Sowing Density Effects in Cotton Yields and Its Components

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Plant Material, Treatments and Experimental Design

2.3. Management of Trials and Data Collection

2.4. Statistical Analysis

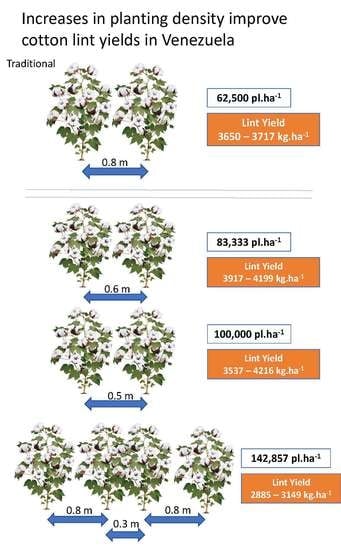

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United States Department of Agriculture. Cotton: World Markets and Trade. USDA—Foreign Agricultural Service. Monthly Report December. 2018. Available online: https://apps.fas.usda.gov/psdonline/circulars/cotton.pdf (accessed on 22 February 2019).

- FAO FAOSTAT Statistics Database. 2019. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 19 February 2019).

- Gonzalez, T.; Salas, R. El cultivo de algodón en Venezuela. In Análisis de la Situación Agrícola de Rubros Seleccionados en Venezuela Durante el Periodo 2000–2010; Revista Alcance N°72; Facultad de Agronomía. UCV: Maracay, Venezuela, 2012; pp. 177–192. [Google Scholar]

- Navarro, R.; Gutierrez, M.; Alfonzo, N.; Piñango, L. Cultivo del Algodon en las Zonas de Vega del rio Orinoco y sus Afluentes; Instituto Nacional de Investigaciones Agricolas: Maracay, Venezuela, 2010; p. 70. [Google Scholar]

- Mendez-Natera, J.R.; Garcia-Cedeño, L.E.; Fendel-Alvarez, J.E.; Merzo-Pinto, J.F. Evaluación de la calidad de la fibra en catorce cultivares de algodón (Gossypium hirsutum L.) bajo condiciones de sabana. Rev. UDO Agric. 2003, 3, 17–23. [Google Scholar]

- Gonzalez, T.; Monteverde, E.; Marin, C.; Madriz, P. Comparación de tres métodos para estimar estabilidad del rendimiento en nueve variedades de algodón. Interciencia 2007, 32, 344–348. [Google Scholar]

- Guzman, M.; Vilain, L.; Rondon, T. Increasing genetic diversity of cotton breeding programs in Venezuela. Turk. J. Field Crops 2018, 23, 151–158. [Google Scholar] [CrossRef]

- Bednarz, C.W.; Bridges, D.C.; Brown, S.M. Analysis of cotton yield stability across population densities. Agron. J. 2000, 92, 128–135. [Google Scholar] [CrossRef]

- Bednarz, C.W.; Shurley, W.D.; Anthony, W.S.; Nichols, R.L. Yield, quality, and profitability of cotton produced at varying plant densities. Agron. J. 2005, 97, 235–240. [Google Scholar] [CrossRef]

- Siebert, J.D.; Stewart, A.M. Influence of plant density on cotton response to mepiquat chloride application. Agron. J. 2006, 98, 1634–1639. [Google Scholar] [CrossRef]

- Read, J.J.; Reddy, K.R.; Jenkins, J.N. Yield and fiber quality of upland cotton as influenced by nitrogen and potassium nutrition. Eur. J. Agron. 2006, 24, 282–290. [Google Scholar] [CrossRef]

- Kawakami, E.M.; Oosterhuis, D.M.; Snider, J.L.; Mozaffari, M. Physiological and yield responses of field-grown cotton to application of urea with the urease inhibitor NBPT and the nitrification inhibitor DCD. Eur. J. Agron. 2012, 43, 147–154. [Google Scholar] [CrossRef]

- Han, H.Y.; Deng, F.J.; Li, B.C.; Yang, B.Y.; Yang, L.Y.; Lin, H.; Wang, X.T. Effect of plant density on cotton yield and quality in Xinjiang. Jiangsu J. Agric. Sci. 2009, 4, 98–100. [Google Scholar]

- Yang, G.Z.; Zhou, M.Y. Multi-location investigation of optimum planting density and boll distribution of high yielding cotton (G. hirsutum L.) in Hubei province, China. Agric. Sci. China 2010, 9, 1749–1757. [Google Scholar] [CrossRef]

- Gaytan-Mascorro, A.; Palomo-Gil, A.; Reta-Sanchez, D.G.; Godoy-Avila, S.; García-Castañeda, E.A. Respuesta del algodón cv. Cian precoz 3 al espaciamiento entre surcos y densidad poblacional. I. Rendimiento, precocidad y calidad de fibra. Phyton 2004, 73, 57–67. [Google Scholar]

- Venugopalan, M.V.; Kranthi, K.R.; Blaise, D.; Lakde, S.; Shankaranarayanan, K. High density planting system in cotton—The Brazil experience and Indian initiatives. Cotton Res. J. 2013, 5, 172–185. [Google Scholar]

- Zhi, X.Y.; Han, Y.C.; Li, Y.B.; Wang, G.P.; Du, W.L.; Li, X.X.; Mao, S.C.; Feng, L. Effects of plant density on cotton yield components and quality. J. Integr. Agric. 2016, 15, 1469–1479. [Google Scholar] [CrossRef] [Green Version]

- Briggs, R.E.; Patterson, L.L.; Massey, G.D. Within and between-Row Spacing of Cotton; Arizona Annual Report; University of Arizona Agriculture and Extension Service: Tucson, AZ, USA, 1967; pp. 6–7. [Google Scholar]

- Yang, G.Z.; Luo, X.J.; Nie, Y.C.; Zhang, X.L. Effects of plant density on yield and canopy micro environment in hybrid cotton. J. Integr. Agric. 2014, 13, 2154–2163. [Google Scholar] [CrossRef]

- Bednarz, C.W.; Nichols, R.L.; Brown, S.M. Plant density modifications of cotton within-boll yield components. Crop Sci. 2006, 46, 2076–2080. [Google Scholar] [CrossRef]

- Kerby, T.A.; Cassman, K.G.; Keeley, M. Genotypes and plant densities for narrow-row cotton systems. I. Height, nodes, earliness, and location of yield. Crop Sci. 1990, 30, 644–649. [Google Scholar] [CrossRef]

- Reddy, K.N.; Burke, I.C.; Boykin, J.C.; Willford, J.R. Narrow-row cotton production under irrigation and non-irrigated environment: Plant population and lint yield. J. Cotton Sci. 2009, 13, 48–55. [Google Scholar]

- Culpepper, A.S.; York, A.C. Weed management in ultra narrow row cotton (Gossypium hirsutum). Weed Technol. 2000, 14, 19–29. [Google Scholar] [CrossRef]

- Wilson, D.G.; York, A.C.; Edmisten, K.L. Narrow-row cotton response to mepiquat chloride. J. Cotton Sci. 2007, 11, 177–185. [Google Scholar]

- Stephenson, D.O.; Brecke, B.J. Weed management in single vs. twin-row cotton (Gossypium hirsutum). Weed Technol. 2010, 24, 275–280. [Google Scholar] [CrossRef]

- Enriquez-Sanchez, M.; Segura-Castruita, M.A.; Preciado-Rangel, P.; Orozco-Vidal, J.A.; Yescas-Coronado, P.; de Avila-Velasquez, C. Cotton production in double and triple row with subsurface irrigation. Terra Latinoam. 2006, 25, 155–161. [Google Scholar]

- Clawson, E.L.; Cothren, J.T.; Blouin, D.C. Nitrogen fertilization and yield of cotton in ultra-narrow and conventional row spacings. Agron. J. 2006, 98, 72–79. [Google Scholar] [CrossRef]

- McCarty, J.C.; Cash, L., III; Jenkins, J.N. Effects of within-Row Plant Spacings on Growth, Boll Retention, and Yield of Four Cotton Cultivars; Bulletin 1191; Mississippi Agricultural & Forestry Experiment Station, Mississippi State University: Starkville, MS, USA, 2011; p. 12. [Google Scholar]

- Zhi, X.; Han, Y.; Mao, S.; Wang, G.; Feng, L.; Yang, B.; Fan, Z.; Du, W.; Lu, J.; Li, Y. Light spatial distribution in the canopy and crop development in cotton. PLoS ONE 2014, 9, e113409. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Wang, L.; Ali, S.; Tung, S.A.; Hafeez, A.; Yang, G. Optimal planting density and sowing date can improve cotton yield by maintaining reproductive organ biomass and enhancing potassium uptake. Field Crops Res. 2017, 214, 164–174. [Google Scholar] [CrossRef]

- McCarty, J.C.; Jenkins, J.N.; Hayes, R.W.; Wubben, M.J. Effects of plant density on boll retention and yield of cotton in the MidSouth. Am. J. Plant Sci. 2017, 8, 891–906. [Google Scholar] [CrossRef]

- Bednarz, C.W.; Nichols, R.L.; Brown, S.M. Within-boll yield components of high yielding cotton cultivars. Crop Sci. 2007, 47, 2108–2112. [Google Scholar] [CrossRef]

- Jones, W.M.; Joy, K.; Smith, C.W. Within-boll yield components and fiber traits of upland cotton. Crop Sci. 2014, 54, 1057–1061. [Google Scholar] [CrossRef]

- Darawsheh, M.K.; Aivalakis, G.; Bouranis, D.L. Effect of cultivation system on cotton development, seed-cotton production and lint quality. J. Plant Sci. Biotechnol. 2007, 1, 206–213. [Google Scholar]

| Source of Variation | df | LY (kg ha−1) | BW (g) | LP (%) | SB (boll−1) | SI (g) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Replication (Rep) | 2 | 15,579 | 0.0208 | 0.1539 | 0.1148 | 0.2228 | |||||

| Sowing density (Trat) | 3 | 3,716,671 | *** | 1.5745 | *** | 3.4216 | *** | 8.4482 | *** | 3.8261 | *** |

| Genotype (Gen) | 1 | 1,876,630 | *** | 0.9090 | *** | 1.6260 | *** | 5.1040 | *** | 1.8625 | *** |

| Year | 2 | 421,222 | * | 0.1618 | * | 0.4648 | ** | 1.4109 | ** | 0.5605 | ** |

| Trat × Gen | 3 | 97,700 | * | 0.1751 | * | 0.1841 | 0.8480 | * | 0.2938 | * | |

| Trat × Year | 6 | 114,712 | 0.0654 | 0.0925 | 0.2746 | 0.0943 | |||||

| Gen × Year | 2 | 269,942 | 0.0809 | 0.1595 | 0.4777 | 0.1624 | |||||

| Trat × Gen × Year | 6 | 288,374 | * | 0.1370 | * | 0.1878 | 0.4233 | 0.2257 | |||

| Error | 46 | 104,976 | 0.0441 | 0.1012 | 0.2566 | 0.1059 | |||||

| Grand Mean | 3659.3 | 6.31 | 41.25 | 24.74 | 10.05 | ||||||

| Minimum mean | 2349.0 | 5.20 | 40.11 | 23.15 | 9.02 | ||||||

| Maximum mean | 4625.0 | 7.06 | 42.31 | 26.90 | 10.98 | ||||||

| SD | 563.87 | 0.37 | 0.53 | 0.86 | 0.56 | ||||||

| CV (%) | 15.41 | 3.33 | 0.77 | 2.05 | 3.24 | ||||||

| LY (kg ha−1) | BW (g) | LP (%) | SB (boll−1) | SI (g) | |

|---|---|---|---|---|---|

| Pooled error | 35 | 35 | 32 | 33 | 32 |

| Remaining | 65 | 65 | 68 | 67 | 68 |

| Year | 6 | 5 | 7 | 7 | 8 |

| Genotype (Gen) | 13 | 14 | 12 | 12 | 14 |

| Sowing Density (Trat) | 76 | 73 | 75 | 77 | 71 |

| Gen × Trat | 6 | 8 | 6 | 4 | 7 |

| LY | BW | SB | SI | |

|---|---|---|---|---|

| BW | 0.98** | |||

| SB | 0.72** | 0.41 | ||

| SI | 0.45* | 0.65* | 0.88** | |

| LP | 0.89** | 0.96** | 0. 36 | 0.33 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzman, M.; Vilain, L.; Rondon, T.; Sanchez, J. Sowing Density Effects in Cotton Yields and Its Components. Agronomy 2019, 9, 349. https://doi.org/10.3390/agronomy9070349

Guzman M, Vilain L, Rondon T, Sanchez J. Sowing Density Effects in Cotton Yields and Its Components. Agronomy. 2019; 9(7):349. https://doi.org/10.3390/agronomy9070349

Chicago/Turabian StyleGuzman, Manuel, Luis Vilain, Tatiana Rondon, and Juan Sanchez. 2019. "Sowing Density Effects in Cotton Yields and Its Components" Agronomy 9, no. 7: 349. https://doi.org/10.3390/agronomy9070349

APA StyleGuzman, M., Vilain, L., Rondon, T., & Sanchez, J. (2019). Sowing Density Effects in Cotton Yields and Its Components. Agronomy, 9(7), 349. https://doi.org/10.3390/agronomy9070349