The Energy Efficiency of the Production and Conversion of Spring Triticale Grain into Bioethanol

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Experiment

2.2. Energy Intensity of Spring Triticale Production

- ETR—tractors; EM—machines; ET—transport vehicles; EE—employees; ED—fuel; EFR—fertilizers; EP—pesticides

2.3. Analysis of The Content of Starch and Ethanol Efficiency

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Balat, M.; Balat, H. Recent trends in global production and utilization of bio-ethanol fuel. Appl. Energy 2009, 86, 2273–2282. [Google Scholar] [CrossRef]

- COM (Commission of the European Communities), 2008. Available online: http://www.europarl.europa.eu/RegData/docs_autres_institutions/commission_europeenne/com/2008/0030/COM_COM(2008)0030_EN.pdf (accessed on 15 January 2015).

- Ragauskas, A.J.; Williams, C.K.; Davison, B.H.; Britovsek, G.; Cairney, J.; Eckert, C.A.; Frederick, W.J.; Hallett, J.P.; Leak, D.J.; Liotta, C.L.; et al. The path forward for biofuels and biomaterials. Science 2006, 311, 484–489. [Google Scholar] [CrossRef] [PubMed]

- Belboom, S.; Bodson, B.; Leonard, A. Does the production of Belgian bioethanol fit with European requirements on GHG emissions? Case of wheat. Biomass Bioenergy 2015, 74, 58–65. [Google Scholar] [CrossRef]

- Bielski, S.; Dubis, B.; Jankowski, K. The energy efficiency of production and conversion of winter triticale biomass into biofuels. Przem. Chem. 2015, 94, 1798–1801. [Google Scholar]

- Davis-Knight, H.R.; Weightman, R.M. The Potential of Triticale as a Low Input Cereal for Bioethanol Production. Project Report No. 434. July 2008. Available online: https://cereals.ahdb.org.uk/media/408618/pr434-final-project-report.pdf (accessed on 15 January 2019).

- Ho, D.P.; Ngo, H.H.; Gou, W. A mini review on renewable sources for biofuel. Bioresour. Technol. 2014, 169, 742–749. [Google Scholar] [CrossRef] [PubMed]

- Mojović, L.; Pejin, D.; Grujić, O.; Markov, S.; Pejin, J.; Rakin, M.; Vukašinović, M.; Nikolić, S.; Savić, D. Progress in the production of bioethanol on starch-based feedstocks. Chem. Ind. Chem. Eng. Q. 2009, 15, 211–226. [Google Scholar] [CrossRef]

- OECD. International Energy Agency. In Energy Technology Perspectives, Scenarios & Strategies to 2050; OECD: Paris, France, 2008. [Google Scholar]

- Gnansounou, E. Assessing the sustainability of biofuels: A logic-based model. Energy 2011, 36, 2089–2096. [Google Scholar] [CrossRef]

- McKenzie, R.H.; Bremer, E.; Middelton, A.B.; Beres, B.; Yoder, C.; Hietamaa, C.; Pfiffner, P.; Kereliuk, G.; Pauly, D.; Henriquez, B. Agronomic practices for bioethanol production from spring triticale in Alberta. Can. J. Plant Sci. 2014, 94, 15–22. [Google Scholar] [CrossRef]

- Lewandowski, I.; Kauter, D. The influence of nitrogen fertilizer on the yield and combustion quality of whole grain crops for solid fuel use. Ind. Crops Prod. 2003, 17, 103–117. [Google Scholar]

- Kindred, D.R.; Verhoeven, T.M.O.; Weightman, R.M.J.; Swanston, S.; Agu, R.C.; Brosnan, J.M.; Sylvester-Bradley, R. Effects of variety and fertiliser nitrogen on alcohol yield, grain yield, starch and protein content, and protein composition of winter wheat. J. Cereal Sci. 2008, 48, 46–57. [Google Scholar] [CrossRef]

- Cantale, C.; Petrazzuolo, F.; Correnti, A.; Farneti, A.; Felici, F.; Latini, A.; Galeffi, P. Triticale for bioenergy production. Agric. Agric. Sci. Procedia 2016, 8, 609–616. [Google Scholar] [CrossRef]

- Rosenberger, A.; Kaul, H.P.; Senn, T.; Aufhammer, W. Improving the energy balance of bioethanol production from winter cereals: The effect of crop production intensity. Appl. Energy 2001, 68, 51–67. [Google Scholar] [CrossRef]

- Kučerova, J. The effect of year, site and variety on the quality characteristics and bioethanol yield of winter triticale. J. Inst. Brew. 2007, 113, 142–146. [Google Scholar] [CrossRef]

- Klikocka, H.; Narolski, B.; Michałkiewicz, G. The effects of tillage and soil mineral fertilization on the yield and yield components of spring barley. Plant Soil Environ. 2014, 60, 255–261. [Google Scholar] [CrossRef]

- Eurostat Database. Available online: http://ec.europa.eu/invest-in-research/monitoring/statistical01_en.htm (accessed on 15 January 2019).

- Obuchovski, W.; Banaszak, Z.; Makowska, A.; Łuczak, M. Factors affecting usefulness of triticale grain for bioethanol production. J. Sci. Food Agric. 2010, 90, 2506–2511. [Google Scholar] [CrossRef]

- Jansone, I.; Malecka, S.; Miglane, V. Suitability of winter triticale varieties for bioethanol production in Latvia. Agron. Res. 2010, 8, 573–582. [Google Scholar]

- Swanston, J.S.; Smith, P.L.; Thomas, W.T.B.; Sylvester-Bradley, R.; Kindred, D.; Brosnan, J.M.; Bringhurst, T.A.; Agu, R.C. Stability, across environments, of grain and alcohol yield, in soft wheat varieties grown for grain distilling or bioethanol production. J. Sci. Food Agric. 2014, 94, 3234–3240. [Google Scholar] [CrossRef]

- Bielski, S.; Dubis, B.; Budzyński, W. Influence of nitrogen fertilization on the technological value of semi-dwarf grain winter triticale varieties Alekto and Gniewko. Pol. J. Nat. Sci. 2015, 30, 325–336. [Google Scholar]

- Lewandowski, I.; Schmidt, U. Nitrogen, energy and land use efficiencies of miscanthus, reed canary grass and triticale as determined by the boundary line approach. Agric. Ecosyst. Environ. 2006, 112, 335–346. [Google Scholar] [CrossRef]

- Wojtkowiak, K.; Stępień, A.; Warechowska, M.; Markowska, A. Effect of nitrogen fertilization method on the yield and quality of Milewo variety spring triticale grain. Pol. J. Nat. Sci. 2015, 30, 173–184. [Google Scholar]

- Smith, T.C.; Kindred, D.R.; Brosnan, J.M.; Weightman, R.M.; Shepherd, M.; Sylvester-Bradley, R. Wheat as a feedstock for alcohol production. In HGCA Research Review 61; HGCA: Warwickshire, UK, 2006. [Google Scholar]

- Burczyk, H. Usability of the cereals for generation of renewable energy– according to the research results. Probl. Inż. Roln. 2011, 3, 43–51. (In Polish) [Google Scholar]

- Janušauskaitė, D. Analysis of grain yield and its components in spring triticale under different N fertilization regimes. Zemdirb. Agric. 2014, 101, 381–388. [Google Scholar] [CrossRef][Green Version]

- Beres, B.L.; Pozniak, C.J.; Bressler, D.C.; Gibreel, A.; Eudes, F.; Graf, R.J.; Randhawa, H.; Salmon, D.; McLeod, G.; Dion, Y.; et al. A Canadian ethanol feedstock study to benchmark the relative performance of triticale: II. Grain quality and ethanol production. Agron. J. 2013, 105, 1707–1720. [Google Scholar] [CrossRef][Green Version]

- Knapowski, T.; Ralcewicz, M.; Barczak, B.; Kozera, W. Effect of nitrogen and zinc fertilizing on bread-making quality of spring triticale cultivated in Notec Valley. Pol. J. Environ. Stud. 2009, 18, 227–233. [Google Scholar]

- Hirel, B.; Tétu, T.; Lea, P.; Dubois, F. Improving nitrogen use efficiency in crops for sustainable agriculture. Sustainability 2011, 3, 1452–1485. [Google Scholar] [CrossRef]

- Czarnocki, S.; Starczewski, J.; Kapela, K. Comparison of the consumption of fuel and working time for a number of alternative pre-sowing soil preparation technologies. Inż. Roln. 2008, 4, 209–215. (In Polish) [Google Scholar]

- Dopka, D. Energy efficiency of various pre-sow cultivation systems on the example of winter triticale. Ann. UMCS E 2004, 59, 2071–2077. (In Polish) [Google Scholar]

- Dobek, T.; Dobek, M.; Šařec, O. Evaluation of the economic and energy efficiency of the production of winter triticale and winter rapeseed used for biofuel production purposes. Inż. Roln. 2010, 1, 161–168. (In Polish) [Google Scholar]

- Burešova, I.; Hřivna, L. Effect of wheat gluten proteins on bioethanol yield from grain. Appl. Energy 2011, 88, 1205–1210. [Google Scholar] [CrossRef]

| Years | Months (k) | Sum—Mean (III-VIII) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| III | IV | V | VI | VII | VIII | †k | p | t | |

| 2012 | 1.0 | 0.7 | 1.1 | 1.2 | 0.9 | 1.8 | 1.3 | 330.2 | 2923 |

| 2013 | 1.1 | 1.2 | 1.8 | 2.3 | 0.9 | 0.5 | 1.6 | 395.6 | 2638 |

| 2014 | 2.3 | 1.1 | 5.2 | 1.7 | 2.2 | 1.4 | 2.3 | 619.7 | 2440 |

| 1981–2005 | 5.1 | 1.8 | 1.5 | 1.6 | 1.7 | 1.0 | 1.6 | 367.7 | 2353 |

| Tillage Systems | Nitrogen Dosage | Grain Yield | Starch Content | Starch Yield | Efficiency of Ethanol | Bioethanol Yield | Agronomic Effectiveness of N Fertilizer |

|---|---|---|---|---|---|---|---|

| (t ha−1) | (%) | (t ha−1) | (L t−1) | (L ha−1) | (L 1 kg N−1 Applied) | ||

| TRD | 0 | 3.777 a | 66.67 a | 2.518 a | 478.9 a | 1808.9 a | - |

| 40 | 5.190 a | 66.70 a | 3.462 a | 479.2 a | 2487.3 a | 16.96 a | |

| 80 | 5.803 a | 66.70 a | 3.871 a | 479.2 a | 2780.7 a | 12.15 bc | |

| 120 | 5.967 a | 66.90 a | 3.992 a | 480.6 a | 2667.9 a | 8.82 c | |

| Mean | 5.184 A | 66.74 A | 3.461 A | 479.5 A | 2486.2 A | 13.64 A | |

| RED | 0 | 3.413 a | 67.03 a | 2.287 a | 481.6 a | 1643.4 a | - |

| 40 | 4.103 a | 66.97 a | 2.747 a | 481.1 a | 1973.5 a | 8.25 c | |

| 80 | 4.777 a | 66.70 a | 3.184 a | 479.2 a | 2287.7 a | 8.05 c | |

| 120 | 5.020 a | 66.87 a | 3.355 a | 480.4 a | 2410.2 a | 6.39 c | |

| Mean | 4.328 B | 66.89 A | 2.893 B | 480.6 A | 2078.7 B | 7.56 B | |

| Nitrogen dosage | 0 | 3.395 C | 66.85 A | 2.403 C | 480.3 A | 1726.1 C | - |

| 40 | 4.647 B | 66.83 A | 3.105 B | 480.1 A | 2230.4 B | 12.61 A | |

| 80 | 5.290 AB | 66.70 A | 3.528 AB | 479.2 A | 2534.3 AB | 10.10 B | |

| 120 | 5.493 A | 66.88 A | 3.673 A | 480.5 A | 2639.1 A | 7.61 C | |

| Year | 2012 | 4.748 B | 66.59 B | 3.160 B | 478.4 C | 2270.3 B | 8.21B C |

| 2013 | 5.108 A | 66.81 AB | 3.413 A | 480.0 AB | 2452.0 A | 12.35 A | |

| 2014 | 4.414 C | 67.05 A | 2.958 C | 481.7 A | 2125.1 B | 9.75 B | |

| Mean | 4.756 | 66.82 | 3.177 | 480.0 | 2282.5 | 10.10 AB | |

| Tillage Systems | Nitrogen Dosage | Direct Energy Carries | Raw Materials and Materials | Investments | Human Labor | Total | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| (MJ ha−1) | (%) | (MJ ha−1) | (%) | (MJ ha−1) | (%) | (MJ ha−1) | (%) | (MJ ha−1) | ||

| TRD | 0 | 2564 | 31.0 | 3208 | 38.8 | 1743 | 21.1 | 760 | 9.2 | 8275 |

| 40 | 2564 | 22.6 | 6288 | 55.4 | 1743 | 15.4 | 760 | 6.7 | 11355 | |

| 80 | 2807 | 19.1 | 9368 | 63.6 | 1743 | 11.8 | 816 | 5.5 | 14734 | |

| 120 | 2994 | 16.6 | 12448 | 69.1 | 1743 | 9.7 | 840 | 4.7 | 18026 | |

| Mean | 2733 | 22.3 | 7828 | 56.7 | 1743 | 14.5 | 794 | 6.5 | 13097 | |

| RED | 0 | 2138 | 27.7 | 3208 | 41.6 | 1747 | 22.7 | 616 | 8.0 | 7710 |

| 40 | 2138 | 19.8 | 6288 | 58.3 | 1747 | 16.2 | 616 | 5.7 | 10790 | |

| 80 | 2381 | 16.8 | 9368 | 66.1 | 1747 | 12.3 | 672 | 4.7 | 14169 | |

| 120 | 2567 | 14.7 | 12448 | 71.3 | 1747 | 10.0 | 696 | 4.0 | 17460 | |

| Mean | 2306 | 19.8 | 7828 | 59.3 | 1747 | 15.3 | 650 | 5.6 | 12532 | |

| Nitrogen dosage | 0 | 2351 | 29.4 | 3208 | 40.2 | 1745 | 21.9 | 688 | 8.6 | 7993 |

| 40 | 2351 | 21.2 | 6288 | 56.8 | 1745 | 15.8 | 688 | 6.2 | 11073 | |

| 80 | 2594 | 17.9 | 9368 | 64.8 | 1745 | 12.1 | 744 | 5.1 | 14452 | |

| 120 | 2781 | 15.7 | 12448 | 70.2 | 1745 | 9.8 | 768 | 4.3 | 17743 | |

| Mean | 2519 | 21.1 | 7828 | 58.0 | 1745 | 14.9 | 722 | 6.1 | 12815 | |

| Tillage Systems | Nitrogen Dosage | Unit | Fertilizers | Pesticides | Seeds | Total | ||

|---|---|---|---|---|---|---|---|---|

| N | P | K | ||||||

| TRD and RED ‡ | 0 | MJ ha−1 | 0 | 1260 | 1000 | 448 | 500 | 3208 |

| % † | 0.00 | 39.28 | 31.17 | 13.97 | 15.59 | 100.00 | ||

| 40 | MJ ha−1 | 3080 | 1260 | 1000 | 448 | 500 | 6288 | |

| % | 48.98 | 20.04 | 15.90 | 7.12 | 7.95 | 100.00 | ||

| 80 | MJ ha−1 | 6160 | 1260 | 1000 | 448 | 500 | 9368 | |

| % | 65.76 | 13.45 | 10.67 | 4.78 | 5.34 | 100.00 | ||

| 120 | MJ ha−1 | 9240 | 1260 | 1000 | 448 | 500 | 12448 | |

| % | 74.23 | 10.12 | 8.03 | 3.60 | 4.02 | 100.00 | ||

| Mean | MJ ha−1 | 4620 | 1260 | 1000 | 448 | 500 | 7828 | |

| % | 59.02 | 16.10 | 12.77 | 5.72 | 6.39 | 100.00 | ||

| Tillage Systems | Nitrogen Dosage | Unit | Soil Tillage | Fertilization | Care and Protection | Sowing | Harvest and Transport | Total |

|---|---|---|---|---|---|---|---|---|

| TRD | 0 | MJ ha− | 1377 | 354 | 365 | 407 | 1803 | 4307 |

| % † | 31.97 | 9.46 | 8.23 | 8.48 | 41.87 | 100.00 | ||

| 40 | MJ ha−1 | 1377 | 354 | 365 | 407 | 1803 | 4307 | |

| % | 31.97 | 9.46 | 8.23 | 8.48 | 41.87 | 100.00 | ||

| 80 | MJ ha−1 | 1377 | 354 | 365 | 407 | 2046 | 4550 | |

| % | 30.26 | 8.95 | 8.02 | 8.02 | 44.97 | 100.00 | ||

| 120 | MJ ha−1 | 1377 | 354 | 365 | 407 | 2234 | 4737 | |

| % | 29.07 | 8.60 | 7.71 | 7.71 | 47.15 | 100.00 | ||

| Mean | MJ ha−1 | 1377 | 354 | 365 | 407 | 1972 | 4476 | |

| % | 30.76 | 7.91 | 8.15 | 9.09 | 44.06 | 100.00 | ||

| RED | 0 | MJ ha−1 | 955 | 354 | 365 | 407 | 1803 | 3886 |

| % | 24.59 | 10.49 | 9.39 | 9.39 | 46.41 | 100.00 | ||

| 40 | MJ ha−1 | 955 | 354 | 365 | 407 | 1803 | 3886 | |

| % | 24.59 | 10.49 | 9.39 | 9.39 | 46.41 | 100.00 | ||

| 80 | MJ ha−1 | 955 | 354 | 365 | 407 | 2046 | 4129 | |

| % | 23.14 | 9.87 | 8.84 | 8.84 | 49.57 | 100.00 | ||

| 120 | MJ ha−1 | 955 | 354 | 365 | 407 | 2234 | 4316 | |

| % | 22.14 | 9.44 | 8.46 | 8.46 | 51.75 | 100.00 | ||

| Mean | MJ ha−1 | 955 | 354 | 365 | 407 | 1972 | 4056 | |

| % | 23.55 | 8.73 | 9.00 | 10.03 | 48.62 | 100.00 | ||

| Nitrogen dosage | 0 | MJ ha−1 | 1166 | 354 | 365 | 407 | 1803 | 4095 |

| % | 28.47 | 8.64 | 8.91 | 9.94 | 44.03 | 100.00 | ||

| 40 | MJ ha−1 | 1166 | 354 | 365 | 407 | 1803 | 4095 | |

| % | 28.47 | 8.64 | 5.91 | 9.94 | 44.03 | 100.00 | ||

| 80 | MJ ha−1 | 1166 | 354 | 365 | 407 | 2046 | 4338 | |

| % | 26.88 | 8.16 | 8.41 | 9.38 | 47.16 | 100.00 | ||

| 120 | MJ ha−1 | 1166 | 354 | 365 | 407 | 2234 | 4526 | |

| % | 25.76 | 7.82 | 8.06 | 8.99 | 49.36 | 100.00 | ||

| Mean | MJ ha−1 | 1166 | 354 | 365 | 407 | 1972 | 4264 | |

| % | 27.35 | 8.30 | 8.56 | 9.55 | 46.25 | 100.00 | ||

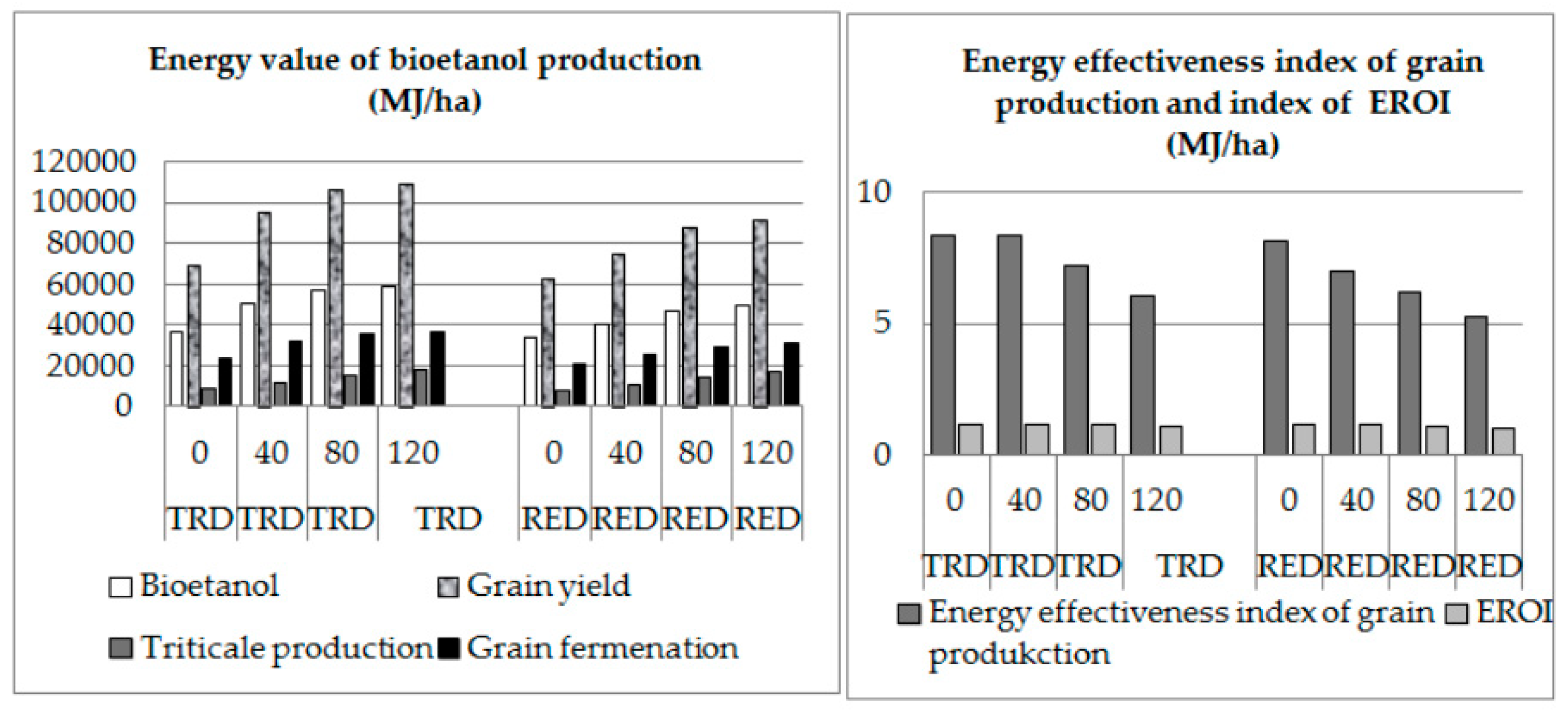

| Tillage Systems | Nitrogen Dosage | Energy Value of Grain Yield | Energy Expenditure on Producing Yield | Energy Intensity | Energy Value of Bioethanol | Energy Value of Inputs on Grain Fermentation | EROI |

|---|---|---|---|---|---|---|---|

| MJ ha−1 | MJ ha−1 | ||||||

| TRD | 0 | 69340 a | 8275 a | 8.379 a | 36901 c | 23045 c | 1.174 a |

| 40 | 95288 a | 11355 a | 8.392 a | 50741 b | 31688 b | 1.176 a | |

| 80 | 106549 a | 14734 a | 7.232 a | 56730 a | 35428 a | 1.130 a | |

| 120 | 109548 a | 18026 a | 6.077 a | 58505 a | 36537 a | 1.071 a | |

| Mean | 95181 A | 13097 A | 7.267 A | 50719 A | 31675 A | 1.138 A | |

| RED | 0 | 62667 a | 7710 a | 8.128 a | 33525 d | 20936 c | 1.162 a |

| 40 | 75337 a | 10790 a | 6.982 a | 40259 c | 25142 c | 1.111 a | |

| 80 | 87700 a | 14169 a | 6.190 a | 46668 b | 29145 b | 1.070 a | |

| 120 | 92167 a | 17460 a | 5.279 a | 49169 b | 30706 b | 1.014 a | |

| Mean | 79468 B | 12532 B | 6.341 B | 42405 B | 26482 B | 1.089 B | |

| Nitrogen dosage | 0 | 66004 D | 7993 D | 8.258 A | 35213 C | 21991 C | 1.168 A |

| 40 | 85312 C | 11073 C | 7.705 B | 45500 B | 28415 B | 1.144 B | |

| 80 | 97124 B | 14452 B | 6.720 C | 51699 A | 32287 A | 1.100 C | |

| 120 | 100858 A | 17743 A | 5.684 D | 53837 A | 33622 A | 1.043 D | |

| Year | 2012 | 87164 B | 12815 A | 6.802 B | 46314 B | 28923 B | 1.113 B |

| 2013 | 93773 A | 12815 A | 7.317 A | 50022 A | 31239 A | 1.139 A | |

| 2014 | 81036 C | 12815 A | 6.323 C | 43351 C | 27073 C | 1.088 C | |

| Mean | 87325 | 12815 | 6.814 | 46562 | 29079 | 1.114 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klikocka, H.; Kasztelan, A.; Zakrzewska, A.; Wyłupek, T.; Szostak, B.; Skwaryło-Bednarz, B. The Energy Efficiency of the Production and Conversion of Spring Triticale Grain into Bioethanol. Agronomy 2019, 9, 423. https://doi.org/10.3390/agronomy9080423

Klikocka H, Kasztelan A, Zakrzewska A, Wyłupek T, Szostak B, Skwaryło-Bednarz B. The Energy Efficiency of the Production and Conversion of Spring Triticale Grain into Bioethanol. Agronomy. 2019; 9(8):423. https://doi.org/10.3390/agronomy9080423

Chicago/Turabian StyleKlikocka, Hanna, Armand Kasztelan, Aneta Zakrzewska, Teresa Wyłupek, Bogdan Szostak, and Barbara Skwaryło-Bednarz. 2019. "The Energy Efficiency of the Production and Conversion of Spring Triticale Grain into Bioethanol" Agronomy 9, no. 8: 423. https://doi.org/10.3390/agronomy9080423

APA StyleKlikocka, H., Kasztelan, A., Zakrzewska, A., Wyłupek, T., Szostak, B., & Skwaryło-Bednarz, B. (2019). The Energy Efficiency of the Production and Conversion of Spring Triticale Grain into Bioethanol. Agronomy, 9(8), 423. https://doi.org/10.3390/agronomy9080423