PM2.5 in Indoor Air of a Bakery: Chemical Characterization and Size Distribution

Abstract

:1. Introduction

2. Experiments

2.1. Sampling Site

2.2. PM2.5 Indoor Sampling

2.3. Particle Size Distribution

2.4. Inorganic Components Analyses

2.5. Carbonaceous Fraction and Anhydrosugars Analysis

3. Results

3.1. PM2.5 Concentrations

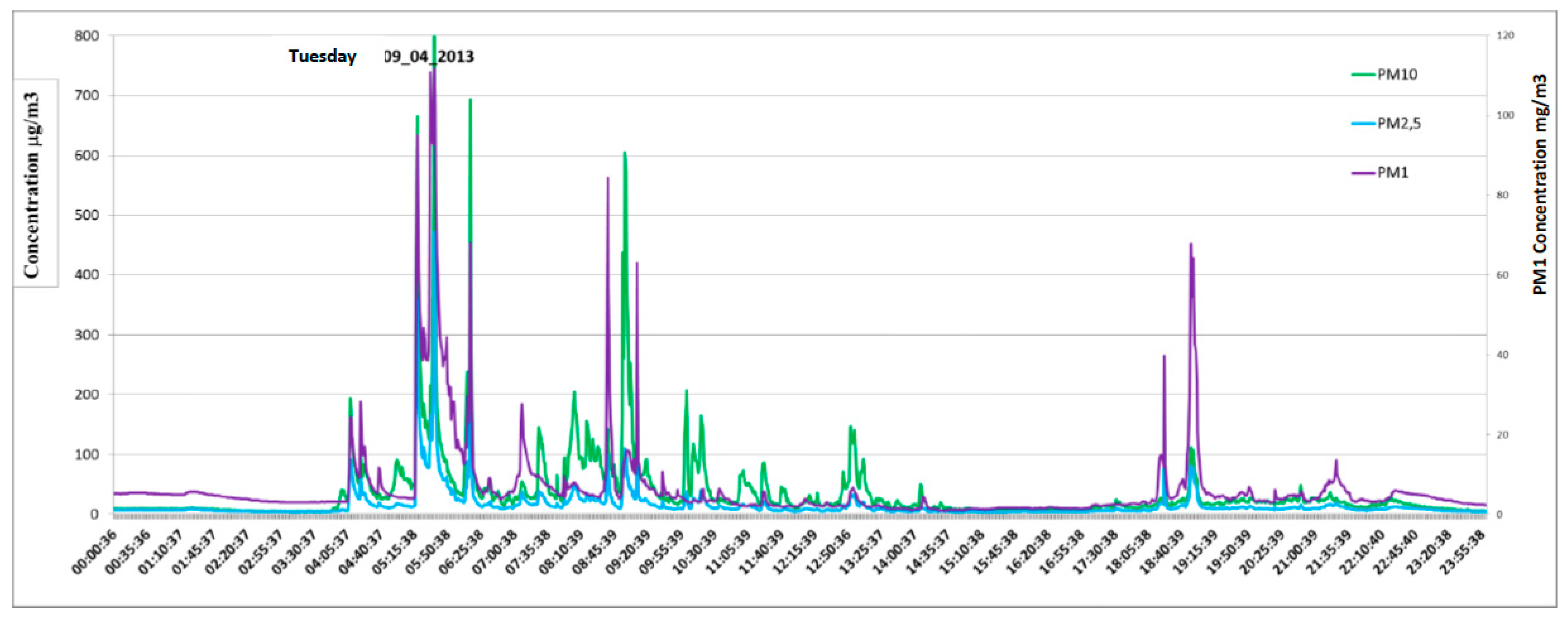

3.2. Optical Particle Counts (OPC): Fine and Coarse Fraction Trends and Tendency of Derived Parameters

3.3. PM2.5 Chemical Composition

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ielpo, P.; Taurino, M.R.; Buccolieri, R.; Placentino, C.M.; Gallone, F.; Ancona, V.; Di Sabatino, S. Polycyclic aromatic hydrocarbons in a bakery indoor air: Trends, dynamics, and dispersion. Environ. Sci. Pollut. Res. 2018, 25, 28760–28771. [Google Scholar] [CrossRef]

- Koistinen, K.J.; Hänninen, O.; Rotko, T.; Edwards, R.D.; Moschandreas, D.; Jantunen, M.J. Behavioral and environmental determinants of personal exposures to PM2.5 in EXPOLIS-Helsinki, Finland. Atmos. Environ. 2001, 35, 2473–2481. [Google Scholar] [CrossRef]

- Scapellato, M.L.; Canova, C.; de Simone, A.; Carrieri, M.; Maestrelli, P.; Simonato, L.; Bartolucci, G.B. Personal PM10 exposure in asthmatic adults in Padova, Italy: Seasonal variability and factors affecting individual concentrations of particulate matter. Int. J. Hyg. Environ. Health 2009, 212, 626–636. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Saborit, J.M.; Stark, C.; Harrison, R.M. Carcinogenic potential, levels and sources of polycyclic aromatic hydrocarbon mixtures in indoor and outdoor environments and their implications for air quality standards. Environ. Int. 2011, 37, 383–392. [Google Scholar] [CrossRef] [PubMed]

- Varghese, B.M.; Hansen, A.L.; Williams, S.; Bi, P.; Hanson-Easey, S.; Barnett, A.G.; Heyworth, J.S.; Sim, M.R.; Rowett, S.; Nitschke, M.; et al. Heat-related injuries in Australian workplaces: Perspectives from health and safety representatives. Saf. Sci. 2020, 126. [Google Scholar] [CrossRef]

- Madureira, J.; Slezakova, K.; Silva, A.I.; Lage, B.; Mendes, A.; Aguiar, L.; Pereira, M.C.; Teixeira, J.P.; Costa, C. Assessment of indoor air exposure at residential homes: Inhalation dose and lung deposition of PM10, PM2.5 and ultrafine particles among newborn children and their mothers. Sci. Total Environ. 2020, 717. [Google Scholar] [CrossRef] [PubMed]

- Downward, G.S.; van der Zwaag, H.P.; Simons, L.; Meliefste, K.; Tefera, Y.; Carreon, J.R.; Vermeulen, R.; Smit, L.A.M. Occupational exposure to indoor air pollution among bakery workers in Ethiopia; A comparison of electric and biomass cookstoves. Environ. Pollut. 2018, 233, 690–697. [Google Scholar] [CrossRef]

- Brant, A. Baker’s asthma. Curr. Opin. Allergy Clin. Immunol. 2007, 7, 152–155. [Google Scholar] [CrossRef]

- Jacobs, J.H.; Meijster, T.; Meijer, E.; Suarthana, E.; Heederick, D. Wheat allergen exposure and the prevalence of work-related sensitization and allergy in bakery workers. Allergy 2008, 63, 1597–1604. [Google Scholar] [CrossRef]

- Suarthana, E.; Vergouwe, Y.; Moons, K.G.; de Monchy, J.; Grobbee, D.; Heederick, D.; Meijer, E. A diagnostic model for the detection of sensitization to wheat allergens was developed and validated in bakery workers. J. Clin. Epidemiol. 2010, 63, 1011–1019. [Google Scholar] [CrossRef]

- Ade, S.; Adjobimey, M.; Agodokpessi, G.; Kouassi, M.S.; Gounongbe, F.A.; Cisse, I.; Hounkpatin, S.H.R. Asthma symptoms in bakeries at parakou, benin. Pulm. Med. 2020, 2020, 376–382. [Google Scholar] [CrossRef] [PubMed]

- Previdi, M.; Marracini, P.; Farioli, L. Allergopatie respiratorie professionali: Monitoraggio ambientale, aeroallergeni, prevenzione. Med. Lav. 1988, 89, 481–498. [Google Scholar]

- Patussi, V.; Portello, A.; Chermaz, E.; Sernagiotto, F.; De Noni, R.; Lorusso, A.; Collareta, A.; Valentini, F.; Agnesi, R.; Dal Vecchio, L.; et al. Allergic disease due to wheat flour. Allergy 1995, 26, 88. [Google Scholar]

- Geyssant, M.E.; Barthélemy, J.F.; Mouchot, L.; Paris, C.; Zmirou-Navierdoi, D. Exposure of bakery and pastry apprentices to airborne flour dust using PM2.5 and PM10 personal samplers. BMC Public Health 2007, 7, 311. [Google Scholar]

- Khan, S.; Khaskheli, M.H.; Nabi, G.; Deverajani, B.R.; Memon, N.; Shar, G.A. Immunological study of different fraction of wheat proteins. Pak. J. Pharm. Sci. 2018, 31, 1437–1440. [Google Scholar]

- Aidoo, H.; Beach, J.; Elbourne, R.; Galarneau, J.M.F.; Straube, S.; Cherry, N. Estimation and validation of flour exposure in bakeries in Alberta, Canada. Ann. Work Expo. Health 2018, 62, 1096–1108. [Google Scholar] [CrossRef] [PubMed]

- De Zotti, R.; Larese, F.; Bovenzi, M.; Negro, C.; Molinari, S. Allergic airway disease in Italian bakers and pastry makers. Occup. Environ. Med. 1994, 51, 548–552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fishwick, D.; Curran, A.D. Variability in the diagnosis of occupational asthma and implications for clinical practice. Curr. Opin. Allergy Clin. Immunol. 2008, 8, 140–144. [Google Scholar] [CrossRef] [PubMed]

- Tarlo, S.M.; Malo, J.-L. An official american thoracic society proceedings: Work-related asthma and airway diseases: Presentations and discussion from the fourth jack pepys workshop on asthma in the workplace. Ann. Am. Thorac. Soc. 2013, 10, S17–S24. [Google Scholar] [CrossRef] [Green Version]

- Previdi, M.; Farioli, L.; Marracini, P. Risultati delle indagini nei panifici milanesi. In Proceedings of the Rischi e Strumenti Operativi per la Prevenzione nel Settore Della Panificazione, Milan, Italy, 23 November 1998; pp. 10–15. [Google Scholar]

- Saia, B.; Baruffini, A.; Cirla, A.M. Valutazione dell’esposizione ad allergeni professionali. Acta Med. Mediterr. 1997, 135, 234–243. [Google Scholar]

- Cotton, D.J.; Dosman, J.A. Grain dust and health. III. Environmental factors. Ann. Intern. Med. 1978, 89, 420–421. [Google Scholar] [CrossRef] [PubMed]

- Cotton, D.J.; Graham, B.L.; Li, K.Y.; Froh, F.; Barnett, G.D.; Dosman, J.A. Effects of grain dust exposure and smoking on respiratory symptoms and lung function. J. Occup. Med. 1983, 25, 131–141. [Google Scholar] [PubMed]

- Hurst, T.S.; Dosman, J.A. Characterization of health effects of grain dust exposures. Am. J. Ind. Med. 1990, 17, 27–32. [Google Scholar] [CrossRef] [PubMed]

- Poulsen, K.B.; Nielsen, H.W. Health problems among persons exposed to grain dust (Review) [Helbredsgener hos personer udsat for kornstøv.]. Ugeskr Laeger 1991, 153, 1986–1990. [Google Scholar]

- Chan-yeung, M.; Dimich-ward, H.; Enarson, D.A.; Kennedy, S.M. Five cross-sectional studies of grain elevator workers. Am. J. Epidemiol. 1992, 136, 1269–1279. [Google Scholar] [CrossRef] [PubMed]

- Fonn, S.; Groeneveld, H.T.; deBeer, M.; Becklake, M.R. Relationship of respiratory health status to grain dust in a Witwatersrand grain mill: Comparison of workers’ exposure assessments with industrial hygiene survey findings. Am. J. Ind. Med. 1993, 24, 401–411. [Google Scholar] [CrossRef] [PubMed]

- Gimenez, C.; Fouad, K.; Choudat, D.; Bouscaillou, P.; Leib, E.; Laureillard, J. Chronic and acute respiratory effects among grain mill workers. Int. Arch. Occup. Environ. Health 1995, 67, 311–315. [Google Scholar] [CrossRef] [PubMed]

- Massin, N.; Bohadana, A.B.; Wild, P.; Kolopp-Sarda, M.N.; Toamain, J.P. Airway responsiveness to methacholine, respiratory symptoms, and dust exposure levels in grain and flour mill workers in eastern france. Am. J. Ind. Med. 1995, 27, 859–869. [Google Scholar] [CrossRef]

- Peelen, S.J.M.; Heederik, D.; Dimich-Ward, H.D.; Chan-Yeung, M.; Kennedy, S.M. Comparison of dust related respiratory effects in Dutch and Canadian grain handling industries: A pooled analysis. Occup. Environ. Med. 1996, 53, 559–566. [Google Scholar] [CrossRef]

- Musk, A.W.; Venables, K.M.; Crook, B.; Nunn, A.J.; Hawkins, R.; Crook, G.D.W.; Graneek, B.J.; Tee, R.D.; Farrer, N.; Johnson, D.A.; et al. Respiratory symptoms, lung function, and sensitisation to flour in a British bakery. Br. J. Ind. Med. 1989, 46, 636–642. [Google Scholar] [CrossRef] [Green Version]

- Hauggaard-Nielsen, H.E.; Mundus, S.; Jensen, E.S. Grass-clover undersowing affects nitrogen dynamics in a grain legume-cereal arable cropping system. Field Crop. Res. 2012, 136, 23–31. [Google Scholar] [CrossRef]

- Buonanno, G.; Morawska, L.; Stabile, L. Particle emission factors during cooking activities. Atmos. Environ. 2009, 43, 3235–3242. [Google Scholar] [CrossRef] [Green Version]

- Zhai, S.R.; Albritton, D. Airborne particles from cooking oils: Emission test and analysis on chemical and health implications. Sustain. Cities Soc. 2020, 52. [Google Scholar] [CrossRef]

- El-Sharkawy, M.F.; Javed, W. Study of indoor air quality level in various restaurants in Saudi Arabia. Environ. Prog. Sustain. Energy 2018, 37, 1713–1721. [Google Scholar] [CrossRef]

- Massey, D.; Kulshrestha, A.; Masih, J.; Taneja, A. Seasonal trends of PM10, PM5.0, PM2.5 & PM1.0 in indoor and outdoor environments of residential homes located in North-Central India. Build Environ. 2012, 47, 223–231. [Google Scholar]

- Dario, R.; Uva, J.; Trani, G.; Falco, S.; Ancona, V.; Petrera, L. Evaluation of the dustiness of a Bakery: An integrated system with an experimental electronic device. G. Ital. Med. Lav. Ergon. 2012, 34, 744–747. [Google Scholar]

- Salthammer, T.; Schripp, T.; Wientzek, S.; Wensing, M. Impact of operating wood-burning fireplace ovens on indoor air quality. Chemosphere 2014, 103, 205–211. [Google Scholar] [CrossRef]

- Daellenbach, K.R.; Stefenelli, G.; Bozzetti, C.; Vlachou, A.; Fermo, P.; Gonzalez, R.; Piazzalunga, A.; Colombi, C.; Canonaco, F.; Hueglin, C.; et al. Long-term chemical analysis and organic aerosol source apportionment at nine sites in central Europe: Source identification and uncertainty assessment. Atmos. Chem. Phys. 2017, 17, 13265–13282. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Gao, J.; He, Y.; Cao, L.; Li, A.; Mo, S.; Chen, Y.; Cao, Y. Determination of time- and size-dependent fine particle emission with varied oil heating in an experimental kitchen. J. Environ. Sci. 2017, 51, 157–164. [Google Scholar] [CrossRef]

- Ielpo, P.; Fermo, P.; Comite, V.; Mastroianni, D.; Viviano, G.; Salerno, F.; Tartari, G. Chemical characterization of biomass fuel particulate deposits and ashes in households of Mt. Everest region (NEPAL). Sci. Total Environ. 2016, 573, 751–759. [Google Scholar] [CrossRef] [Green Version]

- Cattaneo, A.; Fermo, P.; Urso, P.; Perrone, M.G.; Piazzalunga, A.; Tarlassi, J.; Carrer, P.; Cavallo, D.M. Particulate-bound polycyclic aromatic hydrocarbon sources and determinants in residential homes. Environ. Pollut. 2016, 218, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Gibbs, R.; Whitby, R.; Johnson, R. Experimental measurement of particulate emissions from a diesel operated with particulate laden intake air. In Proceedings of the Chemical and Physical Processes in Combustion, Fall Technical Meeting, the Eastern States Section, Philadelphia, PA, USA, 4–6 November 1985; p. 84. [Google Scholar]

- Armstrong, B.; Hutchinson, E.; Unwin, J.; Fletcher, T. Lung cancer risk after exposure to polycyclic aromatic hydrocarbons: A review and meta-analysis. Environ. Health Perspect. 2004, 112, 970–978. [Google Scholar] [CrossRef] [PubMed]

- Fermo, P.; Piazzalunga, A.; Vecchi, R.; Ga, V. Set-up of extraction procedures for ions quantification in aerosol samples. Chem. Eng. Trans. 2006, 10, 203–208. [Google Scholar]

- Piazzalunga, A.; Bernardoni, V.; Fermo, P.; Vecchi, R. Optimisation of analytical procedures for the quantification of ionic and carbonaceous fractions in the atmospheric aerosol and applications to ambient samples. Anal. Bioanal. Chem. 2013, 405, 1123–1132. [Google Scholar] [CrossRef]

- Fermo, P.; Piazzalunga, A.; Vecchi, R.; Valli, G.; Mb, C. A TGA/FT-IR study for measuring OC and EC in aerosol samples. Atmos. Chem. Phys. 2006, 6, 255–266. [Google Scholar] [CrossRef] [Green Version]

- Piazzalunga, A.; Belis, C.; Bernardoni, V.; Cazzuli, O.; Fermo, P.; Valli, G.; Vecchi, R. Estimates of wood burning contribution to PM by the macro-tracer method using tailored emission factors. Atmos. Environ. 2011, 45, 6642–6649. [Google Scholar] [CrossRef]

- Genga, A.; Ielpo, P.; Siciliano, M.; Siciliano, T. Carbonaceous particles and aerosol mass closure in PM2.5 collected in a port city. Atmos. Res. 2017, 183, 245–254. [Google Scholar] [CrossRef]

- Cuccia, E.; Massabò, D.; Ariola, V.; Bove, M.C.; Fermo, P.; Piazzalunga, A.; Prati, P. Size-resolved comprehensive characterization of airborne particulate matter. Atmos. Environ. 2013, 67, 14–26. [Google Scholar] [CrossRef]

- American Conference of Governmental Industrial Hygienists (ACGIH). 2018. TLVs and BEIs. Available online: https://www.acgih.org/ (accessed on 28 September 2018).

- Luo, L.; Wu, Y.; Xiao, H.; Zhang, R.; Lin, H.; Zhang, X.; Kao, S.-J. Origins of aerosol nitrate in Beijing during late winter through spring. Sci. Total Environ. 2019, 653, 776–782. [Google Scholar] [CrossRef]

- Benetello, F.; Squizzato, S.; Hofer, A.; Masiol, M.; Khan, M.B.; Piazzalunga, A.; Fermo, P.; Formenton, G.M.; Rampazzo, G.; Pavoni, B.; et al. Estimation of local and external contributions of biomass burning to PM2.5 in an industrial zone included in a large urban settlement. Environ. Sci. Pollut. Res. 2017, 24, 2100–2115. [Google Scholar] [CrossRef]

- Torvela, T.; Tissari, J.; Sippula, O.; Kaivosoja, T.; Leskinen, J.; Virén, A.; Lähde, A.; Jokiniemi, J. Effect of wood combustion conditions on the morphology of freshly emitted fine particles. Atmos. Environ. 2014, 87, 65–76. [Google Scholar] [CrossRef]

- Shah, K.V.; Cieplik, M.K.; Betrand, C.I.; van de Kamp, W.L.; Vuthaluru, H.B. Correlating the effects of ash elements and their association in the fuel matrix with the ash release during pulverized fuel combustion. Fuel Process. Technol. 2010, 91, 531–545. [Google Scholar] [CrossRef]

- Tissari, J.; Lyyränen, J.; Hytönen, K.; Sippula, O.; Tapper, U.; Frey, A.; Saarnio, K.; Pennanen, A.S.; Hillamo, R.; Salonen, R.O.; et al. Fine particle and gaseous emissions from normal and smouldering wood combustion in a conventional masonry heater. Atmos. Environ. 2008, 42, 7862–7873. [Google Scholar] [CrossRef]

- Mota Lima, F.D.; Pérez-Martínez, P.J.; Andrade, M.d.F.; Kumar, P.; de Miranda, R.M. Characterization of particles emitted by pizzerias burning wood and briquettes: A case study at Sao Paulo, Brazil. Environ. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef]

- Infofarine. Available online: http://www.infofarine.it/le-proprieta-nutrizionali/ (accessed on 12 December 2015).

| Sampling Range | Mean Concentration (µg/m3) | Standard Dev (µg/m3) | Max Concentration (µg/m3) | Min Concentration (µg/m3) | Number of Samples |

|---|---|---|---|---|---|

| 3:00–9:00 | 110 | 16 | 140 | 79 | 10 |

| 9:00–13:30 | 118 | 47 | 281 | 77 | 10 |

| 14:00–21:00 | 65 | 8 | 82 | 55 | 10 |

| 21:00–3:00 | 67 | 11 | 89 | 54 | 10 |

| Sampling Interval | HCOO− Mean Std | Cl− Mean Std | NO2− Mean Std | NO3− Mean Std | SO42− Mean Std | C2O42− Mean Std | Na+ Mean Std | NH4+ Mean Std | K+ Mean Std | Mg2+ Mean Std | Ca2+ Mean Std |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3:00–9:00 | 0.20 | 3.09 | 1.65 | 1.07 | 4.84 | 1.18 | 2.22 | 1.16 | 3.87 | 0.20 | 13.12 |

| 0.05 | 2.49 | 0.38 | 0.67 | 0.76 | 0.19 | 2.17 | 1.50 | 2.88 | 0.07 | 6.47 | |

| 9:00–13:30 | 0.24 | 2.04 | 4.58 | 1.65 | 6.60 | 1.53 | 3.64 | 1.62 | 5.08 | 0.34 | 16.45 |

| 0.03 | 1.01 | 0.93 | 0.38 | 2.40 | 0.26 | 2.67 | 1.53 | 4.51 | 0.25 | 7.41 | |

| 14:00–21:00 | 0.22 | 1.67 | 2.37 | 0.94 | 4.51 | 0.96 | 0.91 | 1.32 | 1.67 | 0.17 | 9.45 |

| 0.06 | 2.79 | 0.81 | 0.35 | 1.19 | 0.14 | 0.24 | 1.02 | 0.50 | 0.14 | 2.11 | |

| 21:00–3:00 | 0.19 | 2.15 | 2.74 | 1.20 | 5.01 | 1.08 | 1.99 | 2.16 | 2.52 | 0.10 | 8.26 |

| 0.01 | 2.21 | 0.96 | 0.43 | 1.30 | 0.19 | 1.78 | 1.40 | 1.89 | 0.03 | 2.71 |

| Site | OC (µg/m3) | EC (µg/m3) | K+ (µg/m3) |

|---|---|---|---|

| PeP winter | 5.3 ± 3.0 | 2.0 ± 0.8 | 0.38 ± 0.26 |

| PeP summer | 3.8 ± 1.2 | 1.5 ± 0.6 | 0.36 ± 0.20 |

| San Nicola winter | 5.2 ± 2.5 | 1.8 ± 0.9 | 0.37 ± 0.23 |

| San Nicola summer | 4.0 ± 3.3 | 1.6 ± 0.9 | 0.51 ± 0.58 |

| Casamssima winter | 7.6 ± 2.9 | 1.9 ± 1.1 | 0.42 ± 0.21 |

| Casamssima summer | 3.8 ± 0.7 | 1.4 ± 0.4 | 0.39 ± 0.12 |

| Bakery | 14 (min)–36 (max) | 0.23 (min)–1.08 (max) | 1.67 (min)–6.55(max) |

| Sampling Interval | LG/K+ Average Ratio | Ratio Standard Deviation |

|---|---|---|

| 3:00–9:00 | 0.37 | 0.27 |

| 9:00–13:30 | 0.05 | 0.02 |

| 14:00–21:00 | 0.09 | 0.04 |

| 21:00–3:00 | 0.05 | 0.02 |

| Sodium (mg) | Potassium (mg) | Iron (mg) | Calcium (mg) | Phosphorus (mg) | Thiamine (mg) | Riboflavin (mg) | Niacin (mg) | |

|---|---|---|---|---|---|---|---|---|

| Type 00 Flour | 3 | 126 | 0.7 | 17 | 76 | 0.1 | 0.03 | 1 |

| Type 0 Flour | 2 | 140 | 0.9 | 18 | 160 | 0.25 | 0.04 | 1.2 |

| Wholemeal Flour | 3 | 337 | 3 | 28 | 300 | 0.4 | 0.16 | 5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ielpo, P.; Placentino, C.M.; Genga, A.; Ancona, V.; Uricchio, V.F.; Fermo, P. PM2.5 in Indoor Air of a Bakery: Chemical Characterization and Size Distribution. Atmosphere 2020, 11, 415. https://doi.org/10.3390/atmos11040415

Ielpo P, Placentino CM, Genga A, Ancona V, Uricchio VF, Fermo P. PM2.5 in Indoor Air of a Bakery: Chemical Characterization and Size Distribution. Atmosphere. 2020; 11(4):415. https://doi.org/10.3390/atmos11040415

Chicago/Turabian StyleIelpo, Pierina, Claudia Marcella Placentino, Alessandra Genga, Valeria Ancona, Vito Felice Uricchio, and Paola Fermo. 2020. "PM2.5 in Indoor Air of a Bakery: Chemical Characterization and Size Distribution" Atmosphere 11, no. 4: 415. https://doi.org/10.3390/atmos11040415