Agrivoltaics: Integration of Reused PV Modules

Abstract

1. Introduction

2. Materials and Methods

2.1. Location and Conditions of the Test

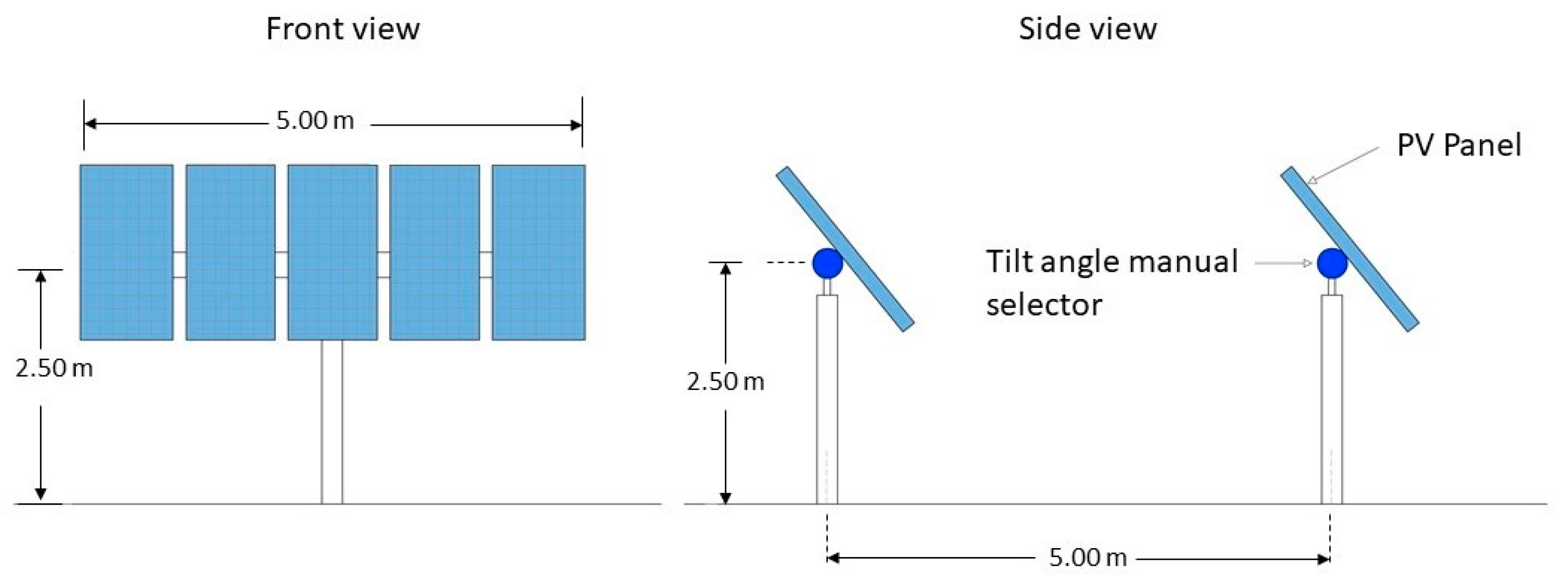

2.2. Installation of the Photovoltaic System

2.3. Design of the Plantation and Treatments

2.4. Sampling and Measures

2.5. Statistic Analysis

2.6. Photovoltaic Data Collection and Parameters Monitored

- Electrical performance: the power output of the reused string PV modules was monitored continuously using a data acquisition system integrated into the selected inverters. Variables like current and voltage output were recorded every 5 min to capture diurnal and seasonal performance variations.

- Thermal response and cooling effect: module temperature was measured using temperature sensors attached to the backsheet of the PV panels.

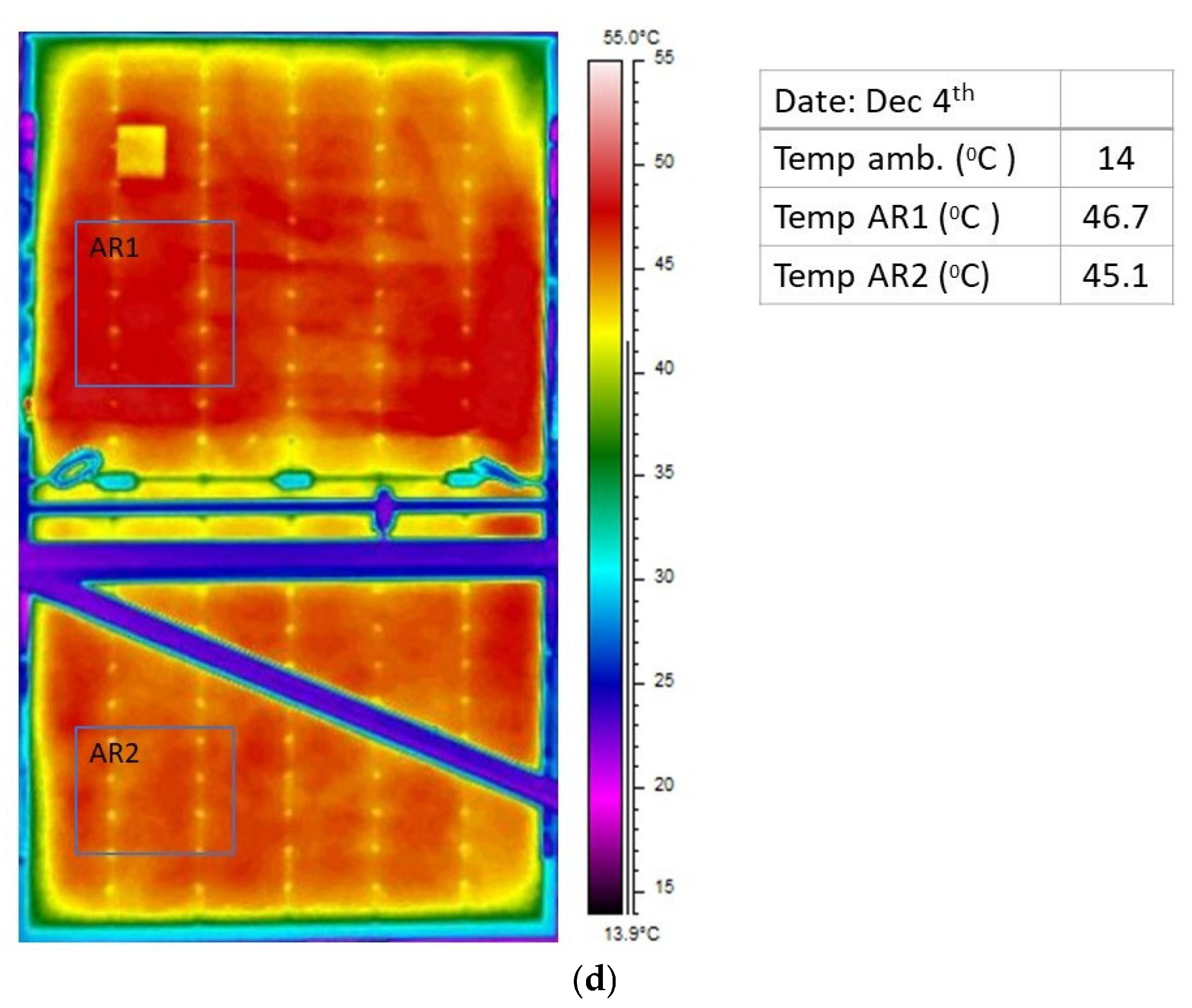

- Infrared thermography (IR) images: IR images were captured under operational conditions using a FLIR SC640 Thermal Imaging camera, which had a temperature reading accuracy of ±2 °C, a focal plane array of 640 × 480, and a thermal sensitivity of 60 mK at 30 °C. The images were acquired periodically for optimal thermographic analysis depending on favorable weather conditions.

3. Results

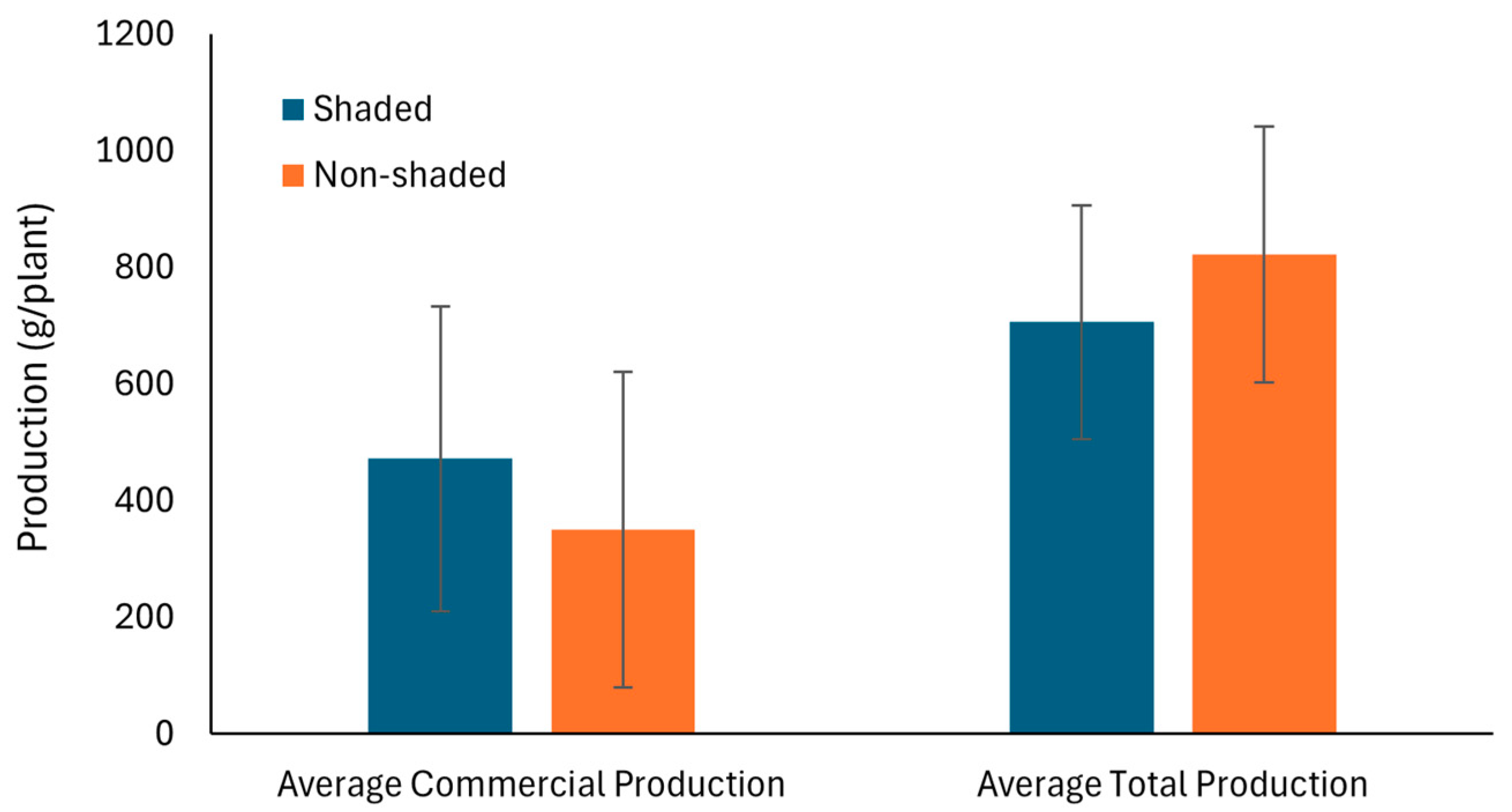

3.1. Crop Total Yield

3.1.1. Commercial Tomato (Mature Fruit) Production

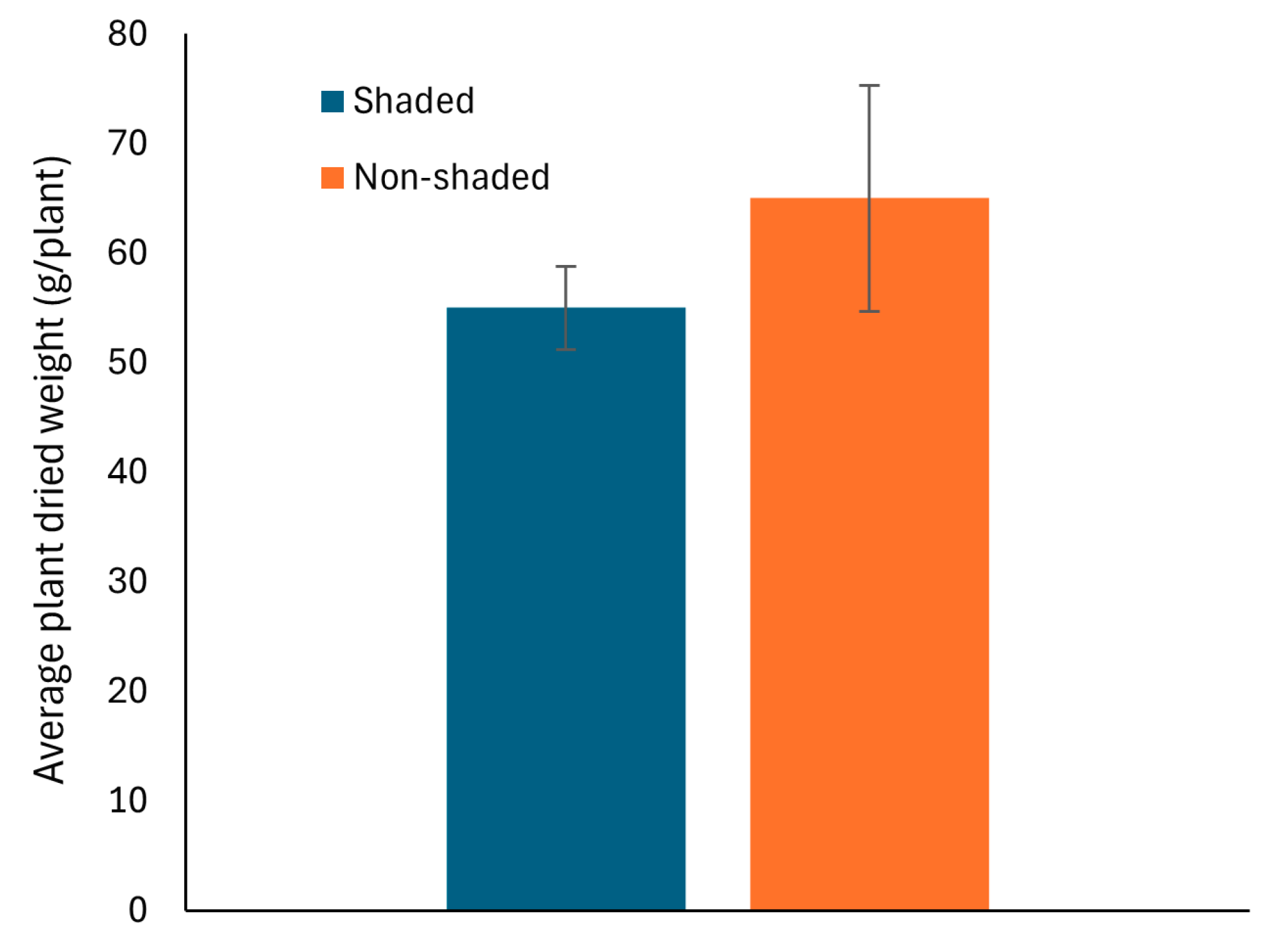

3.1.2. Fruit Production Analysis

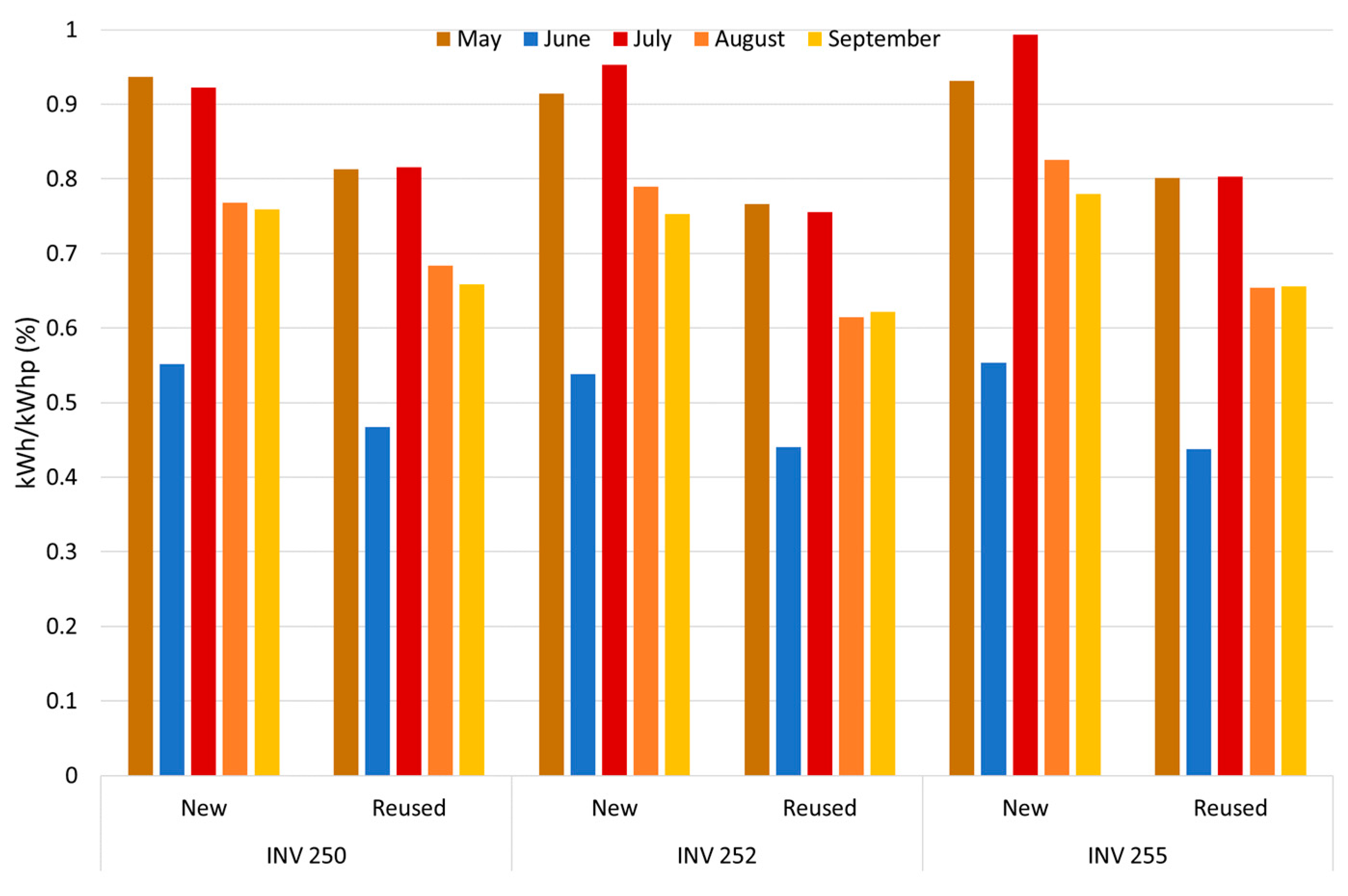

3.2. Electrical Performance Analysis

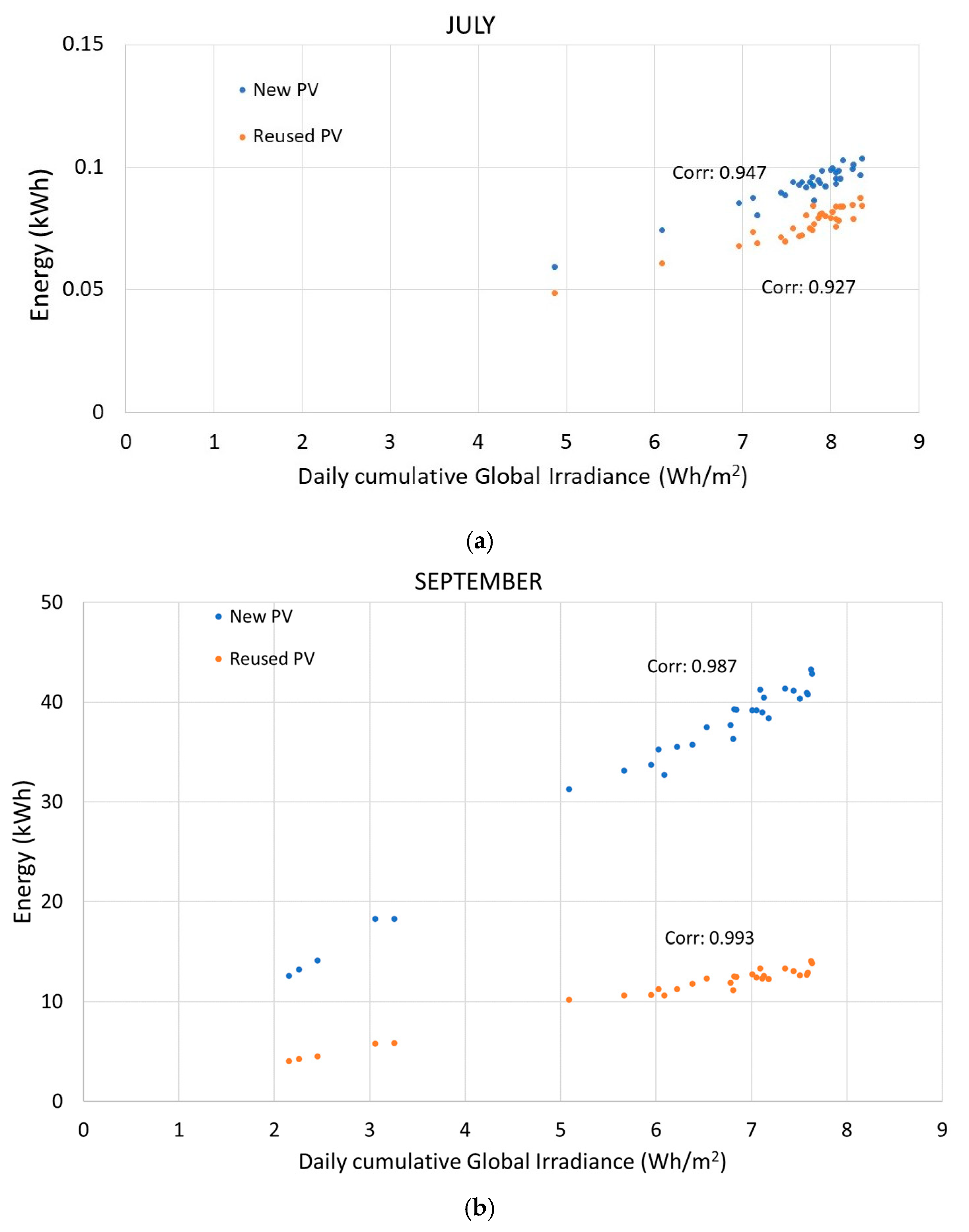

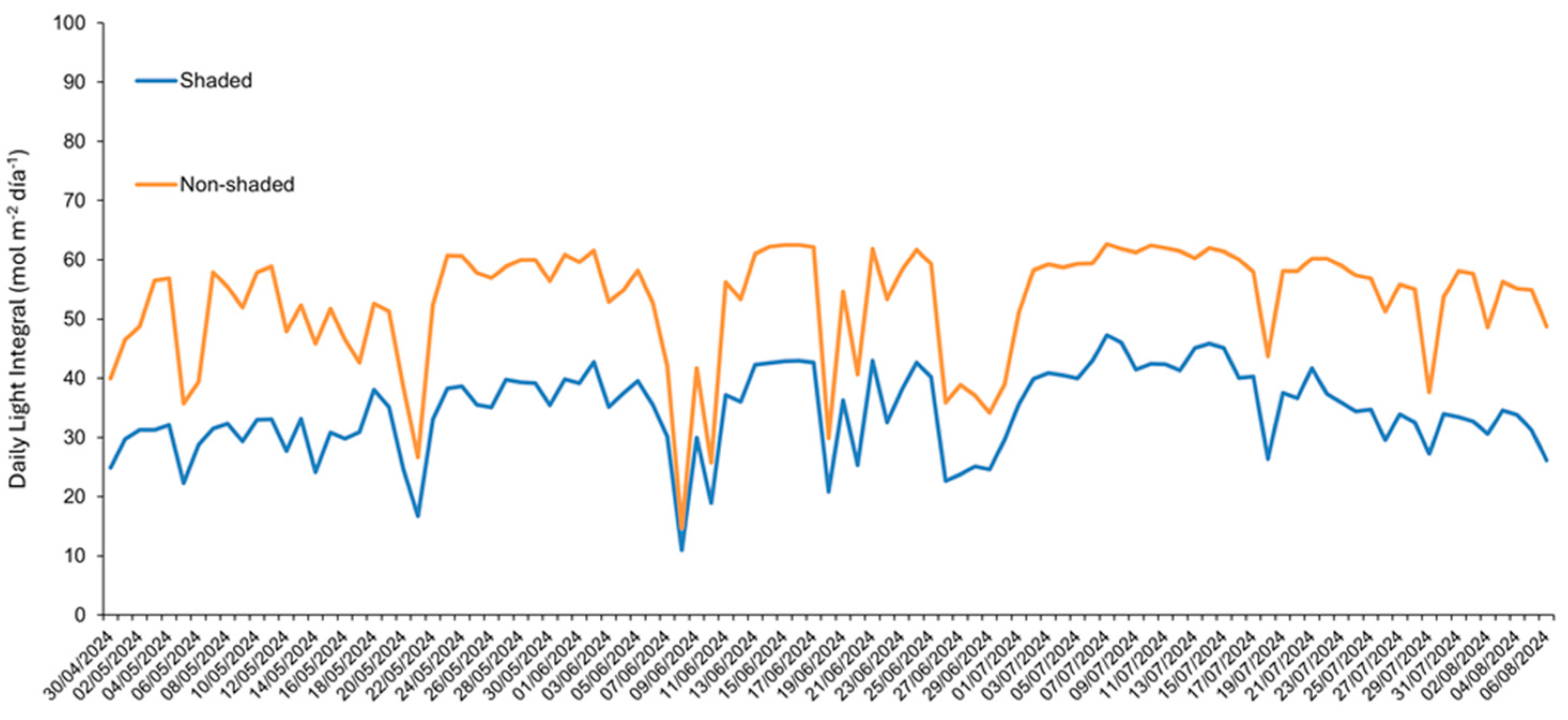

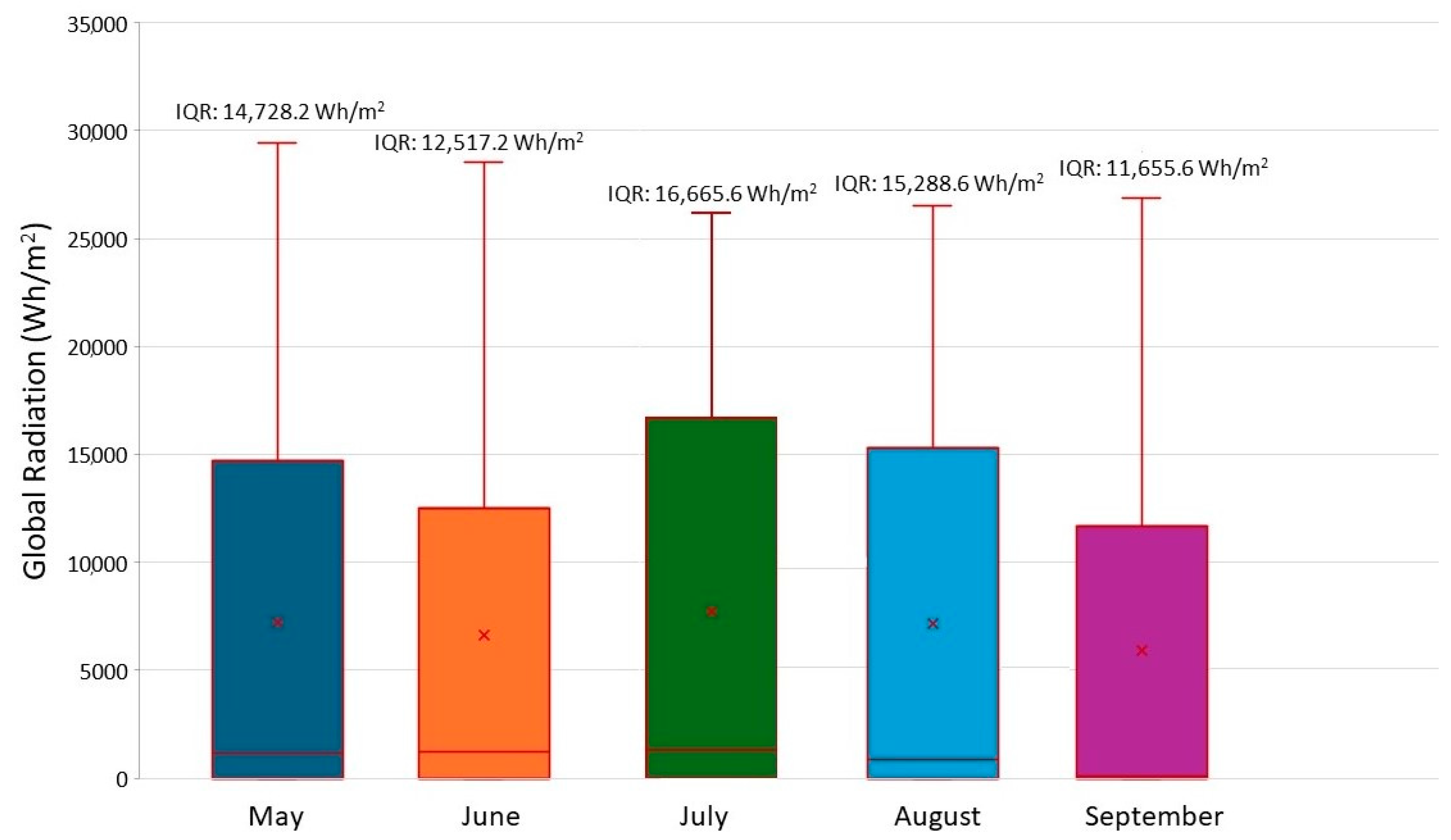

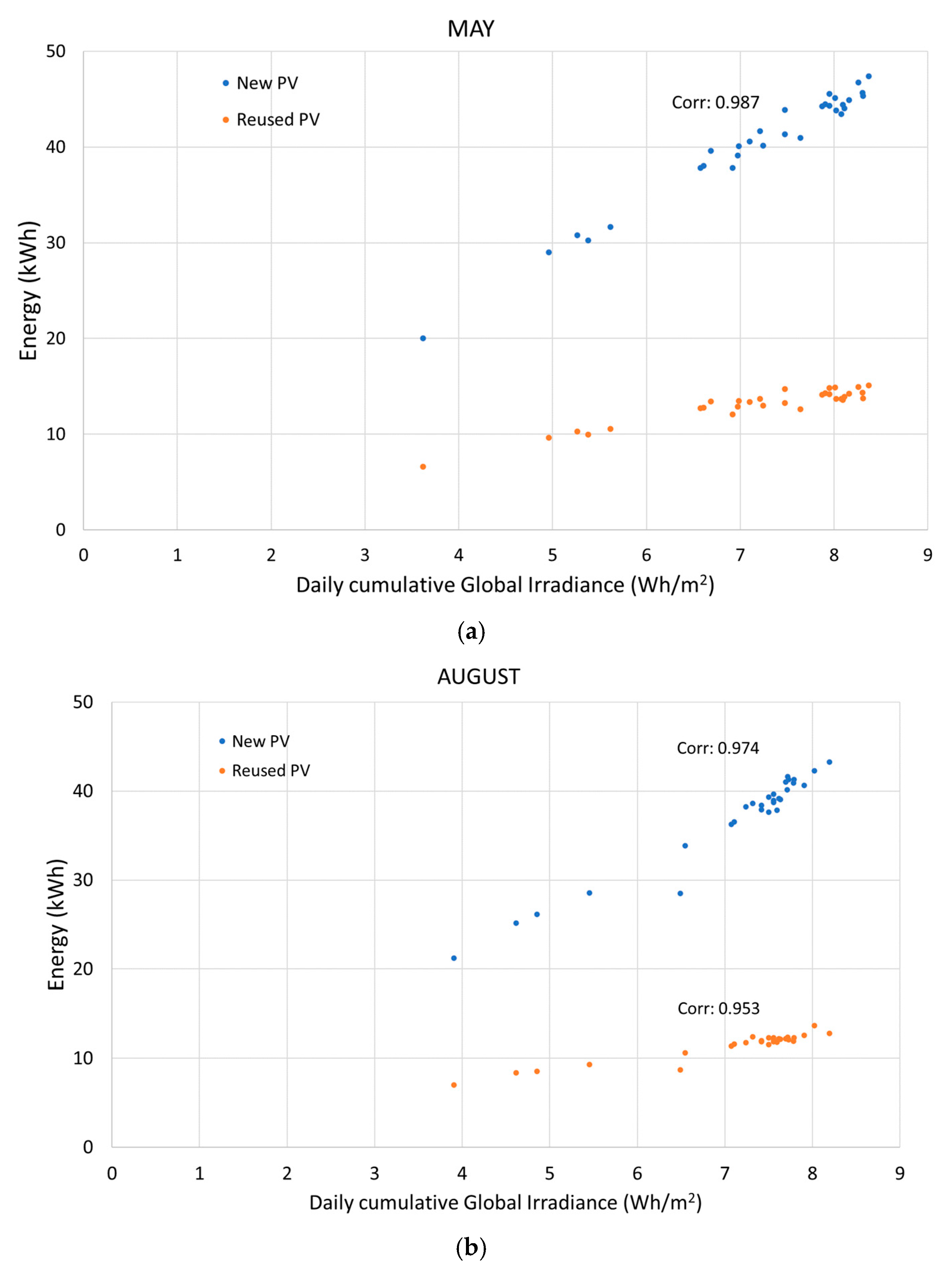

3.2.1. Irradiance and Energy

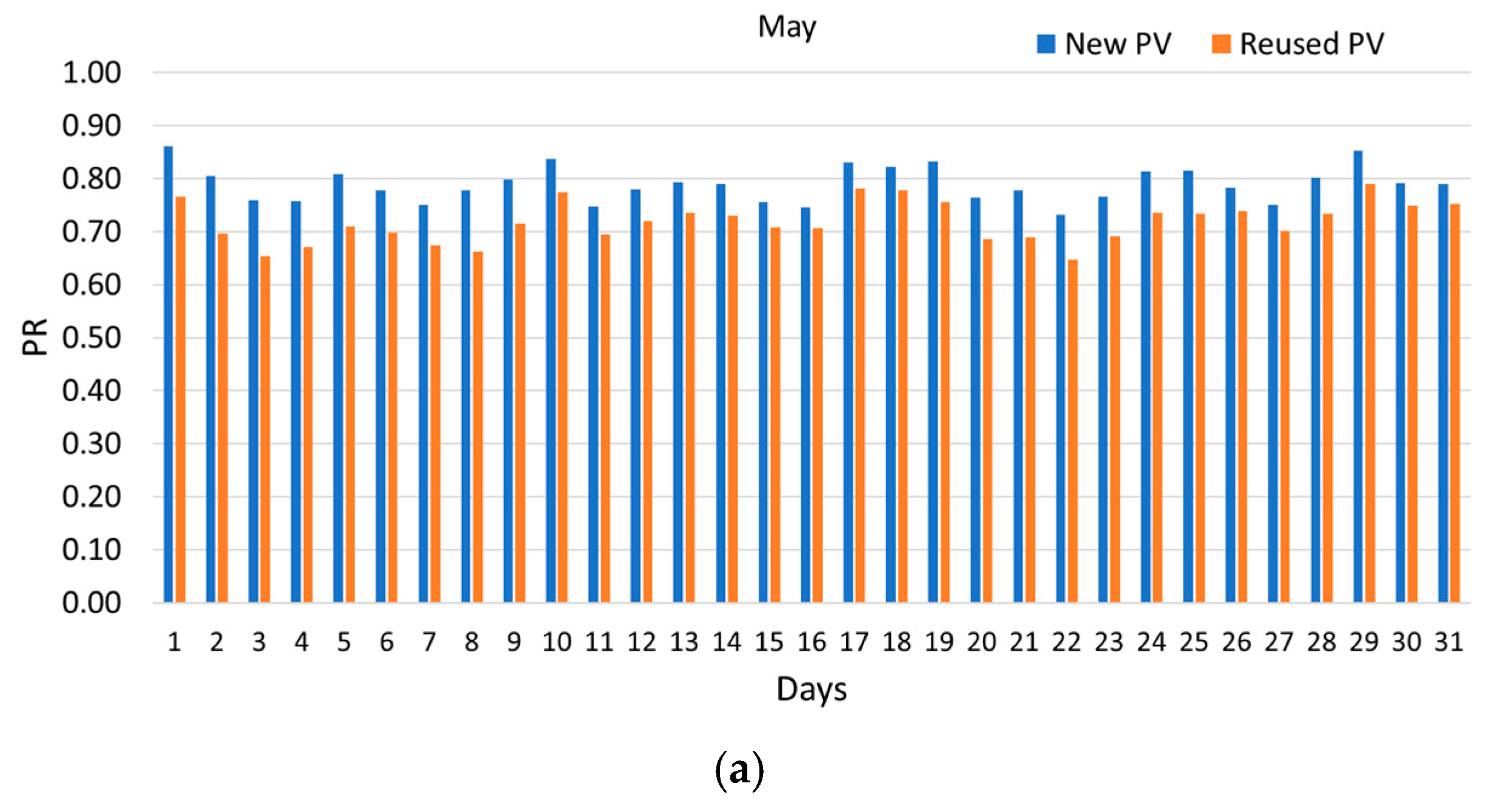

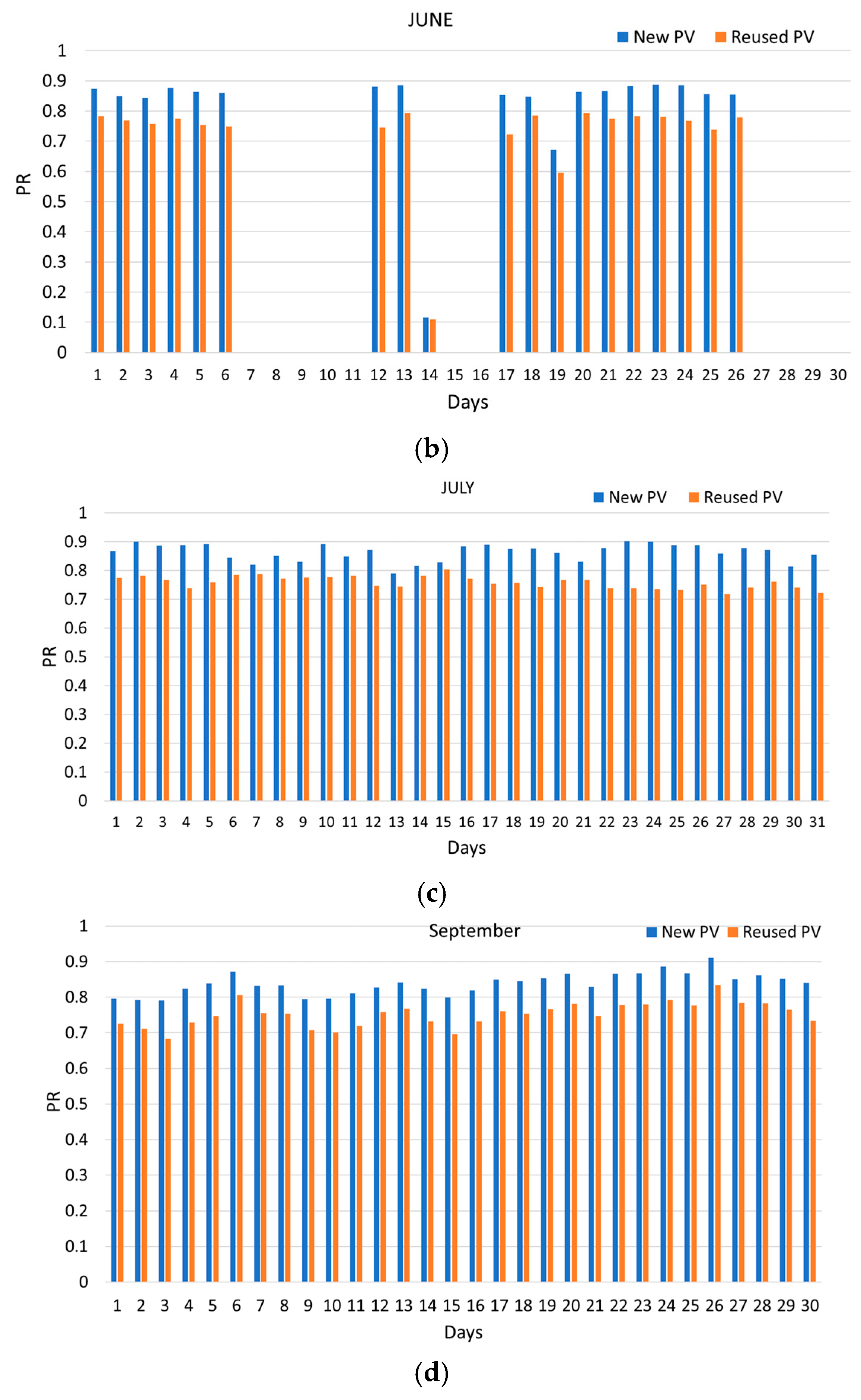

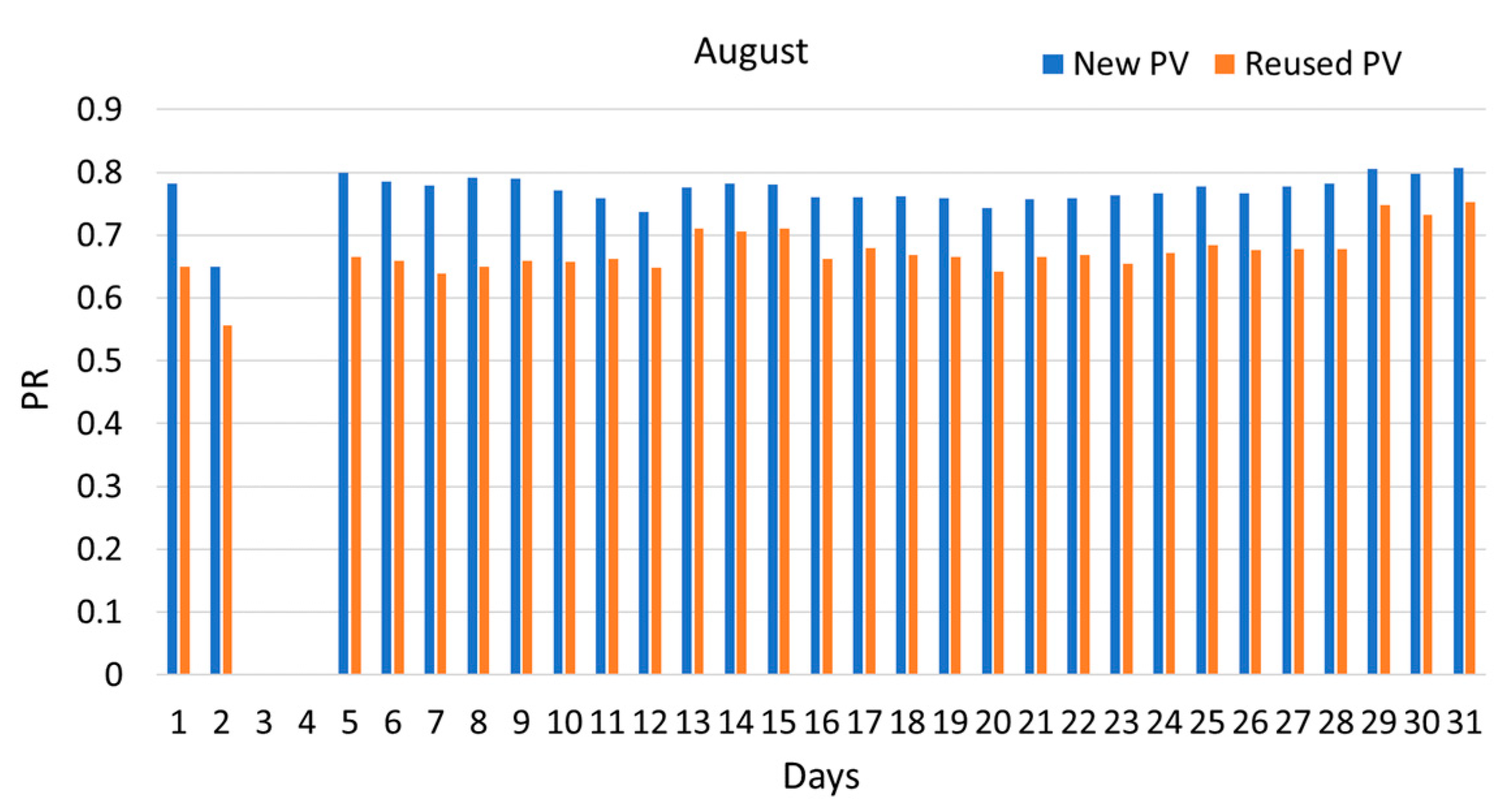

3.2.2. Performance Ratio (PR)

3.2.3. Infrared Thermography Inspection

3.2.4. Reused Panels’ Operational Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Turnley, J.W.; Grant, A.; Schull, V.Z.; Cammarano, D.; Sesmero, J.; Agrawal, R. The viability of photovoltaics on agricultural land: Can PV solve the food vs fuel debate? J. Clean Prod. 2024, 469, 143191. [Google Scholar] [CrossRef]

- Al Mamun, M.A.; Dargusch, P.; Wadley, D.; Zulkarnain, N.A.; Aziz, A.A. A Review of Research on Agrivoltaic Systems; Elsevier Ltd.: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Magarelli, A.; Mazzeo, A.; Ferrara, G. Fruit Crop Species with Agrivoltaic Systems: A Critical Review. Agronomy 2024, 14, 722. [Google Scholar] [CrossRef]

- Aroca-Delgado, R.; Pérez-Alonso, J.; Callejón-Ferre, Á.J.; Díaz-Pérez, M. Morphology, yield and quality of greenhouse tomato cultivation with flexible photovoltaic rooftop panels (Almería-Spain). Sci. Hortic. 2019, 257, 108768. [Google Scholar] [CrossRef]

- La Notte, L.; Giordano, L.; Calabrò, E.; Bedini, R.; Colla, G.; Puglisi, G.; Reale, A. Hybrid and organic photovoltaics for greenhouse applications. Appl. Energy 2020, 278, 115582. [Google Scholar] [CrossRef]

- Van de Ven, D.J.; Capellan-Peréz, I.; Arto, I.; Cazcarro, I.; De Castro, C.; Patel, P.; Gonzalez-Eguino, M. The potential land requirements and related land use change emissions of solar energy. Sci. Rep. 2021, 11, 2907. [Google Scholar] [CrossRef]

- Magarelli, A.; Mazzeo, A.; Ferrara, G. Exploring the Grape Agrivoltaic System: Climate Modulation and Vine Benefits in the Puglia Region, Southeastern Italy. Horticulturae 2025, 11, 160. [Google Scholar] [CrossRef]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Guan, J.; Sun, J.; Shi, X.; Wei, J. Review of full-spectrum solar energy systems based on spectral splitting technology. Int. J. Hydrogen Energy 2024, 81, 1235–1255. [Google Scholar] [CrossRef]

- Bruhwyler, R.; Sánchez, H.; Meza, C.; Lebeau, F.; Brunet, P.; Dabadie, G.; Dittmann, S.; Gottschalg, R.; Negroni, J.J. Vertical agrivoltaics and its potential for electricity production and agricultural water demand: A case study in the area of Chanco, Chile. Sustain. Energy Technol. Assess. 2023, 60, 103425. [Google Scholar] [CrossRef]

- Feuerbacher, A.; Herrmann, T.; Neuenfeldt, S.; Laub, M.; Gocht, A. Estimating the economics and adoption potential of agrivoltaics in Germany using a farm-level bottom-up approach. Renew. Sustain. Energy Rev. 2022, 168, 112784. [Google Scholar] [CrossRef]

- Ferrara, G.; Boselli, M.; Palasciano, M.; Mazzeo, A. Effect of shading determined by photovoltaic panels installed above the vines on the performance of cv. Corvina (Vitis vinifera L.). Sci. Hortic. 2023, 308, 111595. [Google Scholar] [CrossRef]

- Kadowaki, M.; Yano, A.; Ishizu, F.; Tanaka, T.; Noda, S. Effects of greenhouse photovoltaic array shading on Welsh onion growth. Biosyst. Eng. 2012, 111, 290–297. [Google Scholar] [CrossRef]

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimise land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Giri, N.C.; Mohanty, R.C. Design of agrivoltaic system to optimize land use for clean energy-food production: A socio-economic and environmental assessment. Clean Technol. Environ. Policy 2022, 24, 2595–2606. [Google Scholar] [CrossRef]

- Marrou, H.; Dufour, L.; Wery, J. How does a shelter of solar panels influence water flows in a soil-crop system? Eur. J. Agron. 2013, 50, 38–51. [Google Scholar] [CrossRef]

- Ya’acob, M.E.; Lu, L.; Zulkifli, S.A.; Roslan, N.; Ahmad, W.F.H.W. Agrivoltaic approach in improving soil resistivity in large scale solar farms for energy sustainability. Appl. Energy 2023, 352, 121943. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, H.; Pan, S.; Wang, Q.; He, J.; Jia, X. An agrivoltaic park enhancing ecological, economic and social benefits on degraded land in Jiangshan, China. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2022. [Google Scholar] [CrossRef]

- Rosillo, F.G.; Nieto-Morone, M.B.; Esteva, J.B.; Soriano, F.; Temprano, S.; González, C.; del Carmen Alonso-García, M. Repairing ribbon bus bar interruptions in photovoltaic modules using non-intrusive interruption location. Renew. Energy 2024, 223, 120012. [Google Scholar] [CrossRef]

- Nieto-Morone, M.B.; Rosillo, F.G.; Muñoz-García, M.A.; Alonso-García, M.C. Enhancing photovoltaic module sustainability: Defect analysis on partially repaired modules from Spanish PV plants. J. Clean Prod. 2024, 461, 142575. [Google Scholar] [CrossRef]

- IEC TS 61215; Crystalline Silicon Terrestrial Photovoltaic Modules—Design Qualification and Type Approval. International Electrotechnical Commission: Geneva, Switzerland, 2005.

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998. [Google Scholar]

- Bleiholder, H.; Weber, E.; Lancashire, P.; Feller, C.; Buhr, L.; Hees, M. Growth stages of mono- and dicotyledonous plants. BBCH Monogr. 2001, 158, 20180906-074619. [Google Scholar]

- Song, J.; Chen, Z.; Zhang, A.; Wang, M.; Jahan, M.S.; Wen, Y.; Liu, X. The Positive Effects of Increased Light Intensity on Growth and Photosynthetic Performance of Tomato Seedlings in Relation to Night Temperature Level. Agronomy 2022, 12, 343. [Google Scholar] [CrossRef]

- Kläring, H.-P.; Krumbein, A. The Effect of Constraining the Intensity of Solar Radiation on the Photosynthesis, Growth, Yield and Product Quality of Tomato. J. Agron. Crop. Sci. 2013, 199, 351–359. [Google Scholar] [CrossRef]

- Higashide, T. Light interception by tomato plants (Solanum lycopersicum) grown on a sloped field. Agric. For. Meteorol. 2009, 149, 756–762. [Google Scholar] [CrossRef]

- Marrou, H.; Wery, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Tani, A.; Shiina, S.; Nakashima, K.; Hayashi, M. Improvement in lettuce growth by light diffusion under solar panels. J. Agric. Meteorol. 2014, 70, 139–149. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Schwarz, D.; Thompson, A.J.; Kläring, H.P. Guidelines to use tomato in experiments with a controlled environment. Front. Plant Sci. 2014, 5, 625. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Semeraro, T.; Calisi, A.; Aretano, R.; Rotolo, C.; Lenucci, M.S.; Santino, A.; Piro, G.; De Caroli, M. Effects of the Agrivoltaic System on Crop Production: The Case of Tomato (Solanum lycopersicum L.). Appl. Sci. 2024, 14, 3095. [Google Scholar] [CrossRef]

- Zhang, H.; Xiong, Y.; Huang, G.; Xu, X.; Huang, Q. Effects of water stress on processing tomatoes yield, quality and water use efficiency with plastic mulched drip irrigation in sandy soil of the Hetao Irrigation District. Agric. Water Manag. 2017, 179, 205–214. [Google Scholar] [CrossRef]

- Muñoz-García, M.Á.; Moreda, G.P.; Nieto-Morone, M.B.; Alonso-García, M.C. A real case of thin film PV alternatives to cSi based on a-Si and CdTe. Results after eleven years operating at same conditions. Renew. Energy 2025, 240, 122173. [Google Scholar] [CrossRef]

- Daniel-Durandt, F.M.; Rix, A.J. The long-term influence of wind and temperature on performance and degradation within an utility-scale photovoltaic plant. IET Renew. Power Gener. 2024, 19, e13182. [Google Scholar] [CrossRef]

- Limmanee, A.; Sitthiphol, N.; Jaroensathainchok, S.; Pluemkamon, R.; Kotesopa, S.; Udomdachanut, N.; Krajangsang, T.; Hongsingthong, A. Preliminary Identification of Functional Decommissioned Solar Photovoltaic Modules from Solar Farms: A case study in Thailand. IOP Conf. Ser. Earth Environ. Sci. Inst. Phys. 2023, 1199, 012002. [Google Scholar] [CrossRef]

- Tsanakas, I.J.A.; Oreski, G.; Eder, G.; Gassner, A.; van der Heide, A.; Ariolli, D.M.G.; Hernandez, G.O.; Moser, D.; Wambach, K. Toward Reuse-Ready PV: A Perspective on Recent Advances, Practices, and Future Challenges. Adv. Energy Sustain. Res. 2024, 2400237. [Google Scholar] [CrossRef]

| JINERGY PV MODULE—JNMM144-450L | |

|---|---|

| Max. Power at STC [W] | 450 |

| Max. Power Voltage [V] | 41.36 |

| Max. Power Current [A] | 10.89 |

| Open circuit Voltage [V] | 49.98 |

| Short circuit Current [A] | 11.50 |

| Module Efficiency [%] | 20.70 |

| Temperature Coefficient Voltage [%/°C] | −0.29 |

| Temperature Coefficient Current [%/°C] | 0.04 |

| Temperature Coefficient Power [%/°C] | −0.35 |

| TOP SOLAR PV MODULE—TSM-160M | |

|---|---|

| Max. Power at STC [W] | 165 |

| Max. Power Voltage [V] | 35.00 |

| Max. Power Current [A] | 4.71 |

| Open circuit Voltage [V] | 43.70 |

| Short circuit Current [A] | 5.14 |

| Module Efficiency [%] | 15.50 |

| Temperature Coefficient Voltage [%/°C] | −0.34 |

| Temperature Coefficient Current [%/°C] | 0.05 |

| Temperature Coefficient Power [%/°C] | −0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nieto-Morone, M.-B.; Muñoz-García, M.-Á.; Pérez López, D.; Bernal-Basurco, C.; García Rosillo, F.; Alonso-García, M.d.C. Agrivoltaics: Integration of Reused PV Modules. Agronomy 2025, 15, 730. https://doi.org/10.3390/agronomy15030730

Nieto-Morone M-B, Muñoz-García M-Á, Pérez López D, Bernal-Basurco C, García Rosillo F, Alonso-García MdC. Agrivoltaics: Integration of Reused PV Modules. Agronomy. 2025; 15(3):730. https://doi.org/10.3390/agronomy15030730

Chicago/Turabian StyleNieto-Morone, María-Beatriz, Miguel-Ángel Muñoz-García, David Pérez López, Carlota Bernal-Basurco, Félix García Rosillo, and María del Carmen Alonso-García. 2025. "Agrivoltaics: Integration of Reused PV Modules" Agronomy 15, no. 3: 730. https://doi.org/10.3390/agronomy15030730

APA StyleNieto-Morone, M.-B., Muñoz-García, M.-Á., Pérez López, D., Bernal-Basurco, C., García Rosillo, F., & Alonso-García, M. d. C. (2025). Agrivoltaics: Integration of Reused PV Modules. Agronomy, 15(3), 730. https://doi.org/10.3390/agronomy15030730