Techno-Economic Assessment of Air and Water Gap Membrane Distillation for Seawater Desalination under Different Heat Source Scenarios

Abstract

:1. Introduction

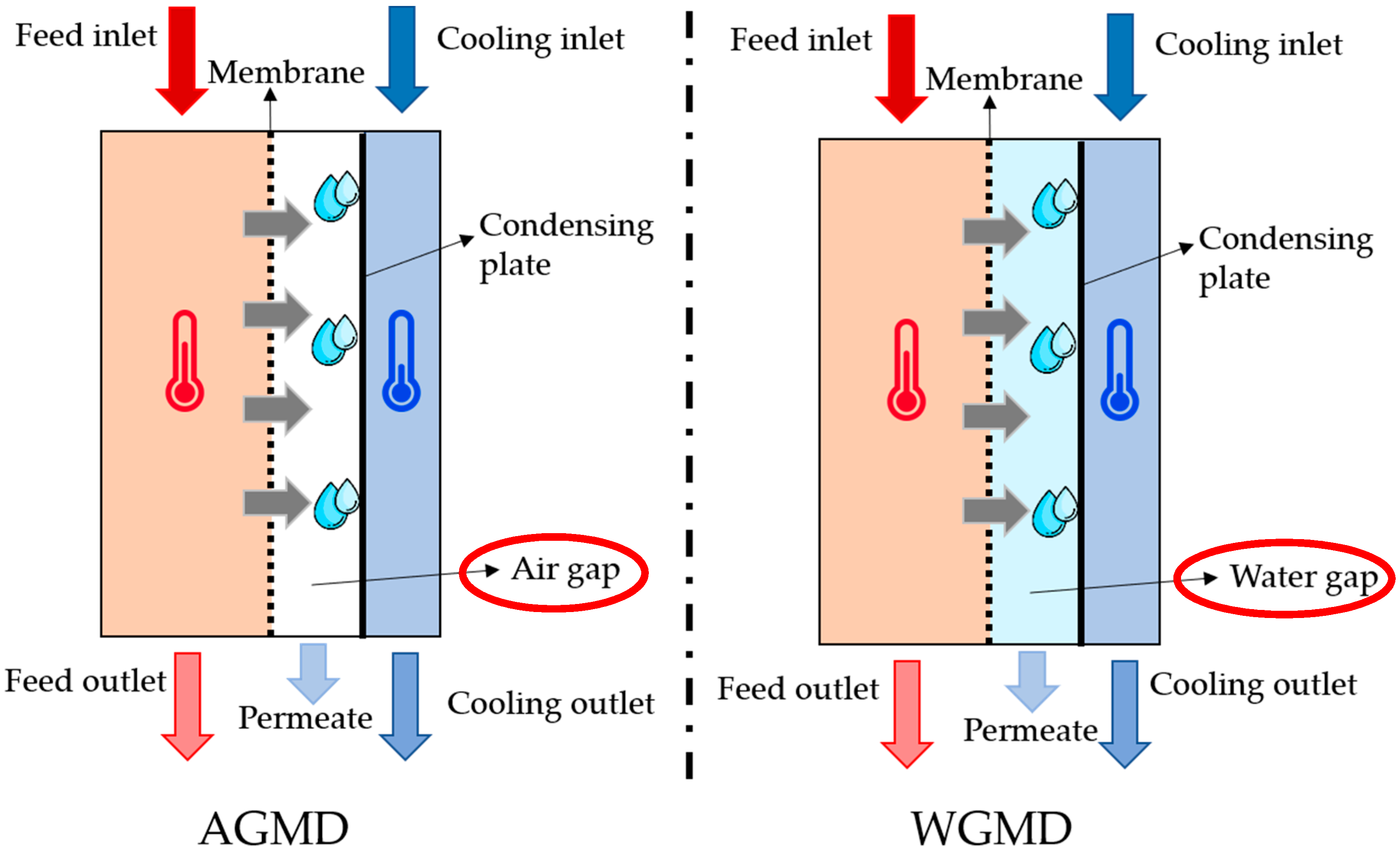

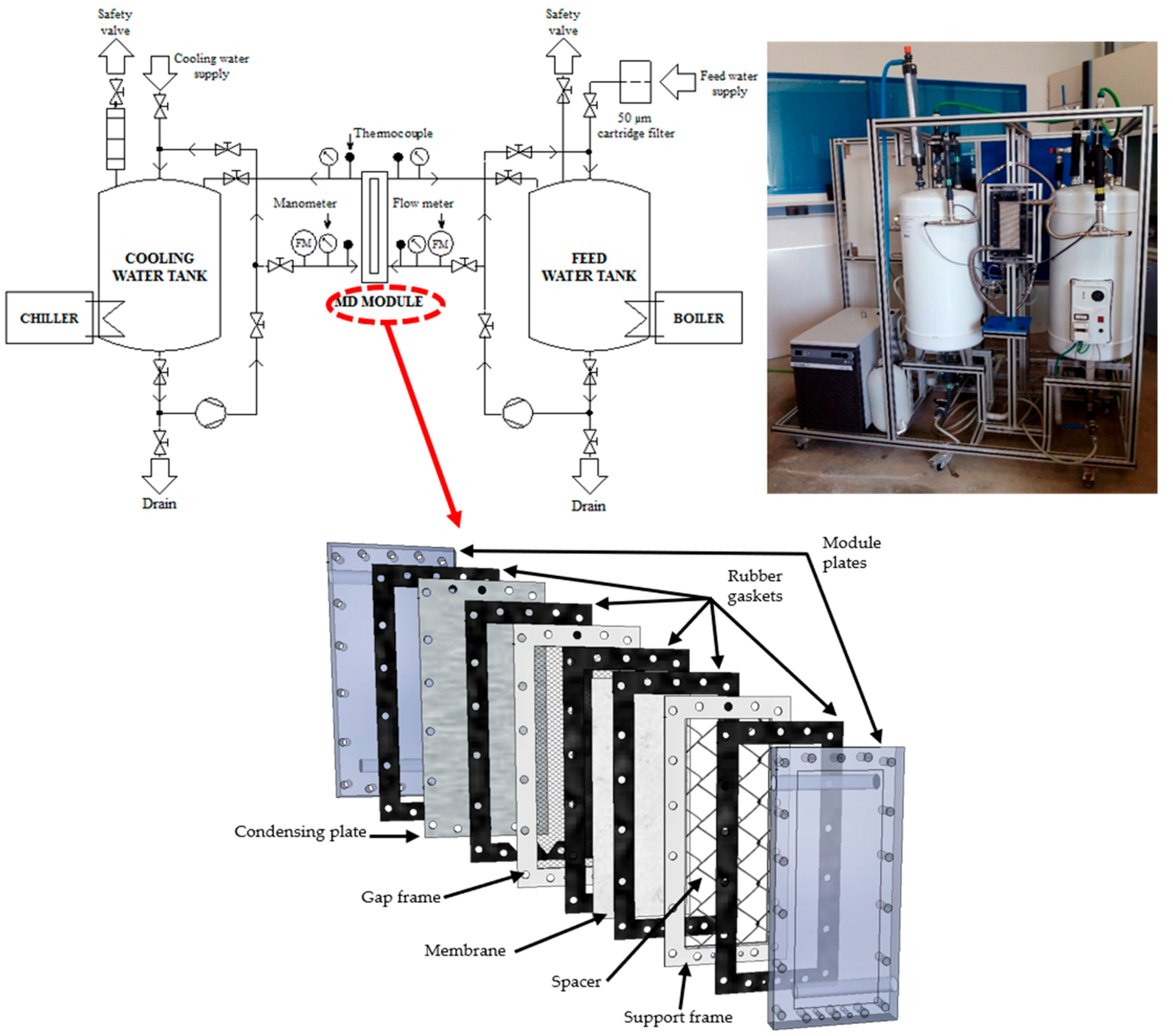

2. Materials and Methods

2.1. Assumptions and Boundary Conditions

2.2. Cost Calculation Methods

2.2.1. Preliminary Estimations

2.2.2. Total Investment Costs

2.2.3. Operational Costs

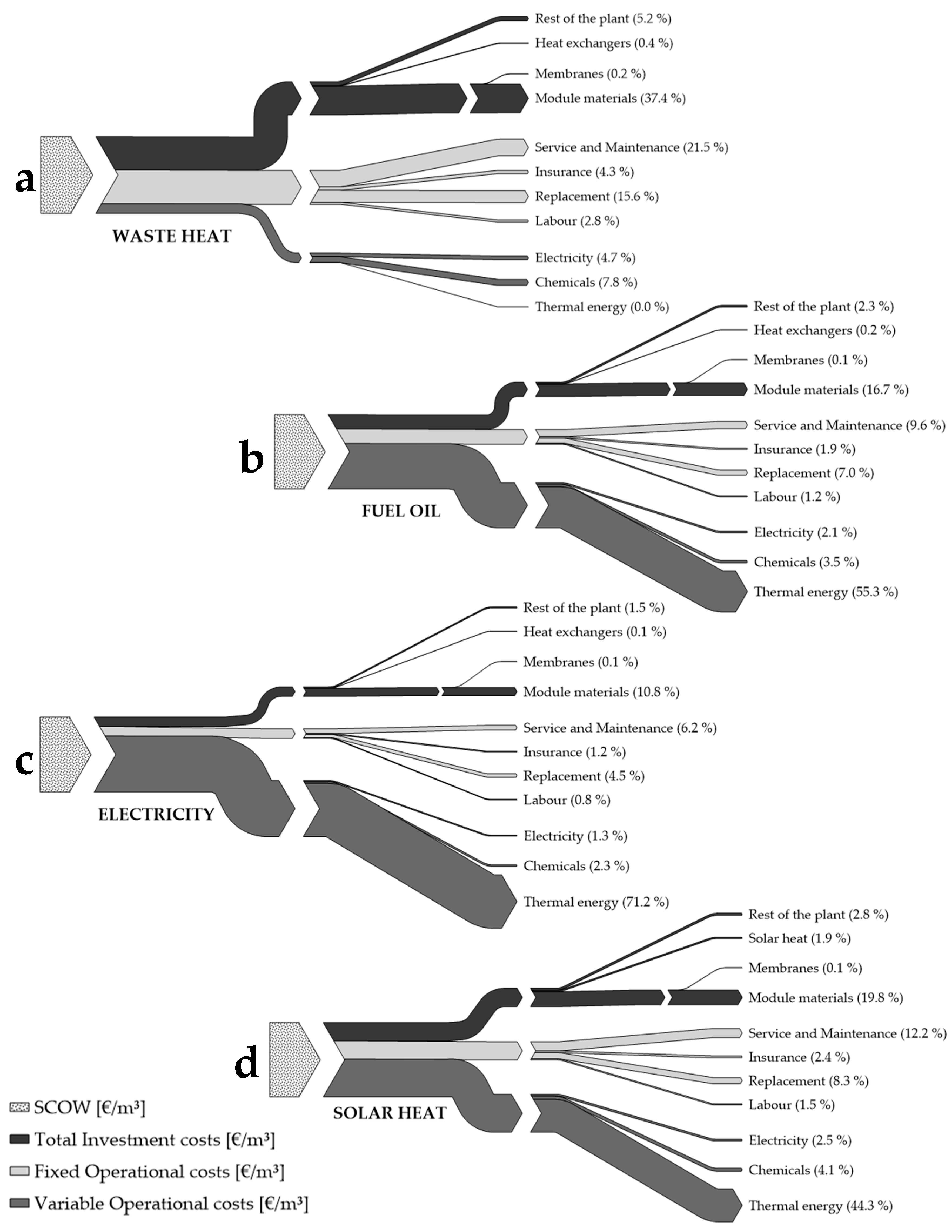

3. Results and Discussion

3.1. Comprehensive Cost of Water Assessment for Each MD Configuration, Capacities and Heat Source Scenarios

3.2. Sensitivity Analysis for Heat Source Scenarios

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mezher, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-economic assessment and environmental impacts of desalination technologies. Desalination 2011, 266, 263–273. [Google Scholar] [CrossRef]

- Mat Nawi, N.I.; Bilad, M.R.; Zolkhiflee, N.; Nordin, N.A.H.; Lau, W.J.; Narkkun, T.; Faungnawakij, K.; Arahman, N.; Mahlia, T.M.I. Development of a novel corrugated polyvinylidene difluoride membrane via improved imprinting technique for membrane distillation. Polymers 2019, 11, 865. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A review on reverse osmosis and nanofiltration membranes for water purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef] [PubMed]

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse osmosis desalination: A state-of-the-art review. Desalination 2019, 459, 59–104. [Google Scholar] [CrossRef] [Green Version]

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar] [CrossRef]

- Baaqeel, H.; El-Halwagi, M. Optimal multiscale capacity planning in seawater desalination systems. Processes 2018, 6, 68. [Google Scholar] [CrossRef]

- Medina, J.A. 20 years evolution of desalination costs in Spain. In Proceedings of the International Conference on Desalination Costing; 2004; pp. 293–309. Available online: http://132.68.226.240/english/pdf/IDS/85.pdf (accessed on 8 July 2019).

- Filippini, G.; Al-Obaidi, M.A.; Manenti, F.; Mujtaba, I.M. Design and economic evaluation of solar-powered hybrid multi effect and reverse osmosis system for seawater desalination. Desalination 2019, 465, 114–125. [Google Scholar] [CrossRef]

- Ruiz-Aguirre, A.; Andrés-Mañas, J.A.; Zaragoza, G. Evaluation of permeate quality in pilot scale membrane distillation systems. Membranes 2019, 9, 69. [Google Scholar] [CrossRef]

- Bennett, A. Developments in desalination and water reuse. Filtr. Sep. 2015, 52, 28–33. [Google Scholar] [CrossRef]

- Zotalis, K.; Dialynas, E.; Mamassis, N.; Angelakis, A.; Zotalis, K.; Dialynas, E.G.; Mamassis, N.; Angelakis, A.N. Desalination technologies: Hellenic experience. Water 2014, 6, 1134–1150. [Google Scholar] [CrossRef]

- Jones, E.; Qadir, M.; van Vliet, M.T.H.; Smakhtin, V.; Kang, S. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef]

- Alkaisi, A.; Mossad, R.; Sharifian-Barforoush, A. A Review of the Water Desalination Systems Integrated with Renewable Energy. In Energy Procedia; Elsevier: Amsterdam, The Netherlands, 2017; pp. 268–274. [Google Scholar] [CrossRef]

- Kurihara, M.; Takeuchi, H.; Ito, Y. A Reliable seawater desalination system based on membrane technology and biotechnology considering reduction of the environmental impact. Environments 2018, 5, 127. [Google Scholar] [CrossRef]

- Ziolkowska, J.R. Is desalination affordable?—Regional cost and price analysis. Water Resour. Manag. 2015, 29, 1385–1397. [Google Scholar] [CrossRef]

- Drioli, E.; Tocci, E.; Macedonio, F.; Drioli, E.; Tocci, E.; Macedonio, F. Membrane science and membrane engineering: A successful story. Gen. Chem. 2019, 5, 180027. [Google Scholar] [CrossRef]

- Al-Obaidani, S.; Curcio, E.; Macedonio, F.; Di Profio, G.; Al-Hinai, H.; Drioli, E. Potential of membrane distillation in seawater desalination: Thermal efficiency, sensitivity study and cost estimation. J. Memb. Sci. 2008, 323, 85–98. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Karanasiou, A.; Kostoglou, M.; Karabelas, A. An experimental and theoretical study on separations by vacuum membrane distillation employing hollow-fiber modules. Water 2018, 10, 947. [Google Scholar] [CrossRef]

- Gryta, M. Effectiveness of water desalination by membrane distillation process. Membranes 2012, 2, 415–429. [Google Scholar] [CrossRef]

- Duong, H.C.; Duke, M.; Gray, S.; Cooper, P.; Nghiem, L.D. Membrane scaling and prevention techniques during seawater desalination by air gap membrane distillation. Desalination 2016, 397, 92–100. [Google Scholar] [CrossRef]

- Guan, G.; Yao, C.; Lu, S.; Jiang, Y.; Yu, H.; Yang, X. Sustainable operation of membrane distillation for hypersaline applications: Roles of brine salinity, membrane permeability and hydrodynamics. Desalination 2018, 445, 123–137. [Google Scholar] [CrossRef]

- Schwantes, R.; Bauer, L.; Chavan, K.; Dücker, D.; Felsmann, C.; Pfafferott, J. Air gap membrane distillation for hypersaline brine concentration: Operational analysis of a full-scale module—New strategies for wetting mitigation. Desalination 2018, 444, 13–25. [Google Scholar] [CrossRef]

- Kujawa, J.; Cerneaux, S.; Kujawski, W.; Knozowska, K. Hydrophobic ceramic membranes for water desalination. Appl. Sci. 2017, 7, 402. [Google Scholar] [CrossRef]

- Al-Furaiji, M.; Arena, J.T.; Ren, J.; Benes, N.; Nijmeijer, A.; McCutcheon, J.R. Triple-layer nanofiber membranes for treating high salinity brines using direct contact membrane distillation. Membranes 2019, 9, 60. [Google Scholar] [CrossRef] [PubMed]

- Lawson, K.W.; Lloyd, D.R. Membrane distillation. J. Memb. Sci. 1997, 124, 1–25. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Hilal, N. Air gap membrane distillation: A detailed study of high saline solution. Desalination 2017, 403, 179–186. [Google Scholar] [CrossRef] [Green Version]

- Guillen-Burrieza, E.; Ruiz-Aguirre, A.; Zaragoza, G.; Arafat, H.A. Membrane fouling and cleaning in long term plant-scale membrane distillation operations. J. Memb. Sci. 2014, 468, 360–372. [Google Scholar] [CrossRef]

- Essalhi, M.; Khayet, M. Fundamentals of membrane distillation. In Pervaporation, Vapour Permeation and Membrane Distillation; Elsevier: Amsterdam, The Netherlands, 2015; pp. 277–316. [Google Scholar] [CrossRef]

- Wang, P.; Chung, T.-S.S. Recent advances in membrane distillation processes: Membrane development, configuration design and application exploring. J. Memb. Sci. 2015, 474, 39–56. [Google Scholar] [CrossRef]

- González, D.; Amigo, J.; Suárez, F. Membrane distillation: Perspectives for sustainable and improved desalination. Renew. Sustain. Energy Rev. 2017, 80, 238–259. [Google Scholar] [CrossRef]

- Ruiz-Aguirre, A. Evaluación de Sistemas Comerciales en Espiral de Destilación por Membranas y su Aplicación al Tratamiento de Aguas. Ph.D. Thesis, Universidad de Almería, Almería, Spain, 2017. [Google Scholar]

- Macedonio, F.; Drioli, E. Membrane distillation development. In Sustainable Water and Wastewater Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 133–159. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Hilal, N. Membrane Distillation-Principles, Applications, Configurations, Design, and Implementation; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Amaya-Vías, D.; López-Ramírez, J.A.; Gray, S.; Zhang, J.; Duke, M. Diffusion behavior of humic acid during desalination with air gap and water gap membrane distillation. Water Res. 2019, 158, 182–192. [Google Scholar] [CrossRef]

- Francis, L.; Ghaffour, N.; Alsaadi, A.A.; Amy, G.L. Material gap membrane distillation: A new design for water vapor flux enhancement. J. Memb. Sci. 2013, 448, 240–247. [Google Scholar] [CrossRef] [Green Version]

- Woldemariam, D.; Martin, A.; Santarelli, M. Exergy analysis of air-gap membrane distillation systems for water purification applications. Appl. Sci. 2017, 7, 301. [Google Scholar] [CrossRef]

- Cui, Z.; Zhang, Y.; Li, X.; Wang, X.; Wang, Z.; Zhao, S. Optimization of novel composite membranes for water and mineral recovery by vacuum membrane distillation. Desalination 2018, 440, 39–47. [Google Scholar] [CrossRef]

- Silva, T.L.S.; Morales-Torres, S.; Esteves, C.M.P.; Ribeiro, A.R.; Nunes, O.C.; Figueiredo, J.L.; Silva, A.M.T. Desalination and removal of organic micropollutants and microorganisms by membrane distillation. Desalination 2018, 437, 121–132. [Google Scholar] [CrossRef]

- Criscuoli, A.; Drioli, E. Vacuum membrane distillation for the treatment of coffee products. Sep. Purif. Technol. 2019, 209, 990–996. [Google Scholar] [CrossRef]

- Mostafa, M.G.; Zhu, B.; Cran, M.; Dow, N.; Milne, N.; Desai, D.; Duke, M. Membrane distillation of meat industry effluent with hydrophilic polyurethane coated polytetrafluoroethylene membranes. Membranes 2017, 7, 55. [Google Scholar] [CrossRef] [PubMed]

- Hausmann, A.; Sanciolo, P.; Vasiljevic, T.; Ponnampalam, E.; Quispe-Chavez, N.; Weeks, M.; Duke, M. Direct contact membrane distillation of dairy process streams. Membranes 2011, 1, 48–58. [Google Scholar] [CrossRef]

- Laqbaqbi, M.; García-Payo, M.C.; Khayet, M.; El Kharraz, J.; Chaouch, M. Application of direct contact membrane distillation for textile wastewater treatment and fouling study. Sep. Purif. Technol. 2019, 209, 815–825. [Google Scholar] [CrossRef]

- Leaper, S.; Abdel-Karim, A.; Gad-Allah, T.A.; Gorgojo, P. Air-gap membrane distillation as a one-step process for textile wastewater treatment. Chem. Eng. J. 2019, 360, 1330–1340. [Google Scholar] [CrossRef]

- Villalobos García, J.; Dow, N.; Milne, N.; Zhang, J.; Naidoo, L.; Gray, S.; Duke, M. Membrane distillation trial on textile wastewater containing surfactants using hydrophobic and hydrophilic-coated polytetrafluoroethylene (PTFE) membranes. Membranes 2018, 8, 31. [Google Scholar] [CrossRef]

- Yang, X.; Duke, M.; Zhang, J.; Li, J.-D. Modeling of heat and mass transfer in vacuum membrane distillation for ammonia separation. Sep. Purif. Technol. 2019, 224, 121–131. [Google Scholar] [CrossRef]

- Amaya-Vías, D.; Tataru, L.; Herce-Sesa, B.; López-López, J.A.; López-Ramírez, J.A. Metals removal from acid mine drainage (Tinto River, SW Spain) by water gap and air gap membrane distillation. J. Memb. Sci. 2019, 582, 20–29. [Google Scholar] [CrossRef]

- Jia, F.; Yin, Y.; Wang, J. Removal of cobalt ions from simulated radioactive wastewater by vacuum membrane distillation. Prog. Nucl. Energy 2018, 103, 20–27. [Google Scholar] [CrossRef]

- Schwantes, R.; Chavan, K.; Winter, D.; Felsmann, C.; Pfafferott, J. Techno-economic comparison of membrane distillation and MVC in a zero liquid discharge application. Desalination 2018, 428, 50–68. [Google Scholar] [CrossRef] [Green Version]

- The National Academies of Sciences Engineering and Medicine. The Power of Change: Innovation for Development and Deployment of Increasingly Clean Electric Power Technologies; National Academies Press: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Camacho, L.M.; Dumée, L.; Zhang, J.; Li, J.-d.; Duke, M.; Gomez, J.; Gray, S. Advances in membrane distillation for water desalination and purification applications. Water 2013, 5, 94–196. [Google Scholar] [CrossRef]

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef] [PubMed]

- Papapetrou, M.; Cipollina, A.; La Commare, U.; Micale, G.; Zaragoza, G.; Kosmadakis, G. Assessment of methodologies and data used to calculate desalination costs. Desalination 2017, 419, 8–19. [Google Scholar] [CrossRef]

- Pinto, F.S.; Marques, R.C. Desalination projects economic feasibility: A standardization of cost determinants. Renew. Sustain. Energy Rev. 2017, 78, 904–915. [Google Scholar] [CrossRef]

- Winter, D. Membrane Distillation—A Thermodynamic, Technological and Economic Analysis. Ph.D. Thesis, University of Kaiserslautern, Kaiserslautern, Germany, 2015. Available online: https://www.reiner-lemoine-stiftung.de/pdf/dissertationen/Dissertation-Daniel_Winter.pdf (accessed on 3 July 2019).

- Noor, I.E.; Coenen, J.; Martin, A.; Dahl, O.; Åslin, M. Experimental investigation and techno-economic analysis of tetramethylammonium hydroxide removal from wastewater in nano-electronics manufacturing via membrane distillation. J. Memb. Sci. 2019, 579, 283–293. [Google Scholar] [CrossRef]

- Zare, S.; Kargari, A. Membrane Properties in Membrane Distillation; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Yang, X.; Fane, A.G.; Wang, R. Membrane distillation: Now and future. Desalination 2014, 373–424. [Google Scholar] [CrossRef]

- Kress, N. Desalination technologies. In Marine Impacts of Seawater Desalination; Elsevier: Amsterdam, The Netherlands, 2019; pp. 11–34. [Google Scholar] [CrossRef]

- Susanto, H. Towards practical implementations of membrane distillation. Chem. Eng. Process. Process Intensif. 2011, 50, 139–150. [Google Scholar] [CrossRef]

- Kesieme, U.K.; Milne, N.; Aral, H.; Cheng, C.Y.; Duke, M. Economic analysis of desalination technologies in the context of carbon pricing, and opportunities for membrane distillation. Desalination 2013, 323, 66–74. [Google Scholar] [CrossRef] [Green Version]

- Burn, S.; Hoang, M.; Zarzo, D.; Olewniak, F.; Campos, E.; Bolto, B.; Barron, O. Desalination techniques—A review of the opportunities for desalination in agriculture. Desalination 2015, 364, 2–16. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-water-environment nexus underpinning future desalination sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Towler, G.; Sinnott, R. Chemical Engineering Design Principles, Practice and Economics of Plant and Process Design, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Amaya-Vías, D.; Nebot, E.; López-Ramírez, J.A. Comparative studies of different membrane distillation configurations and membranes for potential use on board cruise vessels. Desalination 2018, 429, 44–51. [Google Scholar] [CrossRef]

- Micari, M.; Moser, M.; Cipollina, A.; Fuchs, B.; Ortega-Delgado, B.; Tamburini, A.; Micale, G. Techno-economic assessment of multi-effect distillation process for the treatment and recycling of ion exchange resin spent brines. Desalination 2019, 456, 38–52. [Google Scholar] [CrossRef]

- Agashichev, S.P. Analysis of integrated co-generative schemes including MSF, RO and power generating systems (present value of expenses and “levelised” cost of water). Desalination 2004, 164, 281–302. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Kavadias, K.A.; Kondili, E. Renewable energy desalination plants for the Greek islands—Technical and economic considerations. Desalination 2004, 170, 187–203. [Google Scholar] [CrossRef]

- Moser, M.; Trieb, F.; Fichter, T.; Kern, J.; Hess, D. A flexible techno-economic model for the assessment of desalination plants driven by renewable energies. Desalin. Water Treat. 2014, 1–15. [Google Scholar] [CrossRef]

- Shahabi, M.P.; McHugh, A.; Anda, M.; Ho, G. Comparative economic and environmental assessments of centralised and decentralised seawater desalination options. Desalination 2015, 376, 25–34. [Google Scholar] [CrossRef]

- Loutatidou, S.; Arafat, H.A. Techno-economic analysis of MED and RO desalination powered by low-enthalpy geothermal energy. Desalination 2015, 365, 277–292. [Google Scholar] [CrossRef]

- Suárez, A.; Fernández, P.; Ramón Iglesias, J.; Iglesias, E.; Riera, F.A. Cost assessment of membrane processes: A practical example in the dairy wastewater reclamation by reverse osmosis. J. Memb. Sci. 2015, 493, 389–402. [Google Scholar] [CrossRef]

- Abraham, T.; Luthra, A. Socio-economic & technical assessment of photovoltaic powered membrane desalination processes for India. Desalination 2011, 268, 238–248. [Google Scholar]

- Bilton, A.M.; Wiesman, R.; Arif, A.F.M.; Zubair, S.M.; Dubowsky, S. On the feasibility of community-scale photovoltaic-powered reverse osmosis desalination systems for remote locations. Renew. Energy 2011, 36, 3246–3256. [Google Scholar] [CrossRef]

- Hossam-Eldin, A.; El-Nashar, A.M.; Ismaiel, A. Investigation into economical desalination using optimized hybrid renewable energy system. Int. J. Electr. Power Energy Syst. 2012, 43, 1393–1400. [Google Scholar] [CrossRef]

- Choi, Y.; Cho, H.; Shin, Y.; Jang, Y.; Lee, S. Economic evaluation of a hybrid desalination system combining forward and reverse osmosis. Membranes 2016, 6, 3. [Google Scholar] [CrossRef] [PubMed]

- Mokhtari, H.; Ahmadisedigh, H.; Ebrahimi, I. Comparative 4E analysis for solar desalinated water production by utilizing organic fluid and water. Desalination 2016, 377, 108–122. [Google Scholar] [CrossRef]

- Palenzuela, P.; Alarcón-Padilla, D.-C.; Zaragoza, G. Large-scale solar desalination by combination with CSP: Techno-economic analysis of different options for the Mediterranean Sea and the Arabian Gulf. Desalination 2015, 366, 130–138. [Google Scholar] [CrossRef]

- Valladares Linares, R.; Li, Z.; Yangali-Quintanilla, V.; Ghaffour, N.; Amy, G.; Leiknes, T.; Vrouwenvelder, J.S. Life cycle cost of a hybrid forward osmosis—Low pressure reverse osmosis system for seawater desalination and wastewater recovery. Water Res. 2016, 88, 225–234. [Google Scholar] [CrossRef]

- Osipi, S.R.; Secchi, A.R.; Borges, C.P. Cost assessment and retro-techno-economic analysis of desalination technologies in onshore produced water treatment. Desalination 2018, 430, 107–119. [Google Scholar] [CrossRef]

- Mabrouk, A.N.; Fath, H.E.S. Technoeconomic study of a novel integrated thermal MSF–MED desalination technology. Desalination 2015, 371, 115–125. [Google Scholar] [CrossRef]

- Leiva-Illanes, R.; Escobar, R.; Cardemil, J.M.; Alarcón-Padilla, D.-C. Comparison of the levelized cost and thermoeconomic methodologies—Cost allocation in a solar polygeneration plant to produce power, desalted water, cooling and process heat. Energy Convers. Manag. 2018, 168, 215–229. [Google Scholar] [CrossRef]

- Rahimi, B.; May, J.; Christ, A.; Regenauer-Lieb, K.; Chua, H.T. Thermo-economic analysis of two novel low grade sensible heat driven desalination processes. Desalination 2015, 365, 316–328. [Google Scholar] [CrossRef]

- Killingtveit, Å. Hydropower. Manag. Glob. Warm. 2019, 265–315. [Google Scholar]

- de Vos, R.; Sawin, J. READy: Renewable Energy Action on Deployment. Policies for Accelerated Deployment of Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Rand, D.A.J.; Moseley, P.T. Electrochemical Energy Storage for Renewable Sources and Grid Balancing; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Berrada, A.; Loudiyi, K. Gravity Energy Storage; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Wittholz, M.K.; O’Neill, B.K.; Colby, C.B.; Lewis, D. Estimating the cost of desalination plants using a cost database. Desalination 2008, 229, 10–20. [Google Scholar] [CrossRef]

- Sommariva, C.; Hogg, H.; Callister, K. Forty-year design life: The next target Material selection and operating conditions in thermal desalination plants. Desalination 2001, 136, 169–176. [Google Scholar] [CrossRef]

- I. Renewable Energy Agency, Solar Heat for Industrial Processes. 2015. Available online: http://www.irena.org (accessed on 12 July 2019).

- Eurostat, Electricity Price Statistics. 2018. Available online: https://ec.europa.eu/eurostat/statisticsexplained/ (accessed on 12 July 2019).

- E.C.M. IDEA. Regulated Energy Price Report. 2019. Available online: https://www.idae.es/sites/default/files/estudios_informes_y_estadisticas/combustibles_y_carburantes_mayo_2019.pdf (accessed on 12 July 2019).

- Saffarini, R.B.; Summers, E.K.; Arafat, H.A.; Lienhard V, J.H. Technical evaluation of stand-alone solar powered membrane distillation systems. Desalination 2012, 286, 332–341. [Google Scholar] [CrossRef]

- Zaragoza, G.; Ruiz-Aguirre, A.; Guillén-Burrieza, E. Efficiency in the use of solar thermal energy of small membrane desalination systems for decentralized water production. Appl. Energy 2014, 130, 491–499. [Google Scholar] [CrossRef]

- Gopi, G.; Arthanareeswaran, G.; Ismail, A.F. Perspective of renewable desalination by using membrane distillation. Chem. Eng. Res. Des. 2019, 144, 520–537. [Google Scholar]

- Vannoni, C.; Battisti, R.; Drigo, S. Potencial for Solar Heat in Industrial Processes. 2008. Available online: http://www.aee-intec.at/0uploads/dateien561.pdf (accessed on 12 July 2019).

- Karagiannis, I.C.; Soldatos, P.G. Water desalination cost literature: Review and assessment. Desalination 2008, 223, 448–456. [Google Scholar] [CrossRef]

- Al-Karaghouli, A.; Kazmerski, L.L. Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes. Renew. Sustain. Energy Rev. 2013, 24, 343–356. [Google Scholar] [CrossRef]

- Rabiee, H.; Khalilpour, K.R.; Betts, J.M.; Tapper, N. Energy-water nexus: Renewable-integrated hybridized desalination systems. In Polygeneration with Polystorage for Chemical and Energy Hubs; Academic Press: Cambridge, MA, USA, 2019; pp. 409–458. [Google Scholar] [CrossRef]

- Cipollina, A.; Micale, G.; Rizzuti, L. Seawater Desalination. Conventional and Renewable Energy Processes; Springer: Heidelberg, Germany, 2009. [Google Scholar] [CrossRef]

| Capacity a | Feedwater | Configuration | Energy factors | Costs b | References |

|---|---|---|---|---|---|

| 20 | Seawater | AGMD | Solar powered | 16.42 | [34,60] |

| 24,000 | Seawater | DCMD | Heat recovery | 1.07 | [34] |

| 24,000 | Seawater | DCMD | No heat recovery | 1.12 | [34] |

| 30,000 | Seawater | n.a | n.a | 0.56–1.57 | [57,61] |

| n.a | Seawater | DCMD | Solar powered | 13.68–16.42 | [62] |

| n.a | Seawater | DCMD | Geothermal | 11.86 | [62] |

| n.a | Seawater | DCMD | Waste heat | 1–1.37 | [62] |

| n.a | Seawater | AGMD | Solar powered | 16.70 | [62] |

| n.a | Seawater | AGMD | Waste heat | 4.84 | [62] |

| n.a | Seawater | VMD | Solar powered | 14.6 | [62] |

| n.a | Seawater | VMD | Waste heat | 1.82 | [62] |

| 10 | Wastewater | AGMD | Waste heat | 8.21–8.94 | [49] |

| 1000 | Wastewater | AGMD | Waste heat | 4.01–4.38 | [49] |

| 30,000 | n.a | n.a | n.a | 2.01 | [34] |

| 30,000 | n.a | n.a | Waste heat | 0.6 | [34,57] |

| 24,000 | n.a | DCMD | Heat recovery | 1.07 | [34] |

| n.a | n.a | DCMD | Waste heat | 0.58 | [34] |

| 0.1 | Brackish water | AGMD | Solar powered | 13.68 | [34,60] |

| n.a | n.a | DCMD | Solar powered/Heat recovery | 11.59 | [34] |

| n.a | n.a | AGMD | Solar powered/Heat recovery | 17 | [34] |

| n.a | n.a | VMD | Solar powered/Heat recovery | 14.6 | [34] |

| 0.017 | n.a | n.a | Geothermal | 11.86 | [34,62] |

| n.a | n.a | DCMD | No heat recovery | 1.12 | [34] |

| 24,000 | n.a | n.a | n.a | 1.07–1.82 | [63] |

| n.a | n.a | n.a | n.a | 0.24–118 | [17,34,58,59] |

| Membrane type | Flat hydrophobic PTFE membranes with 0.45 µm pore size. |

| MD module | Flat MD module with an effective area of 0.025 m2. |

| MD plant capacity | Raw water maximum capacity treatment of 0.6 m3 per hour. |

| MD configurations | WGMD and AGMD. |

| Permeate fluxes | 13.08 L h−1 m−2 and 6.73 L h−1 m−2 for WGMD and AGMD, respectively. |

| Feed water characteristics | Seawater from Bay of Cadiz (Spain) without any pretreatment. Conductivity of 47,000 µS cm−1 and pH 8.10 |

| Operating temperatures | 70 °C for feed inlet temperature and 18°C for cooling water cycle. |

| MD Heat Source Scenario | Price of Thermal Energy (€ kWh−1) |

|---|---|

| 1. Waste heat | 0 * |

| 2. Fuel oil burning | 0.052 [92] |

| 3. Electricity grid | 0.103 [91] |

| 4. Solar Heat | 0.035 [90] |

| WGMD | 1. WASTE HEAT | 2. FUEL OIL BURNING | 3. ELECTRICITY GRID | 4. SOLAR HEAT | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (m3 d−1) | Capacity (m3 d−1) | Capacity (m3 d−1) | Capacity (m3 d−1) | |||||||||||||||||||||

| 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | |||||||||||||

| € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | |

| CF | 1.67 | 45.2 | 1.07 | 45.5 | 0.69 | 44.2 | 1.67 | 29.7 | 1.07 | 25.0 | 0.69 | 19.8 | 1.67 | 22.1 | 1.07 | 17.2 | 0.69 | 12.8 | 1.74 | 33.6 | 1.11 | 29.5 | 0.72 | 24.4 |

| CSM | 0.84 | 22.9 | 0.53 | 22.7 | 0.34 | 21.5 | 0.84 | 15.0 | 0.53 | 12.4 | 0.34 | 9.6 | 0.84 | 11.2 | 0.53 | 8.6 | 0.34 | 6.2 | 0.90 | 17.5 | 0.57 | 15.1 | 0.36 | 12.2 |

| CI | 0.17 | 4.6 | 0.11 | 4.5 | 0.07 | 4.3 | 0.17 | 3.0 | 0.11 | 2.5 | 0.07 | 1.9 | 0.17 | 2.2 | 0.11 | 1.7 | 0.07 | 1.2 | 0.18 | 3.5 | 0.11 | 3.0 | 0.07 | 2.4 |

| CRM | 0.61 | 16.6 | 0.39 | 16.5 | 0.24 | 15.6 | 0.61 | 10.9 | 0.39 | 9.0 | 0.24 | 7.0 | 0.61 | 8.1 | 0.39 | 6.2 | 0.24 | 4.5 | 0.61 | 11.8 | 0.39 | 10.2 | 0.24 | 8.3 |

| CL | 0.04 | 1.2 | 0.04 | 1.8 | 0.04 | 2.8 | 0.04 | 0.8 | 0.04 | 1.0 | 0.04 | 1.2 | 0.04 | 0.6 | 0.04 | 0.7 | 0.04 | 0.8 | 0.04 | 0.8 | 0.04 | 1.1 | 0.04 | 1.5 |

| CV | 0.32 | 8.7 | 0.21 | 8.9 | 0.19 | 12.5 | 2.25 | 40.0 | 2.13 | 50.0 | 2.12 | 60.9 | 4.16 | 55.3 | 4.05 | 65.5 | 4.04 | 74.8 | 1.62 | 31.3 | 1.51 | 40.1 | 1.50 | 51.0 |

| CCH | 0.12 | 3.3 | 0.12 | 5.2 | 0.12 | 7.8 | 0.12 | 2.2 | 0.12 | 2.9 | 0.12 | 3.5 | 0.12 | 1.6 | 0.12 | 2.0 | 0.12 | 2.3 | 0.12 | 2.4 | 0.12 | 3.2 | 0.12 | 4.1 |

| CThermal | 0.00 | 0.0 | 0.00 | 0.0 | 0.00 | 0.0 | 1.92 | 34.3 | 1.92 | 45.1 | 1.92 | 55.3 | 3.84 | 51.1 | 3.84 | 62.1 | 3.84 | 71.2 | 1.30 | 25.1 | 1.30 | 34.6 | 1.30 | 44.3 |

| CEL | 0.20 | 5.4 | 0.09 | 3.7 | 0.07 | 4.7 | 0.20 | 3.5 | 0.09 | 2.0 | 0.07 | 2.1 | 0.20 | 2.6 | 0.09 | 1.4 | 0.07 | 1.3 | 0.20 | 3.8 | 0.09 | 2.3 | 0.07 | 2.5 |

| aI | 1.70 | 46.1 | 1.07 | 45.6 | 0.67 | 43.3 | 1.70 | 30.2 | 1.07 | 25.0 | 0.67 | 19.4 | 1.70 | 22.5 | 1.07 | 17.3 | 0.67 | 12.5 | 1.82 | 35.1 | 1.14 | 30.4 | 0.72 | 24.6 |

| CrMD | 0.21 | 5.6 | 0.13 | 5.4 | 0.08 | 5.2 | 0.21 | 3.7 | 0.13 | 3.0 | 0.08 | 2.3 | 0.21 | 2.7 | 0.13 | 2.1 | 0.08 | 1.5 | 0.21 | 4.0 | 0.13 | 3.4 | 0.08 | 2.8 |

| CHX | 0.02 | 0.5 | 0.01 | 0.5 | 0.01 | 0.4 | 0.02 | 0.3 | 0.01 | 0.3 | 0.01 | 0.2 | 0.02 | 0.2 | 0.01 | 0.2 | 0.01 | 0.1 | 0.14 | 2.7 | 0.09 | 2.3 | 0.06 | 1.9 |

| Cmemb | 0.01 | 0.2 | 0.01 | 0.2 | 0.00 | 0.2 | 0.01 | 0.2 | 0.01 | 0.1 | 0.00 | 0.1 | 0.01 | 0.1 | 0.01 | 0.1 | 0.00 | 0.1 | 0.01 | 0.2 | 0.01 | 0.1 | 0.00 | 0.1 |

| CmatMD | 1.46 | 39.7 | 0.92 | 39.5 | 0.58 | 37.4 | 1.46 | 26.1 | 0.92 | 21.7 | 0.58 | 16.7 | 1.46 | 19.5 | 0.92 | 14.9 | 0.58 | 10.8 | 1.46 | 28.2 | 0.92 | 24.5 | 0.58 | 19.8 |

| TOTAL | 3.68 | 100 | 2.34 | 100 | 1.56 | 100 | 5.61 | 100 | 4.27 | 100 | 3.48 | 100 | 7.53 | 100 | 6.18 | 100 | 5.40 | 100 | 5.18 | 100 | 3.77 | 100 | 2.94 | 100 |

| AGMD | 1. WASTE HEAT | 2. FUEL OIL BURNING | 3. ELECTRICITY GRID | 4. SOLAR HEAT | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (m3 d−1) | Capacity (m3 d−1) | Capacity (m3 d−1) | Capacity (m3 d−1) | |||||||||||||||||||||

| 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | 10 | 100 | 1000 | |||||||||||||

| € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | € m−3 | % | |

| CF | 2.71 | 47.1 | 1.72 | 47.2 | 1.10 | 46.3 | 2.71 | 35.3 | 1.72 | 30.9 | 1.10 | 25.6 | 2.71 | 28.2 | 1.72 | 23.0 | 1.10 | 17.7 | 2.78 | 38.4 | 1.77 | 34.9 | 1.13 | 30.1 |

| CSM | 1.36 | 23.6 | 0.86 | 23.4 | 0.54 | 22.6 | 1.36 | 17.7 | 0.86 | 15.3 | 0.54 | 12.5 | 1.36 | 14.1 | 0.86 | 11.4 | 0.54 | 8.7 | 1.42 | 19.5 | 0.89 | 17.6 | 0.56 | 15.0 |

| CI | 0.27 | 4.7 | 0.17 | 4.7 | 0.11 | 4.5 | 0.27 | 3.5 | 0.17 | 3.1 | 0.11 | 2.5 | 0.27 | 2.8 | 0.17 | 2.3 | 0.11 | 1.7 | 0.28 | 3.9 | 0.18 | 3.5 | 0.11 | 3.0 |

| CRM | 1.04 | 18.0 | 0.66 | 17.9 | 0.41 | 17.3 | 1.04 | 13.5 | 0.66 | 11.8 | 0.41 | 9.6 | 1.04 | 10.8 | 0.66 | 8.7 | 0.41 | 6.6 | 1.04 | 14.3 | 0.66 | 12.9 | 0.41 | 11.0 |

| CL | 0.04 | 0.8 | 0.04 | 1.2 | 0.04 | 1.8 | 0.04 | 0.6 | 0.04 | 0.8 | 0.04 | 1.0 | 0.04 | 0.5 | 0.04 | 0.6 | 0.04 | 0.7 | 0.04 | 0.6 | 0.04 | 0.9 | 0.04 | 1.1 |

| CV | 0.32 | 5.6 | 0.21 | 5.7 | 0.19 | 8.2 | 2.25 | 29.2 | 2.13 | 38.2 | 2.12 | 49.2 | 4.16 | 43.3 | 4.05 | 54.0 | 4.04 | 64.8 | 1.62 | 22.4 | 1.51 | 29.8 | 1.50 | 39.8 |

| CCH | 0.12 | 2.1 | 0.12 | 3.3 | 0.12 | 5.1 | 0.12 | 1.6 | 0.12 | 2.2 | 0.12 | 2.8 | 0.12 | 1.3 | 0.12 | 1.6 | 0.12 | 2.0 | 0.12 | 1.7 | 0.12 | 2.4 | 0.12 | 3.2 |

| CThermal | 0.00 | 0.0 | 0.00 | 0.0 | 0.00 | 0.0 | 1.92 | 25.0 | 1.92 | 34.5 | 1.92 | 44.7 | 3.84 | 40.0 | 3.84 | 51.3 | 3.84 | 61.7 | 1.30 | 17.9 | 1.30 | 25.7 | 1.30 | 34.6 |

| CEL | 0.20 | 3.4 | 0.09 | 2.4 | 0.07 | 3.1 | 0.20 | 2.6 | 0.09 | 1.5 | 0.07 | 1.7 | 0.20 | 2.1 | 0.09 | 1.1 | 0.07 | 1.2 | 0.20 | 2.7 | 0.09 | 1.7 | 0.07 | 1.9 |

| aI | 2.73 | 47.4 | 1.72 | 47.1 | 1.09 | 45.5 | 2.73 | 35.5 | 1.72 | 30.8 | 1.09 | 25.2 | 2.73 | 28.4 | 1.72 | 22.9 | 1.09 | 17.4 | 2.85 | 39.3 | 1.80 | 35.4 | 1.13 | 30.1 |

| CrMD | 0.21 | 3.6 | 0.13 | 3.5 | 0.08 | 3.4 | 0.21 | 2.7 | 0.13 | 2.3 | 0.08 | 1.9 | 0.21 | 2.2 | 0.13 | 1.7 | 0.08 | 1.3 | 0.21 | 2.8 | 0.13 | 2.5 | 0.08 | 2.2 |

| CHX | 0.02 | 0.3 | 0.01 | 0.3 | 0.01 | 0.3 | 0.02 | 0.2 | 0.01 | 0.2 | 0.01 | 0.2 | 0.02 | 0.2 | 0.01 | 0.1 | 0.01 | 0.1 | 0.14 | 1.9 | 0.09 | 1.7 | 0.06 | 1.5 |

| Cmemb | 0.01 | 0.3 | 0.01 | 0.3 | 0.01 | 0.2 | 0.01 | 0.2 | 0.01 | 0.2 | 0.01 | 0.1 | 0.01 | 0.2 | 0.01 | 0.1 | 0.01 | 0.1 | 0.01 | 0.2 | 0.01 | 0.2 | 0.01 | 0.2 |

| CmatMD | 2.49 | 43.2 | 1.57 | 43.0 | 0.99 | 41.6 | 2.49 | 32.4 | 1.57 | 28.2 | 0.99 | 23.0 | 2.49 | 25.9 | 1.57 | 21.0 | 0.99 | 15.9 | 2.49 | 34.3 | 1.57 | 30.9 | 0.99 | 26.3 |

| TOTAL | 5.76 | 100 | 3.65 | 100 | 2.38 | 100 | 7.69 | 100 | 5.58 | 100 | 4.31 | 100 | 9.60 | 100 | 7.49 | 100 | 6.23 | 100 | 7.26 | 100 | 5.08 | 100 | 3.77 | 100 |

| Desalination Technology | Feedwater | Capacity (m3 d−1) | Costs (€ m−3) | References |

|---|---|---|---|---|

| RO | Seawater | <100 | 1.20–15 | [11,97] |

| Seawater | 250–1000 | 1.00–3.14 | [11,97] | |

| Seawater | 1000–4800 | 0.56–1.32 | [11,97,98,99] | |

| Seawater | 128,000 | 0.24–0.49 | [63] | |

| Brackish water | <20 | 4.50–10.32 | [11,97,98,99] | |

| Brackish water | 20–1200 | 0.62–1.06 | [11,97,98,99] | |

| Brackish water | 40,000–46,000 | 0.21–0.43 | [11,97,98,99] | |

| - | 1000 | 1.64 | [100] | |

| MED | Seawater | <100 | 2.00–8.00 | [11,97,98,99] |

| Seawater | 12,000–55,000 | 0.76–1.20 | [11,97,98,99,100] | |

| - | 1000 | 1.26–1.32 | [100] | |

| Seawater | 91,000–320,000 | 0.38–0.74 | [11,97,98,99] | |

| MSF | SW | 23,000–528,000 | 0.42–1.40 | [11,97,98,99,100] |

| - | 1000 | 1.09–1.22 | [100] | |

| - | 50,000–70,000 | 0.51–1.60 | [59,63] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaya-Vías, D.; López-Ramírez, J.A. Techno-Economic Assessment of Air and Water Gap Membrane Distillation for Seawater Desalination under Different Heat Source Scenarios. Water 2019, 11, 2117. https://doi.org/10.3390/w11102117

Amaya-Vías D, López-Ramírez JA. Techno-Economic Assessment of Air and Water Gap Membrane Distillation for Seawater Desalination under Different Heat Source Scenarios. Water. 2019; 11(10):2117. https://doi.org/10.3390/w11102117

Chicago/Turabian StyleAmaya-Vías, David, and Juan Antonio López-Ramírez. 2019. "Techno-Economic Assessment of Air and Water Gap Membrane Distillation for Seawater Desalination under Different Heat Source Scenarios" Water 11, no. 10: 2117. https://doi.org/10.3390/w11102117

APA StyleAmaya-Vías, D., & López-Ramírez, J. A. (2019). Techno-Economic Assessment of Air and Water Gap Membrane Distillation for Seawater Desalination under Different Heat Source Scenarios. Water, 11(10), 2117. https://doi.org/10.3390/w11102117