cana-de-Açúcar (Saccharum spp.). Master’s Thesis, Escola Superior de Agricultura Luiz de Queiroz, Piracicaba, Brazil, 1991. [Google Scholar]

- Assumpção, J.C.d. Comparação dos Extratores EDTA, DTPA e Acetato de Amônio (NH4OAc) com o Extrator de Mehlich, na Determinação de Micronutrientes em Solos Tropicais. Master’s Thesis, Universidade Federal Fluminense, Niterói, Brazil, 1995. [Google Scholar]

- Vitti, G.C. Avaliação e Interpretação do Enxofre no Solo e na Planta, 1st ed.; FCAV/UNESP: Jaboticabal, Brazil, 1989. [Google Scholar]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; Moraes, G.; Leonardo, J.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Raij, B.V.; Camargo, A.P.; Cantarella, H.; Silva, N.M. Alumínio trocável e saturação em bases como critérios para recomendação de calagem. Bragantia 1983, 42, 149–156. [Google Scholar] [CrossRef]

- de Sousa, D.M.G.; Lobato, E. Calagem e Adubação Para Culturas Anuais e Semiperenes, 2nd ed.; Embrapa: Brasília, Brazil, 2004. [Google Scholar]

- Malavolta, E.; Vitti, G.C.; Oliveira, S.A.d. Avaliação do Estado Nutricional das Plantas: Princípios e Aplicações, 2nd ed.; Associação Brasileira para Pesquisa de Potássio e do Fósforo: Piracicaba, Brazil, 1997. [Google Scholar]

- Brasil Ministério da Agricultura e da Reforma Agrária. Regras Para Análise de Sementes, 1st ed.; Mapa: Brasília, Brazil, 1992. [Google Scholar]

- Bates, D.; Mächler, M.; Bolker, B.M.; Walker, S.C. Fitting linear mixed-effects using lme4. arXiv 2014, arXiv:1406.5823. [Google Scholar]

- Searle, S.R.; Speed, F.M.; Milliken, G.A. Population marginal means in the linear model: Na alternative to least squares means. Am. Stat. 2012, 34, 216–221. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2022; Available online: https://www.R-project.org/ (accessed on 1 January 2022).

- Urano, E.O.M.; Kurihara, C.H.; Maeda, S.; Vitorino, A.C.T.; Gonçalves, M.C.; Marchetti, M.E. Determinação de teores ótimos de nutrientes em soja pelos métodos chance matemática, sistema integrado de diagnose e recomendação e diagnose da composição nutricional. Rev. Bras. Ciênc. Solo 2007, 31, 63–72. [Google Scholar] [CrossRef]

- Crusciol, C.A.C.; Artigiani, A.C.C.A.; Arf, O.; Carmeis Filho, A.C.A.; Soratto, R.P.; Nascente, A.S.; Alvarez, R.C.F. Soil fertility, plant nutrition, and grain yield of upland rice affected by surface application of lime, silicate, and phophogypsum in a tropical no-till system. Catena 2016, 137, 87–99. [Google Scholar] [CrossRef]

- Dancer, W.S.; Peterson, L.A.; Chesters, G. Ammonification and nitrification of n as influenced by soil pH and previous n treatments. Soil Sci. Soc. Am. J. 1973, 37, 67–69. [Google Scholar] [CrossRef]

- Carmeis Filho, A.C.A.; Penn, C.; Crusciol, C.A.C.; Calonego, J.C. Lime and phosphorus impacts on soil organic matter pools in a tropical Oxisol under long-term no-tillage conditions. Agric. Ecosyst. Environ. 2017, 241, 11–23. [Google Scholar] [CrossRef]

- Malavolta, E. Fósforo e Adubação Fosfatada no Cerrado, 1st ed.; Sotave: Goiânia, Brazil, 1984. [Google Scholar]

- Resende, H.O.; Braz, M.G.; Smaniotto, A.O.; Tempesta, I.F.; Costa, C.H.M.; Cruz, S.C.S. Residual effect of gypsum and phosphate fertilization on the second corn crop. J. Agric. Sci. 2019, 11, 535–546. [Google Scholar] [CrossRef]

- Oliveira, E.L.; Pavan, M.A. Control of soil acidity in no-tillage system for soybeanproduction. Soil Till. Res. 1996, 38, 47–57. [Google Scholar] [CrossRef]

- Caires, E.F.; Fonseca, A.F.; Mendes, J.; Chueiri, W.A.; Madruga, E.F. Produção de milho, trigo e soja em função das alterações das características químicas do solo pela aplicação de calcário e gesso na superfície, em sistema de plantio direto. Rev. Bras. Ciênc. Solo 1999, 23, 315–327. [Google Scholar] [CrossRef]

- Soratto, R.P.; Crusciol, C.A.C. Atributos químicos do solo decorrentes da aplicação em superfície de calcário e gesso em Sistema de Plantio Direto recém-implantado. Rev. Bras. Ciênc. Solo 2008, 32, 675–688. [Google Scholar] [CrossRef]

- Pereira, C.S.; Freitas, A.A.; Chapla, M.V.; Lange, A. Doses de potássio com a presença de enxofre na cultura da soja. Glob. Scien. Technol. 2016, 9, 22–32. [Google Scholar] [CrossRef]

- Piccin, M.; Amado, T.J.C.; Fiorin, J.E. Estratégias de manejo para melhoria da camada de enraizamento profunda de um Latossolo. Rev. Ciênc. Agrár. 2020, 43, 174–183. [Google Scholar] [CrossRef]

- Caires, E.F.; Banzatto, D.A.; Fonseca, A.F. Calagem na superfície em sistema plantio direto. Rev. Bras. Ciênc. Solo 2000, 24, 161–169. [Google Scholar] [CrossRef]

- Tejo, D.P.; Fernandes, C.H.S.; Buratto, J.S. Soja: Fenologia, morfologia e fatores que interferem na produtividade. Rev. Cient. Eletr. Agron. 2019, 35, 1–9. [Google Scholar]

- Piccin, M.; Keller, C.; Amado, T.J.C.; Pedron, V.F.; Santos, G.H.; Batista, D.J.O.; Baptistella, M.H.B. Limitações físicas e químicas do subsolo para o aprofundamento radicular em SPD. Rev. Agron. Bras. 2019, 3, 3. [Google Scholar] [CrossRef]

- Vargas, J.P.R.; Santos, D.R.; Bastos, M.C.; Schaefer, G.; Parisi, P.B. Application forms and types of soil acidity corrective: Changes in depth chemical atributes in long term period experimente. Soil Till. Res. 2019, 185, 47–60. [Google Scholar] [CrossRef]

- Tiritan, C.S.; Büll, L.T.; Crusciol, C.A.C.; Carmeis Filho, A.C.A.; Fernandes, D.M.; Nascente, A.S. Tillage system and lime application in a tropical region: Soil chemical fertility and corn yield in succession to degraded pastures. Soil Till Res. 2016, 155, 437–447. [Google Scholar] [CrossRef]

| Layer | pH CaCl2 | Ca | Mg | Al | H+Al | K | * P | S |

|---|---|---|---|---|---|---|---|---|

| cm | ---------------- cmolc dm−3 ------------------ | --------mg dm−3--------- | ||||||

| 00–20 | 4.90 | 1.87 | 0.80 | 0.06 | 4.80 | 49.0 | 3.90 | 10.90 |

| 20–40 | 4.70 | 1.00 | 0.47 | 0.05 | 4.10 | 28.0 | 1.90 | 41.10 |

| 40–60 | 5.30 | 0.76 | 0.33 | 0.00 | 3.10 | 18.0 | 1.90 | 49.50 |

| 60–80 | 5.10 | 0.81 | 0.37 | 0.04 | 2.90 | 15.0 | 1.40 | 41.50 |

| 80–100 | 5.50 | 0.71 | 0.37 | 0.00 | 2.60 | 17.0 | 1.30 | 13.20 |

| Layer | O.M. | O.C. | B | Cu | Fe | Mn | Zn | Na |

| cm | ---------- g dm−3 -------- | ------------------------- mg dm−3 ----------------------------- | ||||||

| 0–20 | 29.70 | 17.2 | 0.10 | 24.6 | 34.9 | 31.8 | 37.7 | 3.80 |

| 20–40 | - | - | - | 20.3 | 43.1 | 18.9 | 9.20 | 2.40 |

| 40–60 | - | - | - | 19.2 | 48.4 | 11.9 | 3.90 | 2.50 |

| 60–80 | - | - | - | 20.8 | 54.0 | 12.0 | 3.00 | 2.30 |

| 80–100 | - | - | - | 21.4 | 52.3 | 11.0 | 3.00 | 2.60 |

| Layer | CEC | Base Sat. | Al Sat. | Clay | Silt | Sand | ||

| cm | cmolc dm−3 | ----------%---------- | -------------g kg−1------------- | |||||

| 0–20 | 7.60 | 36.8 | 2.10 | 640 | 75 | 285 | ||

| 20–40 | 5.60 | 27.5 | 3.10 | - | - | - | ||

| 40–60 | 4.20 | 27.1 | 0.00 | - | - | - | ||

| 60–80 | 4.10 | 29.8 | 3.20 | - | - | - | ||

| 80–100 | 3.70 | 30.3 | 0.00 | - | - | - | ||

| Treatments | CFI | SD | PH | FP |

|---|---|---|---|---|

| mm | cm | cm | ||

| Subsoiling liming | 47.30 a | 3.94 a | 42.90 a | 18.10 a |

| Subsoiling + superficial liming | 46.70 a | 3.97 a | 43.10 a | 17.60 a |

| Subsoiling | 47.50 a | 4.23 a | 41.20 a | 18.10 a |

| Control | 45.80 a | 3.99 a | 40.50 a | 19.00 a |

| Depth | ||||

| Superficial | 47.00 a | 3.96 a | 43.00 a | 17.90 a |

| Incorporated at 60 cm | 47.00 a | 3.94 a | 42.30 a | 17.50 a |

| Spacing between rods | ||||

| Subsoiling 0.75 | 48.10 a | 4.14 a | 44.80 a | 19.40 a |

| Subsoiling 0.37 | 48.50 a | 4.22 a | 45.30 a | 19.70 a |

| Treatments | N | P | K | Ca | Mg | S |

|---|---|---|---|---|---|---|

| g kg−1 | ||||||

| Subsoiling liming | 20.80 a | 2.92 a | 24.80 a | 9.08 a | 3.66 a | 3.08 a |

| Subsoiling + superficial liming | 18.70 a | 3.06 a | 24.80 a | 9.44 a | 3.92 a | 3.02 a |

| Subsoiling | 16.70 ab | 2.60 a | 24.00 a | 7.92 ab | 3.61 a | 2.70 a |

| Control | 12.40 b | 2.41 a | 23.40 a | 5.31 b | 3.15 a | 2.72 a |

| Depth | ||||||

| Superficial | 19.10 a | 2.90 a | 22.50 a | 8.84 a | 3.70 a | 2.98 a |

| Incorporated at 60 cm | 16.30 b | 2.37 b | 19.60 a | 6.93 b | 3.24 b | 2.78 a |

| Spacing | ||||||

| Subsoiling 0.75 | 17.20 a | 2.35 a | 21.20 a | 6.43 a | 3.37 a | 2.69 b |

| Subsoiling 0.37 | 16.10 a | 2.62 a | 21.00 a | 7.84 a | 3.58 a | 3.07 a |

| Treatments | PFINAL | PP | GP | GPD | MTG |

|---|---|---|---|---|---|

| g | |||||

| Superficial liming | 251,543 a | 85.50 a | 82.30 a | 2.34 a | 165 a |

| Subsoiling + superficial liming | 242,593 a | 88.10 a | 81.70 a | 2.25 a | 158 b |

| Subsoiling | 252,469 a | 79.00 ab | 79.40 a | 2.25 a | 154 b |

| Control | 258,642 a | 68.10 b | 70.40 a | 2.20 a | 146 c |

| Depth | |||||

| Superficial | 247,068 a | 86.80 a | 92.10 a | 2.41 a | 166 a |

| Incorporated 60 cm | 237,037 a | 74.90 b | 87.80 a | 2.35 a | 159 b |

| Spacing | |||||

| Subsoiling 0.75 | 263,881 a | 81.90 a | 87.20 a | 2.32 a | 163 a |

| Subsoiling 0.37 | 252,770 a | 87.40 a | 86.50 a | 2.36 a | 166 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smaniotto, A.O.; Castoldi, G.; Laurindo, A.K.O.A.; Silva, T.L.; Tempesta, I.F.; Paim, T.d.P.; Costa, C.H.M.d.; Cruz, S.C.S. Subsoiling Operations Concurrent to the Distribution of Acidity Amendments in the Soil Profile: The Response from Soybeans. Agronomy 2024, 14, 1893. https://doi.org/10.3390/agronomy14091893

Smaniotto AO, Castoldi G, Laurindo AKOA, Silva TL, Tempesta IF, Paim TdP, Costa CHMd, Cruz SCS. Subsoiling Operations Concurrent to the Distribution of Acidity Amendments in the Soil Profile: The Response from Soybeans. Agronomy. 2024; 14(9):1893. https://doi.org/10.3390/agronomy14091893

Chicago/Turabian StyleSmaniotto, Alex Oliveira, Gustavo Castoldi, Adryel Kayro Oliveira Adorno Laurindo, Thiago Lopes Silva, Izamara Fonseca Tempesta, Tiago do Prado Paim, Claudio Hideo Martins da Costa, and Simério Carlos Silva Cruz. 2024. "Subsoiling Operations Concurrent to the Distribution of Acidity Amendments in the Soil Profile: The Response from Soybeans" Agronomy 14, no. 9: 1893. https://doi.org/10.3390/agronomy14091893

APA StyleSmaniotto, A. O., Castoldi, G., Laurindo, A. K. O. A., Silva, T. L., Tempesta, I. F., Paim, T. d. P., Costa, C. H. M. d., & Cruz, S. C. S. (2024). Subsoiling Operations Concurrent to the Distribution of Acidity Amendments in the Soil Profile: The Response from Soybeans. Agronomy, 14(9), 1893. https://doi.org/10.3390/agronomy14091893