Formate Emission in the Mainstream Aerosols of Heated Tobacco Products Distributed in Japan

Abstract

:1. Introduction

2. Materials and Methods

2.1. Heated Tobacco Products

2.2. Measurement of Formate and Acetate

2.3. Statistical Analysis

3. Results

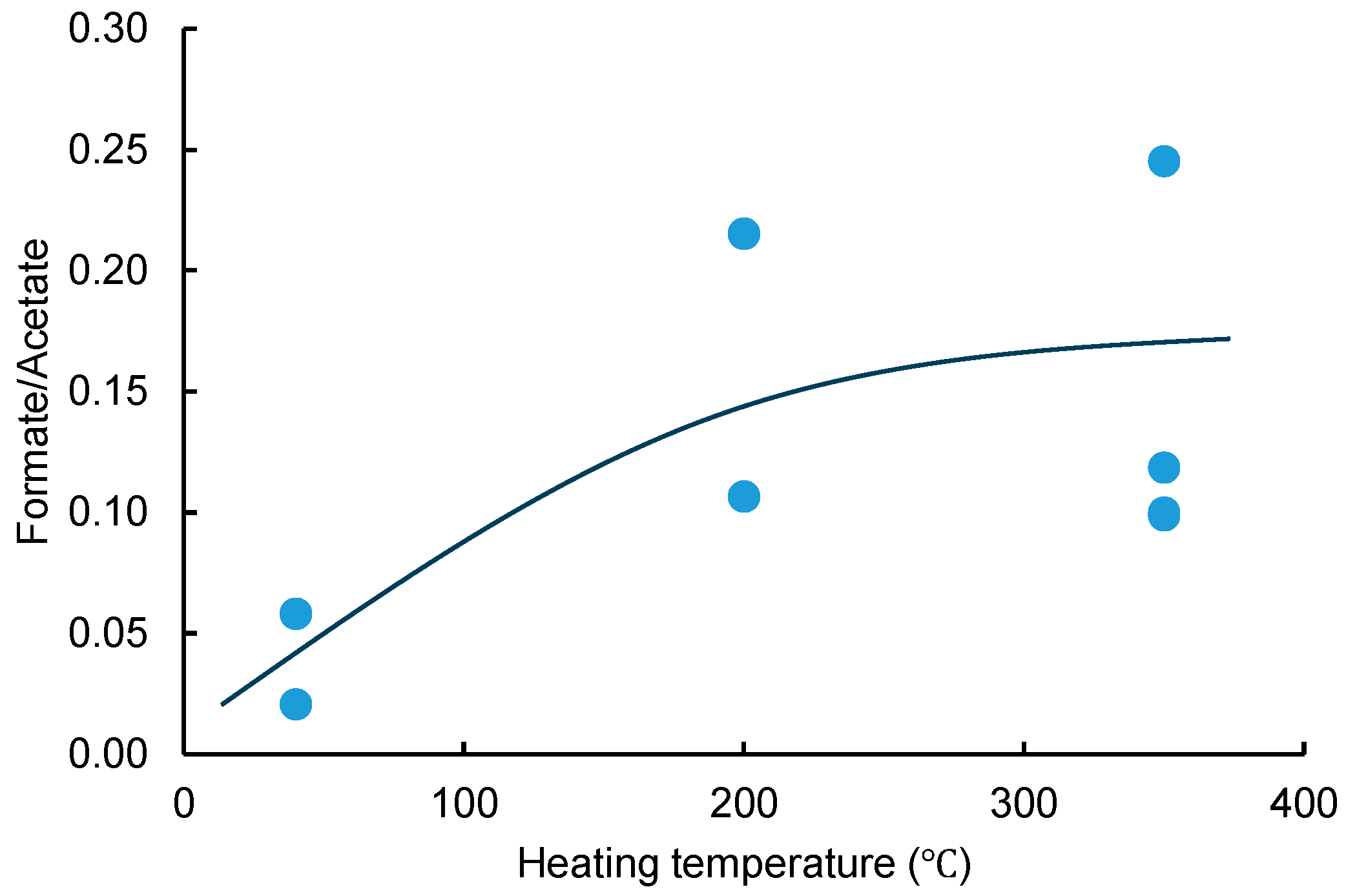

3.1. Emission Amounts of Formate and Acetate

3.2. Gas to Particle Distribution of Formate and Acetate

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benowitz, N.L. Nicotine addiction. N. Engl. J. Med. 2010, 362, 2295–2303. [Google Scholar] [CrossRef] [PubMed]

- Foster, J.A. Consideration of vaping products as an alternative to adult smoking: A narrative review. Subst. Abus. Treat. Prev. Policy 2023, 18, 67. [Google Scholar] [CrossRef] [PubMed]

- Hartmann-Boyce, J.; Begh, R.; Aveyard, P. Electronic cigarettes for smoking cessation. BMJ 2018, 360, j5543. [Google Scholar] [CrossRef] [PubMed]

- Hori, A.; Tabuchi, T.; Kunugita, N. Rapid increase in heated tobacco product (HTP) use from 2015 to 2019: From the Japan ‘Society and New Tobacco’ Internet Survey (JASTIS). Tob. Control 2021, 30, 474–475. [Google Scholar] [CrossRef]

- Simonavicius, E.; McNeill, A.; Shahab, L.; Brose, L.S. Heat-not-burn tobacco products: A systematic literature review. Tob. Control 2019, 28, 582–594. [Google Scholar] [CrossRef]

- Dusautoir, R.; Zarcone, G.; Verriele, M.; Garçon, G.; Fronval, I.; Beauval, N.; Allorge, D.; Riffault, V.; Locoge, N.; Guidice, J.M.L.; et al. Comparison of the chemical composition of aerosols from heated tobacco products, electronic cigarettes and tobacco cigarettes and their toxic impacts on the human bronchial epithelial BEAS-2B cells. J. Hazard. Mat. 2021, 401, 123417. [Google Scholar] [CrossRef]

- Cancelada, L.; Sleiman, M.; Tang, X.; Russell, M.L.; Montesinos, V.N.; Litter, M.I.; Gundel, L.A.; Destaillats, H. Heated tobacco products: Volatile emissions and their predicted impact on indoor air quality. Environ. Sci. Technol. 2019, 53, 7866–7876. [Google Scholar] [CrossRef]

- Uchiyama, S.; Noguchi, M.; Takagi, N.; Hayashida, H.; Inaba, Y.; Ogura, H.; Kunugita, N. Simple determination of gaseous and particulate compounds generated from heated tobacco products. Chem. Res. Toxicol. 2018, 31, 585–593. [Google Scholar] [CrossRef]

- Bentley, M.C.; Almstetter, M.; Arndt, D.; Knorr, A.; Martin, E.; Pospisil, P.; Maeder, S. Comprehensive chemical characterization of the aerosol generated by a heated tobacco product by untargeted screening. Anal. Bioanal. Chem. 2020, 412, 2675–2685. [Google Scholar] [CrossRef]

- The National Institute for Occupational Safety and Health (NIOSH). Formic Acid. Available online: https://www.cdc.gov/niosh/npg/npgd0296.html (accessed on 23 July 2024).

- Ghorbani, H.; Nezami, A.; Sheikholeslami, B.; Hedjazi, A.; Ahmadimanesh, M. Simultaneous measurement of formic acid, methanol and ethanol in vitreous and blood samples of postmortem by headspace GC-FID. J. Occup. Med. Toxicol. 2018, 13, 1. [Google Scholar] [CrossRef]

- Sádecká, J.; Polonský, J. Determination of organic acids in tobacco by capillary isotachophoresis. J. Chromatogr. A 2003, 988, 161–165. [Google Scholar] [CrossRef] [PubMed]

- Kalianos, A.G. Phenolics and acids in leaf and their relationship to smoking quality and aroma. Rec. Adv. Tob. Sci. 1976, 2, 61–79. [Google Scholar]

- Lu, X.; Zhang, H.; Cao, Y.; Pang, Y.; Zhou, G.; Huang, H.; Li, J.; Jiang, J.; Yang, Q. A Comprehensive Study on the Acidic Compounds in Gas and Particle Phases of Mainstream Cigarette Smoke. Processes 2023, 11, 1694. [Google Scholar] [CrossRef]

- Stevenson, T.; Proctor, R.N. The secret and soul of Marlboro: Phillip Morris and the origins, spread, and denial of nicotine freebasing. Am. J. Public Health 2008, 98, 1184–1194. [Google Scholar] [CrossRef] [PubMed]

- Wayne, G.F.; Conolly, G.N.; Henningfield, J. Brand differences of free-base nicotine delivery in cigarette smoke: The view of the tobacco industry documents. Tob. Control 2006, 15, 189–198. [Google Scholar] [CrossRef]

- Sekine, Y.; Yamamoto, T. Physical and chemical property of mainstream aerosol generated from heated tobacco products. Indoor Environ. 2021, 24, 135–144. (In Japanese) [Google Scholar] [CrossRef]

- CORESTA. Cooperation Centre for Scientific Research Relative to Tobacco: CORESTA Recommended Method No. 81. Routine Analytical Machine for E-Cigarette Aerosol Generation and Collection—Definitions and Standard Conditions. 2015. Available online: https://www.coresta.org/sites/default/files/technical_documents/main/CRM_81.pdf (accessed on 23 July 2024).

- Yamamoto, T.; Sekine, Y.; Sohara, K.; Nakai, S.; Yanagisawa, Y. Effect of Heating Temperature on Ammonia Emission in the Mainstream Aerosols from Heated Tobacco Products. Toxics 2022, 10, 592. [Google Scholar] [CrossRef]

- Curran-Everett, D.; Benos, D.J.; American Physiological Society. Guidelines for reporting statistics in journals published by the American Physiological Society. Am. J. Physiol. Endocrinol. Metab. 2004, 287, E189–E191. [Google Scholar] [CrossRef]

- Pankow, J.; Mader, B.T.; Lorne, M.I.; Luo, W.; Pavlick, A.; Liang, C. Conversion of nicotine in tobacco smoke to its volatile and available free-base form through the action of gaseous ammonia. Environ. Sci. Technol. 1997, 31, 2428–2433. [Google Scholar] [CrossRef]

- van Amsterdam, J.; Sleijffers, A.; van Spiegel, P.; Blom, R.; Witte, M.; van de Kassteele, J.; Blokland, M.; Steerenberg, P.; Opperhuizen, A. Effect of ammonia in cigarette tobacco on nicotine absorption in human smokers. Food Chem. Toxicol. 2011, 49, 3025–3030. [Google Scholar] [CrossRef]

- Yelon, J.A.; Simpson, R.L.; Gudjonsson, O. Formic Acid Inhalation Injury: A Case Report. J. Burn Care Rehabil. 1996, 17, 241–242. [Google Scholar] [CrossRef] [PubMed]

- Saliba, N.A.; Hellani, A.E.; Honein, E.; Salman, R.; Talih, S.; Zeaiter, J.; Shihadeh, A. Surface chemistry of electronic cigarette electrical heating coils: Effects of metal type on propylene glycol thermal decomposition. J. Anal. Appl. Pyrolysis 2018, 134, 520–525. [Google Scholar] [CrossRef] [PubMed]

| HTP | Heating Temp. (°C) | Flavour Type | Abbreviation | Puff Number |

|---|---|---|---|---|

| A | 350 | Regular | AR | 10 |

| Menthol | AM | |||

| B | 350 (maximum) | Regular | BR | 10 |

| Menthol | BM | |||

| C | 200 | Regular | CR | 10 |

| Menthol | CM | |||

| D | 40 | Regular | DR | 50 |

| Menthol | DM |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawaguchi, M.; Sekine, Y. Formate Emission in the Mainstream Aerosols of Heated Tobacco Products Distributed in Japan. Atmosphere 2024, 15, 1045. https://doi.org/10.3390/atmos15091045

Kawaguchi M, Sekine Y. Formate Emission in the Mainstream Aerosols of Heated Tobacco Products Distributed in Japan. Atmosphere. 2024; 15(9):1045. https://doi.org/10.3390/atmos15091045

Chicago/Turabian StyleKawaguchi, Masaki, and Yoshika Sekine. 2024. "Formate Emission in the Mainstream Aerosols of Heated Tobacco Products Distributed in Japan" Atmosphere 15, no. 9: 1045. https://doi.org/10.3390/atmos15091045