Air Pollutants and CO2 Emissions in Industrial Parks and Evaluation of Their Green Upgrade on Regional Air Quality Improvement: A Case Study of Seven Cities in Henan Province

Abstract

:1. Introduction

2. Materials and Methods

2.1. Regional Overview

2.2. Estimation of Emission Inventory

2.3. Emission Reduction Scenario Setting

2.4. Air Quality Model

3. Results and Discussion

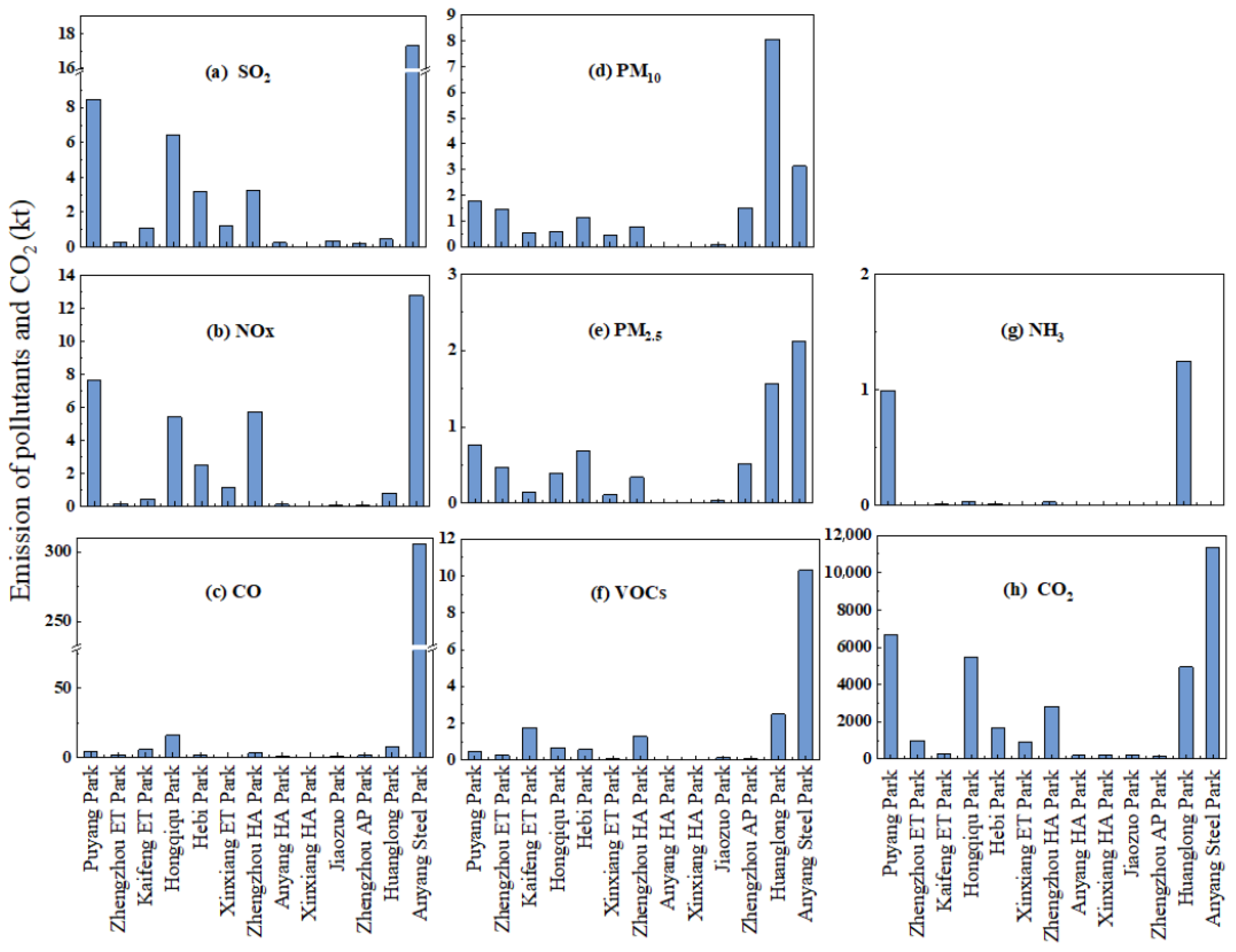

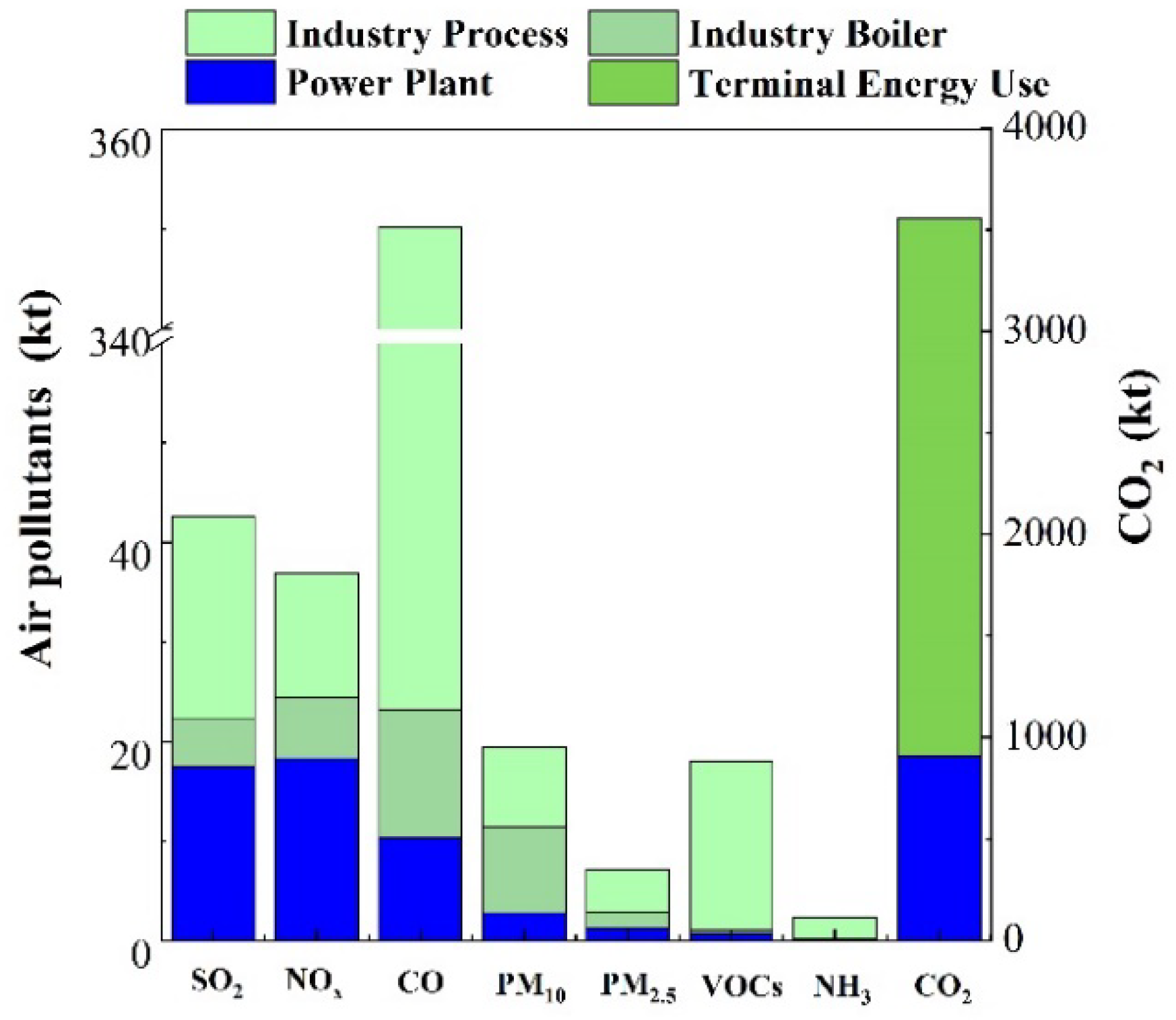

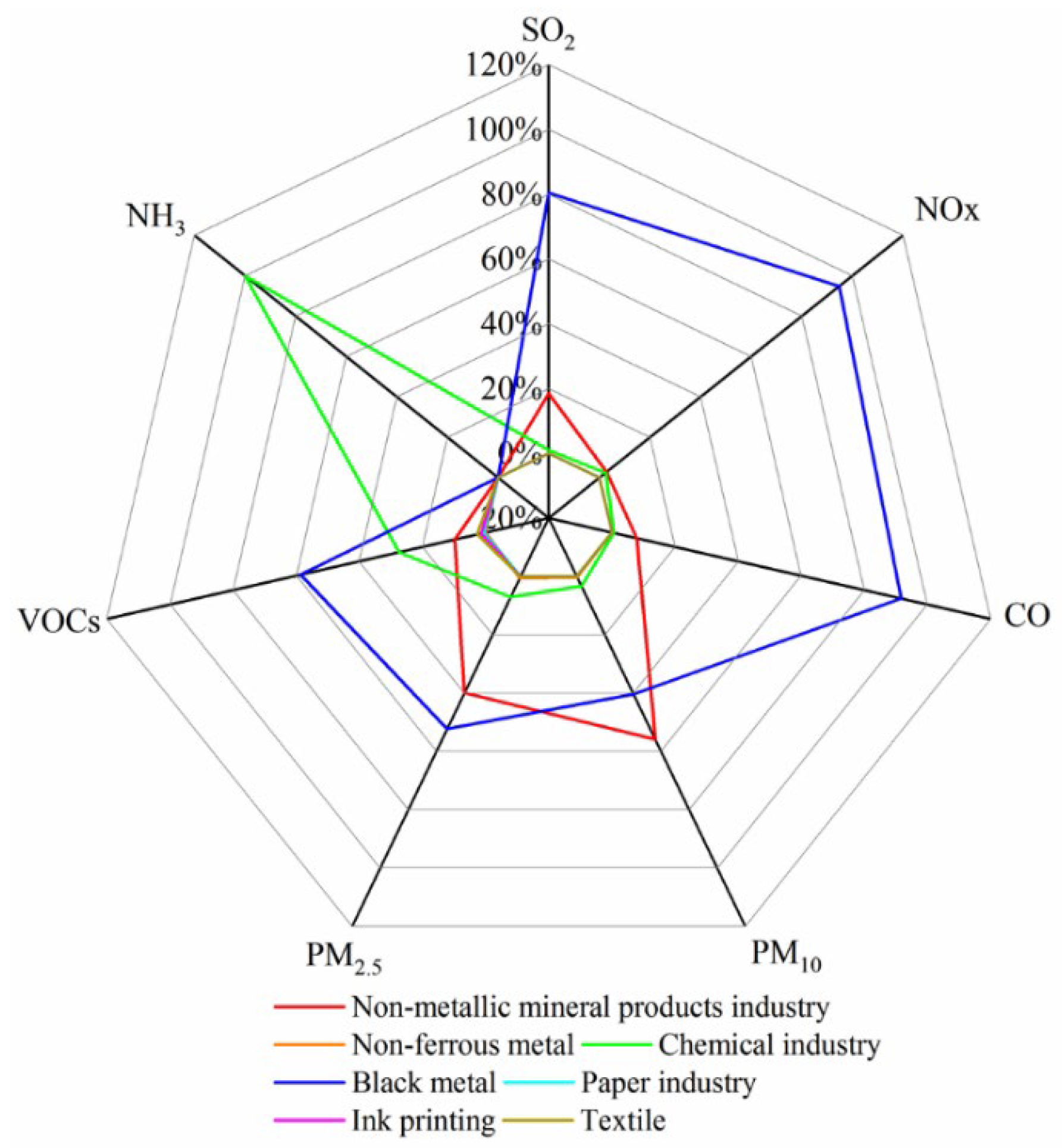

3.1. Emissions of Industrial Parks

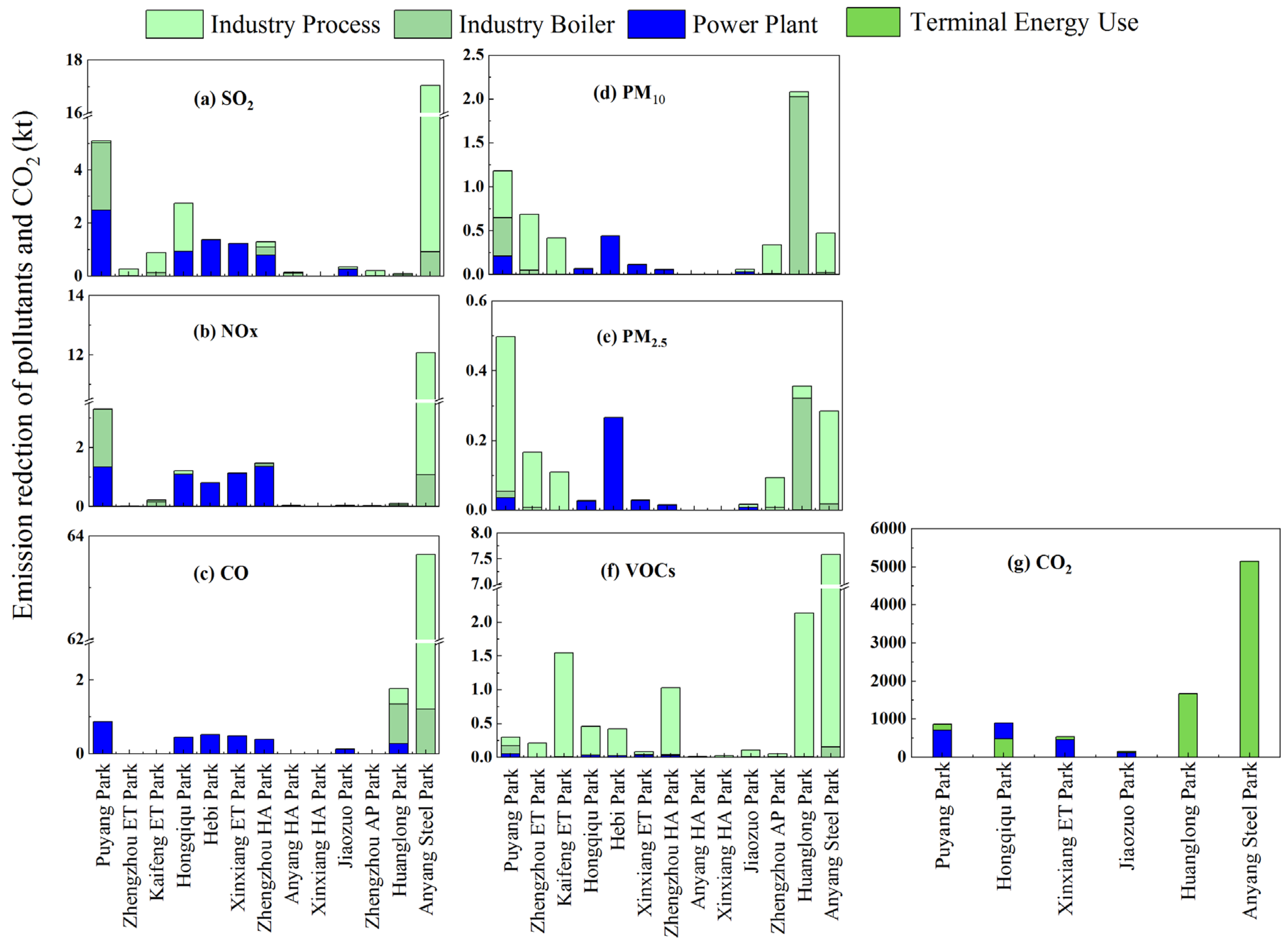

3.2. The Emission Reduction Potential under the Green Upgrade Scenario

3.3. The Effects of Industrial Park Emissions on PM2.5 Concentrations in Seven Cities

3.4. Uncertainty Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, J.P.; Zang, N.; Xu, Y.; Chen, L.J. Green development index of the Chinese national economic-technology development area. Acta Ecol. Sin. 2018, 38, 7082–7092. (In Chinese) [Google Scholar] [CrossRef]

- Guo, Y.; Tian, J.; Chen, L. Managing energy infrastructure to decarbonize industrial parks in China. Nat. Commun. 2020, 11, 981. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shan, Y.; Liu, J.; Liu, Z.; Xu, X.; Shao, S.; Wang, P.; Guan, D. New provincial CO2 emission inventories in China based on apparent energy consumption data and updated emission factors. Appl. Energy 2016, 184, 742–750. [Google Scholar] [CrossRef] [Green Version]

- Fang, D.; Chen, B.; Hayat, T.; Alsaedi, A. Emergy evaluation for a low-carbon industrial park. J. Clean. Prod. 2017, 163, S392–S400. [Google Scholar] [CrossRef]

- Tan, X.; Zeng, Y.; Gu, B.; Tan, X.; Xu, B. The accounting for greenhouse gas emissions of a low-carbon industrial park in China: A case study in Chongqing. Energy Procedia 2017, 142, 3176–3181. [Google Scholar] [CrossRef]

- Wang, H.; Lei, Y.; Wang, H.; Liu, M.; Yang, J.; Bi, J. Carbon reduction potentials of China’s industrial parks: A case study of Suzhou Industry Park. Energy 2013, 55, 668–675. [Google Scholar] [CrossRef]

- Feng, J.C.; Yan, J.Y.; Yu, Z.; Zeng, X.L.; Xu, W.J. Case study of an industrial park toward zero carbon emission. Appl. Energy 2018, 209, 65–78. [Google Scholar] [CrossRef]

- Pyakurel, P.; Wright, L. Energy and resources cooperation for greenhouse gases emissions reduction of industrial sector. Energy Environ. 2021, 32, 635–647. [Google Scholar] [CrossRef]

- Tang, Q.; Lei, Y.; Chen, X.; Xue, W. Air Quality improvement scenario for China during the 13th five-year plan period. Asian J. Atmos. Environ. 2017, 11, 33–36. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.T.; Cai, S.Y.; Wang, S.X.; Zhao, B.; Chang, X.; Hao, J.M. Development of a unit-based industrial emission inventory in the Beijing–Tianjin–Hebei region and resulting improvement in air quality modeling. Atmos. Chem. Phys. 2019, 19, 3447–3462. [Google Scholar] [CrossRef] [Green Version]

- Sueyoshi, T.; Li, A.; Liu, X. Exploring sources of China’s CO2 emission: Decomposition analysis under different technology changes. Eur. J. Oper. Res. 2019, 279, 984–995. [Google Scholar] [CrossRef]

- Du, H.; Li, J.; Wang, Z.; Yang, W.; Chen, X.; Wei, Y. Sources of PM2.5 and its responses to emission reduction strategies in the Central Plains Economic Region in China: Implications for the impacts of COVID-19. Environ. Pollut. 2021, 288, 117783. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.-Q.; Xing, J.; Chen, W.-Y.; Li, F.; Zhu, Y. Rapid Evaluation of the effects of policies corresponding to air quality, carbon emissions and energy consumption: An example from Shenzhen, China. Atmosphere 2021, 12, 1221. [Google Scholar] [CrossRef]

- Huang, B.; Jiang, P.; Wang, S.; Zhao, J.; Wu, L. Low carbon innovation and practice in Caohejing High-Tech Industrial Park of Shanghai. Int. J. Prod. Econ. 2016, 181, 367–373. [Google Scholar] [CrossRef]

- Ji, J.; Wang, S.; Ma, Y.; Lu, C.; Liang, T.; Zhang, R. Pollutant emission reduction of energy efficiency enhancement and energy cascade utilization in an energy-intensive industrial park in China. Environ. Sci. Pollut. Res. 2020, 27, 35017–35030. [Google Scholar] [CrossRef]

- Chen, D.S.; Liang, D.Y.; Li, L.; Guo, X.R.; Lang, J.L.; Zhou, Y. The temporal and spatial changes of ship-contributed PM2.5 due to the inter-annual meteorological variation in Yangtze river delta, China. Atmosphere 2021, 12, 722. [Google Scholar] [CrossRef]

- Cheng, F.-Y.; Feng, C.-Y.; Yang, Z.-M.; Hsu, C.-H.; Chan, K.-W.; Lee, C.-Y.; Chang, S.-C. Corrigendum to “Evaluation of real-time PM2.5 forecasts with the WRF-CMAQ modeling system and weather-pattern-dependent bias-adjusted PM2.5 forecasts in Taiwan”. Atmos. Environ. 2021, 254, 118263. [Google Scholar] [CrossRef]

- Yang, X.C.; Wu, Q.; Zhao, R.; Cheng, H.Q.; He, H.J.; Ma, Q.; Wang, L.N.; Luo, H. New method for evaluating winter air quality: PM2.5 assessment using Community Multi-Scale Air Quality Modeling (CMAQ) in Xi’an. Atmos. Environ. 2019, 211, 18–28. [Google Scholar] [CrossRef]

- Tan, J.N.; Zhang, Y.; Ma, W.C.; Yu, Q.; Wang, Q.; Fu, Q.Y.; Zhou, B.; Chen, J.M.; Chen, L. Evaluation and potential improvements of WRF/CMAQ in simulating multi-levels air pollution in megacity Shanghai, China. Stoch. Environ. Res. Risk Assess. Hydrol. Hydraul. 2016, 31, 2513–2526. [Google Scholar] [CrossRef]

- Liu, S.H.; Hua, S.B.; Wang, K.; Qiu, P.P.; Liu, H.J.; Wu, B.B.; Shao, P.Y.; Liu, X.Y.; Wu, Y.M.; Xue, Y.F.; et al. Spatial-Temporal variation characteristics of air pollution in Henan of China: Localized emission inventory, WRF/Chem simulations and potential source contribution analysis. Sci. Total Environ. 2018, 624, 396–406. [Google Scholar] [CrossRef]

- Xiao, C.C.; Chang, M.; Guo, P.K.; Yuan, M.Y.; Xu, C.Q.; Song, X.H.; Xiong, X.Y.; Li, Y.; Li, Z.Q. Characteristics analysis of industrial atmospheric emission sources in Beijing–Tianjin–Hebei and Surrounding Areas using data mining and statistics on different time scales. Atmos. Pollut. Res. 2020, 11, 11–26. [Google Scholar] [CrossRef]

- Li, C.; Li, H.J.; Feng, S.D.; Liu, X.Y.; Guo, S. A study on the spatiotemporal characteristics and change trend of the atmospheric environmental carrying capacity in the Jing-Jin-Ji region, China. J. Clean. Prod. 2019, 211, 27–35. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, L.; Che, W.; Zheng, Z.; Yin, S. A highly resolved temporal and spatial air pollutant emission inventory for the Pearl River Delta region, China and its uncertainty assessment. Atmos. Environ. 2009, 43, 5112–5122. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Industrial Classification for National Economic Activities; National Bureau of Statistics: Beijing, China, 2017. Available online: http://www.stats.gov.cn/Tjsj/tjbz/hyflbz/201905/P020190716349644060705.pdf (accessed on 8 February 2022).

- Wang, C.; Yin, S.S.; Yu, S.J.; Wei, J.H.; Gu, X.K.; Gong, M.M.; Zhang, R.Q. A 2013-based Atmospheric Ammonia Emission Inventory and Its Characteristic of Spatial Distribution in Henan Province. Environ. Sci. 2018, 39, 1023–1030. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, S.; Huang, Z. Establishment of Regional High Resolution Atmospheric Emission Source Inventory and Its Application; China Science Publishing & Media Ltd.: Beijing, China, 2014; ISBN 9787030389114. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006; Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 20 December 2021).

- Ministry of Ecology and Environment of the People’s Republic of China. Announcement on the release of the “Second National Pollution Source Census Bulletin. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk01/202006/t20200610_783547.html (accessed on 20 December 2021).

- National Bureau of Statistics (NBS). China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2018; Available online: http://cdi.cnki.net/Titles/SingleNJ?NJCode=N2019080025 (accessed on 20 December 2021).

- The State Council of the People’s Republic of China (SCPC). Action Plan for Upgrading and Transformation of Coal Power Conservation and Emission Reduction (2014–2020). Available online: http://www.gov.cn/gongbao/content/2015/content_2818468.htm (accessed on 25 November 2021).

- Development and Reform Commission of Henan Province. The Planning and Construction Measures of Henan Province for Cogeneration. Available online: http://fgw.henan.gov.cn/2019/05-24/794775.html (accessed on 25 November 2021).

- The State Council of the People’s Republic of China (SCPC). Strategy for Revolution in Energy Production and Consumption (2016–2030). Available online: http://www.gov.cn/xinwen/2017-04/25/content_5230568.htm (accessed on 25 November 2021).

- National Public Service Platform for Standards Information. Energy Consumption Limit of Synthetic Ammonia Unit Product (GB-21344). Available online: http://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D80C3BD3A7E05397BE0A0AB82A (accessed on 8 February 2022).

- National Center for Atmospheric Research. WRF Users Page. Available online: https://www2.mmm.ucar.edu/wrf/users/ (accessed on 25 November 2021).

- United States Environmental Protection Agency (U.S. EPA). CMAQ: The Community Multiscale Air Quality Modeling System. Available online: https://www.epa.gov/cmaq (accessed on 25 November 2021).

- Im, U.; Markakis, K.; Unal, A.; Kindap, T.; Poupkou, A.; Incecik, S.; Yenigun, O.; Melas, D.; Theodosi, C.; Mihalopoulos, N. Study of a winter PM episode in Istanbul using the high resolution WRF/CMAQ modeling system. Atmos. Environ. 2010, 44, 3085–3094. [Google Scholar] [CrossRef]

- Wang, C.; Yin, S.S.; Bai, L.; Zhang, X.C.; Gu, X.K.; Zhang, H.; Lu, Q.; Zhang, R.Q. High-Resolution ammonia emission inventories with comprehensive analysis and evaluation in Henan, China, 2006–2016. Atmos. Environ. 2018, 193, 11–23. [Google Scholar] [CrossRef]

- MEIC Model. Multi-Resolution Emission Inventory for China. Available online: http://www.meicmodel.org (accessed on 25 November 2021).

- Ashworth, K.; Wild, O.; Hewitt, C.N. Sensitivity of isoprene emissions estimated using MEGAN to the time resolution of input climate data. Atmos. Chem. Phys. 2010, 10, 1193–1201. [Google Scholar] [CrossRef] [Green Version]

- China Air Quality Online Monitoring and Analysis Platform. Available online: https://www.aqistudy.cn/historydata/about.php (accessed on 25 November 2021).

- Boylan, J.W.; Russell, A.G. PM and light extinction model performance metrics, goals, and criteria for three-dimensional air quality models. Atmos. Environ. 2006, 40, 4946–4959. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Wang, L.; Zhang, Q.; Duan, F.K.; He, K.B. Application of WRF/Chem over East Asia: Part I. Model evaluation and intercomparison with MM5/CMAQ. Atmos. Environ. 2016, 124, 285–300. [Google Scholar] [CrossRef] [Green Version]

- Long, W.Q.; Wang, S.S.; Lu, C.Y.; Xue, R.Y.; Liang, T.; Jiang, N.; Zhang, R.Q. Quantitative assessment of energy conservation potential and environmental benefits of an iron and steel plant in China. J. Clean. Prod. 2020, 273, 123163. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China (MEC). Guideline on Available Technologies of Pollution Prevention and Control for Thermal Power Plant (HJ 2301-2017). Available online: http://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/wrfzjszc/201706/t20170609_415755.shtml (accessed on 25 November 2021).

- Bai, L.; Lu, X.; Yin, S.S.; Zhang, H.; Ma, S.L.; Wang, C.; Li, Y.S.; Zhang, R.Q. A recent emission inventory of multiple air pollutant, PM2.5 chemical species and its spatial-temporal characteristics in central China. J. Clean. Prod. 2020, 269, 122114. [Google Scholar] [CrossRef]

- Wang, K.; Wang, S.S.; Liu, L.; Yue, H.; Zhang, R.Q.; Tang, X.Y. Environmental co-benefits of energy efficiency improvement in coal-fired power sector: A case study of Henan Province, China. Appl. Energy 2016, 184, 810–819. [Google Scholar] [CrossRef]

- Cheng, J.; Tong, D.; Zhang, Q.; Liu, Y.; Lei, Y.; Yan, G.; Yan, L.; Yu, S.; Cui, R.Y.; Clarke, L.; et al. Pathways of China’s PM2.5 air quality 2015–2060 in the context of carbon neutrality. Natl. Sci. Rev. 2021, 8, nwab078. [Google Scholar] [CrossRef] [PubMed]

- Janhall, S.; Olofson, K.F.G.; Andersson, P.U.; Pettersson, J.B.C.; Hallquist, M. Evolution of the urban aerosol during winter temperature inversion episodes. Atmos. Environ. 2006, 40, 5355–5366. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China. Environmental Air Quality Standards. Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/dqhjbh/dqhjzlbz/201203/t20120302_224165.shtml (accessed on 25 November 2021).

- Ministry of Ecology and Environment of the People’s Republic of China (MEC). Overview of National Ecological Environment Quality in 2020. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk15/202103/t20210302_823100.html (accessed on 25 November 2021).

- Gao, G.; Wang, S.; Xue, R.; Liu, D.; Ren, H.; Zhang, R. Uncovering the characteristics of air pollutants emission in industrial parks and analyzing emission reduction potential: Case studies in Henan, China. Sci Rep 2021, 11, 23709. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Emission Source Statistics Survey Production and Emission Accounting Method and Coefficient Manual. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk01/202106/t20210618_839512.html (accessed on 19 December 2021).

- Pham, T.B.T.; Manomaiphiboon, K.; Vongmahadlek, C. Development of an inventory and temporal allocation profiles of emissions from power plants and industrial facilities in Thailand. Sci. Total. Environ. 2008, 397, 103–118. [Google Scholar] [CrossRef]

- He, M.; Wang, X.R.; Han, L. Inventory and characteristics of atmospheric fixed pollution source emissions in Sichuan Province. Acta. Sci. Circumst. 2013, 33, 3127–3137. (In Chinese) [Google Scholar] [CrossRef]

- Huang, C.; Chen, C.H.; Li, L.; Cheng, Z.; Wang, H.L.; Wang, Y.J.; Huang, H.Y.; Zhang, G.F.; Chen, Y.R. Study on the characteristics of anthropogenic air pollutants emission in the Yangtze River Delta. Acta. Sci. Circumst. 2011, 1858–1871. (In Chinese) [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (U.S.EPA). AP-42: Compilation of Air Emission Factors. Available online: https://www.epa.gov/air-emissions-factors-and-quantification/ap-42-compilation-air-emission-factors (accessed on 19 December 2021).

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Technical Guidelines for Compilation of Air Pollutant Source Emission Inventory. Available online: http://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/wrfzjszc/201812/t20181225_685872.shtml (accessed on 19 December 2021).

- Yin, S.; Zheng, J.; Zhang, L.; Zhong, L. Anthropogenic ammonia emission inventory and characteristics in the Pearl River Delta Region. Environ. Sci. 2010, 31, 1146–1151. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, Y.; Yang, L.; Fu, L.X.; He, K.B.; Wang, S.X.; Hao, J.M.; Chen, J.C.; Li, C.Y. The impact of transportation control measures on emission reductions during the 2008 Olympic Games in Beijing, China. Atmos. Environ. 2010, 44, 285–293. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, Q.A.; Nielsen, C.; He, K.B. An inventory of primary air pollutants and CO2 emissions from cement production in China, 1990–2020. Atmos. Environ. 2011, 45, 147–154. [Google Scholar] [CrossRef]

- Bo, Y.; Cai, H.; Xie, S.D. Spatial and temporal variation of historical anthropogenic NMVOCs emission inventories in China. Atmos. Chem. Phys. 2008, 8, 7297–7316. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; He, K.; Zhang, Q.; Liu, Z. Technology-based emission inventory of particulate matters (PM) from cement industry. Environ. Sci. 2008, 29, 2366–2371. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, B.; Ma, J.Z. Development of an air pollutant emission inventory for Tianjin. Acta. Sci. Circumst. 2008, 28, 368–375. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, Y.; Nielsen, C.P.; McElroy, M.B.; Zhang, L.; Zhang, J. CO emissions in China: Uncertainties and implications of improved energy efficiency and emission control. Atmos. Environ. 2012, 49, 103–113. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China (MEE). Technical Guidelines for Compiling the Primary Source Emission Inventory of Inhalable Particulate Matter. Available online: http://www.mee.gov.cn/gkml/hbb/bgg/201408/t20140828_288364.htm. (accessed on 19 December 2021).

- National Development and Reform Commission. (NDRC). Provincial Greenhouse Gas Inventory. Available online: http://cn.edcmee.org.cn/ptfb/zcbz/202106/P020210601177040314696.pdf (accessed on 19 December 2021).

- National Development and Reform Commission (NDRC). National Key Energy-Saving and Low-Carbon Technology Promotion Catalogue. 2017. Available online: http://www.gov.cn/xinwen/2017-04/01/content_5182743.htm (accessed on 25 November 2021).

- Xu, Y.; Hu, J.L.; Ying, Q.; Hao, H.K.; Wang, D.X.; Zhang, H.L. Current and future emissions of primary pollutants from coal-fired power plants in Shaanxi, China. Sci. Total. Environ. 2017, 595, 505–514. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China (MEC). Guideline on Available Techniques of Pollution Prevention and Control for Industrial Boiler. Available online: http://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/201909/t20190911_733464.html (accessed on 19 December 2021).

- Chinese Academy of Environmental Planning (CAEP) China Carbon Dioxide Capture Utilization and Storage (CCUS) Annual Report. 2021. Available online: http://www.caep.org.cn/sy/dqhj/gh/202107/t20210725_851241.shtml (accessed on 19 December 2021).

- Zhang, Y.S.; Li, C.; Yan, Q.S.; Han, S.J.; Zhao, Q.Y.; Yang, L.M.; Liu, Y.G.; Zhang, R.Q. Typical industrial sector-based volatile organic compounds source profiles and ozone formation potentials in Zhengzhou, China. Atmos. Pollut. Res. 2020, 11, 841–850. [Google Scholar] [CrossRef]

| Source | Category | Sub-Category |

|---|---|---|

| Power plant | Raw coal | Pulverized coal stove |

| Fluidized-bed furnace | ||

| Garbage/biomass | ||

| Natural gas | ||

| Industry Boiler | Raw coal | Layer burning stove |

| Pulverized coal stove | ||

| Fluidized-bed furnace | ||

| Coke | ||

| Natural gas | ||

| Diesel | ||

| Industry Process | Non-metallic mineral products industry | Cement |

| Crick and tile | ||

| Refractory | ||

| Ceramic | ||

| Glass | ||

| Non-ferrous metal | Electrolytic aluminum | |

| Aluminum oxide | ||

| Chemical industry | Fertilizers | |

| Printing and dyeing | ||

| Synthetic rubber | ||

| Polypropylene | ||

| Viscose fiber | ||

| Paint | ||

| Ammonia synthesis | ||

| Black metal | Electric steelmaking | |

| Converter steelmaking | ||

| Hot rolled steel | ||

| Paper industry | ||

| Textile |

| Industrial Park Type | Unit | SO2 | NOx | CO | PM10 | PM2.5 | VOCs | NH3 | CO2 |

|---|---|---|---|---|---|---|---|---|---|

| Energy-intensive IP | Emissions (kt) | 34 | 28 | 335 | 14 | 5 | 14 | 2 | 29,455 |

| Percent of total emissions | 80% | 71% | 95% | 73% | 70% | 78% | 97% | 83% | |

| Mixed IP | Emissions (kt) | 4 | 9 | 9 | 3 | 1 | 2 | 0 | 4274 |

| Percent of total emissions | 10% | 22% | 2% | 18% | 18% | 9% | 2% | 11% | |

| Emerging IP Average | Emissions (kt) | 4 | 3 | 7 | 2 | 1 | 2 | 0 | 1917 |

| Percent of total emissions | 10% | 7% | 2% | 9% | 12% | 13% | 1% | 5% |

| Industrial Park Type | Unit | SO2 | NOx | CO | PM10 | PM2.5 | VOCs | CO2 |

|---|---|---|---|---|---|---|---|---|

| Energy-intensive IP | Emission reductions (kt) | 26 | 17 | 67 | 4 | 1 | 11 | 9273 |

| Percent of total emission | 87% | 87% | 99% | 67% | 65% | 76% | 99% |

| Pollutant | Simulation Value (μg/m3) | Observed Value (μg/m3) | NMB | NME | MFB | MFE |

|---|---|---|---|---|---|---|

| PM2.5 | 67.34 | 65.02 | 5.73% | 31.10% | 3.11% | 30.15% |

| City | 2017 Base Year PM2.5 Concentrations of Different Months and Annual Average (μg/m3) | ||||

|---|---|---|---|---|---|

| January | April | July | October | Annual Average | |

| Anyang | 255 | 69 | 30 | 42 | 99 |

| Hebi | 150 | 45 | 22 | 42 | 65 |

| Jiaozuo | 98 | 38 | 27 | 39 | 50 |

| Kaifeng | 158 | 48 | 19 | 41 | 66 |

| Puyang | 133 | 40 | 15 | 38 | 57 |

| Xinxiang | 132 | 48 | 24 | 40 | 61 |

| Zhengzhou | 145 | 63 | 33 | 51 | 73 |

| Average | 153 | 50 | 24 | 42 | 67 |

| City | PM2.5 Concentration (μg/m3) | ||||

|---|---|---|---|---|---|

| January | April | July | October | Annual Average | |

| Anyang | 145 | 49 | 24 | 37 | 64 |

| Hebi | 119 | 42 | 21 | 38 | 55 |

| Jiaozuo | 95 | 37 | 26 | 38 | 49 |

| Kaifeng | 132 | 42 | 16 | 36 | 57 |

| Puyang | 129 | 40 | 15 | 38 | 55 |

| Xinxiang | 121 | 47 | 24 | 38 | 58 |

| Zhengzhou | 138 | 63 | 33 | 50 | 71 |

| Average | 125 | 46 | 23 | 39 | 58 |

| City | PM2.5 Concentration (μg/m3) | ||||

|---|---|---|---|---|---|

| January | April | July | October | Annual Average | |

| Anyang | 110 | 21 | 6 | 5 | 36 |

| Hebi | 32 | 3 | 0 | 4 | 10 |

| Jiaozuo | 3 | 0 | 0 | 1 | 1 |

| Kaifeng | 26 | 6 | 3 | 4 | 10 |

| Puyang | 4 | 1 | 0 | 0 | 1 |

| Xinxiang | 11 | 1 | 0 | 2 | 4 |

| Zhengzhou | 7 | 0 | 0 | 1 | 2 |

| Average | 28 | 5 | 1 | 3 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hei, W.; Li, X.; Gao, G.; Wang, S.; Zhang, R.; Wang, K. Air Pollutants and CO2 Emissions in Industrial Parks and Evaluation of Their Green Upgrade on Regional Air Quality Improvement: A Case Study of Seven Cities in Henan Province. Atmosphere 2022, 13, 383. https://doi.org/10.3390/atmos13030383

Hei W, Li X, Gao G, Wang S, Zhang R, Wang K. Air Pollutants and CO2 Emissions in Industrial Parks and Evaluation of Their Green Upgrade on Regional Air Quality Improvement: A Case Study of Seven Cities in Henan Province. Atmosphere. 2022; 13(3):383. https://doi.org/10.3390/atmos13030383

Chicago/Turabian StyleHei, Wanting, Xiao Li, Gengyu Gao, Shanshan Wang, Ruiqin Zhang, and Ke Wang. 2022. "Air Pollutants and CO2 Emissions in Industrial Parks and Evaluation of Their Green Upgrade on Regional Air Quality Improvement: A Case Study of Seven Cities in Henan Province" Atmosphere 13, no. 3: 383. https://doi.org/10.3390/atmos13030383

APA StyleHei, W., Li, X., Gao, G., Wang, S., Zhang, R., & Wang, K. (2022). Air Pollutants and CO2 Emissions in Industrial Parks and Evaluation of Their Green Upgrade on Regional Air Quality Improvement: A Case Study of Seven Cities in Henan Province. Atmosphere, 13(3), 383. https://doi.org/10.3390/atmos13030383