Study on the Influence of the Cell Structure on the Pressure Drop of Gasoline Particulate Filter

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mathematical Model

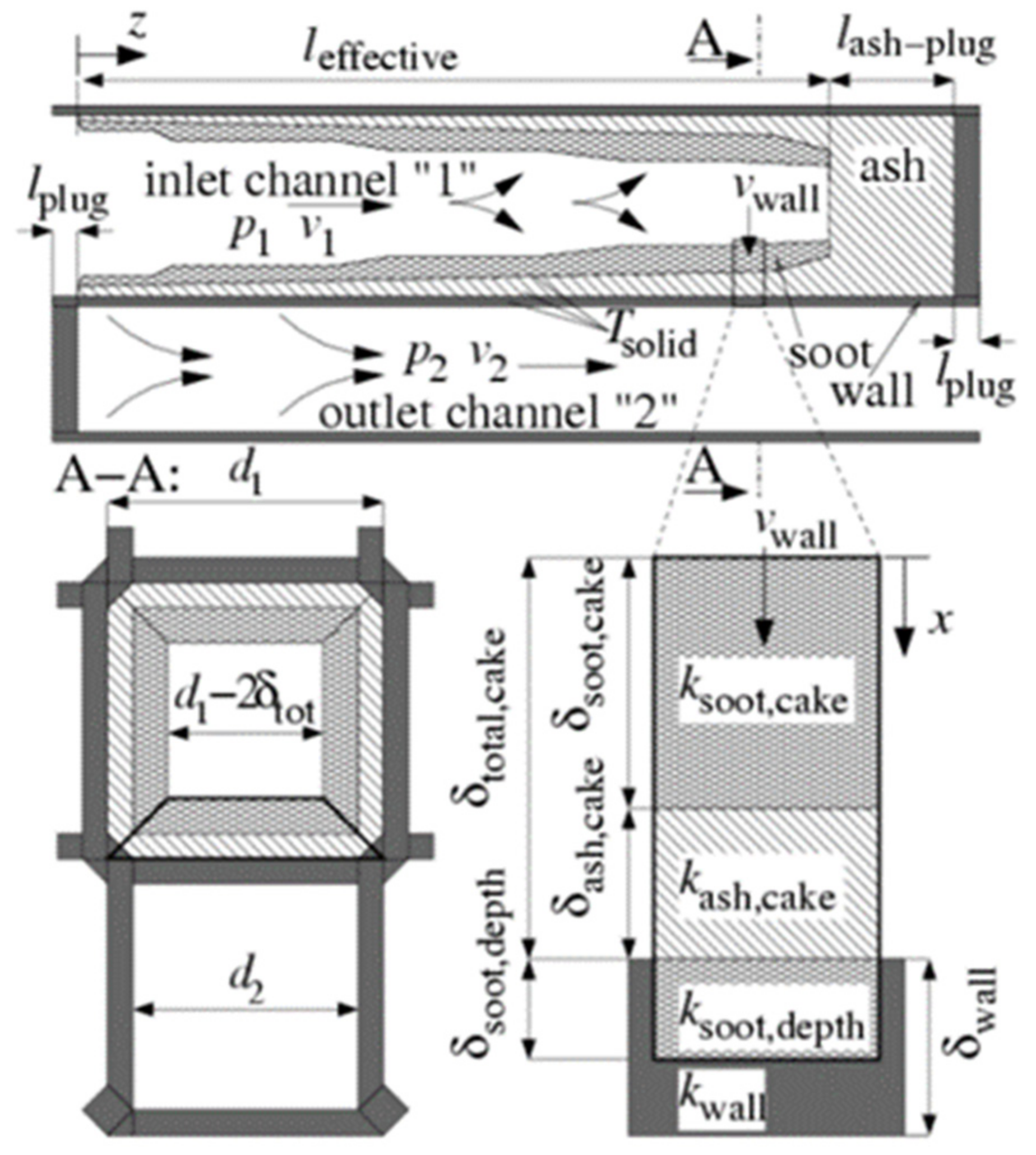

2.1.1. GPF Internal Flow Field Model

2.1.2. GPF Internal Pressure Drop Model

2.2. Model Building

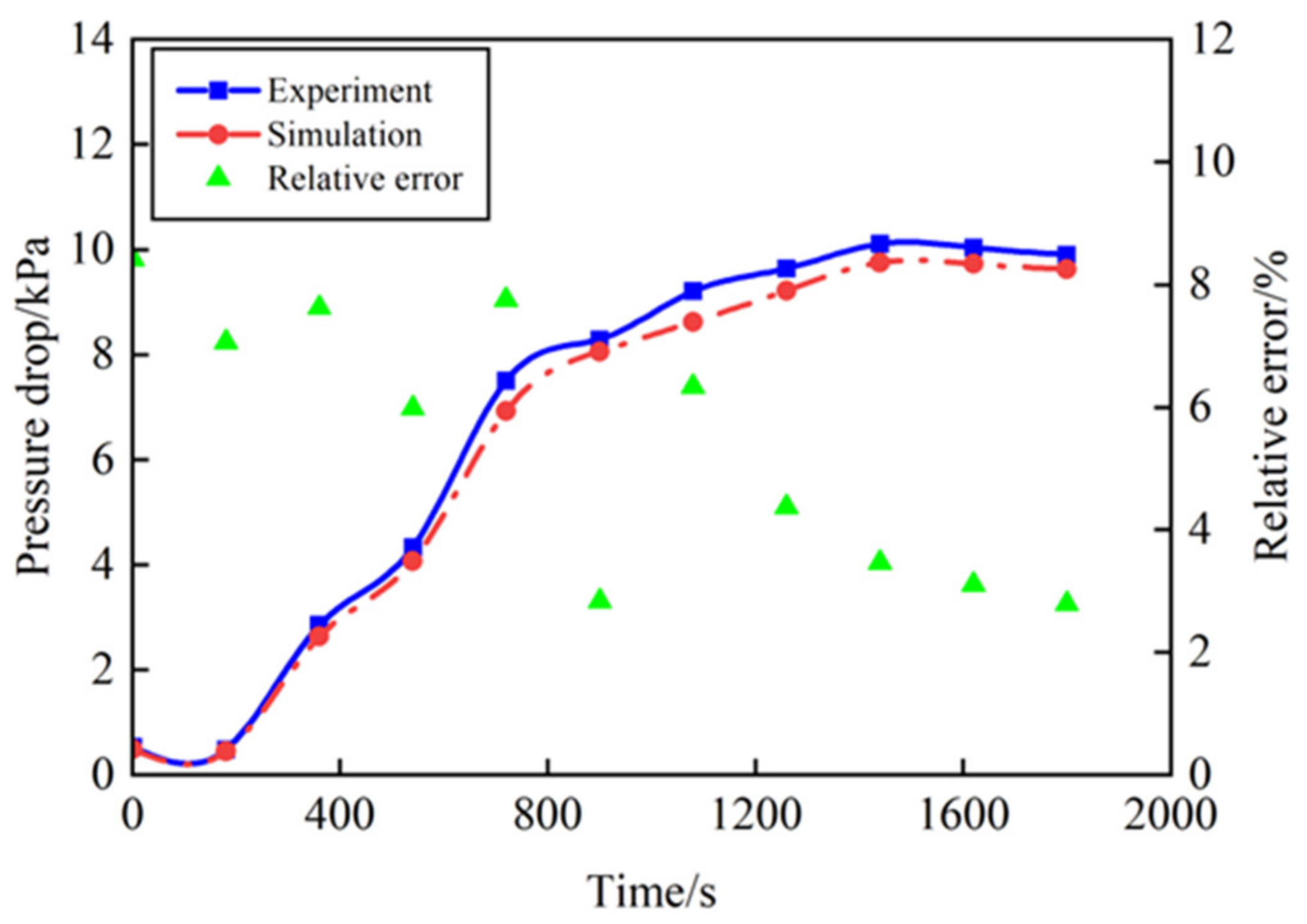

2.3. Model Verification

3. Results and Discussion

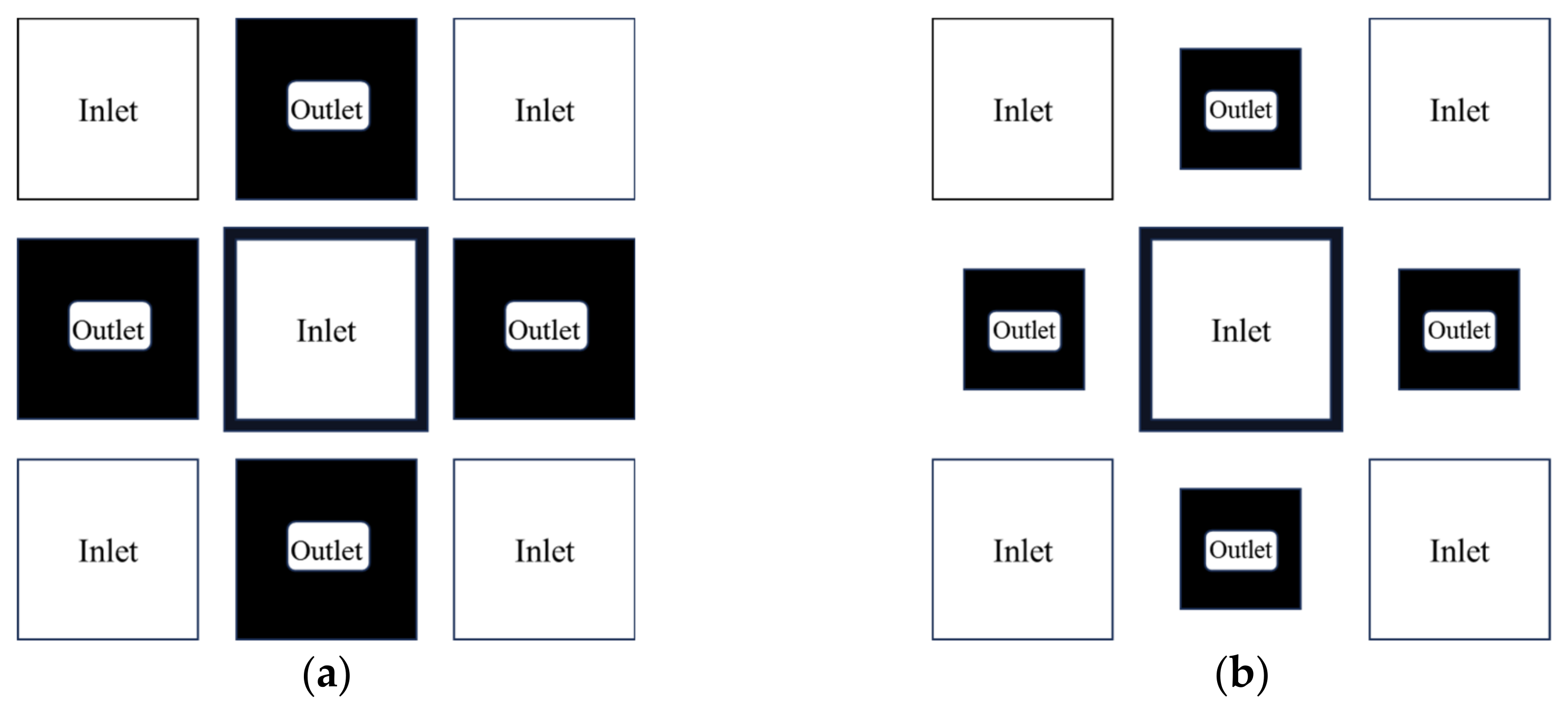

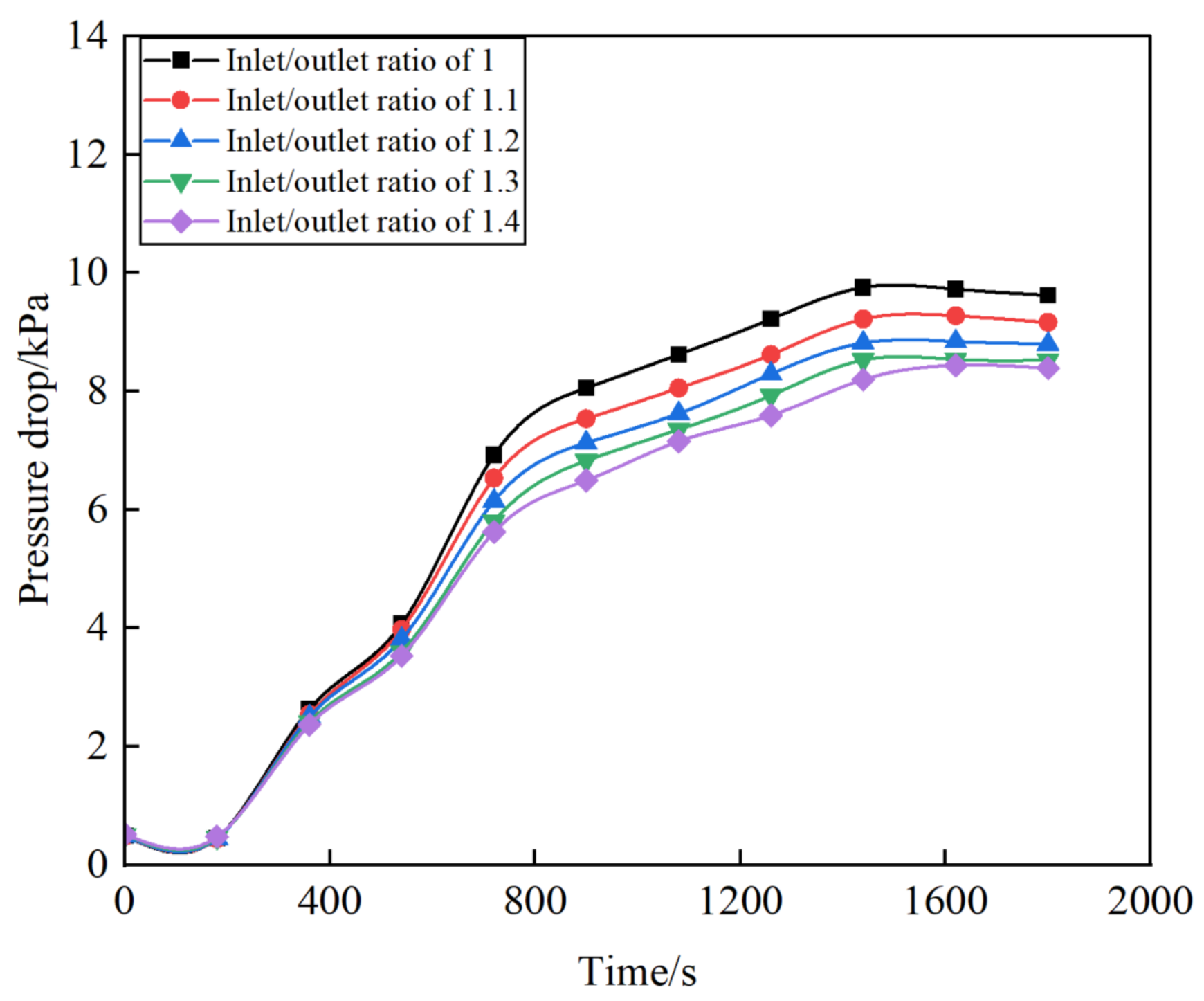

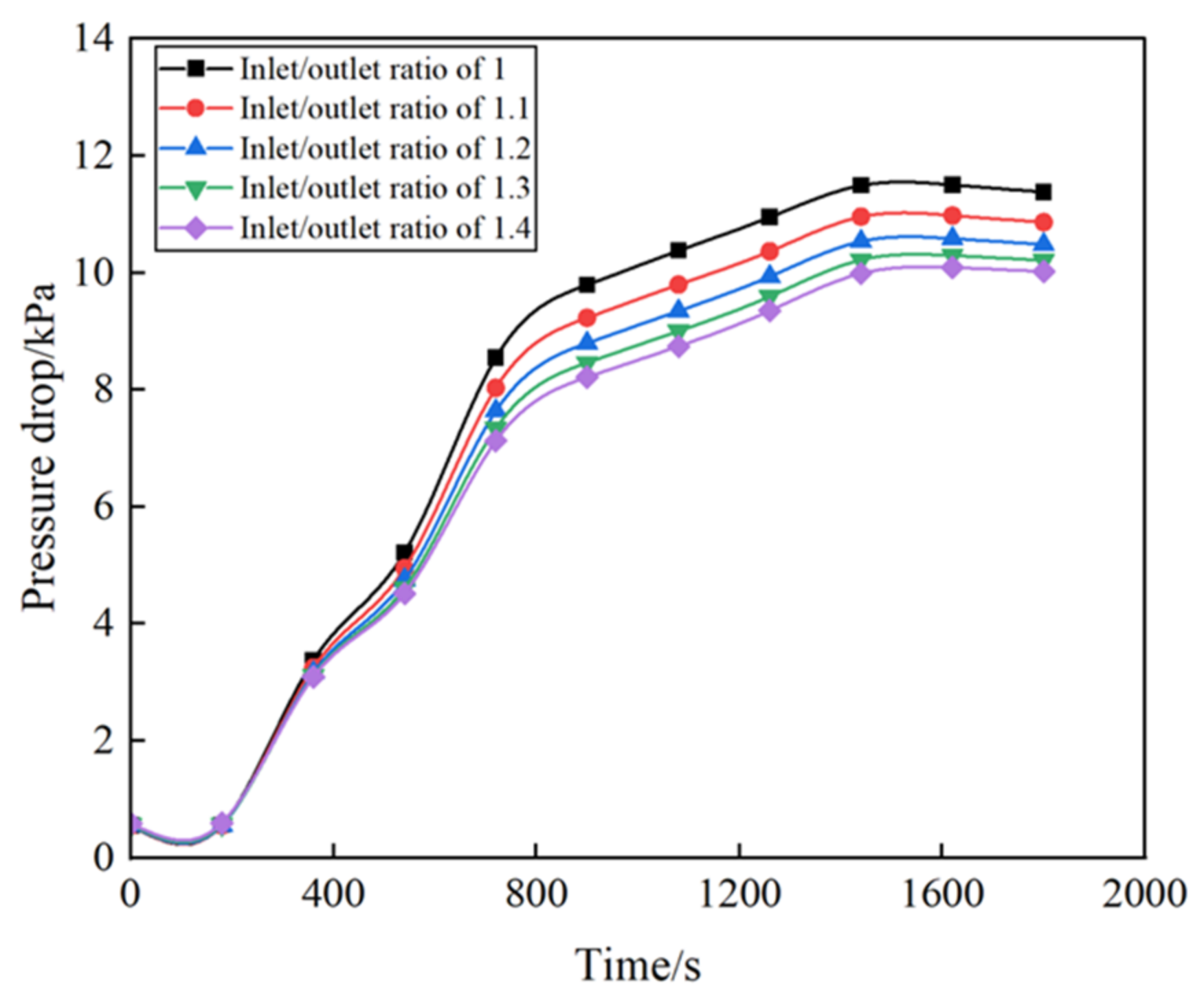

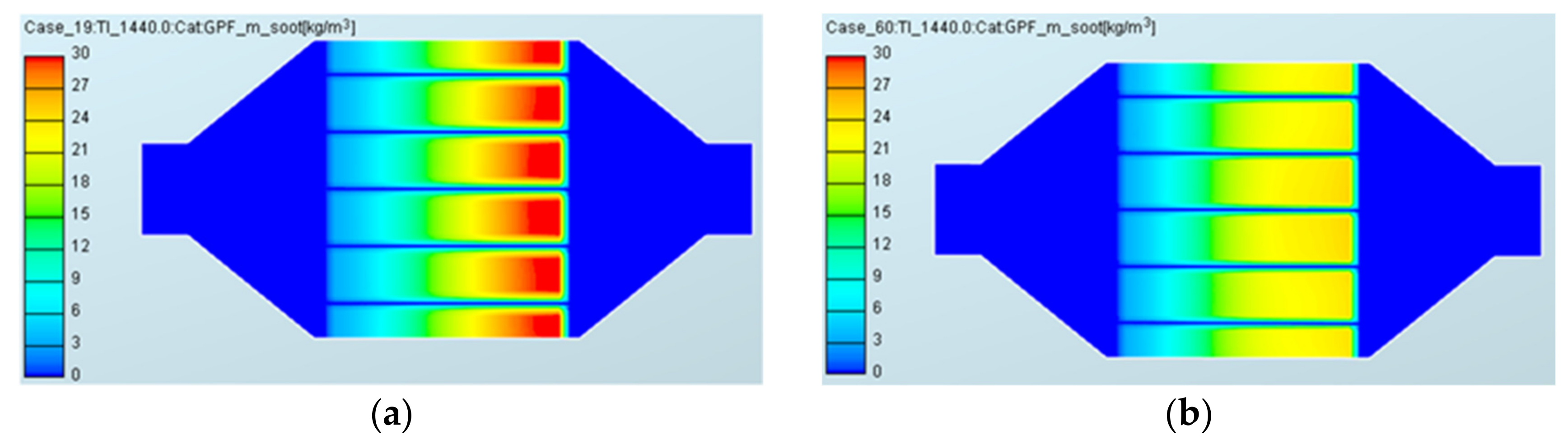

3.1. Effect of Asymmetric Cell Structure on Pressure Drop

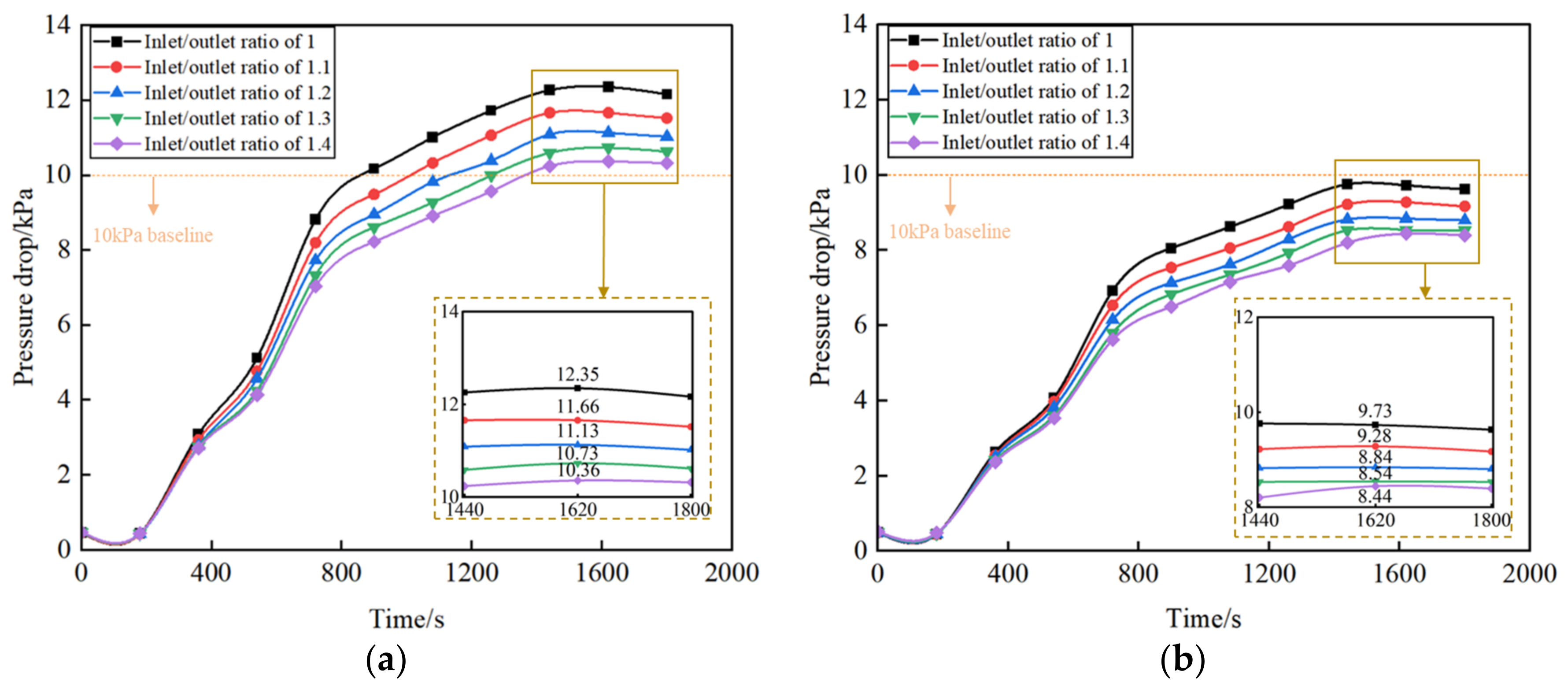

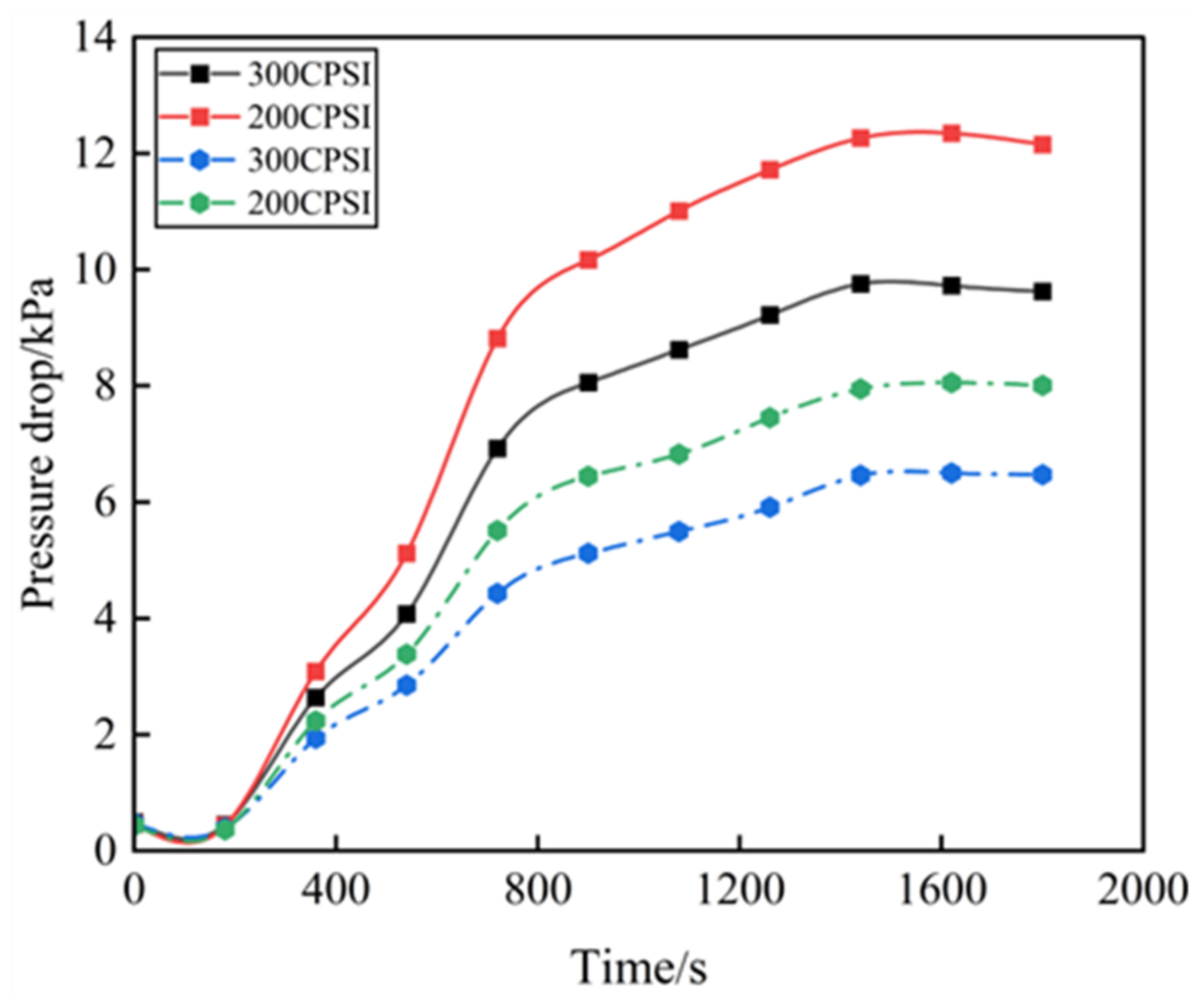

3.1.1. Effect of Asymmetric Cell Side Length Ratio on Pressure Drop Characteristics of GPF at Different Cell Densities

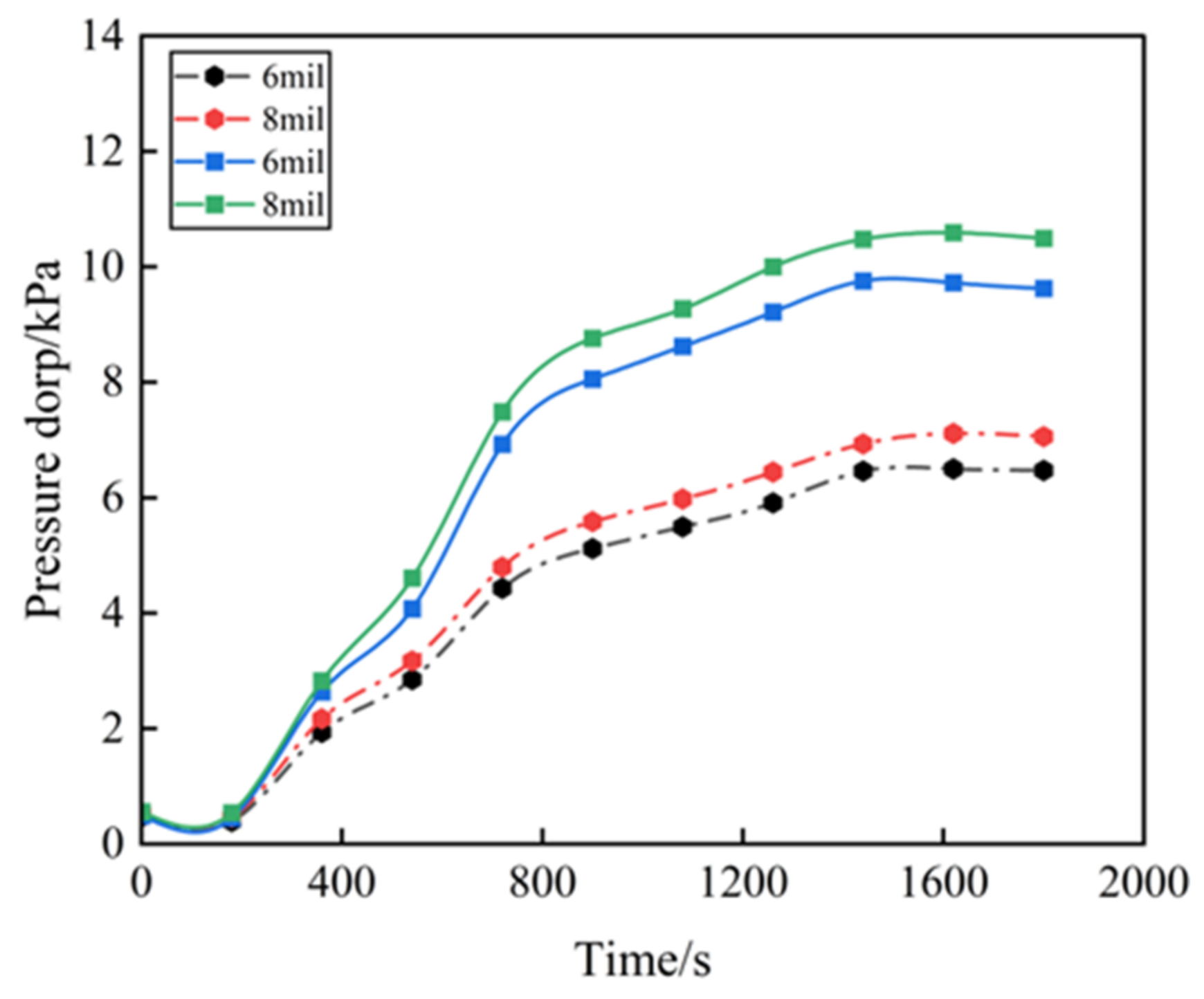

3.1.2. Effect of Asymmetric Cell Side Length Ratio on Pressure Drop Characteristics of GPF at Different Filter Wall Thicknesses

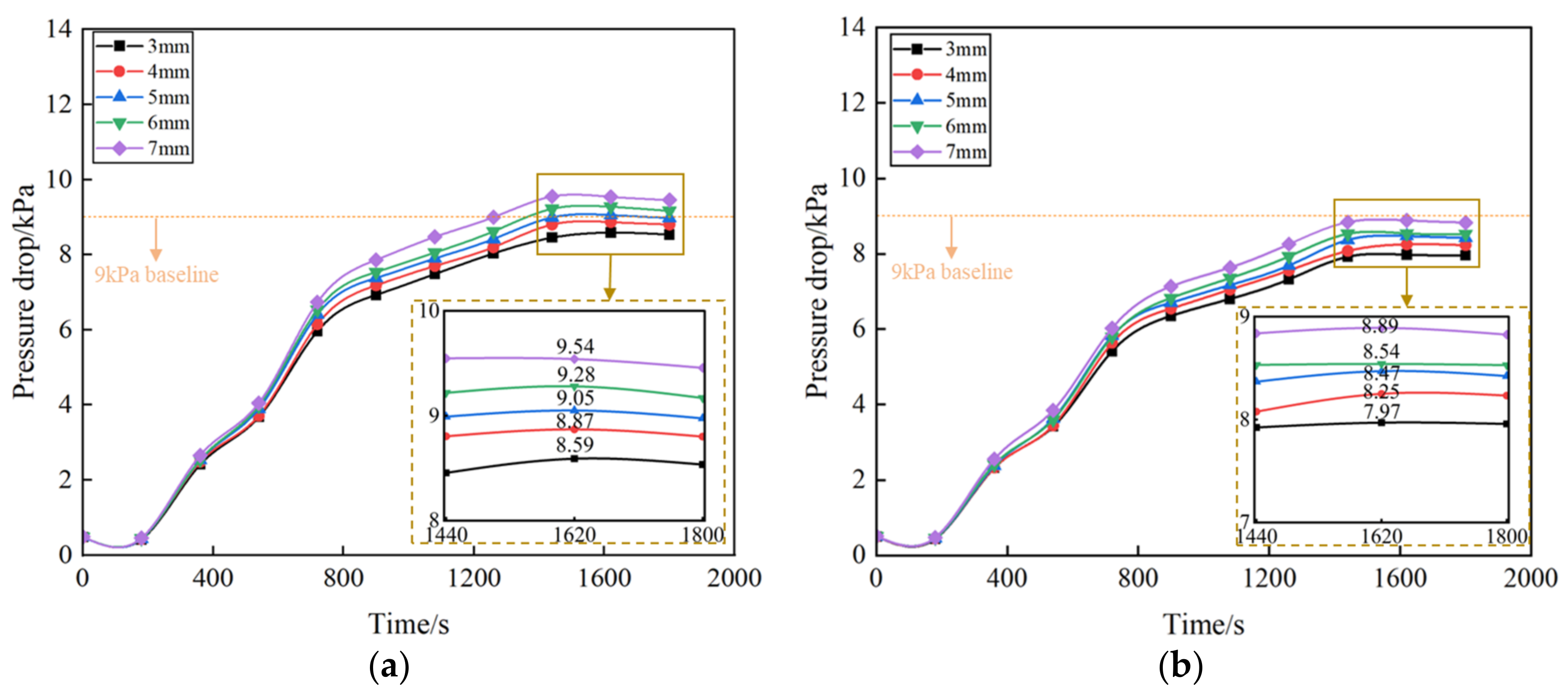

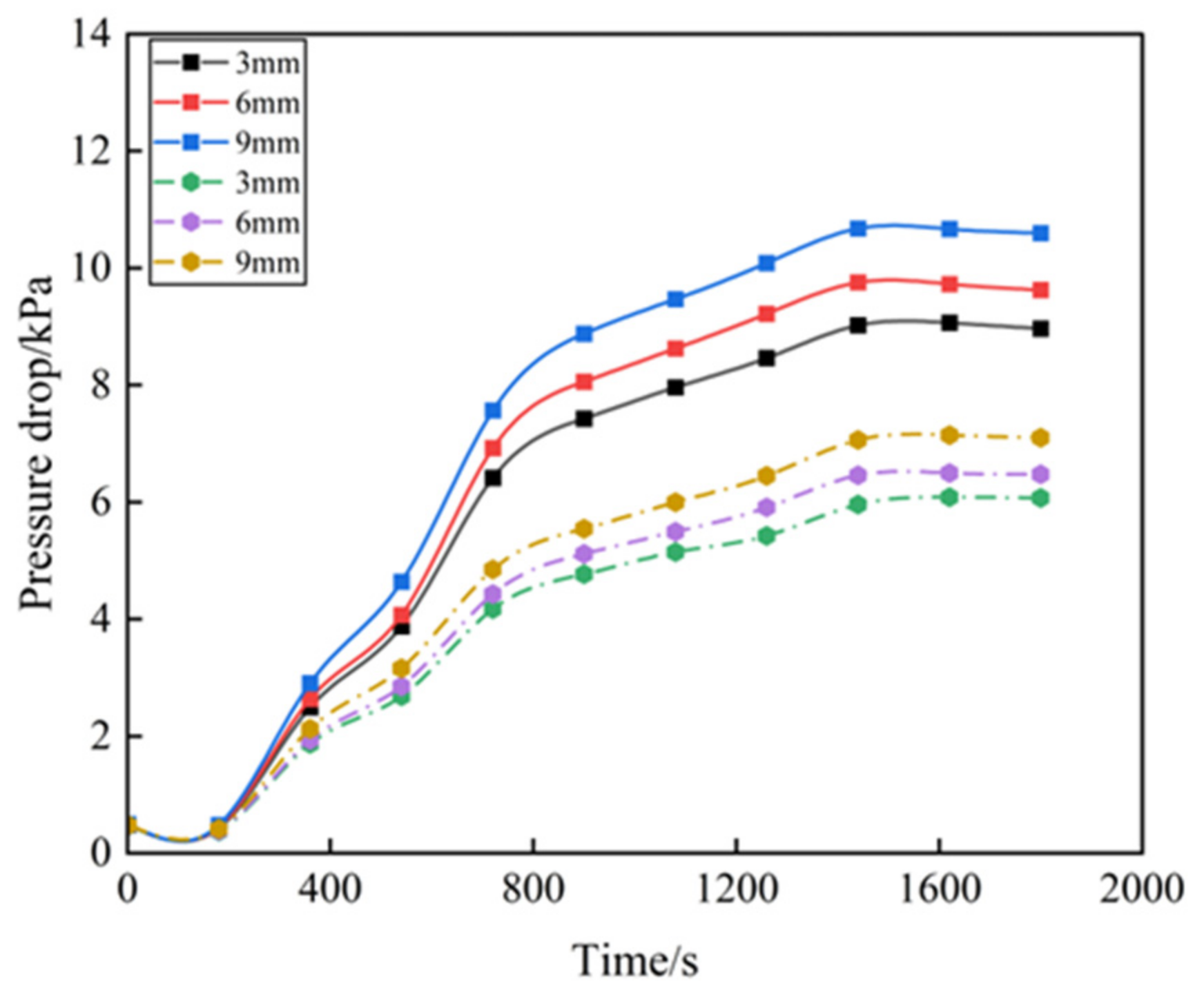

3.1.3. Effect of Asymmetric Cell Side Length Ratio on Pressure Drop Characteristics of GPF at Different Plug Lengths

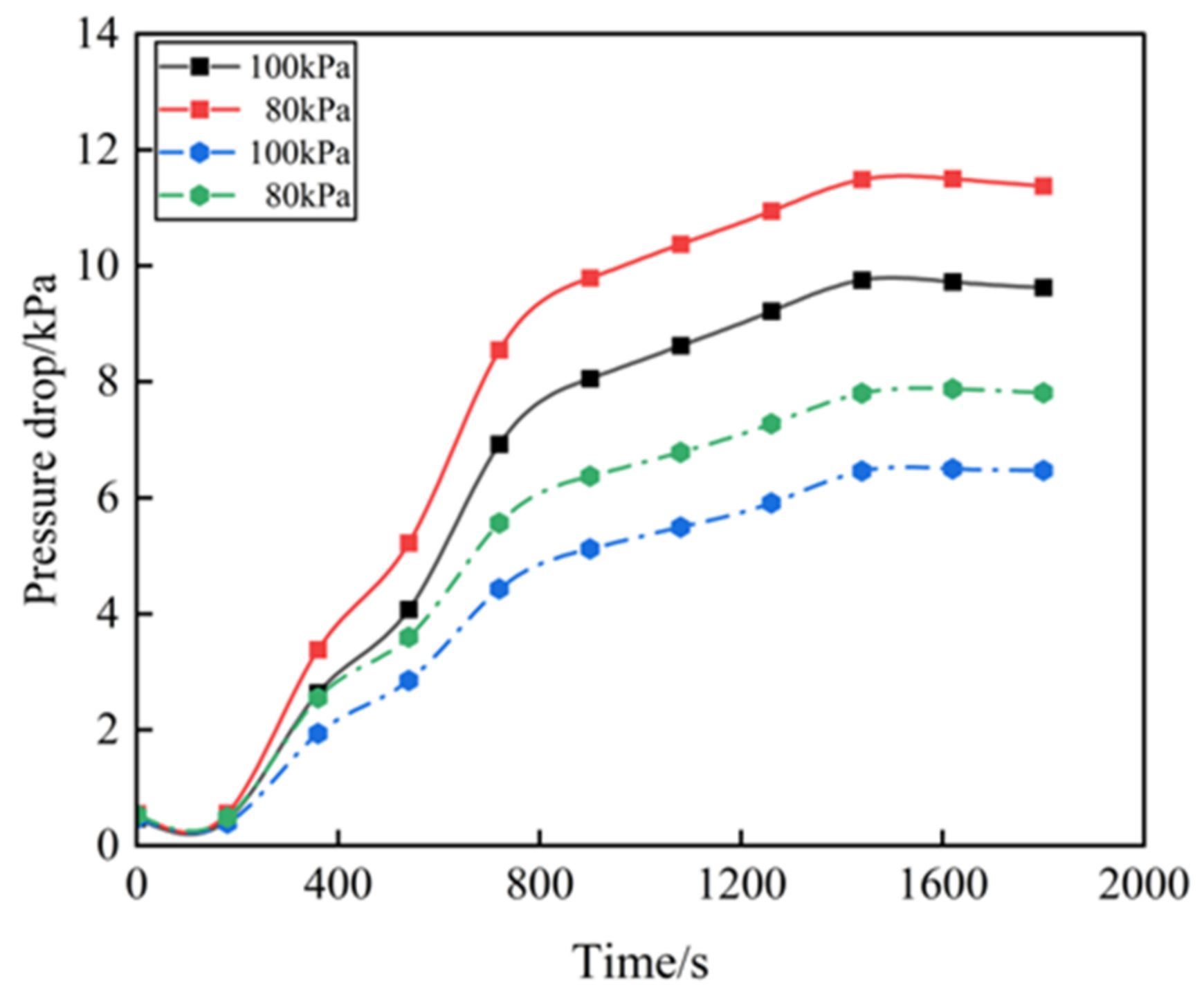

3.1.4. Effect of Asymmetric Cell Side Length Ratio on Pressure Drop Characteristics of GPF at Different Altitudes

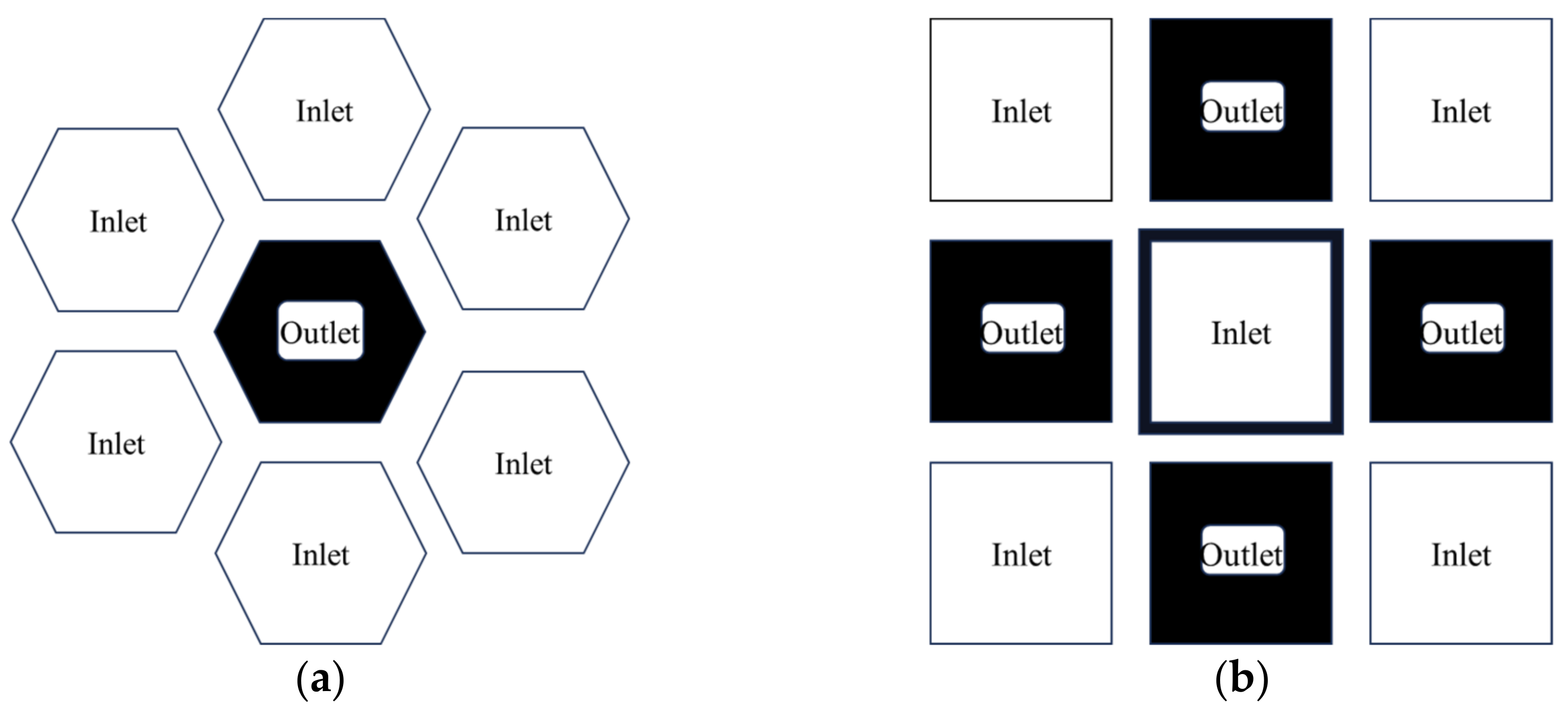

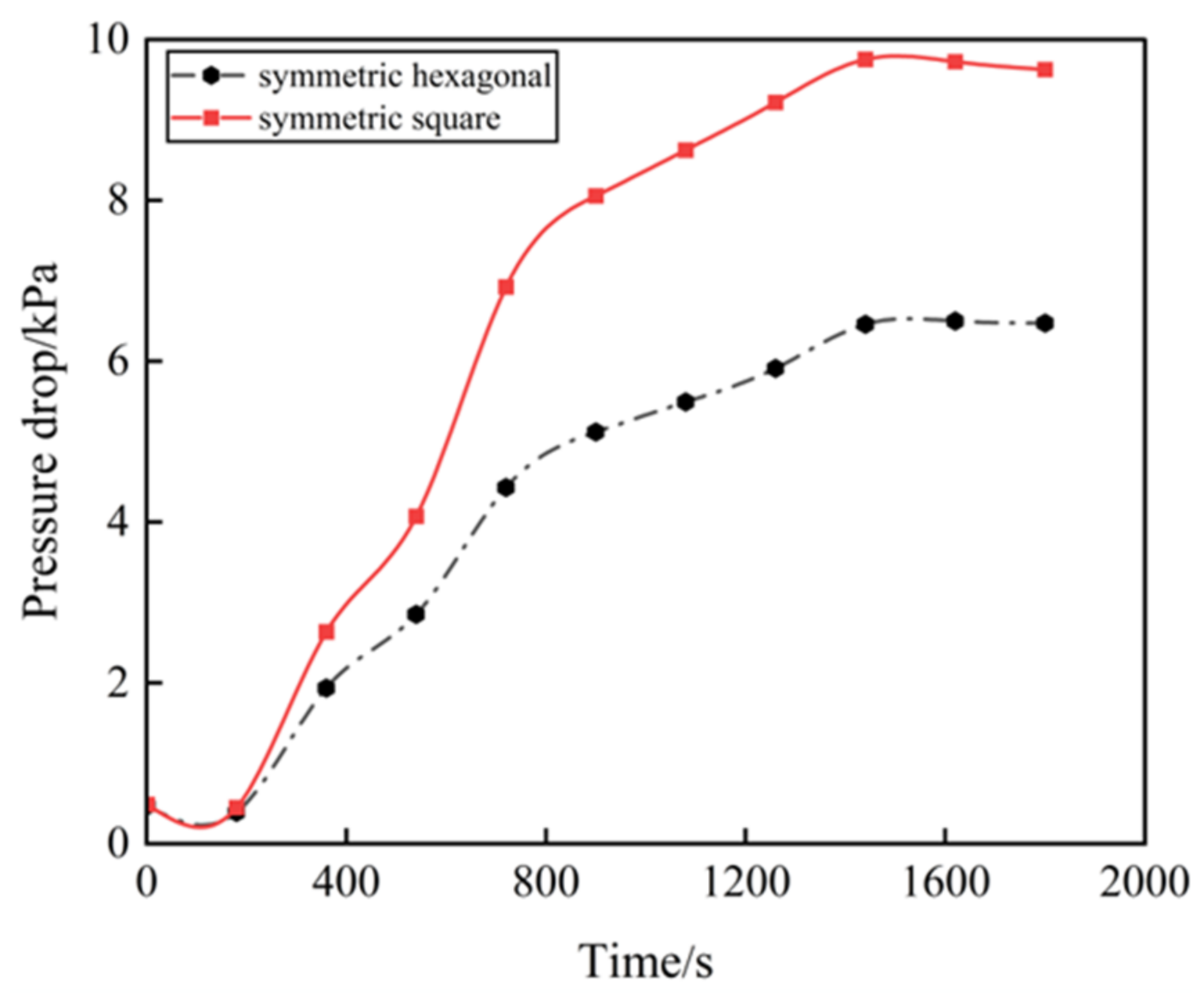

3.2. Effect of Cell Structure Shape on GPF Pressure Drop

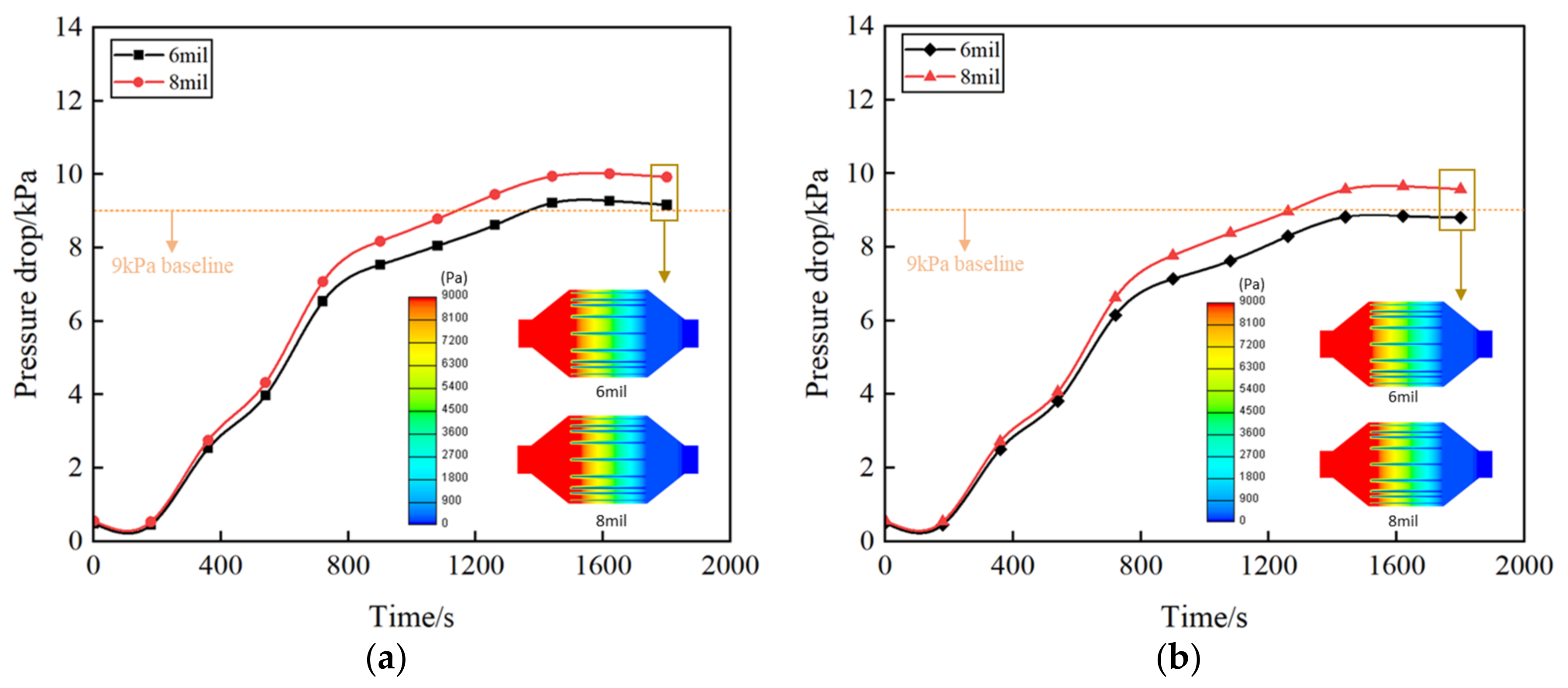

3.2.1. Effect of Cell Structure Shape on GPF Pressure Drop Characteristics under Different Cell Densities

3.2.2. Effect of Cell Structure Shape on GPF Pressure Drop Characteristics under Different Filter Wall Thicknesses

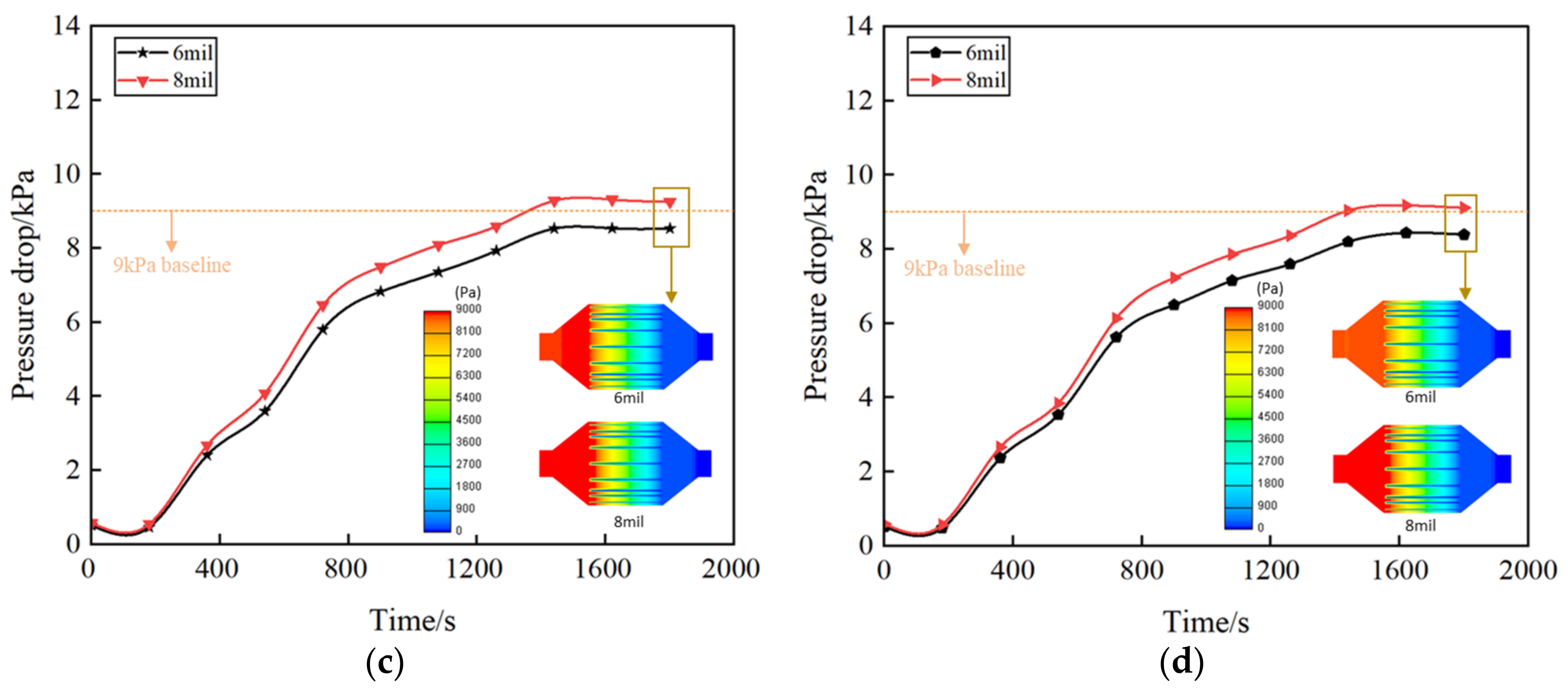

3.2.3. Effect of Cell Structure Shape on GPF Pressure Drop Characteristics under Different Plug Lengths

3.2.4. Effect of Cell Structure Shape on GPF Pressure Drop Characteristics under Different Altitudes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ni, T.; Han, B.; Bai, Z. Source apportionment of PM10 in four cities of northeastern China. Aerosol Air Qual. Res. 2012, 12, 571–582. [Google Scholar] [CrossRef]

- Li, H.; Wang, Q.; Yang, M.; Li, F.; Wang, J.; Sun, Y.; Wang, C.; Wu, H.; Qian, X. Chemical characterization and source apportionment of PM2.5 aerosols in a megacity of Southeast China. Atmos. Res. 2016, 181, 288–299. [Google Scholar] [CrossRef]

- Zhu, R.; Hu, J.; Bao, X.; He, L.; Lai, Y.; Zu, L.; Li, Y.; Su, S. Tailpipe emissions from gasoline direct injection (GDI) and port fuel injection (PFI) vehicles at both low and high ambient temperatures. Environ. Pollut. 2016, 216, 223–234. [Google Scholar] [CrossRef]

- Ko, J.; Kim, K.; Chung, W.; Myung, C.-L.; Park, S. Characteristics of on-road particle number (PN) emissions from a GDI vehicle depending on a catalytic stripper (CS) and a metal-foam gasoline particulate filter (GPF). Fuel 2019, 238, 363–374. [Google Scholar] [CrossRef]

- Davis, S.C.; Williams, S.E.; Boundy, R.G.; Moore, S. 2015 Vehicle Technologies Market Report; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2016. [Google Scholar]

- Duronio, F.; De Vita, A.; Allocca, L.; Anatone, M. Gasoline direct injection engines—A review of latest technologies and trends. Part 1: Spray breakup process. Fuel 2020, 265, 116948. [Google Scholar] [CrossRef]

- Joshi, A.; Johnson, T.V. Gasoline particulate filters—A review. Emiss. Control Sci. Technol. 2018, 4, 219–239. [Google Scholar] [CrossRef]

- Rotondi, R. Modeling mixture formation in a gasoline direct injection engine. J. Appl. Mech. 2006, 73, 931–939. [Google Scholar] [CrossRef]

- Adam, F.; Olfert, J.; Wong, K.F.; Kunert, S.; Richter, J.M. Effect of Engine-Out Soot Emissions and the Frequency of Regeneration on Gasoline Particulate Filter Efficiency; SAE Technical Paper; SAE: Warrendale, PA, USA, 2020. [Google Scholar]

- Martínez-Munuera, J.C.; Zoccoli, M.; Giménez-Mañogil, J.; García-García, A. Lattice oxygen activity in ceria-praseodymia mixed oxides for soot oxidation in catalysed Gasoline Particle Filters. Appl. Catal. B Environ. 2019, 245, 706–720. [Google Scholar] [CrossRef]

- Jang, J.; Lee, J.; Choi, Y.; Park, S. Reduction of particle emissions from gasoline vehicles with direct fuel injection systems using a gasoline particulate filter. Sci. Total Environ. 2018, 644, 1418–1428. [Google Scholar] [CrossRef]

- Kontses, A.; Triantafyllopoulos, G.; Ntziachristos, L.; Samaras, Z. Particle number (PN) emissions from gasoline, diesel, LPG, CNG and hybrid-electric light-duty vehicles under real-world driving conditions. Atmos. Environ. 2020, 222, 117126. [Google Scholar] [CrossRef]

- Yue, H.; Lehmen, A.; Van Nieuwstadt, M.; Pan, Z.; Wang, J.; Fang, Z. A study on the filtration efficiency and regeneration capacity of the gasoline particulate filter. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 346–361. [Google Scholar] [CrossRef]

- Lee, Z.; Kim, T.; Park, S. Influences of exhaust load and injection timing on particle number emissions in a gasoline direct injection engine. Fuel 2020, 268, 117344. [Google Scholar] [CrossRef]

- Saito, C.; Nakatani, T.; Miyairi, Y.; Yuuki, K.; Makino, M.; Kurachi, H.; Heuss, W.; Kuki, T.; Furuta, Y.; Kattouah, P.; et al. New Particulate Filter Concept to Reduce Particle Number Emissions; SAE Technical Paper; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Ito, Y.; Shimoda, T.; Aoki, T.; Shibagaki, Y.; Yuuki, K.; Sakamoto, H.; Vogt, C.; Matsumoto, T.; Heuss, W.; Kattouah, P.; et al. Advanced Ceramic Wall Flow Filter for Reduction of Particulate Number Emission of Direct Injection Gasoline Engines; SAE Technical Paper; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Zuo, Q.; Yang, X.; Zhu, X.; Guan, Q.; Wei, K.; Shen, Z.; Zhu, G.; Zhang, B. Effects of structural optimization design of gasoline particulate filter on soot emission and performance of GDI engine. Int. J. Environ. Sci. Technol. 2022, 19, 11199–11216. [Google Scholar] [CrossRef]

- Niu, Y.; Zhang, T.; Liu, X.; Feng, S.; Zhang, Q. Simulation study of GPF performance based AVL-FIRE. J. Hebei Univ. Technol. 2018, 47, 37–41. [Google Scholar]

- Kannan, R.; Ramappan, V.; Mehta, Z.; Govindula, S.S.; Zielinski, A.; Thornton, M.; Gillim, A.; Paramadhayalan, T. Pressure Drop Performance of Gasoline Particulate Filters-Experimental and Modeling Study; SAE Technical Paper; SAE: Warrendale, PA, USA, 2022. [Google Scholar]

- Ito, Y.; Shimoda, T.; Aoki, T.; Yuuki, K.; Sakamoto, H.; Kato, K.; Thier, D.; Kattouah, P.; Ohara, E.; Vogt, C. Next Generation of Ceramic Wall Flow Gasoline Particulate Filter with Integrated Three Way Catalyst; SAE Technical Paper; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Shimoda, T.; Ito, Y.; Saito, C.; Nakatani, T.; Shibagaki, Y.; Yuuki, K.; Sakamoto, H.; Vogt, C.; Matsumoto, T.; Furuta, Y.; et al. Potential of a Low Pressure Drop Filter Concept for Direct Injection Gasoline Engines to Reduce Particulate Number Emission; SAE Technical Paper; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Piscaglia, F.; Ferrari, G. A novel 1D approach for the simulation of unsteady reacting flows in diesel exhaust after-treatment systems. Energy 2009, 34, 2051–2062. [Google Scholar] [CrossRef]

- Yao, S.; Wang, K.; Zhang, X.; Song, C.; Lei, H.; Lv, G. Simulation study on the regeneration equilibrium state of gasoline particulate filters. Chin. Intern. Combust. Engine Eng. 2021, 42, 93–99. [Google Scholar]

- Villata, G.; Tarabocchia, A.; Bozzolini, V.; Caroca, J.; Russo, N.; Fino, D.; Saracco, G.; Specchia, V. Pollutants emissions during mild catalytic DPF regeneration in light-duty vehicles. SAE Int. J. Fuels Lubr. 2009, 2, 78–87. [Google Scholar] [CrossRef]

- Li, L. Simulation Analysis and Experimental Verification GPF Technology of GDI Engines; Hebei University of Technology: Tianjin, China, 2015. [Google Scholar]

- Chen, Z.; Li, Z.; Jiao, P.; Zhang, W.; Gao, L. Simulation DPF with different characteristics channels. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering, Wuhan, China, 15–17 April 2011; pp. 5302–5305. [Google Scholar]

- Tsuneyoshi, K.; Yamamoto, K. Experimental study of hexagonal and square diesel particulate filters under controlled and uncontrolled catalyzed regeneration. Energy 2013, 60, 325–332. [Google Scholar] [CrossRef]

- Xiao, G.; Li, B.; Tian, H.; Leng, X.; Long, W. Numerical study on flow and pressure drop characteristics of a novel type asymmetric wall-flow diesel particulate filter. Fuel 2020, 267, 117148. [Google Scholar] [CrossRef]

- Tsuneyoshi, K.; Yamamoto, K. A study on the cell structure and the performances of wall-flow diesel particulate filter. Energy 2012, 48, 492–499. [Google Scholar] [CrossRef]

- Wang, D.; Tan, P.; Zhu, L.; Wang, Y.-H.; Hu, Z.-Y.; Lou, D.-M. Novel soot loading prediction model of diesel particulate filter based on collection mechanism and equivalent permeability. Fuel 2021, 286, 119409. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of channels per square inch | |

| Wall thickness (mm) | |

| Carrier density (kg·m−3) | |

| Thermal conductivity (W·(m·K)−1) | |

| Specific heat capacity (J·(kg·K)−1) | |

| Porous wall permeability (m2) | |

| Soot layer permeability (m2) | |

| Deep soot layer permeability (m2) | |

| Deep soot thickness (mm) | |

| Deep soot layer density (kg·m−3) | |

| Initial soot layer density (kg·m−3) | |

| Amount of soot in the exhaust (kg Particle·kg Gas−1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; He, C.; Yang, N.; Li, J.; Chen, Y.; Yu, H.; Wang, D.; Yao, Y. Study on the Influence of the Cell Structure on the Pressure Drop of Gasoline Particulate Filter. Atmosphere 2024, 15, 805. https://doi.org/10.3390/atmos15070805

Huang L, He C, Yang N, Li J, Chen Y, Yu H, Wang D, Yao Y. Study on the Influence of the Cell Structure on the Pressure Drop of Gasoline Particulate Filter. Atmosphere. 2024; 15(7):805. https://doi.org/10.3390/atmos15070805

Chicago/Turabian StyleHuang, Lishuan, Chao He, Nan Yang, Jiaqiang Li, Yanlin Chen, Haisheng Yu, Dongge Wang, and Yangyu Yao. 2024. "Study on the Influence of the Cell Structure on the Pressure Drop of Gasoline Particulate Filter" Atmosphere 15, no. 7: 805. https://doi.org/10.3390/atmos15070805