Stabilized Electrospun Polyacrylonitrile Fibers for Advancements in Clean Air Technology

Abstract

:1. Introduction

1.1. Electrospun Polyacrylonitrile Fibers

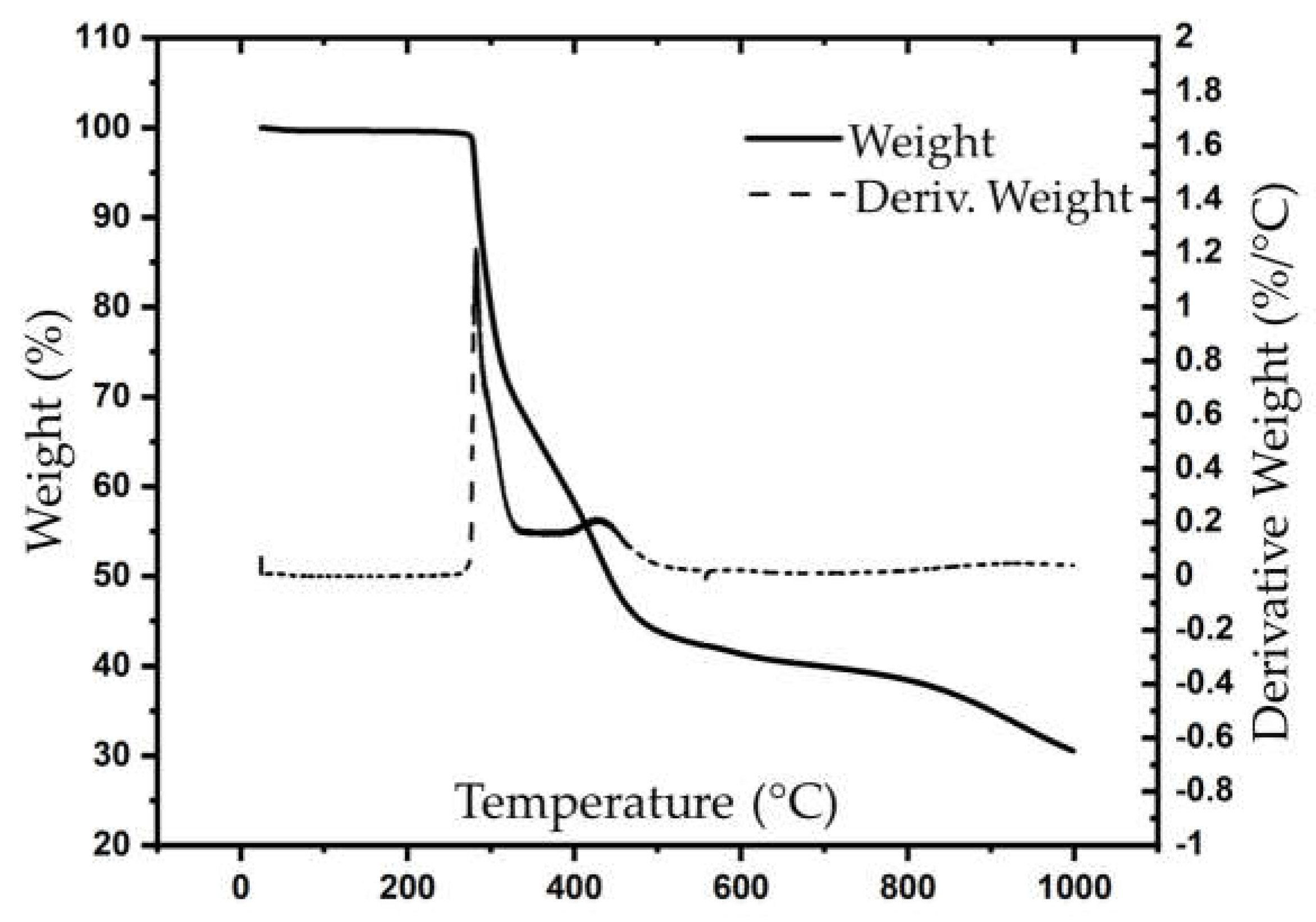

1.2. Polyacrylonitrile Stabilization

2. Materials and Methods

2.1. Solution Preparation

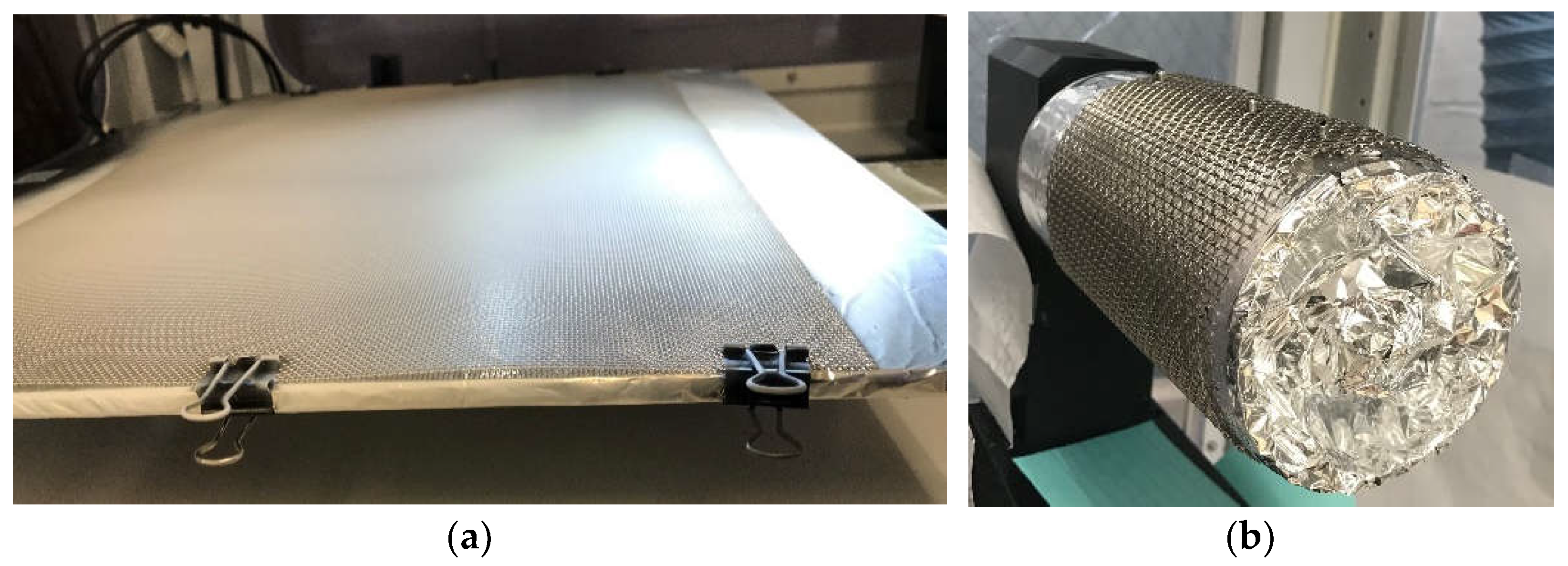

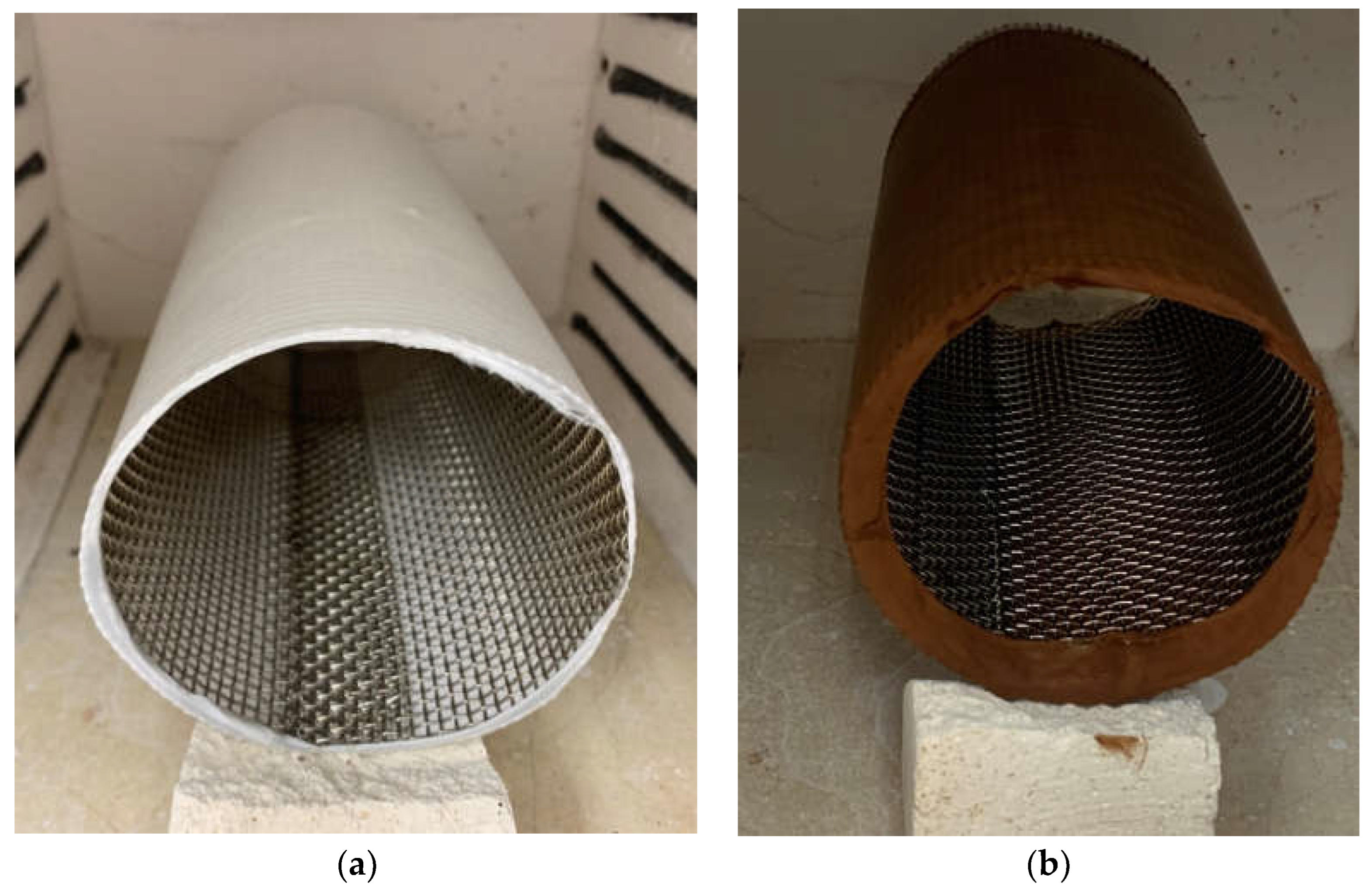

2.2. Stainless Steel Woven Wire Mesh

2.3. Electrospinning

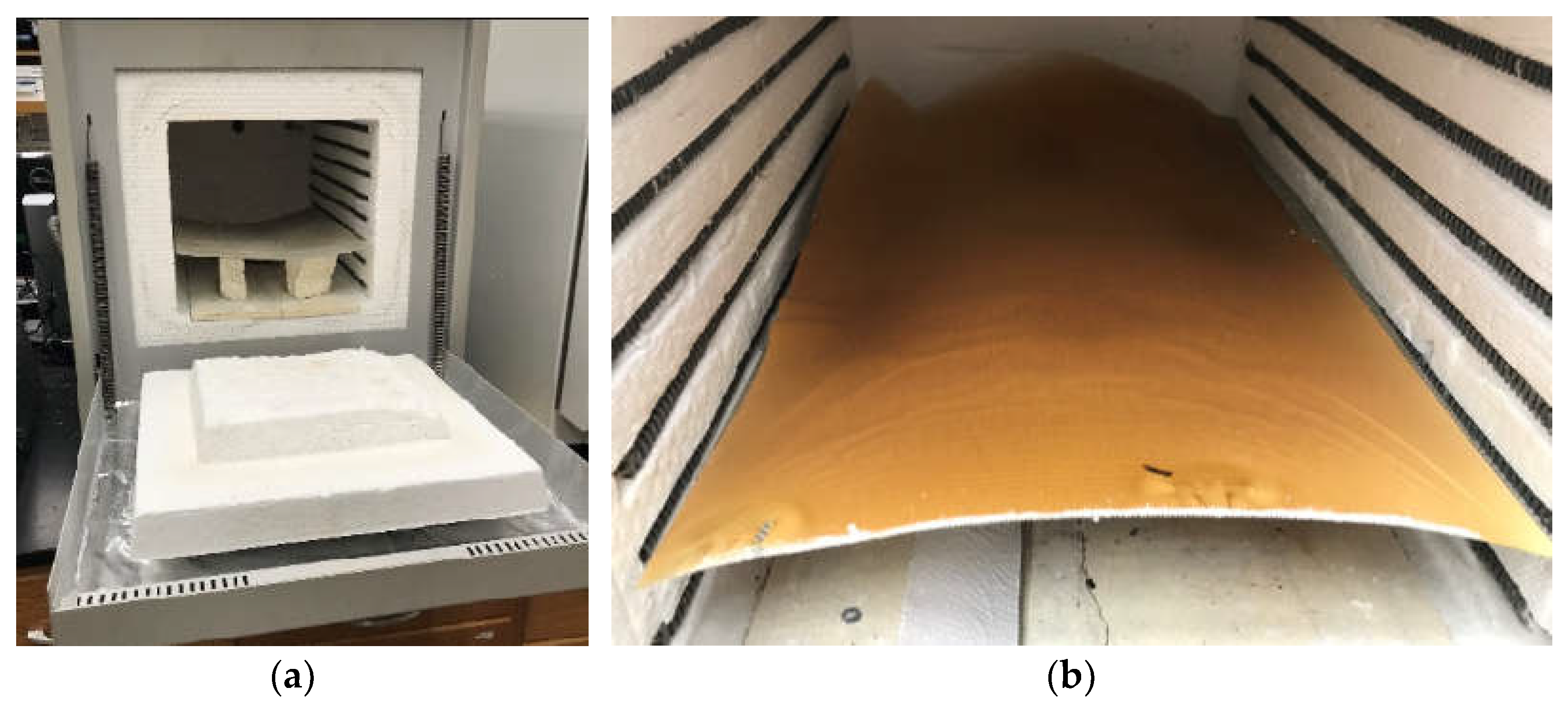

2.4. Polyacrylonitrile Stabilization

2.5. Polyacrylonitrile Nonwoven Media Characterization

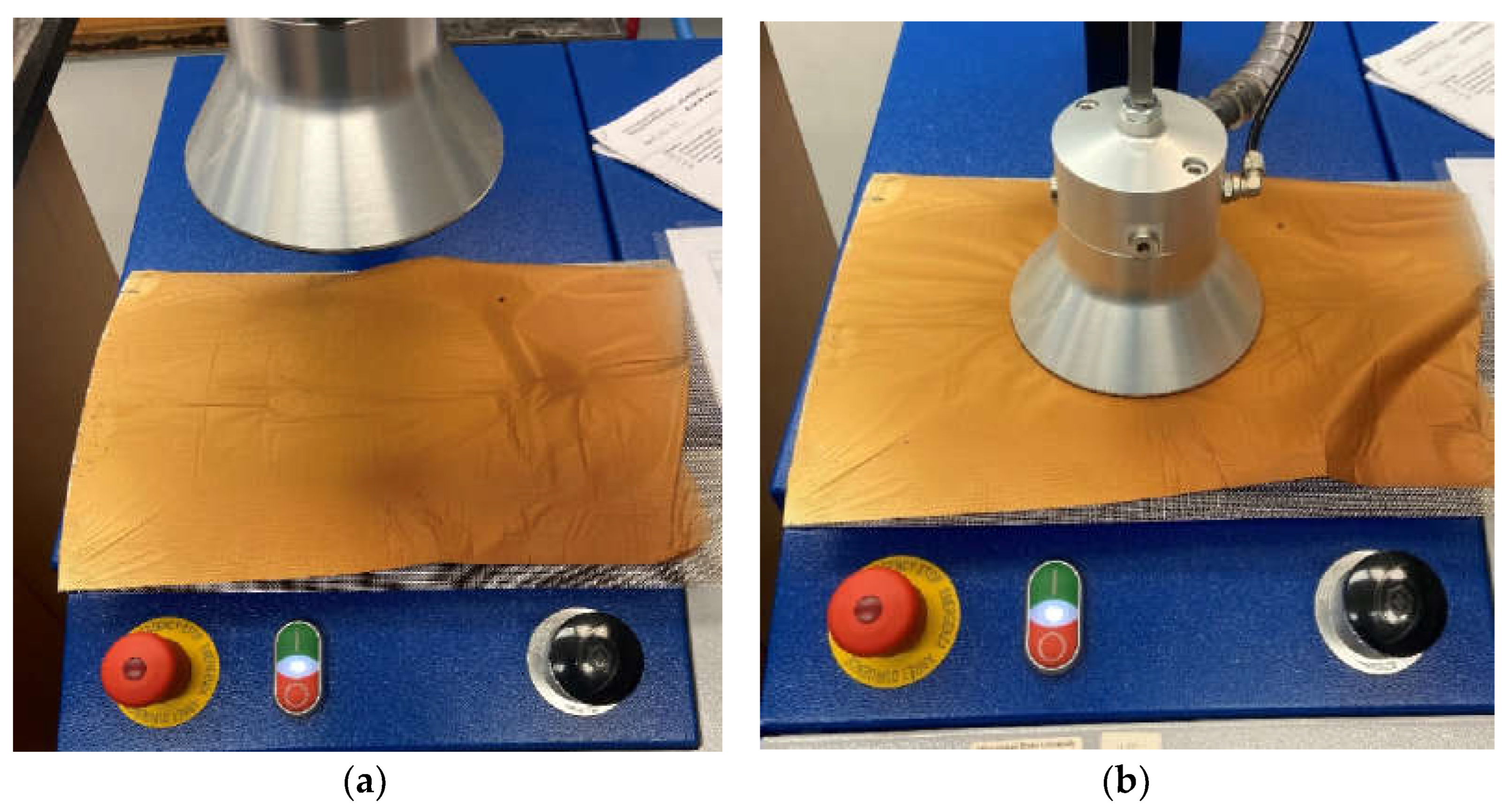

2.6. Air Filtration Testing

3. Results

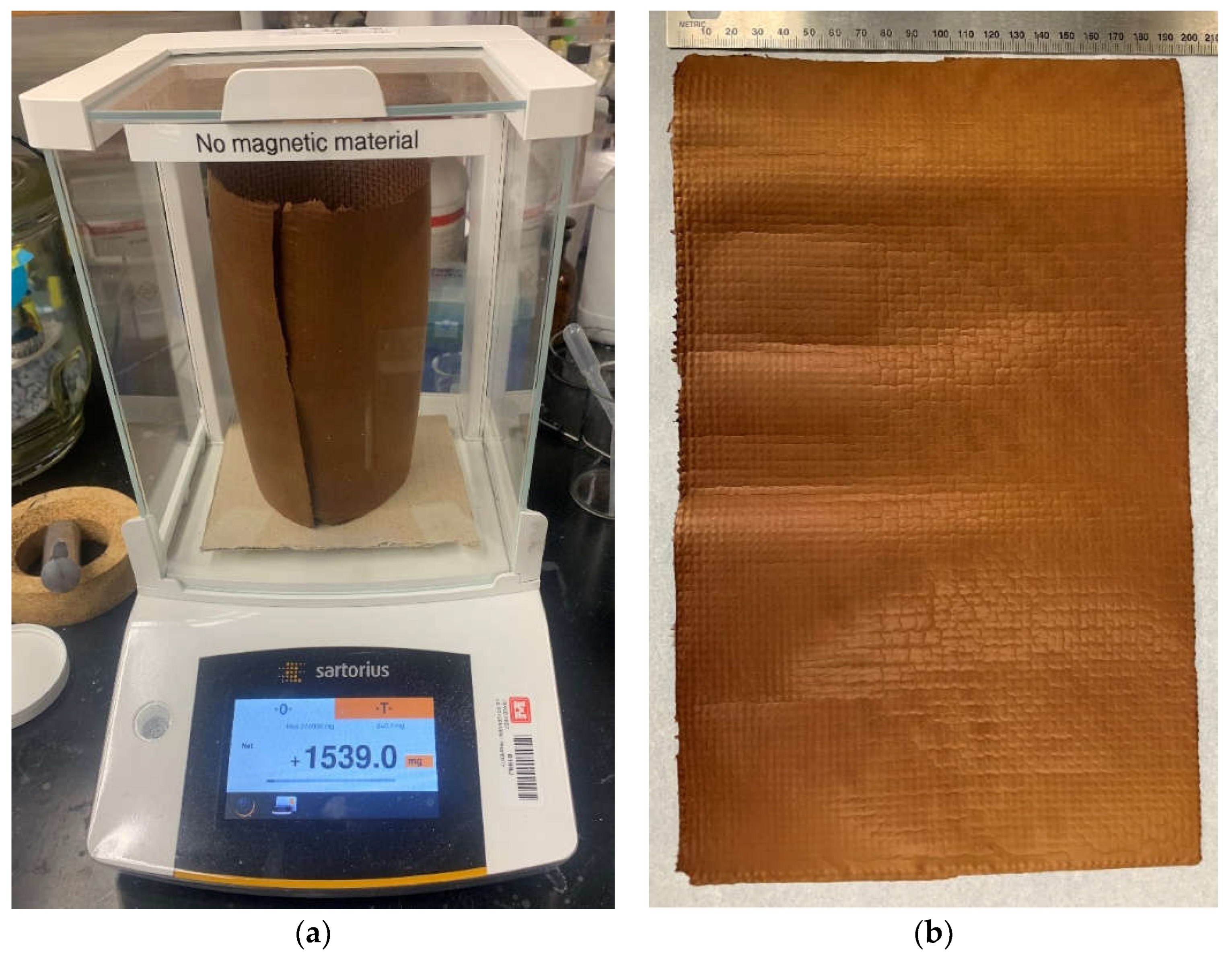

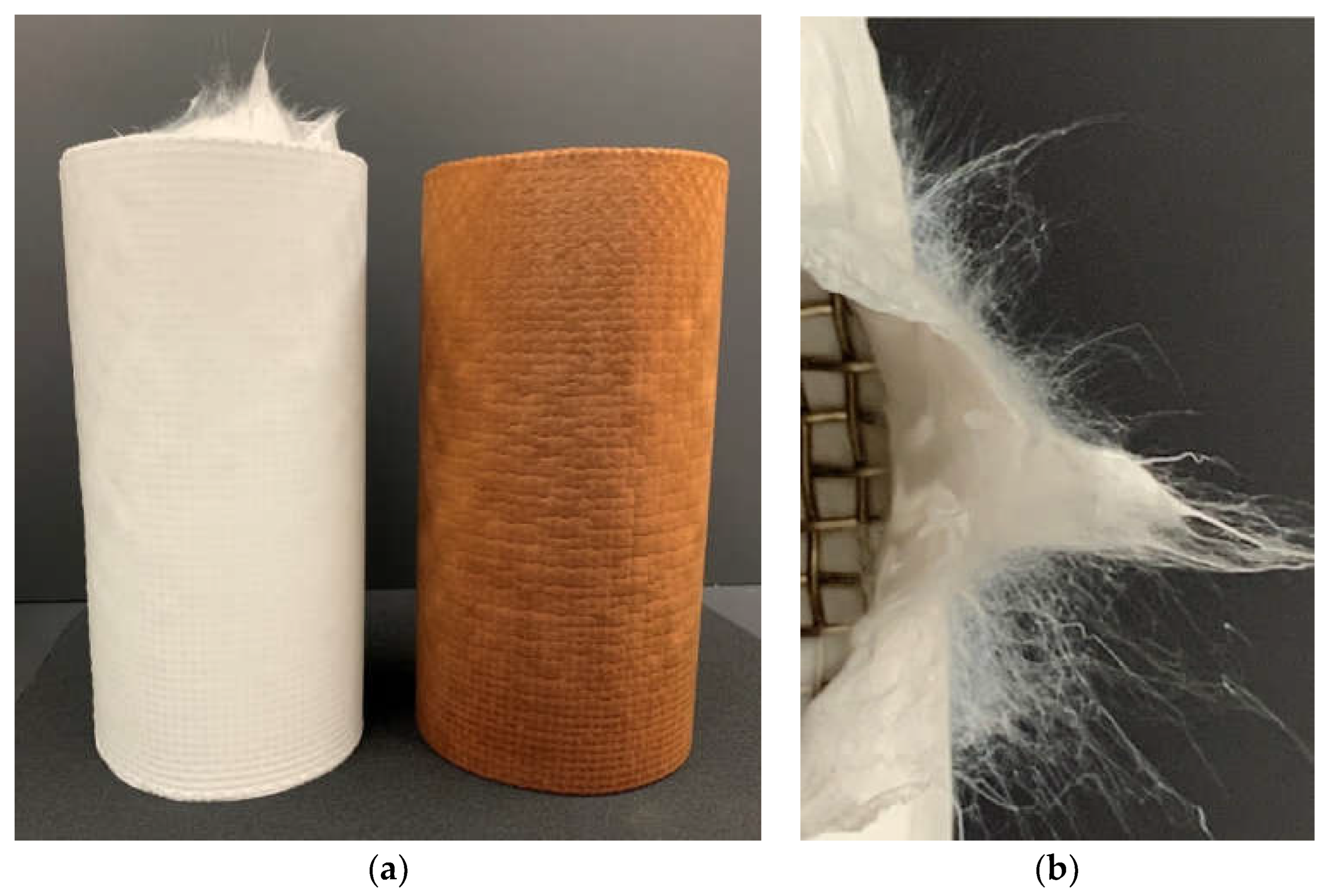

3.1. As-Spun Nonwoven Fibrous Media

3.2. Effects of Stabilization

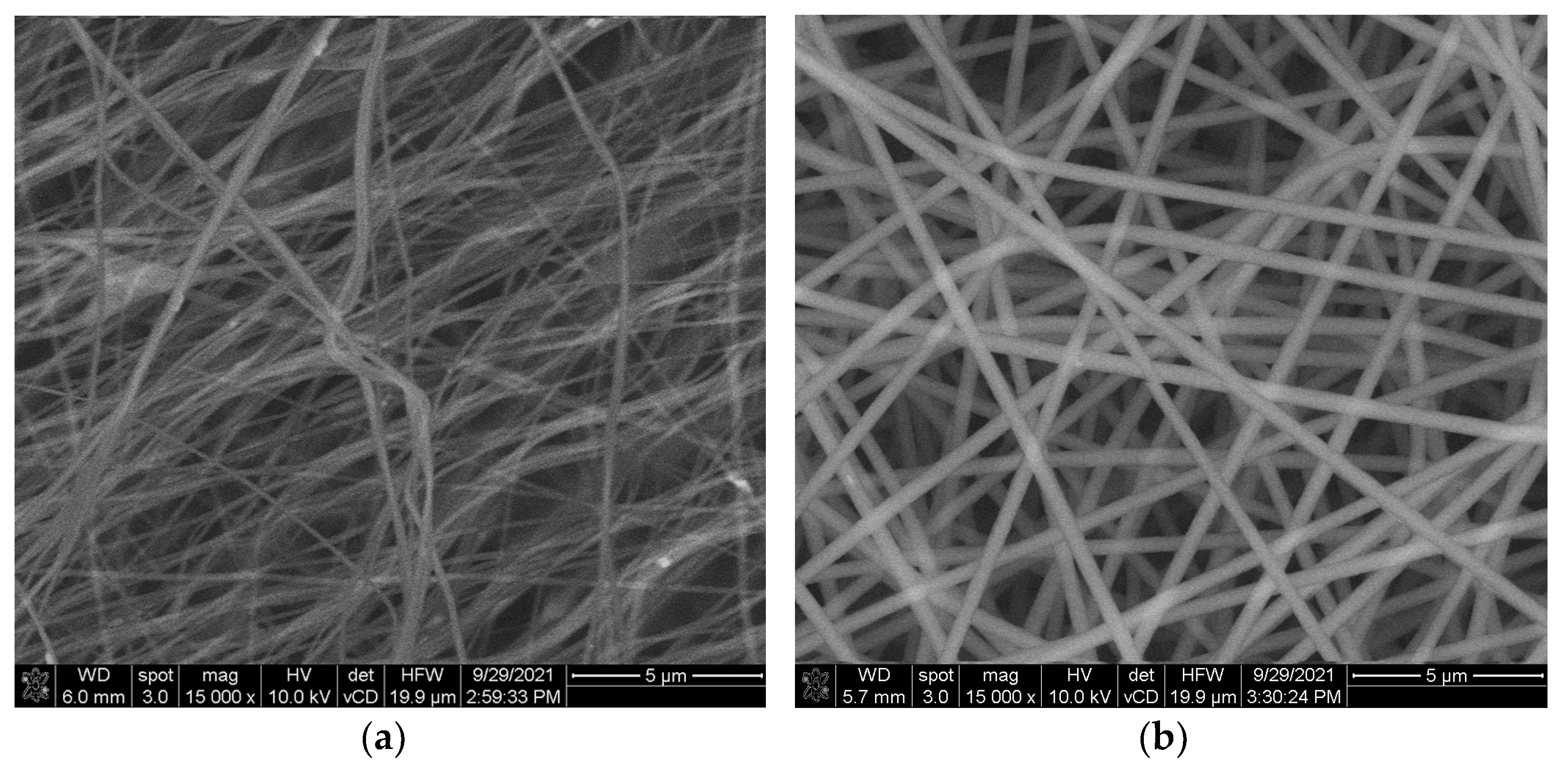

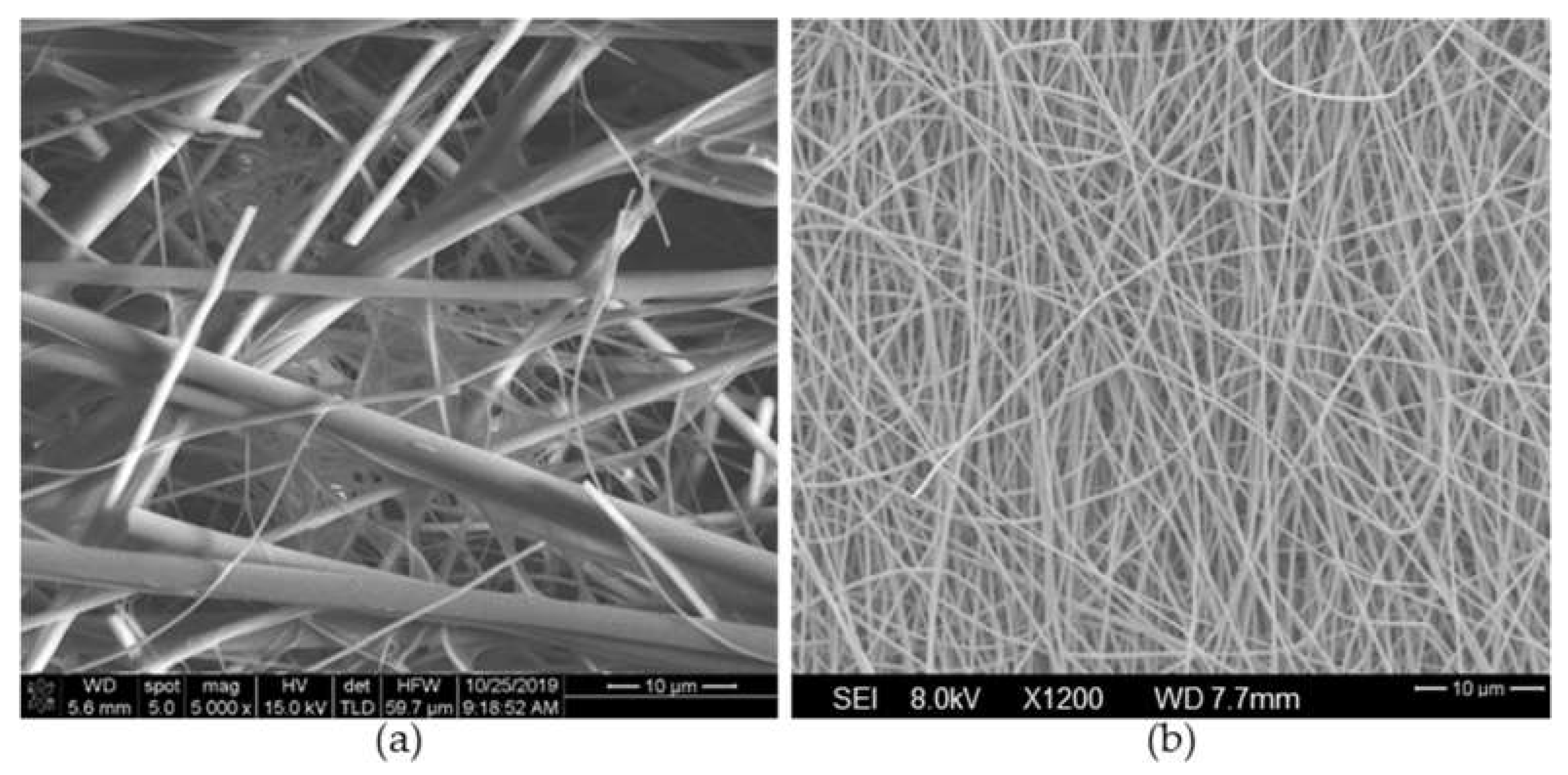

3.3. SEM Imaging of Nonwoven Fibrous Media

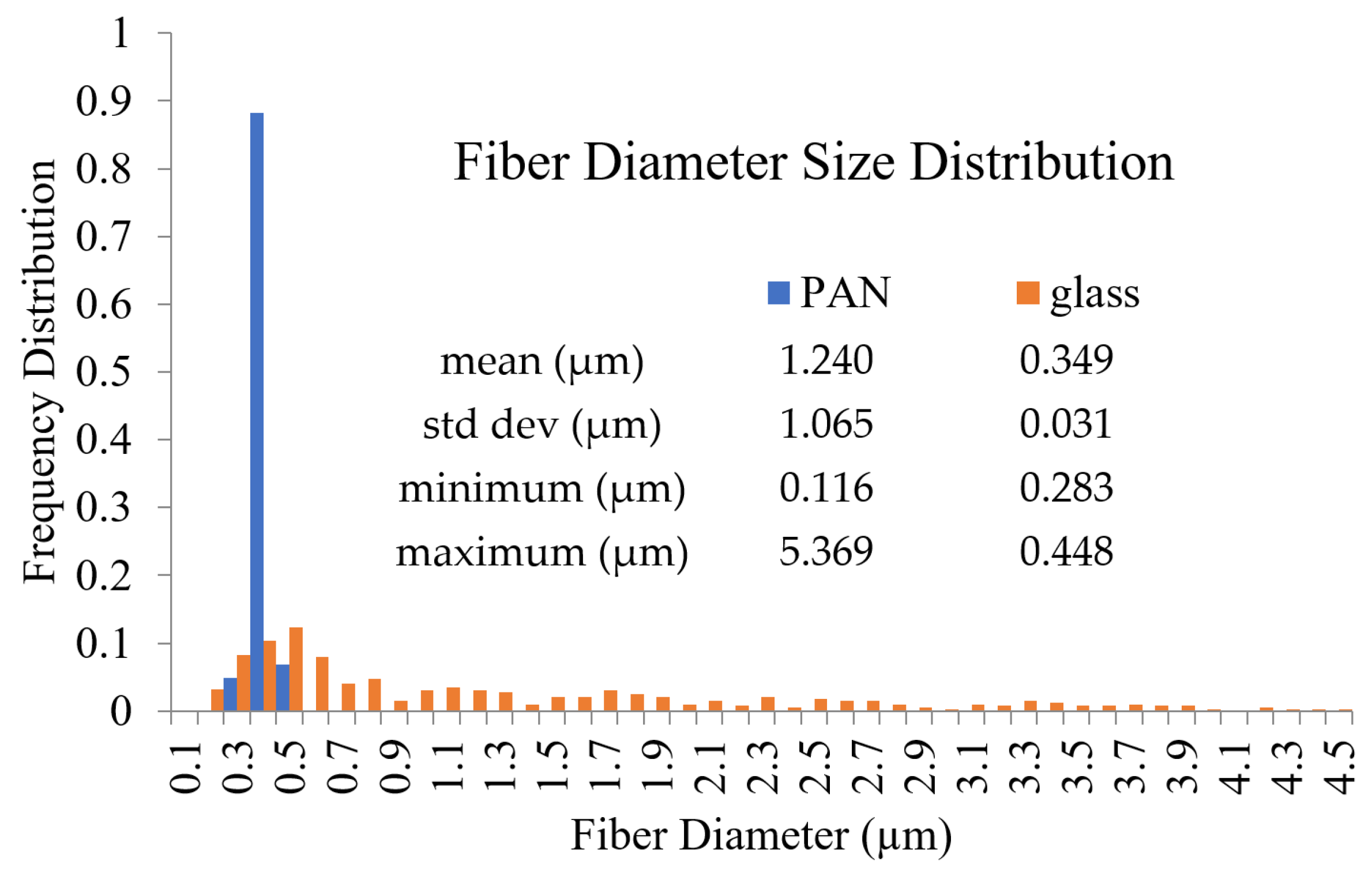

3.4. Fiber Diameter Measurements

3.5. Air Filtration Testing

3.5.1. Air Filtration Performance Standards

3.5.2. Air Filtration Efficiency

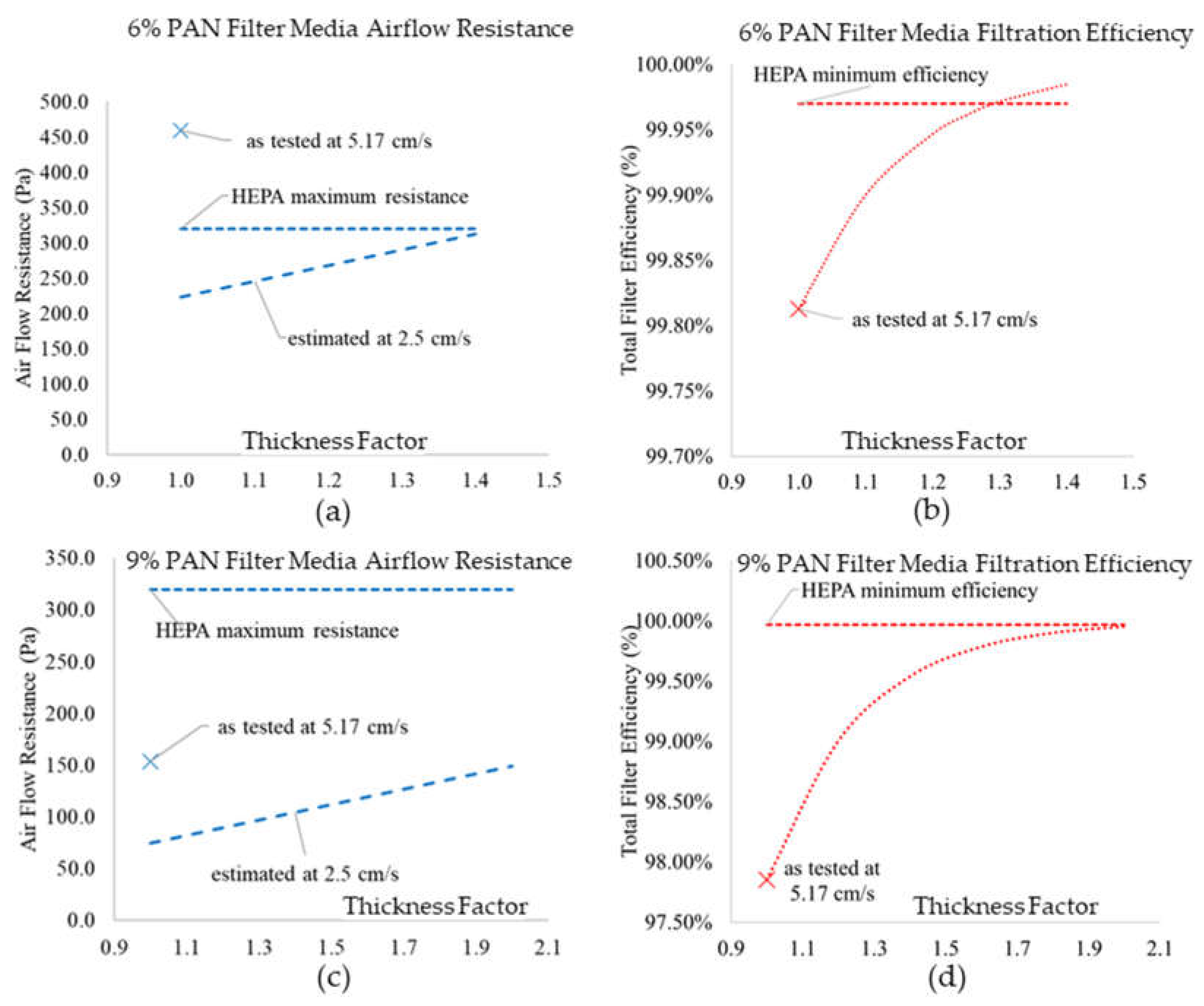

3.5.3. Airflow Resistance

4. Discussion

4.1. Effects of Fiber Diameter and Solidity on Air Filtration Efficiency

4.2. Effects of Fiber Diameter on Airflow Resistance

4.3. Estimated Change in Filtration Efficiency for Thicker Media and Slower Air Velocity

4.4. Estimated Change in Airflow Resistance for Thicker Media and Slower Air Velocity

4.5. Figure of Merit Comparison

4.6. Comparison of Stabilized Polyacrylonitrile Mesh with Glass Fiber HEPA Media

5. Conclusions and Future Research

5.1. Recommendation for Future Research

5.2. The Use of Graphene in Air Purification

5.3. Activated Carbon Air Filter Media

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mukherjee, A.; Agrawal, M. A Global Perspective of Fine Particulate Matter Pollution and Its Health Effects. In Reviews of Environmental Contamination and Toxicology Volume 244; de Voogt, P., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 5–51. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Actions on Air Quality: A Global Summary of Policies and Programmes to Reduce Air Pollution. Nairobi, 2 July 2017. 2021. Available online: http://www.unep.org/resources/assessment/actions-air-quality (accessed on 7 March 2022).

- Cavaliere, S. Electrospinning for Advanced Energy and Environmental Applications; Routledge: Oxfordshire, UK; CRC Press: Boca Raton, FL, USA, 2017; Available online: https://www.routledge.com/Electrospinning-for-Advanced-Energy-and-Environmental-Applications/Cavaliere/p/book/9781138749085 (accessed on 3 February 2023).

- Schumacher, S.; Banda Sanchez, A.; Caspari, A.; Staack, K.; Asbach, C. Testing Filter-Based Air Cleaners with Surrogate Particles for Viruses and Exhaled Droplets. Atmosphere 2022, 13, 1538. [Google Scholar] [CrossRef]

- Szczotko, M.; Orych, I.; Mąka, Ł.; Solecka, J. A Review of Selected Types of Indoor Air Purifiers in Terms of Microbial Air Contamination Reduction. Atmosphere 2022, 13, 800. [Google Scholar] [CrossRef]

- Fermo, P.; Artíñano, B.; De Gennaro, G.; Pantaleo, A.M.; Parente, A.; Battaglia, F.; Colicino, E.; Di Tanna, G.; Goncalves da Silva Junior, A.; Pereira, I.G.; et al. Improving indoor air quality through an air purifier able to reduce aerosol particulate matter (PM) and volatile organic compounds (VOCs): Experimental results. Environ. Res. 2021, 197, 111131. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. Code on Nuclear Air and Gas Treatment ASME AG-1-2019; ASME: New York, NY, USA, 2020. [Google Scholar]

- Finkenauer, L.R.; Lee, S.B.; Kelly, J.P.; Haslam, J.J. Fire- and Water-Resistant Prefilter; LLNL-TR-771457; Lawrence Livermore National Lab. (LLNL): Livermore, CA, USA, 2019. [Google Scholar] [CrossRef]

- Conway, J. HEPA Filters Used in the Department of Energy’s Hazardous Facilities; Defense Nuclear Safety Board: Washington, DC, USA, 1999; DNFSB/TECH-23. Available online: https://www.dnfsb.gov/documents/reports/technical-reports/hepa-filters-used-department-energys-hazardous-facilities (accessed on 12 March 2023).

- Beckman, I.P.; Berry, G.; Cho, H.; Riveros, G. Alternative High-Performance Fibers for Nonwoven HEPA Filter Media. Aerosol Sci. Eng. 2022, 1–23. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Lv, H.; Guo, S.; Zhang, G.; He, W.; Wu, Y.; Yu, D.-G. Electrospun Structural Hybrids of Acyclovir-Polyacrylonitrile at Acyclovir for Modifying Drug Release. Polymers 2021, 13, 4286. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Xu, X.; Fu, J.; Yu, D.-G.; Liu, Y. Recent Progress in Electrospun Polyacrylonitrile Nanofiber-Based Wound Dressing. Polymers 2022, 14, 3266. [Google Scholar] [CrossRef]

- Xu, X.; Lv, H.; Zhang, M.; Wang, M.; Zhou, Y.; Liu, Y.; Yu, D.-G. Recent progress in electrospun nanofibers and their applications in heavy metal wastewater treatment. Front. Chem. Sci. Eng. 2023, 1–27. [Google Scholar] [CrossRef]

- Guo, L.; Zhao, B.; Jia, Y.; He, F.; Chen, W. Mitigation Strategies of Air Pollutants for Mechanical Ventilated Livestock and Poultry Housing—A Review. Atmosphere 2022, 13, 452. [Google Scholar] [CrossRef]

- Hartati, S.; Zulfi, A.; Maulida, P.Y.D.; Yudhowijoyo, A.; Dioktyanto, M.; Saputro, K.E.; Noviyanto, A.; Rochman, N.T. Synthesis of Electrospun PAN/TiO2/Ag Nanofibers Membrane as Potential Air Filtration Media with Photocatalytic Activity. ACS Omega 2022, 7, 10516–10525. [Google Scholar] [CrossRef]

- Roche, R.; Yalcinkaya, F. Electrospun Polyacrylonitrile Nanofibrous Membranes for Point-of-Use Water and Air Cleaning. ChemistryOpen 2019, 8, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Wang, Y.; Xu, L.; Wang, M. Fabrication and Characterization of Electrospun Aligned Porous PAN/Graphene Composite Nanofibers. Nanomaterials 2019, 9, 1782. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Hsu, P.-C.; Lee, H.-W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015, 6, 6205. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.J.; Shiratori, N.; Lee, G.H.; Miyawaki, J.; Mochida, I.; Yoon, S.-H.; Jang, J. Activated carbon nanofiber produced from electrospun polyacrylonitrile nanofiber as a highly efficient formaldehyde adsorbent. Carbon 2010, 48, 4248–4255. [Google Scholar] [CrossRef]

- Sundarrajan, S.; Tan, K.L.; Lim, S.H.; Ramakrishna, S. Electrospun Nanofibers for Air Filtration Applications. Procedia Eng. 2014, 75, 159–163. [Google Scholar] [CrossRef] [Green Version]

- Gupta, B.S.; Afshari, M. Polyacrylonitrile fibers. In Handbook of Properties of Textile and Technical Fibres; Elsevier: Amsterdam, The Netherlands, 2018; pp. 545–593. [Google Scholar] [CrossRef]

- Newcomb, B.A.; Chae, H.G. The properties of carbon fibers. In Handbook of Properties of Textile and Technical Fibres; Elsevier: Amsterdam, The Netherlands, 2018; pp. 841–871. [Google Scholar] [CrossRef]

- Beckman, I.; Lozano, C.; Freeman, E.; Riveros, G. Fiber Selection for Reinforced Additive Manufacturing. Polymers 2021, 13, 2231. [Google Scholar] [CrossRef] [PubMed]

- Khayyam, H.; Naebe, M.; Zabihi, O.; Zamani, R.; Atkiss, S.; Fox, B. Dynamic Prediction Models and Optimization of Polyacrylonitrile (PAN) Stabilization Processes for Production of Carbon Fiber. IEEE Trans. Ind. Inform. 2015, 11, 887–896. [Google Scholar] [CrossRef]

- Yördem, O.S.; Papila, M.; Menceloğlu, Y.Z. Effects of electrospinning parameters on polyacrylonitrile nanofiber diameter: An investigation by response surface methodology. Mater. Des. 2008, 29, 34–44. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Kumar, S. Electrospinning of polyacrylonitrile nanofibers. J. Appl. Polym. Sci. 2006, 102, 1023–1029. [Google Scholar] [CrossRef]

- Wu, M.; Wang, Q.; Li, K.; Wu, Y.; Liu, H. Optimization of stabilization conditions for electrospun polyacrylonitrile nanofibers. Polym. Degrad. Stab. 2012, 97, 1511–1519. [Google Scholar] [CrossRef]

- Fitzer, E.; Frohs, W.; Heine, M. Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 1986, 24, 387–395. [Google Scholar] [CrossRef]

- Szepcsik, B.; Pukánszky, B. The mechanism of thermal stabilization of polyacrylonitrile. Thermochim. Acta 2019, 671, 200–208. [Google Scholar] [CrossRef] [Green Version]

- TSI Incorporated. Certitest Automated Filter Tester Model 8130A l Specification Sheet. Available online: https://tsi.com/getmedia/061e0676-ae77-43c5-baf3-f8bd1fd2fb93/Filter%20Tester%208130A_US_5001770_RevC_Web?ext=.pdf (accessed on 12 March 2023).

- Gebhart, J. Optical Direct-Reading Techniques: Light Intensity Systems. In Aerosol Measurement: Principles, Techniques, and Applications, 2nd ed.; Wiley-InterScience, Inc.: Hoboken, NJ, USA; pp. 419–454.

- ImageJ Image Processing and Analysis in Java. Available online: https://imagej.net/ij/index.html (accessed on 12 March 2023).

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Charvet, A.; Thomas, D. 6—Filtration of Liquid Aerosols. In Aerosol Filtration, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 161–188. [Google Scholar]

- Davies, C.N. Air Filtration; Academic Press: London, UK; New York, NY, USA, 1973. [Google Scholar]

- Hinds, W.C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles, 2nd ed.; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Brown, R.C. Air filtration: An Integrated Approach to the Theory and Applications of Fibrous Filters; Pergamon Press: Oxford, UK; New York, NY, USA, 1993. [Google Scholar]

- Berry, G.; Beckman, I.; Cho, H. A comprehensive review of Particle loading models of fibrous air filters. J. Aerosol Sci. 2022, 167, 106078. [Google Scholar] [CrossRef]

- Beckman, I.P.; Berry, G.; Cho, H.; Riveros, G. Digital Twin Geometry for Fibrous Air Filtration Media. Fibers 2021, 9, 84. [Google Scholar] [CrossRef]

- Davies, C.N. The Separation of Airborne Dust and Particles. Proc. Inst. Mech. Eng. 1953, 167, 185–213. [Google Scholar] [CrossRef] [Green Version]

- Centers for Disease Control and Prevention. Climate Change Decreases the Quality of the Air we Breathe. Available online: https://www.cdc.gov/climateandhealth/pubs/air-quality-final_508.pdf (accessed on 12 March 2023).

- Zhang, L.; Aboagye, A.; Kelkar, A.; Lai, C.; Fong, H. A review: Carbon nanofibers from electrospun polyacrylonitrile and their applications. J. Mater. Sci. 2014, 49, 463–480. [Google Scholar] [CrossRef]

- Kumar, V.; Lee, Y.-S.; Shin, J.-W.; Kim, K.-H.; Kukkar, D.; Fai Tsang, Y. Potential applications of graphene-based nanomaterials as adsorbent for removal of volatile organic compounds. Environ. Int. 2020, 135, 105356. [Google Scholar] [CrossRef]

- Dai, H.; Liu, X.; Zhang, C.; Ma, K.; Zhang, Y. Electrospinning Polyacrylonitrile/Graphene Oxide/Polyimide nanofibrous membranes for High-efficiency PM2.5 filtration. Sep. Purif. Technol. 2021, 276, 119243. [Google Scholar] [CrossRef]

- Li, J.; Hu, Y.; Qiu, H.; Yang, G.; Zheng, S.; Yang, J. Coaxial electrospun fibres with graphene oxide/PAN shells for self-healing waterborne polyurethane coatings. Prog. Org. Coat. 2019, 131, 227–231. [Google Scholar] [CrossRef]

| Gauge | Use | Aperture (μm) | Wire Diameter (μm) | Open Area (%) |

|---|---|---|---|---|

| 20-gauge SS mesh | Flat Plate | 900 | 400 | 52 |

| 8-gauge SS mesh | Roller | 2500 | 800 | 60 |

| Trial | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Polyacrylonitrile (by weight) | 6.0 | 9.0 | 9.0 | 9.0 | 9.0 | 9.0 |

| Electrospinning Details | ||||||

| Orientation | Flat | Flat | Flat | Roller | Roller | Roller |

| Needle Gauge | 23 | 23 | 23 | 23 | 23 | 23 |

| Tip-to-collector (cm) | 15 | 15 | 15 | 15 | 15 | 15 |

| Electric Potential (kV) | 20 | 20 | 20 | 25 | 25 | 30 |

| Pump Rate (mL/h) | 0.8 | 0.8 | 0.9 | 1.1 | 1.1 | 1.1 |

| Pump Time (min) | 213 | 173 | 233 | 545 | 545 | 1091 |

| Roller Speed (rpm) | - | - | - | 180 | 180 | 180 |

| Total Deposition (mL) | 2.84 | 2.30 | 3.49 | 10.0 | 10.0 | 20.0 |

| Stabilization Details | ||||||

| Stabilization Temp (°C) | 270 | 270 | 270 | 270 | 270 | 270 |

| Temp Ramp (°C/min) | 5.0 | 5.0 | 5.0 | 1.0 | 1.0 | 1.0 |

| Stabilization Time (min) | 240 | 120 | 240 | 240 | 240 | 240 |

| Resultant Mass | ||||||

| Stabilized Mass (mg) | - | - | 764.1 | 825.0 | 1257.3 | |

| Areal density (mg/cm2) | - | - | 1.194 | 1.289 | 1.965 |

| 6% PAN Media Trial #1 | 9% PAN Media Trial #3 | |

|---|---|---|

| Fiber Diameter Mean (nm) | 216.1 | 461.6 |

| Fiber Diameter Standard Deviation (nm) | 69.2 | 96.9 |

| Airflow Velocity (cm/s) | 5.15 | 5.17 |

| Particle Penetration (%) | 2.17 | 2.38 |

| Initial Filtration Efficiency (%) | 97.83 | 97.62 |

| Initial Airflow Resistance (Pa) | 512.9 | 157.9 |

| Calculated Figure of Merit (1/Pa) | 0.0137 | 0.0250 |

| Estimates for Clean Media | Airflow Velocity (cm/s) | Airflow Resistance (Pa) | Total Filter Efficiency (%) | Figure of Merit (1/Pa) |

|---|---|---|---|---|

| HEPA Standard | 2.5 | 320.0 | 99.97 | 0.0253 |

| 6% Media as Tested | 5.2 | 459.0 | 99.81 | 0.0137 |

| 6% Media (estimated at 1.4× thickness) | 2.5 | 311.9 | >99.98 | >0.0282 |

| 9% Media as Tested | 5.2 | 154.0 | 97.85 | 0.0250 |

| 9% Media (estimated at 2× thickness) | 2.5 | 148.9 | >99.95 | >0.0516 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beckman, I.P.; Berry, G.; Ucak-Astarlioglu, M.; Thornell, T.L.; Cho, H.; Riveros, G. Stabilized Electrospun Polyacrylonitrile Fibers for Advancements in Clean Air Technology. Atmosphere 2023, 14, 573. https://doi.org/10.3390/atmos14030573

Beckman IP, Berry G, Ucak-Astarlioglu M, Thornell TL, Cho H, Riveros G. Stabilized Electrospun Polyacrylonitrile Fibers for Advancements in Clean Air Technology. Atmosphere. 2023; 14(3):573. https://doi.org/10.3390/atmos14030573

Chicago/Turabian StyleBeckman, Ivan P., Gentry Berry, Mine Ucak-Astarlioglu, Travis L. Thornell, Heejin Cho, and Guillermo Riveros. 2023. "Stabilized Electrospun Polyacrylonitrile Fibers for Advancements in Clean Air Technology" Atmosphere 14, no. 3: 573. https://doi.org/10.3390/atmos14030573

APA StyleBeckman, I. P., Berry, G., Ucak-Astarlioglu, M., Thornell, T. L., Cho, H., & Riveros, G. (2023). Stabilized Electrospun Polyacrylonitrile Fibers for Advancements in Clean Air Technology. Atmosphere, 14(3), 573. https://doi.org/10.3390/atmos14030573