New Makeup Air Method through Ceiling for Kitchen Ventilation in Severely Cold Regions and Its Effect on Air Environment

Abstract

:1. Introduction

2. Experimental Measurements

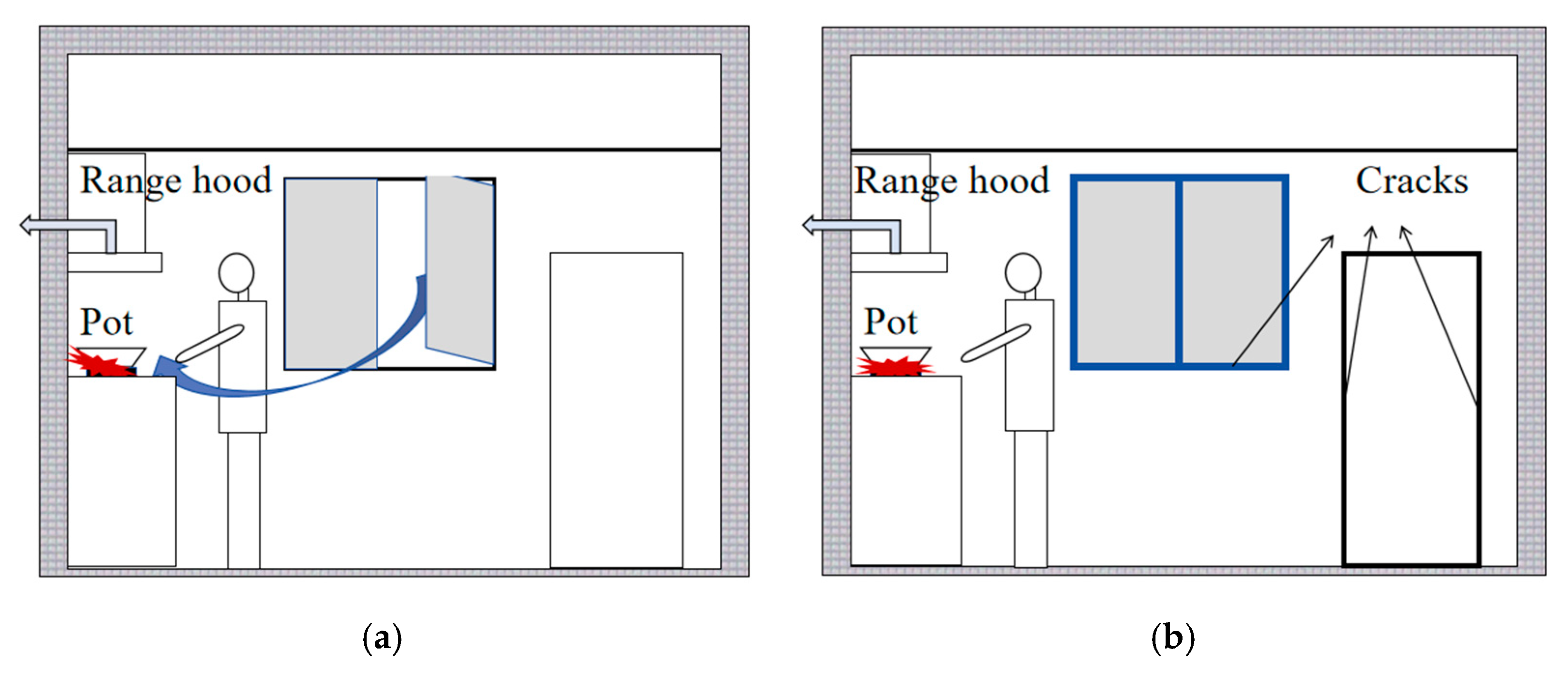

2.1. Development of CMA System for Severely Cold Region

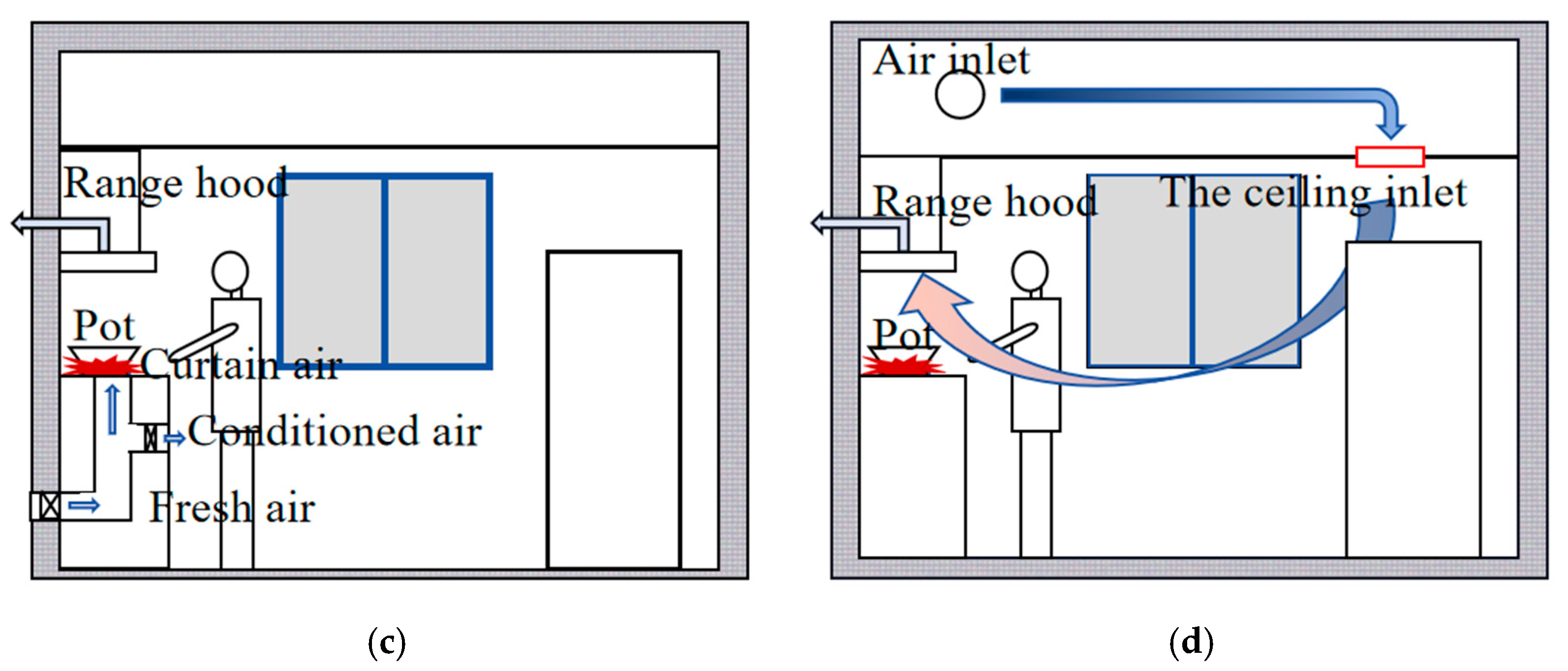

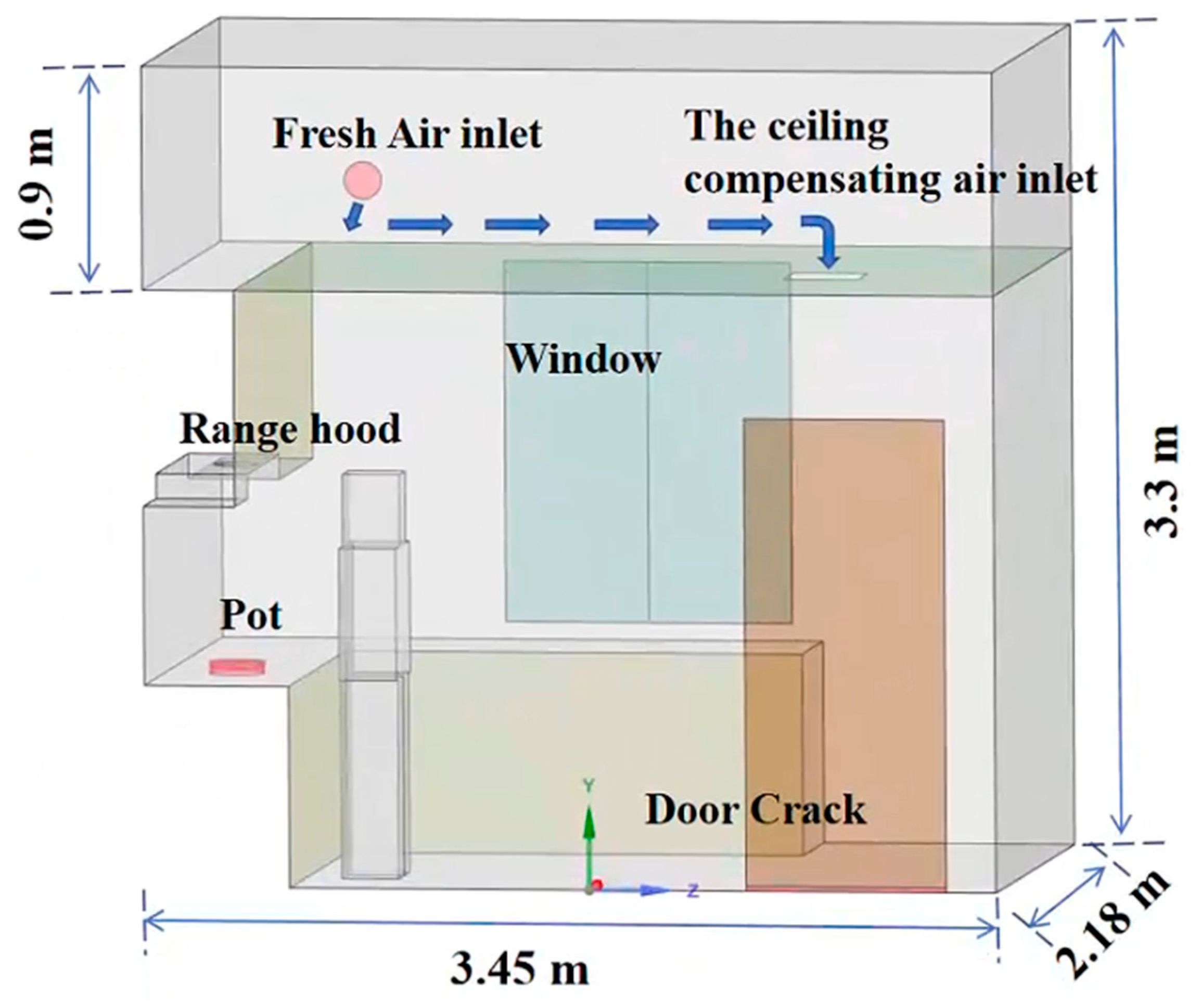

2.2. Experimental Setup

2.2.1. Experimental System

2.2.2. The Test Procedure

3. Numerical Simulation

3.1. Governing Equations

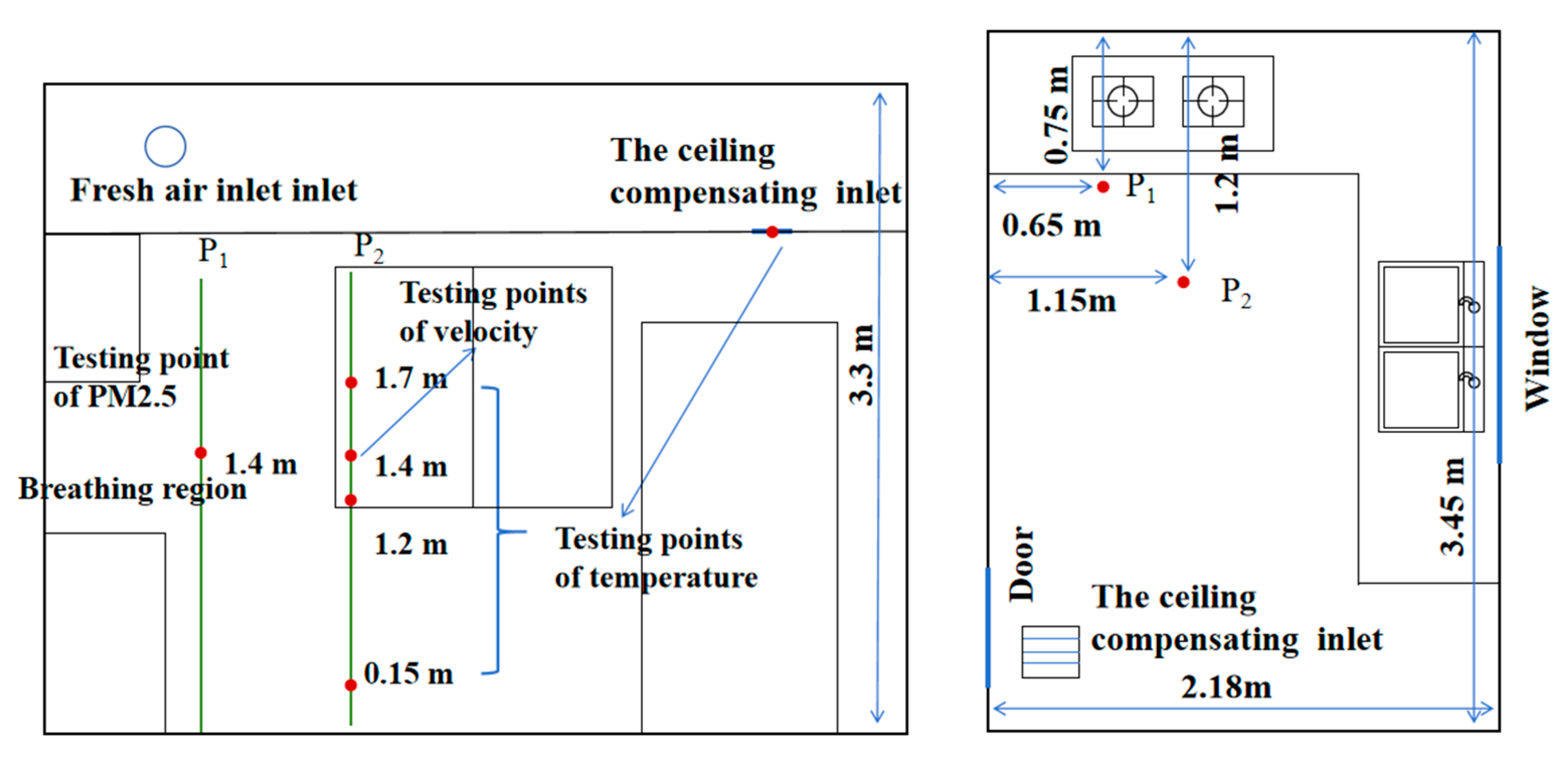

3.2. Geometry Model and Grid Generation

3.3. Boundary Conditions and Calculation Cases

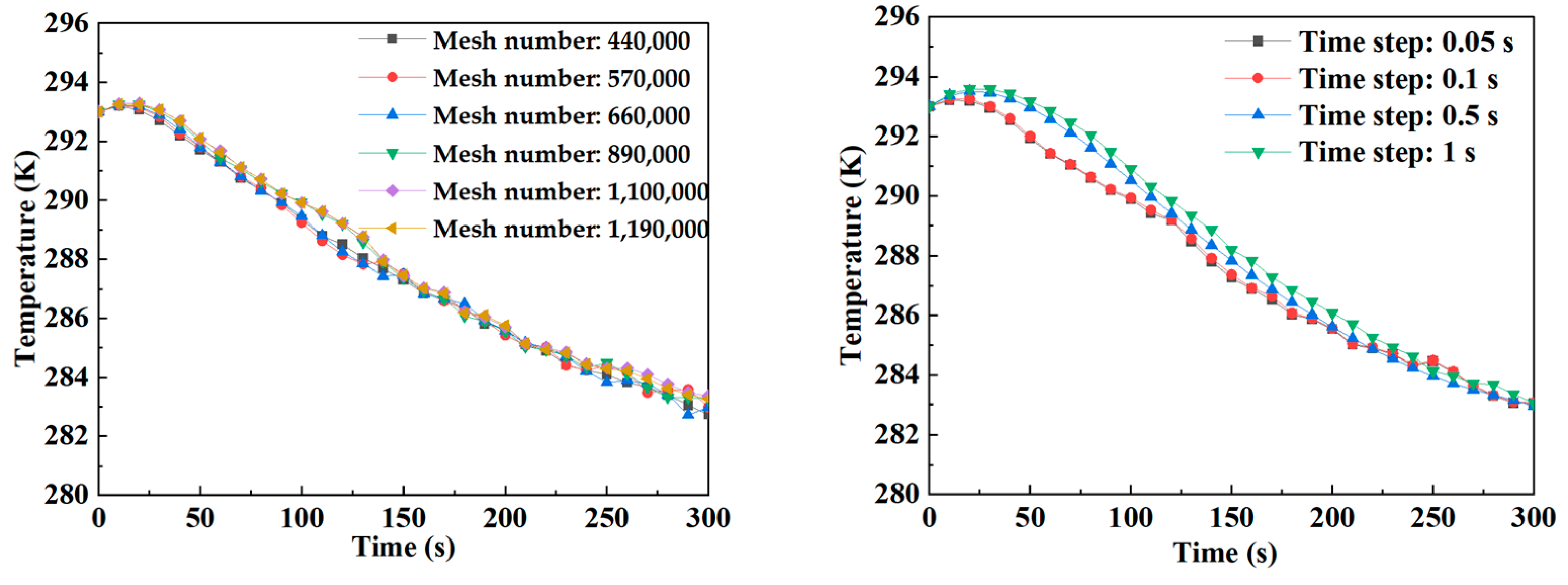

3.4. Grid Independence Verification

4. Results and Discussion

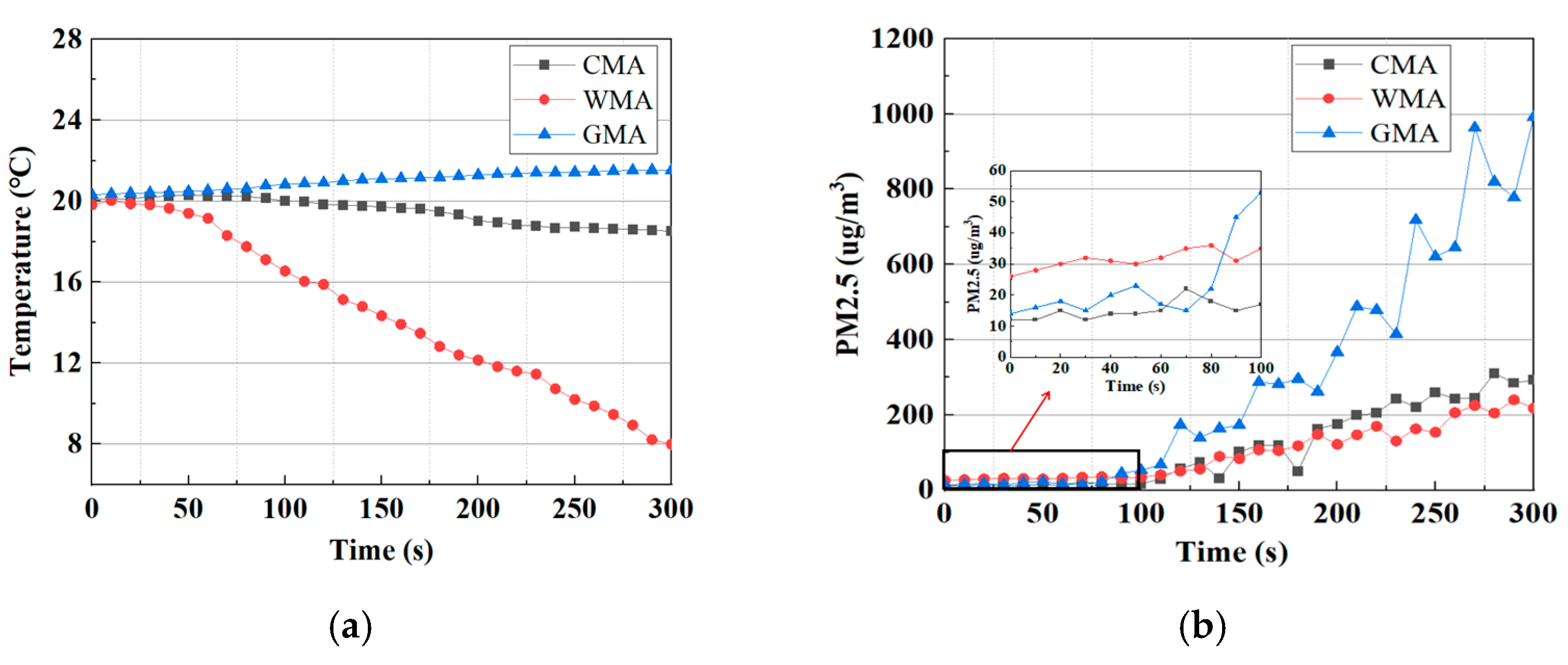

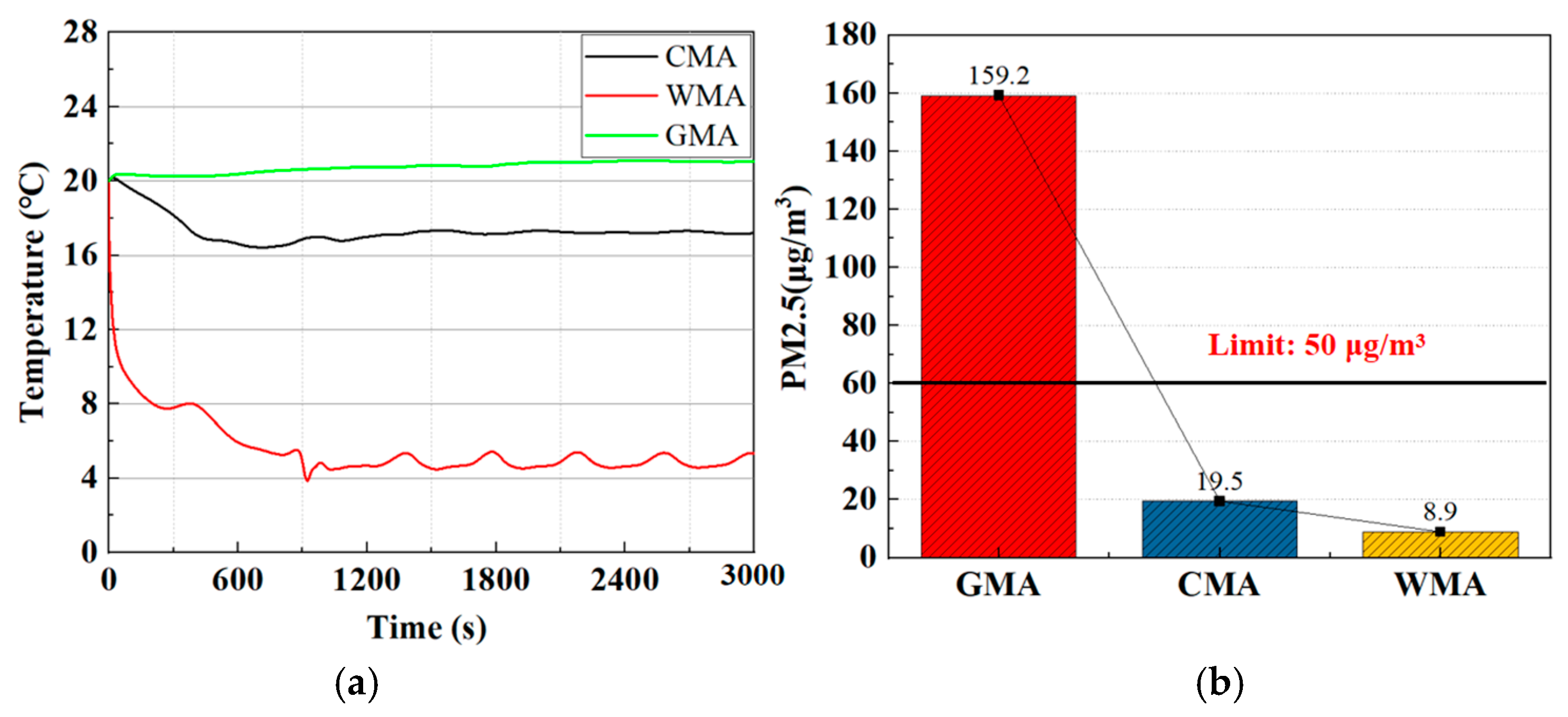

4.1. Experimental Results under Ventilation Systems with CMA Scheme, WMA Scheme, and GMA Scheme

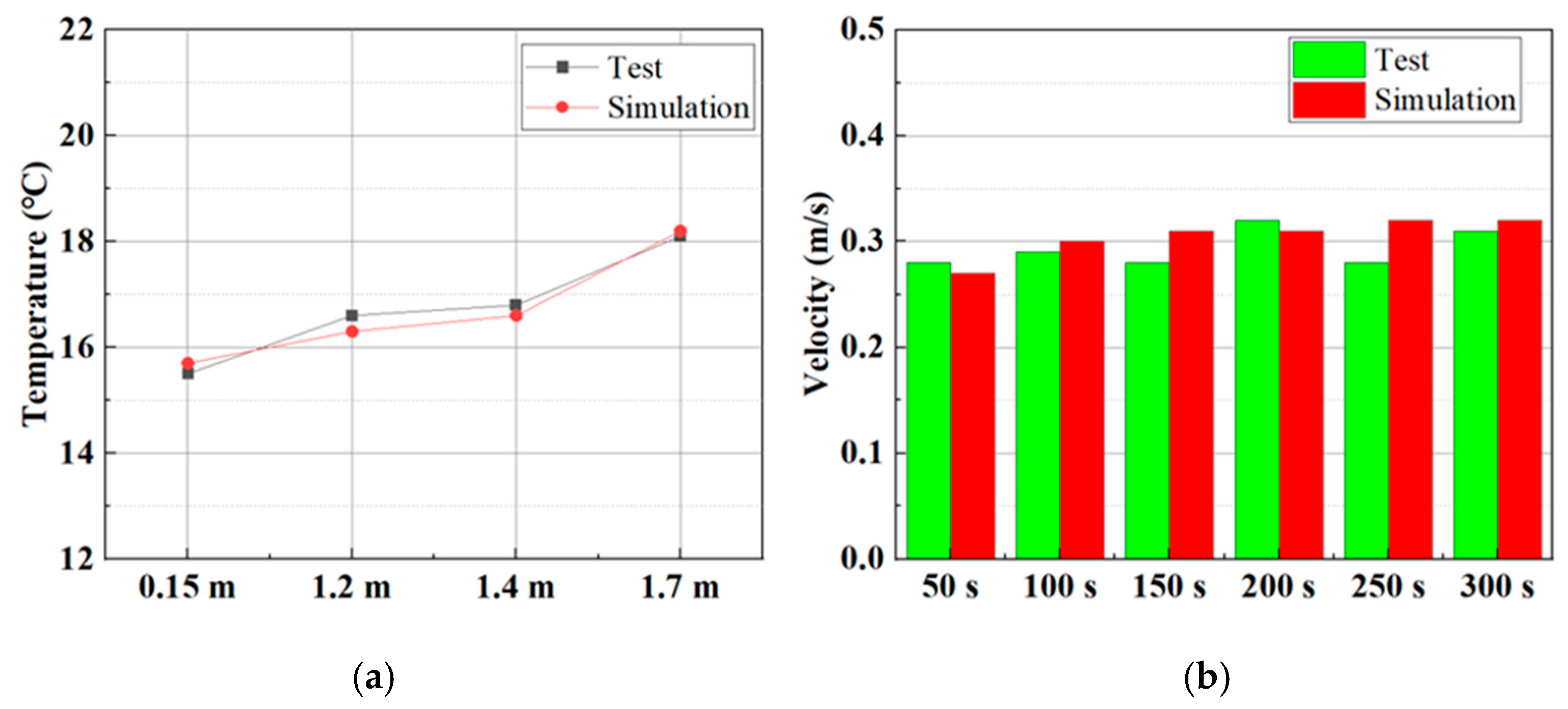

4.2. Model Validation

4.3. Simulation Results

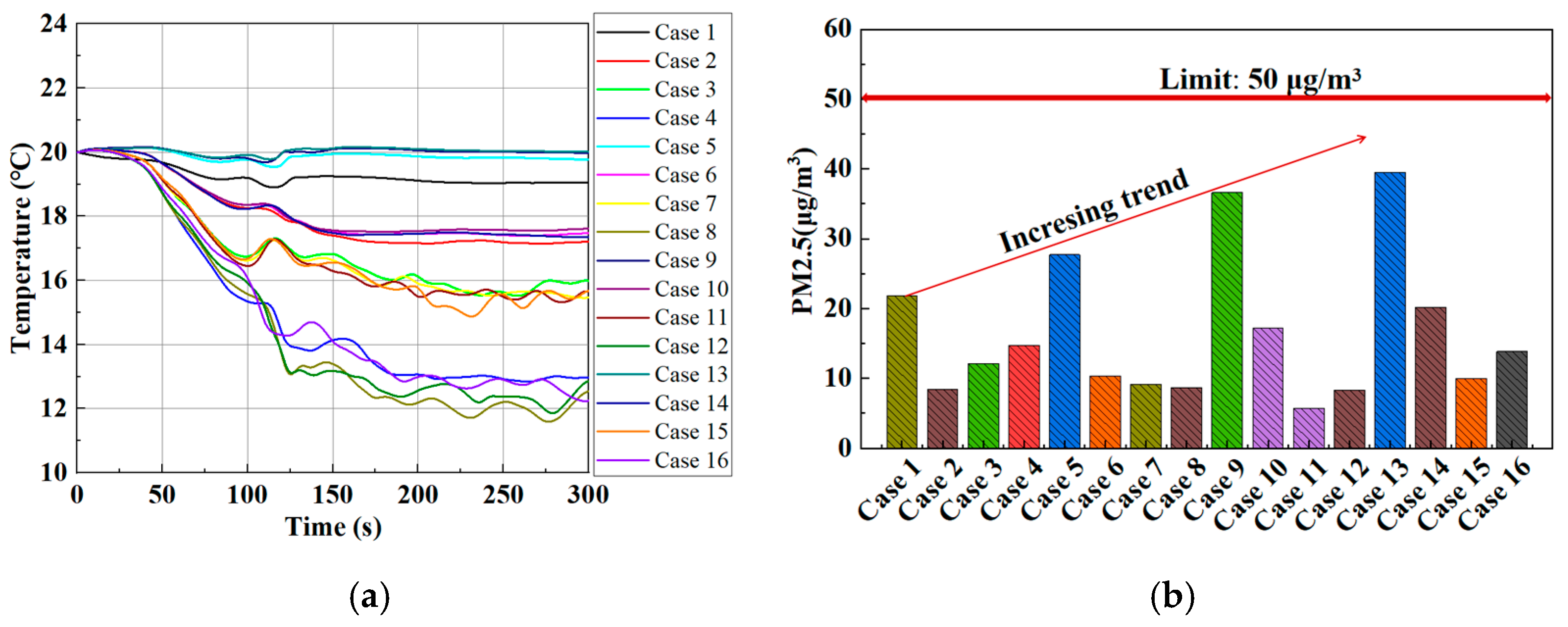

4.3.1. The Influence of the Size of Air Inlet and Ceiling Inlets

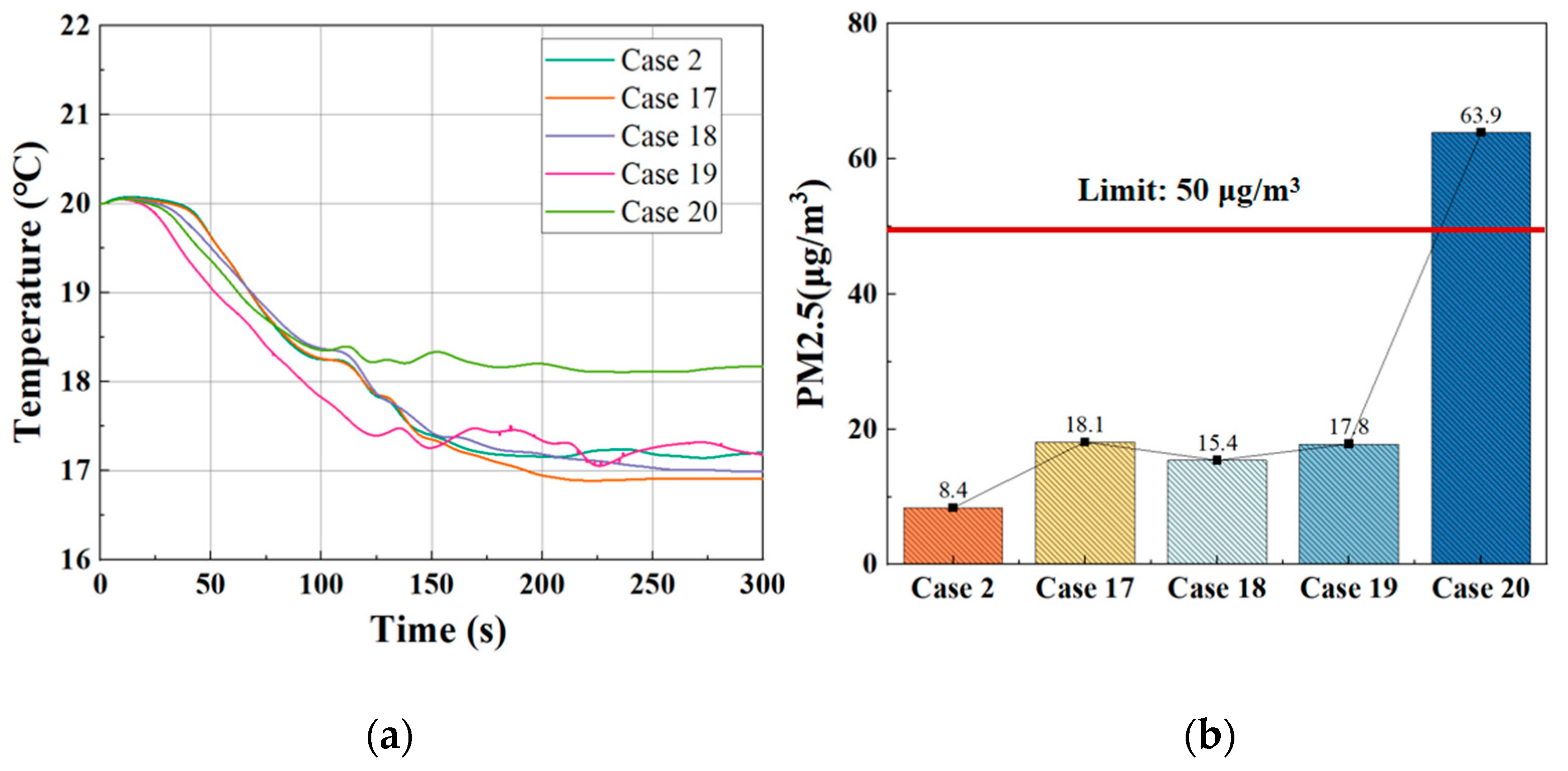

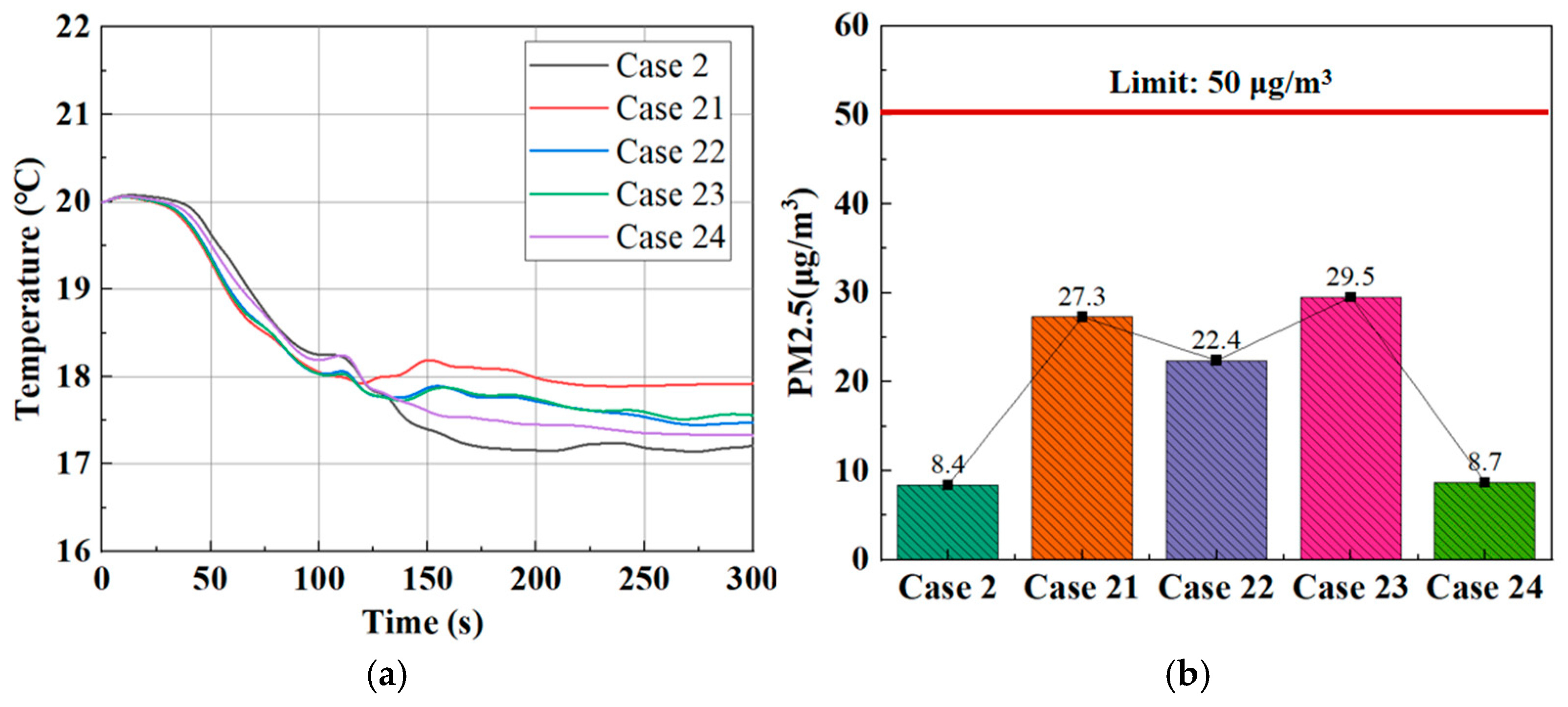

4.3.2. The Influence of the Layout and Shape of the Ceiling Inlets

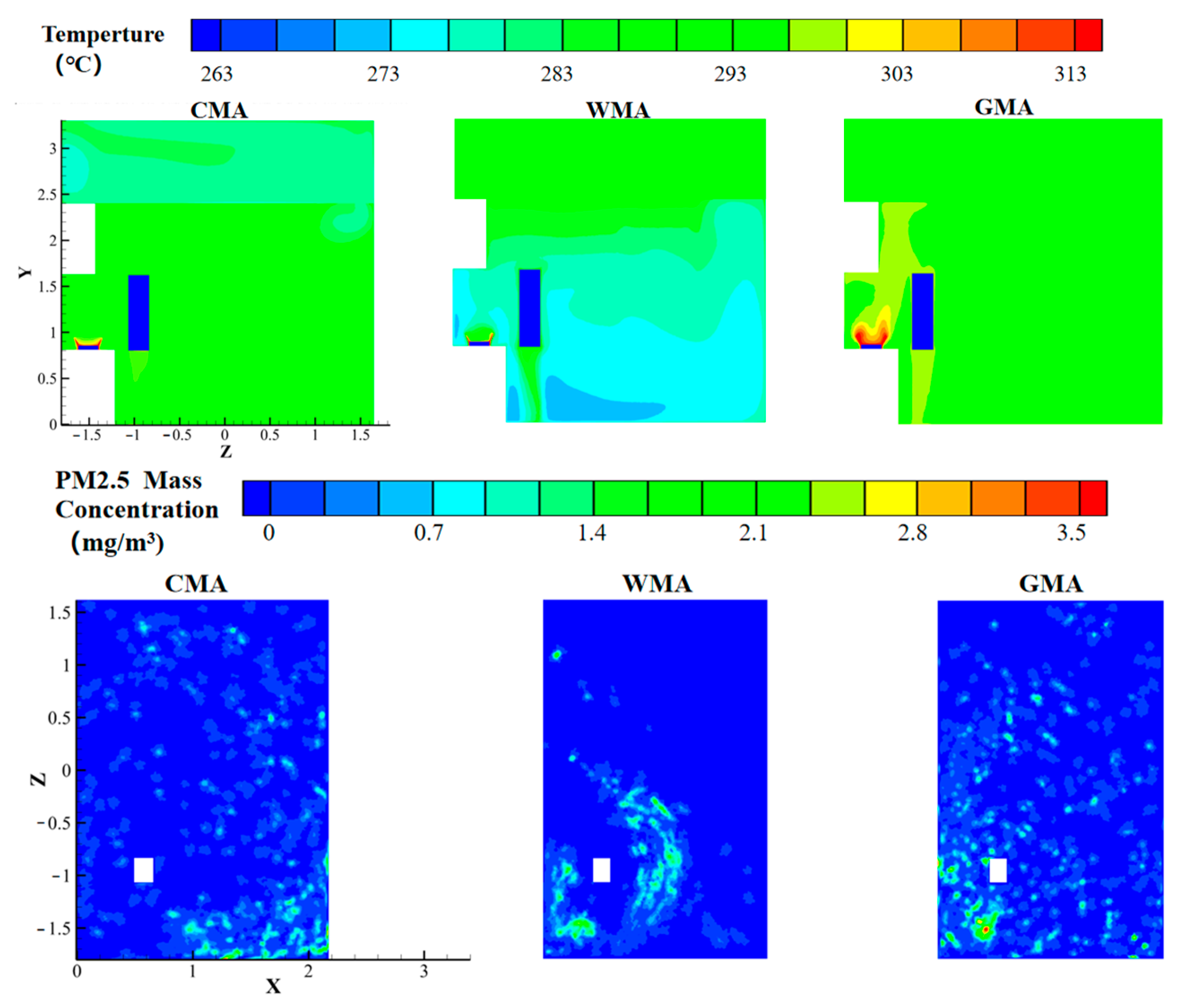

4.3.3. Respiratory Zone Parameters under Kitchen Ventilation System with CMA, WMA, and GMA

5. Conclusions

- The CMA scheme effectively balanced indoor temperature maintenance and air quality aggravation during winter in a severely cold region. Under the representative outdoor cold condition of −9.1 °C in Shenyang, China, the CMA scheme reduced the concentration of PM2.5 by 87% compared with the GMA scheme. Moreover, it increased the indoor temperature by over 11.9 °C compared with the WMA scheme. Under the CMA scheme, the indoor temperature remains above 17 °C, and the PM2.5 concentration is below 50 μg/m3.

- The average relative error between the experimental and simulated data is within 6.1%. The experimental results showed that there was a minimal difference in the PM2.5 concentration and indoor temperature changes in the kitchen under the ventilation systems with the CMA scheme, WMA scheme, and GMA scheme during the initial cooking stage. The difference appears and increases after cooking for 50 s and 100 s, respectively. The vertical temperature difference between the head and feet was 2.6 °C under the ventilation system with the CMA scheme.

- In the CMA scheme, the size of the air inlet had the largest impact. This was followed by the layout of the ceiling inlets and the size and shape of the ceiling inlets. Considering the temperature around the human body and the concentration of PM2.5 in the breathing zone, this article recommends using the CMA scheme with the air inlet diameter range of 120–160 mm, which achieves good performance in balancing the two environmental parameters.

- The layout of the ceiling inlets had a significant impact on the PM2.5 concentration in the respiratory zone. However, it had a relatively minor impact on the temperature around the human body. When the ceiling inlets are symmetrically arranged, the PM2.5 concentration in the breathing zone is the highest, reaching 63.9 μg/m3. Therefore, this article does not recommend a symmetrical arrangement of ceiling inlets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, K.L.; Song, J.S.; Feng, G.H.; Chang, Q.P.; Jiang, B.; Wang, J.; Sun, W.; Li, H.X.; Wang, J.M.; Fang, X.S. Indoor air quality analysis of residential buildings in northeast China based on field measurements and longtime monitoring. Build. Environ. 2018, 144, 171–183. [Google Scholar] [CrossRef]

- Wag, J.; Huang, K.L.; Feng, G.H.; Song, J.S. Analysis of winter formaldehyde and volatile organic compound pollution characteristics of residential kitchens in severe cold regions of northeast China. Indoor Built Environ. 2021, 30, 1226–1243. [Google Scholar] [CrossRef]

- Huang, K.L.; Sun, W.; Feng, G.H.; Wag, J.; Song, J.S. Indoor air quality analysis of 8 mechanically ventilated residential buildings in northeast China based on long-term monitoring. Sustain. Cities Soc. 2020, 54, 101947. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Zhao, B. Reducing human exposure to PM2.5 generated while cooking typical Chinese cuisine. Build. Environ. 2020, 168, 106522. [Google Scholar] [CrossRef]

- Wang, M. Simulation Study on the Influence of Kitchen Structure and Layout on Kitchen Air Quality. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2015. [Google Scholar]

- Wang, J. Analysis of Winter Formaldehyde and VOCs Pollution Characteristics of Residential Kitchens in Severe Cold Regions and the Optimization of Make-Up Air. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2019. [Google Scholar]

- Li, J. Simulation Study on Environment of Residential Kitchen Based on Novel Ventilation System. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar]

- Zeng, L.J.; Du, B.W.; Lv, L.P.; Gao, J.; Zhang, C.Q.; Tong, L.Q.; Liu, G.D. Occupant exposure and ventilation conditions in Chinese residential kitchens: Site survey and measurement for an old residential community in Shanghai. J. Build. Eng. 2020, 31, 101406. [Google Scholar] [CrossRef]

- GB 50736-2012; Design Code for Heating Ventilation and Air Conditioning of Civil Buildings. China Architecture & Building Press: Beijing, China, 2012.

- GB 17713-2022; Range Hoods and Other Cooking Fume Extractors. China Quality Inspection Press: Beijing, China, 2022.

- T/CECS850-2021; Design Standard of Air Pollution Control via Ventilation for Residential Kitchens. China Architecture & Building Press: Beijing, China, 2021.

- Zhao, Y.J.; Zhao, B. Emissions of air pollutants from Chinese cooking: A literature review. Build. Simul. 2018, 11, 977–995. [Google Scholar] [CrossRef]

- Hussein, T.; Glytsos, T.; Ondráček, J.; Zdimal, V.; Hameri, K.; Lazaridis, M.; Smolik, J.; Kulmala, M. Particle size characterization and emission rates during indoor activities in a house. Atmos. Environ. 2006, 40, 4285–4307. [Google Scholar] [CrossRef]

- He, L.Y.; Hu, M.; Huang, X.F.; Yu, B.D.; Zhang, Y.H.; Liu, D.Q. Measurement of emissions of fine particulate organic matter from Chinese cooking. Atmos. Environ. 2004, 38, 6557–6564. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Son, Y.J.; Li, L.H.; Wood, N.D.; Senerat, A.M.; Jovan, P. Healthy home interventions: Distribution of PM2.5 emitted during cooking in residential settings. Build. Environ. 2022, 207, 108448. [Google Scholar] [CrossRef]

- Singer, B.C.; Pass, R.Z.; Delp, W.W.; Lorenzetti, D.M.; Maddalena, R.L. Pollutant concentrations and emission rates from natural gas cooking burners without and with range hood exhaust in nine California homes. Build. Environ. 2017, 122, 215–229. [Google Scholar] [CrossRef]

- Torkmahalleh, M.A.; Gorjinezhad, S.; Unluevcek, H.S.; Hopke, P.K. Review of factors impacting emission/concentration of cooking generated particulate matter. Sci. Total Environ. 2017, 586, 1046–1056. [Google Scholar] [CrossRef] [PubMed]

- Sharma, R.; Balasubramanian, R. Evaluation of the effectiveness of a portable air cleaner in mitigating indoor human exposure to cooking-derived airborne particles. Environ. Res. 2020, 183, 109192. [Google Scholar] [CrossRef] [PubMed]

- Tang, R.J.; Pfrang, C. Indoor particulate matter (PM) from cooking in UK students’ studio flats and associated intervention strategies: Evaluation of cooking methods, PM concentrations and personal exposures using low-cost sensors. Environ. Sci. Atmos. 2023, 3, 537–551. [Google Scholar] [CrossRef]

- Jovan, P.; Young, J.S.; Brant, S.; Liu, Q. Cooking emission control with IoT sensors and connected air quality interventions for smart and healthy homes: Evaluation of effectiveness and energy consumption. Energy Build. 2023, 286, 112932. [Google Scholar]

- O’Leary, C.; Jones, B.J.; Sani, D.; Hall, I.P. Setting the standard: The acceptability of kitchen ventilation for the English housing stock. Build. Environ. 2019, 166, 106417. [Google Scholar] [CrossRef]

- Zhou, B.; Chen, F.; Dong, Z.; Nielsen, P.V. Study on pollution control in residential kitchen based on the push-pull ventilation system. Build. Environ. 2016, 107, 99–112. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, A.; Tao, P.; Gao, R. The impact of various hood shapes, and side panel and exhaust duct arrangements, on the performance of typical Chinese style cooking hoods. Build. Simul. 2013, 6, 139–149. [Google Scholar] [CrossRef]

- Huang, R.F.; Nian, Y.C.; Chen, J.K.; Peng, K.L. Improving flow and spillage characteristics of range hoods by using an inclined air-curtain technique. Ann. Occup. Hyg. 2011, 55, 164–179. [Google Scholar]

- Huang, R.F.; Nian, Y.C.; Chen, J.K. Static condition differences in conventional and inclined air-curtain range hood flow and spillage characteristics. Environ. Eng. Sci. 2010, 27, 513–522. [Google Scholar] [CrossRef]

- Liu, S.; Cao, Q.; Zhao, X.; Lu, Z.; Deng, Z.; Dong, J.; Lin, X.; Qing, K.; Zhang, W.; Chen, Q. Improving indoor air quality and thermal comfort in residential kitchens with a new ventilation system. Build. Environ. 2020, 180, 107016. [Google Scholar] [CrossRef]

- Yi, K.W.; Kim, Y.I.; Bae, G.N. Effect of air flow rates on concurrent supply and exhaust kitchen ventilation system. Indoor Built Environ. 2016, 25, 180–190. [Google Scholar] [CrossRef]

- Wang, R.S. Simulation and Optimization of Air Distribution in Residential Kitchen in Winter in Severe Cold Area. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2021. [Google Scholar]

- Chen, C.; Zhao, Y.; Zhao, B. Emission rates of multiple air pollutants generated from Chinese residential cooking. Environ. Sci. Technol. 2018, 52, 1081–1087. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.L.; Wang, R.S.; Feng, G.H.; Wang, J.; Yu, M.; He, N. Ventilation status of the residential kitchens in severe cold region and improvement based on simulation: A case of Shenyang, China. J. Air Waste Manag. Assoc. 2022, 72, 935–950. [Google Scholar] [CrossRef]

- GB/T 18204.18-2013; Public Health Testing Methods—Part 1: Physical Factors. China Standards Press: Beijing, China, 2013.

- Elghobashi, S. On predicting particle-laden turbulent flows. Appl. Sci. Res. 1994, 52, 309–329. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, Y.; Li, X.; Yang, X.; Huang, D. Comparison of indoor aerosol particle concentration and deposition in different ventilated rooms by numerical method. Build. Environ. 2004, 39, 1–8. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Q. Experimental measurements and numerical simulations of particle transport and distribution in ventilated rooms. Atmos. Environ. 2006, 40, 3396–3408. [Google Scholar] [CrossRef]

- Chen, C.; Liu, W.; Lin, C.H.; Chen, Q. Comparing the Markov Chain Model with the Eulerian and Lagrangian Models for Indoor Transient Particle Transport Simulations. Aerosol. Sci. Technol. 2015, 49, 857–871. [Google Scholar] [CrossRef]

- Shi, S.; Yang, J.; Liang, Y. Indoor distribution and personal exposure of cooking-generated PM2.5 in rural residences of China: A multizone model study. Build. Simul. 2023, 16, 1299–1315. [Google Scholar] [CrossRef]

- Xiang, J.; Hu, L.; Hao, J.; Wu, S.; Cao, J.; Seto, E. Characterization of time- and size-dependent particle emissions and decay from cooking oil fumes in residence: Impacts of various intervention measures. Build. Simul. 2023, 16, 1149–1158. [Google Scholar] [CrossRef]

- Yu, L.; Jiankai, D.; Yu, W.; Zheng, W.; Jiang, Y. Numerical investigation on the influence of natural make-up air in Chinese-style residential kitchen on indoor environment in a partitioned household. Sustain. Energy Technol. Assess. 2021, 46, 101244. [Google Scholar]

- Lumin, C.; Ke, Y.; Fuping, Q.; Zheng, Z.; Lu, J.; Han, Y. Numerical investigation of non-spherical particle deposition characteristics on filter media. Build. Simul. 2023, 16, 1331–1343. [Google Scholar]

- Xu, G.P.; Wang, J.G. CFD modeling of particle dispersion and deposition coupled with particle dynamical models in a ventilated room. Atmos. Environ. 2017, 166, 300–314. [Google Scholar] [CrossRef]

- Shih, T.H.; Liou, W.W.; Shabbir, A.; Yang, Z.A.; Zhu, J. A new k-ԑ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Bjørn, E.; Nielsen, P.V. Dispersal of exhaled air and personal exposure in displacement ventilated rooms. Indoor Air 2002, 12, 147–164. [Google Scholar] [CrossRef]

- Gao, N.; Niu, J. CFD study on micro-environment around human body and personalized ventilation. Build. Environ. 2004, 39, 795–805. [Google Scholar] [CrossRef]

- Jie, C.; Jun, G.; Bowen, D. Experimental Research on Emission Profile of Oil Fume Particle Sources in the Oil Heating Process. Build. Energy Environ. 2018, 37, 33–36. [Google Scholar]

- GB 50019-2003; Code for Design of Heating Ventilation and Air Conditioning. China Standards Press: Beijing, China, 2003.

- Zhao, M.; Xu, F.Z.; Ming, H.Q.; Xi, T.; Hou, Y.H.; Guan, J.H. Analysis of winter temperature change in Shenyang from 1951 to 2010. In Proceedings of the 33rd Annual Meeting of the Chinese Meteorological Society S5: Addressing Climate Change, Low Carbon Development, and Ecological Civilization Construction, Xi’an, China, 2 November 2016; pp. 397–402. [Google Scholar]

- GB/T 18883-2022; Standards of Indoor Air Quality. China Standards Press: Beijing, China, 2022.

- ANSI/ASHARE 55; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and AirConditioning Engineers (ASHARE): Atlanta, GA, USA, 2013.

| Standard Number | Title of Standard | Air Change Volume |

|---|---|---|

| GB 50736-2012 [9] | Design code for heating ventilation and air conditioning of civil buildings | 300–500 m3/h and ≥3 times/h |

| GB 17713-2022 [10] | Range hoods and other cooking fume extractors | ≥7 m3/min |

| T/CECS 850-2021 [11] | Design standard for air pollution control via ventilation of residential kitchens | 300–500 m3/h |

| Equipment | Range | Accuracy |

|---|---|---|

| RS485 | −40 °C~60 °C | ±0.5 °C |

| Testo (405 i) | 1~10 m/s | ±0.1 m/s |

| DUST-TRAK-II (8534) | 0.001~150 mg/m3 | 0.001 mg/m3 |

| Case | Air Inlet | Ceiling Inlet | ||

|---|---|---|---|---|

| Diameter | Number | Size/Diameter | Number | |

| Case 1 | 80 mm | 1 | 100 mm × 1800 mm | 1 |

| Case 2 | 120 mm | 1 | 100 mm × 1800 mm | 1 |

| Case 3 | 160 mm | 1 | 100 mm × 1800 mm | 1 |

| Case 4 | 200 mm | 1 | 100 mm × 1800 mm | 1 |

| Case 5 | 80 mm | 1 | 100 mm × 1500 mm | 1 |

| Case 6 | 120 mm | 1 | 100 mm × 1500 mm | 1 |

| Case 7 | 160 mm | 1 | 100 mm × 1500 mm | 1 |

| Case 8 | 200 mm | 1 | 100 mm × 1500 mm | 1 |

| Case 9 | 80 mm | 1 | 100 mm × 1200 mm | 1 |

| Case 10 | 120 mm | 1 | 100 mm × 1200 mm | 1 |

| Case 11 | 160 mm | 1 | 100 mm × 1200 mm | 1 |

| Case 12 | 200 mm | 1 | 100 mm × 1200 mm | 1 |

| Case 13 | 80 mm | 1 | 100 mm × 900 mm | 1 |

| Case 14 | 120 mm | 1 | 100 mm × 900 mm | 1 |

| Case 15 | 160 mm | 1 | 100 mm × 900 mm | 1 |

| Case 16 | 200 mm | 1 | 100 mm × 900 mm | 1 |

| Case 17 | 120 mm | 1 | 100 mm × 600 mm | 3 |

| Case 18 | 120 mm | 1 | 100 mm × 600 mm | 3 |

| Case 19 | 120 mm | 1 | 100 mm × 600 mm | 3 |

| Case 20 | 120 mm | 1 | 100 mm × 900 mm | 2 |

| Case 21 | 120 mm | 1 | 20 mm | 572 |

| Case 22 | 120 mm | 1 | 40 mm | 144 |

| Case 23 | 120 mm | 1 | 60 mm | 64 |

| Case 24 | 120 mm | 1 | 80 mm | 36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Huang, K.; Feng, G.; Cao, G.; Li, A.; Teng, X. New Makeup Air Method through Ceiling for Kitchen Ventilation in Severely Cold Regions and Its Effect on Air Environment. Atmosphere 2024, 15, 1109. https://doi.org/10.3390/atmos15091109

Li X, Huang K, Feng G, Cao G, Li A, Teng X. New Makeup Air Method through Ceiling for Kitchen Ventilation in Severely Cold Regions and Its Effect on Air Environment. Atmosphere. 2024; 15(9):1109. https://doi.org/10.3390/atmos15091109

Chicago/Turabian StyleLi, Xiaoxu, Kailiang Huang, Guohui Feng, Guanyu Cao, Ainong Li, and Xu Teng. 2024. "New Makeup Air Method through Ceiling for Kitchen Ventilation in Severely Cold Regions and Its Effect on Air Environment" Atmosphere 15, no. 9: 1109. https://doi.org/10.3390/atmos15091109

APA StyleLi, X., Huang, K., Feng, G., Cao, G., Li, A., & Teng, X. (2024). New Makeup Air Method through Ceiling for Kitchen Ventilation in Severely Cold Regions and Its Effect on Air Environment. Atmosphere, 15(9), 1109. https://doi.org/10.3390/atmos15091109