Behaviors of Chromium in Coal-Fired Power Plants and Associated Atmospheric Emissions in Guizhou, Southwest China

Abstract

:1. Introduction

2. Methodology

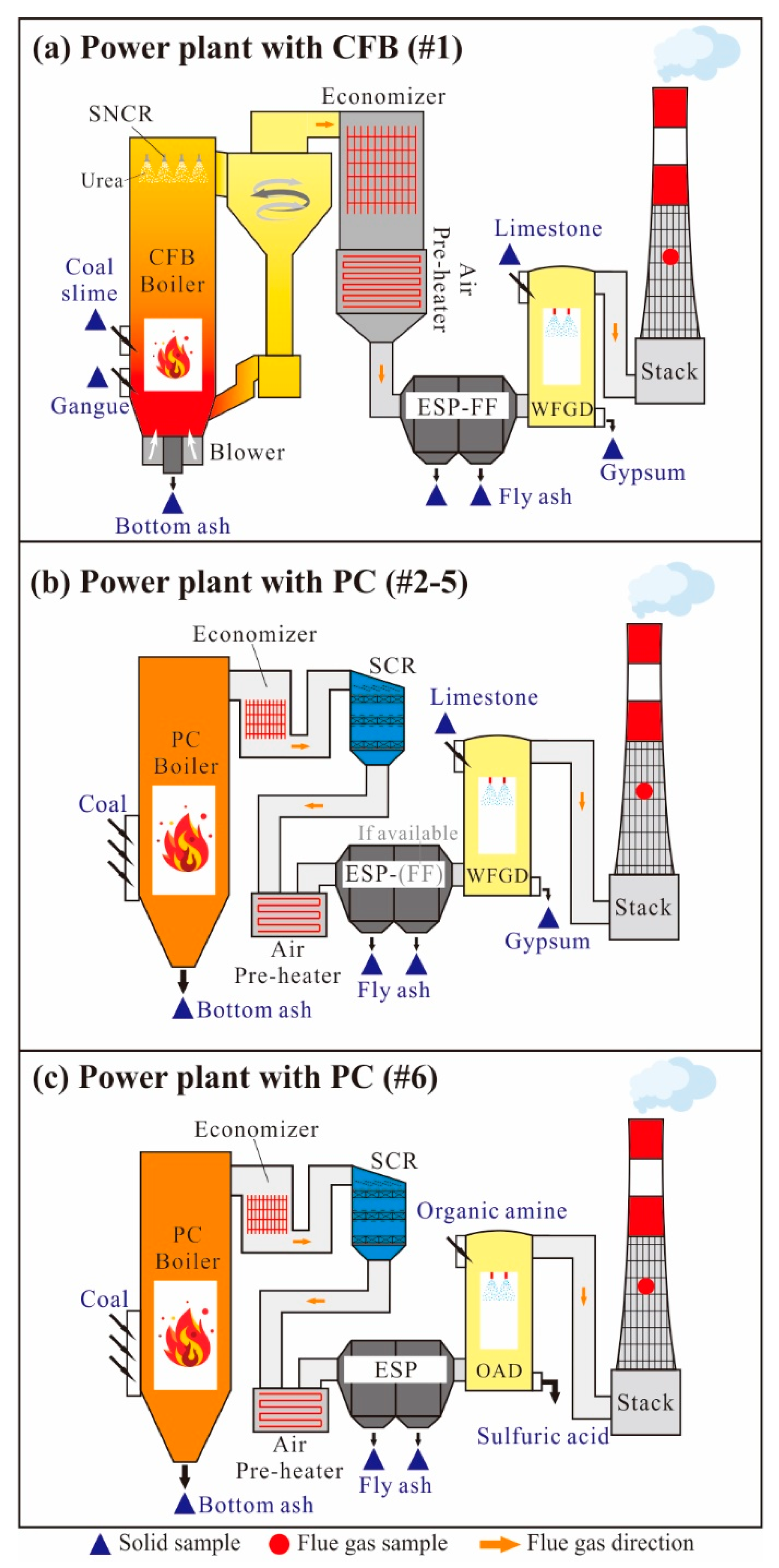

2.1. Power Plants and Sample Collection

2.2. Analysis Methods

2.3. Quality Assurance and Quality Control

2.4. Relative Enrichment Index and Atmospheric Emission Factor of Chromium

2.4.1. Relative Enrichment Index

2.4.2. Atmospheric Emission Factors

3. Results and Discussion

3.1. Proximate and Ultimate Analysis of the Feed Coal

3.2. Cr in Bottom Ash, ESP/ESP–FF Fly Ash, Limestone, and Gypsum

3.3. Atmospheric Emissions and Mass Balance of Cr

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bai, X.; Ding, H.; Lian, J.; Ma, D.; Yang, X.; Sun, N.; Xue, W.; Chang, Y. Coal production in China: Past, present, and future projections. Intern. Geol. Rev. 2018, 60, 535–547. [Google Scholar] [CrossRef]

- National Bureau of Statistic of China 2018. China Statistical Yearbook; China Statistics Press: Beijing, China, 2018. (In Chinese)

- Clarke, L.B. The fate of trace elements during coal combustion and gasification: An overview. Fuel 1993, 72, 731–736. [Google Scholar] [CrossRef]

- Gratz, L.E.; Eckley, C.S.; Schwantes, S.J.; Mattson, E. Ambient mercury observations near a coal-fired power plant in a Western, U.S. urban area. Atmosphere 2019, 10, 176. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yang, Z.; Qin, S.; Panchal, B.; Sun, Y.; Niu, H. Distribution characteristics and migration patterns of hazardous trace elements in coal combustion products of power plants. Fuel 2019, 258, 116062. [Google Scholar] [CrossRef]

- Goodarzi, F. Assessment of elemental content of milled coal, combustion residues, and stack emitted materials: Possible environmental effects for a Canadian pulverized coal-fired power plant. Intern. J. Coal Geol. 2006, 65, 17–25. [Google Scholar] [CrossRef]

- USEPA (U.S. Environmental Protection Agency). Clean Air Act Amendments of 1990; 1st Congress (1989–1990); USEPA: Washington, DC, USA, 1990.

- MEE (Ministry of Ecology and Environment of the People’s Republic of China). List of Toxic and Hazardous Air Pollutants (Year of 2018). Available online: http://www.mee.gov.cn/xxgk2018/xxgk/xxgk01/201901/t20190131_691779.html (accessed on 25 January 2019).

- Talovskaya, A.V.; Yazikov, E.G.; Osipova, N.A.; Lyapina, E.E.; Litay, V.V.; Metreveli, G.; Kim, J. Mercury pollution in snow cover around thermal power plants in cities (Omsk, Kemerovo, Tomsk Regions, Russia). Geogr. Environ. Sustain. 2019, 12, 132–147. [Google Scholar] [CrossRef] [Green Version]

- Tang, S.; Feng, X.; Qiu, J.; Yin, G.; Yang, Z. Mercury speciation and emissions from coal combustion in Guiyang, southwest China. Environ. Res. 2007, 105, 175–182. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Fu, C.; Tang, L.; Chen, J.; Wu, T.; Lin, C.J.; Feng, X.; Fu, X. Fate of mercury in two CFB utility boilers with different fueled coals and air pollution control devices. Fuel 2019, 251, 651–659. [Google Scholar] [CrossRef]

- Guo, X.; Zheng, C.G.; Xu, M.H. Characterization of arsenic emissions from a coal-fired power plant. Energy Fuels 2004, 18, 1822–1826. [Google Scholar] [CrossRef]

- Chen, J.; Liu, G.; Kang, Y.; Wu, B.; Sun, R.; Zhou, C.; Wu, D. Atmospheric emissions of F, As, Se, Hg, and Sb from coal-fired power and heat generation in China. Chemosphere 2013, 90, 1925–1932. [Google Scholar] [CrossRef]

- Swaine, D.J. Trace Elements in Coal; Butterworth-Heinemann Ltd.: Oxford, UK, 1990. [Google Scholar]

- Huggins, F.E.; Shah, N.; Huffman, G.P.; Kolker, A.; Crowley, S.; Palmer, C.A.; Finkelman, R.B. Mode of occurrence of chromium in four US coals. Fuel Process. Technol. 2000, 63, 79–92. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, G.; Qi, C.; Cheng, S.; Sun, R. Chemical speciation and combustion behavior of chromium (Cr) and vanadium (V) in coals. Fuel 2016, 184, 42–49. [Google Scholar] [CrossRef]

- Fu, B.; Liu, G.; Sun, M.; Hower, J.C.; Mian, M.M.; Wu, D.; Wang, R.; Hu, G. Emission and transformation behavior of minerals and hazardous trace elements (HTEs) during coal combustion in a circulating fluidized bed boiler. Environ. Pollut. 2018, 242, 1950–1960. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Jin, B.; Zhong, Z.; Xiao, R.; Tang, Z.; Ren, H. Trace elements (Mn, Cr, Pb, Se, Zn, Cd and Hg) in emissions from a pulverized coal boiler. Fuel Process. Technol. 2004, 86, 23–32. [Google Scholar] [CrossRef]

- Udayanga, W.D.C.; Veksha, A.; Giannis, A.; Lisak, G.; Chang, V.W.C.; Lim, T.T. Fate and distribution of heavy metals during thermal processing of sewage sludge. Fuel 2018, 226, 721–744. [Google Scholar] [CrossRef]

- Galbreath, K.C.; Zygarlicke, C.J. Formation and chemical speciation of arsenic-, chromium-, and nickel-bearing coal combustion PM2.5. Fuel Process. Technol. 2004, 85, 701–726. [Google Scholar] [CrossRef]

- Świetlik, R.; Trojanowska, M.; Łożyńska, M.; Molik, A. Impact of solid fuel combustion technology on valence speciation of chromium in fly ash. Fuel 2014, 137, 306–312. [Google Scholar] [CrossRef]

- Tian, H.; Liu, K.; Zhou, J.; Lu, L.; Hao, J.; Qiu, P.; Gao, J.; Zhu, C.; Wang, K.; Hua, S. Atmospheric emission inventory of hazardous trace elements from China’s coal-fired power plants--temporal trends and spatial variation characteristics. Environ. Sci. Technol. 2014, 48, 3575–3582. [Google Scholar] [CrossRef]

- Song, D.Y.; Ma, Y.J.; Qin, Y.; Wang, W.F.; Zheng, C.G. Volatility and mobility of some trace elements in coal from Shizuishan Power Plant. J. Fuel Chem. Technol. 2011, 39, 328–332. [Google Scholar] [CrossRef]

- Zhao, S.; Duan, Y.; Li, Y.; Liu, M.; Lu, J.; Ding, Y.; Gu, X.; Tao, J.; Du, M. Emission characteristic and transformation mechanism of hazardous trace elements in a coal-fired power plant. Fuel 2018, 214, 597–606. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Liu, Z.; Gu, Y.; Norris, P.; Xu, H.; Pan, W.P. Coeffect of air pollution control devices on trace element emissions in an ultralow emission coal-fired power plant. Energy Fuels 2019, 33, 248–256. [Google Scholar] [CrossRef]

- Li, W.; Zhai, J. Both ash and sulfur content and calorific value in Chinese steam coals. Coal Convers. (Meitanzhuanhua) 1994, 17, 12–25, (In Chinese with English Abstract). [Google Scholar]

- Bureau of statistics of Guizhou Province. Guizhou Statistical Yearbook 2018; China Statistics Press: Beijing, China, 2018. (In Chinese)

- Feng, X.; Hong, Y.; Hong, B.; Ni, J. Mobility of some potentially toxic trace elements in the coal of Guizhou, China. Environ. Geol. 2000, 39, 372–377. [Google Scholar] [CrossRef]

- Dai, S.; Ren, D.; Tang, Y.; Yue, M.; Hao, L. Concentration and distribution of elements in Late Permian coals from western Guizhou Province, China. Intern. J. Coal Geol. 2005, 61, 119–137. [Google Scholar] [CrossRef]

- Dai, S.; Finkelman, R.B. Coal geology in China: An overview. Intern. Geol. Rev. 2018, 60, 531–534. [Google Scholar] [CrossRef] [Green Version]

- Ito, S.; Yokoyama, T.; Asakura, K. Emissions of mercury and other trace elements from coal-fired power plants in Japan. Sci. Total Environ. 2006, 368, 397–402. [Google Scholar] [CrossRef]

- USEPA (U.S. Environmental Protection Agency). Test Method 5. Determination of Particulate Matter Emissions from Stationary Sources; USEPA: Washington, DC, USA, 1996.

- Chen, D.; Liu, X.; Han, J.; Jiang, M.; Xu, Y.; Xu, M. Measurements of particulate matter concentration by the light scattering method: Optimization of the detection angle. Fuel Process. Technol. 2018, 179, 124–134. [Google Scholar] [CrossRef]

- GB/T 212-2008. Proximate Analysis of Coal; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2008. (In Chinese)

- GB/T 214-2007. Determination of Total Sulfur in Coal; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2007. (In Chinese)

- GB/T 213-2008. Determination of Calorific Value of Coal; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2008. (In Chinese)

- Qi, L.; Grégoire, D.C. Determination of trace elements in twenty-six Chinese geochemistry reference materials by inductively coupled plasma-mass spectrometry. Geostand. Geoanal. Res. 2000, 24, 51–63. [Google Scholar]

- Meij, R. Trace elements behavior in coal-fired power plants. Fuel Process. Technol. 1994, 39, 199–217. [Google Scholar] [CrossRef]

- Wang, H.; Song, Q.; Yao, Q.; Chen, C.H. Experimental study on removal effect of wet flue gas desulfurization system on fine particles from a coal-fired power plant. Proc. CSEE 2008, 28, 1–7, (In Chinese with English Abstract). [Google Scholar]

- Meij, R.; te Winkel, H. The emissions and environmental impact of PM10 and trace elements from a modern coal-fired power plant equipped with ESP and wet FGD. Fuel Process. Technol. 2004, 85, 641–656. [Google Scholar] [CrossRef]

- Zhao, S.; Duan, Y.; Tan, H.; Liu, M.; Wang, X.; Wu, L.; Wang, C.; Lv, J.; Yao, T.; She, M.; et al. Migration and emission characteristics of trace elements in a 660 mw coal-fired power plant of China. Energy Fuels 2016, 30, 5937–5944. [Google Scholar] [CrossRef]

- GB/T 15224.2-2010. Classification for Quality of Coal-Part 2: Sulfur Content; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2010. (In Chinese)

- GB/T 15224.3-2010. Classification for Quality of Coal-Part 3: Calorific Value; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2010. (In Chinese)

- GB/T 15224.1-2010. Classification for Quality of Coal-Part 1: Ash; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2010. (In Chinese)

- Dai, S.; Ren, D.; Chou, C.L.; Finkelman, R.B.; Seredin, V.V.; Zhou, Y. Geochemistry of trace elements in Chinese coals: A review of abundances, genetic types, impacts on human health, and industrial utilization. Intern. J. Coal Geol. 2012, 94, 3–21. [Google Scholar] [CrossRef]

- GB/T 20475.2-2006. Classification for Content of Harmful Elements in Coal-Part 2: Chlorine; Issued by the Chinese General Administration of Quality Supervision, Inspection and Quarantine and the Standardization Administration of China: Beijing, China, 2006. (In Chinese)

- Ketris, M.P.; Yudovich, Y.E. Estimations of Clarkes for Carbonaceous biolithes: World averages for trace element contents in black shales and coals. Intern. J. Coal Geol. 2009, 78, 135–148. [Google Scholar] [CrossRef]

- Luttrell, G.; Kohmuench, J.N.; Yoon, R.H. An evaluation of coal preparation technologies for controlling trace element emissions. Fuel Process. Technol. 2000, 65–66, 407–422. [Google Scholar] [CrossRef]

- Brownfield, M.E.; Affolter, R.H.; Stricker, G.D.; Hildebrand, R.T. High chromium contents in Tertiary coal deposits of northwestern Washington—A key to their depositional history. Intern. J. Coal Geol. 1995, 27, 153–169. [Google Scholar] [CrossRef]

- Wilczyńska-Michalik, W.; Dańko, J.; Michalik, M. Characteristics of particulate matter emitted from a coal-fired power plant. Pol. J. Environ. Stud. 2020, 29, 1411–1420. [Google Scholar] [CrossRef]

- Li, X.; Bi, X.; Li, Z.; Zhang, L.; Li, S.; Chen, J.; Feng, X.; Fu, X. Atmospheric lead emissions from coal-fired power plants with different boilers and APCDs in Guizhou, Southwest China. Energy Fuels 2019, 33, 10561–10569. [Google Scholar] [CrossRef]

- Zhou, X.; Bi, X.; Li, X.; Li, S.; Chen, J.; He, T.; Li, Z. Fate of cadmium in coal-fired power plants in Guizhou, Southwest China: With emphasis on updated atmospheric emissions. Atmos. Pollut. Res. 2020, 11, 920–927. [Google Scholar] [CrossRef]

- Goodarzi, F.; Huggins, F.E.; Sanei, H. Assessment of elements, speciation of As, Cr, Ni and emitted Hg for a Canadian power plant burning bituminous coal. Intern. J. Coal Geol. 2008, 74, 1–12. [Google Scholar] [CrossRef]

- Swanson, S.M.; Engle, M.A.; Ruppert, L.F.; Affolter, R.H.; Jones, K.B. Partitioning of selected trace elements in coal combustion products from two coal-burning power plants in the United States. Intern. J. Coal Geol. 2013, 113, 116–126. [Google Scholar] [CrossRef]

- Zhang, Y.; Nakano, J.; Liu, L.; Wang, X.; Zhang, Z. Trace element partitioning behavior of coal gangue-fired CFB plant: Experimental and equilibrium calculation. Environ. Sci. Pollut. Res. 2015, 22, 15469–15478. [Google Scholar] [CrossRef]

- GB 16297-1996. Integrated Emission Standard of Air Pollutants; Issued by the Environmental Protection Agency of China: Beijing, China, 1996. (In Chinese)

- Zhou, C.; Liu, G.; Fang, T.; Wu, D.; Lam, P.K.S. Partitioning and transformation behavior of toxic elements during circulated fluidized bed combustion of coal gangue. Fuel 2014, 135, 1–8. [Google Scholar] [CrossRef]

- Huggins, F.; Goodarzi, F. Environmental assessment of elements and polyaromatic hydrocarbons emitted from a Canadian coal-fired power plant. Intern. J. Coal Geol. 2009, 77, 282–288. [Google Scholar] [CrossRef]

- Zhao, S.; Duan, Y.; Wang, C.; Liu, M.; Lu, J.; Tan, H.; Wang, X.; Wu, L. Migration behavior of trace elements at a coal-fired power plant with different boiler loads. Energy Fuels 2017, 31, 747–754. [Google Scholar] [CrossRef]

- Zhao, S.; Duan, Y.; Li, C.; Li, Y.; Chen, C.; Liu, M.; Lu, J. Partitioning and emission of hazardous trace elements in a 100 MW coal-fired power plant equipped with selective catalytic reduction, electrostatic precipitator, and wet flue gas desulfurization. Energy Fuels 2017, 31, 12383–12389. [Google Scholar] [CrossRef]

- Zhao, S.; Duan, Y.; Chen, L.; Li, Y.; Yao, T.; Liu, S.; Liu, M.; Lu, J. Study on emission of hazardous trace elements in a 350 MW coal-fired power plant. Part 2. arsenic, chromium, barium, manganese, lead. Environ. Pollut. 2017, 226, 404–411. [Google Scholar] [CrossRef]

- Ondov, J.M.; Choquette, C.E.; Zoller, W.H.; Gordon, G.E.; Biermann, A.H.; Heft, R.E. Atmospheric behavior of trace elements on particles emitted from a coal-fired power plant. Atmos. Environ. 1989, 23, 2193–2204. [Google Scholar] [CrossRef]

- Wu, B.; Bai, X.; Liu, W.; Zhu, C.; Hao, Y.; Lin, S.; Tian, H. Variation characteristics of final size-segregated PM emissions from ultralow emission coal-fired power plants in China. Environ. Pollut. 2020, 259, 113886. [Google Scholar] [CrossRef]

- Li, X.; Zhou, C.; Li, J.; Lu, S.; Yan, J. Distribution and emission characteristics of filterable and condensable particulate matter before and after a low-low temperature electrostatic precipitator. Environ. Sci. Pollut. Res. 2019, 26, 12798–12806. [Google Scholar] [CrossRef]

- GB 13223-2011. Emission Standard of Air Pollutants for the Thermal Power Plants; Issued by the Ministry of Environmental Protection Agency of China and the Chinese General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2011. (In Chinese)

- Wang, C.; Zhang, Y.; Shi, Y.; Liu, H.; Zou, C.; Wu, H.; Kang, X. Research on collaborative control of Hg, As, Pb and Cr by electrostatic fabric-integrated precipitator and wet flue gas desulphurization in coal-fired power plants. Fuel 2017, 210, 527–534. [Google Scholar] [CrossRef]

- Senior, C.L.; Helble, J.J.; Sarofim, A.F. Emissions of mercury, trace elements, and fine particles from stationary combustion sources. Fuel Process. Technol. 2000, 65–66, 263–288. [Google Scholar] [CrossRef]

- Yao, S.; Cheng, S.; Li, J.; Zhang, H.; Jia, J.; Sun, X. Effect of wet flue gas desulfurization (WFGD) on fine particle (PM2.5) emission from coal-fired boilers. J. Environ. Sci. 2019, 77, 32–42. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zhang, Z.; Wang, Y.; Hu, Y.; Liu, W.; Chen, C.; Mei, Y.; Sun, H. PM2.5 emission characteristics of coal-fired power plants in Beijing-Tianjin-Hebei region, China. Atmos. Pollut. Res. 2019, 10, 954–959. [Google Scholar] [CrossRef]

- Dai, H.; Ma, D.; Zhu, R.; Sun, B.; He, J. Impact of control measures on nitrogen oxides, sulfur dioxide and particulate matter emissions from coal-fired power plants in Anhui Province, China. Atmosphere 2019, 10, 35. [Google Scholar] [CrossRef] [Green Version]

- EPRI (Electric Power Research Institute). Characterization of Field Leachates at Coal Combustion Product Management Sites; ERPI Report 1012578; EPRI (Electric Power Research Institute): Charlotte, NC, USA, 2006. [Google Scholar]

- Hao, Y.; Li, Q.; Pan, Y.; Liu, Z.; Wu, S.; Xu, Y.; Qian, G. Heavy metals distribution characteristics of FGD gypsum samples from Shanxi province 12 coal-fired power plants and its potential environmental impacts. Fuel 2017, 209, 238–245. [Google Scholar] [CrossRef]

- Lu, P.; Han, G.; Wu, Q. Chemical characteristics of rainwater in karst rural areas, Guizhou Province, Southwest China. Acta Geochim. 2017, 36, 572–576. [Google Scholar] [CrossRef]

- Xu, W.; Wen, Z.; Shang, B.; Dore, A.J.; Tang, A.; Xia, X.; Zheng, A.; Han, M.; Zhang, L.; Zhao, Y.; et al. Precipitation chemistry and atmospheric nitrogen deposition at a rural site in Beijing, China. Atmos. Environ. 2020, 233, 117253. [Google Scholar] [CrossRef]

| Power Plants | Boiler Type | Installed Capacity | APCDs |

|---|---|---|---|

| #1 | CFB | 2 × 300 MW | SNCR + C-ESP–FF + WFGD |

| #2 | PC | 4 × 600 MW | SCR + C-ESP + WFGD |

| #3 | PC | 3 × 200 MW | SCR + C-ESP–FF + WFGD |

| #4 | PC | 4 × 600 MW | SCR + C-ESP + WFGD |

| #5 | PC | 4 × 300 MW | SCR + C-ESP–FF + WFGD |

| #6 | PC | 2 × 600 MW | SCR + C-ESP + OAD |

| Power Plants | Fuel Type | Proximate Analysis (%) | Ultimate Analysis (%) | Calorific Value (MJ·kg-1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture | Volatile Matter | Ash Yield | Fixed Carbon | Carbon | Hydrogen | Nitrogen | Total Sulphur | Chlorine a | Chromium a | |||

| #1 (No. = 4) | Gangue | 2.89 ± 0.42 | 18.77 ± 0.27 | 45.15 ± 2.83 | 33.19 ± 2.87 | 47.24 ± 3.43 | 3.21 ± 0.13 | 0.85 ± 0.05 | 0.45 ± 0.07 | 183 ± 41 | 85.6 ± 12.2 | 19.29 ± 1.28 |

| #1 (No. = 4) | Coal slime | 9.06 ± 3.18 | 17.53 ± 0.63 | 43.94 ± 4.18 | 29.47 ± 1.69 | 41.86 ± 1.96 | 2.96 ± 0.15 | 0.82 ± 0.03 | 0.29 ± 0.04 | 254 ± 47 | 101.5 ± 9.6 | 17.03 ± 0.79 |

| #2 (No. = 4) | Bituminous | 0.66 ± 0.14 | 15.05 ± 0.72 | 39.56 ± 2.22 | 44.72 ± 1.76 | 51.21 ± 1.72 | 3.04 ± 0.07 | 0.85 ± 0.04 | 2.50 ± 0.27 | 261 ± 25 | 68.6 ± 5.4 | 20.74 ± 0.53 |

| #3 (No. = 4) | Bituminous | 1.22 ± 0.11 | 15.96 ± 1.14 | 45.73 ± 1.94 | 37.09 ± 1.18 | 47.04 ± 3.34 | 3.04 ± 0.20 | 0.79 ± 0.06 | 1.37 ± 0.17 | 227 ± 61 | 95.6 ± 2.5 | 19.19 ± 1.32 |

| #4 (No. = 4) | Bituminous | 1.08 ± 0.13 | 18.07 ± 1.70 | 30.68 ± 2.85 | 50.17 ± 4.50 | 62.38 ± 2.86 | 3.19 ± 0.32 | 1.07 ± 0.08 | 0.64 ± 0.06 | 198 ± 27 | 40.3 ± 7.0 | 24.47 ± 1.19 |

| #5 (No. = 3) | Anthracite | 1.43 ± 0.20 | 8.77 ± 1.21 | 38.08 ± 8.00 | 51.73 ± 9.01 | 52.56 ± 12.81 | 3.64 ± 0.70 | 1.18 ± 0.28 | 3.41 ± 0.86 | 169 ± 56 | 39.5 ± 3.7 | 21.89 ± 4.96 |

| #6 (No. = 6) | Bituminous | 1.26 ± 0.13 | 22.44 ± 0.90 | 32.27 ± 1.96 | 44.03 ± 1.51 | 57.73 ± 1.65 | 4.18 ± 1.07 | 1.19 ± 0.44 | 3.82 ± 0.52 | 499 ± 10 | 44.9 ± 2.5 | 24.25 ± 1.29 |

| Min–Max | 0.66–9.06 | 8.77–22.44 | 30.68–45.73 | 29.47–51.73 | 41.86–62.38 | 2.96–4.18 | 0.79–1.19 | 0.29–3.82 | 169–499 | 39.5–101.5 | 17.03–24.47 | |

| Mean ± SD | 2.51 ± 2.75 | 16.66 ± 3.89 | 39.34 ± 5.64 | 41.49 ± 7.84 | 51.43 ± 6.43 | 3.32 ± 0.41 | 0.96 ± 0.16 | 1.78 ± 1.35 | 256 ± 104 | 68.0 ± 24.8 | 20.98 ± 2.55 | |

| CFPPs | #1 (No. = 4) | #2 (No. = 3) | #3 (No. = 3) | #4 (No. = 3) | #5 (No. = 3) | #6 (No. = 3) |

|---|---|---|---|---|---|---|

| Bottom ash (mg·kg−1) | 187.1 ± 11.2 | 192.4 ± 8.0 | 198.6 ± 4.6 | 550.1 ± 99.3 | 141.7 ± 7.2 | 157.3 ± 6.2 |

| ESP/ESP–FF fly ash (mg·kg−1) | 195.1 ± 5.2 | 155.1 ± 3.0 | 213.5 ± 2.1 | 106.0 ± 5.2 | 130.1 ± 7.9 | 136.4 ± 5.1 |

| Limestone (mg·kg−1) | 15.5 ± 0.5 | 2.3 ± 0.2 | 20.2 ± 1.4 | 26.9 ± 4.1 | 10.9 ± 1.1 | n.d. |

| Gypsum (mg·kg−1) | 38.9 ± 13.2 | 36.6 ± 0.7 | 31.2 ± 3.0 | 42.0 ± 1.0 | 24.0 ± 4.4 | n.d. |

| Coal Combustion Products | #1 | #2 | #3 | #4 | #5 | #6 |

|---|---|---|---|---|---|---|

| Bottom ash | 0.86 | 1.11 | 0.95 | 4.19 | 1.37 | 1.13 |

| ESP/ESP–FF Fly ash | 0.90 | 0.89 | 1.02 | 0.82 | 1.25 | 0.98 |

| CFPPs | #1 | #2 | #3 | #4 | #5 | #6 | Mean + SD |

|---|---|---|---|---|---|---|---|

| Cr in stack gas (μg·Nm−3) | 2.0 ± 0.3 | 2.2 ± 0.1 | 2.1 ± 0.9 | 1.4 ± 0.0 | 1.9 ± 0.0 | 1.4 ± 0.0 | 1.8 ± 0.3 |

| EMF1 (mg·t−1 coal) | 12.64 | 17.04 | 14.77 | 13.07 | 20.85 | 10.77 | 14.86 ± 3.62 |

| EMF2 (μg·(kW·h)−1) | 9.81 | 8.02 | 8.16 | 5.25 | 10.80 | 4.28 | 7.72 ± 2.53 |

| EMF3 (g·TJ−1) | 0.71 | 0.82 | 0.77 | 0.53 | 0.95 | 0.44 | 0.70 ± 0.19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Wang, Q.; Xiao, Z.; Fan, L.; Wang, D.; Li, X.; Du, J.; Cheng, J. Behaviors of Chromium in Coal-Fired Power Plants and Associated Atmospheric Emissions in Guizhou, Southwest China. Atmosphere 2020, 11, 951. https://doi.org/10.3390/atmos11090951

Li Z, Wang Q, Xiao Z, Fan L, Wang D, Li X, Du J, Cheng J. Behaviors of Chromium in Coal-Fired Power Plants and Associated Atmospheric Emissions in Guizhou, Southwest China. Atmosphere. 2020; 11(9):951. https://doi.org/10.3390/atmos11090951

Chicago/Turabian StyleLi, Zhonggen, Qingfeng Wang, Zhongjiu Xiao, Leilei Fan, Dan Wang, Xinyu Li, Jia Du, and Junwei Cheng. 2020. "Behaviors of Chromium in Coal-Fired Power Plants and Associated Atmospheric Emissions in Guizhou, Southwest China" Atmosphere 11, no. 9: 951. https://doi.org/10.3390/atmos11090951