Optimization of Application Parameters for UAV-Based Liquid Pollination in Pear Orchards: A Yield and Cost Perspective

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Equipment

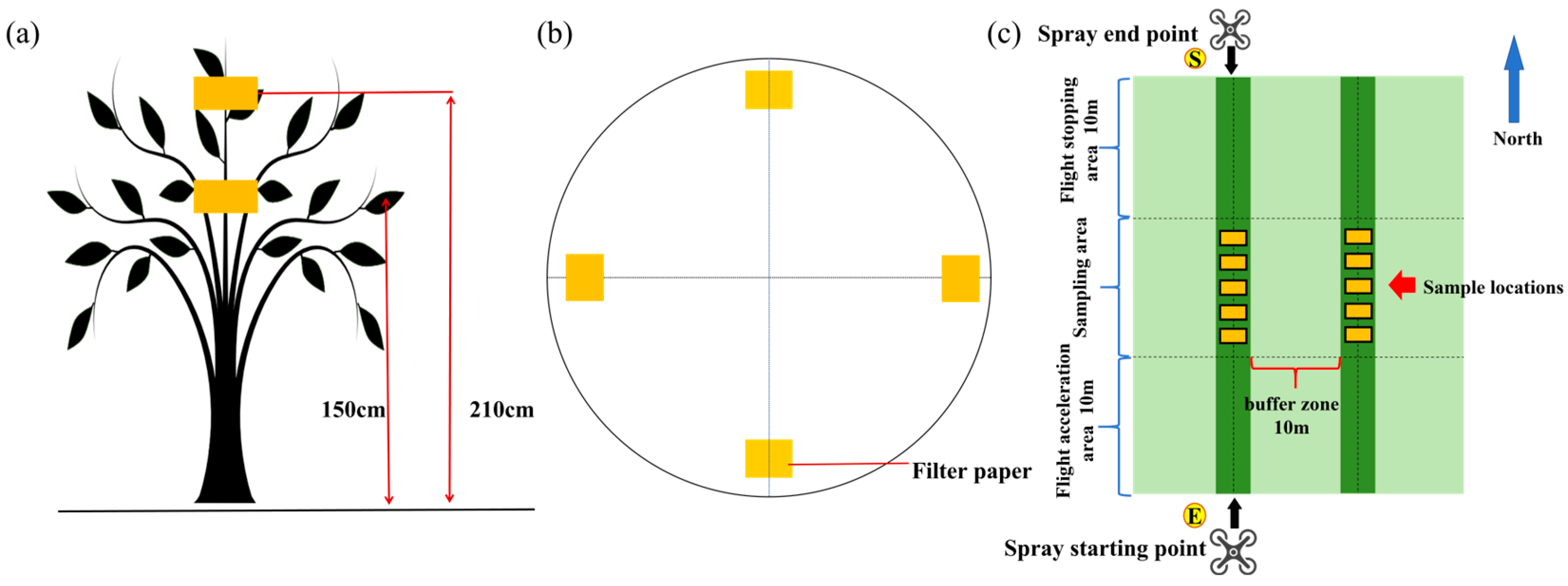

2.3. Test of Droplet Deposition in Canopy under Different Flight Parameters

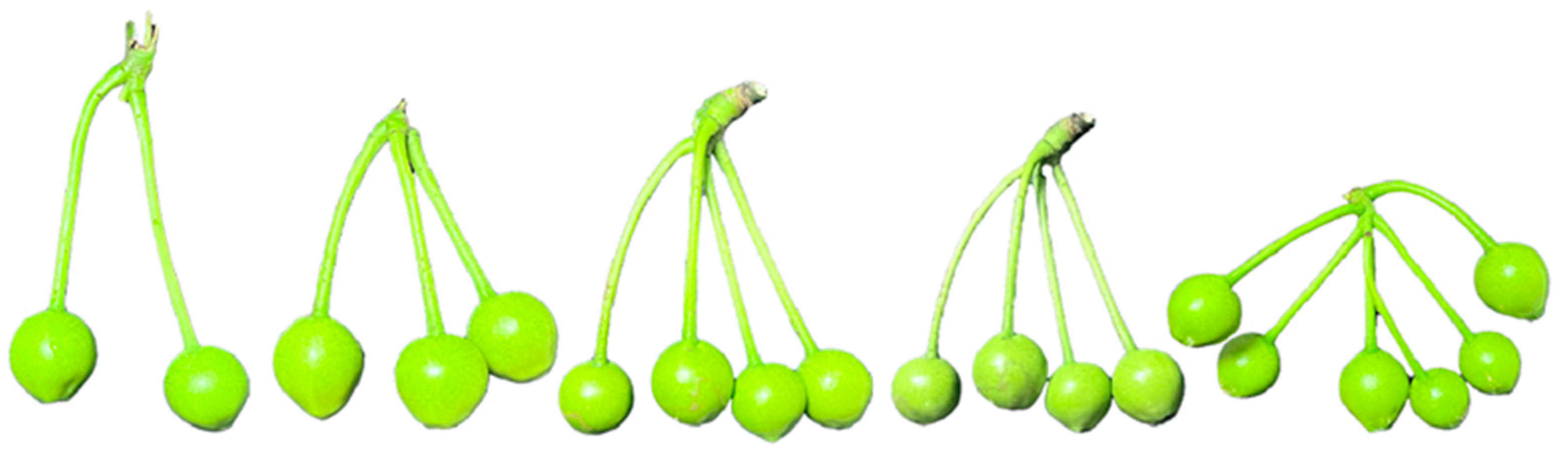

2.4. Test on the Effect of Different Floral Stages and Spraying Frequency on Fruit Set Rate

2.5. Investigation of the Efficiency and Cost of Fruit Thinning Operations

2.6. Data Statistics and Processing

3. Results

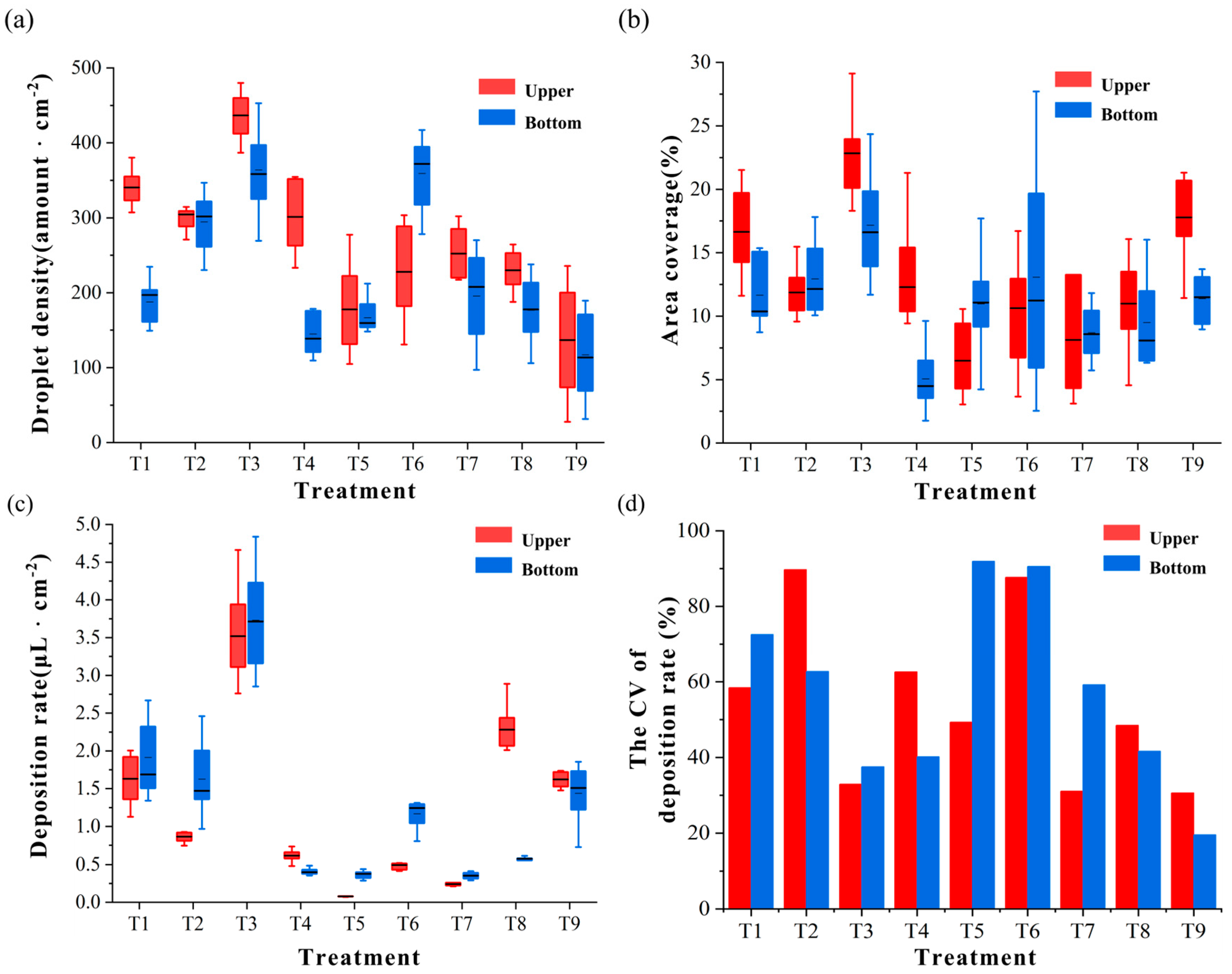

3.1. Analysis of Spray Droplet Deposition Characteristics and Selection of Optimal Operating Parameter Combinations

3.2. Results of Floral Stage and Spraying Frequency on Fruit Set Rate

3.3. Efficiency and Cost Inputs of Fruit Thinning under Different Fruit Set Rates

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, G.-M.; Gu, C.; Qiao, X.; Zhao, B.-Y.; Ke, Y.-Q.; Guo, B.-B.; Hao, P.-P.; Qi, K.-J.; Zhang, S.-L. Characteristic of pollen tube that grew into self style in pear cultivar and parent assignment for cross-pollination. Sci. Hortic. 2017, 216, 226–233. [Google Scholar] [CrossRef]

- Dinis, A.M.; Mesquita, J.F. Uptake of heavy metal salt solutions by pollen grains of Magnolia × soulangeana (Magnoliaceae). Can. J. Bot. 2004, 82, 1758–1767. [Google Scholar] [CrossRef]

- Sakamoto, D.; Hayama, H.; Ito, A.; Kashimura, Y.; Moriguchi, T.; Nakamura, Y. Spray pollination as a labor-saving pollination system in Japanese pear (Pyrus pyrifolia (Burm. f.) Nakai): Development of the suspension medium. Sci. Hortic. 2009, 119, 280–285. [Google Scholar] [CrossRef]

- Kumawat, P.; Rathore, R.S.; Singh, R.P.; Kumar, S. Study the effect of different pollination techniques on date palm production. Sugar Tech 2022, 24, 1887–1893. [Google Scholar] [CrossRef]

- Karimi, H.R.; Mohammadi, N.; Estaji, A.; Esmaeilizadeh, M. Effect of supplementary pollination using enriched pollen suspension with Zn on fruit set and fruit quality of pistachio. Sci. Hortic. 2017, 216, 272–277. [Google Scholar] [CrossRef]

- Tacconi, G.; Michelotti, V.; Cacioppo, O.; Vittone, G. Kiwifruit pollination: The interaction between pollen quality, pollination systems and flowering stage. J. Berry Res. 2016, 6, 417–426. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.; Han, H.; Jiang, Y.; He, X.; Liu, Y.; Wang, D.; Guo, X.; Liang, Z. Influence of Different Liquid Spray Pollination Parameters on Pollen Activity of Fruit Trees—Pear Liquid Spray Pollination as an Example. Horticulturae 2023, 9, 350. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Guo, S.; Li, J.; Yao, W.; Zhan, Y.; Li, Y.; Shi, Y. Distribution characteristics on droplet deposition of wind field vortex formed by multi-rotor UAV. PLoS ONE 2019, 14, e0220024. [Google Scholar] [CrossRef]

- Broussard, M.A.; Coates, M.; Martinsen, P. Artificial pollination technologies: A review. Agronomy 2023, 13, 1351. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, R.; Lu, X.; Quan, S.; Liu, Y.; Lin, C.; Wei, J.; Su, Y.; Yao, R. Pollination parameter optimization and field verification of UAV-based pollination of ‘Kuerle Xiangli’. Agronomy 2022, 12, 2561. [Google Scholar] [CrossRef]

- Mahmud, M.S.; He, L.; Heinemann, P.; Choi, D.; Zhu, H. Unmanned aerial vehicle based tree canopy characteristics measurement for precision spray applications. Smart Agric. Technol. 2023, 4, 100153. [Google Scholar] [CrossRef]

- Xiongkui, H.; Bonds, J.; Herbst, A.; Langenakens, J. Recent development of unmanned aerial vehicle for plant protection in East Asia. Int. J. Agric. Biol. Eng. 2017, 10, 18–30. [Google Scholar] [CrossRef]

- Huang, X.; Dong, X.; Ma, J.; Liu, K.; Ahmed, S.; Lin, J.; Ahmad, F.; Qiu, B. Evaluation and experiment of flight parameter quality of the plant protection UAV based on laser tracker. Agriculture 2021, 11, 628. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, B.; Xue, X.; Sun, T.; Gu, W.; Zhou, F.; Sun, X. Effects of crop protection unmanned aerial system flight speed, height on effective spraying width, droplet deposition and penetration rate, and control effect analysis on wheat aphids, powdery mildew, and head blight. Appl. Sci. 2021, 11, 712. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Lei, X.; Zhao, S.; Lu, J.; Jiang, Y.; Xie, B.; Wang, M. Research progress on efficient pollination technology of crops. Agronomy 2022, 12, 2872. [Google Scholar] [CrossRef]

- Guerra, M.; Álvarez-Taboada, F.; Marabel, V.; Felices, A.M.; Rodríguez-González, Á.; Casquero, P.A. Organic Agricultural Practice: Crop Load Management Enhancing Quality and Storability of High-Russet Pears. Horticulturae 2024, 10, 686. [Google Scholar] [CrossRef]

- Wójcik, P. Quality and ‘Conference’pear storability as influenced by preharvest sprays of calcium chloride. J. Plant Nutr. 2012, 35, 1970–1983. [Google Scholar] [CrossRef]

- Sidhu, R.S.; Bound, S.A.; Hunt, I. Crop load and thinning methods impact yield, nutrient content, fruit quality, and physiological disorders in ‘Scilate’ apples. Agronomy 2022, 12, 1989. [Google Scholar] [CrossRef]

- Dengeru, Y.; Ramasamy, K.; Allimuthu, S.; Balakrishnan, S.; Kumar, A.P.M.; Kannan, B.; Karuppasami, K.M. Study on spray deposition and drift characteristics of UAV agricultural sprayer for application of insecticide in redgram crop (Cajanus cajan L. Millsp.). Agronomy 2022, 12, 3196. [Google Scholar] [CrossRef]

- Matsumoto, S.; Soejima, J.; Maejima, T. Influence of repeated pollination on seed number and fruit shape of ‘Fuji’ apples. Sci. Hortic. 2012, 137, 131–137. [Google Scholar] [CrossRef]

- Awais, M.; Li, W.; Cheema, M.J.M.; Hussain, S.; AlGarni, T.S.; Liu, C.; Ali, A. Remotely sensed identification of canopy characteristics using UAV-based imagery under unstable environmental conditions. Environ. Technol. Innov. 2021, 22, 101465. [Google Scholar] [CrossRef]

- Qin, W.-C.; Qiu, B.-J.; Xue, X.-Y.; Chen, C.; Xu, Z.-F.; Zhou, Q.-Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Chen, S.D.; Lan, Y.; Li, J.Y.; Zhou, Z.Y.; Liu, A.M.; Mao, Y.D. Effect of wind field below unmanned helicopter on droplet deposition distribution of aerial spraying. Int. J. Agric. Biol. Eng. 2017, 10, 67–77. [Google Scholar] [CrossRef]

- Ahmad, F.; Qiu, B.; Dong, X.; Ma, J.; Huang, X.; Ahmed, S.; Chandio, F.A. Effect of operational parameters of UAV sprayer on spray deposition pattern in target and off-target zones during outer field weed control application. Comput. Electron. Agric. 2020, 172, 105350. [Google Scholar] [CrossRef]

- Wang, C.; He, X.; Bonds, J.; Qi, P.; Yang, Y.; Guo, W. Effect of downwash airflow field of octocopter plant protection UAV on droplet deposition distribution characteristics under different flight parameters. Smart Agric. 2020, 2, 124–136. [Google Scholar] [CrossRef]

- Garibaldi, L.A.; Carvalheiro, L.G.; Leonhardt, S.D.; Aizen, M.A.; Blaauw, B.R.; Isaacs, R.; Kuhlmann, M.; Kleijn, D.; Klein, A.M.; Kremen, C. From research to action: Enhancing crop yield through wild pollinators. Front. Ecol. Environ. 2014, 12, 439–447. [Google Scholar] [CrossRef]

- Fotirić Akšić, M.; Cerović, R.; Hjeltnes, S.H.; Meland, M. The effective pollination period of European plum (Prunus domestica L.) cultivars in western Norway. Horticulturae 2022, 8, 55. [Google Scholar] [CrossRef]

- Tominaga, A.; Ito, A.; Sugiura, T.; Yamane, H. How is global warming affecting fruit tree blooming? “Flowering (dormancy) disorder” in Japanese pear (Pyrus pyrifolia) as a case study. Front. Plant Sci. 2022, 12, 787638. [Google Scholar] [CrossRef]

- Losada, J.M.; Herrero, M. Arabinogalactan-protein secretion is associated with the acquisition of stigmatic receptivity in the apple flower. Ann. Bot. 2012, 110, 573–584. [Google Scholar] [CrossRef]

- Roeder, S.; Serra, S.; Musacchi, S. Effective pollination period and parentage effect on pollen tube growth in apple. Plants 2021, 10, 1618. [Google Scholar] [CrossRef]

- Page, M.L.; Williams, N.M. Honey bee introductions displace native bees and decrease pollination of a native wildflower. Ecology 2023, 104, e3939. [Google Scholar] [CrossRef]

- Ramírez-Mejía, A.F.; Chacoff, N.P.; Lomáscolo, S.B.; Woodcock, B.A.; Schmucki, R.; Blendinger, P.G. Optimal pollination thresholds to maximize blueberry production. Agric. Ecosyst. Environ. 2024, 365, 108903. [Google Scholar] [CrossRef]

- Harder, L.D.; Aizen, M.A.; Richards, S.A. The population ecology of male gametophytes: The link between pollination and seed production. Ecol. Lett. 2016, 19, 497–509. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Tateishi, N.; Tanabe, K. Pollen density on the stigma affects endogenous gibberellin metabolism, seed and fruit set, and fruit quality in Pyrus pyrifolia. J. Exp. Bot. 2010, 61, 4291–4302. [Google Scholar] [CrossRef] [PubMed]

- Sanzol, J.; Rallo, P.; Herrero, M. Stigmatic receptivity limits the effective pollination period in ‘Agua de Aranjuez’ pear. J. Am. Soc. Hortic. Sci. 2003, 128, 458–462. [Google Scholar] [CrossRef]

- Dötterl, S.; Gershenzon, J. Chemistry, biosynthesis and biology of floral volatiles: Roles in pollination and other functions. Nat. Prod. Rep. 2023, 40, 1901–1937. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, Z.; Han, H.; Qiao, B.; Li, Y.; He, X.; Liu, Y. Effect of Pre-Germination Temperature Regime on Pollen Germination and Fruit Set in Pear, Pyrus bretschneiderilia. Horticulturae 2023, 9, 1151. [Google Scholar] [CrossRef]

- Lei, X.; Yuan, Q.; Xyu, T.; Qi, Y.; Zeng, J.; Huang, K.; Sun, Y.; Herbst, A.; Lyu, X. Technologies and Equipment of Mechanized Blossom Thinning in Orchards: A Review. Agronomy 2023, 13, 2753. [Google Scholar] [CrossRef]

- Hussain, M.; He, L.; Schupp, J.; Lyons, D.; Heinemann, P. Green fruit segmentation and orientation estimation for robotic green fruit thinning of apples. Comput. Electron. Agric. 2023, 207, 107734. [Google Scholar] [CrossRef]

| Crop Parameters | Messages |

|---|---|

| Crop | Pear |

| Variety | Huangguan |

| Canopy features | Horizontal trellis type |

| Height of crop (m) | 2~2.3 |

| Row-to-row spacing (m) | 2.1 |

| Plant-to-plant spacing (m) | 1.5 |

| Parameters | Values |

|---|---|

| UAV type | DJT25 |

| Main rotor diameter (mm−1) | 1270 |

| Unfold fuselage size (L × W × H mm−1) | 2585 × 2675 × 780 |

| Maximum wheelbase (mm−1) | 1925 |

| Payload capacity (Kg−1) | 20 |

| Self-weight (Kg−1) | 25.4 |

| Maximum take-off weight (Kg−1) | 52 |

| Power source | BAX702-15500mAh-52.22V lithium-ion batteries |

| Type of nozzle | LX8060SZ |

| Number of nozzles | 2 |

| Nozzle spacing (mm−1) | 1368 |

| Fogging particle size (μm−1) | 50–330 |

| Effective spray range (m−1) | 4–7 |

| Treatment | FH (m) | FS (m·s−1) |

|---|---|---|

| T1 | 1.5 | 1 |

| T2 | 1.5 | 1.5 |

| T3 | 1.5 | 2 |

| T4 | 2 | 1 |

| T5 | 2 | 1.5 |

| T6 | 2 | 2 |

| T7 | 3 | 1 |

| T8 | 3 | 1.5 |

| T9 | 3 | 2 |

| Treatment | Flowering Grade | Spraying Times | Date | Wind Velocity | Air Temperature | Field Humidity |

|---|---|---|---|---|---|---|

| 1 | Ⅰ (≤15%) | 2 | March 14th | 0.8 m·s−1 | 20 °C | 71% |

| 2 | Ⅰ (≤15%) | 4 | March 14th | 0.8 m·s−1 | 20 °C | 71% |

| 3 | Ⅰ (≤15%) | 6 | March 14th | 0.7 m·s−1 | 20 °C | 71% |

| 4 | Ⅱ (15~30%) | 2 | March 15th | 0.6 m·s−1 | 23 °C | 70% |

| 5 | Ⅱ (15~30%) | 4 | March 15th | 0.6 m·s−1 | 23 °C | 70% |

| 6 | Ⅱ (15~30%) | 6 | March 15th | 0.6 m·s−1 | 23 °C | 70% |

| 7 | Ⅲ (30~50%) | 2 | March 15th | 0.5 m·s−1 | 25 °C | 70% |

| 8 | Ⅲ (30~50%) | 4 | March 15th | 0.5 m·s−1 | 25 °C | 70% |

| 9 | Ⅲ (30~50%) | 6 | March 15th | 0.6 m·s−1 | 25 °C | 70% |

| 10 | Ⅳ (50~70%) | 2 | March 16th | 0.8 m·s−1 | 20 °C | 74% |

| 11 | Ⅳ (50~70%) | 4 | March 16th | 0.8 m·s−1 | 20 °C | 74% |

| 12 | Ⅳ (50~70%) | 6 | March 16th | 0.8 m·s−1 | 20 °C | 74% |

| 13 | Ⅴ (≥70%) | 2 | March 17th | 0.9 m·s−1 | 18 °C | 80% |

| 14 | Ⅴ (≥70%) | 4 | March 17th | 0.8 m·s−1 | 18 °C | 80% |

| 15 | Ⅴ (≥70%) | 6 | March 17th | 0.8 m·s−1 | 18 °C | 80% |

| Ingredient | Content (%) | Volume or Mass |

|---|---|---|

| Water | Fixed volume to 50 L | |

| Sucrose | 13 | 6.5 kg |

| Xanthan gum | 0.02 | 10 g |

| Calcium nitrate | 0.05 | 25 g |

| Boric acid | 0.01 | 5 g |

| Fine pollen | 0.04~0.08 | 20~40 g |

| Treatment | Position | Spray Droplet Size (μm) | ||

|---|---|---|---|---|

| DV0.1 | DV0.5 | DV0.9 | ||

| T1 | Upper | 103.56 ± 4.47 | 169.67 ± 5.97 | 234.22 ± 4.38 |

| Bottom | 76.17 ± 6.63 | 135.00 ± 12.08 | 213.33 ± 9.90 | |

| T2 | Upper | 109.83 ± 2.04 | 190.75 ± 3.16 | 292.42 ± 4.31 |

| Bottom | 95.00 ± 7.96 | 195.11 ± 5.69 | 286.00 ± 5.12 | |

| T3 | Upper | 92.44 ± 2.88 | 168.00 ± 4.53 | 262.44 ± 11.78 |

| Bottom | 89.45 ± 3.97 | 160.55 ± 13.48 | 271.27 ± 4.53 | |

| T4 | Upper | 119.11 ± 7.86 | 223.11 ± 15.22 | 388.4 ± 7.78 |

| Bottom | 98.57 ± 9.21 | 194.00 ± 8.20 | 335.71 ± 5.59 | |

| T5 | Upper | 71.33 ± 6.67 | 113.00 ± 10.57 | 170.00 ± 6.86 |

| Bottom | 82.92 ± 7.39 | 127.08 ± 8.84 | 247.67 ± 7.48 | |

| T6 | Upper | 90.44 ± 7.99 | 209.33 ± 8.89 | 349.67 ± 12.62 |

| Bottom | 92.10 ± 3.66 | 174.50 ± 15.40 | 319.50 ± 15.03 | |

| T7 | Upper | 106.00 ± 9.02 | 213.00 ± 15.39 | 288.33 ± 17.85 |

| Bottom | 97.17 ± 6.73 | 183.00 ± 5.04 | 328.50 ± 7.28 | |

| T8 | Upper | 84.25 ± 2.25 | 134.00 ± 8.50 | 207.75 ± 18.65 |

| Bottom | 91.33 ± 12.39 | 125.33 ± 3.18 | 221.33 ± 26.77 | |

| T9 | Upper | 130.50 ± 7.96 | 291.00 ± 11.05 | 478.50 ± 11.11 |

| Bottom | 108.60 ± 5.70 | 342.40 ± 13.41 | 462.80 ± 21.87 | |

| Effect and Interaction | df | F Ratio | p Value | Significance |

|---|---|---|---|---|

| Spray times | 2 | 51.920 | 0.000 | ** |

| Flower grade | 4 | 28.135 | 0.000 | ** |

| Spray times × Flower grade | 8 | 17.301 | 0.000 | ** |

| Fruit Thinning | ||

|---|---|---|

| Fruit Set Rate | Efficiency (ha·h−1) | Cost (CNY·ha−1) |

| 40~50% | 0.017 | 776.47 |

| 50~60% | 0.013 | 1015.38 |

| 60~70% | 0.011 | 1200.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; He, M.; Li, M.; Yang, Y.; Li, H.; Xi, W.; Zhang, T. Optimization of Application Parameters for UAV-Based Liquid Pollination in Pear Orchards: A Yield and Cost Perspective. Agronomy 2024, 14, 2033. https://doi.org/10.3390/agronomy14092033

Wang P, He M, Li M, Yang Y, Li H, Xi W, Zhang T. Optimization of Application Parameters for UAV-Based Liquid Pollination in Pear Orchards: A Yield and Cost Perspective. Agronomy. 2024; 14(9):2033. https://doi.org/10.3390/agronomy14092033

Chicago/Turabian StyleWang, Pei, Moxin He, Mingqi Li, Yuheng Yang, Hui Li, Wanpeng Xi, and Tong Zhang. 2024. "Optimization of Application Parameters for UAV-Based Liquid Pollination in Pear Orchards: A Yield and Cost Perspective" Agronomy 14, no. 9: 2033. https://doi.org/10.3390/agronomy14092033