Emission Characteristics of Particulate Matter from Boiling Food

Abstract

:1. Introduction

2. Materials and Methods

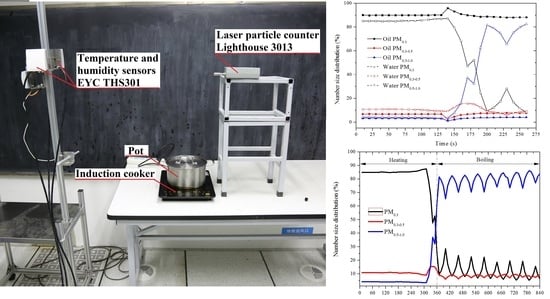

2.1. Particle Emission Experiments for Boiling

2.2. Emission Rate Estimation

2.3. Statistical Analysis

3. Results and Discussion

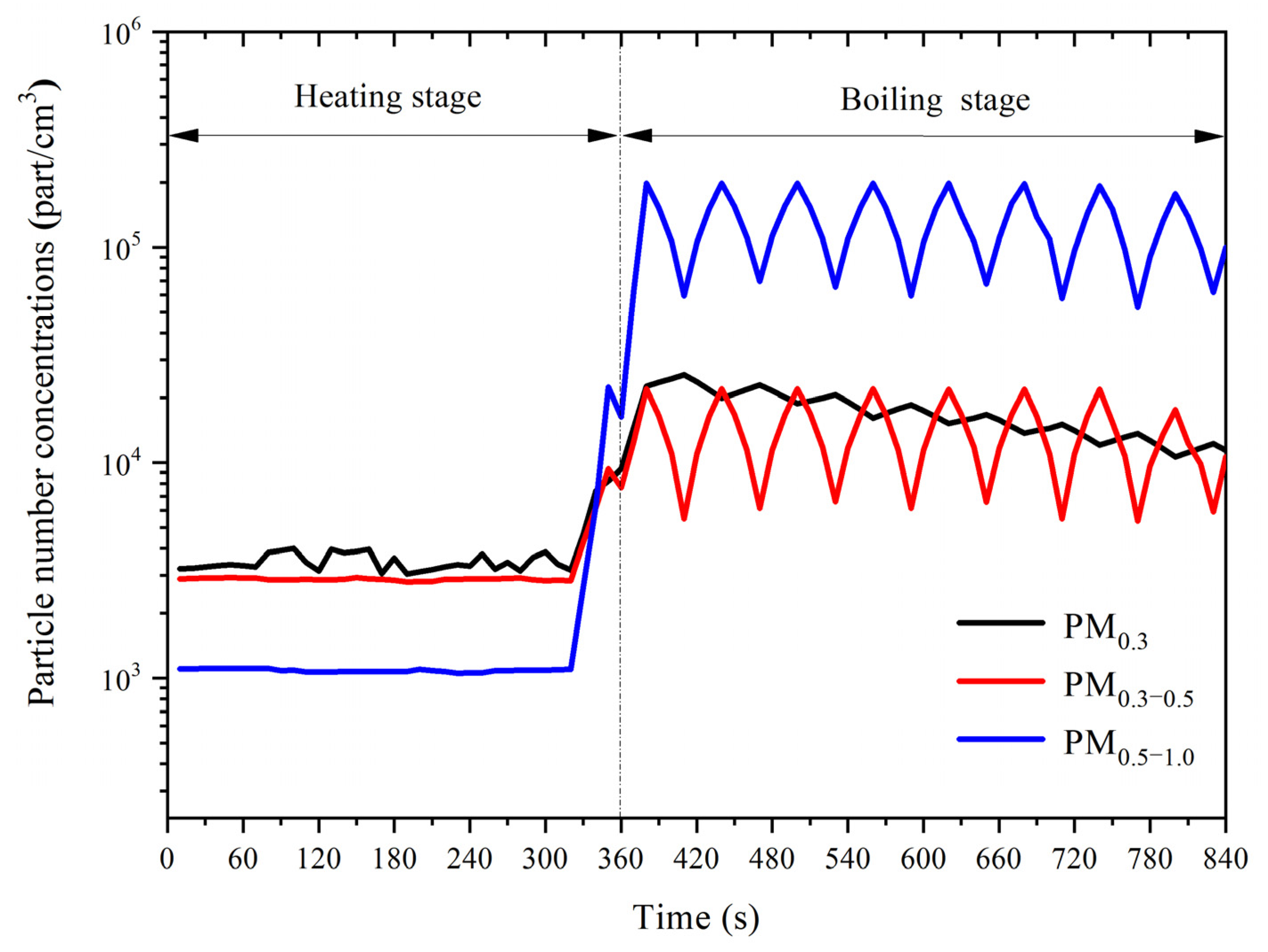

3.1. Particle Number Concentration

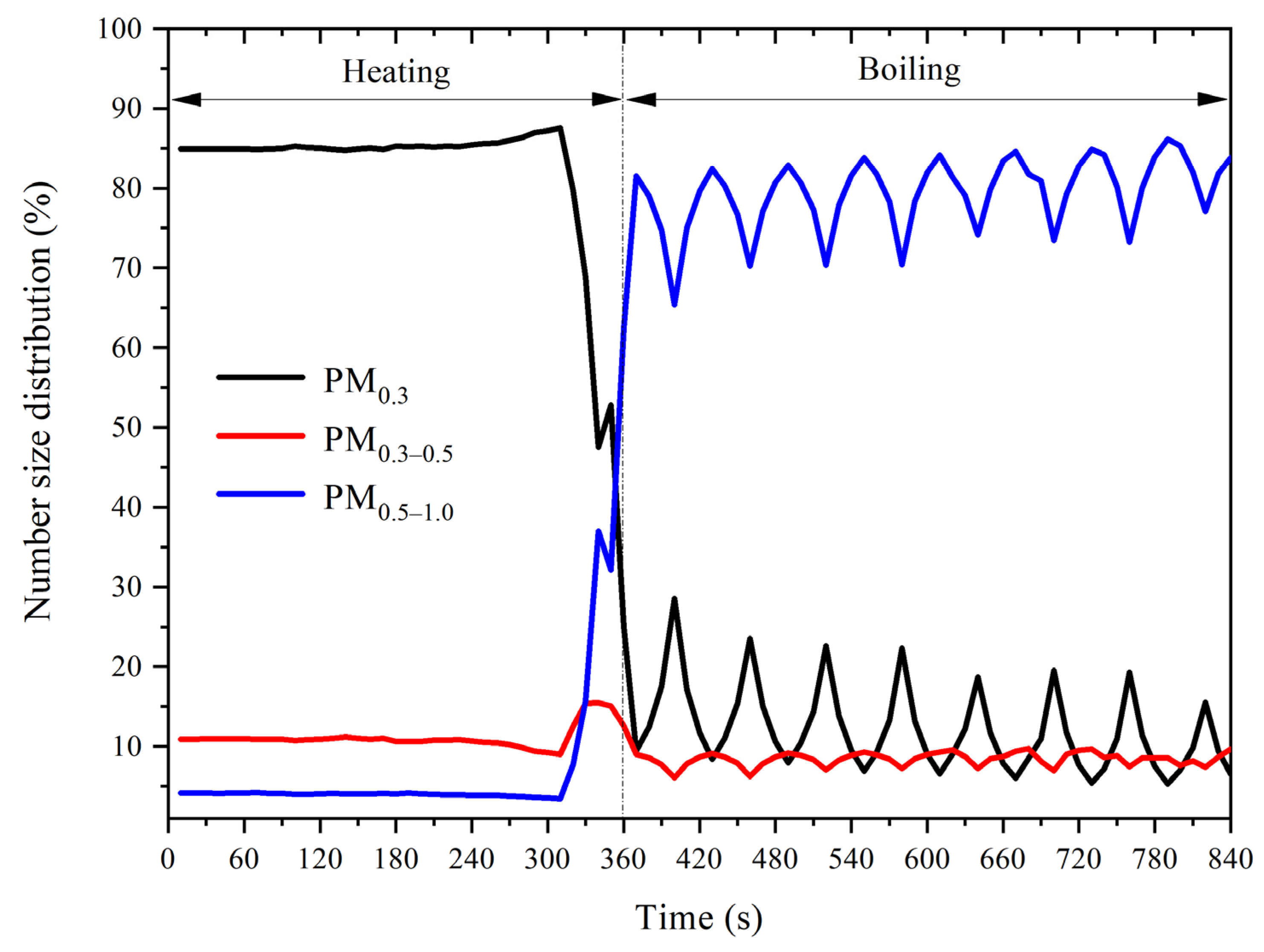

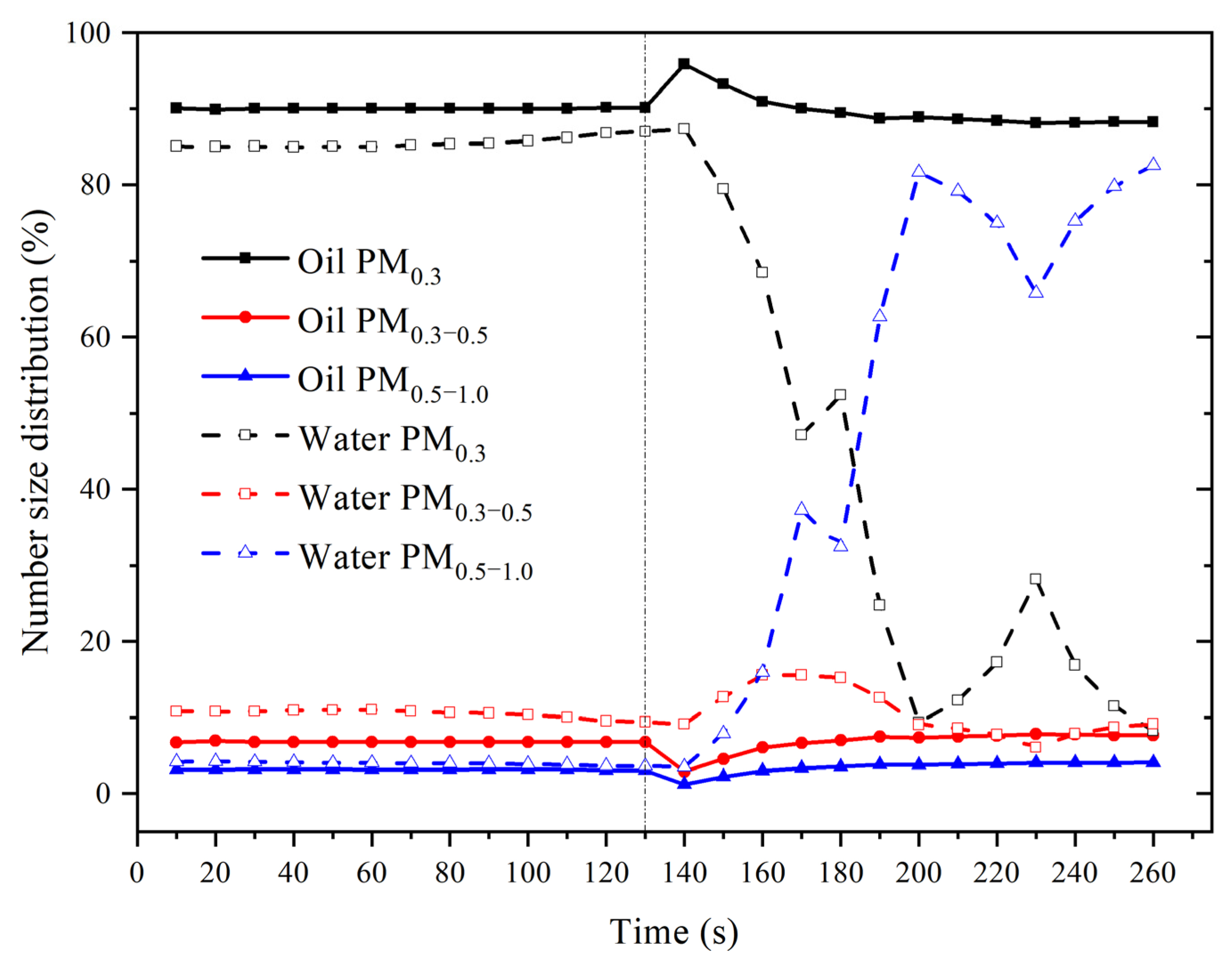

3.2. Particle Size Distribution

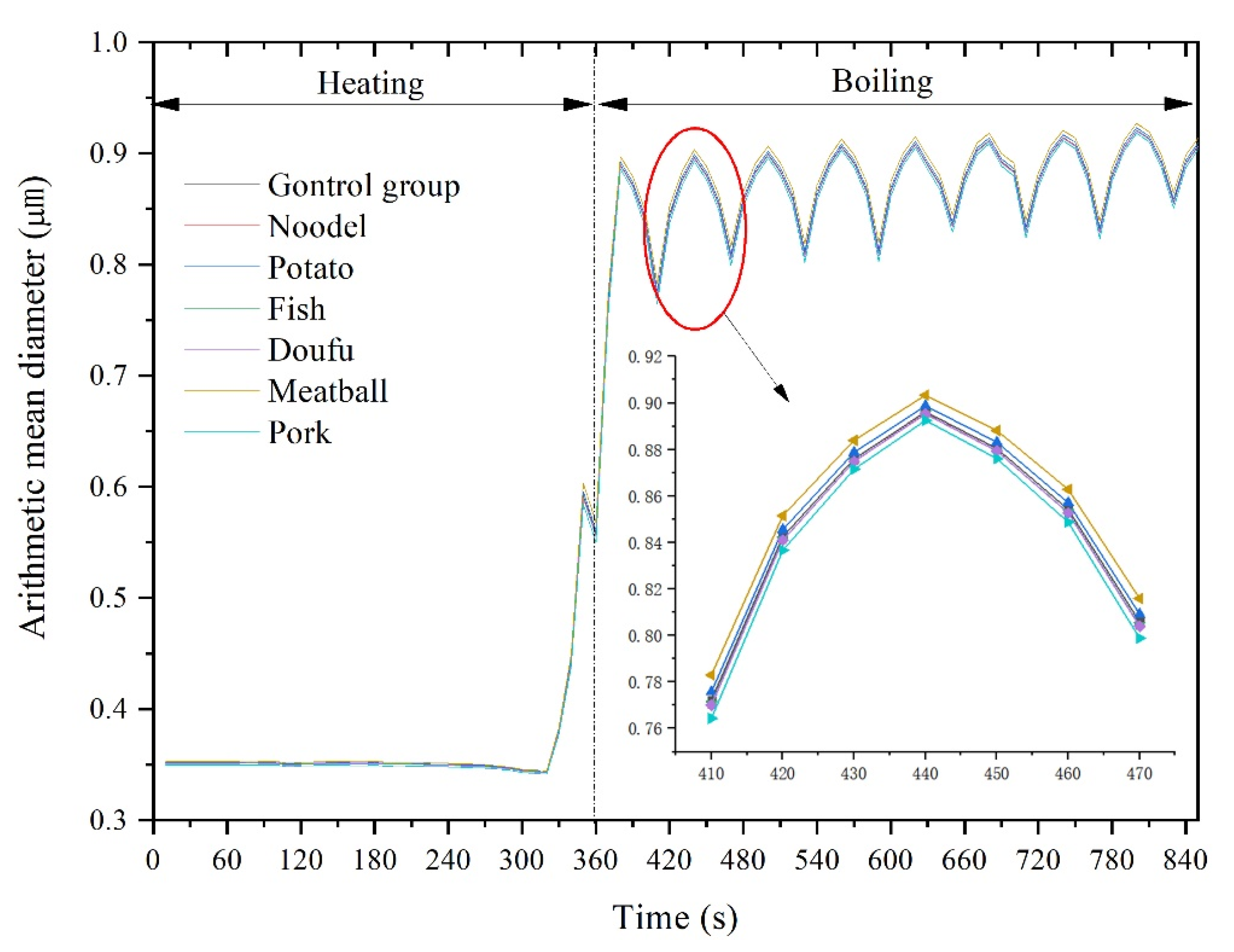

3.3. Particle Arithmetic Mean Diameter

3.4. Particle Emission Characteristics

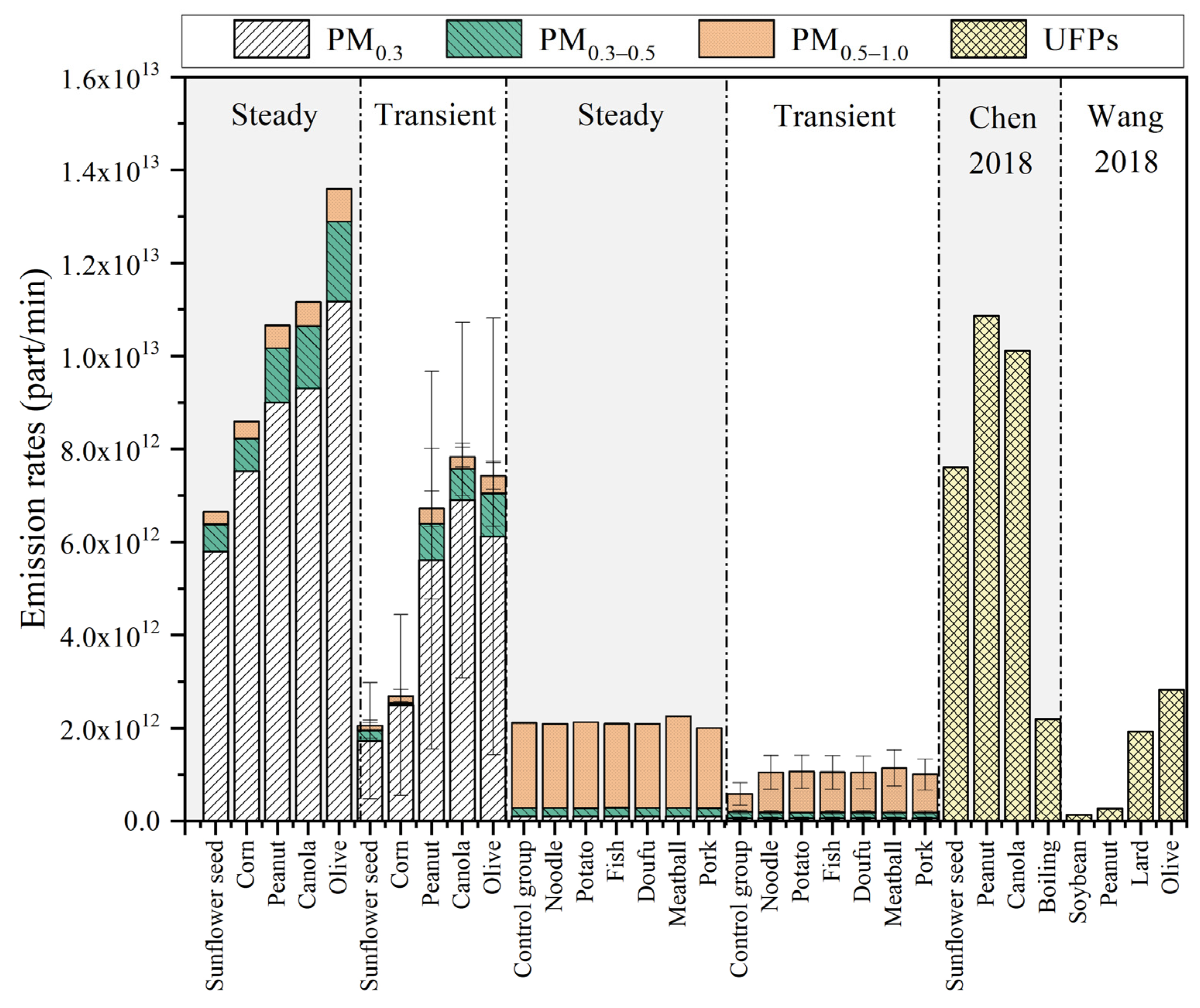

3.5. Particle Emission Rate

4. Conclusions

- In the water-heating process, the particle number concentration, size distribution, and arithmetic mean diameter were unchanged, while within 60 s of heating to boiling, they all changed sharply.

- Water boiling tended to produce more large particles (0.5–1.0 µm), which were significantly different from the emissions of more small-sized particles (less than 0.3 µm) during the oil heating. Neither the food material nor the shape had a significant impact on the particle emission characteristics during the boiling process.

- The number concentrations, size distributions, and arithmetic mean diameters of the particles produced during the boiling process all fluctuated in 60 s. The number concentration of PM0.5–1.0 fluctuated the most, ranging from 143,220.2 part/cm3 (meatball) to 125,031.4 part/cm3 (pork). For the particle size distribution, PM0.3 showed the most significant fluctuation from 15.19% (pork) to 14.00% (meatball). The particle arithmetic mean diameter fluctuated between 0.088 (meatball) and 0.0945 (pork). All the fluctuations diminished over time.

- There was a significant difference between the transient and the steady-state calculation; the steady-state calculation had a high estimate of the emission rate. For PM0.3, PM0.3–0.5, and PM0.5–1.0, the particle emission rates of oil heating were 28.0–112.4, 0.1–3.3, and 1.0–9.3 times the food boiling, respectively. The difference in particle emission between oil heating and boiling mainly concentrated on small particles less than 0.3 µm.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| PM | particulate matter |

| PAHs | polycyclic aromatic hydrocarbons |

| LPG | liquefied petroleum gas |

| SD | standard deviation |

| AER | air exchange rates |

| Symbols | |

| indoor particle concentration | |

| initial indoor particle concentration | |

| peak indoor particle concentration | |

| outdoor particle concentration | |

| penetration efficiency | |

| emission rate | |

| average emission rate | |

| time | |

| initial time | |

| time difference between initial and peak concentration | |

| room volume | |

| total removal rate | |

| Greek Letters | |

| average value | |

| standard deviation | |

References

- Bo, M.; Salizzoni, P.; Clerico, M.; Buccolieri, R. Assessment of Indoor-Outdoor Particulate Matter Air Pollution: A Review. Atmosphere 2017, 8, 136. [Google Scholar] [CrossRef] [Green Version]

- Qi, J.; Liu, L.X.; Wu, J.J. Improving Combustion Technology for Cooking Activities for Pollutant Emission Reduction and Carbon Neutrality. Atmosphere 2022, 13, 561. [Google Scholar] [CrossRef]

- Lu, F.J.; Shen, B.X.; Yuan, P.; Li, S.; Sun, Y.; Mei, X. The emission of PM2.5 in Respiratory Zone from Chinese Family Cooking and Its Health Effect. Sci. Total Environ. 2019, 654, 671–677. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Han, B.; He, F.; Xu, J.; Zhao, R.; Zhang, Y.; Bai, Z. Chemical Characteristic of PM2.5 Emission and Inhalational Carcinogenic Risk of Domestic Chinese Cooking. Environ. Pollut. 2017, 227, 24–30. [Google Scholar] [CrossRef] [PubMed]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Household use of solid fuels and high-temperature frying. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; WHO: Geneva, Switzerland, 2010; Volume 95, p. 1. [Google Scholar]

- Wang, C.; Liu, L.; Liu, X.; Chen, W.; He, G. Mechanisms of Lung Cancer Caused by Cooking Fumes Exposure: A Minor Review. Chin. Med. Sci. J. 2017, 32, 193–197. [Google Scholar]

- Du, W.; Li, X.Y.; Chen, Y.C.; Shen, G. Household Air Pollution and Personal Exposure to Air Pollutants in Rural China—A Review. Environ. Pollut. 2018, 237, 625–638. [Google Scholar] [CrossRef]

- Lee, S.C.; Li, W.M.; Chan, L.Y. Indoor Air Quality at Restaurants with Different Styles of Cooking in Metropolitan Hong Kong. Sci. Total Environ. 2001, 279, 181–193. [Google Scholar] [CrossRef]

- Li, Y.C.; Shu, M.; Ho, S.S.H.; Wang, C.; Cao, J.-J.; Wang, G.-H.; Wang, X.-X.; Wang, K.; Zhao, X.-Q. Characteristics of PM2.5 Emitted from Different Cooking Activities in China. Atmos. Res. 2015, 166, 83–91. [Google Scholar] [CrossRef]

- Cheng, J.H.; Lee, Y.S.; Chen, K.S. Carbonyl Compounds in Dining Areas, Kitchens and Exhaust Streams in Restaurants with Varying Cooking Methods in Kaohsiung, Taiwan. J. Environ. Sci. 2016, 41, 218–226. [Google Scholar] [CrossRef]

- Zhu, L.Z.; Wang, J. Sources and Patterns of Polycyclic Aromatic Hydrocarbons Pollution in Kitchen Air, China. Chemosphere 2003, 50, 611–618. [Google Scholar] [CrossRef]

- Ho, S.S.H.; Yu, J.Z.; Chu, K.W.; Yeung, L.L. Carbonyl Emissions from Commercial Cooking Sources in Hong Kong. J. Air Waste Manag. Assoc. 2006, 56, 1091–1098. [Google Scholar] [CrossRef] [PubMed]

- Ni, K.; Carter, E.; Schauer, J.J.; Ezzati, M.; Zhang, Y.; Niu, H.; Lai, A.M.; Shan, M.; Wang, Y.; Yang, X.; et al. Seasonal Variation in Outdoor, Indoor, and Personal Air Pollution Exposures of Women Using Wood Stoves in the Tibetan Plateau: Baseline assessment for an energy intervention study. Environ. Int. 2016, 94, 449–457. [Google Scholar] [CrossRef] [PubMed]

- Susaya, J.; Kim, K.H.; Ahn, J.W.; Jung, M.-C.; Kang, C.-H. BBQ charcoal Combustion as an Important Source of Trace Metal Exposure to Humans. J. Hazard. Mater. 2010, 176, 932–937. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.W.; Chen, M.Z.; Ge, M.T.; Padua, M.G. Examining the Conceptual Model of Potential Urban Development Patch (PUDP), VOCs, and Food Culture in Urban Ecology: A Case in Chengdu, China. Atmosphere 2022, 13, 1369. [Google Scholar] [CrossRef]

- Vicente, E.D.; Vicente, A.; Evtyugina, M.; Carvalho, R.; Tarelho, L.; Oduber, F.; Alves, C. Particulate and Gaseous Emissions from Charcoal Combustion in Barbecue Grills. Fuel Process. Technol. 2018, 176, 296–306. [Google Scholar] [CrossRef]

- Wang, L.; Xiang, Z.; Stevanovic, S.; Ristovski, Z.; Salimi, F.; Gao, J.; Wang, H.; Li, L. Role of Chinese Cooking Emissions on Ambient Air Quality and Human Health. Sci. Total Environ. 2017, 589, 173–181. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Zhao, B. Emissions of Air Pollutants from Chinese Cooking: A Literature Review. Build. Simul.-China 2018, 11, 977–995. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Chen, C.; Zhao, B. Is Oil Temperature a Key Factor Influencing Air Pollutant Emissions from Chinese Cooking? Atmos. Environ. 2018, 193, 190–197. [Google Scholar] [CrossRef]

- Yi, H.H.; Huang, Y.H.; Tang, X.L.; Zhao, S.; Xie, X.; Zhang, Y. Characteristics of Non-methane Hydrocarbons and Benzene Series Emission from Commonly Cooking Oil Fumes. Atmos. Environ. 2019, 200, 208–220. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Chen, C.; Zhao, B. Emission Characteristics of PM2.5-bound Chemicals from Residential Chinese Cooking. Build. Environ. 2019, 149, 623–629. [Google Scholar] [CrossRef]

- Lai, A.C.K.; Ho, Y.W. Spatial Concentration Variation of Cooking-Emitted Particles in a Residential Kitchen. Build. Environ. 2008, 43, 871–876. [Google Scholar] [CrossRef]

- Gao, J.; Cao, C.; Xiao, Q.; Xu, B.; Zhou, X.; Zhang, X. Determination of Dynamic Intake Fraction of Cooking-Generated Particles in the Kitchen. Build. Environ. 2013, 65, 146–153. [Google Scholar] [CrossRef]

- Rim, D.; Wallace, L.; Nabinger, S.; Persily, A. Reduction of Exposure to Ultrafine Particles by Kitchen Exhaust Hoods: The Effects of Exhaust Flow Rates, Particle Size, and Burner Position. Sci. Total Environ. 2012, 432, 350–356. [Google Scholar] [CrossRef] [PubMed]

- Poon, C.; Wallace, L.; Lai, A.C.K. Experimental Study of Exposure to Cooking Emitted Particles under Single Zone and Two-Zone Environments. Build. Environ. 2016, 104, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.J.; Tao, P.F.; Zhang, B.; Huan, C. Contribution of Chinese Hot Pot and Barbecue Restaurants on Indoor Environmental Parameters. Aerosol Air Qual. Res. 2020, 20, 2925–2940. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Zhang, Z.H.; Ji, C.F.; Liu, L.; Zhang, B.; Huan, C. Characterization of Particulate Matter from Heating and Cooling Several Edible Oils. Build. Environ. 2019, 152, 204–213. [Google Scholar] [CrossRef]

- He, C.; Morawska, L.; Hitchins, J.; Gilbert, D. Contribution from Indoor Sources to Particle Number and Mass Concentrations in Residential Houses. Atmos. Environ. 2004, 38, 3405–3415. [Google Scholar] [CrossRef]

- Wallace, L.A.; Emmerich, S.J.; Howard-Reed, C. Source Strengths of Ultrafine and Fine Particles Due to Cooking with a Gas Stove. Environ. Sci. Technol. 2004, 38, 2304–2311. [Google Scholar] [CrossRef]

- Torkmahalleh, M.A.; Goldasteh, I.; Zhao, Y.; Udochu, N.M.; Rossner, A.; Hopke, P.K.; Ferro, A.R. PM2.5 and Ultrafine Particles Emitted during Heating of Commercial Cooking Oils. Indoor Air 2012, 22, 483–491. [Google Scholar] [CrossRef]

- Lai, A.C.K.; Chen, J. Numerical Study of Cooking Particle Coagulation by using an Eulerian Model. Build. Environ. 2015, 89, 38–47. [Google Scholar] [CrossRef]

- Kim, D.S.; Park, S.H.; Song, Y.M.; Lee, K. Brownian Coagulation of Polydisperse Aerosols in the Transition Regime. J. Aerosol Sci. 2003, 34, 859–868. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Zou, Y.; Cao, Y.; Ren, X.; Li, Y. Evaporation and Movement of Fine Water Droplets Influenced by Initial Diameter and Relative Humidity. Aerosol Air Qual. Res. 2015, 16, 301–313. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Zhao, B. Emission Rates of Multiple Air Pollutants Generated from Chinese Residential Cooking. Environ. Sci. Technol. 2018, 52, 1081–1087. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zheng, X.; Stevanovic, S.; Wu, X.; Xiang, Z.; Yu, M.; Liu, J. Characterization Particulate Matter from Several Chinese Cooking Dishes and Implications in Health Effects. J. Environ. Sci. 2018, 72, 98–106. [Google Scholar] [CrossRef]

| Food | Food Weight (g) | Water (L) | Heating Power (W) | Heating Time (min) | Relative Humidity (%) | Ventilation |

|---|---|---|---|---|---|---|

| Control group | - | 1.5 | 2100 | 14 | 20 | Off |

| Noodle/Potato/Tofu/Fish/Meatball Pork | 320 | 1.5 | 2100 | 14 | 20 | Off |

| Corn oil | 50 mL | - | 800 | 4 | 20 | Off |

| Particle Size (μm) | Food | Mean Concentration ± SD (Part/cm3) | Significant Differences (p < 0.05) | Peak Concentration (Part/cm3) | Significant Differences (p < 0.05) |

|---|---|---|---|---|---|

| 0.3 | Control group | 19,666 ± 4623.6 | — | 28,248 | — |

| Noodle | 19,748 ± 4624.1 | — | 28,366 | — | |

| Potato | 19,458 ± 4574.7 | — | 27,949 | — | |

| Tofu | 19,678 ± 4645.0 | — | 28,265 | — | |

| Fish | 19,757 ± 4626.5 | — | 28,379 | — | |

| Meatball | 19,814 ± 4658.5 | — | 28,461 | — | |

| Pork | 19,589 ± 4605.6 | — | 28,138 | — | |

| 0.3–0.5 | Control group | 9237 ± 6416.1 | — | 21,995 | — |

| Noodle | 9129 ± 6248.6 | — | 21,737 | — | |

| Potato | 8922 ± 6196.8 | — | 21,244 | — | |

| Tofu | 9202 ± 6343.0 | — | 21,912 | — | |

| Fish | 9132 ± 6391.7 | — | 21,745 | — | |

| Meatball | 8922 ± 6229.1 | — | 21,244 | — | |

| Pork | 8893 ± 6176.9 | — | 21,175 | — | |

| 0.5–1.0 | Control group | 73,346 ± 69,685.7 | — | 198,546 | — |

| Noodle | 72,481 ± 70,426.5 | — | 196,203 | — | |

| Potato | 74,078 ± 70,381.3 | — | 200,528 | — | |

| Tofu | 72,481 ± 68,863.5 | — | 196,203 | — | |

| Fish | 72,481 ± 68,867.5 | — | 196,203 | — | |

| Meatball | 79,137 ± 75,187.2 | — | 214,220 | — | |

| Pork | 69,897 ± 65,638.7 | — | 187,015 | — |

| PM0.3 | PM0.3–0.5 | PM0.5–1.0 | ||

|---|---|---|---|---|

| Number concentration (part/cm3) | Control group | 3329.4 ± 1787.1 | 15,394.7 ± 1425.5 | 132,740.4 ± 6755.3 |

| Noodle | 2874.0 ± 1182.4 | 15,214.1 ± 1408.9 | 131,174.3 ± 6676.0 | |

| Potato | 2831.8 ± 1164.9 | 14,868.6 ± 1376.8 | 134,065.5 ± 6823.0 | |

| Fish | 2863.8 ± 1178.2 | 15,336.4 ± 1420.2 | 131,174.3 ± 6675.3 | |

| Doufu | 2875.3 ± 1182.8 | 15,219.3 ± 1409.4 | 131,174.3 ± 6675.9 | |

| Meatball | 2883.7 ± 1186.3 | 14,868.6 ± 1376.8 | 143,220.2 ± 7288.9 | |

| Pork | 2851.1 ± 1172.8 | 14,820.8 ± 1372.4 | 125,031.4 ± 6363.1 | |

| Size distribution (%) | Control group | 14.62 ± 2.37 | 2.27 ± 0.58 | 12.35 ± 2.03 |

| Noodle | 14.79 ± 2.39 | 2.28 ± 0.58 | 12.51 ± 2.04 | |

| Potato | 14.44 ± 2.35 | 2.17 ± 0.56 | 12.28 ± 2.02 | |

| Fish | 14.74 ± 2.38 | 2.29 ± 0.58 | 12.45 ± 2.04 | |

| Doufu | 14.78 ± 2.39 | 2.29 ± 0.58 | 12.50 ± 2.04 | |

| Meatball | 14.00 ± 2.30 | 2.01 ± 0.52 | 11.99 ± 2.00 | |

| Pork | 15.19 ± 2.42 | 2.36 ± 0.59 | 12.83 ± 2.07 | |

| Arithmetic mean diameter (µm) | Control group | 0.0910 ± 0.0148 | ||

| Noodle | 0.0921 ± 0.0149 | |||

| Potato | 0.0903 ± 0.0148 | |||

| Fish | 0.0917 ± 0.0149 | |||

| Doufu | 0.0921 ± 0.0149 | |||

| Meatball | 0.0880 ± 0.0145 | |||

| Pork | 0.0945 ± 0.0151 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Wang, M.; Tao, P.; Qiu, G.; Lu, X. Emission Characteristics of Particulate Matter from Boiling Food. Atmosphere 2023, 14, 167. https://doi.org/10.3390/atmos14010167

Zhao Y, Wang M, Tao P, Qiu G, Lu X. Emission Characteristics of Particulate Matter from Boiling Food. Atmosphere. 2023; 14(1):167. https://doi.org/10.3390/atmos14010167

Chicago/Turabian StyleZhao, Yujiao, Mengyao Wang, Pengfei Tao, Guozhi Qiu, and Xueying Lu. 2023. "Emission Characteristics of Particulate Matter from Boiling Food" Atmosphere 14, no. 1: 167. https://doi.org/10.3390/atmos14010167