Abstract

Ratoon rice is characterized by higher production combined with enhanced rice quality. However, the relationship between the differences in the structure and properties of the starch and variations in the ratoon season and rice quality is still unclear. In this study, we conducted a field experiment in 2023 to assess the relationship between rice quality differences and starch characteristics of four different hybrid rice varieties (Longjingyou1212: LJY1212; Taoyouxiangzhan: TYXZ; Liangyou6326: LY6326; Fengliangyouxiang1: FLYX1) in the ratoon season. In terms of appearance, the chalkiness degrees and chalky grain percentage of LJY1212 (0.6%, 2.3%) and TYXZ (1.2%, 6.0%) were 53.5% and 53.9% lower than those of LY6326 (2.4%, 10.0%) and FLYX1 (1.6%, 7.8%), indicating that the appearances of LJY1212 and TYXZ were better than those of LY6326 and FLYX1. The average amylose contents of LJY1212 (18.5%) and TYXZ (19.0%) were 10.8% higher than those of LY6326 (17.7%) and FLYX1 (15.7%), and there was no significant difference in protein content between the varieties in the ratoon season. Regarding the starch microstructure, the starch granules of LJY1212 and TYXZ in the ratoon season were arranged more closely. The average ratios of 1045/1022 cm−1 of LJY1212 (0.77) and TYXZ (0.76) were 7.0% higher than those of LY6326 (0.71) and FLYX1 (0.72), indicating that the internal orders of LJY1212 and TYXZ’s starch were better than those of LY6326 and FLYX1. The average relative crystallinities of LJY1212 (24.8%) and TYXZ (24.5%) were 5.2% lower than those of LY6326 (25.7%) and FLYX1 (26.6%). The relative crystallinity of starch decreased with the increase in amylose content, while the short-range order degree, gelatinization temperature, and gelatinization enthalpy increased with the increase in amylose content. Therefore, the LJY1212 and TYXZ varieties, with better rice qualities, are recommended for planting in southern China.

1. Introduction

Rice (Oryza sativa L.) is a staple food for about one third of the world’s population. In terms of global cultivated area, it ranks the third among cereals with an annual harvest of 750 million tonnes [1]. Ratoon rice refers to a kind of planting method in which axillary buds germinate on the stubble left after the main-season rice is harvested. With appropriate cultivation and management measures, the axillary buds continue to grow and develop into spikes, which can then be harvested as a second season under this kind of planting method [2]. Compared with ordinary rice, it is widely planted in regions with a higher yield across two seasons. It has the advantages of a short growth period, high daily yield, seed saving, labor saving, water saving, low production cost, and high benefit [3]. Rice ratooning has become a popular multiple-cropping system to increase the grain yield in southern China, where light and temperature resources are sufficient for one seasonal crop but insufficient for two seasons [4,5]. The main goals of current rice breeding programs are high yield and high quality. High-quality rice usually has the characteristics of a good appearance, high head rice rate, and excellent taste [6]. Enhancing the grain productivity per unit area and the rice quality has thus taken on tremendous significance [7,8]. The area suitable for planting ratoon rice in southern China is about 3.3 million ha, and the planted area of ratoon rice is increasing at a rate of no less than 70,000 hectares per year [9].

In recent years, the breeding of ratoon rice varieties and the progress of cultivation techniques have promoted the development of ratoon rice in southern China. With the improvement in people’s living standards, consumers have higher and higher requirements for rice quality. However, at present, there are few studies on the quality of ratoon rice. Some studies have found that the amylose content of rice in the ratoon season was different from that in the main season depending on the variety. A study on the quality of the main crop and ratoon rice found that the processing quality and appearance of ratoon rice were higher than those of the main crop [10]. As an efficient resource-saving rice system, ratoon rice can enhance the rice quality and increase the income of farmers [11]. Duan et al. found that the chalkiness of different rice varieties planted in southern China ranged from 0.7% to 2.0% [12]. Zhang et al. planted four rice varieties with amylose contents in the range of 3.4–21.7% [13]. It can be seen that different genotypes of planted ratoon rice varieties often have different rice quality levels. Currently, there are few studies on the comprehensive quality of rice, which limits the development of the rice industry to a certain extent. Therefore, it is necessary to explore the differences in the comprehensive quality of rice in southern China.

Starch is the main stored carbohydrate that affects rice quality, and it is the main component of the endosperm of rice, primarily consisting of amylose and amylopectin, in which amylose content has a greater impact on the rice quality [14]. The results of a previous study showed that the amylose content of ratoon rice was different from that of the main crop, and the milling quality and appearance of ratoon rice were better than those of the main crop [10]. According to the XRD diffraction pattern, the starch crystal types can be divided into three types, A-, B-, and C-type, among which rice starch belongs to the A-type. It has been shown that amylose distributed in starch granules has a weakening effect on the crystal structure of starch, and there is a significant negative correlation between them [15]. Peng et al. found that the changes in rice starch granules and their size and morphology would affect the eating quality of rice [16]. Amylose usually exists in a helical structure, and its content is an important trait affecting the cooking, milling, and eating quality of rice [17,18]. Starch plays a decisive role in the pasting properties of rice. Starch granules swell and collapse, and amylose exudate and starch granules rupture to form a paste [19]. Deng et al. investigated differences in the starch’s structural and physicochemical properties and textural characteristics in cooked rice between the main crop and ratoon rice [20]. Ling et al. found that the gelatinization temperature and gelatinization enthalpy of rice starch were significantly positively correlated with the amylose content [21]. In general, first of all, the amylose content affects the crystal structure of starch granules and then affects the pasting properties of rice flour. Longvah et al. found that amylose and amylopectin constitute the multi-scale structure of starch [22]. This includes micro-scale starch granules, nano-scale starch amorphous wafers, remote crystal structures, and short-range helical structures. The changes in the multi-scale structure of starch determine the starch’s pasting properties and the eating quality of the rice to a certain extent. Given previous studies, we wanted to explore the relationship between rice quality differences among varieties and starch characteristics of main- and ratoon-season rice.

In this study, we planted four rice varieties in southern China and determined the differences in starch structure and rice quality between the main crop and ratoon rice. We wished to clarify the relationship between differences in rice quality and starch structure in different rice varieties so that we could provide suggestions for planting appropriate rice varieties in southern China.

2. Materials and Methods

2.1. Experimental Site

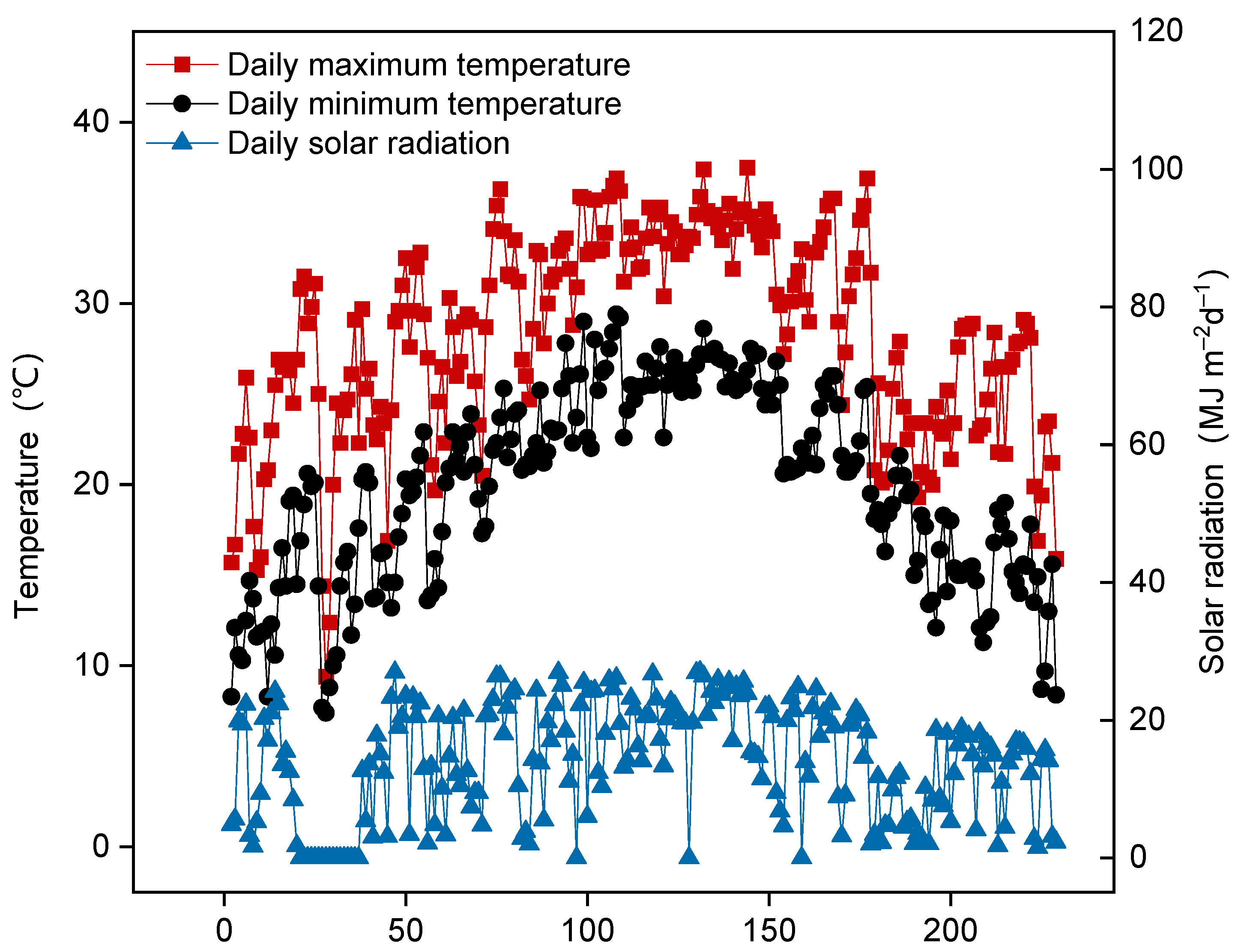

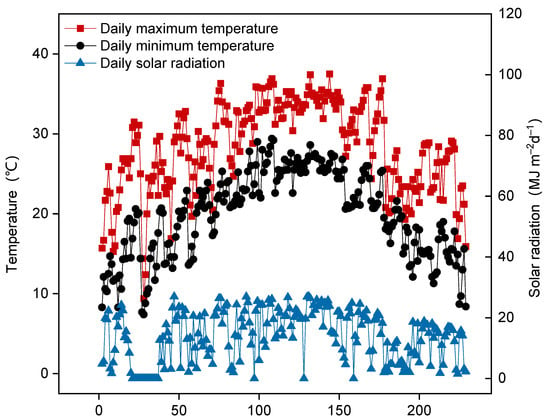

The experiment was conducted at Yangtze University’s experimental farm in Jingzhou, Hubei Province, China (112°31′ E, 30°21′ N) in 2023. Before the experiment, soil samples from the top 20 cm were gathered to assess soil qualities. Soil samples were collected from the four corners and the center of each treatment plot. The yearly soil characteristic value was then calculated using the average of the four soil samples. This area’s soil is gray fluvo-aquic, with a pH of 6.5, 23.6 g kg−1 of organic matter, 1.8 g kg−1 of total nitrogen, 26.3 mg kg−1 of readily available phosphorus, and 136.6 mg kg−1 of available potassium. The experimental site was planted with ratoon rice and was idle in winter. The daily maximum, minimum temperature, and solar radiation during the growing season were measured by meteorological stations near the experimental field. The average daily maximum temperature, daily minimum temperature, and daily solar radiation during the rice growing season in 2023 were 28.3 °C, 19.9 °C, and 13.9 MJ m−2 d−1, respectively (Figure 1).

Figure 1.

Daily maximum and minimum temperature and solar radiation during rice growing season from transplanting to maturity in 2023, in Jingzhou, Hubei Province, China in 2023.

2.2. Experimental Materials

The tested materials were indica hybrid rice varieties suitable for southern China planting, including Longjingyou1212 (LJY1212), Taoyouxiangzhan (TYXZ), Liangyou6326 (LY6326) and Fengliangyouxiang1 (FLYX1) (Table 1). These rice varieties were widely grown in southern China and were considered to be the high-quality rice varieties in the ratoon rice system.

Table 1.

Information on varieties for testing.

2.3. Experimental Design

Pre-germinated seeds were planted at a rate of 25 gm−2 in a seedbed, and seedlings were transplanted to field plots at 27 to 31 days old with hill spacings of 30 cm × 14 cm and two seedlings per hill. The management of crops adhered to accepted cultural practices. The transplantation date was 28 March 2023, which was typical time for planting in Jingzhou. The experiment was designed with 3 replicates per variety. The plot was 32 m2. The main crop was applied with 180 kg N ha−1, base fertilizer:tiller fertilizer:panicle fertilizer = 3:3:4. The base fertilizer was applied 1 day before transplanting, the tillering fertilizer was applied 7 days after transplanting, and the panicle fertilizer was applied to the fourth leaf. N:P2O5:K2O (mass ratio) = 2:1:2, phosphate fertilizer was used as base fertilizer, 50% potassium fertilizer was used as base fertilizer, and 50% potassium fertilizer was used in the fourth leaf. Meanwhile, 75 kg N ha−1 and 45 kg K2O ha−1 were applied to ratoon rice 10 days before harvest, and the cutting height was 40 cm, while 75 kg N ha−1 and 45 kg K2O ha−1 were applied to rewater after harvest. Immediately after the main crop was harvested, water was put on to prevent the stumps from dying in the sun due to high temperatures. Pesticides were extensively used to control insects and prevent yield and biomass losses.

2.4. Sampling and Measurements

2.4.1. Appearance Quality of Rice

The chalky grain percentage and chalkiness degree of rice were determined according to the national standard [23] after threshing, drying in the sun, and winnowing.

2.4.2. Protein Content of Rice

The rice was crushed by a plant pulverizer and then filtered through a 100-mesh sieve determined by the Kjeldahl method [24]. Grain protein content (GPC) = grain nitrogen × 5.95.

2.4.3. Rice Grain Amylose Content

The rice was crushed by a plant pulverizer, and the crushed rice was sieved through 100 mesh. According to the method of Xu [25], the amylose content was determined by iodine colorimetry.

2.4.4. Eigenvalues of RVA Spectrum

The characteristic values of the RVA profile include peak viscosity, hot paste viscosity, final viscosity, breakdown, setback, peak viscosity time, and pasting temperature. The rapid viscosity-measuring instrument (RVA4500, PERTEN, Stockholm, SE, USA) was used for testing, and matching software thermocline for windows was used for analysis.

2.4.5. Starch Isolation

In the main season and the ratoon season, 6 panicles with basically the same panicle size and grain filling at the mature stage were taken from each plot of each variety and marked. The grains were removed, and the empty diseased grains were removed. The grains balanced the water content of rice grains at 40 °C. Then, 5 g of whole grain was put into a 50 mL centrifuge tube, soaked in 40 mL 0.5% NaOH, and placed in the refrigerator at 4 °C for 24 h. After soaking for 24 h, we washed the seeds with clean water, peeled off the seed coat, and placed them in the mortar. We referenced the method described in Deng [26] for starch extraction and stored the extracted starch in a −20 °C refrigerator for later usage.

2.4.6. Determination of Starch Morphology

A small amount of starch was picked with tweezers and dispersed on the conductive glue. Following gold spraying, the scanning electron microscope was directly seen. The voltage was set at 20 kV and the current was 10 mA. A scanning electron microscope (TESCAN VEGA3, Shanghai, China) was used to observe the appearance of starch granules at a magnification of 5000× and photographed.

2.4.7. Measurement of the X-ray Diffraction Pattern and Fourier Transform Infrared Spectrum of Starch

Starch powder absorbs water in a closed container filled with saturated sodium chloride solution for one week. The starch powder after water absorption was placed in a vacuum dryer and dried according to the method of Cai [27]. Using an X-ray diffractometer, under the conditions of voltage of 40 kV, current of 200 mA, rotation range of diffraction angle (2θ) of 5°–50°, scanning speed of 0.3° per second, and step of 0.02°, each sample was scanned for about 3 min to obtain the XRD spectrum data of the sample. The spectrum was converted into text format by MDI Jade 6.0, the XRD spectrum of starch was drawn by Origin, and the relative crystallinity was calculated. Then, 30 mg starch was put into a 2 mL centrifuge tube, and 40 μL of ultrapure water was added to prepare starch emulsion. After, 30 μL of the emulsion was put on the sample stage of attenuated total reflection mode of a Fourier transform infrared spectrometer, and the ultrapure water was used as the reference scanning background. The original spectrum was obtained from the wave number range of 800–4000 cm−1, and the deconvolution operation (half peak width 19 cm−1, enhancement factor 1.9) was carried out to obtain the deconvolution spectrum of the starch sample. The intensities of 1045, 1022 and 995 cm−1 (the distance from the top of the resonance peak to the base of the resonance peak) were calculated by OMNIC 9.2 software, and the ratios of 1045/1022 and 1022/995 cm−1 were calculated.

2.4.8. Determination of Thermodynamic Properties of Starch

The thermal characteristics of starch granules were studied using a differential scanning calorimeter. The melting temperature and melting enthalpy of indium were used to calibrate the temperature and thermal energy of the DSC instrument. A total of 3 mg of starch was mixed with 9 μL of distilled water and placed in a refrigerator at 4 °C for 24 h. The blank crucible was used as a control. The sample is scanned from 25 to 100 °C at a heating rate of 10 °C/min. The main parameters of the DSC curve were initial gelatinization temperature (To), peak temperature (Tp), termination temperature (Tc), and enthalpy change during gelatinization (ΔH).

2.5. Statistical Analysis

Analysis of variance was performed with Statistic 9.0 (Analytical Software, Tallahassee, FL, USA), and means were compared based on the least significant difference (LSD) test at the 0.05 probability level. All figures were constructed using Origin Pro (2023b, Originlab, Northampton, MA, USA).

3. Results

3.1. Quality Difference of Different Indica Hybrid Rice Varieties in the Ratoon Season

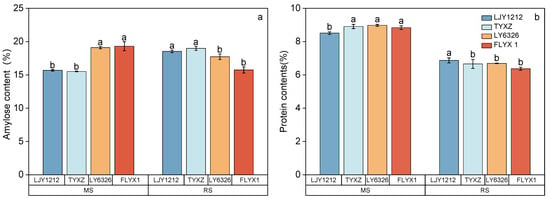

3.1.1. Amylose and Protein Content

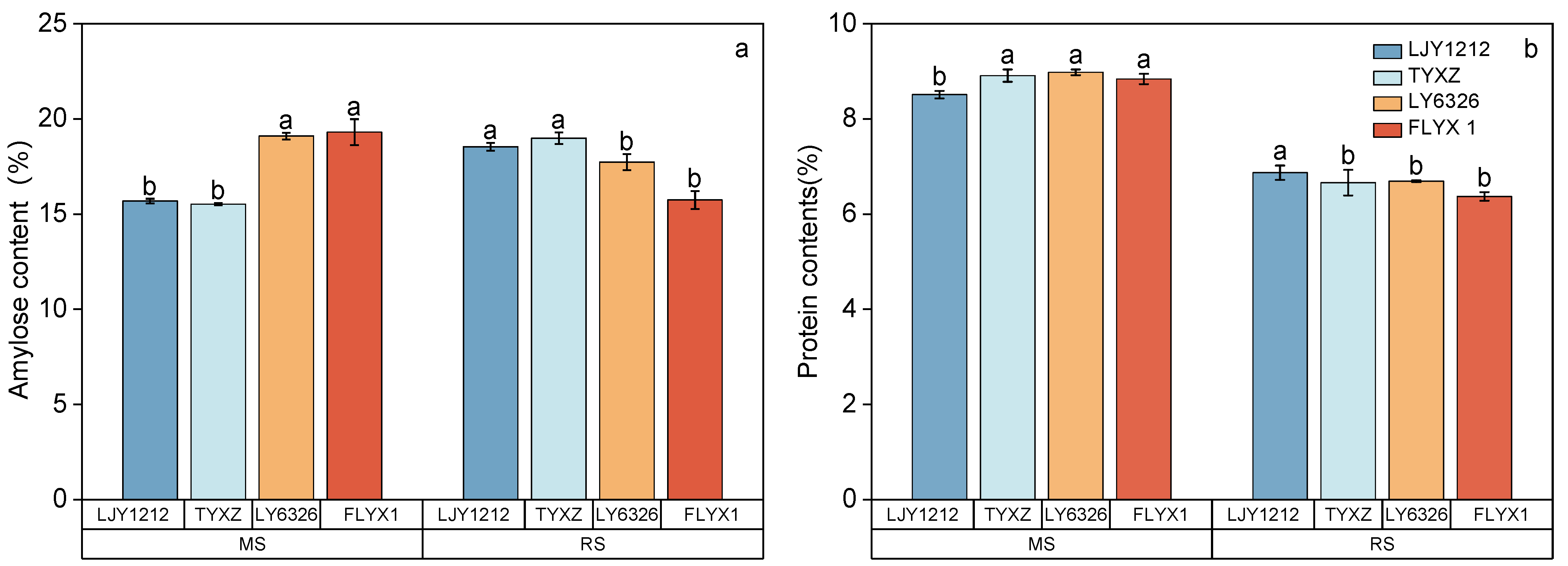

LJY1212 and TYXZ have considerably different amylose content than LY6326 and FLYX1. The amylose contents of LJY1212 and TYXZ in the ratoon season were 18.5% and 19.0%, respectively, while the amylose contents of LY6326 and FLYX1 were 17.7% and 15.7%. Compared with the main season, it decreased by 7.2% and 17.3%, respectively. The average amylose content of LJY1212 and TYXZ in the ratoon season was 10.8% higher than that of LY6326 and FLYX1. The protein content in the ratoon season was significantly lower than that in the main season, but there was no significant difference in protein content among the varieties in the ratoon season (Figure 2).

Figure 2.

Amylose content (a) and protein content (b) of main crop and ratoon rice. Vertical bars indicate standard errors (n = 3). Different letters above the columns indicated statistical significance by LSD at the p < 0.05 level among four rice varieties within the same treatment.

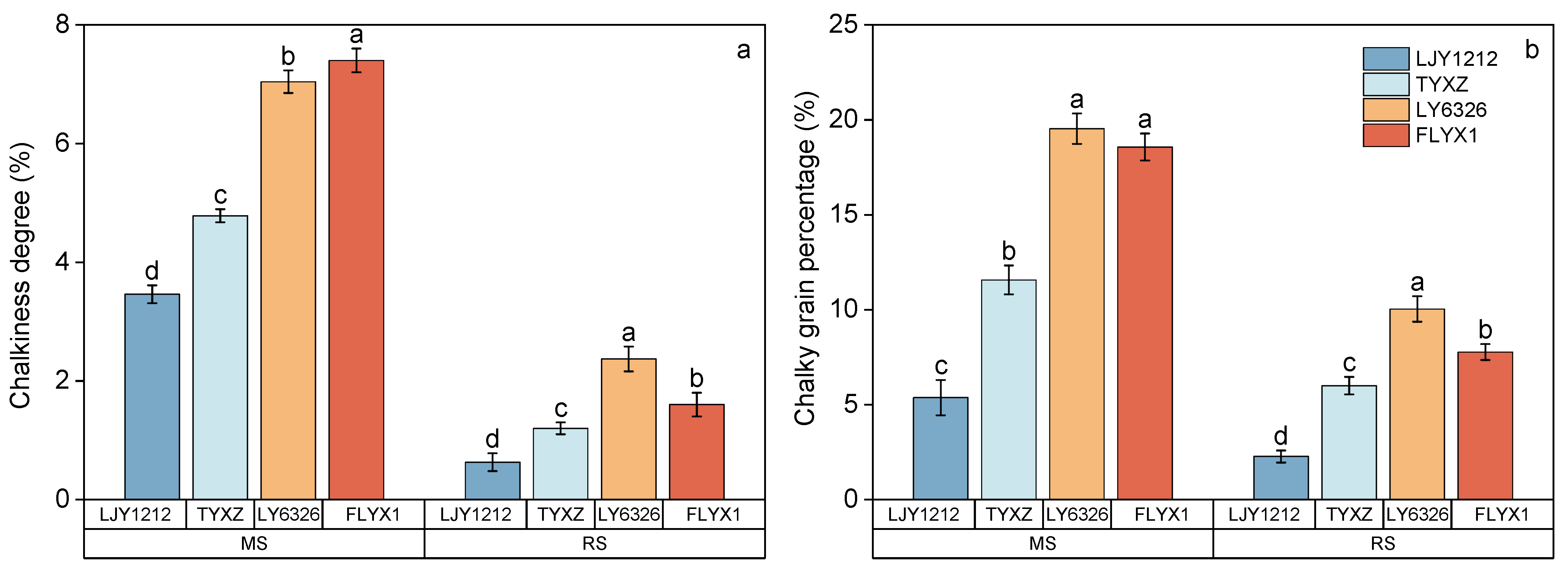

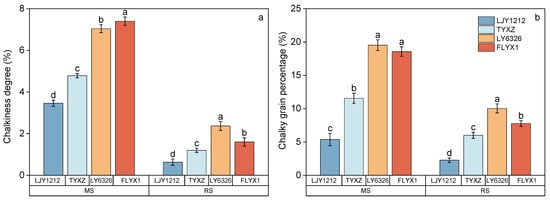

3.1.2. Appearance Quality

In terms of appearance quality, the chalkiness degree and chalky grain percentage of all varieties were significantly lower in the ratoon season than in the main season. The chalky grain percentage of LJY1212 (2.3%) and TYXZ (6.0%) in the ratoon season was 57.7% and 48.1% lower than that in the main season, respectively. The chalky grain percentage of LY6326 (10.0%) and FLYX1 (7.8%) were 48.6% and 58.2% lower than those in the main season, respectively. The chalkiness degree of LJY1212 (0.6%) and TYXZ (1.2%) in the ratoon season was 81.8% and 77.7% lower than that in the main season. The chalkiness degree of LY6326 (2.4%) and FLYX1 (1.6%) was 66.6% and 83.8% lower than that in the main season (Figure 3). The chalkiness degree and chalky grain percentage of LJY1212 and TYXZ were 53.5% and 53.9% lower than those of LY6326 and FLYX1, indicating that the appearance quality of LJY1212 and TYXZ was better than that of LY6326 and FLYX1.

Figure 3.

Differences in chalkiness degree (a) and chalky grain percentage (b) during the ratoon rice among varieties. Vertical bars indicate standard errors (n = 3). Different letters above the columns indicated statistical significance by LSD at the p < 0.05 level among four rice varieties within the same treatment.

3.1.3. RVA Spectrum Characteristics

The peak viscosity and setback value of ratoon rice were significantly higher than those of the main crop, while the breakdown value was significantly lower than that of the main crop. Compared with the main season, the pasting temperature of LJY1212 and TYXZ increased by 12.7% and 8.8%, respectively, while that of LY6326 and FLYX1 decreased by 1.1% and 7.1%, respectively (Table 2). The average pasting temperature of LJY1212 and TYXZ was 5.4% higher than that of LY6326 and FLYX1 in the ratoon season.

Table 2.

RVA profiles of different varieties of main crop and ratoon rice.

3.2. Fine Structure Heterogeneity of Starch in Different Indica Hybrid Rice Varieties

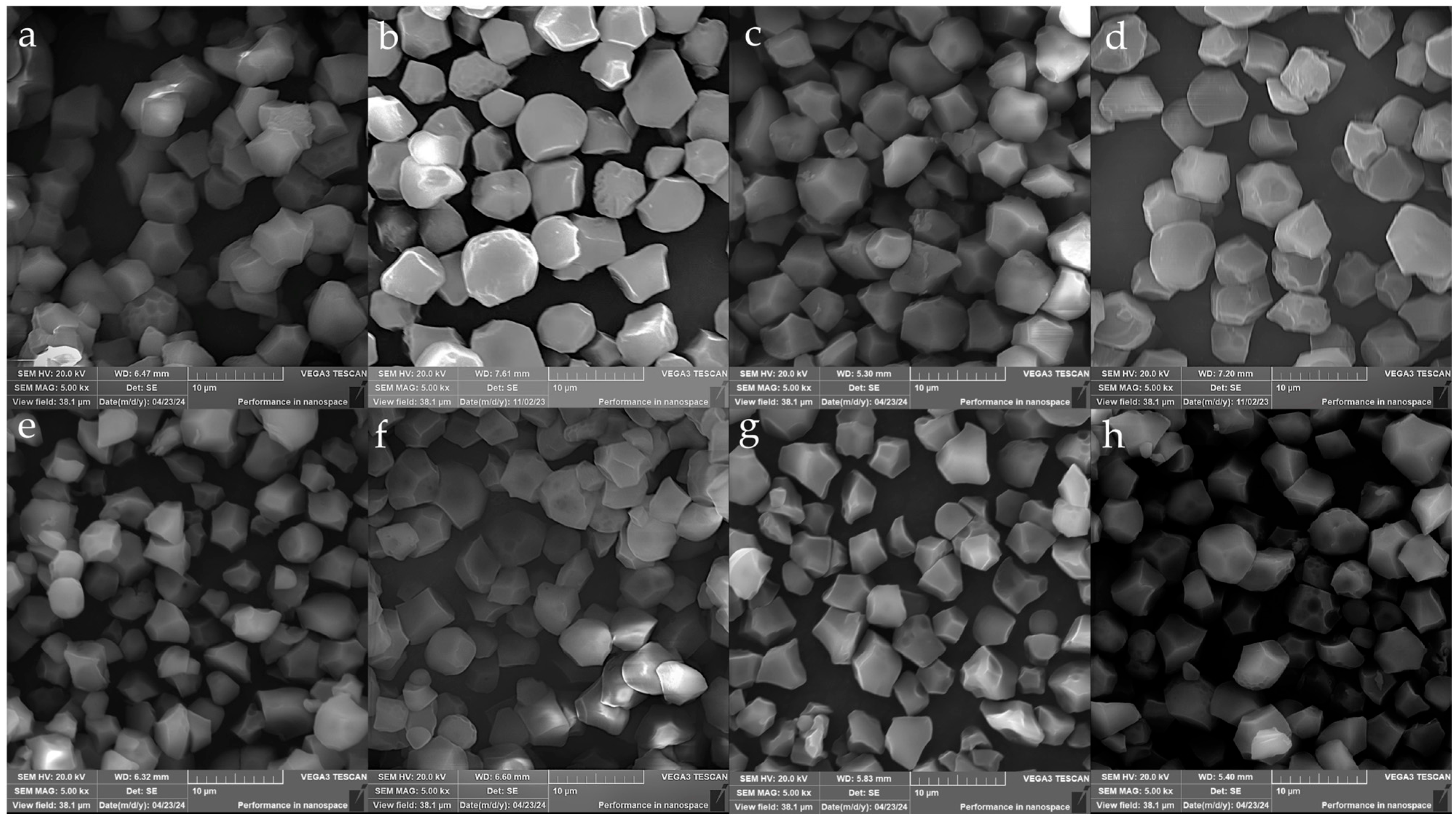

3.2.1. Size Distributions of Starch Granules

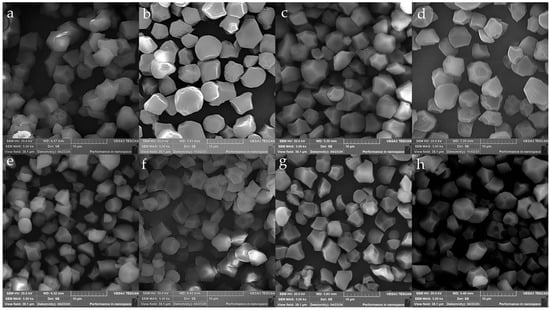

The rice starch granules of LJY1212, TYXZ, LY6326, and FLYX1 showed typical polyhedrons and irregular morphology after amplification of 5.00 kx (Figure 4). Compared with the main season, the surface of rice starch in the ratoon season was smoother, with smaller particles and crisper edges. In the ratoon season, the rice starch granules of LJY1212 and TYXZ were arranged more closely, the shape was irregular, and there were obvious edges and corners, while the rice starch granules of LY6326 and FLYX1 were relatively loose.

Figure 4.

Scanning electron microscopy of starch granules in the main season (a–d) and ratoon season (e–h) of LJY 1212, TYXZ, LY6326, and FLYX1.

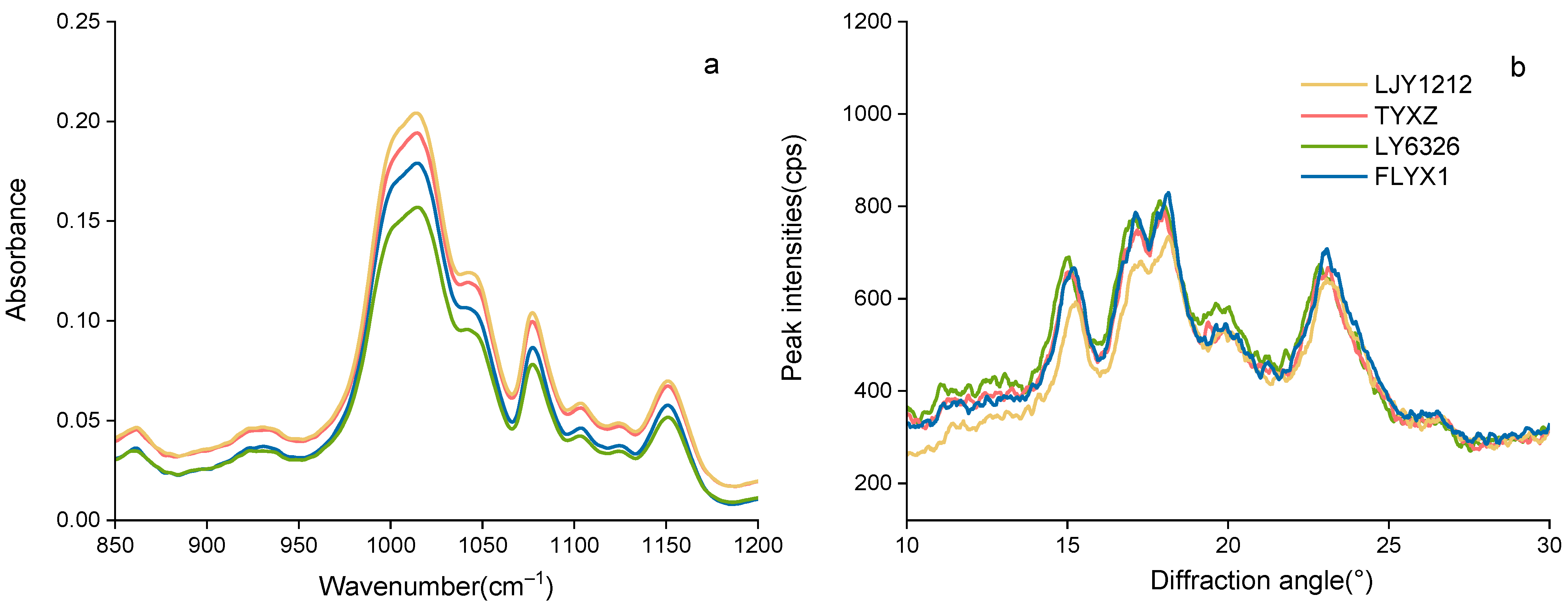

3.2.2. Fourier Transform Infrared Spectrum of Starch

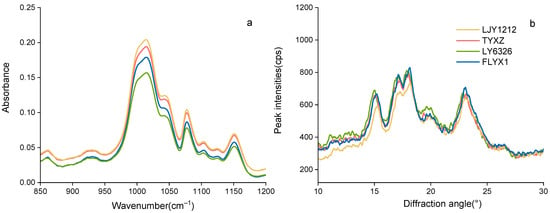

The deconvolution FT-IR spectra of ratoon rice starch resembled a starch absorption rate of 1045/1022 cm−1 (Figure 5a). The ratio of 1045/1022 cm−1 of rice starch in the ratoon season was significantly higher than that in the main season. The starch 1045/1022 cm−1 ratio of LJY1212 and TYXZ increased by 24.2% and 24.6%, while that of LY6326 and FLYX1 in the ratoon season increased by 12.7% and 12.5%, respectively, compared with the main season (Table 3). The higher the ratio of 1045/1022 cm−1 is, the higher the degree of order. The average ratio of 1045/1022 cm−1 of LJY1212 and TYXZ was 7.0% higher than that of LY6326 and FLYX1.

Figure 5.

FTIR spectral (a) and X-ray diffraction pattern (b) for ratoon rice.

Table 3.

Short-range ordering and relative crystallinity of starch at maturity in the main crop and ratoon rice.

3.2.3. Crystallinity Degree

The XRD spectra of the main season and the ratoon season are similar, and there are strong diffraction peaks near 15°, 17°, 18° and 23° (Figure 5b). The diffraction peaks near 17° and 18° are connected double peaks. In the ratoon season, the relative crystallinity of the starch in LJY1212 and TYXZ was 24.8% and 24.5%. This is 7.3% and 9.1% less, respectively, than their main season levels. The average relative crystallinity of both LJY1212 and TYXZ declined by 5.2% during the ratoon season compared to LY6326 and FLYX1.

3.2.4. Thermal Properties

The thermal properties of rice starch are mainly measured by gelatinization temperature (including initial gelatinization temperature, peak temperature, and termination temperature) and gelatinization enthalpy. The gelatinization enthalpy of LJY1212 and TYXZ in the ratoon season was 6.4% and 8.4% higher than that in the main season, while LY6326 and FLYX1 in the ratoon season were 1.6% and 2.1% lower than that in the main season (Table 4).

Table 4.

Thermodynamic properties of starch in the main crop and ratoon rice.

4. Discussion

Rice quality mainly includes processing quality, appearance quality, eating, and nutritional quality in four aspects, with eating quality serving as an important metric for determining the quality of rice. The chalkiness degree of ratoon rice was lower than that of the main crop, which indicated that the appearance quality of ratoon rice was better. Studies have shown that the appearance quality and processing quality of rice were different with different rice varieties under the same cultivation conditions [28]. The key stage of temperature affecting rice quality is the grain filling stage [29]. High temperatures can expedite grouting and shorten the process [30]. The grain filling period temperature of the ratoon season was lower than that of the main season, resulting in an increase in rice quality in the ratoon season. In this study, the chalky grain percentage of the four varieties of ratoon rice was 57.7%, 48.1%, 48.6%, and 58.2% lower than that of the main season, and the chalkiness degree was 81.8%, 77.7%, 66.6%, and 83.8% lower than that of the main season, respectively. The appearance quality in terms of chalkiness degree and chalky grain percentage of the four varieties was significantly better than that of the main season (the aspect ratio of grain shape was also involved in our experiment, but we selected high-quality varieties for the experiment; the difference in this indicator between varieties was not significant, so the data were not presented). Compared with the main crop, the protein content of ratoon rice is lower, while the amylose content of LJY1212 and TYXZ is higher. Excessive or insufficient amylose content in rice can cause it to become too hard or too soft while also affecting the taste and quality of the rice. Among the four varieties tested in this experiment, the amylose content in the ratoon season ranged from 15.7% to 19.0%, indicating that the eating quality of the four varieties was good. However, the amylose content of LJY1212 and TYXZ was higher than that of LY6326 and FLYX1, indicating that the eating quality of LJY1212 and TYXZ was better than that of LY6326 and FLYX1. The protein content in the ratoon season was significantly lower than that in the main season, and there was no significant difference in protein content among the ratoon season varieties. Differences in protein and its components play an important role in the taste and nutritional quality of rice. In the future, we plan to investigate whether there are variations in the protein structure.

Amylose content has a significant impact on rice quality. Amylose content is intimately related to the gelatinization properties and starch crystal structure of rice. The RVA profile characteristic value of ratoon rice starch showed that the disintegration value of ratoon rice was lower than that of main rice, while the setback value was higher than that of main rice. In a specific range, the taste value was negatively correlated with the disintegration value and positively correlated with the setback value [31]. The eating quality of LJY1212 and TYXZ was better than that of LY6326 and FLYX1, which was consistent with the results of Wang et al. [10]. Lii et al. found that the addition of amylose to rice flour would make the starch matrix structure more closely arranged and not easily destroyed, resulting in poor fluidity and increased hardness [32]. It can be seen that the amylose content first impacts the crystal structure of starch granules and then affects the pasting properties of rice flour. Differences in the starch fine structure, among other things, may be the main reason for differences in the flavor quality of rice. Additionally, amylopectin in rice also has a significant impact on the crystal structure and pasting properties of rice starch. The study discovered that the short/long chain ratio of amylopectin has a strong correlation with starch crystallinity. The higher the short/long chain ratio, the higher the crystallinity [33]. The long chain part of amylopectin was negatively correlated with its breakdown value during gelatinization, while the short chain part was positively correlated with its breakdown value during gelatinization [34], and the more the long chain part, the worse the texture of rice [35]. Therefore, we will further investigate the relationship between the chain length distribution and crystallinity of rice starch amylopectin in ratoon rice starch.

Under the SEM, the starch granules of LJY1212 and TYXZ were smaller than those of LY6326 and FLYX1, with irregular shapes, apparent edges and corners, and close arrangement. The gelatinization enthalpy of LJY1212 and TYXZ in the ratoon season was higher than that in the main season, whereas that of LY6326 and FLYX1 was lower than that in the main season, indicating that the difference in gelatinization temperature between different varieties was influenced by morphological changes in starch granules [36]. The average gelatinization enthalpy of LJY1212 and TYXZ was 5.3% higher than that of LY6326 and FLYX1. Starch with high amylose content has a large degree of intermolecular association, and the molecules are arranged closely. The higher the energy needed to destroy its crystal structure, the higher the gelatinization temperature. It indicated that the lower gelatinization temperature (To, Tp, and Tc) of ratoon rice starch may be due to its small molecular size and weak crystal structure. The functional properties of rice starch are affected by its morphology and crystal structure [37,38]. In this study, we investigated how amylose content influences the gelatinization properties of rice starch. Our findings indicate that higher amylose content increases the energy requirement for gelatinization and elevates the gelatinization enthalpy. We characterized the starch granules in both main and ratoon season rice crops, identifying them as predominantly A-type crystals. Notably, the ratoon season rice displayed a lower relative crystallinity compared to the main season rice. Specifically, varieties LJY1212 and TYXZ in the ratoon season showed a 5.2% lower average relative crystallinity than varieties LY6326 and FLYX1. Further investigation found that the decrease in relative crystallinity associated with increased amylose content could be attributed to variations in the chain length distribution of amylose and amylopectin. Cheetham et al. supported this by showing that relative crystallinity decreases as amylose content increases [33]. This structural variation leads to a reduction in the gelatinization temperature and the energy required for gelatinization. Furthermore, the FT-IR spectra showed that the starch in the ratoon season has similar absorption at 1045/1022 cm−1. Still, the ratio is higher than in the main season, indicating a higher degree of surface order in the starch granules of the ratoon season crops. This suggests an increase in cross-linking between starch molecules, potentially influencing the starch’s functional properties.

5. Conclusions

The results showed that the rice quality of different varieties of ratoon rice was different. The amylose content of LJY1212 and TYXZ was higher than that of LY6326 and FLYX1, but the protein content was not significantly different. The chalkiness degree and chalky grain percentage in the ratoon season were lower than those of LY6326 and FLYX1, indicating that LJY121212 and TYXZ had better appearance quality. Under the SEM, the starch granules of LJY1212 and TYXZ rice in the ratoon season were smaller than those of LY6326 and FLYX1, with irregular forms, evident edges and corners, and dense packing. The X-ray diffractometer, Fourier infrared spectrometer, and DSC were utilized to analyze the results. The results revealed that the rice starch granules showed a typical A-type crystal structure. The gelatinization temperature of LJY1212 and TYXZ was higher, the relative crystallinity of starch was lower, and the ordered structure in the starch was higher. The combined performance of LJY1212 and TYXZ was better than that of LY6326 and FLYX1 in terms of chalkiness degree, chalky grain percentage, amylose content, and RVA profiles, allowing LJY1212 and TYXZ to be widely planted in future production in southern China.

Author Contributions

Y.Z. designed the experiments and revised the paper; C.J., S.D. and D.Y. investigated the traits; C.J. analyzed the data and wrote the manuscript; K.L., Z.J., S.S., L.H., X.T. and Y.Z. aided in the conceptualization, scientific rigor, and manuscript editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (2022YFD2301004).

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to send our gratitude to the reviewers.

Conflicts of Interest

The authors declare no conflicts interest.

References

- Deng, J.; Ye, J.Y.; Zhong, X.F.; Yang, Q.Q.; Harrison, M.T.; Wang, C.H.; Huang, L.Y.; Tian, X.H.; Liu, K.; Zhang, Y.B. Optimizing Grain Yield and Radiation Use Efficiency through Synergistic Applications of Nitrogen and Potassium Fertilizers in Super Hybrid Rice. Plants 2023, 12, 2858. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.X.; Chen, H.F.; Zhang, Z.X.; Xu, Q.H.; Tu, N.M.; Fang, C.X.; Ren, W. Research and prospect on physio-ecological properties of ratoon rice yield formation and its key cultivation technology. Chin. J. Eco-Agric. 2015, 23, 392–401. (In Chinese) [Google Scholar] [CrossRef]

- Tang, W.B.; Chen, L.Y.; Xiao, Y.H.; Liu, J.F. Relationships among yield. yield components and some features of ratooning rice. J. Hunan Agric. Univ. 2002, 28, 1–3. (In Chinese) [Google Scholar] [CrossRef]

- Wang, M.T.; Dai, Z.G.; Yu, D.F.; Wang, X.P.; Guan, S.H.; Shao, Y.G.; Zhang, J.X.; Li, X.K. Effects of simplified application of dedicated fertilizer on yield, fertilizer use efficiency and economic benefit in rice-ratoon rice system. Chin. J. Rice Sci. 2022, 36, 531–542. (In Chinese) [Google Scholar] [CrossRef]

- Lin, W.X. Developmental status and problems of rice ratooning. J. Integr. Agric. 2019, 18, 250–251. [Google Scholar] [CrossRef]

- Shang, L.Y.; Liu, Z.C.; Ye, J.Y.; Sheng, T.; Li, R.J.; Deng, J.; Liu, K.; Tian, X.H.; Zhang, Y.B.; Huang, L.Y. Shading at the booting stage improved the grain quality of hybrid rice due to reduced spikelet production. Agriculture 2024, 14, 371. [Google Scholar] [CrossRef]

- Deng, J.; Sheng, T.; Zhong, X.F.; Ye, J.Y.; Wang, C.H.; Huang, L.Y.; Tian, X.H.; Liu, K.; Zhang, Y.B. Delayed leaf senescence improves radiation use efficiency and explains yield advantage of large panicle-type hybrid rice. Plants 2023, 12, 4063. [Google Scholar] [CrossRef]

- Liu, K.; Yang, R.; Deng, J.; Huang, L.; Wei, Z.; Ma, G.; Tian, X.; Zhang, Y. High radiation use efficiency improves yield in the recently developed elite hybrid rice Y-liangyou 900. Field Crops Res. 2020, 253, 107804. [Google Scholar] [CrossRef]

- Xu, F.X.; Xiong, H.; Zhang, L.; Zhu, Y.C.; Jiang, P.; Guo, X.Y.; Liu, M. Progress in research of yield formation of ratooning rice and its high-yielding key regulation technologies. Sci. Agric. Sin. 2015, 48, 1702–1717. (In Chinese) [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.C.; Zhang, Q.; Yu, G.L.; Zhang, W.D.; Huang, J.; Zhu, A.; Liu, L.J. Differences in grain yield and quality in main and ratoon rice in southern Henan province. Chin. J. Rice Sci. 2020, 34, 425–434. (In Chinese) [Google Scholar] [CrossRef]

- Xiong, H.; Ran, M.L.; Xu, F.X.; Hong, S. Achievements and developments of ratooning rice in south of China. Acta Agron. Sin. 2000, 26, 8. (In Chinese) [Google Scholar]

- Duan, M.J.; Wu, Y.Z.; Tian, Y.C.; Liu, Y.W.; Liu, Z.Y.; Chen, F.; Jin, T. Comparision of yield and quality among different ratooning rice varieties. Crops 2018, 34, 61–67. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Y.X.; Ding, Y.F.; Li, G.H.; Huang, P.S.; Wang, S.H. Starch structure and paste property of rice with different amylose content. Acta Agron. Sin. 2007, 33, 1201–1205. (In Chinese) [Google Scholar]

- Gani, A.; Ashwar, B.A.; Akhter, G.; Shah, A.; Wani, I.A.; Masoodi, F.A. Physico-chemical, structural, pasting and thermal properties of starches of fourteen Himalayan rice cultivars. Int. J. Biol. Macromol. 2016, 95, 1101–1107. [Google Scholar] [CrossRef]

- Kong, X.; Zhu, P.; Sui, Z.; Bao, J. Physicochemical properties of starches from diverse rice cultivars varying in apparent amylose content and gelatinisation temperature combinations. Food Chem. 2015, 172, 433–440. [Google Scholar] [CrossRef]

- Peng, Y.; Mao, B.; Zhang, C.; Shao, Y.; Zhao, B. Influence of physicochemical properties and starch fine structure on the eating quality of hybrid rice with similar apparent amylose content. Food Chem. 2021, 353, 129461. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, S.L.; Hong, Y.; Gu, Z.B.; Chen, S. Effects of different rice starch fine structure on retrogradation characteristics. J. Chin. Cereals Oils Assoc. 2024, 39, 117–124. (In Chinese) [Google Scholar] [CrossRef]

- Bao, J.S. Toward understanding the genetic and molecular bases of the eating and cooking qualities of rice1. Cereal Foods World 2012, 57, 148–156. [Google Scholar] [CrossRef]

- Riar, C.S. Effect of composition, granular morphology and crystalline structure on the pasting, textural, thermal and sensory characteristics of traditional rice cultivars. Food Chem. 2019, 280, 303–309. [Google Scholar] [CrossRef]

- Deng, F.; Yang, F.; Li, Q.P.; Zeng, Y.L.; Li, B.; Zhong, X.Y.; Lu, H.; Wang, L.; Chen, H.; Chen, Y.; et al. Differences in starch structural and physicochemical properties and texture characteristics of cooked rice between the main crop and ratoon rice. Food Hydrocoll. 2021, 116, 106643. [Google Scholar] [CrossRef]

- Li, L.S.; Zhang, Q.; Zhang, L.; Wei, C.X. Evaluation of the molecular structural parameters of normal rice starch and their relationships with its thermal and digestion properties. Molecules 2017, 22, 1526. [Google Scholar] [CrossRef] [PubMed]

- Longvah, T.; Prasad, V.S.S. Nutritional variability and milling losses of rice landraces from Arunachal Pradesh, Northeast India. Food Chem. 2020, 318, 126385. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Zhu, Z.; Jin, L.; Min, J.; Chen, N.; Xu, L.; Chen, M.; Zhang, L. Quality of edible rice varieties according to industry standards of the Ministry of Agriculture NY/T-593-2002. China Rice 2003, 2, 41–42. (In Chinese) [Google Scholar]

- Huang, L.Y.; Yang, D.S.; Li, X.X.; Peng, S.B.; Wang, F. Coordination of high grain yield and high nitrogen use efficiency through large sink size and high post-heading source capacity in rice. Field Crops Res. 2019, 233, 49–58. [Google Scholar] [CrossRef]

- Xu, D.; Zhu, Y.; Zhou, L.; Han, C.; Zheng, L.M.; Zhang, H.C.; Wei, H.Y.; Wang, Y.; Liao, A.H.; Cai, S.B. Differences in yield and grain quality among various types of indica/japonica hybrid rice and correlation between quality and climatic factors during grain filling period. Acta Agron. Sin. 2018, 44, 1548–1559. [Google Scholar] [CrossRef]

- Deng, F.; Li, Q.P.; Chen, H.; Zeng, Y.L.; Ren, W.J. Relationship between chalkiness and the structural and thermal properties of rice starch after shading during grain-filling stage. Carbohyd. Polym. 2021, 252, 117212. [Google Scholar] [CrossRef]

- Cai, J.W.; Cai, C.H.; Man, J.M.; Yang, Y.; Zhang, F.M.; Wei, C.X. Crystalline and structural properties of acid-modified lotus rhizome C-type starch. Carbohyd. Polym. 2014, 102, 799–807. [Google Scholar] [CrossRef]

- Tong, H.; Xu, Q.G. Research progress of correlation between rice quality and amylase activity and protein components. Crop Res. 2013, 27, 521–525. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.K.; Wu, L.; Geng, X.; Xia, X.; Wang, X.H.; Xu, Z.J.; Xu, Q. Deciphering the environmental impacts on rice quality for different rice cultivated areas. Rice 2018, 11, 7. [Google Scholar] [CrossRef]

- Gong, J.L.; Zhang, H.C.; Hu, Y.J.; Long, H.Y.; Chang, Y.; Wang, Y.; Xing, Z.P.; Huo, Z.Y. Effects of air temperature during rice grain-filling period on the formation of rice grain yield and its quality. Chin. J. Ecol. 2013, 32, 482–491. (In Chinese) [Google Scholar] [CrossRef]

- Wu, Y.S.; Yao, X.Y.; Cao, G.J.; Chen, C.L.; Xiong, Y.H. Analysis of yield formation and comparison of grain quality of fine quality ratoon rice. Hybrid. Rice 2019, 34, 57–63. (In Chinese) [Google Scholar] [CrossRef]

- Lii, C.Y.; Tsai, M.L.; Tseng, K.H. Effect of amylose content on rheological property of rice starches. Cereal Chem. 1996, 73, 415–420. [Google Scholar]

- Cheetham, N.W.H.; Tao, L. Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study. Carbohyd. Polym. 1998, 36, 277–284. [Google Scholar] [CrossRef]

- Han, X.Z.; Hamaker, B.R. Amylopectin fine structure and rice starch paste breakdown. J. Cereal Sci. 2001, 34, 279–284. [Google Scholar] [CrossRef]

- Cai, Y.X.; Wang, W.; Zhu, Z.W.; Zhang, Z.J.; Zhu, Q.S. The physiochemical characteristics of amylopectin and their relationships to pasting properties of rice flour in different varieties. Sci. Agric. Sin. 2006, 39, 1122–1129. [Google Scholar] [CrossRef]

- Kuang, N.; Zheng, H.; Tang, Q.; Chen, Y.; Wang, X.; Luo, Y. Amylose content, morphology, crystal structure, and thermal properties of starch grains in main and ratoon rice crops. Phyton-Int. J. Exp. Bot. 2021, 90, 1119–1230. [Google Scholar] [CrossRef]

- Tao, H.; Huang, J.S.; Xie, Q.T.; Zou, Y.M.; Wang, H.L.; Wu, X.Y.; Xu, X.M. Effect of multiple freezing-thawing cycles on structural and functional properties of starch granules isolated from soft and hard wheat. Food Chem. 2018, 265, 18–22. [Google Scholar] [CrossRef]

- Dhital, S.; Butardo, V.M., Jr.; Jobling, S.A.; Gidley, M.J. Rice starch granule amylolysis Differentiating effects of particle size, morphology, thermal properties and crystalline polymorph. Carbohyd. Polym. 2015, 115, 305–316. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).