Adsorption of Patent Blue V from Textile Industry Wastewater Using Sterculia alata Fruit Shell Biochar: Evaluation of Efficiency and Mechanisms

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials (Adsorbate and Adsorbent)

2.2. Preparation of Biochar

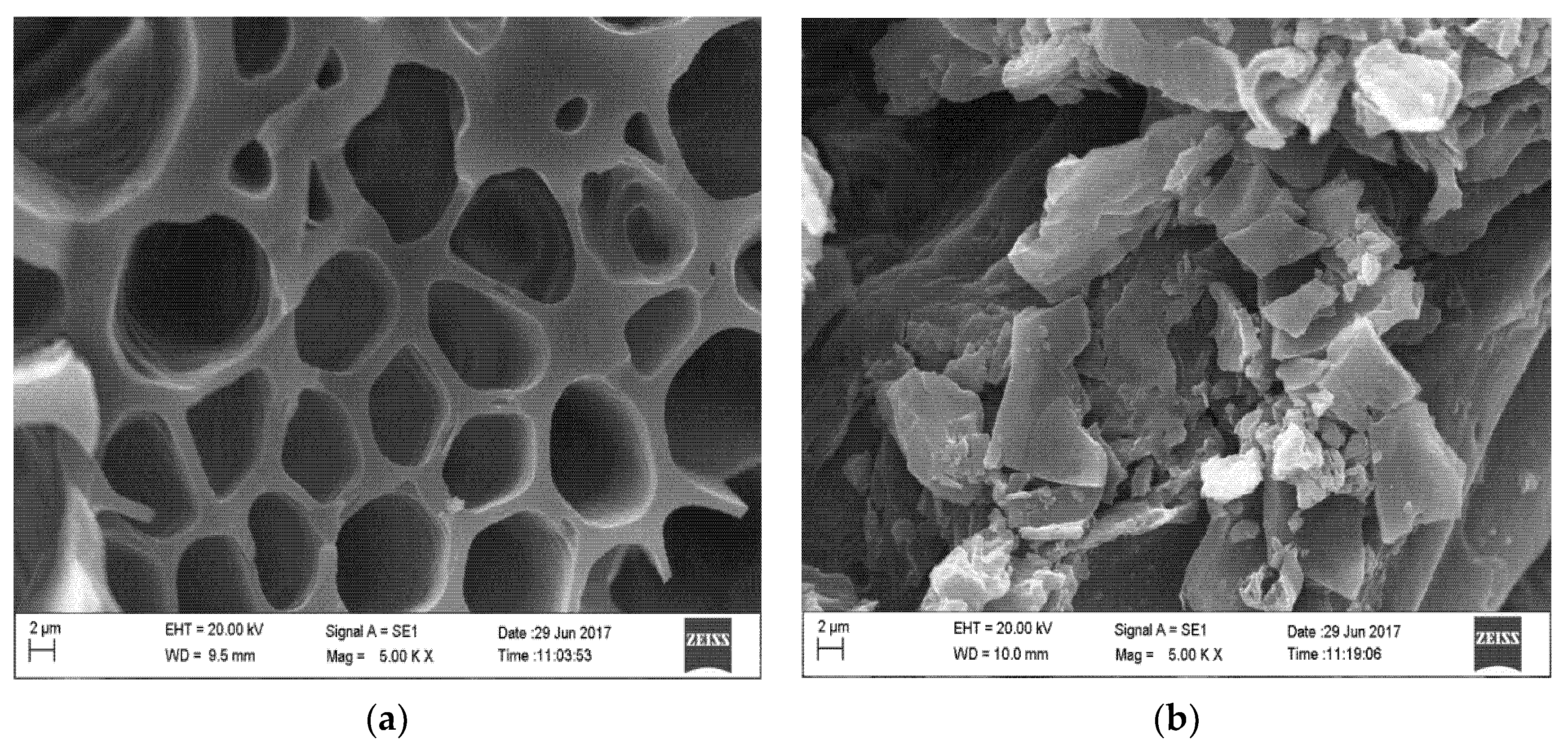

2.3. Characterization of Biochar and Sterculia alata Biomass

2.4. Batch Adsorption Tests

2.5. Adsorption Isotherm Models

2.6. Adsorption Kinetics Studies

3. Result and Discussion

3.1. Production of Biochar and Its Characterization

3.2. Optimization of the Process Conditions for Maximum Removal of Dye

3.2.1. Effect of pH on the Adsorption of Dye

3.2.2. Effect of Adsorbent Dosage

3.2.3. Effect of Initial Dye Concentration

3.2.4. Effect of Contact Time and Temperature

3.2.5. Development of the Adsorption Isotherm

3.2.6. Identification of a Suitable Kinetic Model

3.2.7. Effect of Point of Zero Charge

3.3. Proposed Mechanism for the Adsorption of PB Dye on the Sterculia alata Fruit Shell Surface

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- El-Qada, E.N.; Allen, S.; Walker, G. Adsorption of basic dyes from aqueous solution onto activated carbons. Chem. Eng. J. 2008, 135, 174–184. [Google Scholar] [CrossRef]

- Vikrant, K.; Giri, B.S.; Raza, N.; Roy, K.; Kim, K.H.; Rai, B.N.; Singh, R.S. Recent advancements in bioremediation of dye: Current status and challenges. Bioresour. Technol. 2018, 253, 355–367. [Google Scholar] [CrossRef] [PubMed]

- Mathur, N.; Bhatnagar, P.; Bakre, P. Assessing mutagenicity of textile dyes from Pali (Rajathan) using AMES bioassay. Appl. Ecol. Env. Res. 2005, 4, 111–118. [Google Scholar] [CrossRef]

- Gong, R.; Ye, J.; Dai, W.; Yan, X.; Hu, J.; Hu, X.; Li, S.; Huang, H. Adsorptive removal of methyl orange and methylene blue from aqueous solution with finger-citron-residue-based activated carbon. Ind. Eng. Chem. Res. 2013, 52, 14297–14303. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Zhou, M.; Oturan, M.A. An overview on the removal of synthetic dyes from water by electrochemical advanced oxidation processes. Chemosphere 2018, 197, 210–227. [Google Scholar] [CrossRef]

- Kureel, M.K.; Geed, S.R.; Giri, B.S.; Shukla, A.K.; Rai, B.N.; Singh, R.S.M. Removal of aqueous benzene in the immobilized batch and continuous packed bed bioreactor by isolated Bacillus sp. M1. Resour. Effic. Technol. 2016, 2, S87–S95. [Google Scholar] [CrossRef]

- Kanjanarong, J.; Giri, B.S.; Jaisi, D.P.; Oliveira, F.R.; Boonsawang, P.; Chaiprapat, S.; Singh, R.S.; Balakrishna, A.; Khanal, S.K. Removal of hydrogen sulfide generated during anaerobic treatment of sulfate-laden wastewater using biochar: Evaluation of efficiency and mechanisms. Bioresour. Technol. 2017, 234, 115–121. [Google Scholar] [CrossRef]

- Talha, M.A.; Goswami, M.; Giri, B.S.; Sharma, A.; Rai, B.N.; Singh, R.S. Bioremediation of Congo red dye in immobilized batch and continuous packed bed bioreactor by Brevibacillus parabrevis using coconut shell bio-char. Bioresour. Technol. 2018, 252, 37–43. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, C.; Shu, Y.; Yan, X.; Li, L. Utilization of diatomite/chitosan-Fe (III) composite for the removal of anionic azo dyes from wastewater: Equilibrium, kinetics and thermodynamics. Colloids Surf. A 2015, 468, 129–139. [Google Scholar] [CrossRef]

- Garg, V.K.; Gupta, R.; Yadav, A.B.; Kumar, R. Dye removal from aqueous solution by adsorption on treated sawdust. Bioresour. Technol. 2003, 89, 121–124. [Google Scholar] [CrossRef]

- Gautam, U.K.; Panchakarla, L.S.; Dierre, B.; Fang, X.; Bando, Y.; Sekiguchi, T.; Govindaraj, A.; Golberg, D.; Rao, C.N.R. Solvothermal synthesis, cathodoluminescence, and field-emission properties of pure and N-doped ZnO nano bullets. Adv. Funct. Mater. 2009, 19, 131–141. [Google Scholar] [CrossRef]

- Chen, R.; Wang, W.; Zhao, X.; Zhang, Y.; Wu, S.; Li, F. Rapid hydrothermal synthesis of magnetic CoxNi1_xFe2O4 nanoparticles and their application on removal of Congo red. Chem. Eng. Sci. 2014, 242, 226–233. [Google Scholar] [CrossRef]

- Vikrant, V.; Kim, K.H.; Szulejko, J.E.; Pandey, S.K.; Singh, R.S.; Giri, B.S.; Brown, R.J.C.; Lee, S.H. Bio-filters for the treatment of VOCs and odors-A review. Asian J. Atmos. Environ. (AJAE) 2017, 11, 139–152. [Google Scholar] [CrossRef]

- Vikrant, K.; Kim, K.H.; Ok, Y.S.; Tsang, D.C.W.; Tsang, Y.F.; Giri, B.S.; Singh, R.S. Engineered/designer biochar for the removal of phosphate in water and wastewater. Sci. Total Environ. 2018, 616, 1242–1260. [Google Scholar] [CrossRef] [PubMed]

- Giri, B.S.; Goswami, M.; Singh, R.S. Review on application of agro-waste biomass biochar for adsorption and bioremediation dye. Biomed. J. Sci. Tech. Res. 2017, 1, 1–3. [Google Scholar]

- Bharti, V.; Shahi, A.; Geed, S.R.; Kureel, M.K.; Rai, B.N.; Kumar, S.; Giri, B.S.; Singh, R.S. Biodegradation of reactive orange 16 (RO-16) dye in packed bed bioreactor using seeds of Ashoka and Casuarina as packing medium. Indian J. Biotechnol. 2017, 16, 216–221. [Google Scholar]

- Roy, K.; Verma, K.M.; Vikrant, K.; Goswami, M.; Sonwani, R.K.; Rai, B.N.; Vellingiri, K.; Kim, K.H.; Giri, B.S.; Singh, R.S. Removal of Patent Blue (V) Dye using Indian bael shell biochar: Characterization, application and kinetic studies. Sustainability 2018, 10, 2669. [Google Scholar] [CrossRef] [Green Version]

- Rai, M.K.; Giri, B.S.; Nath, Y.; Bajaj, H.; Soni, S.; Singh, R.P.; Singh, R.S.; Rai, B.N. Adsorption of hexavalent chromium from aqueous solution by activated carbon prepared from almond shell: Kinetics, equilibrium and thermodynamics study. J. Water Supply: Res. Technol. (Aqua) 2018, 67, 724–737. [Google Scholar] [CrossRef]

- Kumar, M.; Giri, B.S.; Kim, K.H.; Singh, R.P.; Rene, E.R.; López, M.E.; Rai, B.N.; Singh, H.; Prasad, D.; Singh, R.S. Performance of a biofilter with compost and activated carbon based packing material for gas-phase toluene removal under extremely high loading rates. Bioresour. Technol. 2019, 285, 121317. [Google Scholar] [CrossRef]

- Chaukura, N.; Murimba, E.C.; Gwenzi, W. Synthesis, characterization and methyl orange adsorption capacity of ferric oxide-biocharnano-composites derived from pulp and paper sludge. Appl. Water Sci. 2017, 7, 2175–2186. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Hung, I.; Gan, Z.; Rojas, O.J.; Lim, K.H.; Park, S. Activated carbon from biochar: Influence of its physicochemical properties on the sorption characteristics of phenanthrene. Bioresour. Technol. 2013, 149, 383–389. [Google Scholar] [CrossRef]

- Singhania, R.R.; Patel, A.K.; Thomas, L.; Goswami, M.; Giri, B.S.; Pandey, A. Industrial enzymes. In Industrial Biorefineries & White Biotechnology; Pandey, A., Höfer, R., Taherzadeh, M., Nampoothiri, M., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 473–497. [Google Scholar]

- Singh, K.; Giri, B.S.; Sahi, A.; Geed, S.R.; Kureel, M.K.; Singh, S.; Dubey, S.K.; Rai, B.N.; Kumar, S.; Upadhyay, S.N.; et al. Biofiltration of xylene using wood charcoal as the biofilter media under transient and high loading conditions. Bioresour. Technol. 2017, 242, 351–358. [Google Scholar] [CrossRef]

- Yan, X.M.; Shi, B.Y.; Lu, J.J.; Feng, C.H.; Wang, D.S.; Tang, H.X. Adsorption and desorption of atrazine on carbon nanotubes. J. Colloid Interface Sci. 2008, 321, 30–38. [Google Scholar] [CrossRef]

- Ncibi, M.C.; Mahjouba, B.; Hamissaa, A.M.B.; Mansourc, R.B.; Seffena, B. Studies on the biosorption of textile dyes from aqueous solutions using Posidonia ceanica. J. Hazard. Mater. 2007, 139, 280–285. [Google Scholar] [CrossRef]

- Aysan, H.; Edebali, S.; Karakayaet, N. Use of chabazite, a naturally abundant zeolite, for the investigation of the adsorption kinetics and mechanism of methylene blue dye. Micropor. Mesopor. Mat. 2016, 235, 78–86. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, C.; Zhao, J.; Ma, L.; Sun, S.; Zhaoa, C. Polyethersulfone enwrapped graphene oxide porous particles for water treatment. Chem. Eng. J. 2013, 215–216, 72–81. [Google Scholar] [CrossRef]

- Rahimi, S.; Moattari, R.M.; Rajabi, L.; Derakhshan, A.A.; Keyhani, M. Iron oxide/hydroxide (a, c-FeOOH) nanoparticles as high potential adsorbents for lead removal from polluted aquatic media. J. Ind. Eng. Chem. 2015, 23, 33–43. [Google Scholar] [CrossRef]

- Ahmad, R.; Kumar, R. Adsorption study of patent blue VF using ginger waste material. J. Iran. Chem. Res. 2008, 1, 85–94. [Google Scholar]

- Desta, M.B. Batch sorption experiments: Langmuir and Freundlich isotherm studies for the adsorption of textile metal ions onto teff straw (Eragrostistef) agricultural waste. J. Thermodyn. 2013, 2013, 375830. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.M.R.; Mukhlish, M.Z.B.; Mazumder, M.S.I.; Ferdous, K.; Prasad, D.M.R.; Hassan, Z. Uptake of Indosol Dark-blue GL dye from aqueous solution by water hyacinth roots powder: Adsorption and desorption study. Int. J. Environ. Sci. Technol. 2014, 11, 1027–1034. [Google Scholar] [CrossRef] [Green Version]

- Ghani, W.A.W.A.K.; Mohd, A.; Mahmoud, D.K.; Rebitanim, N.Z.; Sanyang, L.; Zainudin, R.B. Adsorption of methylene blue on sawdust-derived biochar and its adsorption isotherms. J. Purity Utility React. Environ. 2013, 2, 34–50. [Google Scholar]

- Caglar, E.; Donar, Y.O.; Sinag, A.; Birogul, I.; Bilge, S.; Aydincak, K.; Pliekhov, O. Adsorption of anionic and cationic dyes on biochars, produced by hydrothermal carbonization of waste biomass: Effect of surface functionalization and ionic strength. Turk. J. Chem. 2018, 42, 86–99. [Google Scholar] [CrossRef]

- Al-Degs, Y.S.; El-Barghouthi, M.I.; El-Sheikh, A.H.; Walker, G.M. Effect of solution pH, ionic strength, and temperature on adsorption behavior of reactive dyes on activated carbon. Dyes. Pigm. 2008, 77, 16–23. [Google Scholar] [CrossRef]

- Lee, C.R.; Kim, H.S.; Jang, I.H.; Im, J.H.; Park, N.J. Pseudo first-order adsorption kinetics of N719 dye on TiO2 surface. ACS Appl. Mater. Interfaces 2011, 3, 1953–1957. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Khan, N.; Giri, B.S.; Chowdhary, P.; Chaturvedi, P. Removal of methylene blue dye using rice husk, cow dung and sludge biochar: Characterization, application, and kinetic studies. Bioresour. Technol. 2020, 306, 123202. [Google Scholar] [CrossRef] [PubMed]

- Khan, N.; Chowdhary, P.; Ahmad, A.; Giri, B.S.; Chaturvedi, P. Hydrothermal liquefaction of rice husk and cow dung in mixed-bed-rotating pyrolyzer and application of biochar for dye removal. Bioresour. Technol. 2020, 309, 123294. [Google Scholar] [CrossRef]

- Goswami, M.; Chaturvedi, P.; Sonwani, R.K.; Gupta, A.D.; Singhania, R.R.; Giri, B.S.; Rai, B.N.; Singh, H.; Yadav, S.; Singh, R.S. Application of Arjuna (Terminalia arjuna) seed biochar in hybrid treatment system for the bioremediation of Congo red dye. Bioresour. Technol. 2020, 307, 123203. [Google Scholar] [CrossRef]

- Mittal, H.; Mishra, S.B. Gum ghatti and Fe3O4 magnetic nanoparticles based nanocomposites for the effective adsorption of rhodamine B. Carbohydr. Polym. 2014, 101, 1255–1264. [Google Scholar] [CrossRef]

- El-Said, A.G.; Badawy, N.A.; Abdel-Aal, A.Y.; Garamon, S.E. Optimization parameters for adsorption and desorption of Zn(II) and Se(IV) using rice husk ash: Kinetics and equilibrium. Ionics 2011, 17, 263–270. [Google Scholar] [CrossRef]

- Ruziwa, D.; Chaukura, N.; Gwenzi, W.; Pumure, I. Removal of Zn2+ and Pb2+ ions from aqueous solution using sulphonated waste polystyrene. J. Environ. Chem. Eng. 2015, 3, 2528–2537. [Google Scholar] [CrossRef]

- Yu, B.; Xu, J.; Liu, J.H.; Yang, S.T.; Luo, J.; Zhoua, Q.; Wan, J.; Liao, R.; Wang, H.; Liu, Y. Adsorption behavior of copper ions on graphene oxide-chitosan aero gel. J. Environ. Chem. Eng. 2013, 1, 1044–1050. [Google Scholar] [CrossRef]

| Elements | Biochar | Biomass | ||

|---|---|---|---|---|

| Weight % | Atomic % | Weight % | Atomic % | |

| C | 72.4 | 78.7 | 52.7 | 61.5 |

| N | 6.38 | 5.95 | 0 | 0 |

| O | 16.7 | 13.6 | 41.6 | 36.5 |

| P | 0.52 | 0.22 | 0 | 0 |

| K | 2.76 | 0.92 | 5.71 | 2.05 |

| Mg | 0.60 | 0.32 | 0 | 0 |

| Ca | 0.68 | 0.22 | 0 | 0 |

| Biochar before Adsorption | Biomass before Adsorption | Biochar after Adsorption | Biomass after Adsorption | ||||

|---|---|---|---|---|---|---|---|

| Wavelength (cm−1) | Bond Type | Wavelength (cm−1) | Bond Type | Wavelength (cm−1) | Bond Type | Wavelength (cm−1) | Bond Type |

| 3594.4 | O-H (free) | 3349.1 | Weak N-H (2°amine) | 3218.7 | O-H (H bonded) | 3649.2 | O-H (free) |

| 3219.8 | O-H (bonded) | 2900.6 | CH3, CH2 & CH, O-H (very broad) | 2930.2 | CH3, CH2, CH ( 2 or 3 bands) | 3299.8 | O-H (bending) |

| 2699.3 | C-H (aldehydes C-H) | 2153.7 | Si-H silane,-M=C=O, N=C=S | 1971.9 | C=C (asymmetric stretch) | 3045.2 | =C-H & =CH2 |

| 2258.6 | C≡N (sharp) | 1728.6 | C=O (saturated aldehyde) | 1728.3 | C=O (saturated aldehydes) | 2938.2 | CH3, CH2, CH |

| 1538.6 | NH2 scissoring | 1440.3 | CH2-CH3 (bending) (1°amine) | 1651.3 | C=O (amide) | 2346.4 | Si-H silane, P-H |

| 1435.8 | -CH2 bending | 1019.6 | P-H bending P-OR esters, Si-OR | 1425.5 | -CH2 bending | 1565.4 | NH2 scissoring |

| 876.7 | =C-H & = CH2 | 889.3 | S-OR esters | 1043.1 | C-O-H bending | 1421.1 | -CH2 bending, C-O-H |

| 722.7 | C-H bending & ring | 714.5 | S-OR esters | 689.2 | C-O, C-N | 1195.0 | C-N, C-O, C=S, |

| 567.8 | C-H deformation | 514.3 | S-S (disulfide) | 1049.3 | P-H bending, S=O | ||

| 847.3 | C-H bending & puckering | ||||||

| Biochar | Adsorption Capacity (mg/g) | Type of Dye | References |

|---|---|---|---|

| Activated carbon derived from finger citron residue (FAC) | 934.58 | Methylene Orange | [4] |

| Activated carbon derived from finger citron residue (FAC) | 581.40 | Methylene Blue | [4] |

| Sawdust of the rubber wood (Heveabrasilensis) | 333.33 | Methylene Blue | [33] |

| Cellulose-based and NaOH—functionalized biochar | 234.57 | Methylene Blue | [34] |

| Glucose-based H2SO4—functionalized biochar | 306.13 | Methyl Orange | [34] |

| Ginger waste material (GWM) | 9.560 | Patent Blue V | [29] |

| Sterculia alata | 11.36 | Patent Blue V | This study |

| Model/Kinetics | Parameters and Units | Values |

|---|---|---|

| Freundlich isotherm | Kf (mg/g) | 0.97 |

| N | 4.55 | |

| Langmuir isotherm | R2 | 0.894 |

| Kl (mg/g) | 0.0706 | |

| First order kinetics | Kf (mg/g) | 0.336 |

| R2 | 0.911 | |

| Second order kinetics | Ks (mg/g) | 0.002 |

| R2 | 0.884 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giri, B.S.; Goswami, M.; Kumar, P.; Yadav, R.; Sharma, N.; Sonwani, R.K.; Yadav, S.; Singh, R.P.; Rene, E.R.; Chaturvedi, P.; et al. Adsorption of Patent Blue V from Textile Industry Wastewater Using Sterculia alata Fruit Shell Biochar: Evaluation of Efficiency and Mechanisms. Water 2020, 12, 2017. https://doi.org/10.3390/w12072017

Giri BS, Goswami M, Kumar P, Yadav R, Sharma N, Sonwani RK, Yadav S, Singh RP, Rene ER, Chaturvedi P, et al. Adsorption of Patent Blue V from Textile Industry Wastewater Using Sterculia alata Fruit Shell Biochar: Evaluation of Efficiency and Mechanisms. Water. 2020; 12(7):2017. https://doi.org/10.3390/w12072017

Chicago/Turabian StyleGiri, Balendu Shekher, Mandavi Goswami, Prabhat Kumar, Rahul Yadav, Neha Sharma, Ravi Kumar Sonwani, Sudeep Yadav, Rajendra Prasad Singh, Eldon R. Rene, Preeti Chaturvedi, and et al. 2020. "Adsorption of Patent Blue V from Textile Industry Wastewater Using Sterculia alata Fruit Shell Biochar: Evaluation of Efficiency and Mechanisms" Water 12, no. 7: 2017. https://doi.org/10.3390/w12072017

APA StyleGiri, B. S., Goswami, M., Kumar, P., Yadav, R., Sharma, N., Sonwani, R. K., Yadav, S., Singh, R. P., Rene, E. R., Chaturvedi, P., & Singh, R. S. (2020). Adsorption of Patent Blue V from Textile Industry Wastewater Using Sterculia alata Fruit Shell Biochar: Evaluation of Efficiency and Mechanisms. Water, 12(7), 2017. https://doi.org/10.3390/w12072017