Suggestions on the Development of Environmental Monitoring Technology of CO2 Geological Storage and Leakage under the Background of China’s “Double-Carbon” Strategy

Abstract

1. Introduction

2. Types and Mechanisms of CO2 Geological Storage

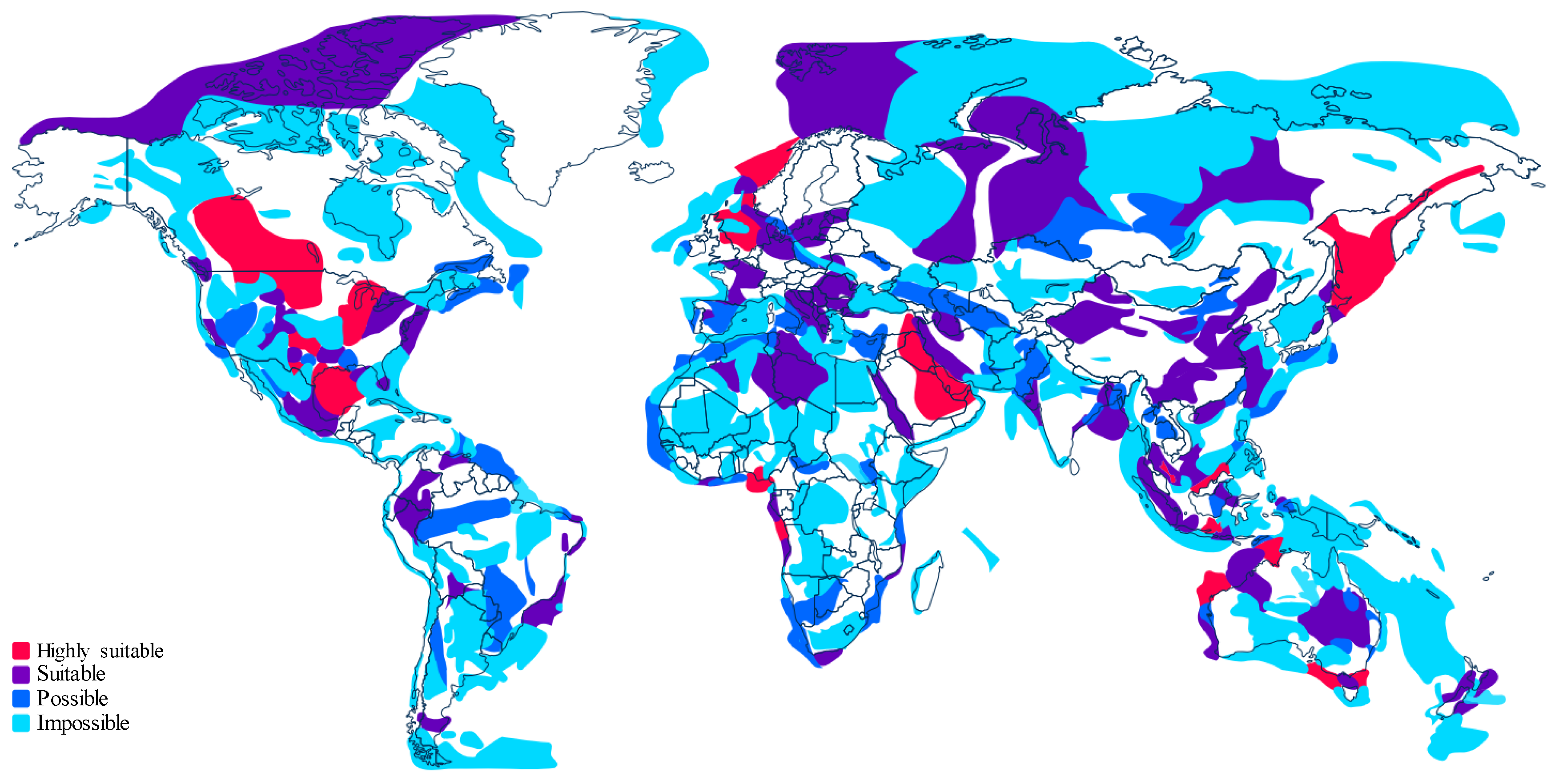

2.1. Types of CO2 Geological Storage

2.1.1. Storage in Depleted Oil and Gas Reservoirs

2.1.2. Storage in Deep Saline Aquifers

2.1.3. Storage in Deep Unmanageable Coal Seams

2.2. Geological Storage Mechanisms of CO2

2.2.1. Physical Storage Mechanism

- (1)

- Structural geological storage

- (2)

- Binding storage

- (3)

- Hydrodynamic storage

2.2.2. Chemical Storage Mechanism

- (1)

- Dissolution storage

- (2)

- Mineralization storage

2.2.3. Adsorption Mechanism

3. Paths and Risks of CO2 Storage Leakage

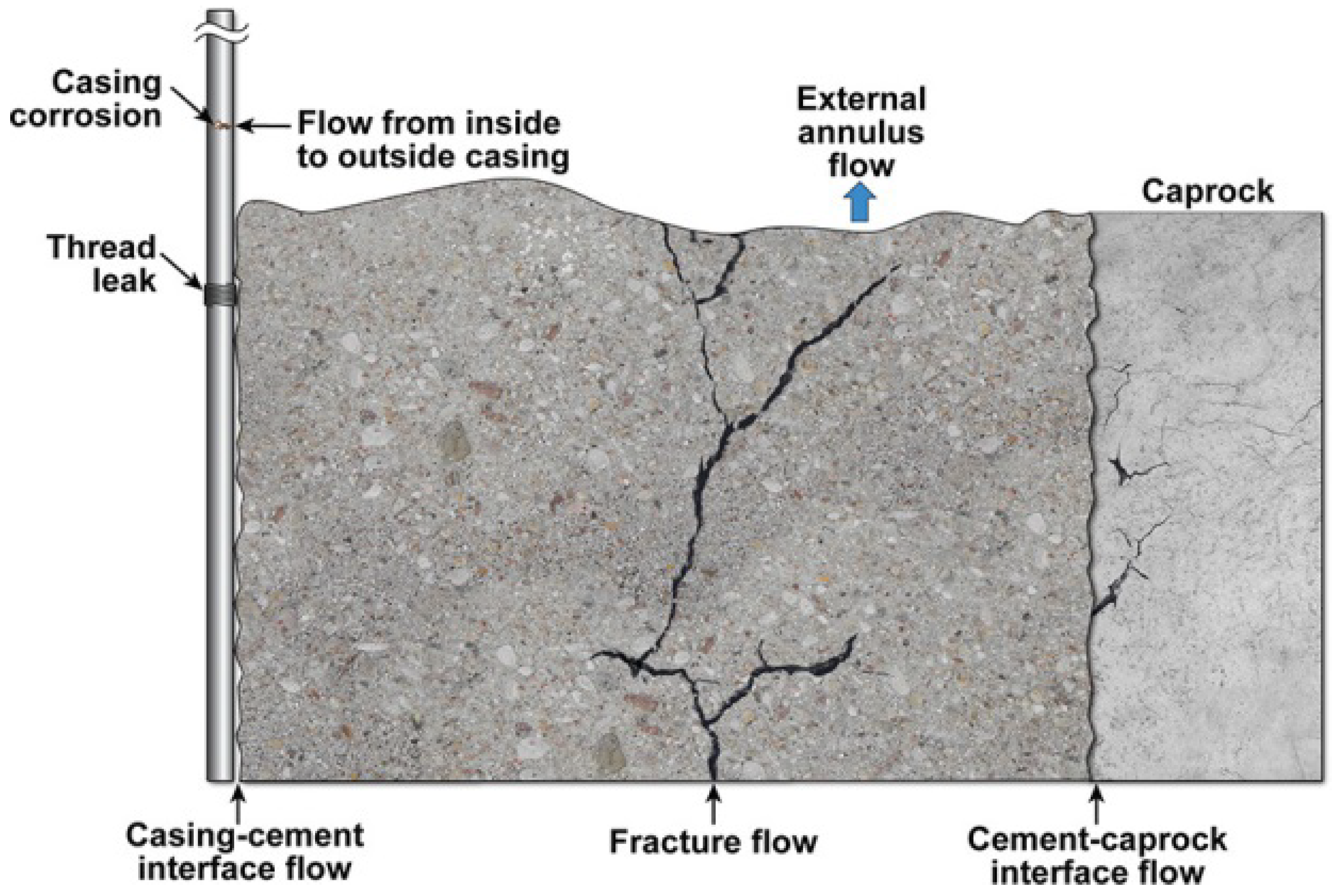

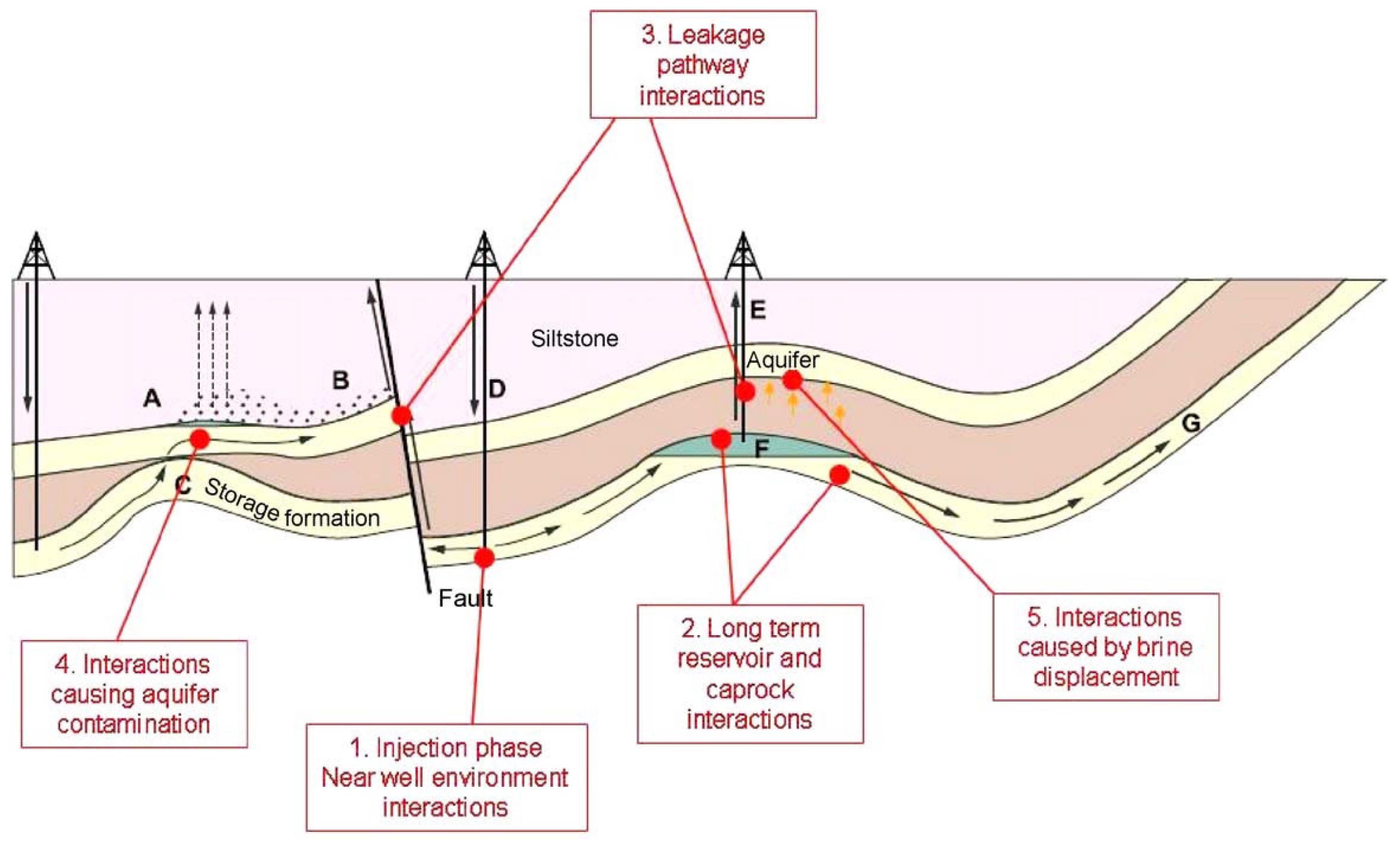

3.1. Paths of CO2 Storage Leakage

3.1.1. Impact on Underground Water

3.1.2. Impact on Soil

3.1.3. Impact on the Surface Atmosphere

4. Environmental Monitoring Technology of CO2 Geological Storage and Leakage

4.1. Underground Water Monitoring

4.2. Soil Monitoring

4.3. Atmospheric Monitoring

5. Technical Development Suggestions

5.1. Current Situation of CCUS Technology in China

5.2. Development Suggestions

5.2.1. Strengthening the Research on CO2 Storage Mechanism and Main Control Factors

5.2.2. Improving the Risk Assessment Method of CO2 Storage

5.2.3. Building a Monitoring Technology System for the Whole Life Cycle of CO2 Storage

5.2.4. Standardizing CO2 Storage and Leakage Risk Response System

6. Conclusions

- (1)

- The geological storage types of CO2 mainly include depleted oil and gas reservoirs, deep saline aquifers and deep unmanageable coal seams, and the main storage mechanisms include physical storage mechanisms, chemical storage mechanisms and adsorption mechanisms, such as structural geological storage, binding storage, hydrodynamic storage, dissolution and storage and so on.

- (2)

- There are three leakage ways in CO2 storage: along the wellbore system, fault/fracture system and caprock system. Once CO2 leaks, it has a certain impact on underground water, soil and atmosphere.

- (3)

- The monitoring of groundwater, soil and atmosphere is the core of the environmental monitoring technology of CO2 geological storage and leakage.

- (4)

- The safe and efficient geological storage of CO2 is the key to achieve the “double carbon” goal in China. In the future, China can promote the progress of CO2 geological storage monitoring technology and help achieve the goal of “double carbon” by strengthening the research on CO2 storage mechanism and main control factors, perfecting the risk assessment method for CO2 storage, constructing the monitoring technology system for the CO2 storage life cycle, and standardizing the CO2 storage risk response system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.F.; Guo, J.F.; Gao, S.J.; Chen, Y. Analysis on the path to achieve the goal of carbon neutrality by 2060 in China. Dev. Res. 2021, 38, 37–47. [Google Scholar]

- International Energy Agency. World Energy Outlook; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Guloren Turan; Alex Zapantis; David Kearns; Eve Tamme; Christina Staib; Tony Zhang; Jamie Burrows; Augus Gillespie; Ian Havercroft; Dominic Rassool; et al. In Global status of CCS 2021; Global CCSInstitute: Victoria, Australia, 2021.

- Brad Page; Guloren Turan; Alex Zapantis; Jamie Burrows; Chris Consoli; Jeff Erikson; Ian Havercroft; David Kearns; Harry Liu; Dominic Rassool; et al. In Global status of CCS 2020; Global CCSInstitute: Victoria, Australia, 2020.

- Dixon, T.; Romanak, K.D. Improving monitoring protocols for CO2 geological storage with technical advances in CO2 attribution monitoring. Int. J. Greenh. Gas Control. 2015, 41, 29–40. [Google Scholar] [CrossRef]

- Zahid, U.; Lim, Y.; Jung, J.; Han, C. CO2 geological storage: A review on present and future prospects. Korean J. Chem. Eng. 2011, 28, 674–685. [Google Scholar] [CrossRef]

- Sun, T.M.; Liu, S.Q.; Wang, T. Research advances on evaluation of CO2 geological storage potential in China. Coal Sci. Technol. 2021, 49, 10–20. [Google Scholar]

- Zheng, Y.X.; Liu, J.J.; Zhang, B.H. The Influence of Geological Storage of Carbon Dioxide on Deformation of Ground Surface in Depleted Reservoirs. J. Hebei Geo Univ. 2019, 42, 1–6. [Google Scholar]

- Liu, Y.F.; Li, X.C.; Fang, Z.M.; Bai, B. Preliminary estimation of CO2 storage capacity in gas fields in China. Rock Soil Mech. 2006, 27, 2277–2281. [Google Scholar]

- Zhang, S.Q.; Guo, J.Q.; Diao, Y.J.; Zhang, H.; Jia, X.F.; Zhang, Y. Technical method for selection of CO2 geological storage project sites in deep saline aquifers. Geol. China 2011, 38, 1640–1651. [Google Scholar]

- Cao, M.L.; Chen, J.P. The site selection geological evaluation of the CO2 storage of the deep saline aquifer. Acta Geol. Sin. 2022, 96, 15. [Google Scholar]

- Cai, B.F.; Li, Q.; Zhang, X.; Cao, C.; Cao, L.B.; Chen, W.H.; Chen, Z.J.; Dong, J.C.; Fan, J.L.; Jiang, Y.; et al. Annual Report of China’s Carbon Dioxide Capture, Utilization and Storage (CCUS) (2021)-Research on CCUS Path in China; Environmental Planning Institute: Beijing, China; Ministry of Ecology: Beijing, China; Wuhan Institute of Geotechnical Mechanics: Wuhan, China; Chinese Academy of Sciences: Beijing, China; China Agenda 21 Management Center: Beijing, China, 2021; Available online: W020210726513427451694.pdf(caep.org.cn) (accessed on 20 November 2022).

- Liu, Y. Research on Influencing Factors of CO2 Displacement of Coal SeamCH4 and Analysis of Field Application; Xi’an University of Science and Technology: Xi’an, China, 2021. [Google Scholar]

- Li, X.; Wei, N.; Liu, Y.; Fang, Z.; Dahowski, R.T.; Davidson, C.L. CO2 point emission and geological storage capacity in China. Energy Procedia 2009, 1, 2793–2800. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. IPCC Special Report on Carbon dioxide Capture and Storage; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018.

- Dong, C. Testing Method Study on Relative Permeability of CO2 Flooding; Northeast Petroleum University: Daqing, China, 2011. [Google Scholar]

- Yu, L. Exploration Research on Technology of Physical Simulation of Carbon Dioxide Geological Storage in Deep Saline Aquifer; Beijing Jiaotong University: Beijing, China, 2010. [Google Scholar]

- Calabrese, M.; Masserano, F. Simulation of Physical-Chemical Processes During Carbon Dioxide Storage in Geological Structures; Society of Petroleum Engineers: Richardson, TX, USA, 2005. [Google Scholar]

- Meng, Q.L. A Numerical Study of Supercritical Carbon Dioxide Migration in Porous Media under Conditions of Saline Aquifers; University of Science and Technology of China: Hefei, China, 2014. [Google Scholar]

- Spiteri, E.; Juanes, R.; Blunt, M.J.; Orr, F.M. Relative-Permeability Hysteresis: Trapping Models and Application to Geological CO2 Storage. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Duan, Z.; Sun, R. An improved model calculating CO2 solubility in pure water and aqueous NaCl solutions from 273 to 533 K and from 0 to 2000 bar. Chem. Geol. 2003, 193, 257–271. [Google Scholar] [CrossRef]

- Nghiem, L.X.; Yang, C.; Shrivastava, V.K.; Kohse, B.F.; Hassam, M.S.; Chen, D.; Card, C. Risk mitigation through the optimization of residual gas and solubility trapping for CO2 storage in saline aquifers. Energy Procedia 2009, 1, 3015–3022. [Google Scholar] [CrossRef]

- Kuo, C.W.; Benson, S.M. Numerical and analytical study of effects of small scale heterogeneity on CO2/brine multiphase flow system in horizontal core floods. Adv. Water Resour. 2015, 79, 1–17. [Google Scholar] [CrossRef]

- Kharaka, Y.K.; Thordsen, J.J.; Hovorka, S.D.; Nance, H.S.; Cole, D.R.; Phelps, T.J.; Knauss, K.G. Potential environmental issues of CO2 storage in deep saline aquifers: Geochemical results from the Frio-I Brine Pilot test, Texas, USA. Appl. Geochem. 2009, 24, 1106–1112. [Google Scholar] [CrossRef]

- Zhang, H.T.; Wen, D.G.; Li, Y.L.; Zhang, J.; Lu, J. Conditions for CO2 geological storage in China and some suggestions. Geol. Bull. China 2005, 24, 1107–1110. [Google Scholar]

- Sorai, M.; Lei, X.; Nishi, Y.; Ishido, T.; Nakao, S. CO2 geological storage. In Handbook of Climate Change Mitigation and Adaptation; Springer International Publishing: Cham, Switzerland, 2022; pp. 1531–1584. [Google Scholar]

- Bai, Y.Y.; Shi, Y.Y.; Lu, M.J.; Liang, Y. Research Progress of CO2 Geological Storage Leakage Path and Monitoring Method under Dual Carbon Targets. J. Yulin Univ. 2021, 31, 43–46. [Google Scholar]

- He, K. Research on Integrity Evolution and Leakage of CO2 Geological Storage System; Northeast Petroleum University: Daqing, China, 2019. [Google Scholar]

- Li, B.; Guo, B.; Li, H.; Shi, Y. An analytical solution to simulate the effect of cement/formation stiffness on well integrity evaluation in carbon storage projects. J. Nat. Gas Sci. Eng. 2015, 27, 1092–1099. [Google Scholar] [CrossRef]

- Zheng, F.; Shi, X.Q.; Wu, J.C.; Zhao, L. Global Sensitivity Analysis of Leakage Risk for CO2Geological Storage in the Saline Aquifer of Yancheng Formation in Subei Basin. Geol. J. China Univ. 2012, 18, 232–238. [Google Scholar]

- Li, Z.P.; Pu, L.X. Geological Safety Margins During CO2 Flooding and Sealing. Spec. Oil GAs Reserv. 2017, 24, 4. [Google Scholar]

- Carroll, S.A.; Iyer, J.; Walsh, S.D.C. Influence of Chemical, Mechanical, and Transport Processes on Wellbore Leakage from Geologic CO2 Storage Reservoirs. Acc. Chem. Res. 2017, 50, 1829–1837. [Google Scholar] [CrossRef]

- Gao, Y. Biogas Losses in Its Accumulation in the Bohaiwan Basin; China University of Petroleum: Beijing, China, 2011. [Google Scholar]

- Gaus, I. Role and impact of CO2–rock interactions during CO2 storage in sedimentary rocks. Int. J. Greenh. Gas Control. 2010, 4, 73–89. [Google Scholar] [CrossRef]

- Wu, J.L.; Ma, J.J. A Discussion about Potential Risks of Geological Storage of CO2. Environ. Sci. Surv. 2012, 31, 89–93. [Google Scholar]

- Hovorka, S.D.; Knox, P.R. Frio brine storage pilot in the Texas Gulf Coast. In Proceedings of the Greenhouse Gas Control Technologies-6th International Conference, Kyoto, Japan, 1–4 October 2002; Pergamon: Oxford, UK, 2003; pp. 583–587. [Google Scholar]

- Ma, J.; Zhu, X.; Liu, D.; Wang, S.; Xue, L.; Li, Q.; Ma, J.; Li, X.; Nie, L.; Zhao, X.; et al. Effects of Simulation Leakage of CCS on Physical-chemical Properties of Soil. Energy Procedia 2014, 63, 3215–3219. [Google Scholar] [CrossRef]

- Zhang, B.H.; Zhang, Q.; Geng, C.X.; Jing, J.J. Influence on Physical and Chemical Properties of Soil for the Leakage of Carbon Dioxide during Geological Storage. Guangdong Chem. Ind. 2016, 43, 3–4. [Google Scholar]

- Ren, S.R.; Li, D.X.; Zhang, L.; Huang, H. Leakage pathways and risk analysis of carbon dioxide in geological storage. Acta Pet. Sin. 2014, 35, 591–601. [Google Scholar]

- Cai, B.F. Geological storage of carbon dioxide and its environmental monitoring. Environ. Econ. 2012, 8, 44–49. [Google Scholar]

- Wang, X.Q.; Ma, D.L.; Xia, F.S.; Zhang, X.M.; Wang, Y.; Mao, W.G. Research Progress on Leakage Monitoring Technology for CO2 Storage. Saf. Environ. Eng. 2020, 27, 12. [Google Scholar]

- Wang, H.; Lin, Q.G.; Guo, J.H.; Tang, S.C.; Wang, W.B.; Liang, X.; Li, S.; Duan, X.Y. Development of a groundwater monitoring system for CO2 leakage of co2-eor storage in loess tableland region. Environ. Eng. 2021, 39, 217–226. [Google Scholar]

- Meckel, T.A.; Hovorka, S.D.; Kalyanaraman, N. Continuous pressure monitoring for large volume CO2 injections. In Proceedings of the 9th International Conference on Greenhouse Gas Control Technologies (GHGT-9), Washington, DC, USA, 16–20 November 2008; Gulf Coast Carbon Center: Fort Myers, FL, USA, 2008. [Google Scholar]

- Bryant, I.D.; Chen, M.Y.; Raghuraman, B.; Raw, I.; Delhomme, J.P.; Chouzenoux, C.; Pohl, D.; Manin, Y.; Rioufol, E.; Oddie, G.; et al. Utility and Reliability of Cemented Resistivity Arrays in Monitoring Waterflood of the Mansfield Sandstone, Indiana, USA. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001. [Google Scholar]

- Yamamoto, H.; Zhang, K.; Karasaki, K.; Marui, A.; Uehara, H.; Nishikawa, N. Large-scale numerical simulation of CO2 geologic storage and its impact on regional groundwater flow: A hypothetical case study at Tokyo Bay, Japan. Energy Procedia 2007, 1, 1871–1878. [Google Scholar] [CrossRef]

- Hovorka, S.D.; Benson, S.M.; Doughty, C.; Freifeld, B.M.; Sakurai, S.; Daley, T.M.; Kharaka, Y.K.; Holtz, M.H.; Trautz, R.C.; Nance, H.S.; et al. Measuring permanence of CO2 storage in saline formations: The Frio experiment. Environ. Geosci. 2006, 13, 105–121. [Google Scholar] [CrossRef]

- Tang, S.C.; Lin, Q.G.; Wang, H.; Jiang, S.J.; Wang, W.B.; Wen, Q.Z.; Chong, S.; Zhang, Y.M.; Guo, J.H. Study on Soil Monitoring System for CO2 Leakage of CO2-EOR and Storage in Loess Tableland Region. Saf. Environ. Eng. 2020, 27, 112–118+125. [Google Scholar]

- Lewicki, J.L.; Fischer, M.L.; Hilley, G.E. Six-week time series of eddy covariance CO2 flux at Mammoth Mountain, California: Performance evaluation and role of meteorological forcing. J. Volcanol. Geotherm. Res. 2008, 171, 178–190. [Google Scholar] [CrossRef]

- Chiodini, G.; Cioni, R.; Guidi, M.; Raco, B.; Marini, L. Soil CO2 flux measurements in volcanic and geothermal areas. Appl. Geochem. 1998, 13, 543–552. [Google Scholar] [CrossRef]

- Zhou, Y.; Ji, R.P.; Hu, W.Y. Advancement and Prospect in Methods and Techniques for Soil Multi-parameter Rapid Detection of China. Soils 2019, 51, 627–634. [Google Scholar]

- Hu, G.J.; Chen, S.L.; Wang, G. Environmental Monitoring Methods for Soil in China: Situation, Problems and Suggestions. Environ. Monit. China 2018, 34, 10. [Google Scholar]

- Doughty, C.; Freifeld, B.M.; Trautz, R.C. Site characterization for CO2 geologic storage and vice versa: The Frio brine pilot, Texas, USA as a case study. Environ. Geol. 2008, 54, 1635–1656. [Google Scholar] [CrossRef]

- Yun, A.; Song, I. Pore fluid substitution effects on elastic wave propagation in Berea sandstone: Implication to seismic monitoring of CO2 geologic storage. Int. J. Greenh. Gas Control. 2022, 115, 103609. [Google Scholar] [CrossRef]

- Oldenburg, C.M.; Lewicki, J.L.; Hepple, R.P. Near-surface monitoring strategies for geologic carbon dioxide storage verification. United States. 2003. [CrossRef]

- Oskarsson, N.; Palsson, K.; Olafsson, H.; Ferreira, T. Experimental monitoring of carbon dioxide by low power IR-sensors: Soil degassing in the Furnas Volcanic Centre, Azores. J. Volcanol. Geotherm. Res. 1999, 92, 181–193. [Google Scholar] [CrossRef]

- Hu, Y.L.; Hao, M.Q.; Chen, G.L.; Sun, R.Y.; Li, S. Technologies and practice of CO2 flooding and storage in China. Pet. Explor. Dev. 2019, 46, 753–766. [Google Scholar] [CrossRef]

- Xiang, Y.; Hou, L.; Du, M.; Jia, N.H.; Lv, W.F. Research progress and development prospect of CCUS-EOR technologies in China. Pet. Geol. Recovery Effic. 2022, 29, 1–17. [Google Scholar]

- Ye, H.; Liu, Q.; Peng, B. Research progress in evaluation of carbon storage potential based on CO2 flooding technology. Clean Coal Technol. 2021, 27, 107–116. [Google Scholar]

- Nie, F.J.; Mao, H.C.; Wang, Q.; Ding, Y. CO2 flooding for enhanced oil recovery technology and field practice in Zhongyuan Oilfield. Pet. Geol. Recovery Effic. 2020, 27, 146–151. [Google Scholar]

- Li, Y. Technical advancement and prospect for CO2 flooding enhanced oil recovery in low permeability reservoirs. Pet. Geol. Recovery Effic. 2020, 27, 1–10. [Google Scholar]

- Wang, B.D.; Zhao, X.L.; Cui, Q.; Wang, Y.S.; Li, Y.L.; Ku, A. Environmental monitoring analysis of injected CO2 in saline layer for shenhua CO2 storage project. Environ. Eng. 2018, 36, 33–37. [Google Scholar]

- Wong, S.; Law, D.; Deng, X.; Robinson, J.; Kadatz, B.; Gunter, W.D.; Jianping, Y.; Sanli, F.; Zhiqiang, F. Enhanced coalbed methane and CO2 storage in anthracitic coals—Micro-pilot test at South Qinshui, Shanxi, China. Int. J. Greenh. Gas Control. 2007, 1, 215–222. [Google Scholar]

- Connell, L.D.; Pan, Z.; Shangzhi, M.; Camilleri, M.; Down, D.; Carras, J.; Wenzhong, Z.; Xiaokang, F.; Benguang, G.; Briggs, C.; et al. Description of a CO2 Enhanced Coal Bed Methane Field Trial Using a Multi-Lateral Horizontal Well. Energy Procedia 2013, 37, 6760–6768. [Google Scholar] [CrossRef]

- Zhou, F.; Hou, W.; Allinson, G.; Wu, J.; Wang, J.; Cinar, Y. A feasibility study of ECBM recovery and CO2 storage for a producing CBM field in Southeast Qinshui Basin, China. Int. J. Greenh. Gas Control. 2013, 19, 26–40. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.; Shangzhi, M.; Sander, R.; Camilleri, M.; Down, D.I.; Carras, J.; Lu, M.; Xiaokang, F.; Wenzhong, Z.; et al. CO2 Injectivity in a Multi-lateral Horizontal Well in a Low Permeability Coal Seam: Results from a Field Trial. Energy Procedia 2013, 37, 5834–5841. [Google Scholar] [CrossRef]

- Song, Y.; He, S.L.; Xue, H.; Qi, Z.B.; Ge, Y.B.; Liu, B.; Yu, J.Q. Environmental Management of Carbon Dioxide Capture, Geological Utilization and Storage Projects. Chin. J. Environ. Manag. 2022, 14, 28–36. [Google Scholar]

- Guo, J.L. Experimental Studies on CO2-Water-Rockinteractions under Geological CO2 Storage Conditions; China University of Geosciences: Beijing, China, 2017. [Google Scholar]

- Liu, T.; Ma, X.; Diao, Y.; Jin, X.; Fu, J.; Zhang, C. Research status of CO2 geological storage potential evaluation methods at home and abroad. Geol. Surv. China 2021, 8, 101–108. [Google Scholar]

- Raza, A.; Rezaee, R.; Gholami, R.; Bing, C.H.; Nagarajan, R.; Hamid, M.A. A screening criterion for selection of suitable CO2 storage sites. J. Nat. Gas Sci. Eng. 2016, 28, 317–327. [Google Scholar] [CrossRef]

- He, X.Q.; Tian, X.H.; Song, D.Z. Progress and expectation of CO2 storage safety in coal seams. Coal Sci. Technol. 2022, 50, 212–219. [Google Scholar]

| Coal-Bearing Region | Estimated Capacity/Mt | Coal-Bearing Region | Estimated Capacity/Mt |

|---|---|---|---|

| Ordos Basin and Hedong-Weibei | 4450 | Northern Tarim | 36 |

| Turpan-Hami Basin | 2200 | Northern Qaitam | 30 |

| Santang Lake | 990 | South Songliao | 28 |

| Eastern Junggar | 650 | Daqin-Wula Mountains | 27 |

| Qinshui Basin | 610 | Youerdusi | 26 |

| Ili Basin | 560 | Middle Qilian coal-bearing region | 25 |

| Northern Junggar | 530 | Dacheng | 25 |

| Southern Junggar | 340 | Jingyuan-Jingtai coal-bearing region | 14 |

| Sanjiang-Mulinhe | 240 | Northern Qilian coal-bearing region | 11 |

| Datong-Ningwu | 160 | Chengde | 11 |

| Yangi Basin | 120 | Dunhua-Fushun coal-bearing region | 11 |

| Huainan | 120 | Huayinshan-Yongrong | 11 |

| Liupanshui | 110 | Kunming Kaiyuan | 10 |

| Eastern Tarim | 100 | Beipiao Coal-bearing region | 8 |

| South Sichuan and North Guizhou | 79 | Jinan | 7 |

| Xuzhou-Huaibei | 78 | Fuxin-Zhangwu | 7 |

| Zhangjiakou | 72 | Yilan-Yitong | 6 |

| Western Shandong | 68 | Yanbian coal-bearing region | 5 |

| Western Henan | 56 | Baise Basin | 5 |

| Bejjing-Tangshan | 55 | Eastern Henan | 4 |

| Eastern Piedmont of Taihang Mountains | 51 | Middle Shandong | 4 |

| Xuanhua-Weixian | 44 | Lianyuan-Shaoyang | 4 |

| Zhuozi-Helan Mountains | 38 | Total storage capacity | 12,000 |

| Project | Monitoring Method | ||

|---|---|---|---|

| Before CO2 Injection | During CO2 Injection | After CO2 Injection | |

| CO2 concentration | Sampling | In situ real-time online monitoring of underwater CO2 concentration monitor | In situ real-time online monitoring of underwater CO2 concentration monitor |

| pH | Sampling | In situ real-time online monitoring of groundwater monitor | In situ real-time online monitoring of groundwater monitor |

| Electrical conductivity | Sampling | In situ real-time online monitoring of groundwater conductivity monitor | In situ real-time online monitoring of groundwater conductivity monitor |

| Temperature and pressure | In situ real-time online monitoring of groundwater by multi-parameter monitor | In situ real-time online monitoring of groundwater by multi-parameter monitor | In situ real-time on line monitoring of groundwater by multi-parameter monitor |

| HCO3− concentration | Sampling | Sampling | Sampling |

| Ca2+ and Mg2+ concentration | Sampling | Sampling | Sampling |

| Monitoring frequency | Once a month | On-line monitoring once every 15 min; Sampling twice a month. | On-line monitoring once every 15 min; Sampling twice a month. |

| Soil Environmental Index | Monitoring Methods | Applied Range |

|---|---|---|

| Soil CO2 flux | Accumulation chamber method | The accumulation chamber with an open bottom is placed in the soil, and the variation of CO2 flow through the soil is calculated based on the change rate of CO2 concentration, which can quickly and effectively determine the CO2 flow in a specific area but can only provide real-time data in a limited area. |

| Soil CO2 concentration | Non-dispersive infrared gas analysis (IRGA) | The soil CO2 concentration is monitored intermittently or continuously, which is convenient to measure and can accurately, quickly and stably reflect CO2 leakage, but it is difficult to determine CO2 leakage rate and total leakage amount. |

| Soil conductivity | (1) Electrode method (2) Sampling method: | (1) The electrode method is mainly used, and the conductivity meter is used to directly measure the soil moisture content. (2) The soil samples are measured in the laboratory, and the results are as follows. The results are more accurate, but in situ monitoring is impossible. |

| Soil moisture content | (1) Positioning method (2) Remote sensing method | (1) It mainly includes the capacitance method, time domain reflection method (TDR), frequency domain reflection method (FDR), etc. It has high precision and can be used for in situ measurement, but the cost is high; (2) The remote sensing method has good penetrability and is suitable for large-scale monitoring, but it is greatly affected by surface parameters and has high cost. |

| Soil pH value | Main electrode method | This method is used to determine the hydrogen ion concentration in the sample by pH meter. In addition, the utilized methods are the mixed indicator colorimetry, pH test paper method, visible light spectrum extraction method, sensor monitoring method, etc. |

| Soil organic carbon content | Infrared method, titration method, spectrophotometry and other methods. | The collected soil gas was measured in the laboratory by non-dispersive methods. |

| No. | Project | Running State | Startup Year | Emission Source | Capture Technique | Transport Method | Storage and Utilization Mode | Production Capacity (10,000 Tons/Year) |

|---|---|---|---|---|---|---|---|---|

| 1 | CO2-EOR Project of Zhongyuan Oilfield, Sinopec | running | 2006 | ammonia tail gas from chemical fertilizer plant | before burning | tanker | EOR | 12 |

| 2 | CO2-EOR Project of Jilin Oilfield, PetroChina | running | 2007 | natural gas purification | before burning | tube | EOR | 35~60 |

| 3 | CCUS Project of Shengli Oilfield, Sinopec | running | 2010 | coal-fired power station | after burning | tanker | EOR | 4 |

| 4 | CO2-ECBM Project of China United Coalbed Methane Co., Ltd. | running | 2010 | purchased gas | - | tanker | ECBM | 0.1~0.2 |

| 5 | CCS Demonstration Project of China Shenhua Energy Co., Ltd. | completed | 2012 | coal to oil | before burning | tanker | saline aquifer storage | 10 |

| 6 | CO2 capture and CO2-EOR Demonstration Project of Yanchang Petroleum | running | 2013 | coal chemical industry | before burning | tanker | EOR | 5 |

| 7 | EOR Project of Daqing oil field, PetroChina | running | 2014 | natural gas purification | before burning | tanker + tube | EOR | 20 |

| 8 | CCUS Demonstration Project of GreenGen.Co., Huaneng Group | building | 2015 | coal-fired power station | before burning | tanker | EOR and saline aquifer storage | 10 |

| 9 | CCUS-EOR Project of Karamay Dunhua Petroleum | running | 2017 | methanol plant | before burning | tanker | EOR | 10 |

| 10 | EOR Project of Changqing Oilfield, PetroChina | running | 2017 | methanol plant | after burning | tanker | EOR | 5~10 |

| 11 | Full-process CCS Demonstration Project of Guohua Electrical Power Corporation | building | 2019 | coal-fired power station | after burning | - | - | 15 |

| 12 | Carbon Capture and Comprehensive Utilization Project of Guoneng Taizhou Company | building | 2020 | coal-fired power station | - | - | EOR | 50 |

| 13 | Offshore CCUS Project in South China Sea of Cnooc | running | 2021 | natural gas purification | - | - | saline aquifer in seabed | 30 |

| 14 | EOR Project of Qilu Petrochemical-Shengli Oilfield, Sinopec | running | 2021 | chemical plant | - | - | EOR | 71~100 |

| 15 | Full-process Demonstration Project of CCUS in East China Petroleum Bureau, Sinopec | building | 2021 | chemical plant | before burning | tanker + ship | EOR | 50~100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Bai, J.; Liao, S.; Cao, S.; Liu, F. Suggestions on the Development of Environmental Monitoring Technology of CO2 Geological Storage and Leakage under the Background of China’s “Double-Carbon” Strategy. Atmosphere 2023, 14, 51. https://doi.org/10.3390/atmos14010051

Cui Y, Bai J, Liao S, Cao S, Liu F. Suggestions on the Development of Environmental Monitoring Technology of CO2 Geological Storage and Leakage under the Background of China’s “Double-Carbon” Strategy. Atmosphere. 2023; 14(1):51. https://doi.org/10.3390/atmos14010051

Chicago/Turabian StyleCui, Yinan, Jiajia Bai, Songlin Liao, Shengjiang Cao, and Fangzhi Liu. 2023. "Suggestions on the Development of Environmental Monitoring Technology of CO2 Geological Storage and Leakage under the Background of China’s “Double-Carbon” Strategy" Atmosphere 14, no. 1: 51. https://doi.org/10.3390/atmos14010051

APA StyleCui, Y., Bai, J., Liao, S., Cao, S., & Liu, F. (2023). Suggestions on the Development of Environmental Monitoring Technology of CO2 Geological Storage and Leakage under the Background of China’s “Double-Carbon” Strategy. Atmosphere, 14(1), 51. https://doi.org/10.3390/atmos14010051