Integrating Life-Cycle Perspectives and Spatial Dimensions of Sewage Sludge Mono-Incineration

Abstract

:1. Introduction

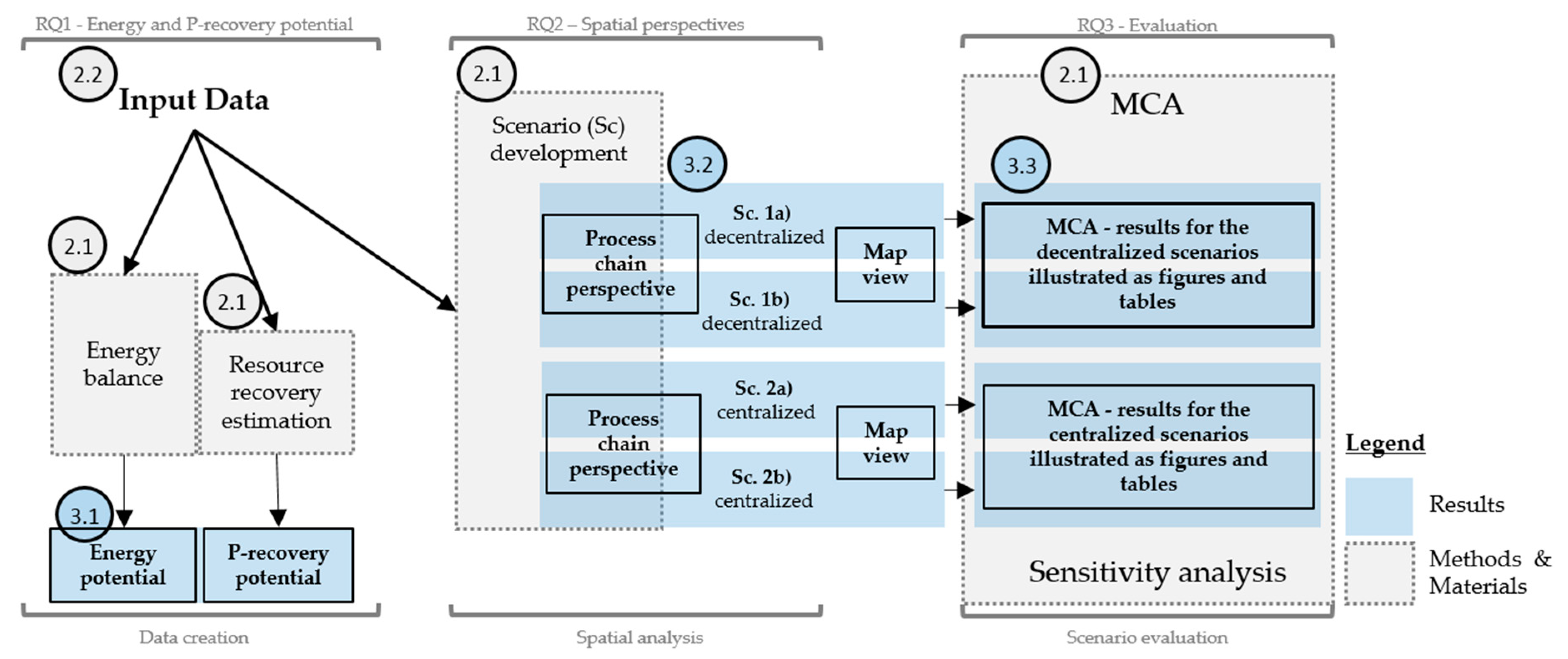

2. Methods and Materials

2.1. Methods

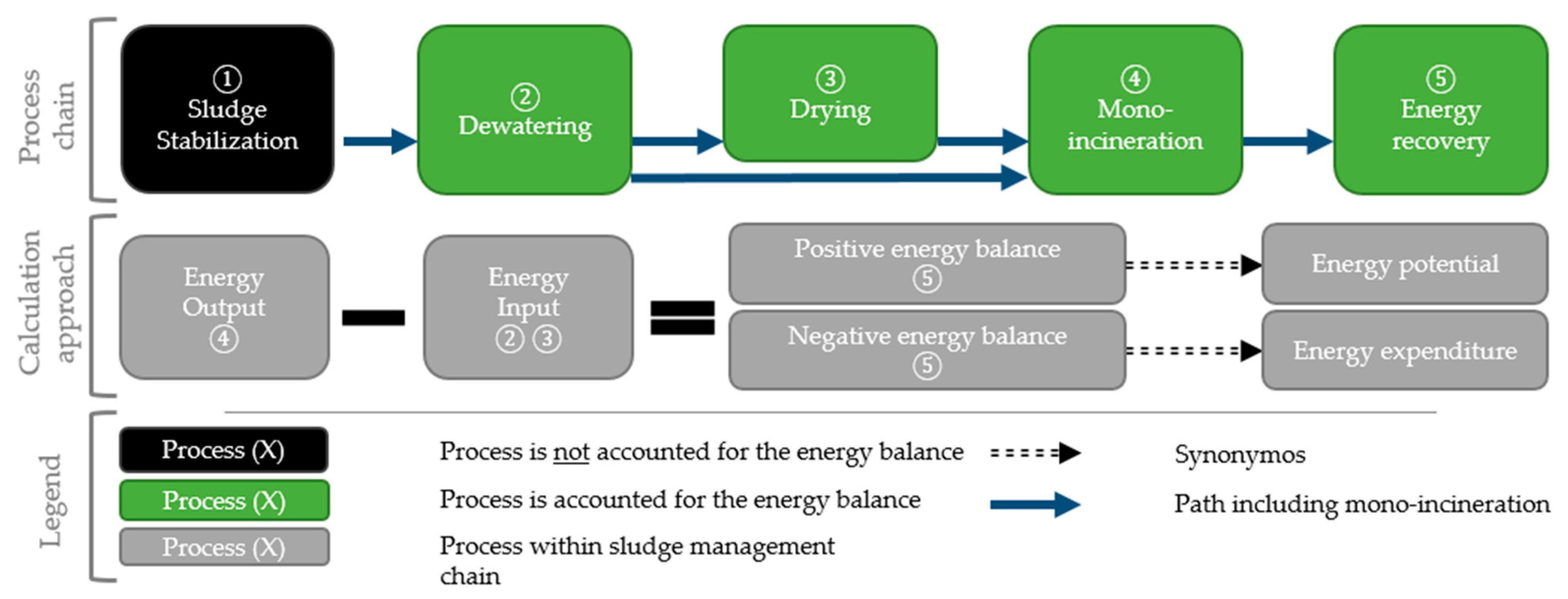

2.1.1. Energy Balance and P-Recovery Potential

Energy Balance

Resource Recovery Estimation

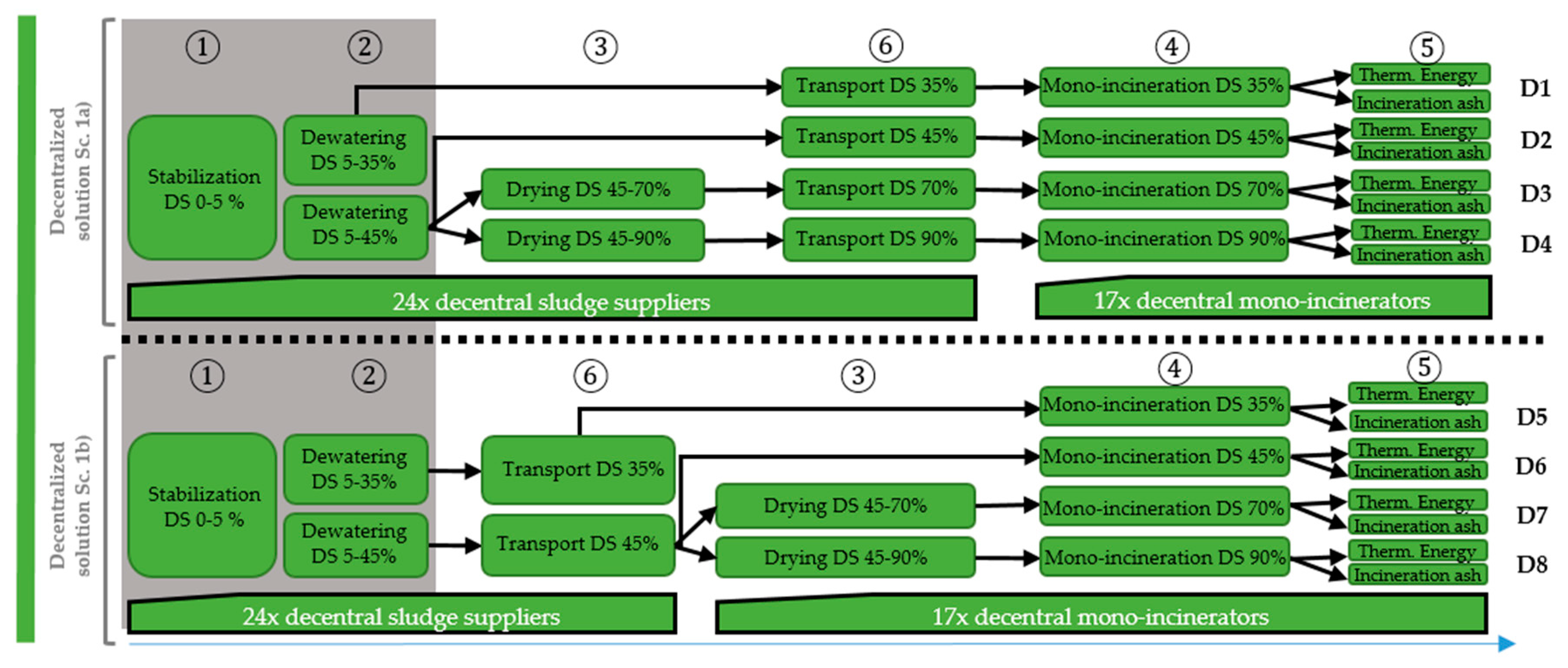

2.1.2. Scenario Development—Spatial Analysis

- (1)

- Mono-incineration will have to expand for future sludge disposal because the existing mono-incineration capacities are not enough to deal with the future demand. This is the starting point to develop scenarios for decentralized and centralized solutions and to assess their feasibility. Both spatial solutions compound an integration process into the existing wastewater treatment system. Assumptions to do this are explained as follows. The existing infrastructure is expanded by the process of sludge transport, as shown in Figure 3.There are two options to include sludge transport in the existing process chain. Sludge can be directly transported before or after it is dried. Relevant factors to identify the subject are developed in consideration of spatial characteristics (level 1) and spatial criteria (level 2). Spatial characteristics contribute to the location of each process from the sludge treatment process chain and therefore only explain the spatial characteristic of the already existing system. In contrast to this, the spatial criteria refer to the measurable unit of sludge transport distance for each spatial solution. Table 3 lists the description for each spatial characteristic and spatial criteria.

- (2)

- In general, level 1, the spatial characteristics of the already existing system, is prioritized because those factors represent the basic setting to be rearranged. As a consequence of this, level 2, the spatial criteria of the developed scenarios, represents the results that have to be further adjusted. This basic scheme is transformed into assumptions for the creation of both the decentralized and centralized scenario.

- (3)

- The objective is to develop possible scenarios for centralized as well as decentralized solutions for mono-incineration. The framework of the basic sludge management process chain is taken as a starting point for restructuring. The principle is to distinguish locally bound and flexible processes to find possible access points in the existing system. Those access points have to be further sorted out by the minimum sludge amount needed to run a mono-incinerator. Afterwards, the limitations by quantity of incineration facilities further limit possible locations. The spatial criterion of sludge transport distance is finally used to optimize the selection. A detailed description of the procedure is summarized in Table 4 and Table 5.

2.1.3. Multiple Criteria Analysis (MCA)

- Definition of Evaluation Criteria:Considered criteria and indicators are used for evaluation of scenarios.

- Value in Use:Values for each indicator are transformed into a value in use. The scale for value in use is defined as y = [0; 1]. Transformed indicators can be used to compare different evaluations among each other.

- Weighting Factor:Each of the criteria is assigned with a weighting factor. The sum of all weighting factors is 100%.

Definition of Evaluation Criteria

Value in Use (Value Score)

Weighting Factor (Weighting of Value Scores)

2.2. Materials

- -

- Transport distance was considered as a loaded journey to the incineration plant and a journey back to the WWTP with no load, as we assumed that sludge transport vehicles cannot be used for other transport demands without cleaning and hygienization.

- -

- Changes in sludge density according to DS content were neglected.

- -

- Thermal energy produced by mono-incineration is first utilized, if possible, to dry the sludge.

3. Results

3.1. Energy and P-Recovery Potential

3.2. Spatial Analysis

3.2.1. Decentralized Scenarios 1a,b

3.2.2. Centralized Scenarios 2a,b

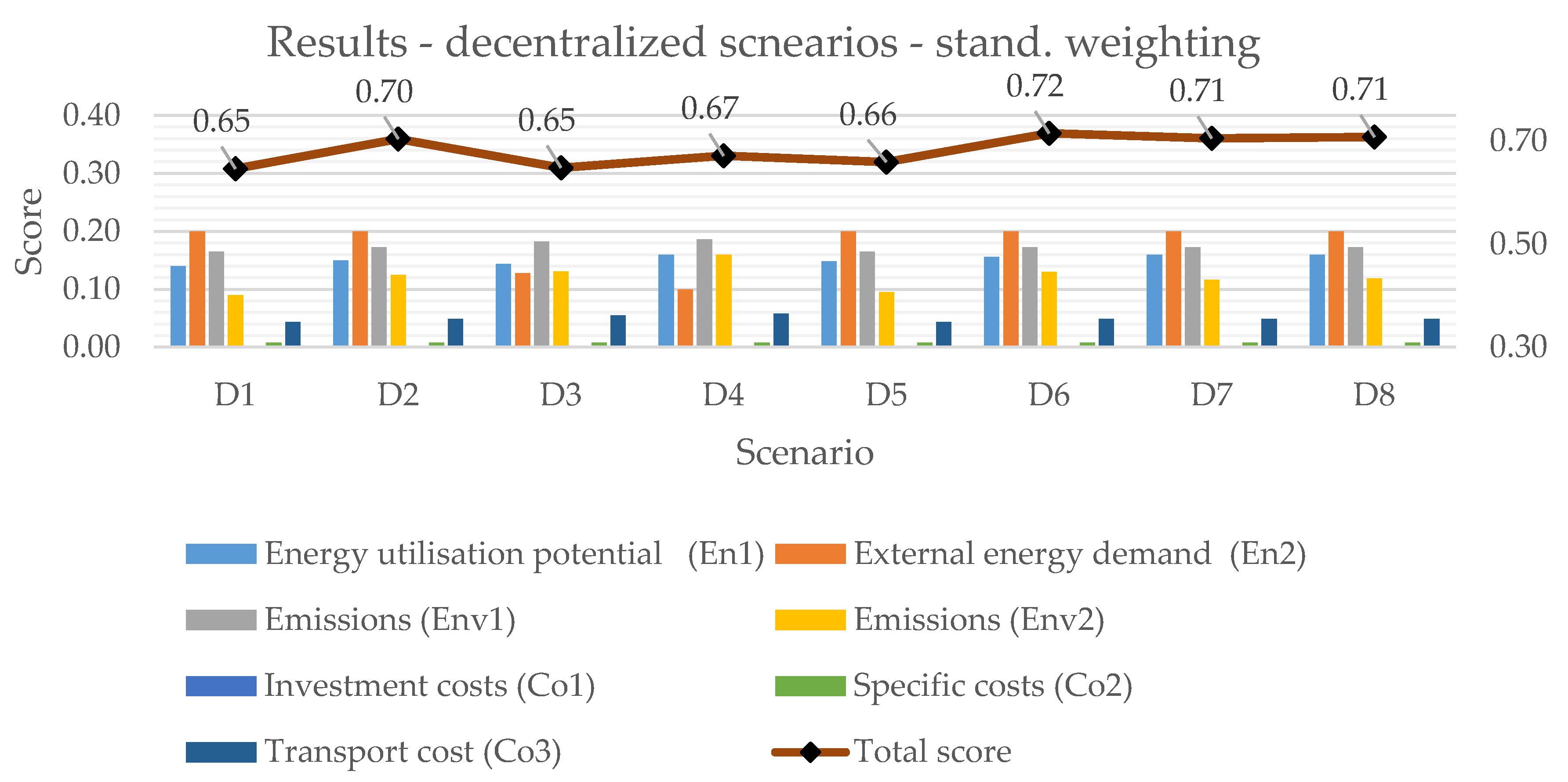

3.3. MCA

3.3.1. Overall Results

Energy (En1 and En2)

Environmental Impact (Env1, Env2)

Cost (Co1, Co2, and Co3)

3.3.2. Sensitivity Analysis

3.3.3. Summary of the MCA

4. Discussion

4.1. Energy- and P-Recovery

4.2. MCA

4.2.1. Investigation into Future Resource Recovery

4.2.2. Considering the Spatial Fabric

4.3. Strengths and Limitations to the Methodology

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Van Loosdrecht, M.C.; Brdjanovic, D. Anticipating the next century of wastewater treatment. Science 2014, 344, 1452–1453. [Google Scholar] [CrossRef] [PubMed]

- Egle, L.; Amann, A.; Rechberger, H.; Zessner, M. Phosphor: Eine kritische und zugleich unzureichend genutzte Ressource der Abwasser-und Abfallwirtschaft—Stand des Wissens und Ausblick für Österreich und Europa. Österreichische Wasser-Und Abfallwirtsch 2016, 68, 118–133. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Daigger, G.; Lee, D.J.; Liu, J.; Ren, N.Q.; Qu, J.; Liu, G.; Butler, D. Evolving wastewater infrastructure paradigm to enhance harmony with nature. Sci. Adv. 2018, 4, eaaq0210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stedman, L. The Wastewater Resource Recovery Facilty of the Future. Water 2015, 21, 41–42. [Google Scholar]

- Kretschmer, F.; Zingerle, T.; Ertl, T. Perspektiven der künftigen Klärschlammbewirtschaftung in Österreich. Österreichische Wasser-Und Abfallwirtsch 2018, 70, 579–587. [Google Scholar] [CrossRef] [Green Version]

- Kretschmer, F.; Neugebauer, G.; Kollmann, R.; Eder, M.; Zach, F.; Zottl, A.; Narodoslawsky, M.; Stöglehner, G.; Ertl, T. Resource recovery from wastewater in Austria: Wastewater treatment plants as regional energy cells. J. Water Reuse Desalin. 2016, 6, 421–429. [Google Scholar] [CrossRef] [Green Version]

- Krüger, O.; Adam, C. Monitoring von Klärschlammmonoverbrennungsaschen hinsichtlich ihrer Zusammensetzung zur Ermittlung ihrer Rohstoffrückgewinnungspotentiale und zur Erstellung von Referenzmaterial für die Überwachungsanalytik. Umweltbundesamt 2014, 49, 27f. Available online: https://www.umweltbundesamt.de/publikationen/monitoring-von-klaerschlammmonoverbrennungsaschen (accessed on 28 April 2020).

- Morf, D.L. Verfahrenstechnische Marktanalyse für die Phosphorrückgewinnung aus dem Abwasserpfad; Office for Waste, Water, Energy and Air (AWEL): Zurich, Switzerland, 2018; p. 100. [Google Scholar]

- Jedelhauser, M.; Mehr, J.; Binder, C. Transition of the Swiss Phosphorus System towards a Circular Economy—Part 2: Socio-Technical Scenarios. Sustainability 2018, 10, 1980. [Google Scholar] [CrossRef] [Green Version]

- Kraus, F.; Zamzow, M.; Conzelmann, L.; Remy, C.; Kleyböcker, A.; Seis, W.; Miehe, U.; Hermann, L.; Hermann, R.; Kabbe, C. Ökobilanzieller Vergleich der P-Rückgewinnung aus dem Abwasserstrom mit der Düngemittelproduktion aus Rohphosphaten unter Einbeziehung von Umweltfolgeschäden und deren Vermeidung; Federal Environment Agency (UBA): Berlin, Germany, 2019; p. 393.

- Hao, X.; Chen, Q.; van Loosdrecht, M.C.M.; Li, J.; Jiang, H. Sustainable disposal of excess sludge: Incineration without anaerobic digestion. Water Res. 2020, 170, 115298. [Google Scholar] [CrossRef]

- Hao, X.; Li, J.; van Loosdrecht, M.C.M.; Jiang, H.; Liu, R. Energy recovery from wastewater: Heat over organics. Water Res. 2019, 161, 74–77. [Google Scholar] [CrossRef] [PubMed]

- Neugebauer, G.; Kretschmer, F.; Kollmann, R.; Narodoslawsky, M.; Ertl, T.; Stoeglehner, G. Mapping Thermal Energy Resource Potentials from Wastewater Treatment Plants. Sustainability 2015, 7, 12988–13010. [Google Scholar] [CrossRef] [Green Version]

- Stoeglehner, G.; Niemetz, N.; Kettl, K.-H. Spatial dimensions of sustainable energy systems: New visions for integrated spatial and energy planning. Energy Sustain. Soc. 2011, 1, 2. [Google Scholar] [CrossRef] [Green Version]

- Lichtenegger, K.; Leitner, A.; Märzinger, T.; Mair, C.; Moser, A.; Wöss, D.; Schmidl, C.; Pröll, T. Decentralized heating grid operation: A comparison of centralized and agent-based optimization. Sustain. Energy Grids Netw. 2020, 21, 100300. [Google Scholar] [CrossRef]

- Schlumberger, D.S. Phosphor-Mining aus Klärschlammasche. Abschlussbericht zu Handen der Baudirektion des Kantons Zürich’. Stiftung Zentrum für nachhaltige Abfall-und Ressourcennutzung (ZAR). Available online: https://awel.zh.ch/internet/baudirektion/awel/de/abfall_rohstoffe_altlasten/abfall/siedlungsabfaelle/klaerschlamm/_jcr_content/contentPar/downloadlist_3/downloaditems/endbericht_phosphor_.spooler.download.1559561800852.pdf/19_02_04_abschlussbericht_pilotierung_phos4life_public.pdf (accessed on 25 July 2019).

- Stoeglehner, G.; Neugebauer, G.; Erker, S.; Narodoslawsky, M. Integrated Spatial and Energy Planning; Springer International Publishing: Cham, Germany, 2016. [Google Scholar]

- Stoeglehner, G.; Erker, S.; Neugebauer, G. ÖREK-Partnerschaft Energieraumplanung. Ergebnispapier der ExpertInnen. Bundesministerium für Land-und Forstwirtschaft, Umwelt und Wasserwirtschaft. 2014. Available online: https://www.oerok.gv.at/fileadmin/Bilder/2.Reiter-Raum_u._Region/1.OEREK/OEREK_2011/PS_Energieraumplanung/Ergebnispapier_Energieraumplanung_2014-06.pdf (accessed on 26 July 2019).

- BAT-WI. Best Available Techniques (BAT) Reference Document for Waste Incineration. European Comission. 2018. Available online: https://eippcb.jrc.ec.europa.eu/reference/BREF/WI/WI_BREF_FD_Black_Watermark.pdf (accessed on 25 September 2019).

- INTECUS GmbH. Technical Guide on the Treatment and Recycling Techniques for Sludge from Municipal Waste Water Treatment; German Environment Agency: Dessau-Roßlau, Germany, 2016.

- DWA. Positionen zur Klaerschlammentsorgung. Deutsche Vereinigung für Wasserwirtschaft. 2015. Available online: https://de.dwa.de/files/_media/content/01_DIE%20DWA/Politikinformationen/Positionspapiere/20150324DWAPositionKlaerschlammentsorgung2015final.pdf (accessed on 28 April 2020).

- Van der Heijden, K. Scenarios. In The Art of Strategic Conversation; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Schwartz, P. The Art of the Long View: The Path to Strategic Insight for Yourself and Your Company; Doubleday Dell Publishing Group: Hoboken, NJ, USA, 1991. [Google Scholar]

- Ehrgott, M.; Naujoks, B.; Stewart, T.J.; Wallenius, J. Multiple Criteria Decision Making for Sustainable Energy and Transportation Systems; Ehrgott, M., Naujoks, B., Stewart, T.J., Wallenius, J., Eds.; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2010; Volume 634. [Google Scholar]

- Figueira, J.; Greco, S.; Ehrogott, M. Multiple Criteria Decision Analysis: State of the Art Surveys; Springer: New York, NY, USA, 2005; Volume 78. [Google Scholar]

- Bättig, M.; Büsser, S.; Frischknecht, R.; Klingler, G.; Küttel, P.; von Schulthess, R. Vergleich verschiedener Entsorgungswege des Klärschlamms aus der Region Luzern mittels Multikriterienanalyse und Ökobilanzen. Bundesamt für Umwelt BAFU. 2011. Available online: https://docplayer.org/27071152-Vergleich-verschiedener-entsorgungswege-des-klaerschlamms-aus-der-region-luzern-mittels-multikriterienanalyse-und-oekobilanzen.html (accessed on 28 April 2020).

- Bättig, M.; Klingler, G.; Dettli, R.; Frischknecht, R.; Tuchschmid, M. Vorstudie für eine Methode zur Bewertung der Entsorgungs- und Nutzungsverfahren von biogenen Abfällen und Hofdünger. Bundesamt für Energie BFE. 2009. Available online: http://www.news.admin.ch/NSBSubscriber/message/attachments/16126.pdf (accessed on 28 April 2020).

- BMNT. Bundes-Abfallwirtschaftsplan 2017. Teil 1. In Bundesministerium für Nachhaltigkeit und Tourismus; Federal Ministry for Sustainability and Tourism (BMNT): Vienna, Austria, 2017; p. 304. [Google Scholar]

- EEA. Waterbase-UWWTD. Urban Waste Water Treatment Directive–reported data—European Environment Agency (EEA). Waterbase-UWWTD: Urban Waste Water Treatment Directive–Reported Data. 2019. Available online: https://www.eea.europa.eu/data-and-maps/data/waterbase-uwwtd-urban-waste-water-treatment-directive-5 (accessed on 22 July 2019).

- DWA. Thermische Behandlung von Klärschlämmen: Monoverbrennung; Deutsche Vereinigung für Wasserwirtschaft, Abwasser und Abfall: Hennef (Sieg), Germany, 2011. [Google Scholar]

- Mathiesen, B.V.; Bertelsen, N.; Schneider, N.C.; García, L.S.; Paardekooper, S.; Thellufsen, J.Z.; Djørup, S.R. Towards a Decarbonised Heating and Cooling Sector in Europe—Unlocking the Potential of Energy Efficiency and District Energy; Department of Planning Aalborg University A.C. Meyers Vænge 15, M2 2450: Copenhagen, Denmark, 2019; Available online: https://vbn.aau.dk/ws/portalfiles/portal/316535596/Towards_a_decarbonised_H_C_sector_in_EU_Final_Report.pdf (accessed on 31 March 2020).

- Public Consulting GmbH. Betriebliche Umweltförderung. Förderungsberechnung. Federal Ministry of Agriculture, Regions and Tourism. 2019. Available online: https://www.umweltfoerderung.at/ (accessed on 30 March 2020).

- Egle, L.; Rechberger, H.; Zessner, M. Endbericht Phosphorbilanz Österreich Grundlage für ein nachhaltiges Phosphormanagement—Gegenwärtige Situation und zukünftige Entwicklung; Bundesministerium für Land- und Forstwirtschaft, Umwelt und Wasserwirtschaft, Sektion VIIWasser Marxergasse 2: Wien, Austria, 2014. [Google Scholar]

- Frank, D.; Kraus, F. Irrungen der Klärschlammverordnung: Aktuelle juristische Sicht zur Phosphor Rückgewinnung aus Klärschlamm. Deutsche Phosphor Palttform. Available online: https://www.deutsche-phosphor-plattform.de/pressemitteilung-irrungen-der-klaerschlammverordnung/ (accessed on 2 December 2019).

- AVV. Gesamte Rechtsvorschrift für Abfallverbrennungsverordnung (Fassung vom 31.12.2015); Federal Legal Information System: Vienna, Austria, 2015. [Google Scholar]

- Amann, A.; Zoboli, O.; Krampe, J.; Rechberger, H.; Zessner, M.; Egle, L. Environmental impacts of phosphorus recovery from municipal wastewater. Resour. Conserv. Recycl. 2018, 130, 127–139. [Google Scholar] [CrossRef]

- Rytec, A.G. Schlussbericht Logistikkonzept und Transportkostenausgleich Zukünftige Klärschlammverwertung im Kanton Zürich ab Mitte 2015; The City of Zurich: Zurich, Switzerland, 2012; p. 31. [Google Scholar]

- Egle, L.; Leutgöb, J.; Schwarzlmüller, E.; Rolland, C. Strategische Umweltprüfung zum Wiener Abfallwirtschaftsplan (Wr. AWP) 2019-2024 und zum Wiener Abfallvermeidungsprogramm (Wr. AVP) 2019-2024 Umweltbericht zur Strategischen Umweltprüfung. 2018 Magistratsabteilung 48-Abfallwirtschaft Straßenreinigung und Fuhrpark. 2018. Available online: https://www.wien.gv.at/umwelt/ma48/service/pdf/sup-umweltbericht-2018.pdf (accessed on 28 April 2020).

- Gwehenberger, G.; Narodoslawsky, M.; Liebmann, B.; Friedl, A. Ecology of scale versus economy of scale for bioethanol production. Biofuels Bioprod. Bioref. 2007, 1, 264–269. [Google Scholar] [CrossRef]

- Gröger, B. Elfter Umweltkontrollbericht. Umweltbundesamt. 2016. Available online: https://www.umweltbundesamt.at/fileadmin/site/publikationen/REP0600.pdf (accessed on 28 April 2020).

- Zach, F.; Erker, S.; Stoeglehner, G. Factors influencing the environmental and economic feasibility of district heating systems—A perspective from integrated spatial and energy planning. Energy Sustain. Soc. 2019, 9, 25. [Google Scholar] [CrossRef]

- Hurni, H.; University of Bern. Durchschnittliche Wärmeverluste je Trassenkilometer. Personal communication, 2019. [Google Scholar]

| Options for Sludge Pretreatment for Mono-Incineration | |

|---|---|

| Option | Characterization |

| ❶ | Dewatering sludge up to 35% DS |

| ❷ | Dewatering sludge up to 45% DS |

| ❸ | Dewatering sludge up to 45%. Add a partially drying up to 70% DS |

| ❹ | Dewatering sludge up to 45%. Add a complete drying up to 90% DS |

| Basic Data Used for the Resource Recovery Estimation | |||

|---|---|---|---|

| Characteristic | Unit | Value | Reference |

| Mean value of ash production from mono-incineration | (%) | 41 | Krüger et al. [7] |

| P-concentrations used to estimate P-recovery potential | (g P/kg ash) | 60, 90, 120 | Kraus et al. [10] |

| Efficiency | (%) | 90 | Morf [8] |

| Relevant Factors | |

|---|---|

| Level 1—Spatial Characteristics | Description |

| ①② Location of Sludge Production | The location of sludge production determines the starting point to distribute the burning material (sewage sludge). This is an important factor because of the thermal potential related to the amount of sludge per location. The dewatering of sludge is critical to make sludge transportable. |

| ③ Location of Drying | The location of sludge drying has a further decisive impact on the transport effort. The wetter the sludge (before drying), the more water needs to be transported to the mono-incinerators. The more water remains in sludge, the more the mass (t/a) and the higher the volume (m3/a) of sludge that needs to be transported. Higher volumes increase the number of transport-journeys, fuel consumption, transport cost, and, finally, transport emissions. In summary, the location of drying plays a potentially important role to evaluate the pros and cons of centralized and decentralized solutions. |

| ④ Location of Mono-Incineration | The position of mono-incineration is a key factor for the determination of the spatial solutions. Material and energy flows change according to the position of incineration. The focus is to create centralized and decentralized scenarios. |

| ⑤ Location of the Final Products | The final outlets are thermal energy and incineration ash. Thermal energy can be utilized within the internal infrastructure or be distributed to external heat consumers. As the incineration ash is the basic source for further P-recovery, the location of primary ash management starts at the mono-incineration plant. |

| Level 2—Spatial Criteria | Descriptions |

| ⑥ Sludge Transport Distance | To the transport distance via lorry (24 t) from the WWTPs to the decentralized or centralized locations for mono-incineration. In principle the following applies: Environmental pollution is rising with a growing distance. |

| Decentralized Scenario. | |

|---|---|

| Level 1—Spatial Characteristics | Description |

| 1. Spatial characteristic of relevant sludge treatment processes | It is distinguished whether a process is locally bound or flexible. |

| 2. Sludge amount ≥ 2000 t DS/a | The WWTP does achieve the required sludge amount to run a mono-incinerator. Therefore, the location of the WWTP represents a possible location for mono-incineration. |

| 3. Sludge amount < 2000 t DS/a | The WWTP does not achieve the required minimum amount of yearly sludge amount to run a mono-incinerator. Therefore, the location of this WWTP is not suitable to run a mono-incinerator. The WWTP functions as a supplier WWTP for the closest possible location for mono-incineration. |

| 4. Regional coverage | No limitation in quantity of mono-incinerators. Each region with enough sludge accumulation receives a mono-incinerator. |

| Level 2—Spatial Criteria | Description |

| 5. Transport distance | Sludge transport should be reduced as much as possible. |

| Centralized Scenario | |

|---|---|

| Level 1—Spatial Characteristic | Description |

| 1. Spatial characteristic of relevant sludge treatment processes | It is distinguished whether a process is locally bound or flexible. |

| 2. Sludge amount | The top 10 WWTPs that produce most of the sludge represent the basic selection (Supplementary Material, Table S13). |

| 3. Regional coverage | Restriction in the quantity of mono-incinerators. The country is separated into 4 regions (A, B, C, D) that receive one mono-incinerator each. |

| Level 2—Spatial Criteria | Description |

| 4. Transport distance | Sludge transport should be reduced as much as possible. |

| No. | Evaluation Criteria | Indicator | Unit |

|---|---|---|---|

| Category 1—Energy | |||

| En1 | Reduced consumption of nonrenewable energy resources | Energy utilization potential | (GWh/a) |

| En2 | Increase in consumption of nonrenewable energy resources | Additional thermal energy demand for sludge drying | (GWh/a) |

| Category 2—Environmental impact | |||

| Env1 | Transport distance | Emissions | (CO2 e./a) |

| Env2 | Substituted CO2 emissions from fossil fuels | Emissions | (CO2 e./a) |

| Category 3—Cost | |||

| Co1 | Economic risk | Investment cost | (€) |

| Co2 | Economic risk | Specific cost | (€/t DS) |

| Co3 | Economic risk | Transport cost | (€/a) |

| No. | Perspective | Standard Weighting | Alternative A | Alternative B |

|---|---|---|---|---|

| Energy | 40% | 25% | 29% | |

| En1 | Reduced consumption of nonrenewable energy resources | 20% | 12.5% | 14.3% |

| En2 | Increase in consumption of nonrenewable energy resources | 20% | 12.5% | 14.3% |

| Environmental impact | 40% | 25% | 29% | |

| Env1 | Transport distance | 20% | 12.5% | 14.3% |

| Env2 | Substituted CO2 emissions from fossil fuels | 20% | 12.5% | 14.3% |

| Economic perspective | 20% | 50% | 43% | |

| Co1 | Investment cost | 6.67% | 16.7% | 14.3% |

| Co2 | Specific cost | 6.67% | 16.7% | 14.3% |

| Co3 | Transport cost | 6.67% | 16.7% | 14.3% |

| Sum | 100% | 100% | 100% |

| Energy Balance | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size Class | WWTPs | Option 1 (DS 35%) Cv: ~3 MJ/kg | Option 2 (DS 45%) Cv: ~5 MJ/kg | Option 3 (DS 70%) Cv: ~8.5 MJ/kg | Option 4 (DS 90%) Cv: ~12 MJ/kg | ||||

| (PE) | (quantity) | electr. (GWh/a) | therm. (GWh/a) | electr. (GWh/a) | therm. (GWh/a) | electr. (GWh/a) | therm. (GWh/a) | electr. (GWh/a) | therm. (GWh/a) |

| 50,000–100,000 | 18 | 10 | 36 | 13 | 47 | 12 | 41 | 12 | 42 |

| 100,001–150,000 | 13 | 13 | 44 | 16 | 57 | 14 | 50 | 15 | 51 |

| >150,000 | 10 | 46 | 162 | 60 | 210 | 52 | 183 | 53 | 186 |

| Sum | 41 | 69 | 242 | 90 | 314 | 78 | 273 | 80 | 279 |

| P-Recovery Potential with Recovery Efficiency 90% | ||||||

|---|---|---|---|---|---|---|

| Size Category | WWTPs | PE | Ash Production | 60 g P/kg ash | 90 g P/kg ash | 120 g P/kg ash |

| (PE) | (Sum) | (t/a) | (t P/a) | (t P/a) | (t P/a) | |

| 50,000–100,000 | 18 | 1,290,911 | 8867 | 479 | 718 | 958 |

| 100,001–150,000 | 13 | 1,583,166 | 10,875 | 587 | 881 | 1174 |

| >150,000 | 10 | 5,791,857 | 39,784 | 2148 | 3222 | 4297 |

| Sum | 41 | 8,665,934 | 59,526 | 3214 | 4822 | 6429 |

| Indicator | No. | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 |

| Energy utilization potential | (En1) | 0.14 | 0.15 | 0.14 | 0.16 | 0.15 | 0.16 | 0.16 | 0.16 |

| External energy demand | (En2) | 0.20 | 0.20 | 0.13 | 0.10 | 0.20 | 0.20 | 0.20 | 0.20 |

| Transport emissions | (Env1) | 0.16 | 0.17 | 0.18 | 0.19 | 0.16 | 0.17 | 0.17 | 0.17 |

| Emission savings | (Env2) | 0.09 | 0.13 | 0.13 | 0.16 | 0.10 | 0.13 | 0.12 | 0.12 |

| Investment costs | (Co1) | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Specific costs | (Co2) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Transport cost | (Co3) | 0.04 | 0.05 | 0.06 | 0.06 | 0.04 | 0.05 | 0.05 | 0.05 |

| Total score | 0.65 | 0.70 | 0.65 | 0.67 | 0.66 | 0.72 | 0.71 | 0.71 | |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | ||

| Energy utilization potential | (En1) | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| External energy demand | (En2) | 0.20 | 0.20 | 0.06 | 0.00 | 0.20 | 0.20 | 0.20 | 0.20 |

| Transport emissions | (Env1) | 0.00 | 0.04 | 0.10 | 0.12 | 0.00 | 0.04 | 0.04 | 0.04 |

| Emission savings | (Env2) | 0.13 | 0.17 | 0.18 | 0.20 | 0.13 | 0.17 | 0.15 | 0.15 |

| Investment costs | (Co1) | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Specific costs | (Co2) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Transport cost | (Co3) | 0.00 | 0.01 | 0.03 | 0.04 | 0.00 | 0.01 | 0.01 | 0.01 |

| Total score | 0.60 | 0.70 | 0.65 | 0.64 | 0.60 | 0.70 | 0.68 | 0.68 |

| Overall Ranking–Standard Weighting (SW), Alternative A (Alt. A), Alternative B (Alt. B) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | ||

| Total score | 0.65 | 0.70 | 0.65 | 0.67 | 0.66 | 0.72 | 0.71 | 0.71 | SW |

| 0.50 | 0.55 | 0.52 | 0.54 | 0.51 | 0.55 | 0.55 | 0.55 | Alt. A | |

| 0.54 | 0.58 | 0.55 | 0.57 | 0.55 | 0.59 | 0.59 | 0.59 | Alt. B | |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | ||

| Total score | 0.60 | 0.70 | 0.65 | 0.64 | 0.60 | 0.70 | 0.68 | 0.68 | SW |

| 0.52 | 0.60 | 0.60 | 0.61 | 0.52 | 0.60 | 0.59 | 0.59 | Alt. A | |

| 0.54 | 0.63 | 0.61 | 0.62 | 0.54 | 0.63 | 0.61 | 0.61 | Alt. B | |

| 2017 | ||||||

|---|---|---|---|---|---|---|

| Size Class (PE) | PE | Proportion | WWTPs | Dry Solids (t/a) | Ash (t/a) | P-Recovery (t/a) |

| ≥1 | 13,912,495 | 100% | 639 | 233,083 | 95,564 | 5200–10,300 |

| ≥2000 | 13,713,703 | 99% | 488 | 229,753 | 94,199 | 5100–10,200 |

| ≥20,000 | 11,139,998 | 81% | 121 | 186,634 | 76,520 | 4100–8200 |

| ≥50,000 | 8,665,934 | 63% | 41 | 145,185 | 59,526 | 3200–6500 |

| 20,000–50,000 | 2,474,064 | 18% | 80 | 41,449 | 16,994 | 900–1800 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagner, D.; Neugebauer, G.; Kretschmer, F.; Stoeglehner, G. Integrating Life-Cycle Perspectives and Spatial Dimensions of Sewage Sludge Mono-Incineration. Water 2020, 12, 1267. https://doi.org/10.3390/w12051267

Wagner D, Neugebauer G, Kretschmer F, Stoeglehner G. Integrating Life-Cycle Perspectives and Spatial Dimensions of Sewage Sludge Mono-Incineration. Water. 2020; 12(5):1267. https://doi.org/10.3390/w12051267

Chicago/Turabian StyleWagner, David, Georg Neugebauer, Florian Kretschmer, and Gernot Stoeglehner. 2020. "Integrating Life-Cycle Perspectives and Spatial Dimensions of Sewage Sludge Mono-Incineration" Water 12, no. 5: 1267. https://doi.org/10.3390/w12051267

APA StyleWagner, D., Neugebauer, G., Kretschmer, F., & Stoeglehner, G. (2020). Integrating Life-Cycle Perspectives and Spatial Dimensions of Sewage Sludge Mono-Incineration. Water, 12(5), 1267. https://doi.org/10.3390/w12051267