The Negative Impact of Blockage on Storm Water Drainage Network

Abstract

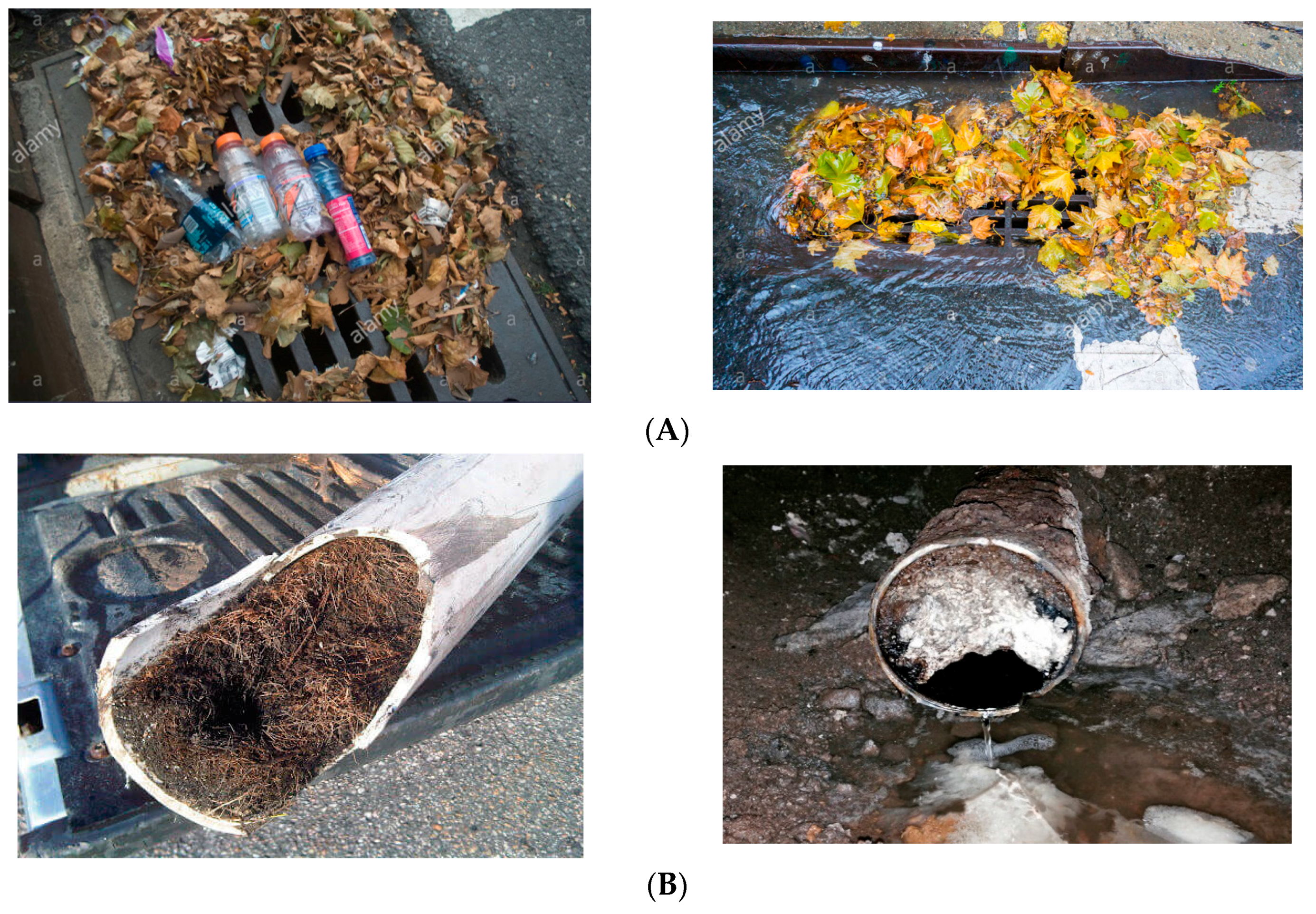

:1. Introduction

2. Materials and Methods

2.1. Dimensional Analysis

| hg: water depth at upstream grate; | Q: the total inlet discharge; |

| g1, g3, g5: refers to the grate’s number; | £: efficiency of discharge = (q/Q); |

| nag: net area of grate; | L: the length of the flume; |

| ab: blockage area of grate; | Lg: the length from the beginning of flume to the grate; |

| AB: relative blockage area (ab /nag); | Lo: relative grate length = (Lg/L); |

| hU: water depth at flume upstream; | hb: height of blockage; |

| Hg: relative water height = hg/hU; | rp: radius of main pipe; |

| Wg: the water spread beside every grate; | HB: relative blockage height within pipe (hb /2rp); |

| W: the flume width; | Lb: length of blockage; |

| Wo: relative water spread width = (Wg/W); | Lp: length of main pipe; |

| q: intercepted discharge; | LB: relative blockage length within pipe (Lb /Lp). |

2.2. Experimental Work

3. Results and Discussion

3.1. First Group: Blockage in Storm Main Pipe

3.1.1. End Pipe Blockage

3.1.2. Effect of Blockage along the Pipe Length

3.2. Second Group: Surface Blockage on Grate

3.3. Third Group: Combined Blockage (Pipe and Grate Blockage)

3.4. Summary of Results

- Relative blockage height (RBH) = 50%

- RBH = 50%, relative blockage length (RBL) = 33%

- RBH = 50%, RBL = 66%

- RBH = 50%, RBL = 100%

- RBH = 50%, RBL = 100%, relative blockage of grate area (RBGA) = 12.5%

- RBH = 50%, RBL = 100%, RBGA = 25%

- RBH = 50%, RBL = 100%, RBGA = 37.5%

- RBH = 50%, RBL = 100%, RBGA = 50%

3.5. Prediction of Efficiency

- LB = relative blockage length (decimal)

- HB = relative blockage height (decimal)

- AB = relative blockage area (decimal)

- Q = flume discharge (L/s)

- = system discharge efficiency (decimal)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Woo, D.C.; Jones, S.J. Hydraulic Characteristics of Two Bicycle Safe Grate Inlet Designs; Final Technical Report, FHWA-RD-74-77; Federal Highway Administration: Washington, DC, USA, 1974.

- Forbes, C. Capacity of Lateral Storm Water Inlets. Civ. Eng. J. 1976, 18, 195–205. [Google Scholar]

- Hotchkiss, H. Improvements in curb opening and grate inlet efficiency. Recent Res. Hydraul. Hydrol. 1994, 1471, 24–30. [Google Scholar]

- Soares, E. Analysis of the Efficiency of an Alternative South Carolina Storm Water Drainage Structure. Master’s Thesis, Clemson University, Clemson, SC, USA, 1991. [Google Scholar]

- Pezzaniti, D.; Johnson, L.; Argue, J. Road Surface Storm Water Drainage Hydraulics, New Design Information. In Proceedings of the 8th International Conference on Urban Storm Drainage, Sydney, Australia, 30 August–3 September 1999. [Google Scholar]

- Russo, B.; Gómez, M. Hydraulic Efficiency of Continuous Transverse Grates for Paved Areas. J. Irrig. Drain. Eng. 2009, 135, 225–230. [Google Scholar] [CrossRef]

- Patil, A.; Patil, J. Effects of Bad Drainage on Roads. Civ. Environ. Res. 2011, 1, 1–7. [Google Scholar]

- Comport, C.; Thornton, I. Hydraulic efficiency of grate and curb inlets for urban storm drainage. J. Hydraul. Eng. 2012, 138, 878–884. [Google Scholar] [CrossRef]

- Beniamino, R.; Manuel, V.; Jackson, A. Estimate the Hydraulic Efficiency of Non tested Continuous Transverse Grates. J. Irrig. Drain. Eng. 2013, 139, 864–871. [Google Scholar]

- Sezenöz, B.; Canan, Ö.; Ahmet, Y.; Şahnaz, T. Numerical Modelling of Continuous Transverse Grates for Hydraulic Efficiency. Master’s Thesis, Engineering Department, Middle East Technical University, Ankara, Turkey, 2014. [Google Scholar]

- Cumhur, Ö.; Gülbin, Ü.; Ahmet, Y.; Ġahnaz, T. Laboratory Investigation of Hydraulic Efficiency of Transverse Grates in Roads. Master’s Thesis, Engineering Department, Middle East Technical University, Ankara, Turkey, 2015. [Google Scholar]

- Manuel, G.; Joan, R.; Beniamino, R.; Eduardo, M. Assessment of inlet efficiency through a 3D simulation: Numerical and experimental comparison. Water Sci. Technol. 2016, 74, 1926–1935. [Google Scholar]

- Veerappan, R.; Le, J. Hydraulic efficiency of road drainage inlets for storm drainage system under clogging effect. In Proceedings of the 5th International Conference on Flood Risk Management and Response, San Servolo, Venice, Italy, 29 June–1 July 2016; Volume 165. [Google Scholar] [CrossRef] [Green Version]

- Zheng, F.; Li, Y.; Zhao, J.; An, J. Energy Dissipation in Circular Drop Manholes under Different Outflow Conditions. Water J. 2017, 9, 752. [Google Scholar] [CrossRef] [Green Version]

- Čarnogurská, M.; Příhoda, M.; Zeleňáková, M.; Lázár, M.; Brestovič, T. Modelling the Profit from Hydropower Plant Energy Generation Using Dimensional Analysis. Pol. J. Environ. Stud. 2016, 25, 73–81. [Google Scholar] [CrossRef]

- Zeleňáková, M.; Čarnogurská, M. A dimensional analysis-based model for the prediction of nitrogen concentrations in Laborec River, Slovakia. Water Environ. J. 2012, 9, 1–8. [Google Scholar] [CrossRef]

- Zeleňáková, M.; Čarnogurská, M.; Slezingr, M.; Słys, D.; Purcz, P. Model based on dimensional analysis for prediction of nitrogen and phosphorus concentrations at the river station Ižkovce, Slovakia. Hydrol. Earth Syst. Sci. 2013, 17, 201–209. [Google Scholar] [CrossRef] [Green Version]

- Tu, M.; Traver, R. Clogging Impacts on Distribution Pipe Delivery of Street Runoff to an Infiltration Bed. Water 2018, 10, 1045. [Google Scholar] [CrossRef] [Green Version]

- Vani, V.; Mohana, M.; Vanishree, D.; Subiksha, K.; Sushanthika, M. Smart Drainage System using Zig Bee and IoT. Int. J. Recent Technol. Eng (IJRTE) 2019, 8. [Google Scholar]

- Hesarkazzazi, S.; Hajibabaei, M.; Reyes-Silva, J.; Krebs, P.; Sitzenfrei, R. Assessing Redundancy in Stormwater Structures Under Hydraulic Design. Water 2020, 12, 1003. [Google Scholar] [CrossRef] [Green Version]

- Buckingham, E. On physically similar systems; illustrations of the use of dimensional equations. Phys. Rev. 1914, 4, 345–376. [Google Scholar] [CrossRef]

| HB (%) | £ For Q = 6.00 L/s and 1.00 L/s, Respectively | (£) AEOD | Efficiency Reduction % |

|---|---|---|---|

| 15% | 34.9%–76.6% | 59% | 0.93% |

| 30% | 34.2%–76.5% | 58% | 0.93% |

| 50% | 27.9%–72.8% | 53% | 6.53% |

| 70% | 15.44%–71.7% | 37% | 16.77% |

| 90% | 4.7%–29.8% | 12% | 46.49% |

| HB (%) | LB (%) | £ For Q = 6.00 L/s and 1.00 L/s, Respectively | (£) AEOD | Efficiency Reduction % |

|---|---|---|---|---|

| 25% | 33% | 35.38%–77.56% | 71% | 0.89% |

| 25% | 67% | 34.96%–76% | 56% | 3.52% |

| 25% | 100% | 25.16%–75.56 | 49% | 10.02% |

| 50% | 33% | 34.96%–75.11% | 58% | 2.49% |

| 50% | 67% | 33.78%–71.78% | 53% | 6.60% |

| 50% | 100% | 20.96%–71.56% | 44% | 15.11% |

| HB (%) | LB (%) | Relative Blockage Area (AB) | £ For Q = 6.00 L/s and 1.00 L/s, Respectively | (£) AEOD | Efficiency Reduction % |

|---|---|---|---|---|---|

| 0 | 0 | 12.5% | 25% to 66.22% | 57.67% | 2.27% |

| 0 | 0 | 25% | 34.09% to 63.7% | 55.16% | 4.78% |

| 0 | 0 | 37.5% | 31.56% to 60.36% | 50.24% | 9.70% |

| 0 | 0 | 50% | 24% to 54.75% | 42.06% | 17.88% |

| 25% | 100% | 12.5% | 24.47% to 63.86% | 48.14% | 11.80% |

| 25% | 100% | 25% | 22.87% to 59.87% | 45.96% | 13.98% |

| 25% | 100% | 37.5% | 20.13% to 56.78% | 42.15% | 17.79% |

| 25% | 100% | 50% | 20.1% to 51.25% | 38.29% | 21.65% |

| 50% | 100% | 12.5% | 20.49% 64.56% | 42.19% | 17.75% |

| 50% | 100% | 25% | 19.96% to 61.67% | 40.66% | 19.28% |

| 50% | 100% | 37.5% | 19.11% to 59.22% | 38.99% | 20.95% |

| 50% | 100% | 50% | 18.36% to 50% | 35.34% | 24.60% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fathy, I.; Abdel-Aal, G.M.; Fahmy, M.R.; Fathy, A.; Zeleňáková, M. The Negative Impact of Blockage on Storm Water Drainage Network. Water 2020, 12, 1974. https://doi.org/10.3390/w12071974

Fathy I, Abdel-Aal GM, Fahmy MR, Fathy A, Zeleňáková M. The Negative Impact of Blockage on Storm Water Drainage Network. Water. 2020; 12(7):1974. https://doi.org/10.3390/w12071974

Chicago/Turabian StyleFathy, Ismail, Gamal M. Abdel-Aal, Maha Rashad Fahmy, Amira Fathy, and Martina Zeleňáková. 2020. "The Negative Impact of Blockage on Storm Water Drainage Network" Water 12, no. 7: 1974. https://doi.org/10.3390/w12071974

APA StyleFathy, I., Abdel-Aal, G. M., Fahmy, M. R., Fathy, A., & Zeleňáková, M. (2020). The Negative Impact of Blockage on Storm Water Drainage Network. Water, 12(7), 1974. https://doi.org/10.3390/w12071974