CO2 Corrosion Rate Prediction for Submarine Multiphase Flow Pipelines Based on Multi-Layer Perceptron

Abstract

1. Introduction

2. Methods

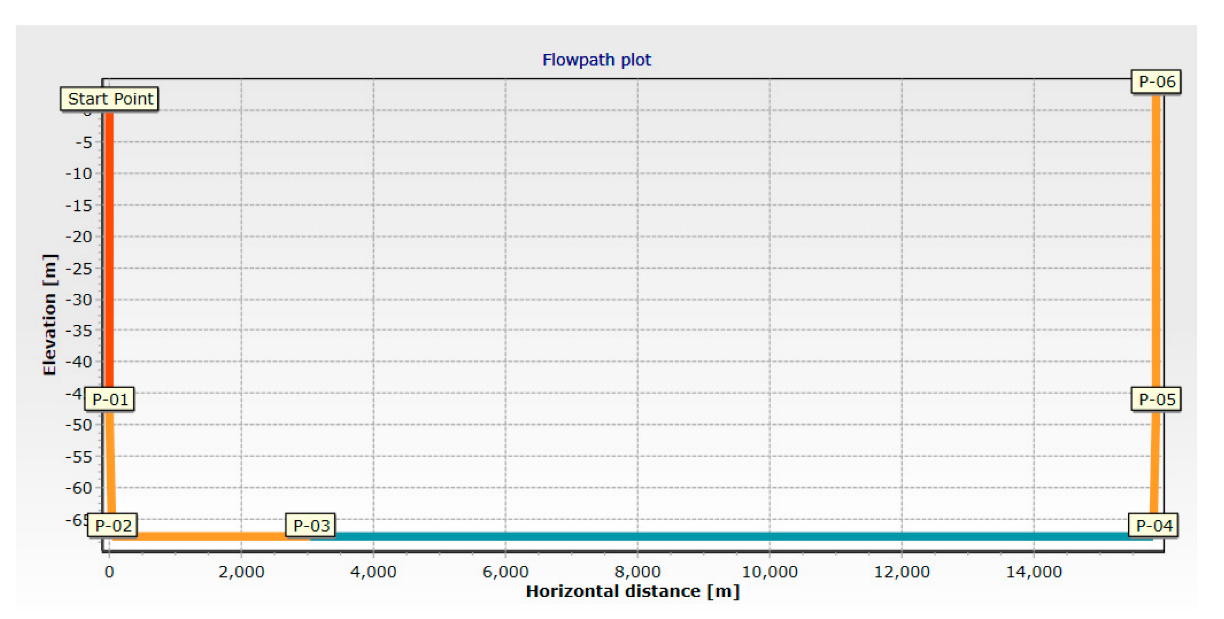

2.1. Data

2.2. Algorithm and Model Introduction

2.2.1. Principal Component Analysis

- (1)

- Calculate the standardized data sample matrix X′mn according to Equation (1):

- (2)

- Calculate the standardized data sample covariance matrix according to Equation (2):

- (3)

- Calculate the eigenvalues and corresponding eigenvectors of the covariance matrix , and calculate the variance contribution rate and the cumulative contribution rate of the principal components according to Equations (3) and (4); additionally, calculate the reduced dimensional principal components according to Equation (5):

2.2.2. De Waard 95

2.2.3. Multiple Linear Regression

2.2.4. Multi-Layer Perceptron Neural Network

2.2.5. Radial Basis Function Neural Network

2.3. Model Evaluation Metrics

3. Results and Discussion

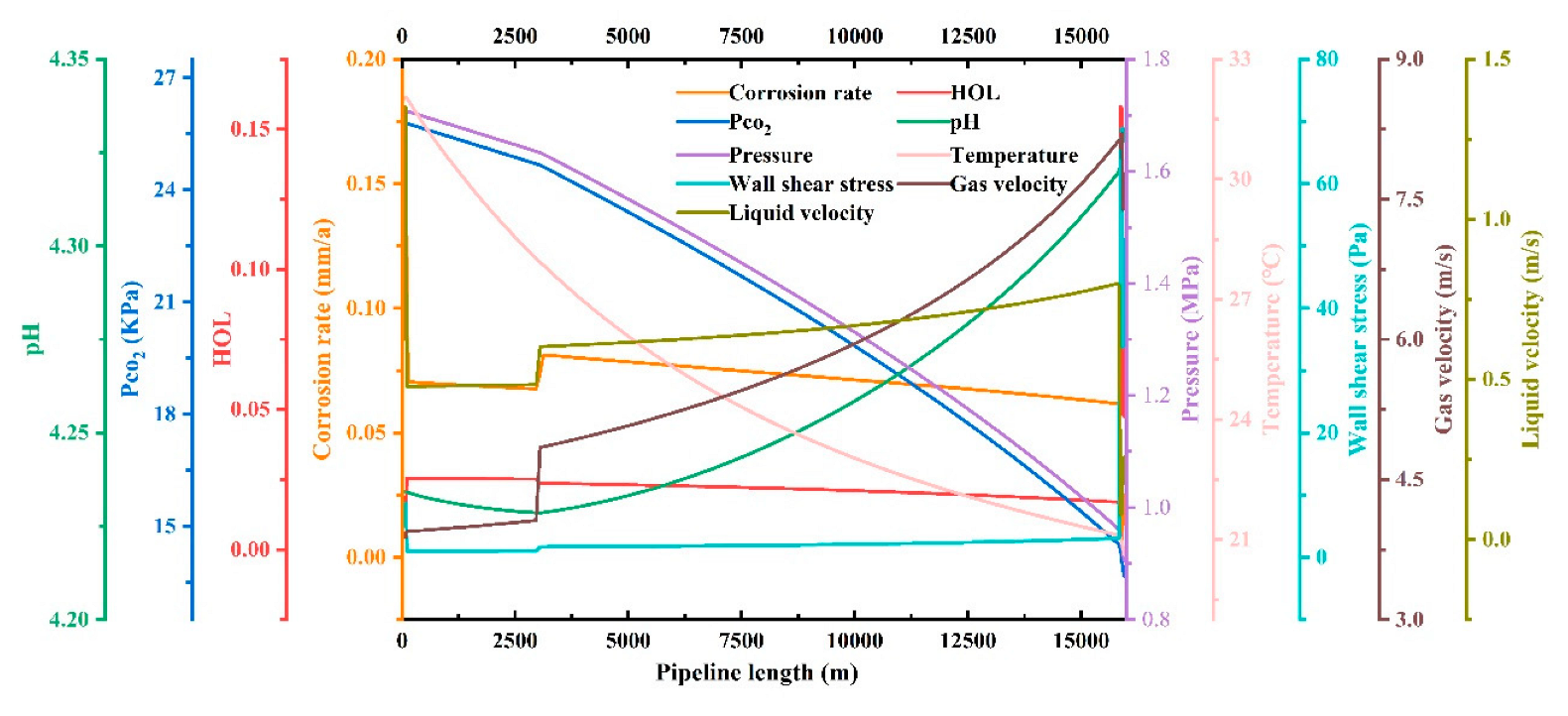

3.1. OLGA Predictive Analysis

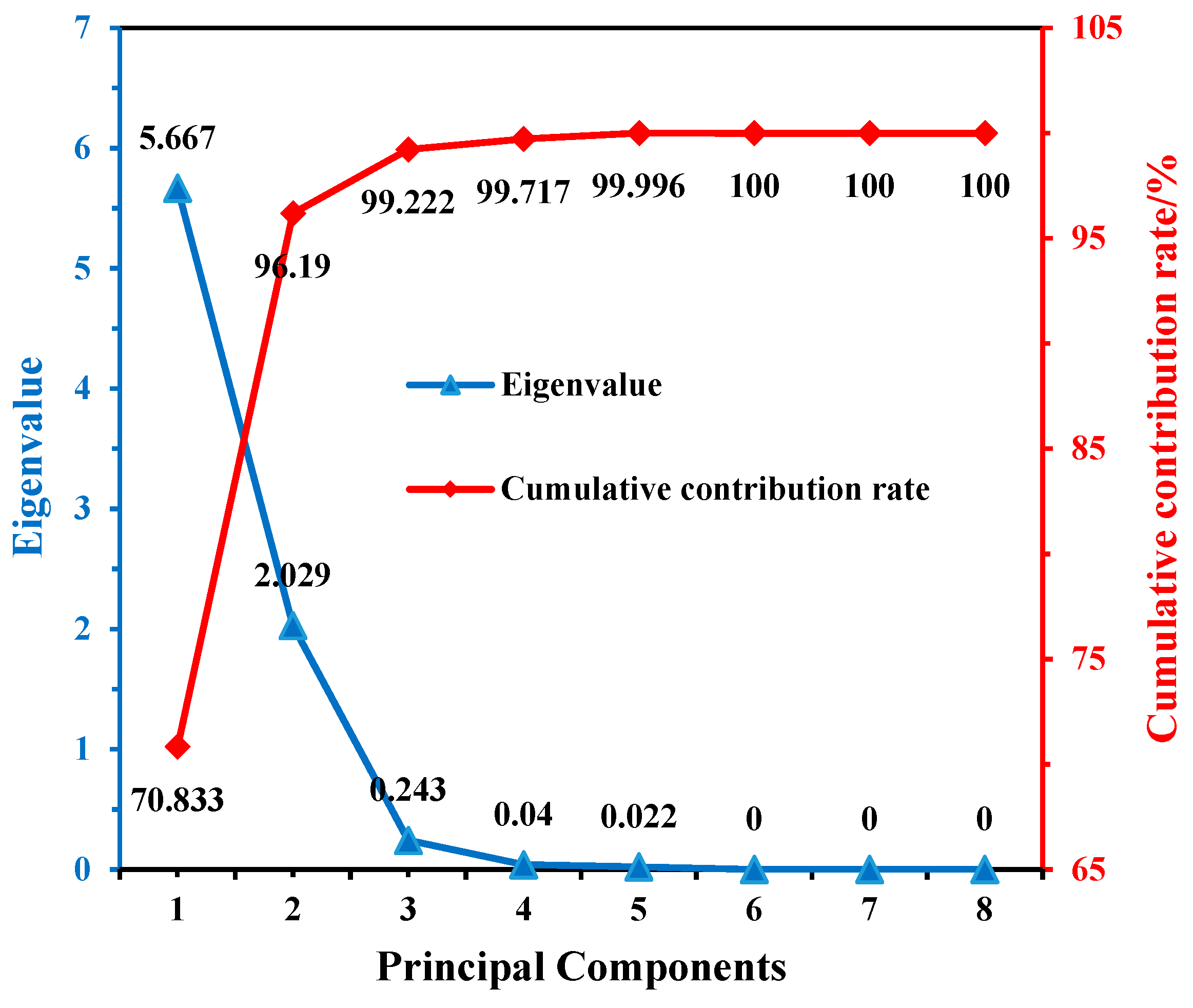

3.2. PCA Algorithm Processing Result

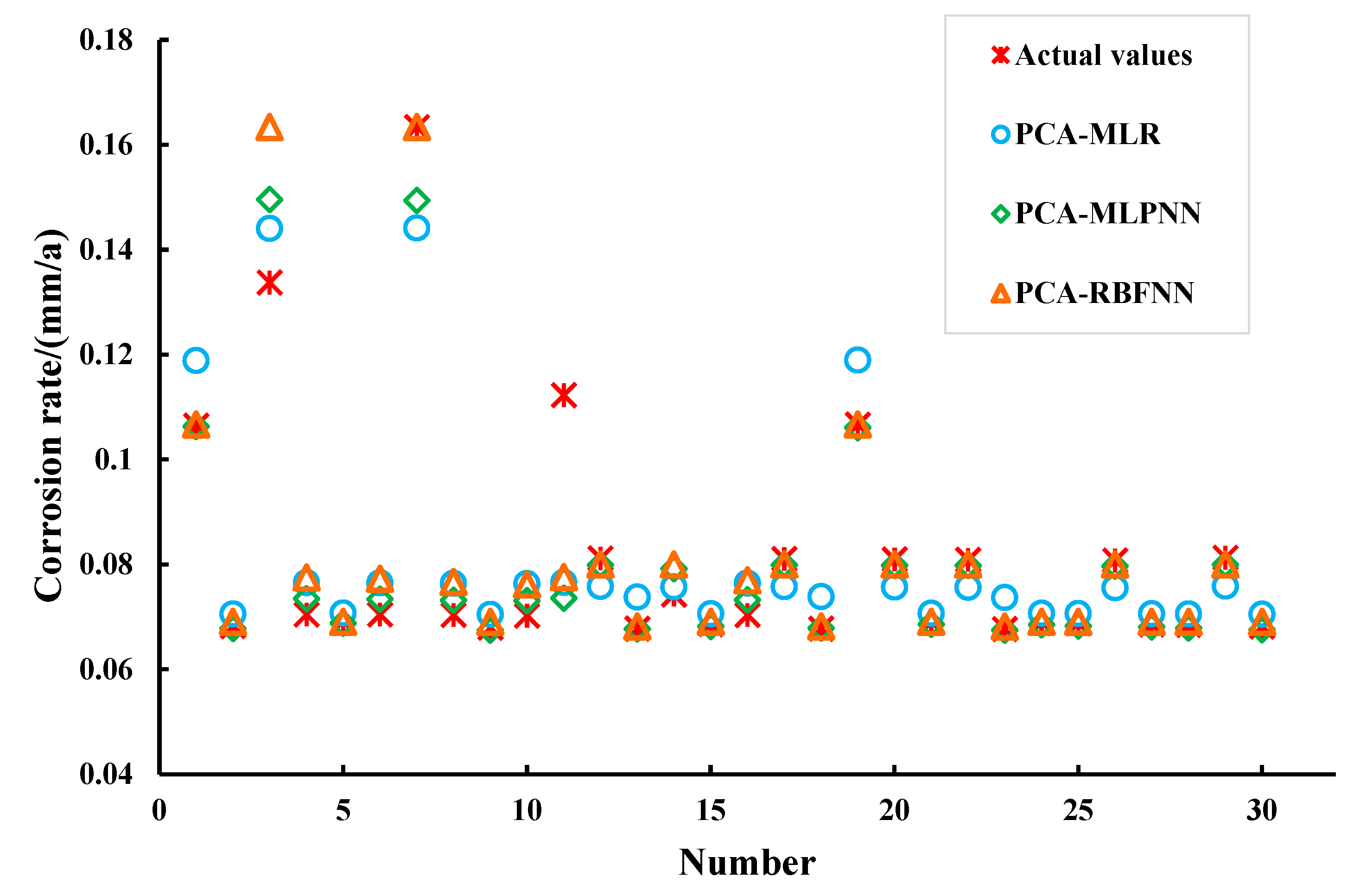

3.3. Comparison of Model Predictions

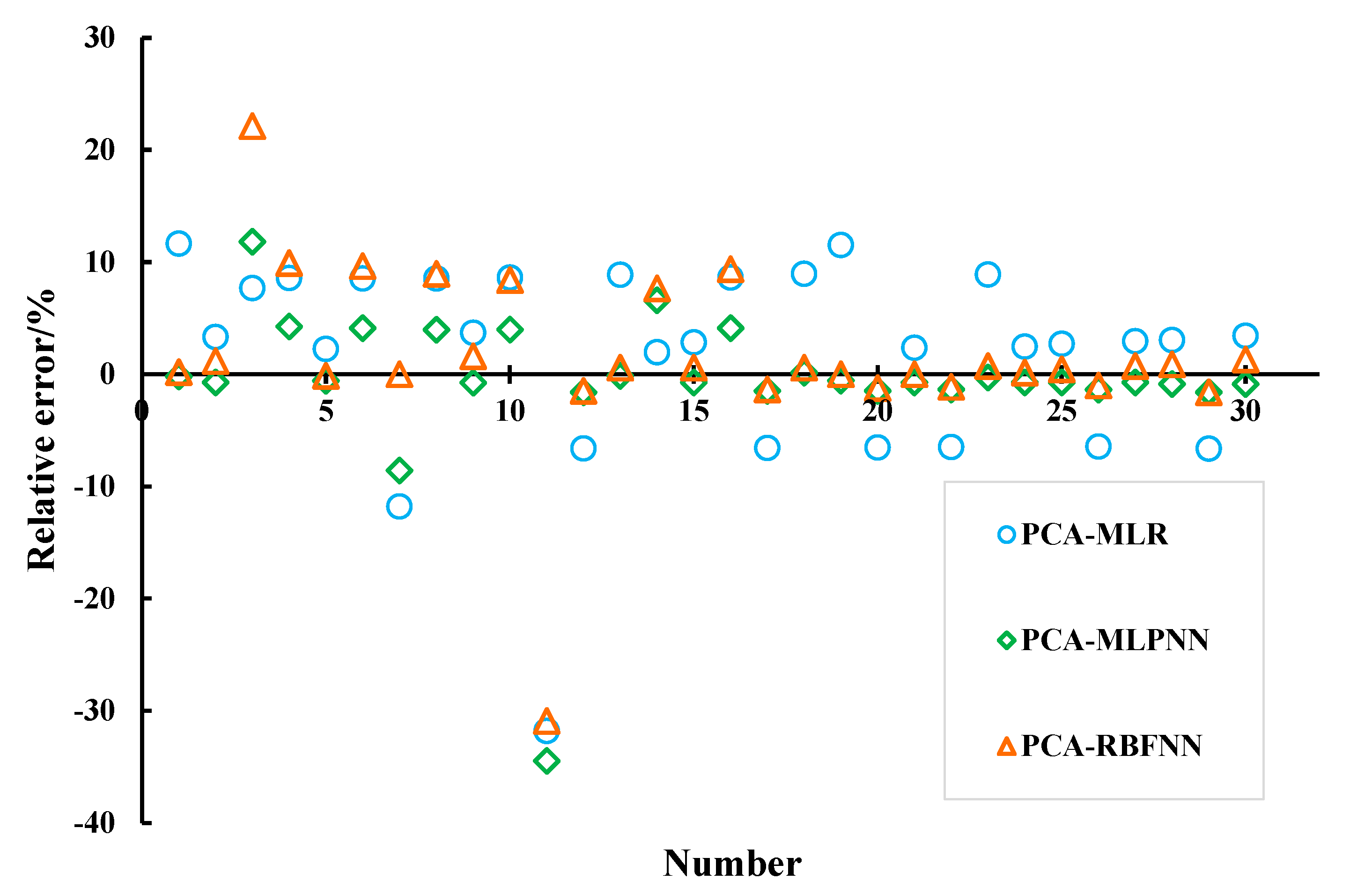

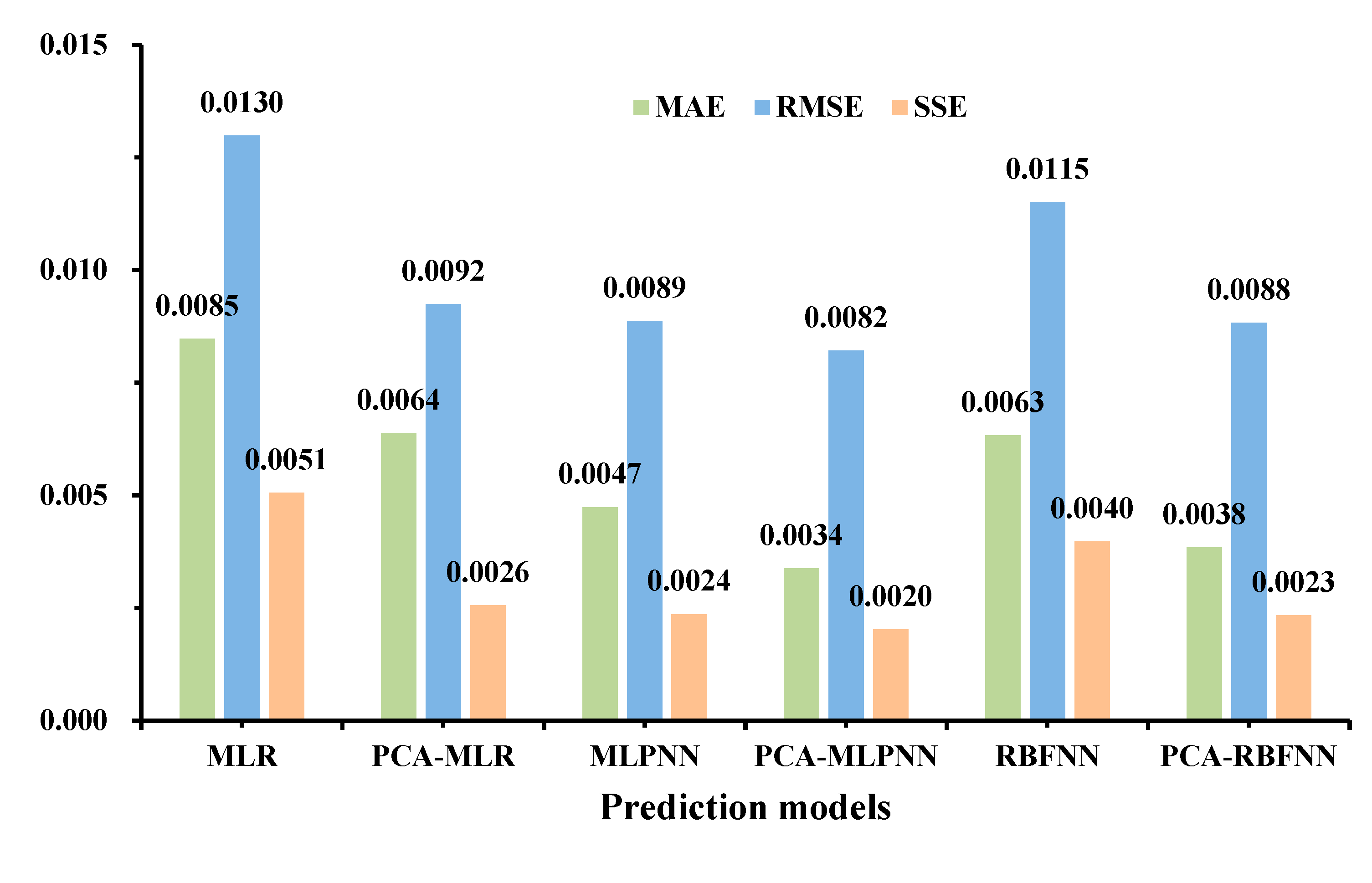

3.4. Model Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, R.Q.; Lei, Z.M. China Submarine Pipeline Engineering Technology Development and Outlook. Oil Gas Storage Transp. 2022, 41, 667–672. [Google Scholar]

- Abbas, M.; Shafiee, M. An Overview of Maintenance Management Strategies for Corroded Steel Structures in Extreme Marine Environments. Mar. Struct. 2020, 71, 102718. [Google Scholar] [CrossRef]

- Veruz, E.G.; Miguel, M.M.; de Souza, G.F.M.; Martins, M.R.; Orlowski, R.T.C.; Vaz, G.L.; de Barros, L.O. Reliability-Based Methodology for the Integrity Management of Subsea Oil and Gas Pipelines Subject to Corrosion Degradation. In Proceedings of the the 32nd International Ocean and Polar Engineering Conference, Shanghai, China, 5–10 June 2022; OnePetro: Dallas, TX, USA, 2022. [Google Scholar]

- Larin, O.; Barkanov, E.; Vodka, O. Prediction of Reliability of the Corroded Pipeline Considering the Randomness of Corrosion Damage and Its Stochastic Growth. Eng. Fail. Anal. 2016, 66, 60–71. [Google Scholar] [CrossRef]

- Ayello, F.; Liu, G.; Zhang, J. Decision Making Through the Application of Bayesian Network for Internal Corrosion Assessment of Pipelines; American Society of Mechanical Engineers Digital Collection: Madrid, Spain, 2018. [Google Scholar]

- Jiménez-Come, M.J.; de la Luz Martín, M.; Matres, V. A Support Vector Machine-Based Ensemble Algorithm for Pitting Corrosion Modeling of EN 1.4404 Stainless Steel in Sodium Chloride Solutions. Mater. Corros. 2019, 70, 19–27. [Google Scholar] [CrossRef]

- Zhao, S.; Liao, K.; Liu, Y.; Miao, C.; Wei, C.; He, G. Corrosion Prediction Model of Submarine Mixed Pipeline X65 Steel under a CO2/Cl− Synergistic System. Arab. J. Sci. Eng. 2022, 47, 11673–11685. [Google Scholar] [CrossRef]

- da Silva, C.A.; Pereira, H.B.; Taqueda, M.E.; Panossian, Z. Prediction Models for Multiphase-flow-induced Corrosion of API X80 Steel in CO2/H2S Environment. Mater. Corros. 2021, 72, 1796–1807. [Google Scholar] [CrossRef]

- Wang, C.; Ma, G.; Li, J.; Dai, Z.; Liu, J. Prediction of Corrosion Rate of Submarine Oil and Gas Pipelines Based on Ia-Svm Model; IOP Publishing: Bristol, UK, 2019; Volume 242, p. 22023. [Google Scholar]

- Lv, Y.; Wang, J.; Wang, J.; Xiong, C.; Zou, L.; Li, L.; Li, D. Steel Corrosion Prediction Based on Support Vector Machines. Chaos Solitons Fractals 2020, 136, 109807. [Google Scholar] [CrossRef]

- Obaseki, M.; Elijah, P.T. Application of Artificial Neural Network Model to Predict Corrosion Rates on Pipeline. J. Newviews Eng. Technol. 2021, 3, 65–74. [Google Scholar]

- Gu, Y.; Wang, M.; Jin, H. Predictive Study of Flow-Accelerated Corrosion Characteristic Parameters Based on the Neural Network. Corrosion 2022, 78, 751–764. [Google Scholar] [CrossRef]

- Jiménez-Come, M.J.; de la Luz Martín, M.; Matres, V.; Baladés, J.D.M. The Use of Artificial Neural Networks for Modelling Pitting Corrosion Behaviour of EN 1.4404 Stainless Steel in Marine Environment: Data Analysis and New Developments. Corrosion Rev. 2020, 38, 339–353. [Google Scholar] [CrossRef]

- Chen, X.; Wang, L.; Huang, Z. Principal Component Analysis Based Dynamic Fuzzy Neural Network for Internal Corrosion Rate Prediction of Gas Pipelines. Math. Probl. Eng. 2020, 2020, 3681032. [Google Scholar] [CrossRef]

- Barton, L.; Laing, I.; Pinto, A.; Ladwa, R. Offshore Oil and Gas Pipeline: Flow Assurance and Corrosion Modelling for Inspection Prioritization; American Society of Mechanical Engineers Digital Collection: Mumbai, India, 2017; Volume 50763, p. V001T03A007. [Google Scholar]

- Han, N. Corrosion Simulation Study of a Natural Gas Pipeline in the South China Sea based on OLGA Software. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2016. [Google Scholar]

- Gao, H.X. Applied Multivariate Statistical Analysis; Peking University: Beijing, China, 2005. [Google Scholar]

- Chunxia, X.; Xiaogang, Q.; Lifang, L. Research on Performance of Complex Networks Based on Principal Component Analysis. J. China Univ. Posts Telecommun. 2019, 26, 40–48. [Google Scholar]

- Deng, X.R. Changqing Oilfield Gathering Pipeline Internal Corrosion Direct Evaluation Technology (MP-ICDA) Research. Master’s Thesis, China University of Petroleum, Beijing, China, 2018. [Google Scholar]

- De Waard, C.; Smith, L.; Bartlett, P.; Cunningham, H. Modelling Corrosion Rates in Oil Production Tubing. Eurocorr. Riva Del Garda Italy 2001, 254. [Google Scholar]

- Eberly, L.E. Multiple Linear Regression. Top. Biostat. 2007, 404, 165–187. [Google Scholar]

- Yu, J.; Xu, L.; Gao, S.; Chen, L.; Sun, Y.; Mao, J.; Zhang, H. Establishment of a Combined Model for Ozone Concentration Simulation with Stepwise Regression Analysis and Artificial Neural Network. Atmosphere 2022, 13, 1371. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning; Springer: Berlin/Heidelberg, Germany, 2013; Volume 112. [Google Scholar]

- Dong, Z.; Zhang, Z.; Dong, Y.; Huang, X. Multi-Layer Perception Based Model Predictive Control for the Thermal Power of Nuclear Superheated-Steam Supply Systems. Energy 2018, 151, 116–125. [Google Scholar] [CrossRef]

- Chen, X.Z.; Tao, L.H. Credit Risk Assessment of SME Supply Chain Finance Based on MLP Neural Network. J. Hunan Univ. Sci. Technol. 2021, 36, 91–99. [Google Scholar] [CrossRef]

- Luo, Z.; Li, T.; Yan, Y.; Zhou, Z.; Zha, G. Prediction of Sound Insulation Performance of Aramid Honeycomb Sandwich Panel Based on Artificial Neural Network. Appl. Acoust. 2022, 190, 108656. [Google Scholar] [CrossRef]

- Peng, S.; Zhang, Z.; Liu, E.; Liu, W.; Qiao, W. A New Hybrid Algorithm Model for Prediction of Internal Corrosion Rate of Multiphase Pipeline. J. Nat. Gas Sci. Eng. 2021, 85, 103716. [Google Scholar] [CrossRef]

| Component | Molar Fraction/% | Component | Molar Fraction/% | Component | Molar Fraction/% |

|---|---|---|---|---|---|

| CO2 | 1.51 | C3H8 | 3.77 | n-C5H12 | 0.16 |

| N2 | 0.65 | i-C4H10 | 0.54 | C6+ | 0.536 |

| CH4 | 83.5 | n-C4H10 | 0.64 | O2 | 0.01 |

| C2H6 | 8.47 | i-C5H12 | 0.19 | H2O | 0.024 |

| Sections | Pipeline Length/m | Pipeline Outside Diameter/mm | Wall Thickness/mm | Pipeline Materials | Anticorrosive Coating |

|---|---|---|---|---|---|

| Standpipe section 1 | 47.7 | 114.3 | 8.6 | X52 | Polyethylene |

| Bend section 1 | 43.4 | 114.3 | 8.6 | X52 | Polyethylene |

| Flat pipe section 1 | 3000 | 114.3 | 8.6 | X52 | Polyethylene |

| Flat pipe section 2 | 12,766 | 114.3 | 12.7 | X52 | Polyethylene |

| Bend section 1 | 57.5 | 114.3 | 8.6 | X52 | Polyethylene |

| Standpipe section 2 | 50.4 | 114.3 | 8.6 | X52 | Polyethylene |

| Number | Act/(mm/a) | PR/(mm/a) | RE/% | ARE/% | |

|---|---|---|---|---|---|

| Mean value | 1 | 0.0637 | 0.0715 | 12.24 | 12.42 |

| Maximum value | 2 | 0.1868 | 0.1634 | 12.53 | |

| Minimum value | 3 | 0.0064 | 0.0072 | 12.50 |

| Input Variable | Output Variable | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| NO. | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | Y |

| 1 | 4.9586 | 3.9248 | 0.6270 | 0.0187 | 25,736.8906 | 4.2342 | 31.9488 | 17.0443 | 0.1065 |

| 2 | 4.9569 | 3.9205 | 0.6273 | 0.0187 | 25,769.4492 | 4.2341 | 32.0150 | 17.0659 | 0.1067 |

| 3 | 8.7768 | 3.8826 | 1.3514 | 0.0090 | 25,770.1992 | 4.2342 | 32.0467 | 17.0664 | 0.1338 |

| 4 | 8.7762 | 3.8806 | 1.3504 | 0.0090 | 25,784.0195 | 4.2342 | 32.0545 | 17.0755 | 0.1634 |

| … | …… | …… | …… | …… | …… | …… | …… | …… | …… |

| 146 | 2.3312 | 6.4497 | 0.6999 | 0.0200 | 18,294.5996 | 4.2735 | 22.2948 | 12.1156 | 0.0686 |

| 147 | 2.3429 | 6.4760 | 0.7015 | 0.0199 | 18,219.6504 | 4.2743 | 22.2638 | 12.0660 | 0.0685 |

| 148 | 2.3548 | 6.5027 | 0.7032 | 0.0199 | 18,144.3809 | 4.2751 | 22.2330 | 12.0161 | 0.0683 |

| 149 | 2.3668 | 6.5298 | 0.7049 | 0.0198 | 18,068.7695 | 4.2759 | 22.2025 | 11.9661 | 0.0682 |

| 150 | 2.3790 | 6.5572 | 0.7066 | 0.0197 | 17,992.8301 | 4.2767 | 22.1723 | 11.9158 | 0.0680 |

| MLR | PCA-MLR | MLPNN | PCA-MLPNN | RBFNN | PCA-RBFNN | |

|---|---|---|---|---|---|---|

| ARE/% | 9.564 | 7.146 | 4.956 | 3.318 | 6.520 | 4.129 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Wang, C.; Shi, L. CO2 Corrosion Rate Prediction for Submarine Multiphase Flow Pipelines Based on Multi-Layer Perceptron. Atmosphere 2022, 13, 1833. https://doi.org/10.3390/atmos13111833

Wang G, Wang C, Shi L. CO2 Corrosion Rate Prediction for Submarine Multiphase Flow Pipelines Based on Multi-Layer Perceptron. Atmosphere. 2022; 13(11):1833. https://doi.org/10.3390/atmos13111833

Chicago/Turabian StyleWang, Guoqing, Changquan Wang, and Lihong Shi. 2022. "CO2 Corrosion Rate Prediction for Submarine Multiphase Flow Pipelines Based on Multi-Layer Perceptron" Atmosphere 13, no. 11: 1833. https://doi.org/10.3390/atmos13111833

APA StyleWang, G., Wang, C., & Shi, L. (2022). CO2 Corrosion Rate Prediction for Submarine Multiphase Flow Pipelines Based on Multi-Layer Perceptron. Atmosphere, 13(11), 1833. https://doi.org/10.3390/atmos13111833