Advanced Treatment of Real Grey Water by SBR Followed by Ultrafiltration—Performance and Fouling Behavior

Abstract

1. Introduction

2. Methodology

2.1. Grey Water Characteristic

2.2. Biological Treatment in SBR

2.3. SBR Effluent Treatemnt by Ultrafilltration–Ultrafiltration Run

2.4. Membrane Fouling Characterization

2.5. Membrane Characterization

2.6. Quality Analysis and Microbiological Assessment

3. Results and Discussion

3.1. Grey Water Treatment in SBR

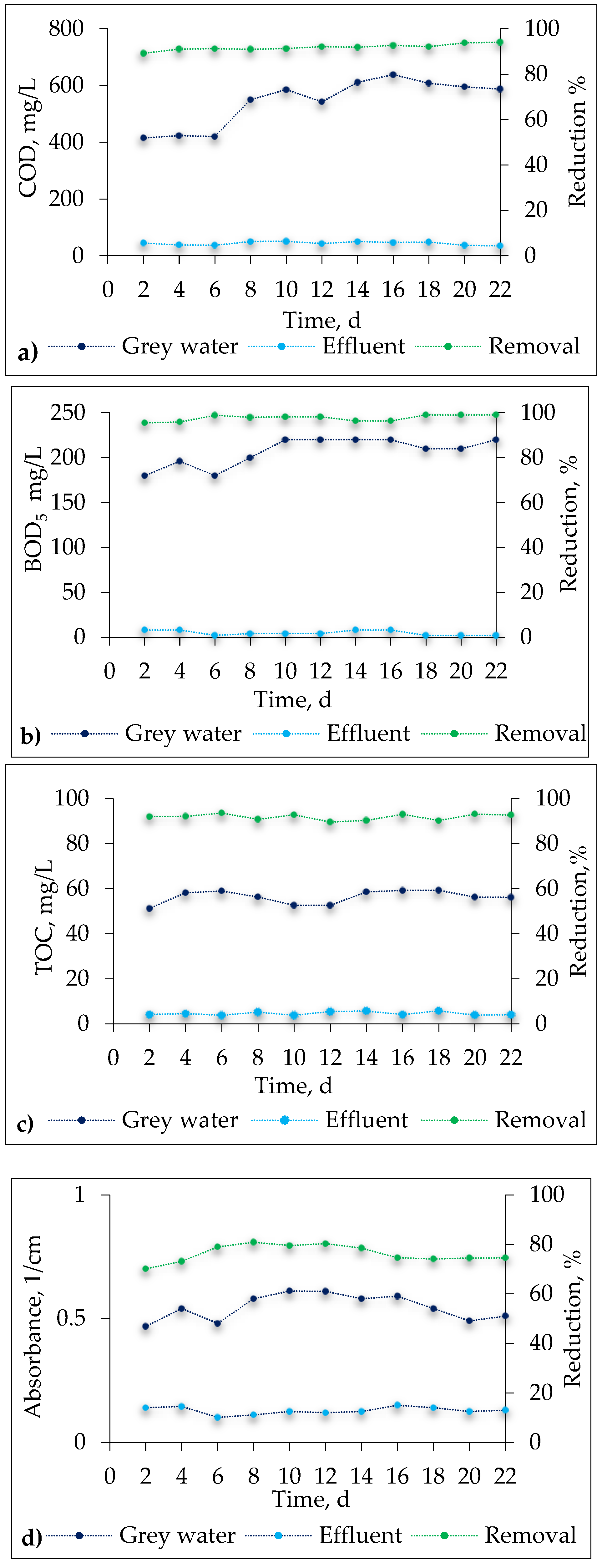

3.1.1. Reduction of COD, BOD5, and TOC

3.1.2. Removal of Biogenic Compounds

3.1.3. Removal of Color and Turbidity

3.2. SBR Effluent Treatment by Ultrafiltration

3.3. Microbiological Quality of Grey Water

3.4. Membrane Permeability and Fouling Behavior in Ultrafiltration

4. Conclusions

- The SBR system ensured the complete removal of nonionic surfactants and 97% removal of anionic surfactants from grey water.

- Removal of phosphate in SBR was, on average, 42%, but its concentration still exceeded acceptable values. It could probably be related to the variable concentration of raw grey water. It was stated that in order to improve the phosphorus reduction, in subsequent studies, the cycle of operation of SBR should be modified by means of changes in the duration of aerobic–anaerobic phases.

- In ultrafiltration treatment, there was an efficiency increase in filtration time due to the formation of a cake layer or concentration effect.

- Treatment efficiency in ultrafiltration was mainly influenced by the cross-flow filtration mode and nature of feed water.

- Membrane properties played an important role in fouling behavior, but did not greatly affect treatment efficiency.

- Membrane DSGM did not show fouling in permeate flux monitoring. It is a consequence of the initial properties of this membrane such as the lowest contact angle and the most negative zeta potential when compared with the BN and V3 membranes, for which fouling was observed.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Use of Freshwater Resources. Available online: https://www.eea.europa.eu/data-and-maps/indicators/use-of-freshwater-resources-2/assessment-3 (accessed on 23 December 2019).

- Xin, D.; Saige, W.; Bin, C. The blue, green and grey water consumption for crop production in Heilongjiang. Energy Procedia 2019, 158, 3908–3914. [Google Scholar]

- Bani-Melhem, K.; Al-Qodah, Z.; Al-Shannag, M.; Qasaimeh, A.; Qtaishat, M.R.; Alkasrawi, M. On the performance of real grey water treatment using a submerged, Membrane bioreactor system. J. Membr. Sci. 2015, 476, 40–49. [Google Scholar] [CrossRef]

- Martínez-Alcalá, I.; Pellicer-Martínez, F.; Fernández-López, C. Pharmaceutical grey water footprint: Accounting, influence of wastewater treatment plants and implications of the reuse. Water Res. 2018, 135, 278–287. [Google Scholar] [CrossRef] [PubMed]

- Galvis, A.; Zambrano, D.A.; Van der Steen, N.P.; Gijzen, H.J. Evaluation of pollution prevention options in the municipal water cycle. J. Clean. Prod. 2014, 66, 599–609. [Google Scholar] [CrossRef]

- Prajapati, B.; Jensen, M.B.; Jørgensen, N.O.G.; Petersen, N.B. Grey water treatment in stacked multi-layer reactors with passive aeration and particle trapping. Water Res. 2019, 161, 181–190. [Google Scholar] [CrossRef]

- WHO. Guidelines for the Safe Use of Wastewater, Excreta and Greywater, Excreta and Greywater Use in Agriculture. 2006. Available online: https://apps.who.int/iris/bitstream/handle/10665/78265/9241546824_eng.pdf;jsessionid=47807504FED628D9A9BB71654F04A9E7?sequence=1 (accessed on 23 December 2019).

- Li, F.; Wichmann, K.; Otterpohl, R. Review of the technological approaches for grey water treatment and reuses. Sci. Total Environ. 2009, 407, 3439–3449. [Google Scholar] [CrossRef]

- Boddu, M.V.; Paul, T.; Page, M.A.; Byl, C.; Ward, L.; Ruan, J. Gray water recycle: Effect of pretreatment technologies on low pressure reverse osmosis treatment, J. Environ. Chem. Eng. 2016, 4, 4435–4443. [Google Scholar] [CrossRef]

- Manouchehri, M.; Kargari, A. Water recovery from laundry wastewater by the cross flow microfiltration process: A strategy for water recycling in residential buildings. J. Clean. Prod. 2017, 168, 227–238. [Google Scholar] [CrossRef]

- Ding, A.; Liang, H.; Li, G.; Derlon, N.; Szivak, I.; Morgenroth, E.; Pronk, W. Impact of aeration shear stress on permeate flux and fouling layer properties in a low pressure membrane bioreactor for the treatment of grey water. Water Res. 2016, 510, 382–390. [Google Scholar] [CrossRef]

- Mohammadi, M.J.; Takdastan, A.; Jorfi, S.; Neisi, A.; Farhadi, M.; Yari, A.R.; Dobaradaran, S.; Khaniabadi, Y.O. Electrocoagulation process to Chemical and Biological Oxygen Demand treatment from carwash grey water in Ahvaz megacity, Iran. Data Brief 2017, 11, 634–639. [Google Scholar] [CrossRef]

- Bani- Melhem, K.; Smith, E. Grey water treatment by a continuous process of an electrocoagulation unit and a submerged membrane bioreactor system. Chem. Eng. J. 2012, 198–199, 201–210. [Google Scholar] [CrossRef]

- Ding, A.; Liang, H.; Li, H.; Szivak, I.; Traber, J.; Pronk, W. A low energy gravity driven membrane bioreactor system for grey water treatment: Permeability and removal performance of organics. J. Membr. Sci. 2017, 542, 408–417. [Google Scholar] [CrossRef]

- Leong, J.; Oha, K.S.; Poh, P.E.; Chong, M.N. Prospects of hybrid rainwater-greywater decentralised system for water recycling and reuse: A review. J. Clean. Prod. 2017, 142, 3014–3027. [Google Scholar] [CrossRef]

- Adamczak, M.; Kamińska, G.; Bohdziewicz, J. Application of waste polymers as basic material for ultrafiltration membranes preparation. Proceedings 2019, 16, 14. [Google Scholar] [CrossRef]

- Drews, A. Membrane fouling in membrane bioreactors—Characterisation, contradictions, cause and cures. J. Membr. Sci. 2010, 363, 1–28. [Google Scholar] [CrossRef]

- Duan, L.; Jiang, W.; Song, Y.; Xia, S.; Hermanowicz, S. The characteristics of extracellular polymeric substances and soluble microbial products in moving bed biofilm reactor-membrane bioreactor. Bioresour. Technol. 2013, 148, 436–442. [Google Scholar] [CrossRef]

- Pinto, A.C.S.; Grossi, L.; Carvalho de Melo, R.A.; Macedo de Assis, T.; Ribeiro, V.M.; Santos Amaral, M.C.; de Souza Figueiredo, K.C. Carwash wastewater treatment by micro and ultrafiltration membranes: Effects of geometry, pore size, pressure difference and feed flow rate in transport properties. J. Water Process Eng. 2017, 17, 143–148. [Google Scholar] [CrossRef]

- Crittenden, J.C.; Trussell, R.R.; Hand, D.W.; Howe, K.J.; Tchobanoglous, J. Water Treatment: Principles and Design, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Dz.U.2014.poz.1800. Directive of the Minister of the Environment from 18th of November 2014. Available online: http://prawo.sejm.gov.pl/isap.nsf/download.xsp/WDU20140001800/O/D20141800.pdf (accessed on 3 January 2020).

- Fountoulakis, M.S.; Markakis, N.; Petousi, I.; Manios, T. Single house on-site grey water treatment using a submerged membrane bioreactor for toilet flushing. Sci. Total Environ. 2016, 551–552, 706–711. [Google Scholar] [CrossRef]

- Guang-Guo, Y. Fate, behavior and effects of surfactants and their degradation products in the environment. Environ. Int. 2006, 32, 417–431. [Google Scholar]

- Ivanković, T.; Hrenović, J. Surfactants in the Environment. Arh. Hig. Rada Toksikol. 2010, 61, 95–110. [Google Scholar] [CrossRef]

- Leal, H.; Temmink, H.; Zeeman, G.; Buisman, C.J.N. Comparison of Three Systems for Biological Greywater Treatment. Water 2010, 2, 155–169. [Google Scholar] [CrossRef]

- Świerczynska, A.; Bohdziewicz, J. Determination of the most effective operating conditions of membrane bioreactor used to industrial wastewater treatment. Environ. Prot. Eng. 2015, 41, 41–51. [Google Scholar]

- Hocaoglua, S.M.; Atasoya, E.; Babana, A.; Orhonb, D. Modeling biodegradation characteristics of grey water in membrane bioreactor. J. Membr. Sci. 2013, 429, 139–146. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Bohdziewicz, J.; Puszczało, E. Treatment of industrial wastewater in the sequential membrane bioreactor. Ecol. Chem. Eng. S 2016, 23, 285–295. [Google Scholar] [CrossRef][Green Version]

- Shang, R.; Verliefde, A.R.D.; Hu, J.; Zeng, Z.; Lu, J.; Kemperman, A.J.B.; Deng, H.; Nijmeijer, K.; Heijman, S.G.J.; Rietveld, L.C. Tight ceramic UF membrane as RO pre-treatment: The role of electrostatic interactions on phosphate rejection. Water Res. 2014, 48, 498–507. [Google Scholar] [CrossRef] [PubMed]

- Peeva, P.D.; Million, N.; Ulbricht, M. Factors affecting the sieving behavior of anti-fouling thin-layer cross-linked hydrogel polyethersulfone composite ultrafiltration membranes. J. Membr. Sci. 2012, 390–391, 99–112. [Google Scholar] [CrossRef]

- Shang, R.; Verliefde, A.R.D.; Hu, J.; Heijmann, S.G.J.; Rietveld, L.C. The impact of EfOM, NOM and cations on phosphate rejection by tight ceramic ultrafiltration. Sep. Purif. Technol. 2014, 132, 289–294. [Google Scholar] [CrossRef]

- Broeckmann, A.; Busch, J.; Wintgens, T.; Marquardt, W. Modeling of pore blocking and cake layer formationin membrane filtration for wastewater treatment. Desalination 2006, 189, 97–109. [Google Scholar] [CrossRef]

- Jermann, D.; Pronk, W.; Boller, M.; Schafer, A.I. The role of NOM fouling for the retention of estradiol and ibuprofen during ultrafiltration. J. Membr. Sci. 2009, 329, 75–84. [Google Scholar] [CrossRef]

- Bohdziewicz, J.; Kamińska, G.; Pawlyta, M.; Łukowiec, D. Comparison of effectiveness of advanced treatment of municipal wastewater by sorption and nanofiltration. Separate processes and integrated systems. Environ Prot. Eng. 2015, 41, 119–132. [Google Scholar]

- García-Martín, N.; Silva, V.; Carmona, F.J.; Palacio, L.; Hernández, A.; Prádanos, P. Pore size analysis from retention of neutral solutes through nanofiltration membranes. The contribution of concentration–polarization. Desalination 2014, 344, 1–11. [Google Scholar] [CrossRef]

- Meng, S.; Zhanf, M.; Yao, M.; Qiu, Z.; Hong, Y.; Lan, W.; Xia, H.; Jin, X. Membrane Fouling and Performance of Flat Ceramic Membranes in the Application of Drinking Water Purification. Water 2019, 11, 2606. [Google Scholar] [CrossRef]

- Kramer, F.C.; Shang, R.; Rietveld, L.C.; Heijman, S.J.G. Influence of pH, multivalent counter ions, and membrane fouling on phosphate retention during ceramic nanofiltration. Sep. Purif. Technol. 2019, 227. [Google Scholar] [CrossRef]

- Arsuaga, J.M.; López-Muñoz, M.J.; Aguado, J.; Sotto, A. Temperature, pH and concentration effects on retention and transport of organic pollutants across thin-film composite nanofiltration membranes. Desalination 2008, 221, 253–258. [Google Scholar] [CrossRef]

- Muthumareeswaran, M.R.; Agarwa, G.P. Feed concentration and pH effect on arsenate and phosphate rejection via polyacrylonitrile ultrafiltration membrane. J. Membr. Sci. 2014, 468, 11–19. [Google Scholar] [CrossRef]

- Acero, J.L.; Benitez, F.J.; Teva, F.; Leal, A.I. Retention of emerging micropollutants from UP water and a municipal secondary effluent by ultrafiltration and nanofiltration. Chem. Eng. J. 2010, 163, 264–272. [Google Scholar] [CrossRef]

- Haas, R.; Opitz, R.; Grischek, T.; Otter, P. The AquaNES Project: Coupling Riverbank Filtration and Ultrafiltration in Drinking Water Treatment. Water 2019, 11, 18. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Bohdziewicz, J.; Kamińska, G.; Wojciechowski, K. Influence of the type of membrane-forming polymer on the membrane fouling. Environ. Prot. Eng. 2016, 42, 197–210. [Google Scholar]

- Ghiasi, S.; Behboudi, A.; Mohammadi, T.; Khanlari, S. Effect of surface charge and roughness on ultrafiltration membranes performance and polyelectrolyte nanofiltration layer assembly, Colloids and Surfaces A. Physicochem. Eng. Asp. 2019, 580. [Google Scholar] [CrossRef]

- Kumari, P.; Modi, A.; Bellare, J. Enhanced flux and antifouling property on municipal wastewater of polyethersulfone hollow fiber membranes by embedding carboxylated multi-walled carbon nanotubes and a vitamin E derivative. Sep. Purif. Technol. 2020, 235. [Google Scholar] [CrossRef]

- Regulation of the Ministry of Health on the Quality of Water Intended for Human Consumption. Available online: https://www.igwp.org.pl/images/artykuly/prawo/Jako%C5%9B%C4%87-wody-przeznaczonej-do-spo%C5%BCycia-przez-ludzi.pdf (accessed on 23 December 2019).

| Parameter | Unit | Value | ||

|---|---|---|---|---|

| Min | Max | Average | ||

| pH | - | 7.47 | 7.88 | 7.6 |

| Conductivity | µS/cm | 735 | 772 | 758 |

| Color | mgPt/L | 182 | 228 | 201 |

| Turbidity | FTU | 26 | 31 | 28.2 |

| AbsorbanceUV254 | 1/cm | 0.468 | 0.611 | 0.55 |

| COD | mg/L | 415 | 638 | 543 |

| BOD5 | mg/L | 190 | 240 | 212 |

| N-NO3− | mg/L | 0.4 | 0.8 | 0.6 |

| P-PO43− | mg/L | 3.8 | 4.6 | 4.15 |

| N-NH4+ | mg/L | 0 | 0.3 | 0.2 |

| Ntot | mg/L | 9.4 | 11.3 | 10.7 |

| Surfactants nonionic | mg/L | 1.33 | 1.64 | 1.42 |

| Surfactants anionic | mg/L | 12.9 | 17.5 | 15.2 |

| TOC | mg/L | 51.2 | 59.3 | 56.3 |

| Symbol | DSGM | V3 | BN |

|---|---|---|---|

| Manufacturer | GE Osmonics (Minnetonka, MN, USA) | Synder (Allison Parkway Vacaville, CA USA) | Synder |

| Polymer material | Polyamide-TFC | PVDF | PVDF |

| MWCO, Da | 8000 | 30,000 | 50,000 |

| Thickness *, µm | 150 | 220 | 200 |

| Parameter | Unit | Grey Water | SBR Effluent | UF Permeate of BN/V3/DSGM |

|---|---|---|---|---|

| Escherichia coli | CFU/100 mL | >100 | >100 | 0 |

| Enterococci | CFU/100 mL | >100 | 3 | 0 |

| Membrane | Contact Angle | Isoelectric Point | ||

|---|---|---|---|---|

| Clean Membrane | Fouled Membrane | Clean Membrane | Fouled Membrane | |

| DSGM | 45.5 ± 3.2 | 46.25 ± 2.8 | - | - |

| V3 | 71.5 ± 1.9 | 73.5 ± 3.8 | 5.05 | 5.25 |

| BN | 75.0 ± 1.4 | 78.6 ± 1.2 | 3.01 | 3.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamińska, G.; Marszałek, A. Advanced Treatment of Real Grey Water by SBR Followed by Ultrafiltration—Performance and Fouling Behavior. Water 2020, 12, 154. https://doi.org/10.3390/w12010154

Kamińska G, Marszałek A. Advanced Treatment of Real Grey Water by SBR Followed by Ultrafiltration—Performance and Fouling Behavior. Water. 2020; 12(1):154. https://doi.org/10.3390/w12010154

Chicago/Turabian StyleKamińska, Gabriela, and Anna Marszałek. 2020. "Advanced Treatment of Real Grey Water by SBR Followed by Ultrafiltration—Performance and Fouling Behavior" Water 12, no. 1: 154. https://doi.org/10.3390/w12010154

APA StyleKamińska, G., & Marszałek, A. (2020). Advanced Treatment of Real Grey Water by SBR Followed by Ultrafiltration—Performance and Fouling Behavior. Water, 12(1), 154. https://doi.org/10.3390/w12010154