Abstract

Sheep farming makes an important socio-economic contribution to Spain’s rural areas by sustaining farming and employment in less favored regions, but it is a low-profit sector because of high operating and regulatory costs. One possible solution would be to raise for slaughter lambs from dairy sheep that are not required as replacements. However, the early weaning of these lambs and their artificial rearing generally lead to reduced growth rates and high mortalities. In the work presented herein, three housing systems (slat + heating plate, slat + infrared lamp, and deep-litter + infrared lamp) were tested on 763 lambs over an eight-month period in a farm located in Ejea de los Caballeros (Zaragoza, Spain), with a view to reducing mortality during the period of artificial lactation. The effect of the environmental parameters of the lamb housing on the development of the lambs was evaluated by monitoring environmental (temperature, relative humidity, CO2 and NH3) and productive parameters (weight, average daily gain, and deaths). The results suggested that the combination of deep litter with straw bedding and infrared lamp heating would be the most favorable option, as it led to the highest average daily gain and the lowest percentage of deaths. From the study of the relationship of the initial weight with deaths, a prediction curve was obtained, defining the maximum prices to be paid per lamb as a function of their initial weight to guarantee the profitability of the raising process. This may be regarded as a valuable guidance for Spanish sheep farmers, as it can reduce their economic uncertainty.

1. Introduction

The Spanish sheep meat sector is going through a deep crisis, which has been aggravated by decreases in the price and in the consumption of lamb meat: according to the Spanish Ministry of Agriculture, Fish and Food (MAPA), per capita consumption has decreased from 2.67 kg in 2006 to 1.62 kg in 2015. This situation has caused a decrease in both the census (from 12,708,383 heads in 2006 to 8,243,484 in 2015, according to the European Statistical Office (EUROSTAT)) and the number of sheep farms (from 122,694 farms in 2007 to 116,296 farms in 2016, according to the Spanish Integrated Animal Traceability System (SITRAN)).

A possible solution to improve this situation would be to raise for slaughter lambs from dairy sheep that are not required as replacements. In the dairy sheep sector, early weaning (0–2 days) based on milk-replacers or solid foods is generally conducted [1,2]. This artificial weaning entails a high percentage of mortality, because it negatively affects the immune function [3,4] and the growth of lambs [5].

Production indices, as well as animal welfare, are directly related to the environmental conditions of livestock housing. The main parameters to take into consideration in sheep housing are the concentration of harmful gases (NH3 and CO2), temperature (T), relative humidity and livestock density [6].

Ammonia, produced by emissions of excreta and manures, has a negative effect on food intake and leads to decreases in body weight gain [7], so it should not exceed 10–15 ppm [8]. High concentrations of CO2, produced by livestock respiration and from the decomposition of manure, cause a decrease in the performance of animals, so values <3500 ppm are recommended [8].

In relation to temperature, the thermal neutral zone for lambs ranges from 15 to 20 °C in the first phase, and from 10 to 18 °C in the second phase [9]. High temperatures negatively affect the growth of lambs, causing animals to devote less time to feeding and spend more downtime [10], while low temperatures also affect lamb growth, as they lead to a decrease in body temperature and to an increase in thermal stress [11]. On the other hand, temperature is correlated with NH3 emissions: in concrete floors: NH3 emissions significantly increase for dairy cattle when the temperature rises from 5 to 35 °C [12].

With regard to relative humidity (RH), it is often assessed together with temperature in a single parameter, the so-called temperature-humidity index (THI), which measures thermal comfort and assesses the risk of heat stress on production and mortality. Relative humidity values in the 65–75% interval [8] and THI values < 72 [13] are advised for the Rasa Aragonesa breed of sheep. In a study conducted by Bello, et al. [14], in which the relationship between environmental parameters and the mortality of lambs in a commercial farm was analyzed, it was observed that humidity was the environmental parameter that showed the highest correlation with mortality in winter, whereas in summer mortality was correlated with temperature, dew point and THI.

The aforementioned parameters can be controlled through ventilation [15], in such a way that the required ventilation flows depend on the time of year, the cleanliness of the housing and the number of animals [8].

Another aspect that should be taken into account is that, unlike other animals, lambs do not have a specific area to excrete their droppings, i.e., lambs rest in the same area in which they defecate and urinate. This favors the use of absorbent materials such as straw on screed [16]. Teixeira, et al. [17] tested other materials such as sawdust or rice husk, finding no significant differences in the performance of lambs. Muñoz–Osorio, et al. [18] compared a system based on plastic or metal slats vs. a concrete floor for intensive male lamb fattening, registering higher productive yields when the slat was used, although with a strong dependence on other factors (food, weather conditions, etc.).

In the present study, different lamb housing systems have also been compared, with the particularity that the tests have been conducted with lambs of dairy breeds separated from their mothers at birth. By using different types of soil and heating systems, we have analyzed which system would be the most favorable with a view to reducing the mortality of lambs during artificial rearing. Moreover, since the experiment has been conducted in real commercial conditions, with variations in the age of the lambs and their initial weight, a survival analysis has also been carried out.

2. Materials and Methods

2.1. Location

The study was carried out in a lamb farm located in the municipality of Ejea de los Caballeros (Zaragoza, Spain). The shed was distributed in pens or corrals, which differed from each other in the type of soil (plastic slat or deep litter bedding with straw) and in the installed heating systems (infrared lamps or heating plates).

2.2. Animal Material

The study was conducted on 763 male lambs of Assaf dairy breed, which came from a farm located in Artajona (Navarra, Spain), and which were distributed over 6 periods: 07/09/2016–05/10/2016, 05/10/2016–08/11/2016, 11/11/2016–30/11/2016, 09/12/2016–03/01/2017, 01/03/2017–29/03/2017, and 29/03/2017–26/04/2017. The 763 lambs were randomly selected from a total of 1034 lambs, distributed among five pens according to Table 1.

Table 1.

Distribution of the lambs into pens for the different periods of study.

In the farm of origin, the lambs were separated from their mothers immediately after birth when they were born during the daytime, and at the beginning of the morning shift when they were born at night (i.e., in less than eight hours). If possible, lactation from the mother was prevented, and the lambs were administered natural colostrum (refrigerated and tempered) twice in the first 24 hours (ca. 100 mL/dose), in addition to a milk-replacer (ELVOR 63; Elvor, Saint-Brice-en-Coglès, Ille-et-Vilaine, France; see Table S1).

The lambs were selected without applying any type of filtering with respect to the weight or age of the animal. The smallest weights corresponded to animals with fewer days of life, associated with clustered births (i.e., associated with those periods in which many lambs were born at once) and which generally led to very homogenous lots. On the other hand, there were periods in which it took several days to gather enough lambs to create a group, and 6–8 days-old animals had to be mixed with 2–4 days-old ones, thus resulting in a higher average input weight of the lot.

After their transport to the shed where the tests were carried out, vitamins (‘Duphafral Multi’ multivitamin injectable solution; Zoetis, Parsippany-Troy Hills, NJ, USA; see Table S2) were administered intramuscularly (0.5 mL of injectable solution/lamb) and the initial weights were determined. The lambs were randomly distributed in the pens, forming lots with an average density of 2.6 animals/m2 (Table 1).

2.3. Housing and Feeding Systems

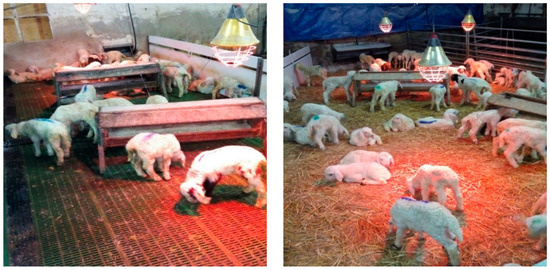

In relation to the type of floor, plastic (polypropylene) slats were installed in some of the pens (Figure 1). The installed slats were of the “wean-to-finish” type, with 1 cm wide slits for the evacuation of the dejections. In the rest of the pens, a deep litter bedding system with straw was used, adding straw and bentonite on a daily basis (300 and 50 g/(m2·day), respectively), and cleaning the pen every 2 weeks.

Figure 1.

Corrals with plastic slat (left) and with a deep litter bedding system with straw (right).

Regarding the heating systems, 175 W infrared (IR) lamps placed 1.5 m high and 150 W heating plates placed at slat level were tested. The latter were equipped with a HF20C/230V power regulator and 16 A switch.

The lambs were fed ad libitum with the same type of milk-replacer used in the farm of origin (Elvor 63) using auto-feeding milk machines for distribution. The milk-replacer was dissolved at 50–60 °C and was served at 40–45 °C. Additionally, a starter feed was supplied (ad libitum), with additives against diarrhea (Ovirum Corderos D3; Ovirum, Zaragoza, Spain; see Table S3) and orf (Ovirum Corderos B1; Ovirum, Zaragoza, Spain; see Table S4), and—in the first days after their arrival—a rehydration product (Hidramix; Asiga, Zaragoza, Spain; see Table S5) was added to the water (30 g/L).

2.4. Monitoring of Environmental Parameters

Temperature, relative humidity, CO2 and NH3 were continuously monitored (every 10 min). HOBO pro v2 Ext Temp/RH datalogger probes (Onset Computer Corp., Bourne, MA, USA) were used to measure the temperature and relative humidity. Probes were installed both inside the shed and outside the building. Carbon dioxide levels were measured using an explosion-proof infrared gas detector, model Dräger PIR 7200 (Drägerwerk, Lübeck, Germany). In the case of NH3, a DrägerSensor NH3 LC-68 09 680 electrochemical sensor and a Dräger Polytron 7000 module were used. A CO2 probe and an NH3 probe were installed on each type of pen, connecting them to a Dräger QuadGard control unit. All indoor probes (Temp/RH, CO2 and NH3) were placed inside the shed at a height of 1.1 m.

2.5. Zootechnical Data Collection

The evolution of the weight of the lambs was controlled through three weighings during the month of artificial lactation: upon arrival, when their identification number (tag) was recorded; after 15 days; and after a month. The mortality of the animals was registered through the identification number, indicating the pen to which they belonged and their day of death.

2.6. Statistical Analysis

Statistical analysis was performed with SPSS v.22 (IBM Inc., Chicago, IL, USA). The following aspects were examined: (i) the effect of the three systems of lamb housing on environmental conditions (ANOVA of the environmental parameters as a function of the lamb housing system); (ii) the variation of environmental conditions as a function of the period of study (ANOVA of the time of the year on the environmental variables to which the lambs were subjected); (iii) the joint effect of the housing system, environmental conditions and initial weight on productive variables (ANCOVA in which the period of study and the type of floor were the independent variables, the initial weight was the covariate, and the average daily gain (ADG) was the dependent variable); and (iv) the effect of the initial weight of the lambs on survival (contingency tables and a receiver operating characteristic (ROC) curve were used).

3. Results

3.1. Effect of the Housing System on the Environmental Conditions

Statistically significant differences were observed for all environmental parameters depending on the housing system (Table 2). The CO2 concentration was significantly lower for the slatted floor system than for the deep litter bedding with straw method, whereas NH3 was significantly higher in the former than in the latter, regardless of the period of the year considered.

Table 2.

ANOVA of the environmental parameters as a function of the lamb housing system. For each environmental variable, the values labeled with different lowercase letters are statistically different according to the Tukey’s test (p < 0.05).

Regarding the indoor temperature, differences between the two heating systems (IR lamp versus heating plate) were lower than 1 °C, so the statistically significant differences can be disregarded from a practical point of view.

In relation to the relative humidity, the straw bedding + IR lamp system was the one that led to the lowest RH values. On the other hand, in the slat-based systems, differences were observed depending on the type of heating: the RH was lower for the IR lamp system than for the heating plate one.

Regarding the THI (calculated using Thom’s formula [19]), significant differences were also observed between management systems, when comparing IR lamp with heating plate.

3.2. Variation of Environmental Conditions as a Function of the Period of Study

Through a factor analysis (not shown), it was possible to see how the environmental variables strongly depended on the seasonal period, while the concentrations of CO2 and NH3 depended (more weakly) on the type of floor. In relation to the former, very significant seasonal differences were observed, as shown in Table 3.

Table 3.

Influence of the time of the year on the environmental variables to which the lambs were subjected. For each environmental variable, the values labeled with different lowercase letters are statistically different according to the Tukey’s test (p < 0.05).

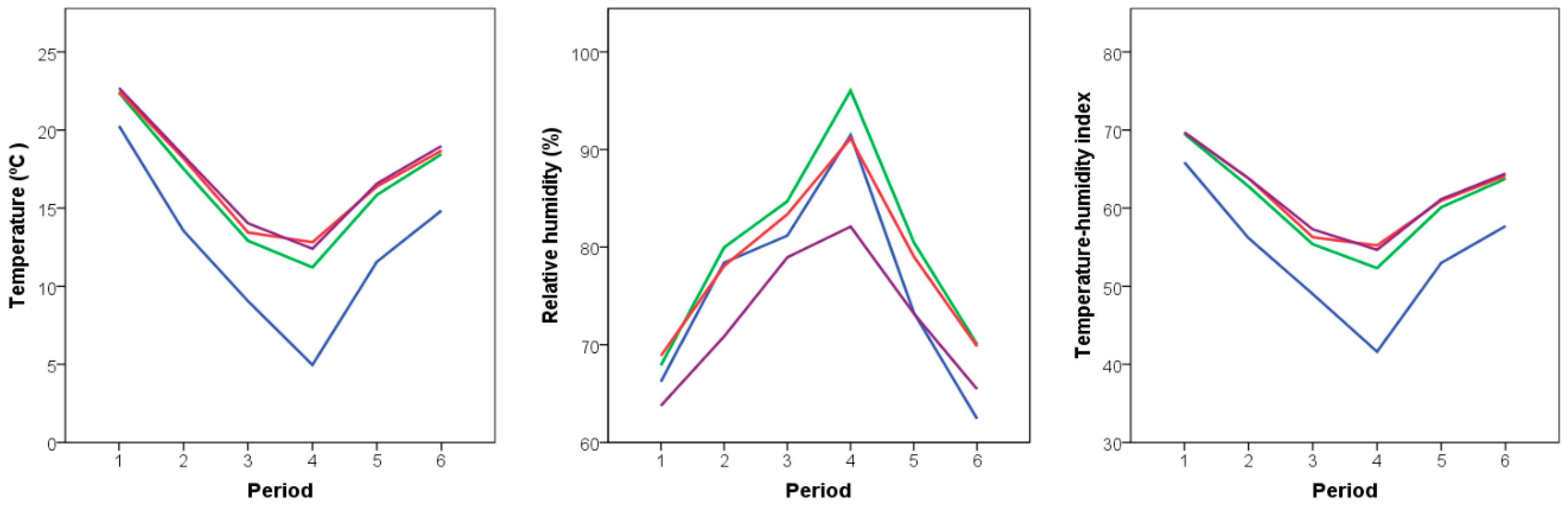

Figure 2 shows the evolution of temperatures, indoor relative humidity and THI for each type of floor as a function of time, thus evidencing the magnitude of the changes from one period to another.

Figure 2.

Temporal evolution of the external environmental conditions (in blue) and of the internal environmental conditions for the three management systems (slat + heating plate in green, slat + IR lamp in red and straw bedding + IR lamp in purple). RH: relative humidity; THI: temperature-humidity index.

3.3. Joint Effect of the Housing System, Environmental Conditions and Initial Weight on Productive Variables

3.3.1. Relationships among the Periods of Study and the Initial Weight, ADG and Percentage of Deaths

The initial weights were very similar in the six periods under study (with average values in the 4.70–4.77 kg range, Table 4), except for period one, in which the initial weights were slightly lower (with a mean value of 4.41 kg). The highest initial weights corresponded to period two. With respect to the average daily gain (ADG), the values were similar for all periods, although the highest ADG corresponded to period three. Regarding the percentage of deaths, no remarkable differences were observed, with values generally within the 10%–30% range, except in period one, in which the percentage of deaths was markedly higher. It is worth noting that in period one, in which the lowest initial weights were recorded (for the reasons explained above), the highest percentage of deaths was also registered.

Table 4.

Variation of the initial weight, average daily gain (ADG) and percentage of deaths as a function of the period of study.

From the ANCOVA analysis (Table 5), it could be inferred that the period of study did not have a significant influence on the ADG, whereas the covariate initial weight had a very significant impact on it. A more in-detail analysis of the influence of the initial weight on other variables and on mortality is presented below.

Table 5.

Tests of between-subjects effects table, in which the period of study was the independent variable, the initial weight was the covariate, and the ADG was the dependent variable.

3.3.2. Relationships among the Lamb Housing System and the Initial Weight, ADG and Percentage of Deaths

Lower weights were registered for the slat + heating plate system than for the other two handling systems (Table 6), but they should be attributed to the low initial weight for the lambs raised in this system during period one. In the rest of the periods, the values were similar.

Table 6.

Variation of the initial weight, average daily gain (ADG) and percentage of deaths as a function of the lamb housing system.

With regard to the ADG, it was not consistent throughout the six study periods, but overall the straw bedding + IR lamp system was the most advantageous, with a mean ADG of 0.22 kg LW/day. As shown from the ANCOVA analysis summarized in Table 7, the type of floor did not have a significant effect on ADG, and again the initial weight did when it was chosen as a covariate.

Table 7.

Tests of between-subjects effects table, in which the type of floor was the independent variable, the initial weight was the covariate, and the ADG was the dependent variable.

In relation to the percentage of deaths, it was also lower for the straw bedding + IR lamp-based system.

3.4. Relationship between Initial Weight and Mortality

As expected, the initial weight significantly influenced the mortality of the lambs (Table 8), with a χ² < 0.001. For an initial weight > 5 kg, the mortality percentage was 8%, compared with 22% for 4–5 kg, 28% for 3.5–4 kg, and 38% for < 3.5 kg.

Table 8.

Influence of the initial weight on mortality throughout the entire artificial lactation period (one month).

When the deaths that occurred during the six study periods (154 deaths) were grouped into two categories: one (deaths that took place in the first 15 days of the artificial lactation period) and two (deaths that took place on days 16–30), it could be observed that 73% (113 deaths) occurred in the first days after arrival. Consequently, the influence of the initial weight on the time of the artificial lactation period in which the deaths occur was analyzed in more detail. In Table 9 it can be observed that the average initial weight of the lambs that died in the first 15 days was of 4.05 kg, while those that died in the second fortnight presented higher average weights (4.42 kg). In the contingency table (not shown), a 20% reduction in deaths in the first period (from 80% to 60%) was found for weights > 4.4 kg, with a χ² = 0.04.

Table 9.

Influence of the initial weight on the fortnight of the artificial lactation period in which the lambs died.

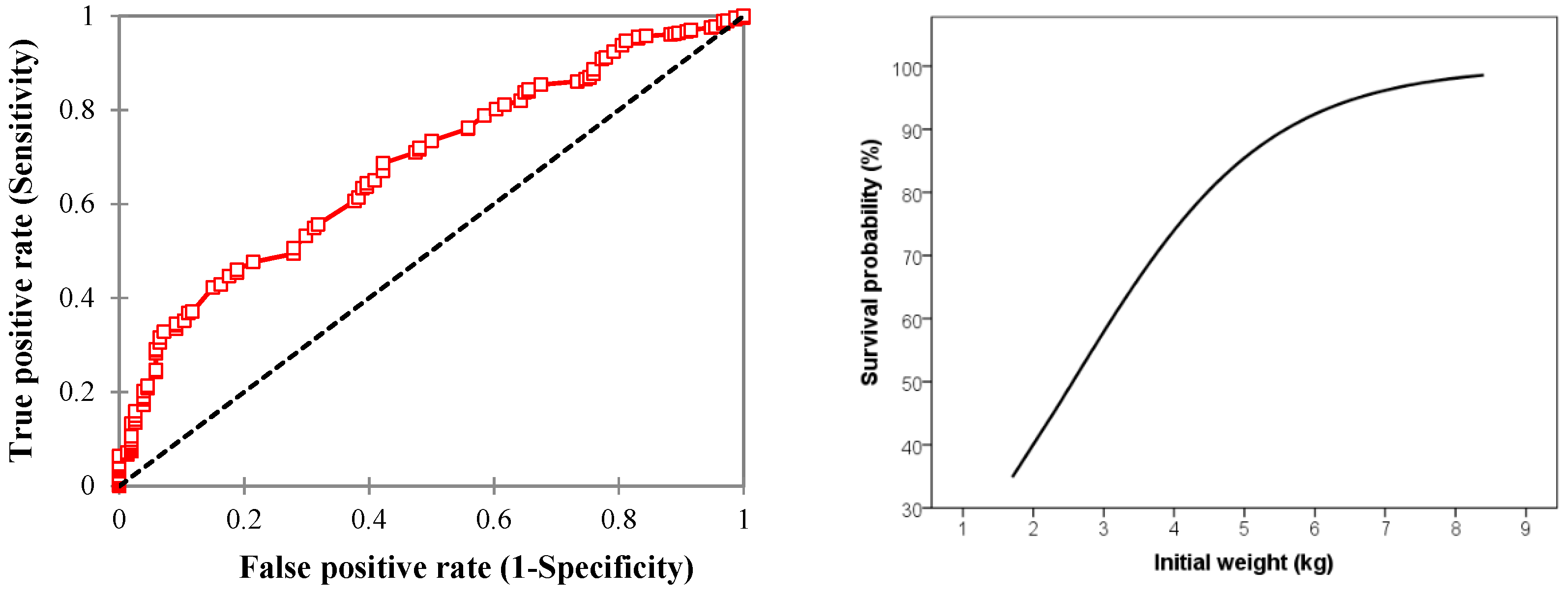

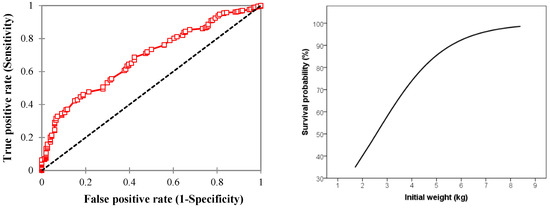

These findings suggested that it would be interesting to estimate the minimum initial weight that would ensure the survival of the animals and, therefore, the viability of the raising and fattening process. From the receiver operating characteristic (ROC) curve (Figure 3, left), a weight of 4.4 kg was estimated as a threshold for animal survival, with an area under the curve (AUC) of 0.682 (sensitivity 0.644, specificity 0.604). On the other hand, by using a binary logistic regression, a plot of the probability of survival as a function of the initial weight was also obtained (Figure 3, right). With the proposed model, 79.7% of the total cases would be correctly classified, and only 1.3% of the dead lambs would be classified as alive.

Figure 3.

ROC curve (left), lamb’s survival probability function as a function of the initial weight (right).

4. Discussion

Apropos of effect of the housing system on the environmental conditions, the results for CO2 levels were in good agreement with the observations made by other authors, but not the ones obtained for NH3 (Table 1). For instance, Philippe, et al. [20] compared a fully-slatted floor vs. straw-flow in pigs housing, and obtained that the average daily emissions per pig fattened on the slatted floor and on the straw bedding were, respectively, 548 g and 406 g CO2 eq, 1.61 and 1.77 kg CO2, and 4.98 and 13.31 g NH3, respectively. This deviation from the results reported in the literature can be attributed to singularities of the farm in which the tests were carried out: being an old shed, the slat was not actually built on top of a deep collection pit with the appropriate slope for the evacuation of the dejections. Under the slat, straw was placed on top of the screed. This implied that the dirty bed was not removed during the breeding period of each lot, resulting in an accumulation of dejections that, in turn, would have led to an increase in the concentration of NH3. The same reason would tentatively explain the fact that the lowest relative humidity was obtained for the straw bedding + IR lamp system, while Seedorf, et al. [21] obtained worse RH results for a straw bedding than for a slat system.

From the results reported in Table 2, it becomes apparent that—as expected—the two localized heating systems tested had strong limitations for the control of the global environmental conditions of the shed, and their influence was limited to the surroundings of the heat emitters. It is also worth noting that the temperatures shown in Table 2 were associated with the ambient temperature, not with the actual apparent temperature perceived by the lambs (given that the warming effect of IR heaters is not via a change in air temperature but through direct transfer of radiant heat). However, in view of the THI results (in the 61.7–62.8 range), lower than 72, the existence of thermal stress could be excluded [13]. Hence, both tested heating systems would fulfill a useful function, but the use of IR lamps would be more versatile, as it is more independent of the floor type.

With regard to the productive parameters, the obtained ADG value for the straw bedding + IR lamp system (0.22 kg LW/day) was lower than that reported for a similar study conducted in a lamb feedlot, in which ADG values of 0.27 kg LW/day were obtained [8]. The ADG value was affected by the initial weight of the lamb, but in this study there were no significant differences between the straw bedding + IR lamp and the slat + IR lamp systems. In a study conducted by Muñoz-Osorio, et al. [18], a higher ADG was obtained with slatted floor (compared to concrete screed), attributing these results to the lower contact of animals with possible pathogens and bacteria in this type of floor. The results presented herein cannot be directly extrapolated, since that study did not include the straw bedding method and the slat system used had limitations, as explained above.

Concerning the mortality, since the initial weight was very similar for the straw bedding + IR lamp and the slat + IR lamp systems, and the percentage of deaths was lower for the former, the deep litter with straw bedding system would be the preferred option.

In regards to the mortality during the first fortnight of each artificial lactation period, it should be clarified that those deaths would not be attributable to the management or to the conditions of the farm. Throughout the experiment, the most frequent causes of mortality were related to respiratory and/or digestive processes: atypical pneumonias that were complicated by the concurrence of digestive processes, present in all animals (coccidia reproduce massively in the states of immune lowering, stress, or bacterial dysbiosis). The intermittent diarrhea leads to a decrease in growth and favors the development of other germs, such as respiratory ones (e.g., pasteurellas), that concur with other predisposing factors: stress due to relocation, deficient colostrum administration, feed changes, sudden temperature changes, mixture of animals. In a study by Minka, et al. [22], the authors concluded that transport stress in animals was the key problem for the animal’s productive life cycle, although completely excluding transport stress factors in livestock production would be impossible.

5. Conclusions

In relation to the influence of the lamb housing system on the environmental conditions, the two heating systems tested (IR lamp and heating plate) achieved adequate comfort in the localized area of the lambs. Relative humidity was lower for the straw-based housing system than for the slatted floor one. The concentrations of harmful gases were very low in all cases. Regarding the productive parameters, the highest ADG was attained for the straw bedding + IR lamp system. The lowest mortality was also achieved for that system. Therefore, it may be inferred that the deep litter bedding with straw + IR lamp heating system would be the most desirable option for its implantation in other feedlots with similar characteristics to those of the one under study. Moreover, its lower installation cost as compared to the slatted floor system would be an additional advantage.

In addition, a strong influence of the initial weight on the ADG and the percentage of deaths was detected. The lambs that entered with low weights (average weight < 4.1 kg) died prematurely. The majority of the deaths (73% of the total) occurred in the first days after arrival. Since the viability and profitability of the process mainly depends on the initial weight of the lambs, a key contribution of the study was the obtaining of a prediction curve that allows to estimate the percentage of deaths based on the initial weight with a success rate of 80%.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4395/9/11/694/s1, Table S1: Ingredients of ELVOR CAB Y CORD 63 PL milk-replacer; Table S2: Composition of Duphafral Multi multivitamin injectable solution; Table S3: Ingredients of OVIRUM CORDEROS B1 complementary mineral feed; Table S4: Ingredients of OVIRUM CORDEROS D3, medicated feeding for lambs from the first days of life; Table S5: Ingredients of HIDRAMIX rehydration product.

Author Contributions

Conceptualization, F.J.G.-R., E.H. and J.Y.; methodology, F.J.G.-R., E.H. and J.Y.; validation, F.J.G.-R. and P.M.-R.; formal analysis, J.P.V.-A., P.M.-R. and F.J.G.-R.; investigation, J.P.V.-A. and E.H.; resources, F.J.G.-R., E.H. and J.Y.; data curation, J.P.V.-A. and P.M.-R.; writing—original draft preparation, J.P.V.-A., P.M.-R. and F.J.G.-R.; supervision, F.J.G.-R., P.M.-R. and J.Y.; Project administration, F.J.G.-R. and J.Y.; funding acquisition, F.J.G.-R. and J.Y.

Funding

This research was funded by OVIARAGON S.C.L. in the framework of the project IDI-20150752.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Napolitano, F.; De Rosa, G.; Sevi, A. Welfare implications of artificial rearing and early weaning in sheep. Appl. Anim. Behav. Sci. 2008, 110, 58–72. [Google Scholar] [CrossRef]

- Weary, D.M.; Jasper, J.; Hötzel, M.J. Understanding weaning distress. Appl. Anim. Behav. Sci. 2008, 110, 24–41. [Google Scholar] [CrossRef]

- Lynch, E.M.; Earley, B.; McGee, M.; Doyle, S. Characterisation of physiological and immunological responses in beef cows to abrupt weaning and subsequent housing. BMC Vet. Res. 2010, 6, 37. [Google Scholar] [CrossRef] [PubMed]

- Ungerfeld, R.; Hotzel, M.J.; Scarsi, A.; Quintans, G. Behavioral and physiological changes in early-weaned multiparous and primiparous beef cows. Animal 2011, 5, 1270–1275. [Google Scholar] [CrossRef] [PubMed]

- Langlands, J.P.; Donald, G.E. The intakes and growth rates of grazing border Leicester × Merino lambs weaned at 21, 49 and 77 days. Anim. Sci. 1975, 21, 175–181. [Google Scholar] [CrossRef]

- Caroprese, M. Sheep housing and welfare. Small Rumin. Res. 2008, 76, 21–25. [Google Scholar] [CrossRef]

- Phillips, C.J.; Pines, M.K.; Latter, M.; Muller, T.; Petherick, J.C.; Norman, S.T.; Gaughan, J.B. Physiological and behavioral responses of sheep to gaseous ammonia. J. Anim. Sci. 2012, 90, 1562–1569. [Google Scholar] [CrossRef] [PubMed]

- García-Ramos, F.J.; Lahera, L.; Horcas, E. Condiciones ambientales en cebaderos de corderos. Mg Mundo Ganad. 2007, 18, 38–43. [Google Scholar]

- Buxadé Carbó, C. Ovino de Carne: Aspectos Claves; Ediciones Mundi-Prensa: Madrid, Spain, 1998; p. 550. [Google Scholar]

- De, K.; Kumar, D.; Saxena, V.K.; Naqvi, S.M. Study of circadian rhythmicity of physiological response and skin temperature of sheep during summer and winter in semi-arid tropical environment. Physiol. Behav. 2017, 169, 16–21. [Google Scholar] [CrossRef] [PubMed]

- Johns, M.A. Rearing Orphan Lambs. Farmnote 78/99; Australian Department of Agriculture and Food: Kensington, Australia, 1995; p. 4. [Google Scholar]

- Pereira, J.; Misselbrook, T.H.; Chadwick, D.R.; Coutinho, J.; Trindade, H. Effects of temperature and dairy cattle excreta characteristics on potential ammonia and greenhouse gas emissions from housing: A laboratory study. Biosys. Eng. 2012, 112, 138–150. [Google Scholar] [CrossRef]

- Santolaria, P.; Yaniz, J.; Fantova, E.; Vicente-Fiel, S.; Palacin, I. Climate factors affecting fertility after cervical insemination during the first months of the breeding season in Rasa Aragonesa ewes. Int. J. Biometeorol. 2014, 58, 1651–1655. [Google Scholar] [CrossRef] [PubMed]

- Bello, J.; Marco, L.; Ruiz, S.; Hernández, V.; Carranza, R.; Mantecón, A.; Lavín, P. Efecto de las Condiciones Ambientales Sobre la Mortalidad de Corderos en un Cebadero Comercial. In Proceedings of the XLI Jornadas Científicasy XVII Jornadas Internacionales de Ovinotecnia y Caprinotecnia; Sociedad Española de Ovinotecnia y Caprinotecnia, Asociación Interprofesional para el Desarrollo Agrario: Talavera de la Reina, Toledo, Spain, 2016; pp. 367–371. [Google Scholar]

- Sevi, A. Influence of Sunlight, Temperature and Environment on the Fatty Acid Composition and Coagulatine Properties of Sheep Milk. In Proceedings of The Future of the Sheep and Goat Dairy Sector International Symposium; Sevi, A., Ed.; International Dairy Federation: Zaragoza, Spain, 2005; pp. 305–311. [Google Scholar]

- Færevik, G.; Andersen, I.L.; Bøe, K.E. Preferences of sheep for different types of pen flooring. Appl. Anim. Behav. Sci. 2005, 90, 265–276. [Google Scholar] [CrossRef]

- Teixeira, D.L.; Miranda-de la Lama, G.; Villarroel, M.; Olleta, J.L.; García-Belenguer, S.; Escós, J.; María, G.A. Effects of alternative bedding substrates on lamb welfare, productive performance, and meat quality during the finishing phase of fattening. J. Vet. Behav. 2015, 10, 171–178. [Google Scholar] [CrossRef][Green Version]

- Muñoz-Osorio, G.A.; Aguilar-Caballero, A.J.; Sarmiento-Franco, L.A.; Wurzinger, M.; Gutiérrez-Reynoso, G.A. The effect of two housing systems on productive performance of hair-type crossbreed lambs in sub-humid tropics of Mexico. J. Appl. Anim. Res. 2017, 45, 384–388. [Google Scholar] [CrossRef]

- Thom, E.C. The Discomfort Index. Weatherwise 1959, 12, 57–61. [Google Scholar] [CrossRef]

- Philippe, F.X.; Laitat, M.; Canart, B.; Vandenheede, M.; Nicks, B. Gaseous emissions during the fattening of pigs kept either on fully slatted floors or on straw flow. Animal 2007, 1, 1515–1523. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Seedorf, J.; Hartung, J.; Schröder, M.; Linkert, K.H.; Pedersen, S.; Takai, H.; Johnsen, J.O.; Metz, J.H.M.; Groot Koerkamp, P.W.G.; Uenk, G.H.; et al. Temperature and Moisture Conditions in Livestock Buildings in Northern Europe. J. Agric. Eng. Res. 1998, 70, 49–57. [Google Scholar] [CrossRef]

- Minka, N.; Ayo, J. Physiological responses of food animals to road transportation stress. Afr. J. Biotechnol. 2010, 9, 6601–6613. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).