Abstract

Water application uniformity is an important performance parameter when designing and operating an irrigation system. Performance tests of a center pivot irrigation system equipped with fixed and rotated spray plate sprinklers (FSPS and RSPS, respectively) were conducted at five travel speeds. The effects of travel speed, collector size, and setting height on water application uniformity were evaluated using Heermann and Hein’s coefficient of uniformity (CUH). The CUH was 12.7% higher for the RSPS than the FSPS and decreased as the travel speed increased. Collector size and setting height affected CUH, and CUH was higher when the collector had a large opening cross-section compared to the collector with a small opening cross-section. CUH was higher when the collector with a low setting height compared to when it a high setting height for the FSPS. However, collector setting height had no effect on CUH for the RSPS. The weighted average water application depth (Dw) decreased as the travel speed increased. Collector size had no significant effect on Dw, but Dw with a low collector setting height was larger than the values with a high collector setting height. The water application rate increased as distance from the pivot point increased and was higher for the FSPS than the RSPS. The results will improve the selection of travel speed and collector when the water application uniformity of a center pivot irrigation system is evaluated.

1. Introduction

A variety of sprinkler irrigation systems are widely available for use, such as center pivot, lateral move, solid set, side roll, traveler, and hand move systems. Among these irrigation systems, center pivot irrigation systems have been shown to be water and labor efficient, and can easily irrigate relatively flat and wide areas of land [1,2,3,4]. Water application uniformity is important when designing and operating a sprinkler irrigation system [5]. Poor water distribution by center pivot systems can lead to surface water ponding, runoff, and leaching of agricultural chemicals into the groundwater [6,7,8,9]. The significant influence of water application uniformity on crop production [10] means that uniform water application should be taken into account when using center pivot irrigation systems.

Center pivot irrigation systems are increasingly equipped with low-pressure sprinklers to reduce energy consumption [11,12]. Currently, fixed and rotated spray plate sprinklers (FSPS and RSPS, respectively) are the two most popular types [13,14,15]. Some studies have evaluated the water application uniformity of the center pivot irrigation system and the effects that various factors have on it. Yan et al. [16] analyzed the effect of the percent timer parameters on the water application distribution of a center pivot irrigation system equipped with FSPS. Ouazaa et al. [17] analyzed the effect of different tower movement dynamics and wind speeds on the water application uniformity of center pivot irrigation systems and found that the sprinkler packages had a strong effect on irrigation performance. Abd El-Wahed et al. [18] evaluated the effect of operating pressure, sprinkler spacing, and height of sprinkler above the ground surface on the water application uniformity of a center pivot irrigation system. Their results showed that the water distribution uniformity increased when the height of the sprinkler above the ground surface was increased because the increased height gave a larger wetted diameter for the same nozzle. Ortiz et al. [10] compared RSPS and FSPS placed at two heights above the ground and found that the RSPS had higher water application uniformities. However, the FSPS and RSPS were simultaneously installed at the system spans. To date, there have been few studies on evaluation of sprinkler type effects on water application uniformity across an entire system.

The effects of travel speed on the water application uniformity of center pivot or lateral move irrigation systems have been reported. However, these studies produced different research results, including no effect [19], a positive effect [20], and a negative effect [21]. Therefore, there needs to be more research on the effect of travel speed on water application uniformity.

The collector also affects evaluation of the water application uniformity of center pivot irrigation systems. Rogers et al. [22] investigated the effect of collector size and spacing on center pivot uniformity evaluations. The results showed that water application uniformity appeared to be relatively insensitive to collector spacing, but uniformity variability and inconsistency was related to collector size. However, the setting height of the collector varied in different studies. Therefore, further research is needed on the effect of collector setting height on water application uniformity.

The objectives of this study were (1) to evaluate the water application uniformity of a center pivot irrigation system equipped with two types of low-pressure sprinklers, and (2) to investigate the effect of travel speed, collector size, and setting height on water application uniformity. The results from these evaluations of water application uniformity in a center pivot irrigation system should help to improve the selection of suitable travel speeds and collectors.

2. Materials and Methods

2.1. Experiment Sites and System Descriptions

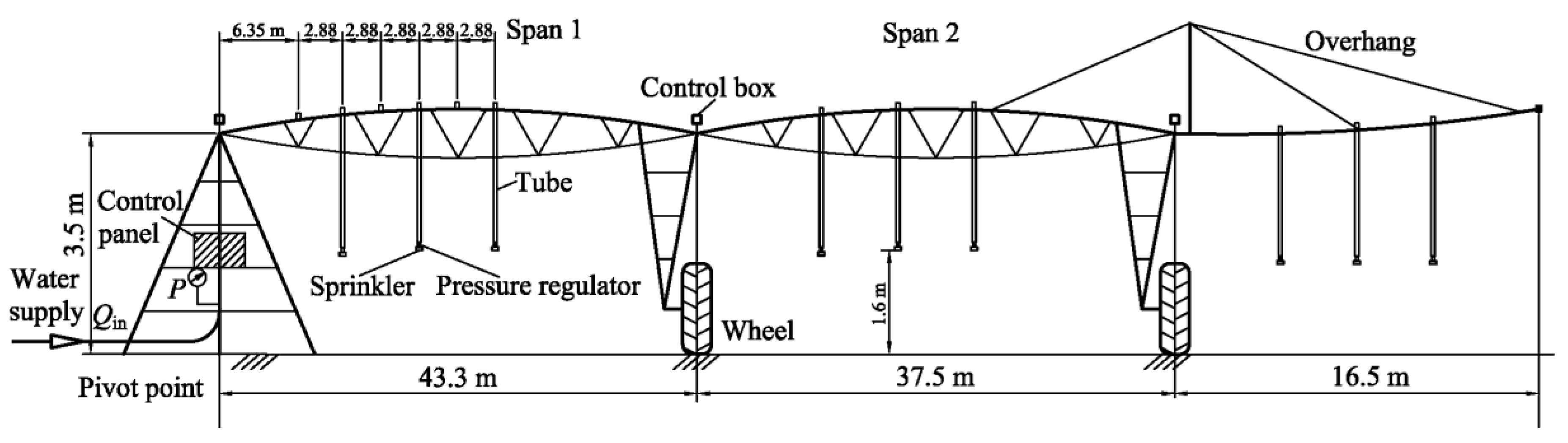

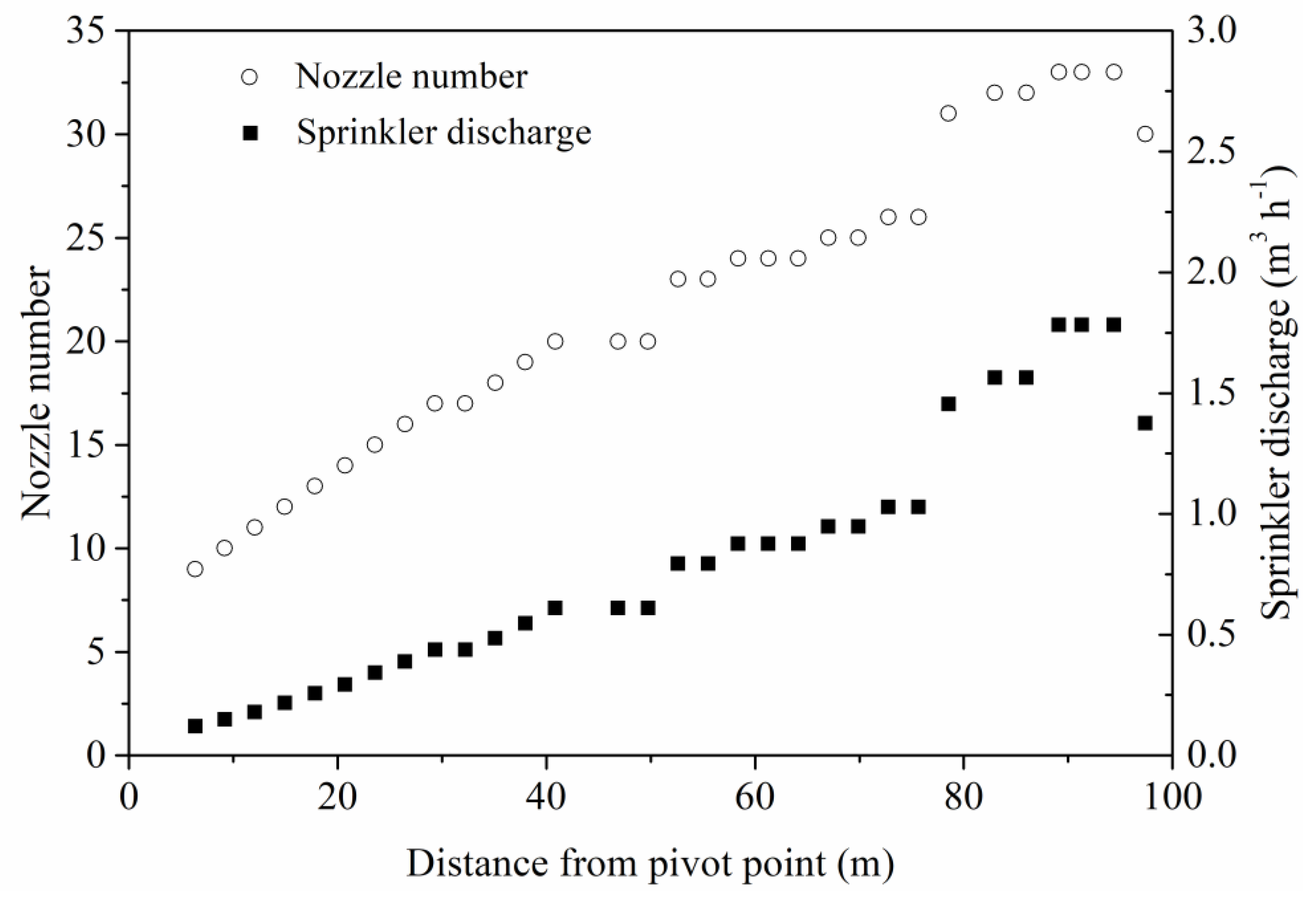

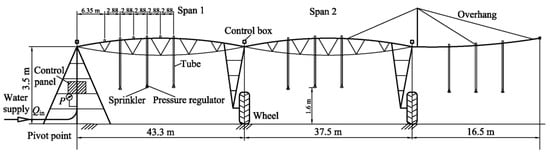

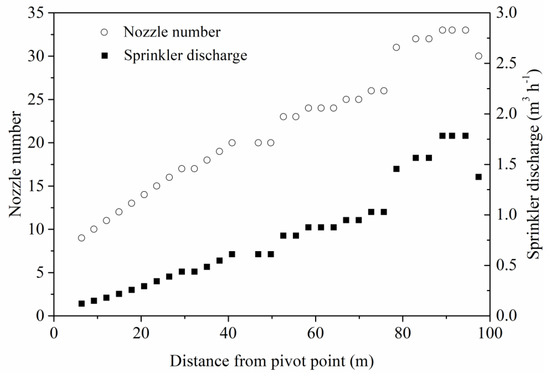

Field tests on a center pivot irrigation system equipped with 31 sprinklers were carried out at Tongzhou Experimental Station, China Agricultural University. The experimental site was in flat terrain located at 39°41’59.38” N, 116°41’0.94” E and had an elevation of 21 m. The center pivot irrigation system had two spans and an overhang as shown in Figure 1. The lateral pipe was 168 mm in diameter and the irrigation water was supplied at a constant pressure of 200 kPa. The FSPS analyzed in this study was a D3000 Sprayhead equipped with the blue deflector plate, and the RSPS was a R3000 Rotator equipped with the brown deflector plate. These sprinklers were set approximately 1.6 m above the ground surface and with a spacing of 2.88 m. Nozzle numbers for the different sizes ranged from #9 to #33 out of the 42 size numbers listed in the 3000 Series 3TN Nozzle System catalog. The sprinklers and the nozzles were manufactured by Nelson Irrigation Corporation (Walla Walla, WA, USA, mention of trademarks does not imply an endorsement). The 31 pressure regulators (103 kPa) were able to maintain a constant sprinkler inlet pressure. The main technical parameters of the system are shown in Table 1, and the nozzle number and sprinkler discharge along the lateral pipe of the investigated system are shown in Figure 2.

Figure 1.

Structural components of the investigated center pivot irrigation system.

Table 1.

Technical parameters of the center pivot irrigation system.

Figure 2.

Nozzle number and sprinkler discharge along the lateral pipe of the center pivot irrigation system.

2.2. Experimental Setup and Test Procedures

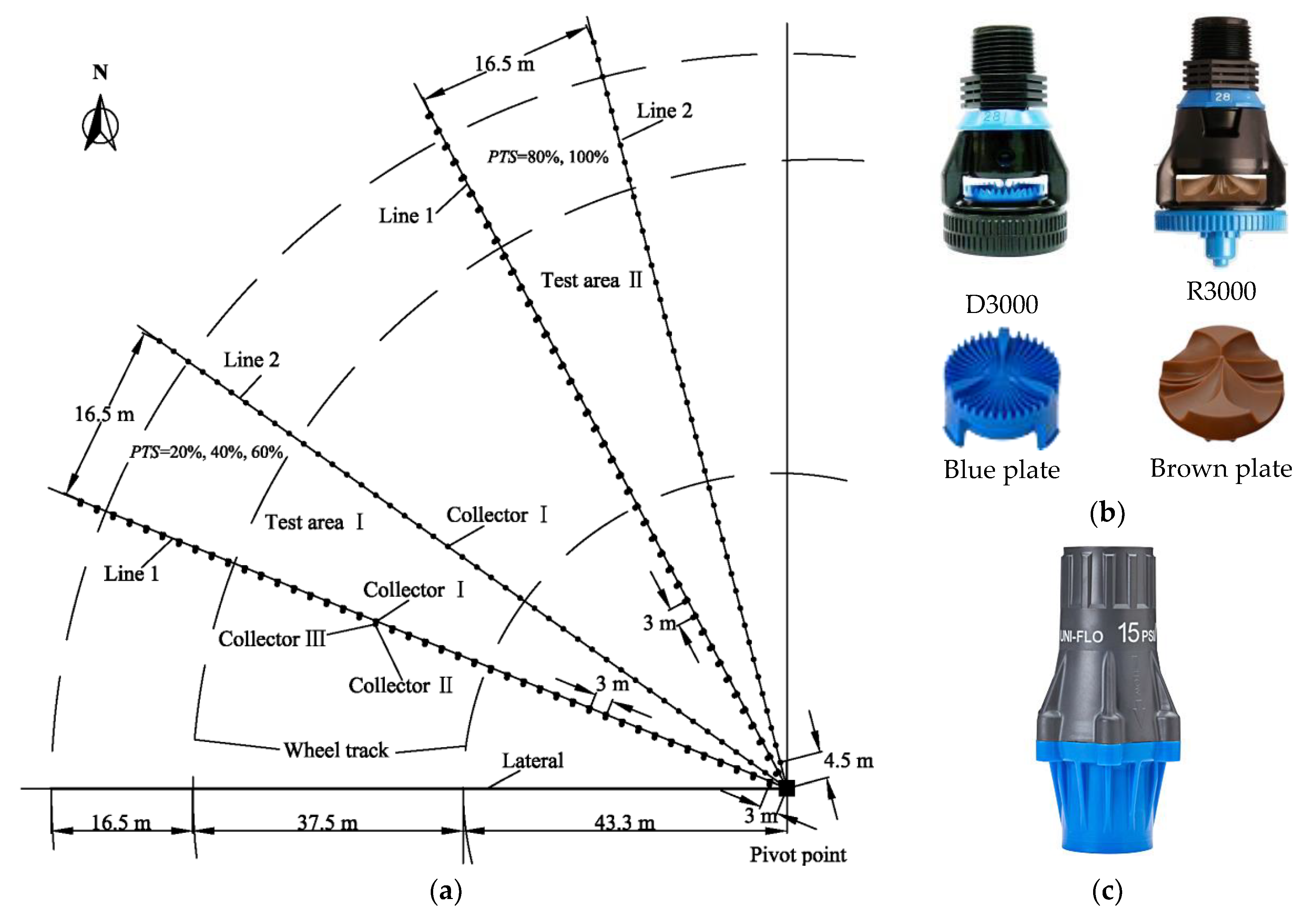

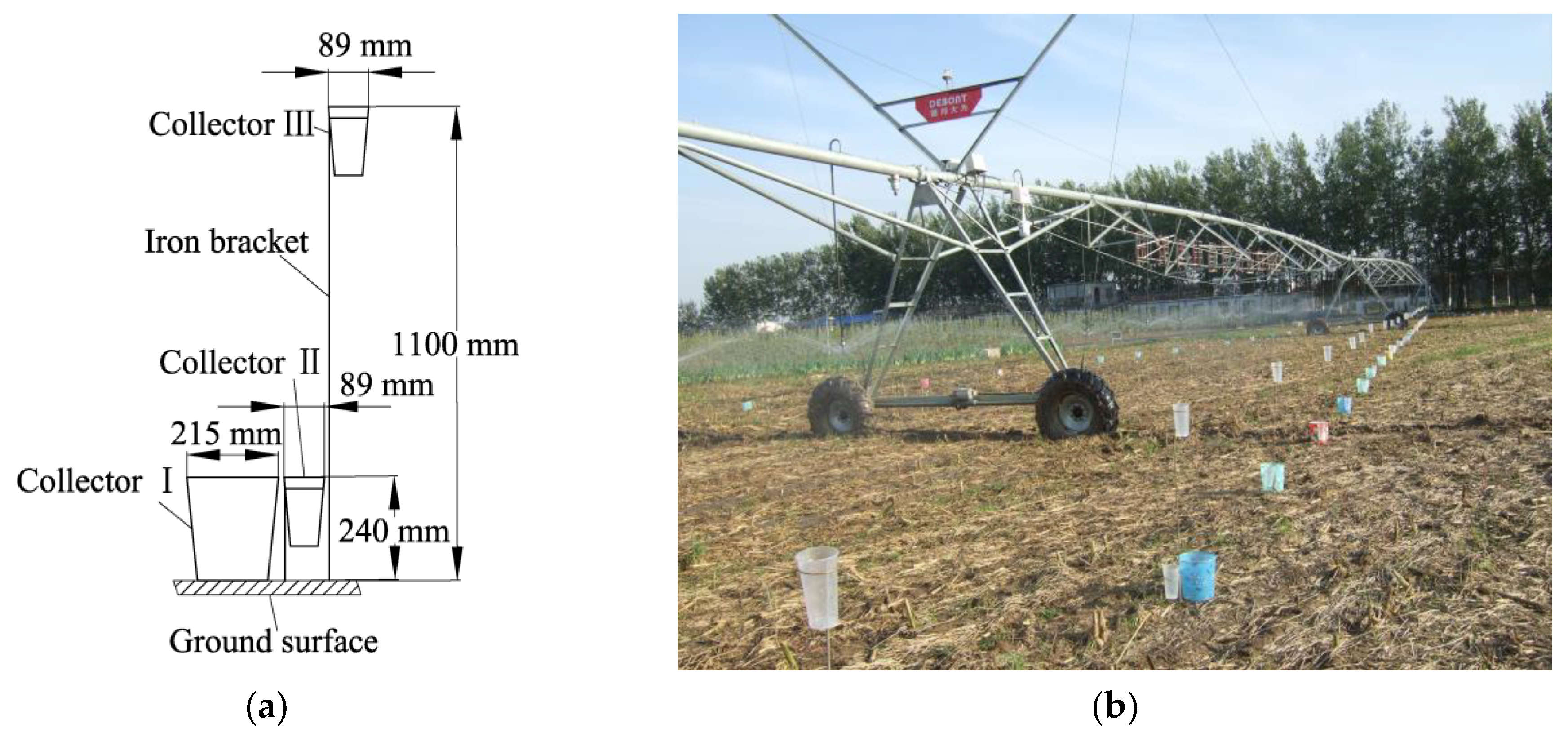

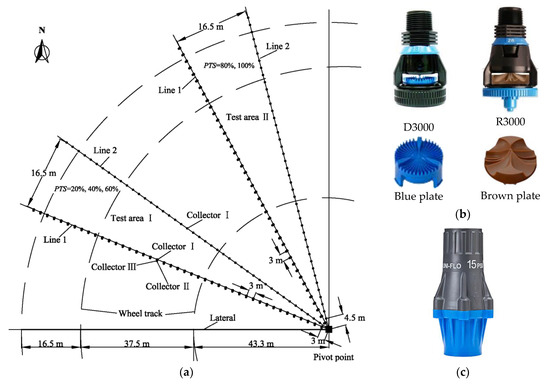

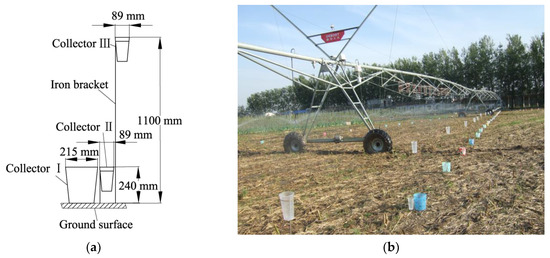

The water application uniformity tests were conducted on the center pivot irrigation system in October 2015 after the maize had been harvested and were in accordance with the ANSI/ASAE S436.1 [23] and ISO 11545 [24] standards. A schematic illustration of the experimental apparatus is shown in Figure 3a. The collectors were 240 mm in height and had an opening diameter of 215 mm. They were uniformly spaced 3 m apart along two radial straight lines and the distance between the distal ends of the two lines was 16.5 m. The operating pressure and discharge of the system were separately measured using a pressure gauge at the pivot pipe and an ultrasonic flowmeter at the water inlet pipe that was connected to the pivot pipe. The water application depth was adjusted by controlling the travel speed, which was governed by a percent timer [16]. There were five percent timer settings (PTSs), which were 20%, 40%, 60%, 80%, and 100%. Water application uniformity tests with PTSs = 20%, 40%, and 60%, were conducted in test area I and the water application uniformity tests with PTSs = 80% and 100% were conducted in test area II. The whole field was relatively flat, and the slope was almost zero in test areas I and II. Wind speed and direction were measured every 15 min by a three-cup anemometer with a DEM6 (Zhonghuan TIG Meteorological Instruments Co., Ltd., Tianjin, China). The water collected in the collectors was weighed on an electrical scale with an accuracy of 0.1 g, and then the applied water volume was converted to the applied water depth by dividing it by the cross-sectional area of the collector. The effects of collector size and setting height on water application uniformity were evaluated using two different collectors and two height settings on Line 1: (1) collector I (215 mm opening diameter, 240 mm in height) was directly placed on the ground surface, and the vertical distance between the sprinkler and the opening of the collector was approximately 1.36 m; (2) collector II (89 mm opening diameter, 160 mm in height) was supported approximately 240 mm above the ground surface by iron brackets, and the vertical distance between the sprinkler and the opening of the collector was approximately 1.36 m; and (3) collector III (89 mm opening diameter, 160 mm in height) was supported approximately 1100 mm above the ground surface by iron brackets, and the vertical distance between the sprinkler and the opening of the collector was approximately 0.5 m (Figure 4). In each test scheme, the time that the four type I collectors received water at particular radial positions (15, 30, 60, and 90 m) was recorded by a stopwatch. The applied water depth was converted to application rate (Ra) by dividing it by the time at which the collector received water [25,26]. The main environmental parameters of the tests are shown in Table 2.

Figure 3.

Schematic diagram of the experimental apparatus used to evaluate the performance of the center pivot irrigation system: (a) schematic diagram of the experiment; (b) FSPS with blue fixed spray-plates (D3000) and RSPS with brown rotated spray-plates (R3000); and (c) pressure regulator (103 kPa).

Figure 4.

Layout of the collectors during the performance evaluation of the center pivot irrigation system: (a) collector size and setting height on Line 1; (b) photograph of the experimental setup.

Table 2.

Main environmental parameters of the field tests.

2.3. Data Analysis

The coefficient of uniformity for the center pivot irrigation system was calculated by a modified version of Heermann and Hein’s formula [23,27] (Equation (1)):

where CUH is Heermann and Hein’s coefficient of uniformity (%), N is the number of collectors used in the data analysis, i is a number used to identify a particular collector, normally beginning with the collector located nearest the pivot point (i = 1) and ending with i = N for the collector furthest from the pivot point, Di is the application depth of the water collected in the ith collector (mm), Si is the distance of the ith collector from the pivot point (m), and Dw is the weighted average application depth of water collected (mm), calculated as Equation (2):

The differences in CUH and Dw of the center pivot irrigation system with two types of sprinklers at different travel speeds and under different collectors were tested using one-way analysis of variance (ANOVA; assessed as significant at the P < 0.05 level). The statistical data analyses and graphs were prepared with SPSS 23.0 analytical software (IBM Corp., Armonk, NY, USA) and OriginPro 2016 software (OriginLab, Northampton, MA, USA).

3. Results and Discussion

3.1. Effect of Travel Speed on Water Distribution and Application Uniformity

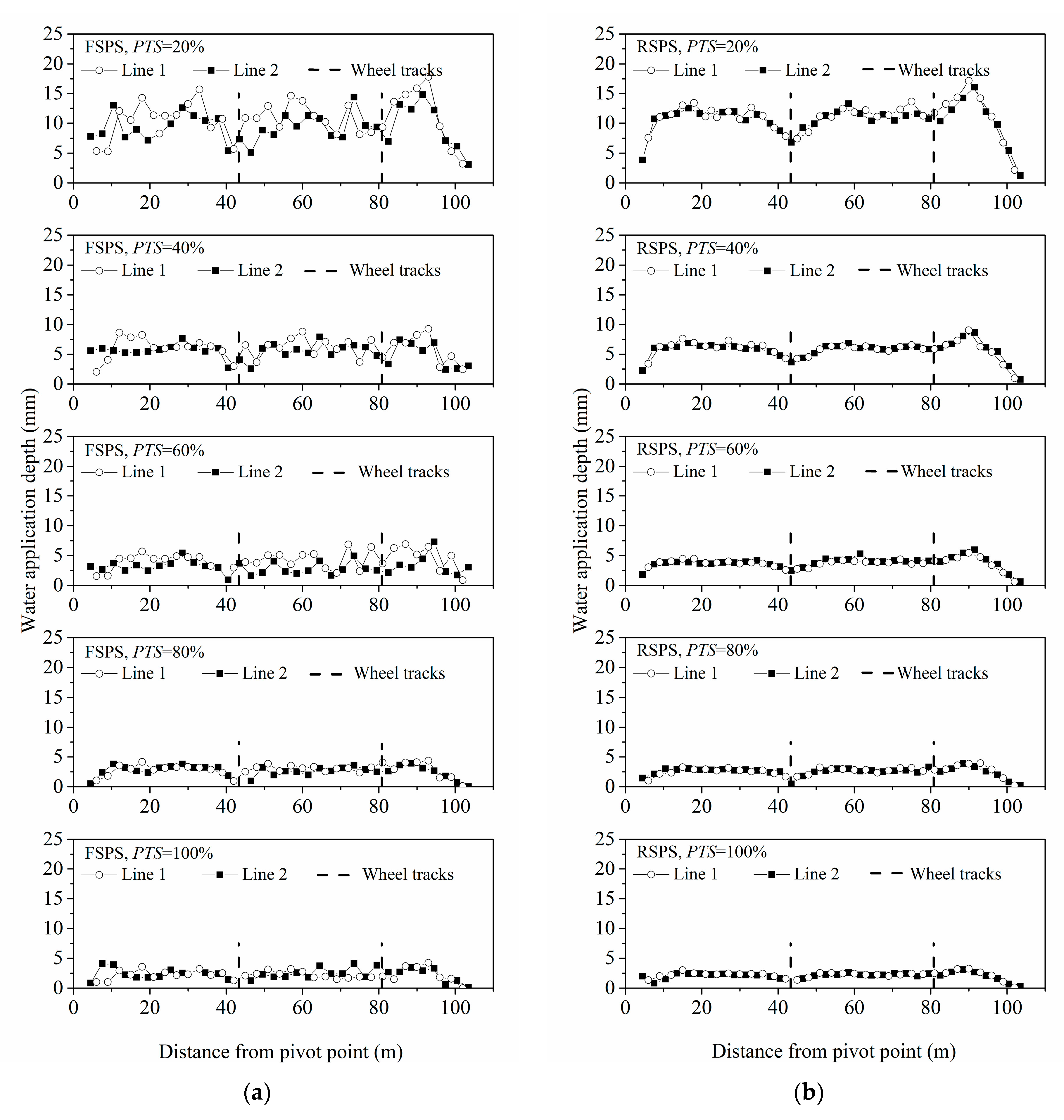

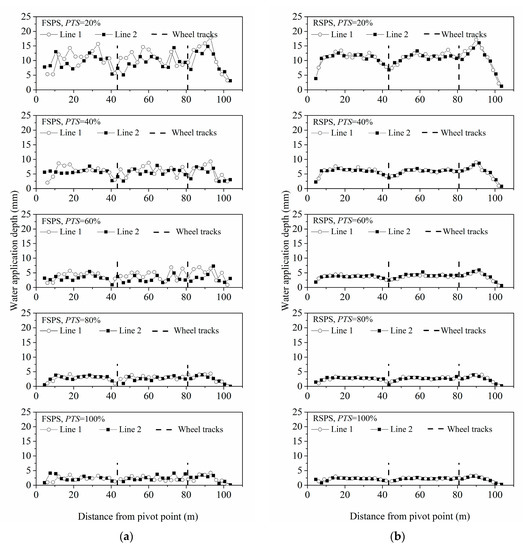

The travel speed of the center pivot has important effects on water distribution and application uniformity. There are different viewpoints and research results about the effect of travel speed on water application uniformity, including no effect [19], a positive effect [20], and a negative effect [21]. In this study, the relationship between water application depth and distance from the pivot point for collector type I is shown in Figure 5 for the FSPS and RSPS at the five travel speeds. It was clear that there were different water application depths along the radius between the two types of sprinklers for the various PTSs. Among them, the Dw values of the five PTSs (20%, 40%, 60%, 80%, and 100%) for the FSPS were 10.1 mm, 5.6 mm, 3.7 mm, 2.7 mm, and 2.3 mm, respectively, whereas they were 10.8 mm, 5.7 mm, 3.8 mm, 2.6 mm, and 2.1 mm for the RSPS, respectively. These findings indicated that the water application depth gradually decreased as the PTS increased for both sprinkler types, which was similar to previous findings by Dogan et al. [19]. The water application depths of the FSPS and RSPS were similar, and the differences between the two sprinkler types did not exceed 0.7 mm for any of the five PTSs. Therefore, sprinkler type had little impact on the water application depth.

Figure 5.

Water application depth versus distance from the pivot point for collector I: (a) FSPS, PTS = 20%–100%; (b) RSPS, PTS = 20%–100%.

The effect of travel speed on the water application uniformity of the center pivot irrigation system was investigated further. Table 3 shows CUH values of the system with the two types of sprinklers for collector I at the five travel speeds. Overall, the RSPS had better CUH values than the FSPS, and the CUH values decreased with PTS for both the sprinklers. These results were in good agreement with those reported by Hills, et al. [21]. For example, the CUH values corresponding to the five PTSs (20%, 40%, 60%, 80%, and 100%) were 72.8%, 73.1%, 67.4%, 70.1%, and 65.0% (69.7% on average) for the FSPS, respectively. However, the values changed to 80.3%, 80.1%, 79.5%, 75.6%, and 77.0% (78.5% on average) when switching from the FSPS to the RSPS, respectively. The CUH values for the RSPS at the five PTSs were 8.8 percentage points higher on average than the FSPS values, and the RSPS produced smaller magnitude changes when the different PTSs were applied than the FSPS (3.3 versus 7.8 percentage points on average, respectively). This might be due to the fact that the rotary spraying characteristics of the RSPS meant that the water overlap between adjacent sprinklers was greater. Taken together, the results showed that the PTS influence on the Dw and CUH values cannot be ignored. A lower PTS led to higher Dw and CUH values, and vice versa. This means that it is critically important to determine the most appropriate PTS when operating a center pivot irrigation system. Although the two sprinkler types had similar Dw values at the same PTS, the CUH improvement was better with the RSPS than with the FSPS. Therefore, the RSPS are more appropriate for center pivot irrigation systems when high water application uniformity is needed.

Table 3.

Water application uniformities of the center pivot irrigation system with FSPS and RSPS for collector I at the five travel speeds.

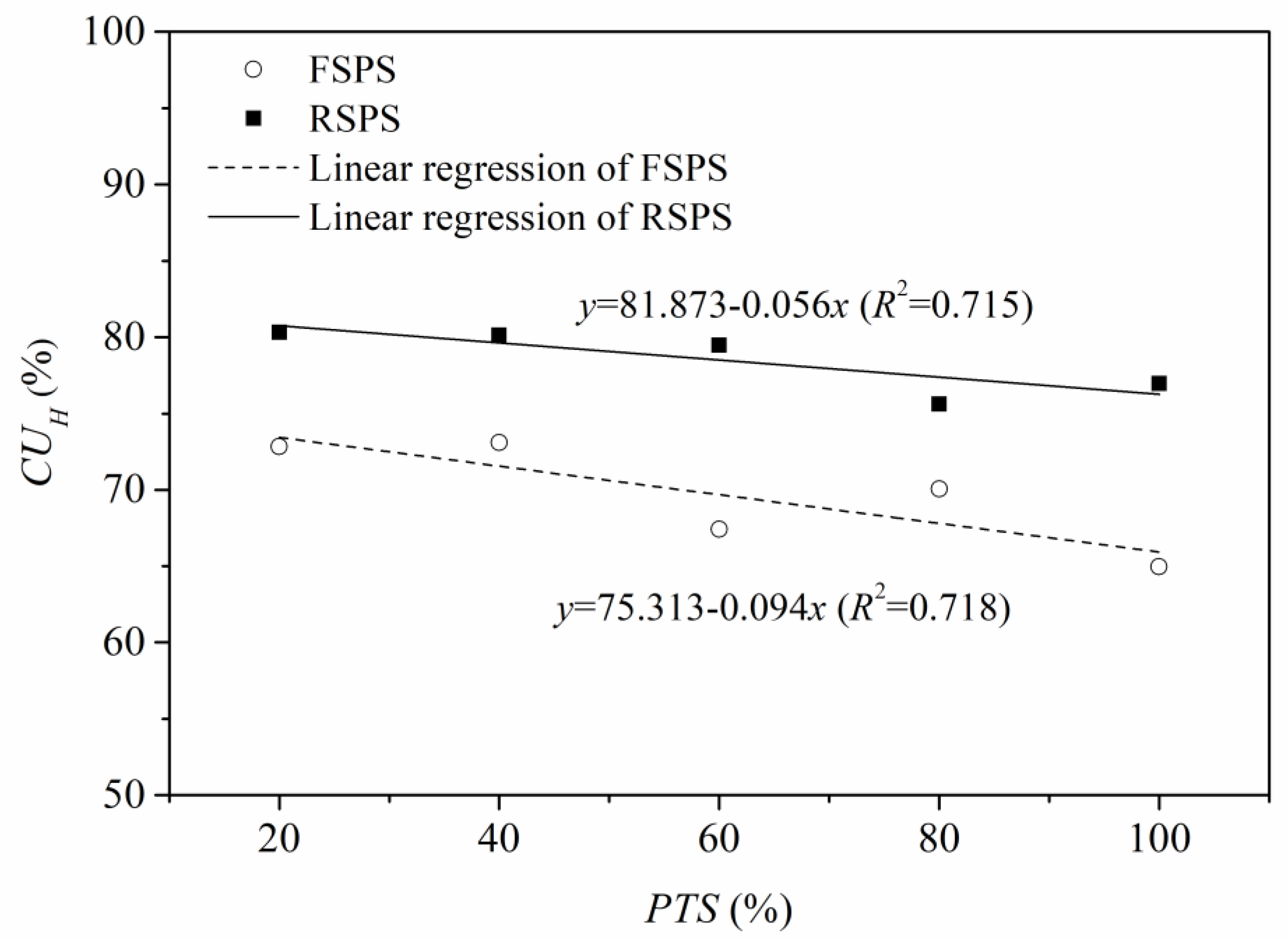

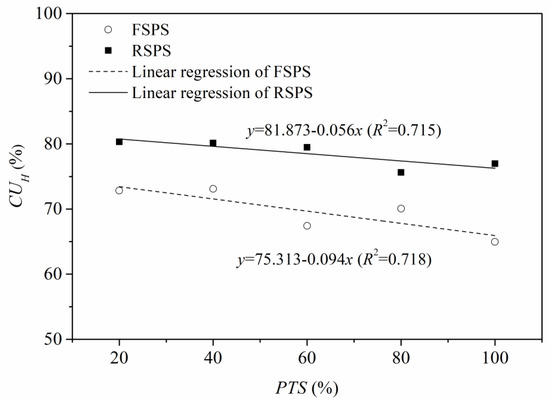

Figure 6 shows the CUH fitting equations for the two sprinkler types at the different PTSs for collector I. Notably, the CUH and PTS values for both the FSPS and RSPS had a good linear function relationship, as shown in the following Equations (3) and (4):

Figure 6.

Relationship between water application uniformity and the travel speed in the center pivot irrigation system with FSPS and RSPS for collector I.

3.2. Effect of Collector Size and Setting Height on Water Distribution and Application Uniformity

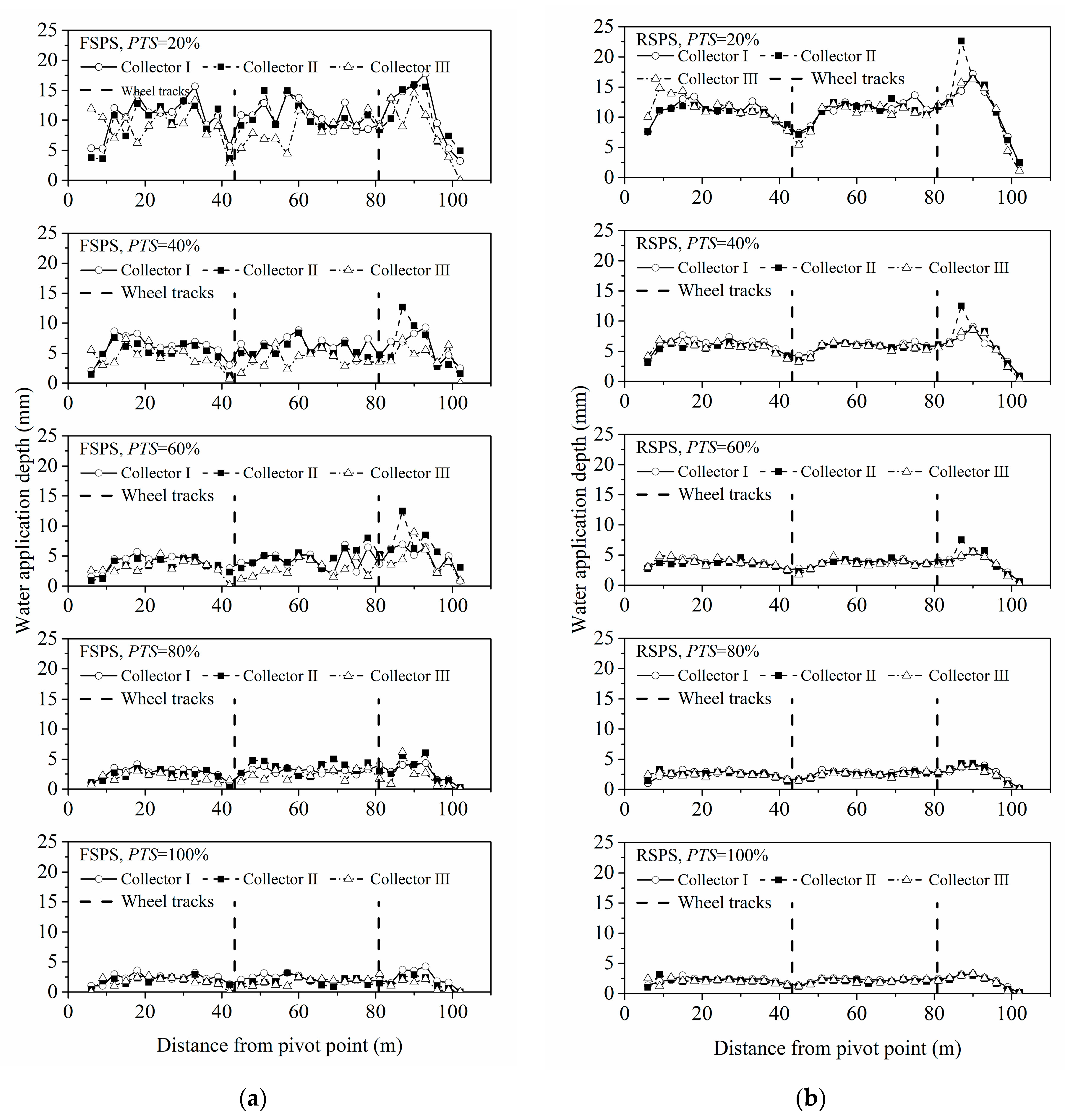

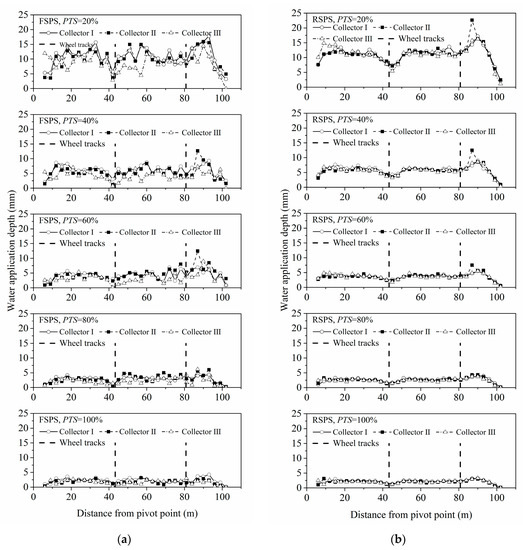

Collector size and setting height are related to the water application depths at the different measuring points, which in turn affect the water application uniformities of center pivot irrigation systems. Figure 7 shows the relationship between water application depth and distance from the pivot point for FSPS and RSPS at the five travel speeds and for the three types of collector. Overall, collectors I and II (low collectors placed directly on the ground and 240 mm above the ground, respectively) had the larger Dw values among the three collector types, followed by collector III (high collector placed 1100 mm above the ground) regardless of the sprinkler type or travel speed. Taking the FSPS as an example, the mean Dw values at the five travel speeds averaged 5.3 mm, 5.2 mm, and 3.9 mm for collectors I, II, and III, respectively (Table 4). These results indicated that the Dw value was not obviously related to the collector size but was inversely proportional to the setting height.

Figure 7.

Water application depth versus distance from the pivot point for the three types of collectors: (a) FSPS, PTS = 20%–100%; (b) RSPS, PTS = 20%–100%.

Table 4.

Weighted average water application depths for the three types of collectors at the five travel speeds.

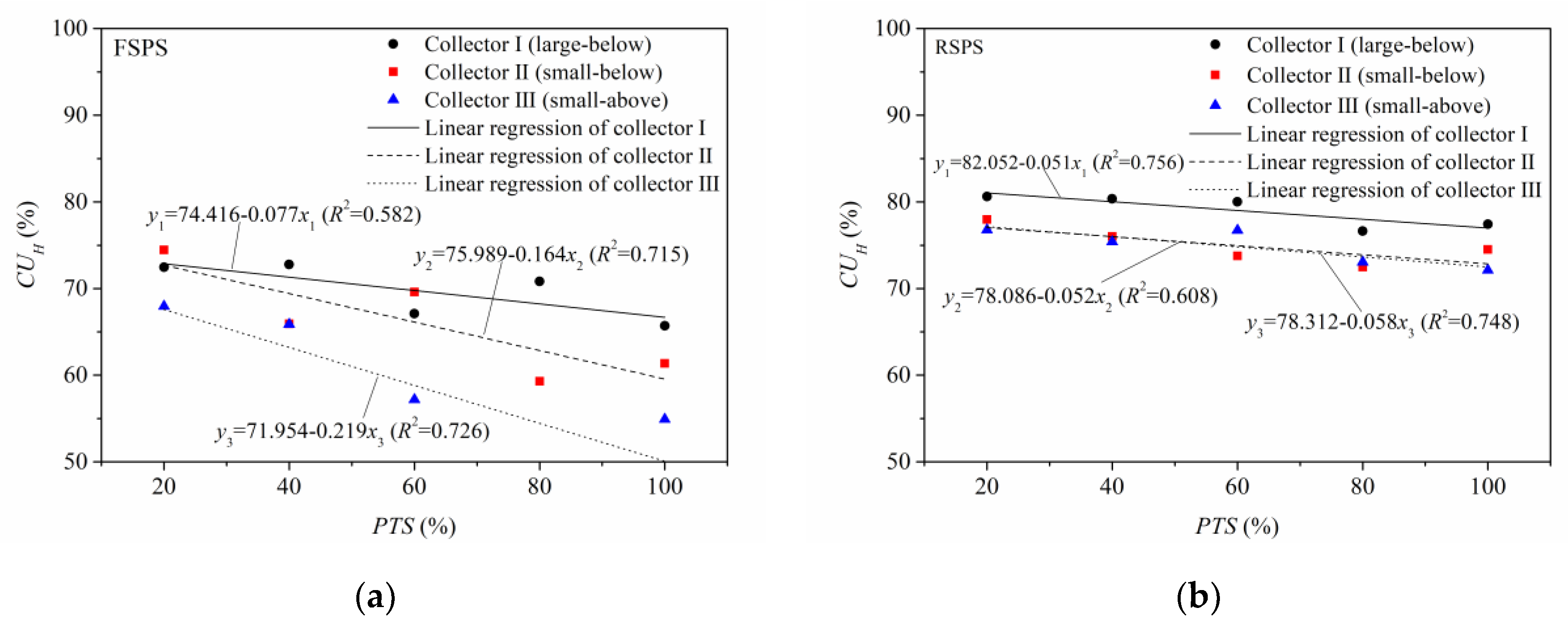

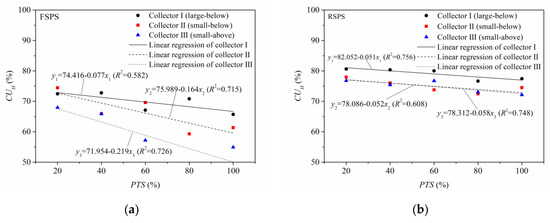

In addition, from the perspective of water application uniformity versus travel speed (Figure 8), the overall CUH values for the large size collectors and the low setting height collectors were above those recorded for the small size collectors and the high setting height collectors, except for individual cases caused by environmental factors. For the FSPS, the mean CUH value of collector I at the five PTSs were 3.6 and 10.9 percentage points higher than the values for collectors II and III, respectively, whereas they were 4.1 and 4.2 percentage points higher for the RSPS, respectively. One possible explanation for this result is that large size and low setting height collectors could more fully achieve water overlap between adjacent sprinklers along the lateral pipe compared to the small size and high height setting collectors, which resulted in higher irrigation uniformity.

Figure 8.

Effects of collector size and setting height on the water application uniformities produced by the two sprinkler types at the five different travel speeds: (a) FSPS; (b) RSPS. Note: subscripts (1, 2, and 3) in the linear regression equations correspond to the different collector levels (I, II and III).

Further analysis indicated that the two linear regression lines (dashed line and dotted line) for the RSPS almost overlapped (Figure 8b), which showed that the CUH values at the various PTSs for collector II were relatively close to the values for collector III because the average difference between the two collector types was only 0.1 percentage points. This occurred because the water from the RSPS had been sufficiently atomized when the jet left the spray plate, which meant that the setting height of the collector had no obvious effect on CUH. In summary, the RSPS had good CUH values for the different collector conditions and played a positive role in reducing the influence of collector setting height on CUH. The highest water application uniformity was achieved using large size collectors and the greatest water application depth was obtained using low height collectors, and vice versa. This provides a basis for the reasonable selection of collectors in future studies on the performance of center pivot irrigation systems.

3.3. Analysis of Variance Results for the Effect of Various Factors on Water Application Uniformity

The effects of various factors (travel speed, collector size, setting height, and sprinkler type) on water application depth and uniformity were further investigated by undertaking an ANOVA of the effect of each factor on the CUH and Dw values (Table 5 and Table 6, respectively). The interaction among various factors was not considered. The results showed that sprinkler type was the only one of these four factors that had a significant effect on CUH (P = 0.000), followed by insignificant collector size (P = 0.164) and setting height (P = 0.338) effects. Travel speed had the smallest effect (P = 0.352) (Table 5). In contrast, although travel speed only had a minor effect on the CUH, its impact on Dw was significant (P = 0.000) (Table 6). These findings revealed that travel speed and sprinkler type have critically important effects on the water application depth and uniformity of center pivot irrigation systems. Therefore, it is important to set an appropriate travel speed for center pivot irrigation systems. This speed is related to crop growth and to the utilization coefficient for irrigation water. Furthermore, RSPS are recommended when using center pivot irrigation systems because they produce better water application uniformities

Table 5.

Analysis of variance results for the effect of various factors on CUH.

Table 6.

Analysis of variance results for the effect of various factors on Dw.

3.4. Water Application Rate

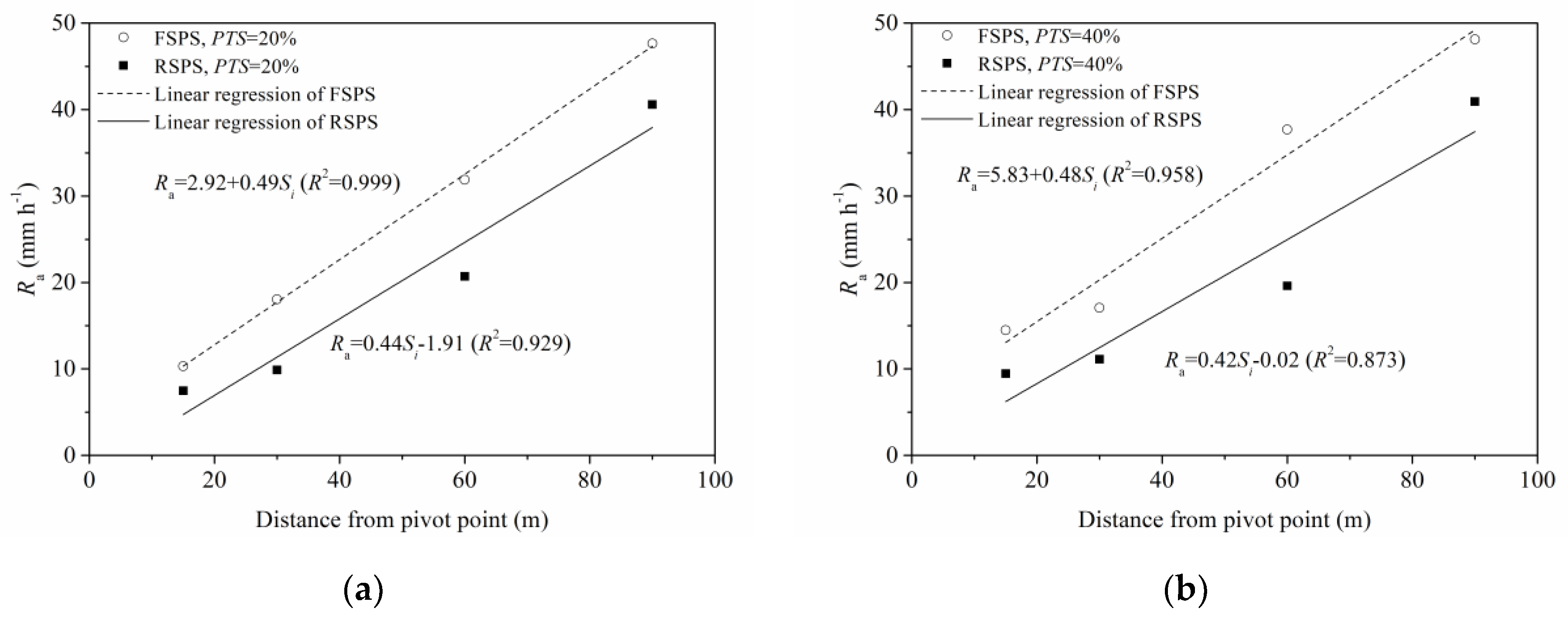

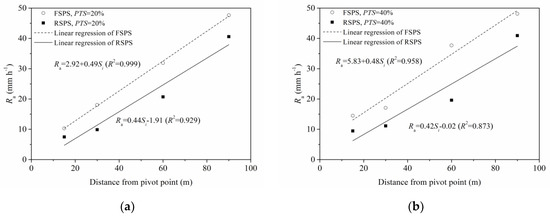

The Ra values at the four typical radial positions (15, 30, 60, and 90 m) in the system equipped with the FSPS and RSPS are shown in Figure 9 at PTS = 20% and 40%. The Ra generally rose as the distance from the pivot point increased. There was a linear relationship between the water application rate and the distance from the pivot point, as shown in the following equations:

Figure 9.

Water application rates at the four radial positions (15, 30, 60, and 90 m) in the center pivot irrigation system with FSPS and RSPS at two travel speeds: (a) PTS = 20%; (b) PTS = 40%.

In theory, travel speed has no effect on Ra [28]. The linear regression Equations (5) and (7) between Ra and Si for FSPS at PTS = 20% and 40% were similar with comparable slope values, which agreed with the theoretical analysis. The same result was obtained for RSPS (linear regression Equations (6) and (8).

Further analysis indicated that the Ra values for FSPS along the lateral pipe were higher than the values for RSPS (Figure 9), which showed that the FSPS had relatively poor Ra values along the lateral pipe of the center pivot irrigation system. Surface runoff is more likely to occur when FSPS are used if the radial position Ra values significantly exceed the soil infiltration rate. Therefore, measures need to be taken to reduce or control surface runoff, such as installing a boomback system [29] or a control apparatus to adjust the sprinkler height [30]. Alternatively, an appropriate polyacrylamide compound could be applied [31].

4. Conclusions

This study investigated the effect of travel speed, collector size, and setting height on the water distribution and application uniformity of a center pivot irrigation system equipped with FSPS and RSPS. The Dw and CUH values gradually decreased as the travel speed increased for both sprinkler types. The CUH was higher for RSPS than for FSPS and the RSPS proved more appropriate for center pivot irrigation systems when high water application uniformity is needed.

The collector size and setting height affected the water application uniformity evaluation. Generally, collector size had no obvious effect on Dw. However, the Dw values for collectors with a high setting height were lower than the values for collectors with a low setting height. The results for both types of sprinklers showed that CUH was higher when the collector had a large opening cross-section compared to the collector with a small opening cross-section. In the case of FSPS, CUH was higher when the collector with a low setting height compared to when it a high setting height. However, the setting height of the collector had no effect on CUH when RSPS were used.

From the ANOVA results, the sprinkler type was the only one of these four factors that had a significant effect on the CUH, followed by the collector size and setting height, and the travel speed had the smallest effect. In contrast, although travel speed only had a minor effect on the CUH, its impact on the Dw was significant. These findings revealed that it important to set an appropriate travel speed and to select a proper sprinkler type for center pivot irrigation systems.

Travel speed had no effect on Ra. However, the Ra values generally rose as the distance from the pivot point increased and were higher for the FSPS than for the RSPS. Furthermore, when the Ra values at a radial position significantly exceeds the soil infiltration rate, then surface runoff is more likely to occur if FSPS are used.

There are some limitations in this study. The water collected in the collectors was not weighed timely during the tests, which might lead to the measurement errors due to water evaporation. Both the collector size and setting height were set as two levels, which might not be sufficient to compare their effects on the water application uniformity. Moreover, the tested center pivot irrigation system had only two spans, with a full length of 97.3 m, which resulted in the difficulty of nozzle configuration and lower CUH values.

Some research scopes need to be investigated in the future. More influencing factors, including wind speed, air temperature, relative humidity, and terrain slope, should be taken into account on the water application uniformity of a center pivot irrigation system. Moreover, more sprinkler types need to be compared to evaluate the water application uniformity according to different crop canopies and heights. Finally, optimal sprinkler package configurations are suggested to meet the requirements of water application uniformity at different climate conditions, crop growth periods and terrain slopes.

Author Contributions

Methodology, Y.L. and H.Y.; investigation, Y.L.; writing–original draft preparation. Y.L.; writing review and editing, H.Y., X.H., and D.C.; supervision, H.Y.; and funding acquisition, H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank the National Natural Science Foundation of China (Grant numbers 51939005, 51679238, and 51321001), the Fundamental Research Funds for the Central Universities (Grant number 2452016177) and the National Key Research and Development Program of China (Grant number 2017YFD0201502).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Martin, D.L.; Kincaid, D.C.; Lyle, W.M. Design and operation of sprinkler systems. In Design and Operation of Farm Irrigation Systems; Hoffman, G.J., Evans, R.G., Jensen, M.E., Martin, D.L., Elliott, R.L., Eds.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; pp. 557–631. [Google Scholar]

- Jiao, J.; Su, D.R.; Wang, Y.D. Dynamics of water vapor content around isolated sprinklers: Description and validation of model. Water 2017, 9, 307. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Sun, B.; Fang, H.Y.; Zhu, D.L.; Yang, L.X.; Li, Z.S. Experimental and simulation investigation on the kinetic energy dissipation rate of a fixed spray-plate sprinkler. Water 2018, 10, 1365. [Google Scholar] [CrossRef]

- Yan, H.J.; Hui, X.; Li, M.N.; Xu, Y.C. Development in sprinkler irrigation technology in China. Irrig. Drain. 2020, 1–13. [Google Scholar] [CrossRef]

- Li, Y.C.; Bai, G.; Yan, H.J. Development and validation of a modified model to simulate the sprinkler water distribution. Comput. Electron. Agr. 2015, 111, 38–47. [Google Scholar] [CrossRef]

- Henggeler, J.C.; Vories, E.D. Evaluating center pivot distribution uniformity from catch can tests. In Proceedings of the 2009 ASABE Annual International Meeting, Reno, NV, USA, 21–24 June 2009; pp. 2416–2429. [Google Scholar]

- Dukes, M.D.; Perry, C. Uniformity testing of variable-rate center pivot irrigation control systems. Precis. Agric. 2006, 7, 205–218. [Google Scholar] [CrossRef]

- Silva, L.L. The effect of spray head sprinklers with different deflector plates on irrigation uniformity, runoff and sediment yield in a Mediterranean soil. Agr. Water Manage. 2006, 85, 243–252. [Google Scholar] [CrossRef]

- Burt, C.M.; Clemmens, A.J.; Strelkoff, T.S.; Solomon, K.H.; Bliesner, R.D.; Hardy, L.A.; Howell, T.A.; Eisenhauer, D.E. Irrigation performance measures: Efficiency and uniformity. J. Irrig. Drain. Eng. 1997, 123, 423–442. [Google Scholar] [CrossRef]

- Ortiz, J.N.; de Juan, J.A.; Tarjuelo, J.M. Analysis of water application uniformity from a centre pivot irrigator and its effect on sugar beet (Beta vulgaris L.) yield. Biosyst. Eng. 2010, 105, 367–379. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Guo, J.J.; Sun, B.; Fang, H.Y.; Zhu, D.L.; Wang, H.L. Modeling and dynamic-simulating the water distribution of a fixed spray-plate sprinkler on a lateral-move sprinkler irrigation system. Water 2019, 11, 2296. [Google Scholar] [CrossRef]

- Rovelo, C.O.R.; Ruiz, N.Z.; Tolosa, J.B.; Felix, J.R.F.; Latorre, B. Characterization and simulation of a low-pressure rotator spray plate sprinkler used in center pivot irrigation systems. Water 2019, 11, 1684. [Google Scholar] [CrossRef]

- Jiao, J.; Wang, Y.D.; Han, L.L.; Su, D.R. Comparison of water distribution characteristics for two kinds of sprinklers used for center pivot irrigation systems. Appl Sci 2017, 7, 421. [Google Scholar] [CrossRef]

- Hills, D.J.; Barragan, J. Application uniformity for fixed and rotating spray plate sprinklers. Appl. Eng. Agric. 1998, 14, 33–36. [Google Scholar] [CrossRef]

- Li, Y.; Yan, H.; Cai, D.; Gu, T.; Sui, R.; Chen, D. Evaluating the water application uniformity of center pivot irrigation systems in Northern China. Int. Agr. Eng. J. 2019, 28, 1–9. [Google Scholar]

- Yan, H.; Jin, H.; Qian, Y. Characterizing center pivot irrigation with fixed spray plate sprinklers. Sci. China. Technol, Sc. 2010, 53, 1398–1405. [Google Scholar] [CrossRef]

- Ouazaa, S.; Latorre, B.; Burguete, J.; Serreta, A.; Playán, E.; Salvador, R.; Paniagua, P.; Zapata, N. Effect of the start-stop cycle of center-pivot towers on irrigation performance: Experiments and simulations. Agr. Water Manage. 2015, 147, 163–174. [Google Scholar] [CrossRef]

- Abd El-Wahed, M.H.; Medici, M.; Lorenzini, G. Harvesting water in a center pivot irrigation system: Evaluation of distribution uniformity with varying operating parameters. J. Eng. Thermophys.-Rus. 2015, 24, 143–151. [Google Scholar] [CrossRef]

- Dogan, E.; Kirnak, H.; Doyan, Z. Effect of varying the distance of collectors below a sprinkler head and travel speed on measurements of mean water depth and uniformity for a linear move irrigation sprinkler system. Biosyst. Eng. 2008, 99, 190–195. [Google Scholar] [CrossRef]

- Salih, S.A.R. Evaluation of speed effect on center pivot irrigation system performance at Waha project under Sudan north state conditions. In Proceedings of the International Conference on Civil and Architecture Engineering, Kuala Lumpur, Malaysia, 6–7 May 2013; pp. 41–42. [Google Scholar]

- Hills, D.J.; Gu, Y.; Rumsey, J.W.; Wallender, W.W. Lateral move water application uniformity relative to machine speed. Trans. ASAE 1988, 31, 527–530. [Google Scholar] [CrossRef]

- Rogers, D.H.; Alam, M.; Shaw, L.K.; Clark, G.A. Impact of collector size and spacing on center pivot uniformity evaluations. In Proceedings of the 2009 ASABE Annual International Meeting, Reno, NV, USA, 21–24 June 2009; pp. 4168–4180. [Google Scholar]

- ASAE Standard. Test Procedure for Determining the Uniformity of Water Distribution of Center Pivot and Lateral Move Irrigation Machines Equipped with Spray or Sprinkler Nozzles; (R2012); ASAE: St. Joseph, MI, USA, 1996; Volume ANSI/ASAE S436.1. [Google Scholar]

- ISO. Agricultural Irrigation Equipment—Center-Pivot and Moving Lateral Irrigation Machines with Sprayer or Sprinkler Nozzles—Determination of Uniformity of Water Distribution; ISO: Geneva, Switzerland, 2009; Volume ISO 11545. [Google Scholar]

- Kincaid, D.C. Application rates from center pivot irrigation with current sprinkler types. Appl. Eng. Agric. 2005, 21, 605–610. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Fordjour, A.; Yuan, S.Q.; Dwomoh, F.; Ye, D.X. Evaluation of hydraulic performance characteristics of a newly designed dynamic fluidic sprinkler. Water 2018, 10, 1301. [Google Scholar] [CrossRef]

- Heermann, D.F.; Hein, P.R. Performance characteristics of self-propelled center-pivot sprinkler irrigation system. Trans. ASAE 1968, 2, 11–15. [Google Scholar] [CrossRef]

- Li, Y. Theoretical and experimental research on hydraulic performance of center pivot irrigation systems and its optimal design. Ph.D Thesis, China Agricultural University, Beijing, China, June 2016. [Google Scholar]

- Nakawuka, P.; Okwany, R.O.; Peters, T.R.; Desta, K.; Sadeghi, S.H. Efficacy of boom systems in controlling runoff under center pivots and linear move irrigation systems. Appl. Eng. Agric. 2014, 30, 797–801. [Google Scholar] [CrossRef][Green Version]

- Zhao, W.; Zhang, M.; Li, J.; Li, Y. Influence of sprinkler height on irrigation performance of center pivot irrigator. Trans. CSAE 2018, 34, 107–112. [Google Scholar] [CrossRef]

- Bjorneberg, D.L.; Aase, J.K. Multiple polyacrylamide applications for controlling sprinkler irrigation runoff and erosion. Appl. Eng. Agric. 2000, 16, 501–504. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).