Feasibility and Affordability of Low-Cost Air Sensors with Internet of Things for Indoor Air Quality Monitoring in Residential Buildings: Systematic Review on Sensor Information and Residential Applications, with Experience-Based Discussions

Abstract

:1. Introduction

- Karagulian et al. [16] published a non-systematic review in 2019 on the performance of LSC in the 105 papers published between 2010 and 2019, which evaluated the quality of data in results and calibrations with different algorithms, with the cost of sensors included in details. However, this work included more commercial devices with LCS rather than individual sensors, and the cost of devices is based on the price of sensors before 2019. In the included references, there were already many works designed with IoT technology, but this review did focus on this aspect.

- Chojer et al. [13] published a systematic review in 2020 among the 35 papers published between 2012 and 2019, which focused on monitoring devices development and related information such as sensor types and principles, detection range, reference instruments, calibration methods, and accuracy vs. reference. In the discussion and conclusion, they focused more on the performance of the devices’ calibration accuracy and how to improve it.

- Saini et al. published two systematic reviews. The one in 2020 [17] discussed more about the measurement system with IoT applications. It summarized useful information, such as on Micro-Control Unit (MCU), data transmission, reading, storage, notification methods, and system power supply methods, in the 40 papers published from 2015 to 2020. The other one in 2021 [18] reviewed 40 papers published between 2015 and 2021. This one focused on and summarized the sensors applied in the included papers, which are classified according to their target parameters, and found answers for the applied sensors, with their features and costs mentioned.

- Sá et al. [15] published a systematic review in 2022 among the 48 papers published before 2021 (and it is also included in this review). This work summarises the sensor information of those applied in fieldwork applications and makes comparisons of their performances.

- García et al. [19] published a non-systematic review in 2022 without specifying the sources of the included papers. It discussed the pros and cons of LCS devices, their applications, and many key issues based on the findings from many previous reviews and related works.

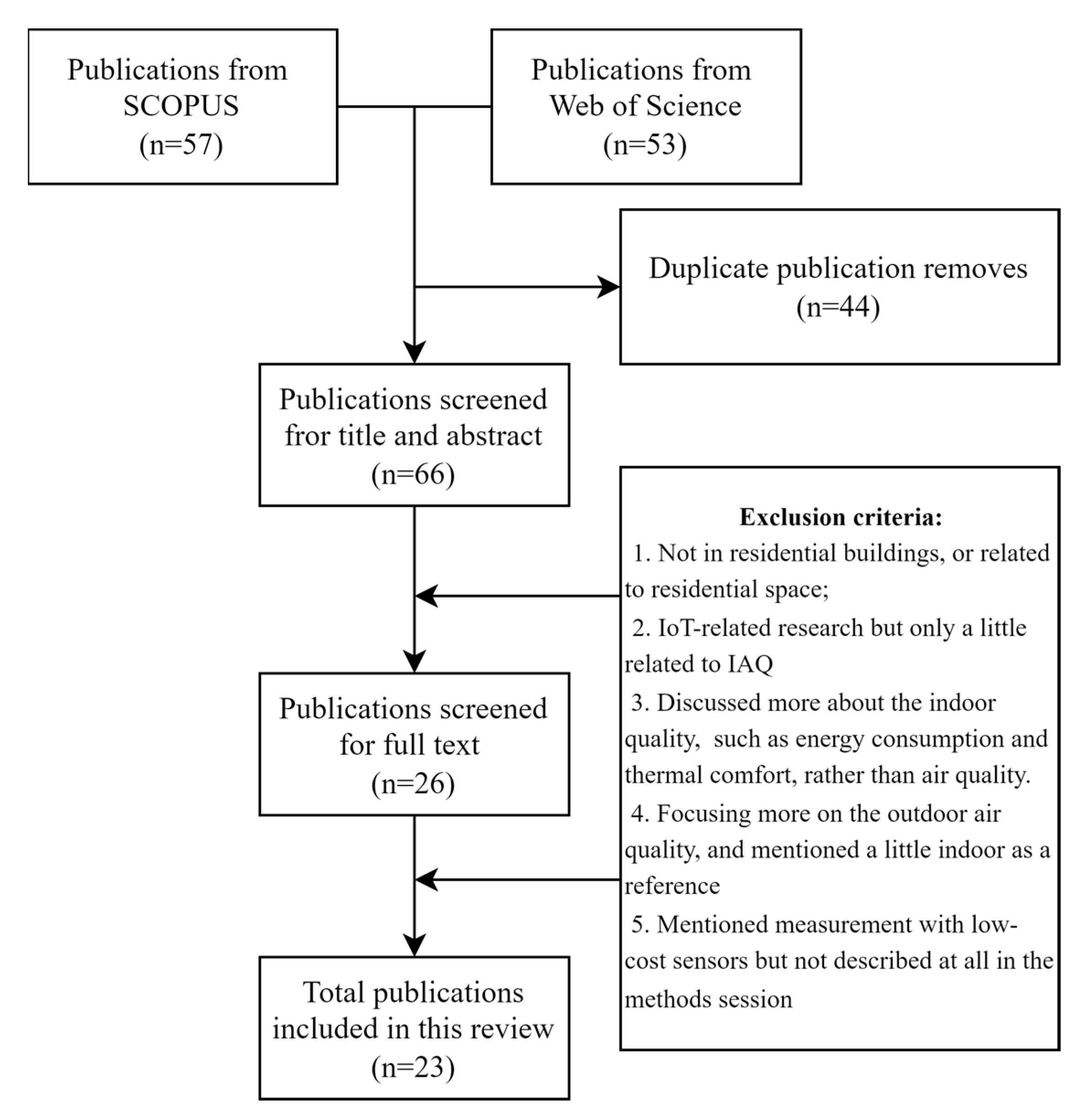

2. Methods

- What is applied: sensor type, target pollutants, used micro-controllers, used data collection platforms, etc.;

- How it is applied in devices: data reading and collection method, sensor interfaces working condition, power supply, costs, etc.;

- How it is applied in fieldwork: sampling numbers, measurement periods, reading intervals, calibration methods, etc.

3. Results

3.1. The Included Papers

- (a)

- LCS application in residential buildings (n = 16);

- (b)

- Testing specific devices and sensor’s performance (n = 4);

- (c)

- Device and IoT system development logs (n = 2);

- (d)

- Review paper (n = 1).

- The included review focused on the performance of LCS in research from 2013 to 2021, such as their application methods and accuracy of results. It covered the research not just in a specific indoor space and did not focus on the application with IoT [15];

- This review does not focus on the resulting data of LCS in the resulting data, but its application methods, especially those in residential buildings, those with IoT technology, their affordability, calibration methods in detail, advantages and limitations for medium/long-term IAQ monitoring in residential buildings, from papers between 2017 and 2023.

3.2. Monitored Parameters and Corresponding Sensors

3.3. Calibration

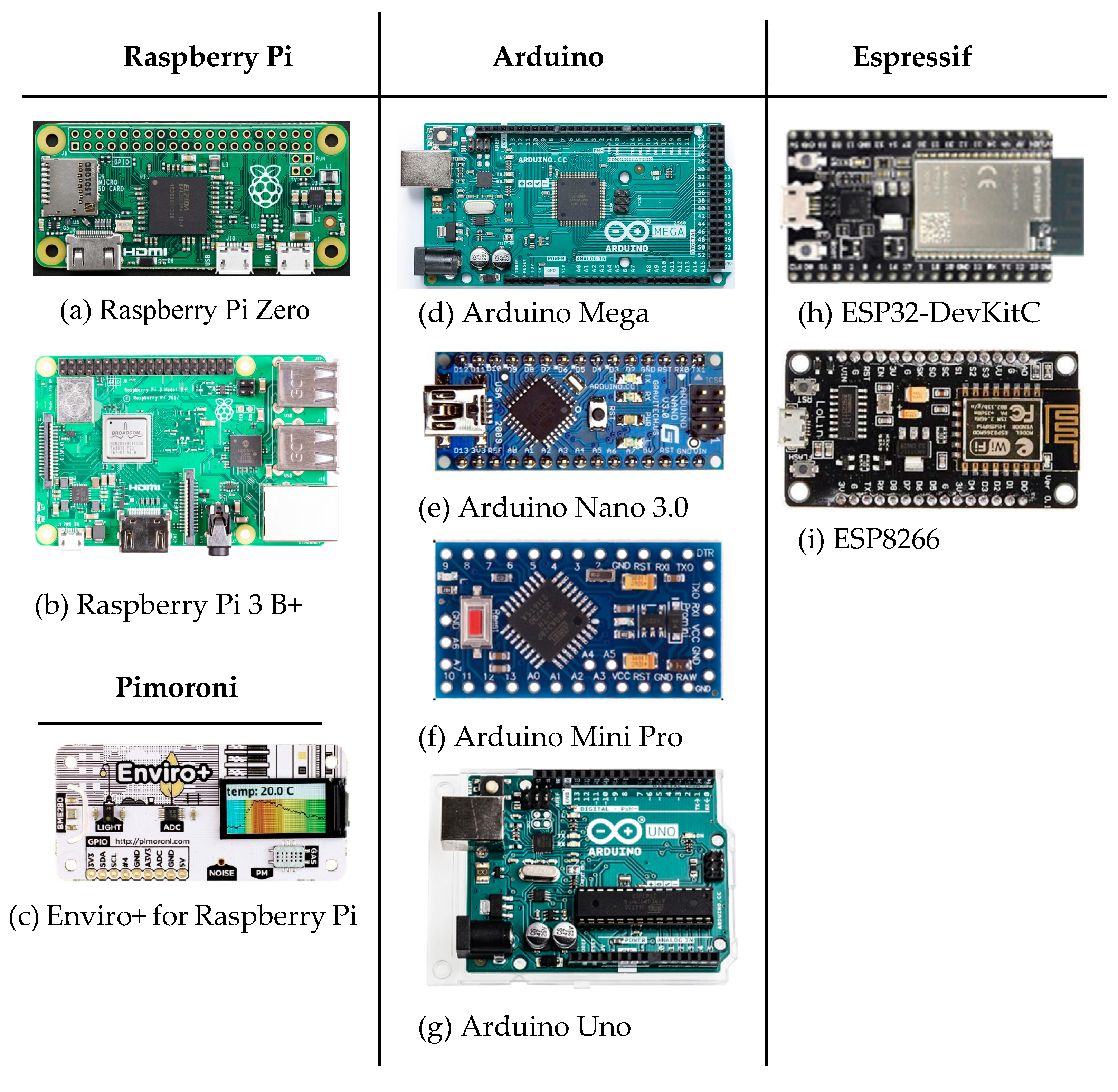

3.4. Micro-Control Unit in Device Development

4. Discussion

4.1. Most Measured Parameters, “User-Friendly” and “Low-Cost” Sensors

4.2. Unclear Definition of “Low-Cost” in Gas Sensor

4.3. The Increase from Device Cost to Commercial Price

- Costs on hardware: it includes the cost of selected sensors, other materials such as those for circuits and coatings, device design and tests, assembling and manufacturing, calibration, etc.;

- Costs on software: end user’s app design, data collection platform design, data collection API (Application Programming Interface) and data storage, online server maintenance, etc.;

- Costs on services: marketing and advertising, after-services for device maintenance, Q&A, etc.;

- Other costs on commercial operations: shipment and storage of devices materials, taxes on company, products and shipping, etc.;

- Profits of the products, etc.

4.4. Some Basic Features of All the Mentioned Sensors in the Included Papers

- The detection range is the maximum range to be detected, but most sensors have another small range with higher accuracy.

- Resolution means when the reading changes, the minimum changes in reading values.

- Drift means how much the value will shift from the accurate level during the time, which is based on the result of simulation, such as the 200-h test by SGP30 [51]. And the lifespan is the expected time to provide reliable readings.

- The interface is the protocol for data reading from sensors, including I2C (Inter-Integrated Circuit), UART (universal asynchronous receiver/transmitter), PWM (Pulse-Width Modulation), SPI (Serial Peripheral Interface), Analog signal and other two special methods (USB (Universal Serial Bus) and ALARM (this is not an abbreviation and it is a particular method in S-300 sensor [52])). They are more dependent on the principles of how sensors read from the environment and are selected by the designer of the sensors.

- Supply Voltage is displayed in “typical voltage (minimum~maximum voltage)”. If the supply voltage is outside of this range, the sensor will not start working or get burned.

- Power consumption is the energy consumption of sensors while working, sleeping, or heating period. It is mentioned in units of W (watt) or A (ampere). It is important to know if the devices are designed to be supplied by the batteries.

| Sensor | Ref. 1 | Measurement Features 4 | Device Development Features | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Parameters 3 | Detect Range | Resolution | Accuracy | Response Time | Drift/Lifespan | Interface | Supply Voltage (V) | Power Consumption | ||

| AHT10 | [53] | T (°C) | −40~85 | 0.01 | ±2 | 5–30 s | <0.04/yr2 | I2C | 3.3 (1.8~3.6) | 3.3 μW(working) 0.9 μW(sleeping) |

| RH (%) | 0–100 | 0.024 | ±0.3 | 8 s | <0.5/yr | |||||

| AirCO2ntrol Mini | [54] | T (°C) | 0~50 | 0.1 | ±1.5 | 20~30 min | NM 2 | USB | 5 | 300 mA (working) |

| CO2 (ppm) | 0~3000 | 1 | ±(100 + 7%) | 2 min | NM | |||||

| AirVisual M25b | — | No information found | ||||||||

| Amphenol Telaire T6703-5 K | [50] | CO2 (ppm) | 0~5000 | NM | ±75 or ±10% | <3 min | 10yr | I2C, UART | (4.5~5.5) | 25 mA (working) |

| BH1750 | [55] | Light (lux) | NM | 1 | NM | NM | NM | I2C | 5 | NM |

| BME280 | [56] | T (°C) | −40~85 | 0.01 | ±1 | NM | NM | I2C, SPI | 1.8 (1.7~3.6) | 340~714 μA (working) 0.1~0.2 μA (sleeping) |

| RH (%) | 0~100 | 0.008 | ±3% | 1 s | 0.5/yr | |||||

| AP(hPa) | 300~1100 | 0.18 | ±1.7 | NM | 1/yr | |||||

| BME680 | [57] | T (°C) | −40~85 | 0.01 | ±1 | NM | NM | I2C, SPI | 1.8 (1.7~3.6) | 340~714 μA (working) 0.15~0.29 μA (sleeping) |

| RH (%) | 0–100 | 0.008 | ±0.3 | 8 s | 0.5/yr | |||||

| AP(hPa) | 300–1100 | 0.18 | ±0.12 | NM | 1/yr | |||||

| IAQ index | 0–500 | 1 | ±15 | <1 s | NM | |||||

| BMP180 | [58] | AP(hPa) | 300~1100 | 0.01 | ±0.12 | NM | 1/yr | 2.5 (1.8~3.6) | 5 μA (working) | |

| BMP280 | [59] | AP(hPa) | 300~1100 | 0.01 | ±1 | NM | 1/yr | 2.5 (1.8~3.6) | 2.8 μA (working) | |

| CO-B4 | [60] | CO (ppm) | 0~1000 | 2 | ±5 | <30 | <10/yr | I2C | (1.7~3.6) | <2.15 mA (working) <5 μA (sleeping) |

| CSS811 | [61,62] | T (°C) | −5~50 | NM | NM | NM | NM | I2C | 3.3 (1.8~3.6) | 60 mW (working) |

| RH (%) | 10~95 | NM | NM | NM | NM | |||||

| TVOC (ppb) | 0~1187 | NM | NM | NM | NM | |||||

| CO2eq (ppm) | 400~8192 | NM | NM | NM | NM | |||||

| DHT22 | [63] | T (°C) | −40~80 | 0.1 | ±0.2 | 2 s | NM | single-bus | (3.3~6) | NM |

| RH (%) | 0~100 | 0.1% | ±1 | 2 s | 0.5%/yr | |||||

| GP2Y1010AU0F | [64] | dust | 0–0.5(mg/m3) | NM | ±0.5V/(0.1 mg/m3) | NM | NM | NM | 5.0 (4.5–5.5) | 11 mA (working) |

| GPY1010AU0F | — | No information found | ||||||||

| HPM Series | [65,66] | PM (2.5/10) (μg/m3) | 0~1000 | NM | ±15 | <6 s | 10yr | UART | 5 (4.8~5.2) | 80 mA (working) |

| HPMA115S0-XXX | The same sensor as HPM Series above | |||||||||

| iAM | — | Product found, but datasheet not found | ||||||||

| K30 | [67] | CO2 (ppm) | 0~5000 | NM | ±(30 + 3%) | NM | >15 yr | I2C, UART | (4.5~14) | NM |

| Lit92 | [68] | T (°C) | -55~150 | NM | ±0.2 | NM | NM | Analog signal | NM | NM |

| MH-Z14 | [69] | CO2 (ppm) | 0~5000 | NM | ±(50 + 5%) | <90 s | >5 yr | UART, Analog signal | (4.5~5.5) | <85 mA (working) |

| MH-Z14A | [70] | CO2 (ppm) | 0~10,000 | NM | ±(50 + 5%) | <120 s | >5 yr | UART, Analog signal | (4.5~5.5) | <60 mA (working) |

| MH-Z19A | [71] | CO2 (ppm) | 0~5000 | NM | ±(50 + 5%) | <60 s | >5 yr | UART | (3.6~5.5) | <18 mA (working) |

| MICS-4514 | [72] | T (°C) | -30~85 | NM | NM | NM | NM | Analog signal | 5 (4.9–5.1) | 76 mW (heating) 8 mW (working) |

| RH (%) | 5–95 | NM | NM | NM | NM | |||||

| Reducing gas (ppm) | 1–1000 | NM | NM | NM | NM | |||||

| Oxiding gas (ppm) | 0.05–10 | NM | NM | NM | NM | |||||

| MICS-6814 | [73] | T (°C) | -30~85 | NM | NM | NM | NM | Analog signal | 5 (4.9–5.1) | 88 mW (heating) 8 mW (working) |

| RH (%) | 5–95 | NM | NM | NM | NM | |||||

| Reducing gas (ppm) | 1–1000 | NM | NM | NM | NM | |||||

| Oxiding gas (ppm) | 0.05–10 | NM | NM | NM | NM | |||||

| NH3 (ppm) | 1–300 | NM | NM | NM | NM | |||||

| MQ7 | [74] | CO (ppm) | 10~500 | NM | NM | NM | NM | Analog signal | 5.0 (4.9–5.1) | <900 mW (heating and working) |

| OPC-N3 | [75] | PM (1.0/2.5/10) (μg/m3) | 0~2000 | NM | NM | NM | NM | SPI, Micro USB | (4.8~5.2) | 180 mA (working) |

| OPC-R1 | [76] | PM (0.35~12.4) (μg/m3) | NM | NM | NM | NM | NM | SPI | (4.8~5.2) | 95~100 mA (working) |

| PASDD Model 11-D | [77] | PM (1/2.5/4/10/coarse) (μg/m3) | 0~100,000 | NM | NM | NM | NM | NA | 13 | 5.4 W (working) |

| Particle numbers (total) | NA 2 | NA | NA | NM | NM | |||||

| PMS3003 | [78] | PM (0.1/0.3/2.5/1.0) (μg/m3) | 0~500 | 1 | ±10% | 10 s | 3 yr | UART | 5.0 (4.5–5.5) | <100 mA |

| Particle numbers (0.3/0.5/1.0) | NA | NA | NA | 10 s | 3 yr | |||||

| PMS6003 | [79] | PM (0.1/0.3/2.5/1.0) (μg/m3) | 0~500 | 1 | ±10% | <10 s | >10 yr | UART | 5.0 (4.5–5.5) | <100 mA |

| Particle numbers (0.3/0.5/1.0) | NA | NA | NA | <10 s | >10 yr | |||||

| PMS7003 | [80] | PM (0.1/0.3/2.5/1.0) (μg/m3) | 0~500 | 1 | ±10% | <10 s | >10 yr | UART | 5.0 (4.5–5.5) | <100 mA |

| Particle numbers (0.3/0.5/1.0) | NA | NA | NA | <10 s | >10 yr | |||||

| PM-Model-II | — | No information found | ||||||||

| Purple Air PA-II | [81,82] | Particle numbers (0.3/0.5/1.0) | 0~500 | 1 | ±10% | <10 s | >3 yr | NA | NA | NA |

| S-300 | [52] | CO2 (ppm) | 0~10,000 | NM | ±(30 + 3%) | 60 s | MN | I2C, UART, PWM, Analog signal, ALARM | 5.0 (4.5–5.5) | 25 mA (working) <0.5 mA (sleeping) |

| SCD30 | [83] | T (°C) | 0~50 | NM | ±(0.4 + 0.023×(T-25)) | 20 s | 0.03/yr (15 yr) | I2C, UART | (3.3~5.5) | 19 mA (working) |

| RH (%) | 0~100 | NM | ±3 | 8 s | 0.25/yr (15 yr) | |||||

| CO2 (ppm) | 0~40,000 | NM | ±(30 + 3%) | <10 s | 50/calibration (15 yr) | |||||

| SCD40 | [84] | T (°C) | −10~60 | NM | ±0.8 | 120 s | 0.03/yr (>10 yr) | I2C | 3.3/5.0 (2.4~5.5) | 15/11 mA (working) |

| RH (%) | 0~100 | NM | ±6 | 90 s | 0.25/yr (>10 yr) | |||||

| CO2 (ppm) | 0~40,000 | NM | ±(50 + 5%) | 60 s | (5 + 5%)/calibration (>10 yr) | |||||

| SDS018 | [85] | PM (2.5/10) (μg/m3) | 0~999.9 | NM | ±(10 + 15%) | 1 s | NM | UART | 5 (4.7~5.3) | 60 mA (working) <4 mA (sleeping) |

| SenseAir S8 | [86] | CO2 (ppm) | 400~10,000 | NM | ±(40 + 3%) | <30 s | >15 yr | UART | (4.5~5.25) | 18 mA (working) |

| SGP30 | [51] | TVOC (ppb) | 0–60,000 | 1–32 | NM | NM | 1.3%/10 yr | I2C | 1.8 (1.62–1.98) | 48.8 mA (working) 2 μA (sleeping) |

| CO2eq (ppm) | 400–60,000 | 1~31 | NM | NM | NM | |||||

| Shinyei ppd42 | [87] | PM (1.0) (pcs/liter) | 0~28,000 | NM | NM | NM | NM | PWM | 5 (4.5~5.5) | 90 mA (working) |

| SHT11 | [88] | T (°C) | −40~123.8 | 0.01 | ±0.5 | 5~30 s | <0.5/yr | I2C | 3.3 (2.4~5.5) | 0.55 mA (working) 0.3 μA(sleeping) |

| RH (%) | 0~100 | 0.05 | ±4.5 | 8 s | <0.04/yr | |||||

| SHT20 | [89] | T (°C) | −40~125 | 0.01~0.04 | ±0.3 | 5~30 s | <0.02/yr | I2C | 3.0 (2.1~3.6) | 0.9 mW (working) 0.5 μW (sleeping) |

| RH (%) | 0~100 | 0.04~0.7 | ±3 | 8 s | <0.25/yr | |||||

| SHT30 | [90] | T (°C) | −40~125 | 0.01 | ±0.2 | > 2 s | <0.03/yr | I2C | 3.0 (2.1~3.6) | 0.9 mW (working) 0.5 μW (sleeping) |

| RH (%) | 0~100 | 0.01 | ±2 | 8 s | <0.25/yr | |||||

| SHT31-D | [90] | T (°C) | −40~125 | 0.01 | ±0.2 | > 2 s | <0.03/yr | I2C | 3.0 (2.1~3.6) | 0.9 mW (working) 0.5 μW (sleeping) |

| RH (%) | 0~100 | 0.01 | ±2 | 8 s | <0.25/yr | |||||

| SPS30 | [91] | PM(1.0/2.5/4/10) (μg/m3) | 0~1000 | 10 | ±10 | 1 s | 10 yr | I2C, UART | 5 (4.5–5.5) | 55 mA (working) 38 μA (sleeping) |

| Particle numbers (0.5/1/2.5/4/10) | NA | NA | NA | 1 s | 10 yr | |||||

| SPEC DGS-NO2 | [92] | NO2 (ppm) | 0~5 | 0.02 | ±3% | <30 s | >5 yr | UART | 3.3 (2.6~3.6) | 14 mW (working) 100 μW (sleeping) |

| SPEC DGS-CO | [93] | CO (ppm) | 0~1000 | 0.1 | ±15% | <30 s | >5 yr | UART | 3.0 (2.6~3.6) | 12 mW (working) |

| SVM30 | [94] | T (°C) | 5~55 | 0.01 | ±1 | NM | <0.02/yr | I2C | 5 (4.5–5.5) | 49 mA (working) |

| RH (%) | 25~75 | 0.01 | ±5 | 8 s | <0.25/yr | |||||

| Ethanol (ppm) | 0~1000 | 0.2% | ±7% | NM | 15%/10 yr | |||||

| H2 (ppm) | 0~1000 | 0.2% | ±7% | NM | 10%/10 yr | |||||

| TVOC (ppb) | 0~60,000 | 1–32 | ±7% | NM | NM | |||||

| CO2eq (ppm) | 400~60,000 | 1~31 | ±7% | NM | NM | |||||

| T-110 | [49] | CO2 (ppm) | 400~10,000 | NM | ±(50 + 3%) | 90 s | NM | UART, Analog signal, PWM | 5 (4.5–5.5) | 20 mA (working) |

| TSL2591 | [95] | Light (lux) | NM | NM | NM | NM | NM | I2C | 3.0 (2.7~3.6) | 20 mA (working) 3.0 mA (sleeping) |

| WZ-S formaldehyde module | [96] | Formaldehyde (ppm) | 0~2 | 0.001 | NM | <40 s | 5 yr | UART | 5 (5~7) | NM |

| Y-Pods | — | A device designed by Hannigan Lab, University of Colorado Boulder. No datasheet was found for it. | ||||||||

4.5. The Skipped Features in Sections 3 (Results) and 4.4

4.6. Calibration Methods of Low-Cost Sensors

- (1)

- Calibration with reference reading sources, whether from research-level devices or local meteorological stations.

- (2)

- Calibration with calibration gas at a confirmed level in the air chamber.

| Reference | Parameters | Reference Devices | Calibration Methods | Data Analysis Methods |

|---|---|---|---|---|

| [24,98] | T | Michell instruments S8000 | Sensors are calibrated with reference devices in a 10 L incubator from 21 to 32 °C. | A linear regression model of the form Yi = α + βXi. |

| PM2.5 | TSI Aerodynamic Particle Sizer Model 3321 | 2-step calibration for PM and CO2 in the test house and environmental chamber: In the test house, 20 devices collocated with reference devices. They filled CO2 to 2000 ppm with pressurized gas to calibrate CO2 and used a nebulizer with 3–5 μm particles to calibrate PM separately. In an 8 m3 environmental chamber, they let the research sit inside for 30 min and move out and measure during the increase and decrease period to calibrate CO2; they used a nebulizer again, while PM2.5 lower than 50 μg/m3, to calibrate PM. | Univariate linear models of the form y = b + mx, with b and m calculated from average value in 3 experiments. | |

| CO2 | LI-COR Model 6252 | |||

| TVOC | No reference devices | Researchers are used as TVOC source in a 27 m3 chamber and calibrated device to output the same values. | By comparing the average, reference curve among test sensors. | |

| CO | N/A | Gas standard with Zero Air Gas (ZAG) was applied to achieve levels of 0, 1, 2, and 4 ppm in a 5 L chamber. The data in the 60 min in the middle of the 2 h test at each standard level are used for calibration. | Four data points at each level are used to fit a linear model to correct CO readings. | |

| [26,100] | PM10, PM2.5 | Palas Fidas 200 | Machine Learning models are applied to calibrate PM readings with Absolute Humidity and Relative Humidity. Then, the readings are compared with a reference device. | Calibration used 4 Machine learning models: Multivariate Linear Regression (MLR), Multi-Layer Perceptron (MLP), Convolution Neural Network (CNN), and Random Forest (RF). Then, they used a scatter plot with a regression-fitted line to evaluate the performance of calibration. |

| [33] | T, RH | meteorological station at the Birmingham International Airport | NM | NM |

| PM1, PM2.5, PM10 | TSI-3330 | TSIs were collocated with the sensor in the target rooms during monitoring. LCS are calibrated according to RH level and calculated the correlation with TSIs’ readings. | Pearson correlation (r). | |

| [14] | T | Model 425 and 435, Testo | All the devices for test and reference are collocated together to compare the readings together. | Linear regression and Pearson correlation coefficients. |

| PM | Grimm Model 1371 (miniWRAS) | |||

| CO2 | The LI-COR 850 | |||

| VOC | GreyWolf IQ-610 and Aeroqual Photoionization Detector | |||

| [34] | PM | Sidepak | The reference device was collocated with one of the devices, and then the data comparison was used to calculate the linear algorithm for the analog reading from the sensors, according to the linear correlation feature between PM level and output voltage. | A linear regression model is provided by the sensor and the calculation for the slope and intercept with comparison to the reference readings. |

| [35] | PM | Thermo Scientific FH 62 C14 | Sensors are deployed close together in the living room and calibrated against the reference device for 50 h immediately prior to the experiment. | Linear regression over the origin, and we used the regression coefficients to calibrate individual particle counters. |

4.7. Possible Solutions for Medium/Long-Term IAQ Monitoring Applications in Residential Buildings

4.7.1. Integrated IAQ Monitoring with Building System

4.7.2. Local Network and Data Storage with IoT

4.7.3. Modular Design of Air Sensors and Components

4.7.4. IAQ Data Real-Time Display

4.7.5. Air Quality Monitoring Network

4.8. Limitations to Implementing Medium/Long-Term IAQ Monitoring in Residential Buildings

4.8.1. Awareness of IAQ from Users

4.8.2. Occupants May Not Realize the Need for and Significance of Medium/Long-Term IAQ Monitoring

4.8.3. Limitations on Low-Cost Sensor Types

4.8.4. Limitations on Pollutant Detection Range, Precision and Accuracy

4.8.5. The Misleading Information about Sensors and MCUs from the Internet and Inadequate Instruction from the Manufacturers

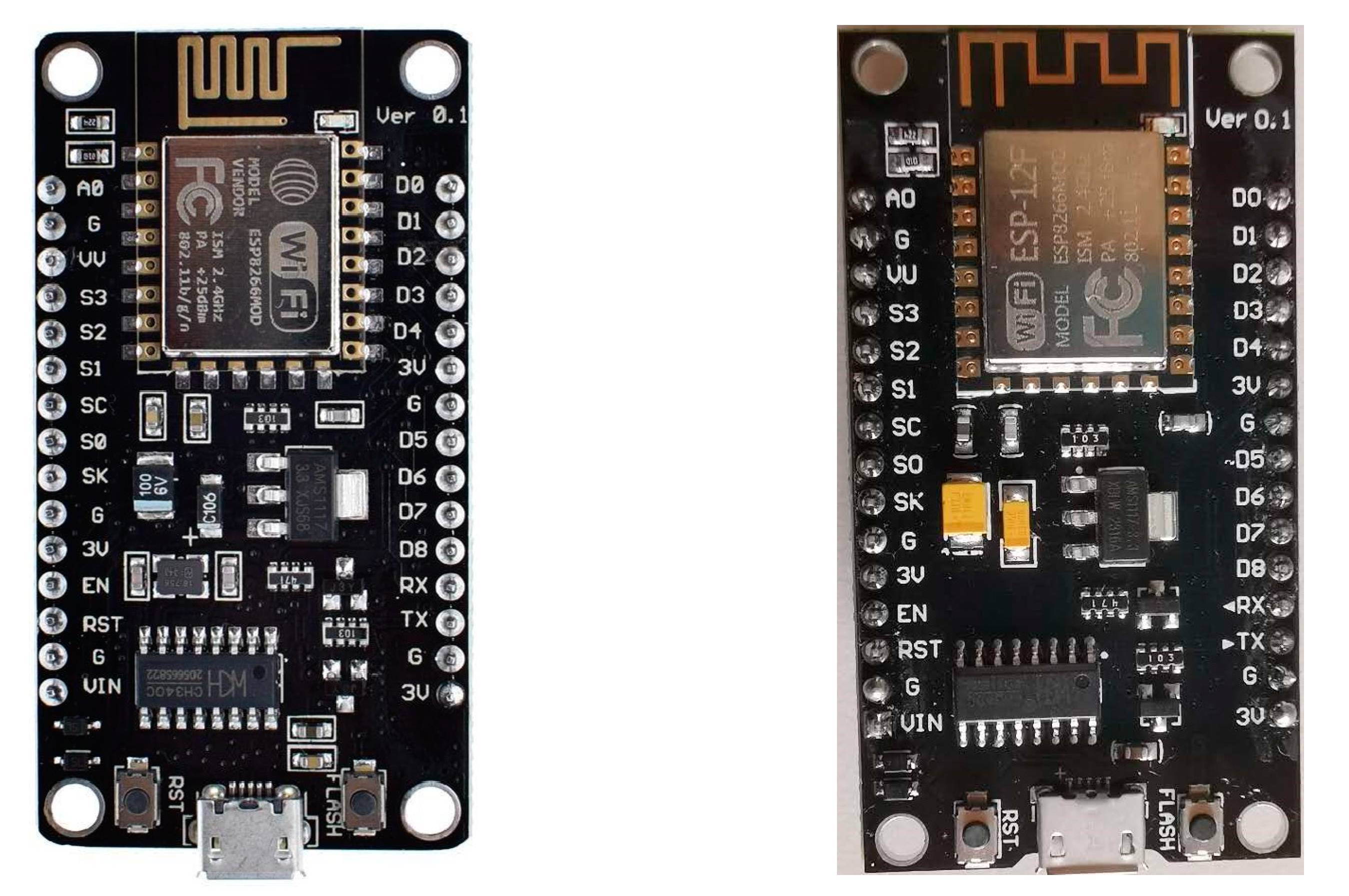

- ESP8266 usually refers to the DevKits based on ESP8266 modules or other clones;

- ESP-12E/F is one of the ESP8266 modules developed by a third-party manufacturer (Ai-Thinker) based on ESP8266EX [103];

- ESP8266EX is one of the SoCs developed by Espressif [97] with Wi-Fi communication;

- Xtensa® L106 is its chips as a microprocessor inside ESP8266EX [97].

4.8.6. Commercial Sensor Platform and Open-Source Integrated Development Environment

5. Conclusions

6. Limitations of This Research

- Some sensors actually are able to measure multiple parameters, but those readings are not used or mentioned in their papers;

- Some names or versions of sensors may not be correctly recorded by the authors of the included papers due to the reasons mentioned in Section 4.8.5;

- The costs of sensors in Table 3 are from at least 2~3 years ago; there may be new prices, and the costs also vary from the local markets in different regions.

- The datasheets of all sensors are not verified one by one, so it is not certain if there are more cases of sensor misuse as mentioned in Section 4.4.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Tahmasebi, F.; Cooper, E.; Stamp, S.; Chalabi, Z.; Burman, E.; Mumovic, D. Exploring the relationship between window operation behavior and thermal and air quality factors: A case study of UK residential buildings. J. Build. Eng. 2022, 48, 103997. [Google Scholar] [CrossRef]

- World Health Organization (WHO). WHO Guidelines for Indoor Air Quality: Selected Pollutants; 9289002131; World Health Organization, Regional Office for Europe: Copenhagen, Denmark, 2010. [Google Scholar]

- World Health Organization (WHO). WHO Global Air Quality Guidelines: Particulate Matter (PM2.5 and PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide; World Health Organization: Geneva, Switzerland, 2021. [Google Scholar]

- Poli, T.; Mainini, A.G.; Speroni, A.; Blanco Cadena, J.D.; Moretti, N. The effect of real-time sensing of a window on energy efficiency, comfort, health and user behavior. In Research for Development; Springer: Berlin/Heidelberg, Germany, 2020; pp. 291–296. [Google Scholar] [CrossRef]

- Settimo, G.; Yu, Y.; Gola, M.; Buffoli, M.; Capolongo, S. Challenges in IAQ for Indoor Spaces: A Comparison of the Reference Guideline Values of Indoor Air Pollutants from the Governments and International Institutions. Atmosphere 2023, 14, 633. [Google Scholar] [CrossRef]

- Settimo, G.; Manigrasso, M.; Avino, P. Indoor air quality: A focus on the european legislation and state-of-the-art research in Italy. Atmosphere 2020, 11, 370. [Google Scholar] [CrossRef]

- Leech, J.A.; Nelson, W.C.; Burnett, R.T.; Aaron, S.; Raizenne, M.E. It’s about time: A comparison of Canadian and American time-activity patterns. J. Expos. Anal. Environ. Epidemiol. 2002, 12, 427–432. [Google Scholar] [CrossRef]

- Brasche, S.; Bischof, W. Daily time spent indoors in German homes–Baseline data for the assessment of indoor exposure of German occupants. Int. J. Hyg. Environ. Health 2005, 208, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Klepeis, N.E.; Nelson, W.C.; Ott, W.R.; Robinson, J.P.; Tsang, A.M.; Switzer, P.; Behar, J.V.; Hern, S.C.; Engelmann, W.H. The National Human Activity Pattern Survey (NHAPS): A resource for assessing exposure to environmental pollutants. J. Expos. Anal. Environ. Epidemiol. 2001, 11, 231–252. [Google Scholar] [CrossRef]

- Capolongo, S.; Settimo, G. Indoor Air Quality in Healing Environments: Impacts of Physical, Chemical, and Biological Environmental Factors on Users. In Indoor Air Quality in Healthcare Facilities; Capolongo, S., Settimo, G., Gola, M., Capolongo, S., Settimo, G., Gola, M., Eds.; Springer Public Health: New York, NY, USA, 2017; pp. 1–11. [Google Scholar] [CrossRef]

- Gola, M.; Settimo, G.; Capolongo, S. No Impacts on Users’ Health: How Indoor Air Quality Assessments Can Promote Health and Prevent Disease. In Internet of Things; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2022; pp. 43–54. [Google Scholar] [CrossRef]

- BRANZ Ltd. Designing Quality Learning Spaces: Ventilation & Indoor Air Quality; Ministry of Education: Wellington, New Zealand, 2007. [Google Scholar]

- Chojer, H.; Branco, P.T.B.S.; Martins, F.G.; Alvim-Ferraz, M.C.M.; Sousa, S.I.V. Development of low-cost indoor air quality monitoring devices: Recent advancements. Sci. Total Environ. 2020, 727, 138385. [Google Scholar] [CrossRef] [PubMed]

- Demanega, I.; Mujan, I.; Singer, B.C.; Andelkovic, A.S.; Babich, F.; Licina, D. Performance assessment of low-cost environmental monitors and single sensors under variable indoor air quality and thermal conditions. Build. Environ. 2021, 187, 107415. [Google Scholar] [CrossRef]

- Sá, J.P.; Alvim-Ferraz, M.C.M.; Martins, F.G.; Sousa, S.I.V. Application of the low-cost sensing technology for indoor air quality monitoring: A review. Environ. Technol. Innov. 2022, 28, 102551. [Google Scholar] [CrossRef]

- Karagulian, F.; Barbiere, M.; Kotsev, A.; Spinelle, L.; Gerboles, M.; Lagler, F.; Redon, N.; Crunaire, S.; Borowiak, A. Review of the performance of low-cost sensors for air quality monitoring. Atmosphere 2019, 10, 506. [Google Scholar] [CrossRef]

- Saini, J.; Dutta, M.; Marques, G. Indoor air quality monitoring systems based on internet of things: A systematic review. Int. J. Environ. Res. Public Health 2020, 17, 4942. [Google Scholar] [CrossRef] [PubMed]

- Saini, J.; Dutta, M.; Marques, G. Sensors for indoor air quality monitoring and assessment through Internet of Things: A systematic review. Environ. Monit. Assess. 2021, 193, 66. [Google Scholar] [CrossRef] [PubMed]

- Ródenas García, M.; Spinazzé, A.; Branco, P.T.B.S.; Borghi, F.; Villena, G.; Cattaneo, A.; Di Gilio, A.; Mihucz, V.G.; Gómez Álvarez, E.; Lopes, S.I.; et al. Review of low-cost sensors for indoor air quality: Features and applications. Appl. Spectrosc. Rev. 2022, 57, 747–779. [Google Scholar] [CrossRef]

- Yang, H.H.; Kwak, M.J.; Kim, K.J.; Kim, H.H. Analysis of Factors Influencing Indoor PM2.5 and CO2 Concentrations in Households using IoT Technology after Indoor Garden Installation. J. People Plant. Environ. 2022, 25, 571–583. [Google Scholar] [CrossRef]

- Justo Alonso, M.; Moazami, T.N.; Liu, P.; Jørgensen, R.B.; Mathisen, H.M. Assessing the indoor air quality and their predictor variable in 21 home offices during the COVID-19 pandemic in Norway. Build. Environ. 2022, 225, 109580. [Google Scholar] [CrossRef] [PubMed]

- Pantelic, J.; Son, Y.J.; Staven, B.; Liu, Q. Cooking emission control with IoT sensors and connected air quality interventions for smart and healthy homes: Evaluation of effectiveness and energy consumption. Energy Build. 2023, 286, 112932. [Google Scholar] [CrossRef]

- Yadav, R.; Chen, C.C.; Lee, C.Y.; Chen, N.T. Establishing a screening system of indoor air pollutants using mems sensor to create internet of things sensing platform. Sens. Mater. 2021, 33, 2275–2285. [Google Scholar] [CrossRef]

- Fritz, H.; Tang, M.; Kinney, K.; Nagy, Z. Evaluating machine learning models to classify occupants’ perceptions of their indoor environment and sleep quality from indoor air quality. J. Air Waste Manag. Assoc. 2022, 72, 1381–1397. [Google Scholar] [CrossRef]

- Kim, H.H.; Kwak, M.J.; Kim, K.J.; Gwak, Y.K.; Lee, J.H.; Yang, H.H. Evaluation of IaQ management using an iot-based indoor garden. Int. J. Environ. Res. Public Health 2020, 17, 1867. [Google Scholar] [CrossRef] [PubMed]

- Kureshi, R.R.; Thakker, D.; Mishra, B.K.; Barnes, J. From Raising Awareness to a Behavioural Change: A Case Study of Indoor Air Quality Improvement Using IoT and COM-B Model. Sensors 2023, 23, 3613. [Google Scholar] [CrossRef]

- Shrestha, P.M.; Humphrey, J.L.; Carlton, E.J.; Adgate, J.L.; Barton, K.E.; Root, E.D.; Miller, S.L. Impact of outdoor air pollution on indoor air quality in low-income homes during wildfire seasons. Int. J. Environ. Res. Public Health 2019, 16, 3535. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, R.; Heydon, J.; Mayfield, M.; Mihaylova, L. Indoor air pollution from residential stoves: Examining the flooding of particulate matter into homes during real-world use. Atmosphere 2020, 11, 1326. [Google Scholar] [CrossRef]

- Hegde, S.; Min, K.T.; Moore, J.; Lundrigan, P.; Patwari, N.; Collingwood, S.; Balch, A.; Kelly, K.E. Indoor household particulate matter measurements using a network of low-cost sensors. Aerosol Air Qual. Res. 2020, 20, 381–394. [Google Scholar] [CrossRef]

- Laltrello, S.; Amiri, A.; Lee, S.H. Indoor Particulate Matters Measured in Residential Homes in the Southeastern United States: Effects of Pandemic Lockdown and Holiday Cooking. Aerosol Air Qual. Res. 2022, 22. [Google Scholar] [CrossRef]

- Connolly, R.E.; Yu, Q.; Wang, Z.; Chen, Y.H.; Liu, J.Z.; Collier-Oxandale, A.; Papapostolou, V.; Polidori, A.; Zhu, Y. Long-term evaluation of a low-cost air sensor network for monitoring indoor and outdoor air quality at the community scale. Sci. Total Environ. 2022, 807, 150797. [Google Scholar] [CrossRef] [PubMed]

- Casey, J.G.; Ortega, J.; Coffey, E.; Hannigan, M. Low-cost measurement techniques to characterize the influence of home heating fuel on carbon monoxide in Navajo homes. Sci. Total Environ. 2018, 625, 608–618. [Google Scholar] [CrossRef] [PubMed]

- Bousiotis, D.; Alconcel, L.N.S.; Beddows, D.C.S.; Harrison, R.M.; Pope, F.D. Monitoring and apportioning sources of indoor air quality using low-cost particulate matter sensors. Environ. Int. 2023, 174, 107907. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Li, J.; Pandey, A.; Pervez, S.; Chakrabarty, R.K.; Biswas, P. Spatio-temporal measurement of indoor particulate matter concentrations using a wireless network of low-cost sensors in households using solid fuels. Environ. Res. 2017, 152, 59–65. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Hou, W.; Zhu, Y.; Zheng, S.; Ainiwaer, S.; Shen, G.; Chen, Y.; Cheng, H.; Hu, J.; Wan, Y.; et al. Temporal and spatial variation of PM2.5 in indoor air monitored by low-cost sensors. Sci. Total Environ. 2021, 770, 145304. [Google Scholar] [CrossRef]

- Sung, W.T.; Hsiao, S.J. Building an indoor air quality monitoring system based on the architecture of the Internet of Things. Eurasip J. Wirel. Commun. Netw. 2021, 2021, 153. [Google Scholar] [CrossRef]

- Taştan, M.; Gökozan, H. Real-time monitoring of indoor air quality with internet of things-based e-nose. Appl. Sci. 2019, 9, 3435. [Google Scholar] [CrossRef]

- Seiderer, A.; Aslan, I.; Dang, C.T.; Andre, E. Indoor Air Quality and Wellbeing—Enabling Awareness and Sensitivity with Ambient IoT Displays. In Proceedings of the AMBIENT INTELLIGENCE (AMI 2019), Rome, Italy, 13–15 November 2019; pp. 266–282. [Google Scholar] [CrossRef]

- Lopes, M.; Reis, J.; Fernandes, A.P.; Lopes, D.; Lourenço, R.; Nunes, T.; Faria, C.H.G.; Borrego, C.; Miranda, A.I. Indoor air quality study using low-cost sensors. WIT Trans. Ecol. Environ. 2020, 244, 1–13. [Google Scholar] [CrossRef]

- Taştan, M. A low-cost air quality monitoring system based on Internet of Things for smart homes. J. Ambient. Intell. Smart Environ. 2022, 14, 351–374. [Google Scholar] [CrossRef]

- Lady Ada. Introducing the Raspberry Pi Zero. 2024. Available online: https://cdn-learn.adafruit.com/downloads/pdf/introducing-the-raspberry-pi-zero.pdf (accessed on 12 June 2024).

- Raspberry Pi Ltd. Raspberry Pi 3 Model B+. 2023. Available online: https://datasheets.raspberrypi.com/rpi3/raspberry-pi-3-b-plus-product-brief.pdf (accessed on 12 June 2024).

- Pimoroni. Enviro for Raspberry Pi—Enviro + Air Quality. Available online: https://shop.pimoroni.com/cdn/shop/products/Enviro-Plus-pHAT-on-white-2_1500x1500_crop_center.jpg?v=1573820030 (accessed on 12 June 2024).

- Arduino®. Arduino® MEGA 2560 Rev3 Product Reference Manual. 2024. Available online: https://docs.arduino.cc/resources/datasheets/A000067-datasheet.pdf (accessed on 12 June 2024).

- Arduino®. Arduino® Nano Product Reference Manual. 2024. Available online: https://docs.arduino.cc/resources/datasheets/A000005-datasheet.pdf (accessed on 12 June 2024).

- Arduino®. Arduino Pro Mini. Available online: https://docs.arduino.cc/retired/boards/arduino-pro-mini/ (accessed on 12 June 2024).

- Espressif. Development Boards. Available online: https://www.espressif.com/en/products/devkits (accessed on 12 June 2024).

- PurpleAir. API Pricing. Available online: https://community.purpleair.com/t/api-pricing/4523 (accessed on 12 June 2024).

- ELT Sensor. T-110 Series. Available online: http://www.eltsensor.co.kr/2016/products/oem_modules/T-110.html (accessed on 28 August 2024).

- Telaire. Telaire T6703 Series CO2 Module. 2022. Available online: https://f.hubspotusercontent40.net/hubfs/9035299/Documents/AAS-920-640E-Telaire-T6703-020619-web.pdf (accessed on 28 August 2024).

- Sensirion. Datasheet SGP30 Sensirion Gas Platfrom. 2020. Available online: https://sensirion.com/media/documents/984E0DD5/61644B8B/Sensirion_Gas_Sensors_Datasheet_SGP30.pdf (accessed on 30 April 2024).

- Sensor, E. ELT Sensor Data Sheet for S-300. 2014. Available online: https://gasdetect.com/wp-content/uploads/2014/08/DS_S-300_v2.2.pdf (accessed on 28 August 2024).

- ASAIR. AHT10 Technical Manual. Available online: https://www.maritex.com.pl/product/attachment/147096/c5093eda6658ef654b651f3d5705c2ef (accessed on 28 August 2024).

- TFA. Bedienungsanleitung Instruction Manual Mode D’emploi Istruzioni per L’uso Gebruiksaanwijzing. 2014. Available online: https://com-tradebyte-core-tbone-media-live.s3.eu-central-1.amazonaws.com/media/1768/1800-600f2260b7b04.pdf (accessed on 28 August 2024).

- Handson Technology. BH1750 Ambient Light Sensor Module. Available online: https://www.handsontec.com/dataspecs/sensor/BH1750%20Light%20Sensor.pdf (accessed on 28 August 2024).

- BOSCH. BME280 Combined Humidity and Pressure Sensor. 2018. Available online: https://www.mouser.com/datasheet/2/783/BST-BME280-DS002-1509607.pdf (accessed on 28 August 2024).

- BOSCH. BME680-Datasheet. 2024. Available online: https://www.bosch-sensortec.com/media/boschsensortec/downloads/datasheets/bst-bme680-ds001.pdf (accessed on 30 April 2024).

- Bosch. Datasheet BMP180 Digital Pressure Sensor. 2013. Available online: https://cdn-shop.adafruit.com/datasheets/BST-BMP180-DS000-09.pdf (accessed on 28 August 2024).

- Bosch. Datasheet BMP280 Digital Pressure Sensor. 2015. Available online: https://cdn-shop.adafruit.com/datasheets/BST-BMP280-DS001-11.pdf (accessed on 28 August 2024).

- Alphasense. Technical Specifications Version 1.1 CO-B4/CO-B4+ Carbon Monoxide Sensor. Available online: https://ametekcdn.azureedge.net/mediafiles/project/oneweb/oneweb/alphasense/products/datasheets/alphasense_co-b4_datasheet_en_2.pdf?revision:87f7d42e-02c4-4b00-b888-bd9c8d07ed3f (accessed on 28 August 2024).

- ams. CCS811 Ultra-Low Power Digital Gas Sensor for Monitoring Indoor Air Quality. 2016. Available online: https://cdn.sparkfun.com/assets/learn_tutorials/1/4/3/CCS811_Datasheet-DS000459.pdf (accessed on 30 April 2024).

- Miller, D. Adafruit CCS811 Air Quality Sensor. 2024. Available online: https://cdn-learn.adafruit.com/downloads/pdf/adafruit-ccs811-air-quality-sensor.pdf (accessed on 30 April 2024).

- Aosong Electronics Co., Ltd. DHT22. Available online: https://www.sparkfun.com/datasheets/Sensors/Temperature/DHT22.pdf (accessed on 28 August 2024).

- SHARP. GP2Y1010AU0F. Available online: https://global.sharp/products/device/lineup/data/pdf/datasheet/gp2y1010au_e.pdf (accessed on 30 April 2024).

- Honeywell. Honeywell Laser Particle Sensor Module HPM-Series. 2016. Available online: https://www.tme.com/Document/e8973830bc95298716ba0a77d39489cc/HPMdte.PDF (accessed on 28 August 2024).

- Honeywell. HPM Series Particulate Matter Sensor. 2021. Available online: https://prod-edam.honeywell.com/content/dam/honeywell-edam/sps/siot/en-us/products/sensors/particulate-matter-sensors-hpm-series/documents/sps-siot-particulate-hpm-series-datasheet-32322550-ciid-165855.pdf (accessed on 28 August 2024).

- Senseair. Senseair K30. 2023. Available online: https://rmtplusstoragesenseair.blob.core.windows.net/docs/publicerat/PSH0131.pdf (accessed on 28 August 2024).

- Littelfuse. USP11492 Thermistor Probe. 2018. Available online: https://www.littelfuse.com/~/media/electronics/datasheets/thermistor_probes_and_assemblies/littelfuse_thermistor_probes_assemblies_straight_usp11492_datasheet.pdf.pdf (accessed on 28 August 2024).

- Zhengzhou Winsen Electronics Technology CO., Ltd. Intelligent Infrared Carbon Dioxide Module (Model: MH-Z14) User’s Manual V2.4. 2014. Available online: https://www.winsen-sensor.com/d/files/MH-Z14.pdf (accessed on 28 August 2024).

- Zhengzhou Winsen Electronics Technology CO., Ltd. Intelligent Infrared Carbon Dioxide Module (Model: MH-Z14A) User’s Manual V1.2. 2019. Available online: https://www.winsen-sensor.com/d/files/MH-Z14A.pdf (accessed on 28 August 2024).

- Zhengzhou Winsen Electronics Technology CO., Ltd. Intelligent Infrared Carbon Dioxide Module (Model: MH-Z19) User’s Manual V1.0. 2015. Available online: https://www.winsen-sensor.com/d/files/PDF/Infrared%20Gas%20Sensor/NDIR%20CO2%20SENSOR/MH-Z19%20CO2%20Ver1.0.pdf (accessed on 28 August 2024).

- SGX Sensortech. Datasheet MiCS-4514 0278 rev 15. Available online: https://www.sgxsensortech.com/content/uploads/2014/08/0278_Datasheet-MiCS-4514.pdf (accessed on 12 June 2024).

- SGX Sensortech. Datasheet MiCS-6814 1143 rev 8. Available online: https://www.sgxsensortech.com/content/uploads/2015/02/1143_Datasheet-MiCS-6814-rev-8.pdf (accessed on 12 June 2024).

- Zhengzhou Winsen Electronics Technology Co., Ltd. Toxic Gas Sensor (Model: MQ-7) Manual. 2014. Available online: https://cdn.sparkfun.com/datasheets/Sensors/Biometric/MQ-7%20Ver1.3%20-%20Manual.pdf (accessed on 28 August 2024).

- Alphasense. OPC-N3 Particle Monitor. Available online: http://www.apollounion.com/Upload/DownFiles/202108/OPC-N3.pdf (accessed on 28 August 2024).

- Alphasense. Alphassense User Manual OPC-R1 Optical Particle Counter. 2019. Available online: https://kolegite.com/EE_library/datasheets_and_manuals/sensors/OPC/072-0500_OPC-R1_manual_issue_1_250219.pdf (accessed on 28 August 2024).

- GROUP, G. 11-D Dust Decoder—Portable Aerosol Spectrometer. Available online: https://www.durag.com/mediafiles/stream/?id=4/1/5/a/415ae9786003f185440db854e09cf07880128d21_Datasheet_11_D_en_final.pdf (accessed on 28 August 2024).

- Yong, Z. Digital Universal Particle Concentration Sensor PMS3003 Series Data Manual. 2016. Available online: https://www.dynamoelectronics.com/descargas/PMS3003.pdf (accessed on 28 August 2024).

- Plantower. PMS6003. Available online: https://www.plantower.com/en/products_33/75.html (accessed on 28 August 2024).

- Yong, Z. Digital Universal Particle Concentration Sensor PMS7003 Series Data Manual. 2016. Available online: https://download.kamami.pl/p564008-PMS7003%20series%20data%20manua_English_V2.5.pdf (accessed on 28 August 2024).

- Yong, Z. Digital Universal Particle Concentration Sensor PMS5003 Series Data Manual. 2016. Available online: https://www.digikey.jp/htmldatasheets/production/2903006/0/0/1/pms5003-series-manual.html (accessed on 28 August 2024).

- Air Quality Sensor Performance Evaluation Center (AQ-SPEC). PurpleAir PA-II. Available online: https://www.aqmd.gov/aq-spec/product/purpleair-pa-ii (accessed on 28 August 2024).

- Sensirion. Datasheet Sensirion SCD30 Sensor Module. 2020. Available online: https://sensirion.com/media/documents/4EAF6AF8/61652C3C/Sensirion_CO2_Sensors_SCD30_Datasheet.pdf (accessed on 28 August 2024).

- Sensirion. SCD4x. 2023. Available online: https://sensirion.com/media/documents/48C4B7FB/64C134E7/Sensirion_SCD4x_Datasheet.pdf (accessed on 28 August 2024).

- Nova Fitness Co., Ltd. Laser PM2.5 Sensor Specificationtd. Product Model: SDS018 Version V1.5. 2015. Available online: https://ecksteinimg.de/Datasheet/SDS018%20Laser%20PM2.5%20Product%20Spec%20V1.5.pdf (accessed on 28 August 2024).

- Senseair. Senseair S8 LP. 2024. Available online: https://rmtplusstoragesenseair.blob.core.windows.net/docs/Dev/publicerat/PSH1944.pdf (accessed on 28 August 2024).

- Shinyei. Particle Sensor Model PPD42NS. 2010. Available online: https://nettigo.eu/attachments/533 (accessed on 28 August 2024).

- Sensirion. Datasheet SHT1x. 2011. Available online: https://sensirion.com/media/documents/BD45ECB5/61642783/Sensirion_Humidity_Sensors_SHT1x_Datasheet.pdf (accessed on 28 August 2024).

- Sensirion. Datasheet SHT20. 2022. Available online: https://sensirion.com/resource/datasheet/sht20 (accessed on 28 August 2024).

- Sensirion. Datasheet SHT3x-DIS. 2022. Available online: https://sensirion.com/media/documents/213E6A3B/63A5A569/Datasheet_SHT3x_DIS.pdf (accessed on 28 August 2024).

- Sensirion. Datasheet SPS30. 2023. Available online: https://sensirion.com/media/documents/8600FF88/64A3B8D6/Sensirion_PM_Sensors_Datasheet_SPS30.pdf (accessed on 28 August 2024).

- SPEC SENSORS. DGS-NO2 Ditital Gas Sensor—Nitrogen Dioxide. 2017. Available online: https://www.spec-sensors.com/wp-content/uploads/2017/01/DGS-NO2-968-043_9-6-17.pdf (accessed on 28 August 2024).

- SPEC SENSORS. DGS-CO Ditital Gas Sensor—Carbon Monoxide. 2017. Available online: https://www.spec-sensors.com/wp-content/uploads/2017/01/DGS-CO-968-034.pdf (accessed on 28 August 2024).

- Sensirion. Datasheet SVM30 Multi-Gas, Humidity and Temperature Sensor Combo Module 2019. Available online: https://sensirion.com/media/documents/9152AD80/616538A9/Sensirion_Gas_Sensors_Datasheet_SVM30.pdf (accessed on 30 April 2024).

- Ams. TSL2591. 2013. Available online: https://cdn-shop.adafruit.com/datasheets/TSL25911_Datasheet_EN_v1.pdf (accessed on 28 August 2024).

- ProSense Technologies Co., Ltd. Dart Sensors WZ-S Formaldehyde Module Operation Manual. Available online: https://www.dart-sensors.com/wp-content/uploads/2017/07/formaldehyde_module_operation-manual.pdf (accessed on 28 August 2024).

- Espressif. ESP8266 A Cost-Effective and Highly Integrated Wi-Fi MCU for IoT Applications. Available online: https://www.espressif.com/en/products/socs/esp8266 (accessed on 12 June 2024).

- Fritz, H.; Bastami, S.; Lin, C.; Nweye, K.; To, T.; Chen, L.; Le, D.; Ibarra, A.; Zhang, W.; Park, J.Y.; et al. Design, fabrication, and calibration of the Building EnVironment and Occupancy (BEVO) Beacon: A rapidly-deployable and affordable indoor environmental quality monitor. Build. Environ. 2022, 222, 109432. [Google Scholar] [CrossRef]

- World Meteorological Organization (WMO). Integrating Low-Cost Sensor Systems and Networks to Enhance Air Quality Applications; World Meteorological Organization (WMO): Geneva, Switzerland, 2024. [Google Scholar]

- Kureshi, R.R.; Mishra, B.K.; Thakker, D.; John, R.; Walker, A.; Simpson, S.; Thakkar, N.; Wante, A.K. Data-Driven Techniques for Low-Cost Sensor Selection and Calibration for the Use Case of Air Quality Monitoring. Sensors 2022, 22, 1093. [Google Scholar] [CrossRef] [PubMed]

- Rampini, L.; Re Cecconi, F. Is the Construction Sector Ready for Artificial Intelligence. In Advances in Science, Technology and Innovation; Springer: Berlin/Heidelberg, Germany, 2024; pp. 165–172. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-85189563498&doi=10.1007%2f978-3-031-52303-8_12&origin=inward&txGid=ba9a0715fb60009f2b3442a70b6b4e88 (accessed on 18 July 2024).

- Mannino, A.; Dejaco, M.C.; Re Cecconi, F. Building information modelling and internet of things integration for facility management-literature review and future needs. Appl. Sci. 2021, 11, 3062. [Google Scholar] [CrossRef]

- AI-Thinker Team. ESP-12E WiFi Module Version1.0. 2015. Available online: https://components101.com/sites/default/files/2021-09/ESP12E-Datasheet.pdf (accessed on 12 June 2024).

- Gherman, M.P.; Cheng, Y.; Gomez, A.; Saukh, O. Compensating Altered Sensitivity of Duty-Cycled MOX Gas Sensors with Machine Learning. In Proceedings of the Annual IEEE Communications Society Conference on Sensor, Mesh and Ad Hoc Communications and Networks workshops, Rome, Italy, 6–9 July 2021; Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-85111740124&doi=10.1109%2fSECON52354.2021.9491586&origin=inward&txGid=1af56e4a183870ee85c4cca3d4f6087f (accessed on 18 July 2023).

| Study Types | Ref. | Publication Year | Place of Research 1 | Research Period | Total Period | Samples | Measured Parameters 2 | Sensors Implemented | Measurement Interval | Calibration | Micro-Controller Unit | Internet Connection | Data Transmission Protocol | Data Collection Platform | Data Analysis Platform |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Devices Application | [20] | 2022 | South Korea | June 2017–May 2019 | 24 months | 10 households | T, RH, CO2, PM2.5 |

| 5 min | NM | NM 3 | Yes | NM | NM | IBM SPSS Statistics software version 27. |

| [21] | 2022 | Trondheim, Norway | 8 December 2020—28 February 2021/ 21 May 2021–21 June 2021 | 3 + 1 month | 21 houses | T, RH, CO2, Formaldehyde, TVOC |

| 5 min | Yes |

| No | N/A 3 | Local memory | IBM® SPSS® (Ver. 28.0). | |

| [22] | 2023 | Rochester, USA | NM | NM | 1 test lab 6 | PM2.5 |

| 2 min | Yes | NA | Yes | BACnet | Well Living Lab Cloud | Microsoft Azure (Microsoft, Redmond, WA, USA) | |

| [23] | 2021 | NM | NM | NM | 1 test lab 6 | VOC |

| NM | NM | NM | NM | Bluetooth | Beacon system | Beacon system | |

| [24] | 2022 | California, USA | July 2016–April2018 | 21 months | 93 residences | T. RH, light, CO2, CO, PM2.5, TVOC, NO2 |

| NM | Yes | NM | NM | NM | NM | NM | |

| [25] | 2020 | Pyeongtaek, South Korea | June 2017–September 2018 | 15 months | 8 households | T, RH, CO2, PM |

| 5 min | NM | NM | Yes | Ethernet | Honeywell | NM | |

| [26] | 2023 | Bradford, UK | September 2021–October 2021 | 2 months | 8 households | T, RH, PM10, PM2.5 |

| 15 min | Yes | NM | Yes | Wi-Fi | NM | NM | |

| [27] | 2019 | Colorado, USA | 17 August–10 October 2016/ 28 June–12 September 2017 | 2 + 3 months | 10 houses in 2016, 19 houses in 2017 | T, RH, CO, PM2.5, Other pollutants with passive samplers 4 |

| NM | Yes | NM | No | NM | Local memory | NM | |

| [28] | 2020 | Sheffield, UK | Janauary–April 2020 | 4 months | 20 households with fuel stoves | T, RH, light, noise, air pressure, distance, CO, PM2.5, PM1, NO2, NH3 |

| 145 s | Yes |

| Yes | Wi-Fi | Virtual server from the University of Sheffield | NM | |

| [29] | 2020 | Cottonwood Heights, USA | 19 May–19 July 2016 | 2 months | 1 house | T, RH, altitude PM, location |

| 1 min | Yes |

| Yes | Ethernet | InfluxDB | NM | |

| [30] | 2022 | North Alabama/Texas, USA | May 2019–May 2020 | 305 days | 2 residences | PM |

| NM | Yes | NM | Yes | NM | NM | NM | |

| [31] | 2022 | Los Angeles, USA | December 2017–June 2019 | 19 months | 1 community with 30 sensors | PM, NO2, Traffic flow |

| 80–120 s | Yes | NM | Yes | Wi-Fi | PurpleAir SERVER | NM | |

| [32] | 2018 | Navajo Nation, USA | February–April 2014 | 3 months | 41 homes | CO |

| 15 s | Yes | NM | No | NA | Local memory | MATLAB | |

| [33] | 2023 | Worcestershire, UK | 16 December 2021–2 February 2022 | 1.5 months | 1 house | T, RH, PM |

| 10 min | Yes | NM | No | NM | NM | NM | |

| [34] | 2017 | Raipur, India | NM | NM | 2 households | PM |

| NM | Yes |

| No | ZigBee | NM | NM | |

| [35] | 2021 | Beijing, China | 14 March–24 March 2020 | 10 days | 14 rooms and 1 outdoor point | PM, particle numbers |

| 1 min | Yes | NM | NM | NM | NM | SPSS Statistics 24 (IBM Corp., NY, USA) | |

| Development Log | [36] | 2021 | N/A | N/A | N/A | N/A | CO2, CO, PM2.5 |

| NM | Yes |

| No | Wi-Fi | Home gas detection and monitoring system | Excel |

| [37] | 2019 | N/A | 21 March–24 March 2019 | 4 days | 1 house | T, RH, CO2, CO, NO2, dust 7 |

| 1 min | Yes |

| Yes | Wi-Fi | Blynk (2.28.17v) IoT platform | NM | |

| Devices Performance Test | [38] | 2019 | NM | N/A | N/A | N/A | T, RH, air pressure, light, CO2, VOC, |

| N/A | Yes |

| Yes | Wi-Fi | PostgreSQL |

|

| [39] | 2020 | Salreu/Gafanha/Aveiro, Portual | September 2019–March 2020 | 6 months | 3 houses | T, RH, CO2, CO, PM10, PM2.5, NO2, OX | Sensors not mentioned | 15 min | Yes | NM | NM | NM | NM | NM | |

| [14] | 2021 | Fribourg, Switzerland. | N/A | N/A | 1 test chamber 6 | T, RH, CO2, PM, TVOC | Many sensors within commercial products 5 | 10 s to 5 min depending on the devices | Yes | N/A | No | N/A | N/A | NumPy package of Python | |

| [40] | 2022 | Manisa, Turkey | 6 Novmber –13 Novmber 2020 | 7 days | 1 house | T, RH, CO2, PM |

| 5 s | Yes |

| Yes | Wi-Fi | Blynk (2.28.17v) IoT platform | NM | |

| Review | [15] | 2022 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| Sensor or Device Code | Manufacturer or Brand 1 | Air Pollutant 2,3 | Environmental Factor 2,3 | Other Parameters | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PM1.0 | PM2.5 | PM10 | dust | CO2 | CH2O | TVOC | VOC | CO | NO2 | NH3 | PN | T | RH | AP | Light | Distance | Altitude | Location | Traffic | ||

| AHT10 | |||||||||||||||||||||

| AirCO2ntrol Mini | TFA | ||||||||||||||||||||

| AirVisual M25b | |||||||||||||||||||||

| Amphenol Telaire T6703-5 K | |||||||||||||||||||||

| BH1750 4 | |||||||||||||||||||||

| BME280 | Bosch | ||||||||||||||||||||

| BME680 | Bosch | ||||||||||||||||||||

| BMP180 | Bosch | ||||||||||||||||||||

| BMP280 | |||||||||||||||||||||

| CO-B4 | Alphasense | ||||||||||||||||||||

| CSS811 | |||||||||||||||||||||

| DHT22 | Aosong Electronics | ||||||||||||||||||||

| GP2Y1010AU0F | SHARP | ||||||||||||||||||||

| GPY1010AU0F | SHARP | ||||||||||||||||||||

| HPM Series | Honeywell | ||||||||||||||||||||

| HPMA115S0-XXX | Honeywell | ||||||||||||||||||||

| iAM | AMS | ||||||||||||||||||||

| K30 | CO2meter | ||||||||||||||||||||

| Lit92 | Littelfuse | ||||||||||||||||||||

| MH-Z14 | |||||||||||||||||||||

| MH-Z14A | |||||||||||||||||||||

| MH-Z19A | |||||||||||||||||||||

| MICS-4514 | |||||||||||||||||||||

| MICS6814 | |||||||||||||||||||||

| MQ7 | |||||||||||||||||||||

| OPC-N3 | Alphasense | ||||||||||||||||||||

| OPC-R1 | Alphasense | ||||||||||||||||||||

| PASDD Model 11-D | Grimm Technologies | ||||||||||||||||||||

| PMS3003 | Plantower | ||||||||||||||||||||

| PMS6003 | Plantower | ||||||||||||||||||||

| PMS7003 | Plantower | ||||||||||||||||||||

| PM-Model-II | Green Built EnvMent | ||||||||||||||||||||

| Purple Air PA-II | PurpleAir | ||||||||||||||||||||

| S-300 | ELT Sensor | ||||||||||||||||||||

| SCD30 | Sensirion | ||||||||||||||||||||

| SCD40 | Sensirion | ||||||||||||||||||||

| SDS018 | NovaFitness | ||||||||||||||||||||

| SenseAir S8 | SenseAir | ||||||||||||||||||||

| SGP30 | Sensirion | ||||||||||||||||||||

| Shintei ppd42 | |||||||||||||||||||||

| SHT11 | Sensirion | ||||||||||||||||||||

| SHT20 | Sensirion | ||||||||||||||||||||

| SHT30 | Sensirion | ||||||||||||||||||||

| SHT31-D | Sensirion | ||||||||||||||||||||

| SPS30 | Sensirion | ||||||||||||||||||||

| SPEC DGS-NO2 | |||||||||||||||||||||

| SPEC DGS-CO | |||||||||||||||||||||

| SVM30 | Sensirion | ||||||||||||||||||||

| T-110 | ELT sensor | ||||||||||||||||||||

| TSL2591 4 | |||||||||||||||||||||

| WZ-S formaldehyde module | DART | ||||||||||||||||||||

| Y-Pods | Hannigan Lab | ||||||||||||||||||||

| LTR-559 4 | |||||||||||||||||||||

| Ultimate GPS breakout 4 | Adafriut | ||||||||||||||||||||

| (VDS)-718,297 4 | CalTrans | ||||||||||||||||||||

| included sensor numbers | 13 | 16 | 9 | 1 | 11 | 1 | 3 | 1 | 6 | 3 | 1 | 1 | 15 | 13 | 2 | 3 | 1 | 1 | 1 | 1 | |

| Sensor Type | Ref. | Parameters | Retail Price | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T | RH | PM | VOC | CO2 | CO | NO2 | |||

| Commercial devices with low-cost sensors mentioned in the literature with their cost 1 | |||||||||

| Netatmo (I/O unit) | [14] | USD 165 | |||||||

| Awair 2nd Edition (Awair) | [14] | USD 199 | |||||||

| Foobot | [14] | USD 199 | |||||||

| Kaiterra Laser Egg (Kaiterra) | [14] | USD 199 | |||||||

| AirU | [29] | USD 200 | |||||||

| AirVisual Pro (AirVisual) | [14] | USD 269 | |||||||

| uHoo (uHoo) | [14] | USD 329 | |||||||

| UMDS | [29] | USD 366 | |||||||

| Clarity Node (Clarity) | [14] | USD 1000 | |||||||

| Research level devices as reference mentioned in the literature with their cost 1 | |||||||||

| TSI Sidepak AM510 | [34] | USD 3500 | |||||||

| AirMetrics MiniVol | [29] | USD 3650 | |||||||

| TSI DustTrak II | [29] | USD 5000 | |||||||

| GRIMM 1.109 | [29] | USD 12,000 | |||||||

| Part of the sensors mentioned in the literature with their costs 1 | |||||||||

| DHT22 | [37] | USD 3.0 | |||||||

| SHT 31 2 | [14] | USD 14.5 | |||||||

| LIT 92 | [14] | USD 16.5 | |||||||

| GP2Y1010AU | [37] | USD 5.0 | |||||||

| PMS7003 | [40] | USD 17.0 | |||||||

| Honeywell HPM series | [29] | <USD 20 | |||||||

| Sharp GP2Y1010 | [29] | <USD 20 | |||||||

| Shinyei PPD42NS | [29] | <USD 20 | |||||||

| Plantower PMS series | [29] | <USD 20 | |||||||

| SDS018 | [14] | USD 26.8 | |||||||

| SPS30 | [14] | USD 46.7 | |||||||

| Alphasense OPC-R1 | [14] | USD 116.0 | |||||||

| Alphasense OPC-N3 | [14,33] | USD 305.0/GBP 250 | |||||||

| MH-Z19A | [40] | USD 15.0 | |||||||

| MH-Z14 | [37] | USD 25.0 | |||||||

| K30 | [14] | USD 85.0 | |||||||

| Alphasense CO-B4 | [32] | USD 80.0 | |||||||

| USB-EL-CO300 | [32] | USD 125.0 | |||||||

| MICS-4514 | [37] | USD 20.0 | |||||||

| Ref. | Parameters | Reference Devices | Calibration Methods |

|---|---|---|---|

| [22] | PM |

| Calibrated at background level, 150, 400, and 900 μg/m3 with the reference device. |

| [27] | PN, BC, CO, NO2 | NM | Calibrated with federal reference monitors from the Colorado Department of Public Health and Environment. |

| [28] | PM |

| Humidity-based bias correction and k -Köhler theory are methods used to calibrate LCS PM sensors with Palas Findas 200 as reference devices. |

| [39] | CO, CO2, NO2, PM10, PM2.5, O3 |

| The two reference devices and the LCS devices had intercomparison as calibration. |

| [29] | PM |

| One calibration week with LCS and four research-level devices together in the rooms (door closed). |

| [40] | T, RH, PM, CO2 |

| 1-week calibration, T and RH calibrated with Xiaomi Mijia; PM and CO2 calibrated with Dienmern DM72B. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Gola, M.; Settimo, G.; Buffoli, M.; Capolongo, S. Feasibility and Affordability of Low-Cost Air Sensors with Internet of Things for Indoor Air Quality Monitoring in Residential Buildings: Systematic Review on Sensor Information and Residential Applications, with Experience-Based Discussions. Atmosphere 2024, 15, 1170. https://doi.org/10.3390/atmos15101170

Yu Y, Gola M, Settimo G, Buffoli M, Capolongo S. Feasibility and Affordability of Low-Cost Air Sensors with Internet of Things for Indoor Air Quality Monitoring in Residential Buildings: Systematic Review on Sensor Information and Residential Applications, with Experience-Based Discussions. Atmosphere. 2024; 15(10):1170. https://doi.org/10.3390/atmos15101170

Chicago/Turabian StyleYu, Yong, Marco Gola, Gaetano Settimo, Maddalena Buffoli, and Stefano Capolongo. 2024. "Feasibility and Affordability of Low-Cost Air Sensors with Internet of Things for Indoor Air Quality Monitoring in Residential Buildings: Systematic Review on Sensor Information and Residential Applications, with Experience-Based Discussions" Atmosphere 15, no. 10: 1170. https://doi.org/10.3390/atmos15101170