Assessment of Community Exposure to Ambient Respirable Crystalline Silica near Frac Sand Processing Facilities

Abstract

:1. Introduction

2. Methods of Sampling and Analysis

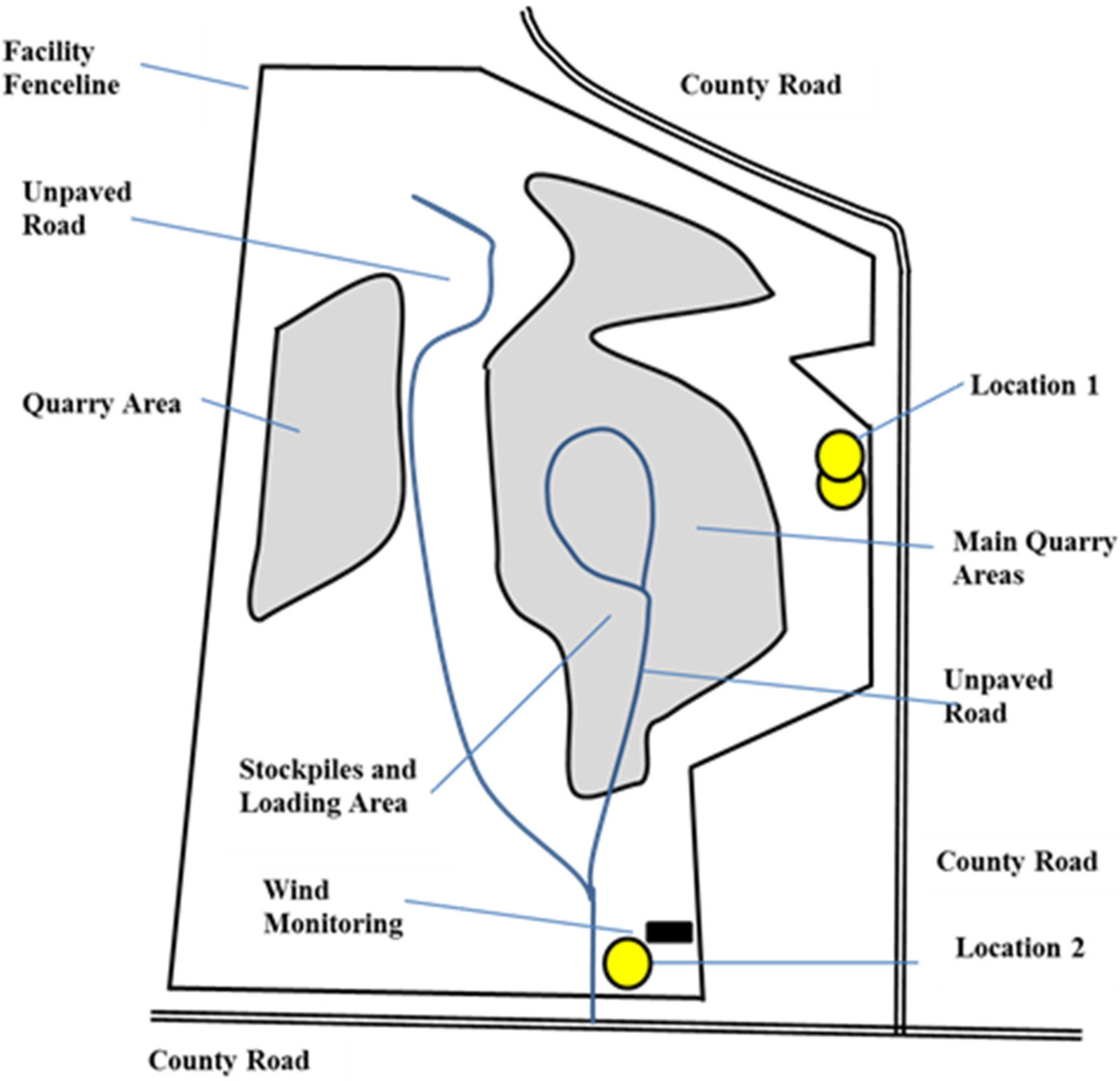

2.1. Facility and Sampling Network Characteristics

| Facility | Number of Samplers | Sampling Dates | Operating Dates |

|---|---|---|---|

| Chippewa Falls Processing Plant Chippewa County, WI | 3 | Oct. 2012–Dec. 2014 | All months |

| DS Mine, Chippewa County, WI | 3 | Oct. 2012–Dec. 2014 | April to November each year |

| S&S Mine, Chippewa County, WI | 3 | Oct. 2012–Dec. 2014 | November to April each year |

| DD Mine, Barron County, WI | 3 | Nov. 2012–Dec. 2014 | November 2012 to April 2013 |

| Total | 12 | - | - |

2.2. Respirable Crystalline Silica Sampling Equipment

2.3. Crystalline Silica Analyses

2.4. Data Analysis

2.5. Program Organization

3. Sampling Results

3.1. Average Respirable Crystalline Silica Concentrations

| Facility and Sampling Location | Number > LOQ | Number < LOQ | % <LOQ | 99th% | (LOQ/) Substituted for < LOQ Values | |||

|---|---|---|---|---|---|---|---|---|

| Mean | Mean 95th% UCL | GM | GSD | |||||

| µg/m3 | µg/m3 | µg/m3 | µg/m3 | µg/m3 | ||||

| Chippewa Falls, Location 1 | 49 | 106 | 68.2 | 1.34 | 0.33 | 0.36 | 0.29 | 1.59 |

| Chippewa Falls, Location 2 | 20 | 133 | 86.9 | 0.65 | 0.26 | 0.27 | 0.24 | 1.33 |

| DS Mine, Location 1 | 19 | 134 | 87.6 | 0.72 | 0.25 | 0.27 | 0.24 | 1.30 |

| DS Mine, Location 2 | 17 | 133 | 88.7 | 0.50 | 0.24 | 0.25 | 0.23 | 1.22 |

| S&S Mine, Location 1 | 13 | 137 | 91.3 | 0.50 | 0.24 | 0.25 | 0.23 | 1.21 |

| S&S Mine, Location 2 | 26 | 123 | 82.6 | 1.44 | 0.30 | 0.33 | 0.26 | 1.52 |

| DD Mine, Location 1 | 18 | 121 | 82.1 | 0.60 | 0.25 | 0.26 | 0.24 | 1.26 |

| DD Mine, Location 2 | 16 | 121 | 88.3 | 0.81 | 0.25 | 0.27 | 0.24 | 1.33 |

| Facility and Sampling Location | Number > LOQ | Number < LOQ | % < LOQ | 99th% | (LOQ/) Substituted for < LOQ Values | |||

|---|---|---|---|---|---|---|---|---|

| Mean | Mean 95th% UCL | GM | GSD | |||||

| µg/m3 | µg/m3 | µg/m3 | µg/m3 | µg/m3 | ||||

| Chippewa Falls Location 1 | 31 | 85 | 73.3 | 1.06 | 0.31 | 0.34 | 0.28 | 1.55 |

| Chippewa Falls, Location 2 | 4 | 114 | 96.6 | 0.31 | 0.22 | 0.28 | 0.22 | 1.09 |

| DS Mine, Location 1 | 6 | 112 | 94.9 | 0.38 | 0.23 | 0.23 | 0.22 | 1.11 |

| DS Mine, Location 2 | 7 | 111 | 94.1 | 0.56 | 0.24 | 0.25 | 0.23 | 1.23 |

| S&S Mine, Location 1 | 9 | 109 | 92.4 | 0.73 | 0.24 | 0.26 | 0.23 | 1.27 |

| S&S Mine, Location 2 | 19 | 99 | 83.9 | 0.81 | 0.27 | 0.29 | 0.25 | 1.39 |

| DD Mine, Location 1 | 4 | 114 | 96.6 | 0.43 | 0.23 | 0.23 | 0.22 | 1.13 |

| DD Mine, Location 2 | 3 | 115 | 97.5 | 0.42 | 0.22 | 0.23 | 0.22 | 1.11 |

3.2. Upwind-Downwind Concentration Differences

3.3. Local Background Concentrations

| Facility | Number of 24 h Samples October 2012–December 2014 | Respirable Crystalline Silica Concentrations | ||

|---|---|---|---|---|

| Average | Maximum µg/m3 | |||

| Values Below LOQ Treated as 0.0 µg/m3 | Values Below LOQ Treated as LOQ/ µg/m3 | |||

| Chippewa Falls | 194 | 0.043 | 0.236 | 0.56 |

| DS Mine | 58 | 0.052 | 0.249 | 0.88 |

| S&S Mine | 182 | 0.067 | 0.260 | 2.10 |

| DD Mine | 124 | 0.015 | 0.228 | 0.63 |

3.4. Sampling Method Performance

4. Discussion

4.1. Comparison of Measured Data with Previous Studies

4.2. Susceptibility of Frac Sand to PM4 Particle Formation

4.3. Sources Contributing to Local Background Concentrations

4.4. Additional Research Needed

5. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- California Office of Environmental Health Hazard Assessment. Chronic Toxicity Summary, Silica (Crystalline, Respirable). 2005. Available online: www//oehha.ca.gov/air/chronic_rels/pdf/SILICAcREL_Final.pdf (accessed on 31 May 2015). [Google Scholar]

- Richards, J.; Brozell, T. Ambient PM4 Crystalline Silica Monitoring Method Development; Report to CalCIMA; California Construction and Industrial Materials Association: Sacramento, CA, USA, 2005. [Google Scholar]

- U.S. Environmental Protection Agency. Reference Method for the Determination of Fine Particulate Matter as PM2.5 in the Atmosphere. 40 CFR Part 50, Appendix L. 1997. Available online: http://www.gpo.gov/fdsys/granule/CFR-2011-title40-vol2/CFR-2011-title40-vol2-part50-appL (accessed on 31 May 2015). [Google Scholar]

- National Institute of Occupational Safety and Health. Method 7500, Silica, Crystalline by XRD (Filter Deposition). Issue 4; 2003. Available online: http://www.cdc.gov/niosh/docs/2003-154/pdfs/7500.pdf (accessed on 31 May 2015). [Google Scholar]

- National Institute of Occupational Safety and Health. Method 0600, Particles Not Otherwise Regulated, Respirable. 1998. Available online: www.cdc.gov/niosh/docs/2003-154/pdfs/0600.pdf (accessed on 31 May 2015). [Google Scholar]

- Richards, J.; Brozell, T.; Rea, C.; Boraston, G.; Hayden, J. PM4 crystalline silica emission factors and ambient concentrations at aggregate-producing sources in California. Air Waste Manag. J. 2005, 59, 1287–1296. [Google Scholar] [CrossRef]

- South Coast Air Quality Management District. Sampling and Analysis of Samples Collected in the Cities of Duarte and Azusa; Report MA 2006-01; South Coast Air Management District: Diamond Bar, CA, USA, 2006.

- South Coast Air Quality Management District (2008). Sampling and Analysis of Samples Collected in the Cities of Duarte and Azusa, Follow-Up #4. Report MA 2008-03. 2008. Available online: http://www.azusarock.com/docs/AQMD2008FollowUp.pdf (accessed on 31 May 2015).

- Wisconsin Department of Natural Resources. Report to the Natural Resources Board, Silica Study. August 2011. Available online: http://dnr.wi.gov/topic/AirQuality/documents/FinalSilicaReport.pdf (accessed on 31 May 2015). [Google Scholar]

- Minnesota Environmental Quality Board. Report on Silica Sand. 20 March 2003. Available online: https://www.eqb.state.mn.us/sites/default/files/documents/March%20Final%20Silica%20Sand%20report%20with%20award%20sticker.pdf (accessed on 12 July 2015).

- U.S Environmental Protection Agency. Probe and Monitoring Path Siting Criteria for Ambient Air Quality Monitoring. 40 CFR Part 58, Appendix E. Amended; 15 January 2013. Available online: http://www.ecfr.gov/cgi-bin/text-idx?tpl=/ecfrbrowse/Title40/40cfr58_main_02.tpl (accessed on 13 July 2015). [Google Scholar]

- U.S. Environmental Protection Agency. Sampling Schedule Calendar. Available online: www.epa.gov/ttnamti1/calendar.html (accessed on 12 July 2015).

- U.S. Environmental Protection Agency. Quality Assurance Handbook for Air Pollution Measurement Systems Volume II Ambient Air Quality Monitoring Program. EPA Publication EPA-454/B-13-003; May 2013. Available online: http://www.epa.gov/ttnamti1/files/ambient/pm25/qa/QA-Handbook-Vol-II.pdf (accessed on 13 July 2015). [Google Scholar]

- Hornung, R.W.; Reed, L.D. Estimation of average concentration in the presence of nondetectable values. Appl. Occup. Environ. Hyg. 1990, 5, 46–51. [Google Scholar] [CrossRef]

- Treutel, Jason; (Wisconsin Department of Natural Resources); Richards, John; (Air Control Techniques, P.C.). Personal communication, 2015.

- U.S Environmental Protection Agency. Quality Assurance Requirements for SLAMS, SPMs, and PSD Air Monitoring. 40 CFR Part 58, Appendix A. Amended; 15 January 2013. Available online: http://www.ecfr.gov/cgi-bin/text-idx?SID=84ef9f0996c2e59ff713c5ea7a8f4ffd&mc=true&node=ap40.6.58_161.a&rgn=div9 (accessed on 16 July 2015). [Google Scholar]

- Minnesota Pollution Control Agency. Winona Community Air Monitoring, January 2014–September 2014. January 2015. Available online: http://www.pca.state.mn.us/index.php/view-document.html?gid=21302 (accessed on 16 July 2015).

- Minnesota Pollution Control Agency. Shakopee Sand (Previously Great Plains Sand) Ambient Air Monitoring, July 2012–December 2013. April 2014. Available online: http://www.pca.state.mn.us/index.php/air/air-quality-and-pollutants/air-pollutants/silica-sand-mining/air-monitoring-data-at-minnesota-silica-sand-facilities.html#shakopee-sands (accessed on 31 May 2015).

- Minnesota Pollution Control Agency. Tiller-North Branch Ambient Air Monitoring, November 2012–December 2013. April 2014. Available online: http://www.pca.state.mn.us/index.php/air/air-quality-and-pollutants/air-pollutants/silica-sand-mining/air-monitoring-data-at-minnesota-silica-sand-facilities.html#tiller-north-branch (accessed on 31 May 2015).

- California Environmental Protection Agency, Air Resources Board. Pilot Monitoring Study of Crystalline Silica in Ambient Air in Lompoc, California. 2003. Available online: http://www.cdpr.ca.gov/docs/specproj/lompoc/arbsilica_0403.pdf (accessed on 31 May 2015). [Google Scholar]

- Stacey, P.; Thorpe, A.; Roberts, P. Levels of Respirable Dust and Respirable Crystalline Silica at Construction Sites. Report of the Health and Safety Laboratory, England; 2011. Available online: http://www.hse.gov.uk/research/rrpdf/rr878.pdf (accessed on 31 May 2015). [Google Scholar]

- Environmental Health Board, Queensland Health. Health Risk Assessment of Community Exposure to Silica from Airport Link/Northern Busway Construction Activities. 2012. Available online: https://www.ehp.qld.gov.au/air/pdf/airportlink-qh-report.pdf (accessed on 31 May 2015). [Google Scholar]

- Shiraki, R.; Holmén, B.A. Airborne respirable silica near a sand and gravel facility in central California: XRD and elemental analysis to distinguish source and background quartz. Environ. Sci. Technol. 2002, 36, 4956–4961. [Google Scholar] [CrossRef] [PubMed]

- Saiyed, H.N.; Sharma, Y.K.; Sadhu, H.G.; Norboo, T.; Patel, P.D.; Patel, T.S.; Venkaiah, K.; Kashyap, S.K. Non-occupational pneumoconiosis at high altitude villages in central Ladakh. Br. J. Ind. Med. 1991, 48, 825–829. [Google Scholar] [CrossRef] [PubMed]

- Bhagia, L.J. Non-occupational exposure to silica dust in vicinity of slate pencil industry, India. Environ. Monit. Assess. 2009, 151, 477–482. [Google Scholar] [CrossRef] [PubMed]

- Davis, B.; Johnson, R.; Stevens, R.; Courtney, W.; Safriet, D. The quartz content and elemental composition of aerosols from selected sites of the EPA Inhalable Particulate Network. Atmos. Environ. 1984, 18, 771–782. [Google Scholar] [CrossRef]

- Wisconsin Department of Natural Resources. Wisconsin Air Quality Trends. April 2014. Available online: http://dnr.wi.gov/files/PDF/pubs/am/AM523.pdf (accessed on 31 May 2015). [Google Scholar]

- U.S. Environmental Protection Agency (EPA). Ambient Levels of Noncancer Health Effects of Inhalable Crystalline and Amorphous Silica; U.S. EPA: Washington, DC, USA, 1996.

- Nieuwenhuijsen, M.J.; Noderer, K.S.; Schenker, M.B.; Vallyathan, V.; Olenchock, S. Personal exposure to dust endotoxin and crystalline silica in California agriculture. Ann. Occup. Hyg. 1995, 32, 24–31. [Google Scholar]

- Norton, M.R.; Gunter, M.F. Relationships between respiratory diseases and quartz-rich dust in Idaho, U.S.A. Am. Mineral. 1999, 84, 1009–1019. [Google Scholar]

- Syzkman, J.; Mintz, D.; Creilson, J.; Wayland, M. Impact of April 2001 Asian Dust Event on Particulate Matter Concentrations in the United States. U.S. EPA Trends Report; 2001. Available online: http://www.epa.gov/airtrends/aqtrnd03/pdfs/1_asiandust.pdf (accessed on 31 May 2015). [Google Scholar]

- Archer, J.; Cooper, G.; Reist, P.; Storm, J.; Nylander-French, L. Exposure to respirable crystalline silica in Eastern North Carolina farm workers. Am. Ind. Hyg. Assoc. J. 2002, 63, 750–755. [Google Scholar] [CrossRef]

- Stopford, C.; Stopford, W. Respirable quartz content of farm soil. Appl. Occup. Environ. Hyg. 1995, 10, 196–199. [Google Scholar] [CrossRef]

- Gillette, D. Soil derived dust as a source of silica: Aerosol properties, emissions, deposition, and transport. J. Expo. Anal. Environ. Epidemiol. 1995, 7, 303–311. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richards, J.; Brozell, T. Assessment of Community Exposure to Ambient Respirable Crystalline Silica near Frac Sand Processing Facilities. Atmosphere 2015, 6, 960-982. https://doi.org/10.3390/atmos6080960

Richards J, Brozell T. Assessment of Community Exposure to Ambient Respirable Crystalline Silica near Frac Sand Processing Facilities. Atmosphere. 2015; 6(8):960-982. https://doi.org/10.3390/atmos6080960

Chicago/Turabian StyleRichards, John, and Todd Brozell. 2015. "Assessment of Community Exposure to Ambient Respirable Crystalline Silica near Frac Sand Processing Facilities" Atmosphere 6, no. 8: 960-982. https://doi.org/10.3390/atmos6080960

APA StyleRichards, J., & Brozell, T. (2015). Assessment of Community Exposure to Ambient Respirable Crystalline Silica near Frac Sand Processing Facilities. Atmosphere, 6(8), 960-982. https://doi.org/10.3390/atmos6080960