Static Liquefaction Capacity of Saturated Undisturbed Loess in South Jingyang Platform

Abstract

:1. Introduction

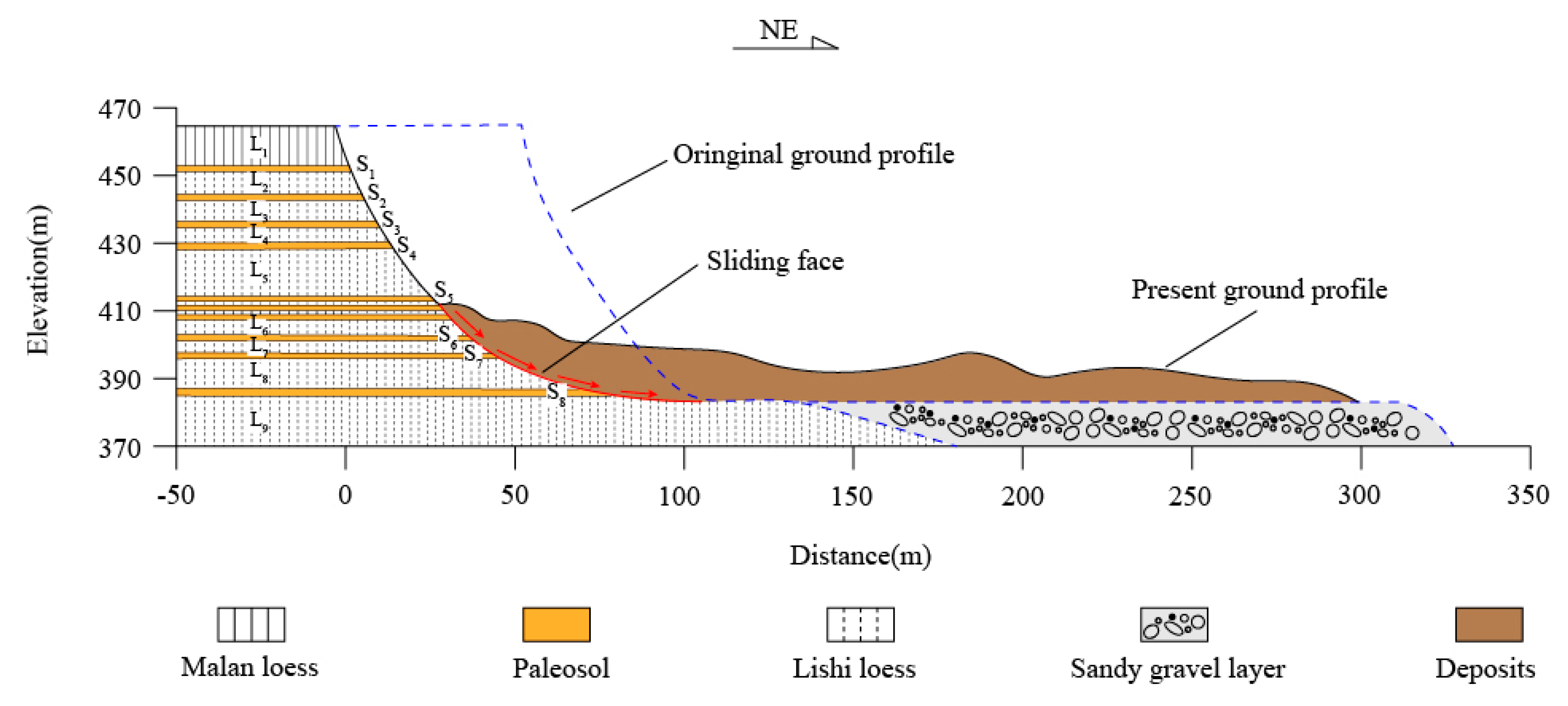

2. Development Characteristics of the Landslide and the Correlation Analysis with Static Liquefaction

3. Experimental Samples and Process

3.1. Experimental Samples

3.2. Experimental Process

- (1)

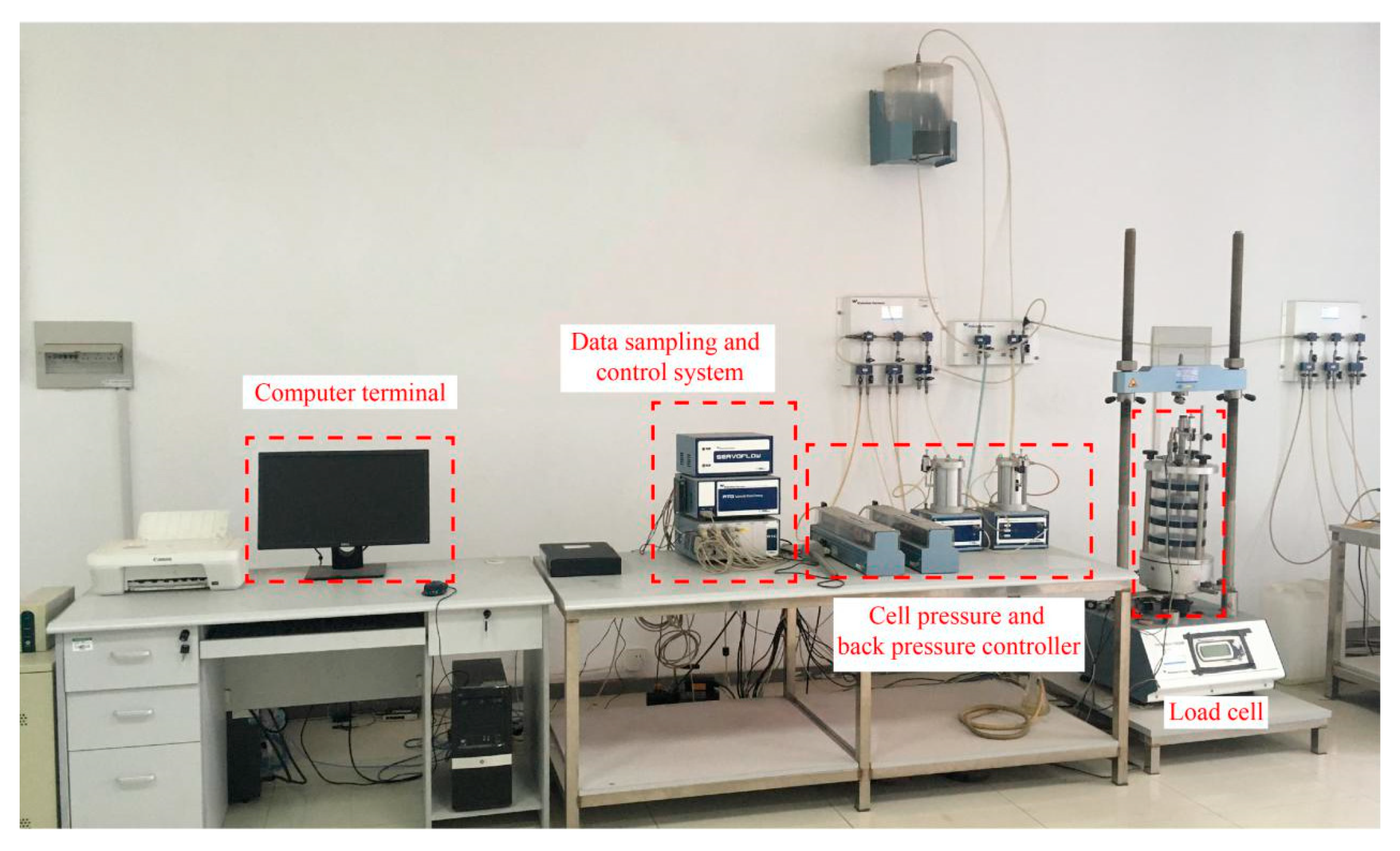

- The undisturbed loess samples were molded into Φ50 mm × 100 mm cylinders according to the requirements of the standard for the soil test method (GB/T 50123-1999) [28]; and these cylinders were placed in the load cell of the Wykeham Farrance (WF, Wykeham Farrance, Milan, Italy) stress path triaxial apparatus (Figure 4). After connecting the pressure sensor, pore water pressure sensor, cell pressure controller, and the back pressure controller with the corresponding port of the load cell, the WF stress path triaxial apparatus was used to carry out the back pressure saturation treatment on the undisturbed loess. ① A 50 kPa cell pressure was applied to the samples, and the back pressure was set at 10 kPa lower than the cell pressure to prevent structural damage of the samples caused by the pore water pressure, which is higher than the confining pressure. After the back pressure inflow was stable, the back pressure was kept constant for 6–8 h to make the water gradually infiltrate the samples. ② Under the premise of ensuring that the cell pressure was 10 kPa higher than the back pressure, the cell pressure and back pressure were applied to the samples step by step. Each stage was increased by 50 kPa and it remained for 6–8 h before conducting the next stage. ③ When the B value was higher than 0.95, the samples were considered to be saturated. Multiple tests showed that the undisturbed loess samples generally required an applied back pressure that ranged from 190 to 240 kPa, and in 1–2 days to ensure that the soil sample reached the saturation state.

- (2)

- To reflect the discrepancy in the static liquefaction characteristics of the undisturbed loess under the different confining pressures (σc′), four confining pressures (150 kPa, 250 kPa, 350 kPa, and 450 kPa, corresponding to the numbers 1–4, respectively, for the ZT and STW loess) were selected. After the saturation of the loess (B ≥ 0.95), the cell pressure and back pressure (the cell pressures were 150 kPa, 250 kPa, 350 kPa, and 450 kPa higher than the back pressure) were set appropriately to ensure that the sample would be isotropically consolidated under four confining pressures. When the confining pressure attained the set value and remained stable, the drainage valve was opened to start the consolidation. In the consolidation process, the pore water pressure and volumetric strain changed rapidly at first and then it tended to be gradually stable. When the pore water pressure dissipated to more than 95% and the volumetric strain remained stable, the consolidation was completed.

- (3)

- After the back pressure saturation and isotropic consolidation, undrained triaxial tests were conducted with a 0.1 mm/min shear rate, according to the relevant provisions of the standard for the soil test methods (GB/T 50123-1999) [28]. To observe the strength change characteristics after the peak value more clearly, a 25% axial strain was taken as the termination condition of these tests.

- (4)

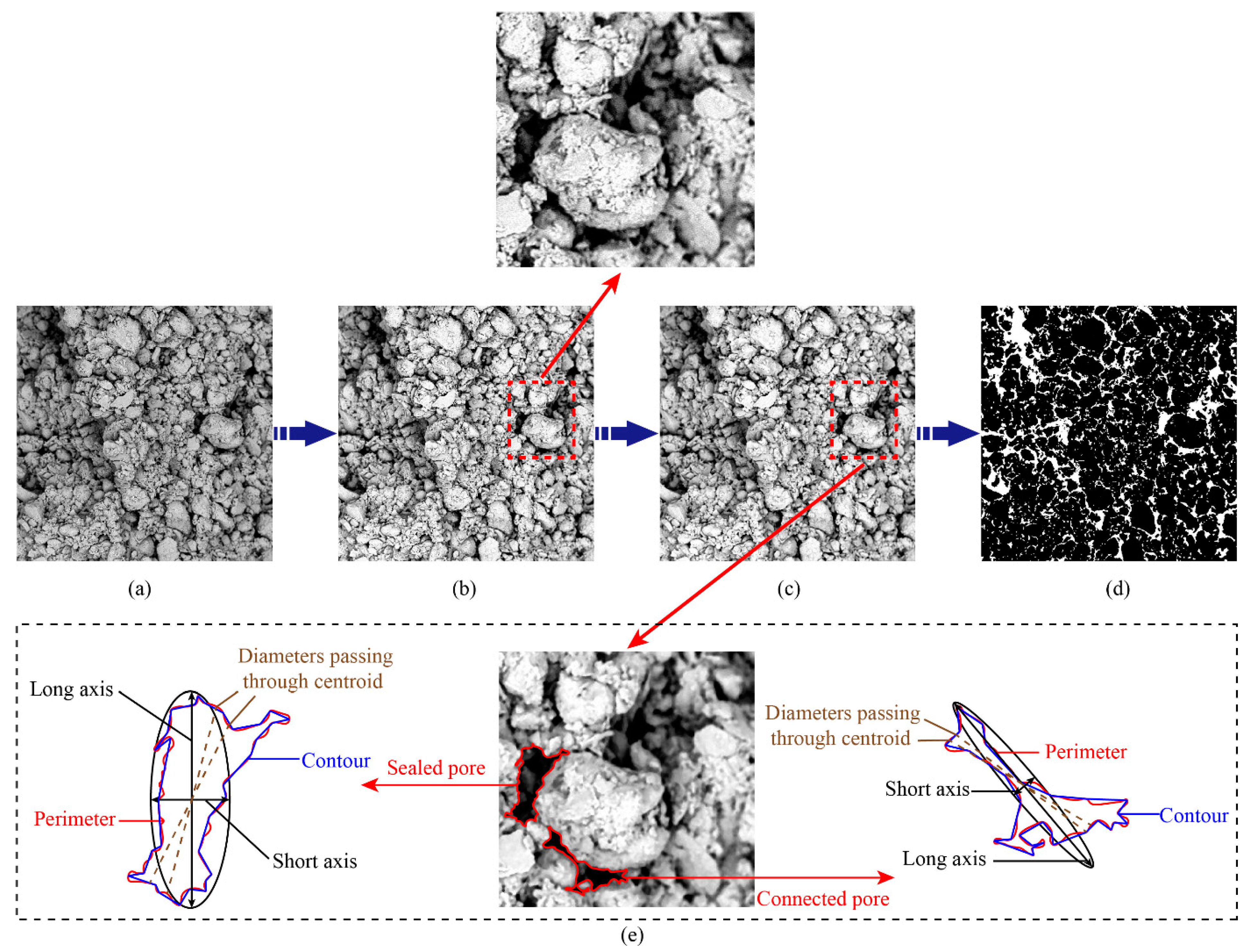

- For preparing the cylindrical samples for the ICU tests, cube samples with a side length of 1–2 cm had to be fabricated. Freeze-drying and section gold spraying treatments were performed successively on the cube samples. Then, the samples were placed under a field emission scanning electron microscope (JSM-7610F) and observed under different magnifications (500× and 2000×). The 500× magnification was used for observing the overall pore structure of the section, and 2000× magnification was used for observing of the occurrence and contact arrangement of the different particles. Five areas were randomly scanned at each magnification.

4. Results

4.1. Macroscopic Characteristics Analysis of the Shear Failure and Static Liquefaction

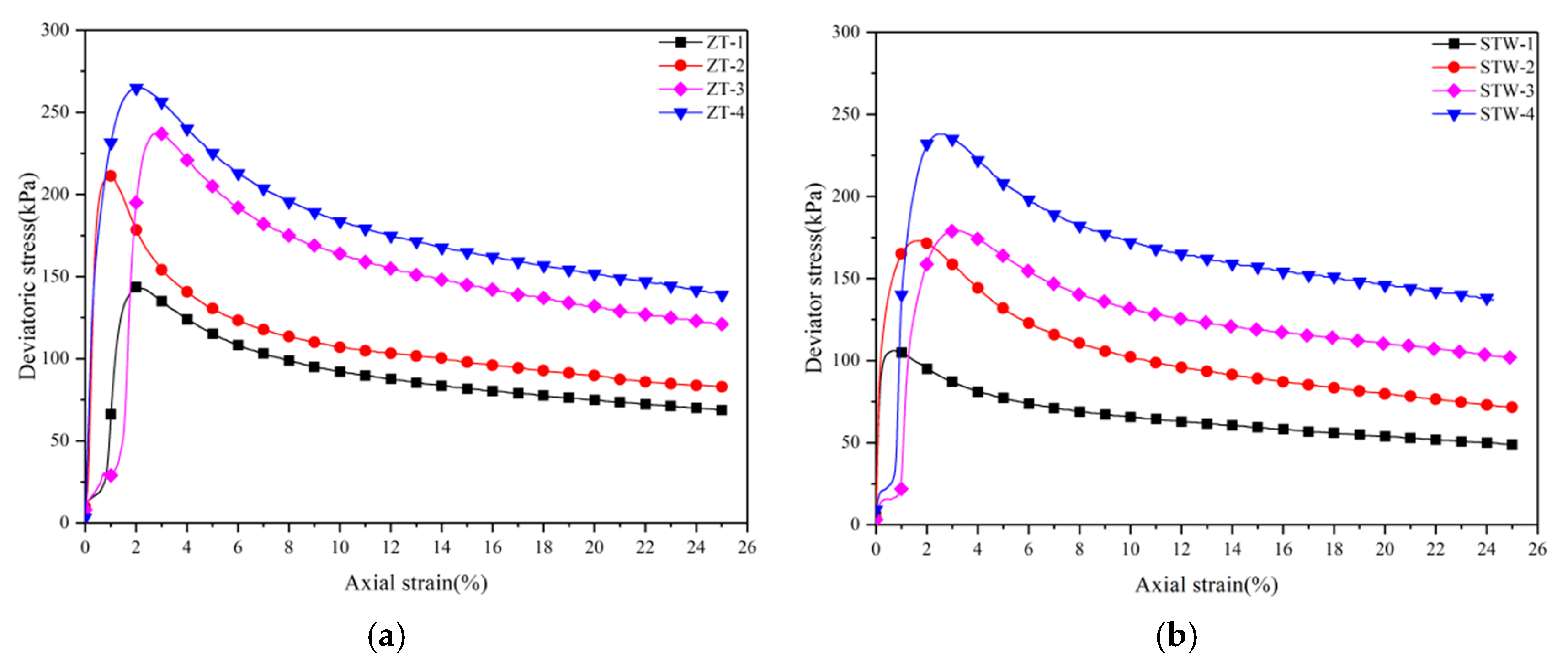

4.1.1. Stress-Strain Characteristics Analysis

- (1)

- Rapid strain hardening stage: At the initial stage of loading, when the axial strain is very small (εa < 3%), the deviator stress rises rapidly and reaches the peak value. The stress-strain curve of this stage is close to the straight line. The larger the confining pressure is, the greater the deviator stress peak value is. The stress-strain curves in this stage indicate that the internal spaced pore structure is compressed under the action of the external load, and that the contact between the particles is closer [29].

- (2)

- Rapid strain softening stage: When the peak strength is reached, the deviator stress decreases sharply, and the corresponding axial strain is about 1–3%. This indicates that the spaced pore structure may be damaged after compression with the increase in strain, and the ability to resist deformation is evidently weakened. There is a strain threshold (εap) between the compression and the failure of the pore structure, which reflects that the structural loess requires a certain compression deformation to undergo structural failure. The stress-strain curves of the ZT and STW loess show that εap is always in a certain range (generally between 1 and 3%). The stress-strain curves of the undisturbed loess in the South Jingyang platform provide similar results [9,12,15,30].

- (3)

- Stable strain softening stage: When the axial strain reaches a certain value (εa = 10–15%), the stress tends to be stable with an increase in the strain. This shows that the strength of the soil structure softens after it has been destroyed. The clay aggregates, which are inlaid with the large framework of the silt particles, may gradually fall into the pore throat channel; this results in the reorganization of the loess structure [16]. With the continuous increase in the strain, the reorganization process of the loess structure tends to be stable, and its initial structure is completely destroyed under the action of the shear stress. In addition, the new orientation arrangement has statistically reached a stable state [31]. Therefore, in the ICU tests of the saturated undisturbed loess, when the axial strain reaches 10–15%, the loess is considered to undergo steady-state deformation. When the loess reaches a steady state, its shear resistance is known as the steady-state strength [32]. Compared with its peak strength, the steady-state strength is about 0.4–0.6. Therefore, there is the possibility of static liquefaction. The above structural changes can also find the corresponding intuitive evidence in the later microstructure morphology analysis.

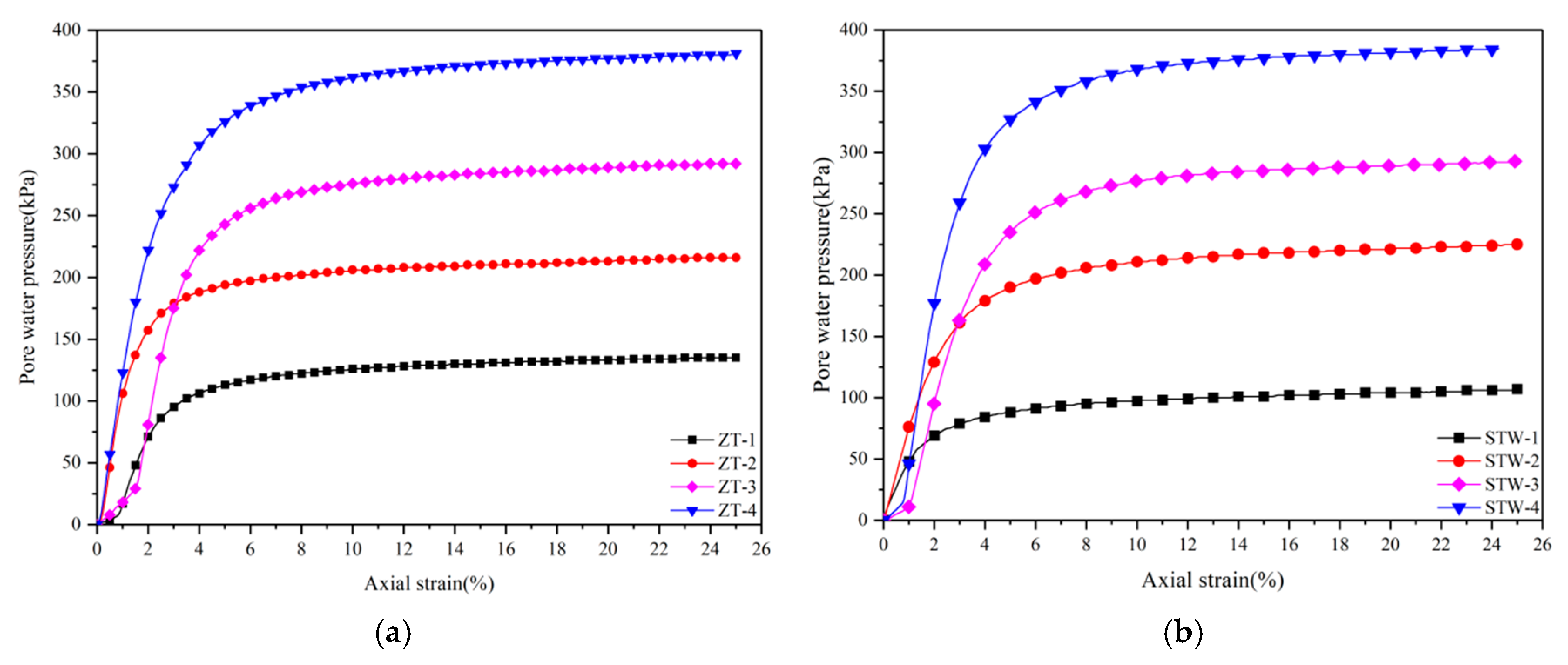

4.1.2. Variation Analysis of the Pore Water Pressure

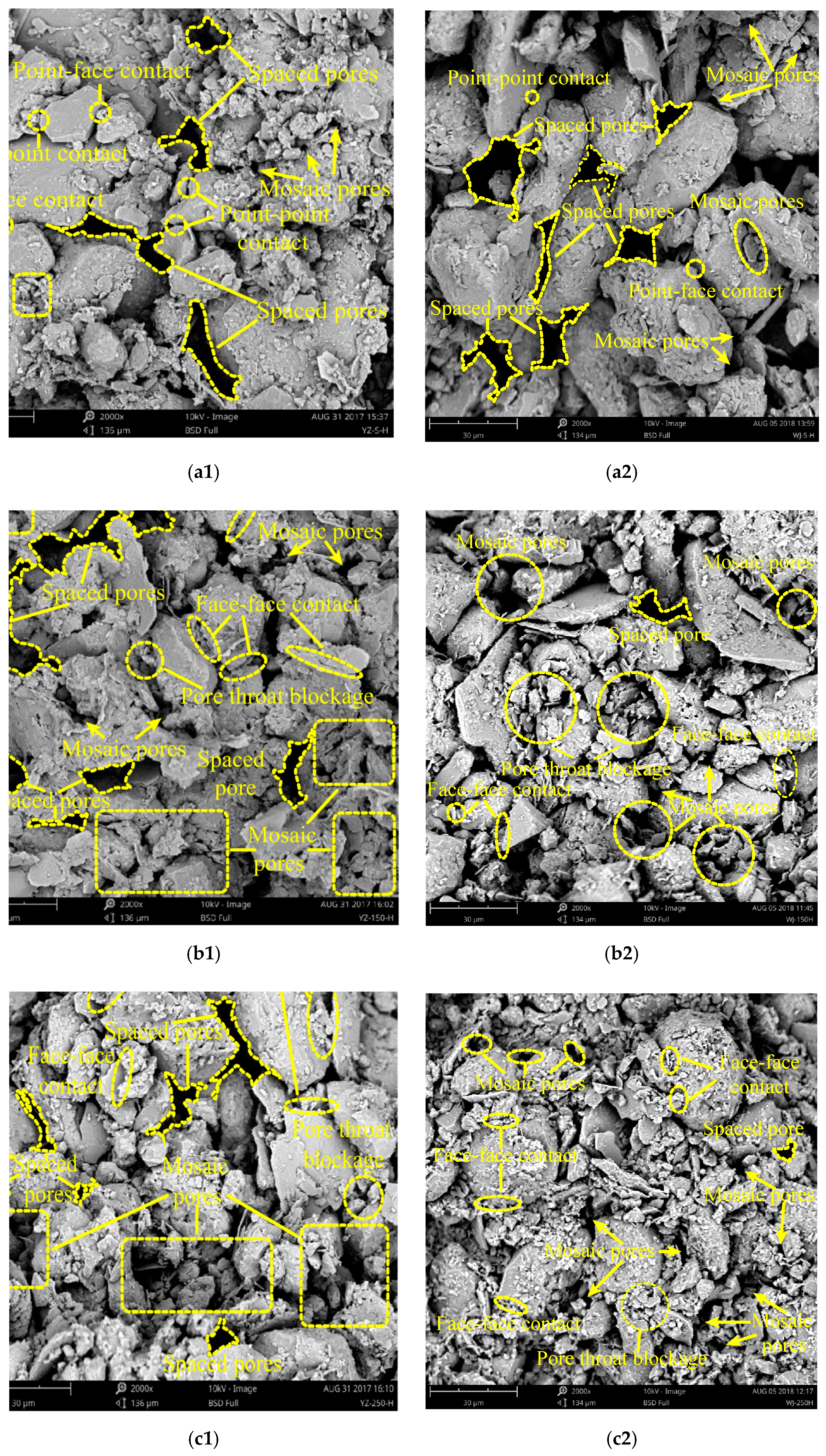

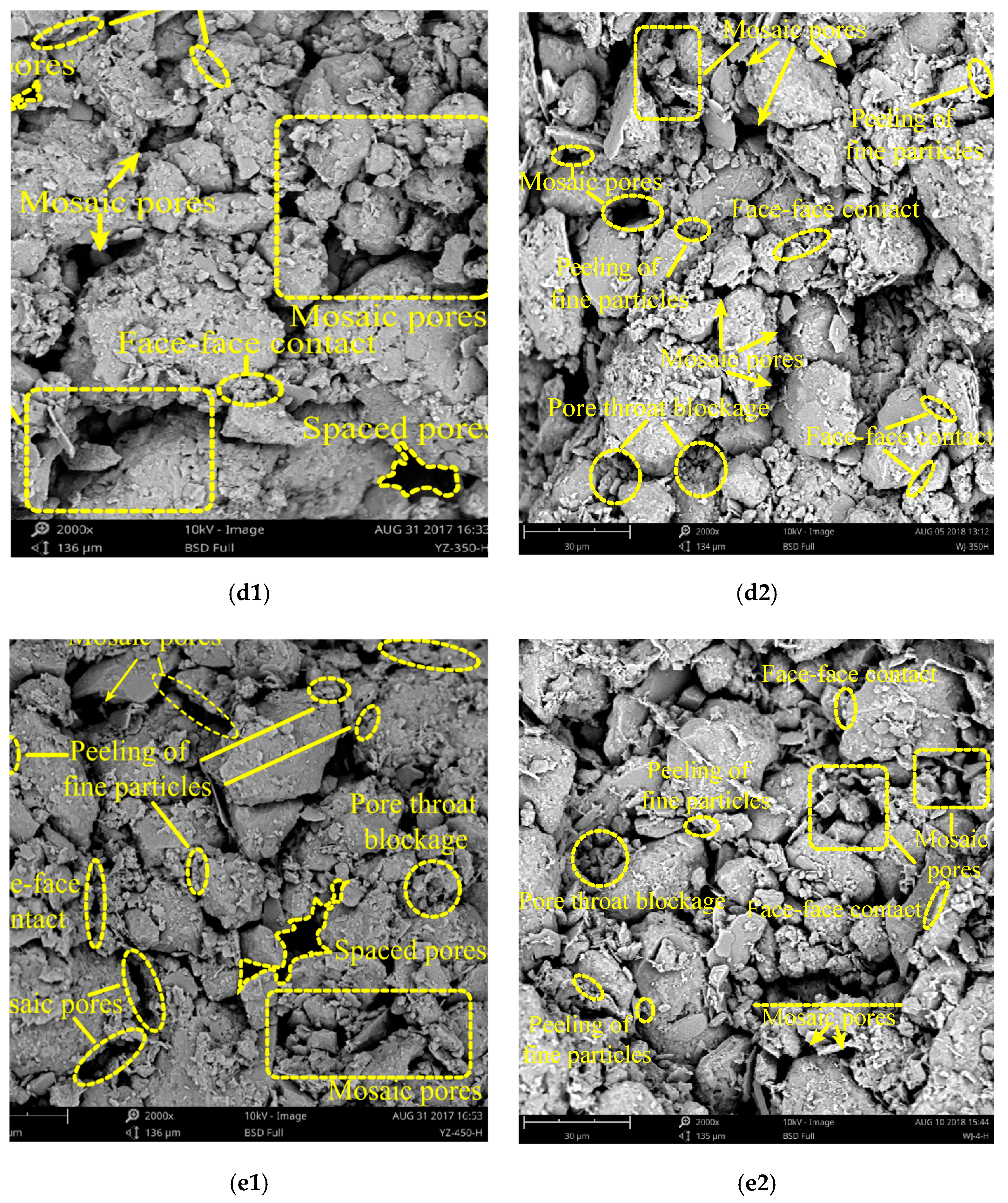

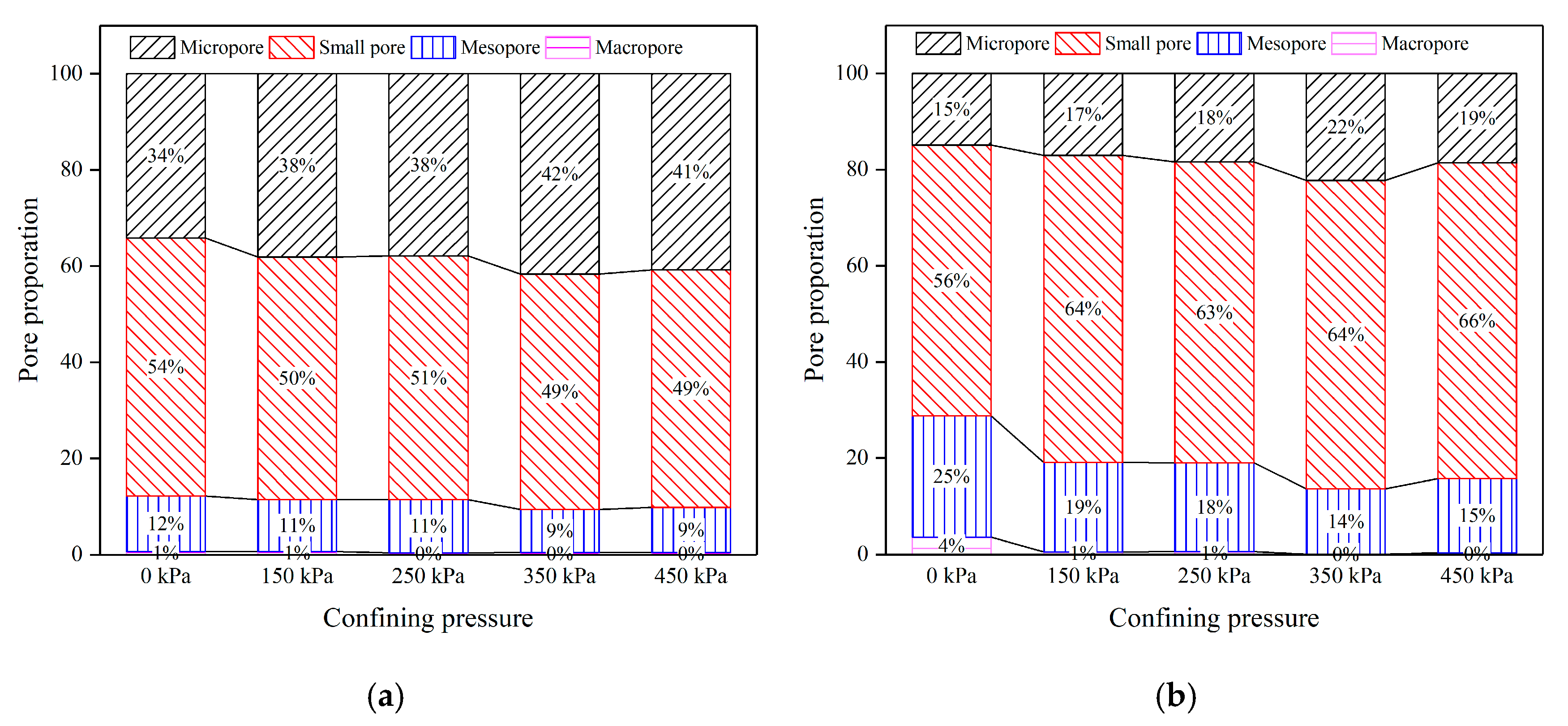

4.2. Analysis of the Microstructure Characteristics before and after the ICU Tests

5. Discussion

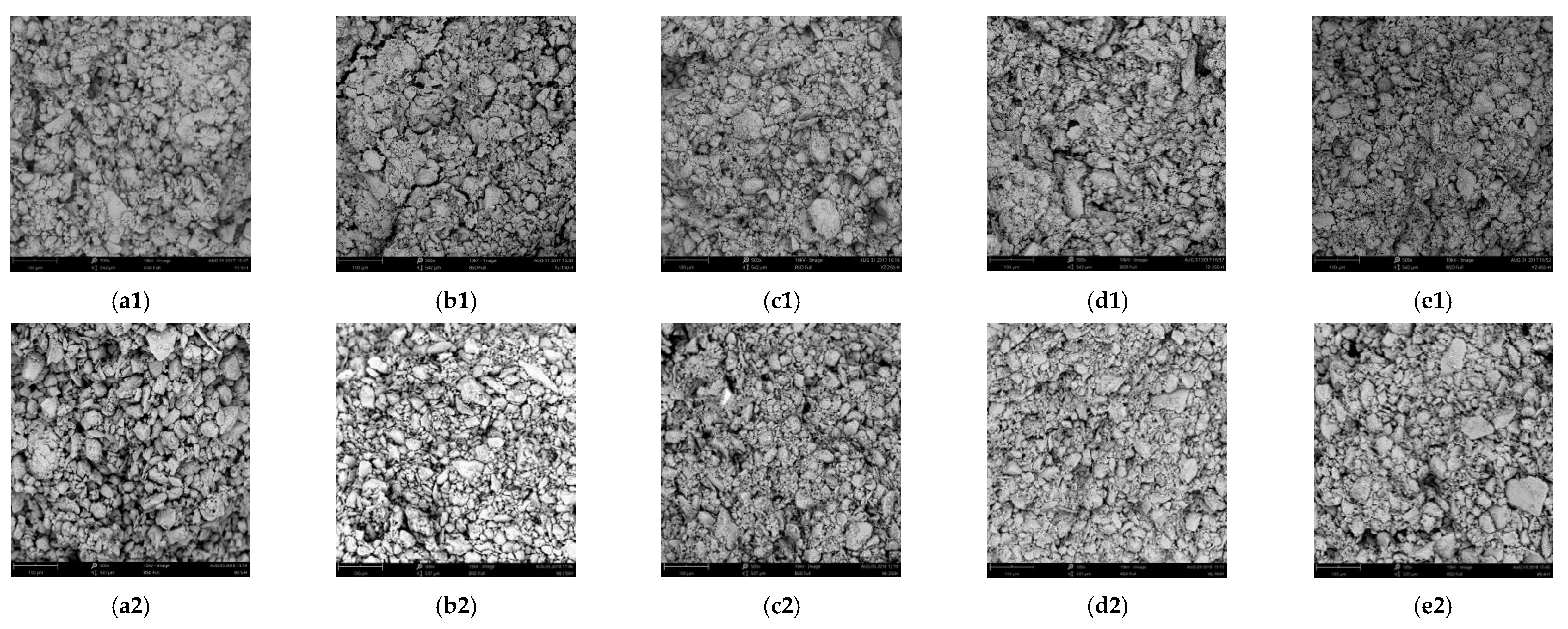

5.1. Analysis of Capacity of Static Liquefaction

5.1.1. Analysis Change Characteristics of the LPI

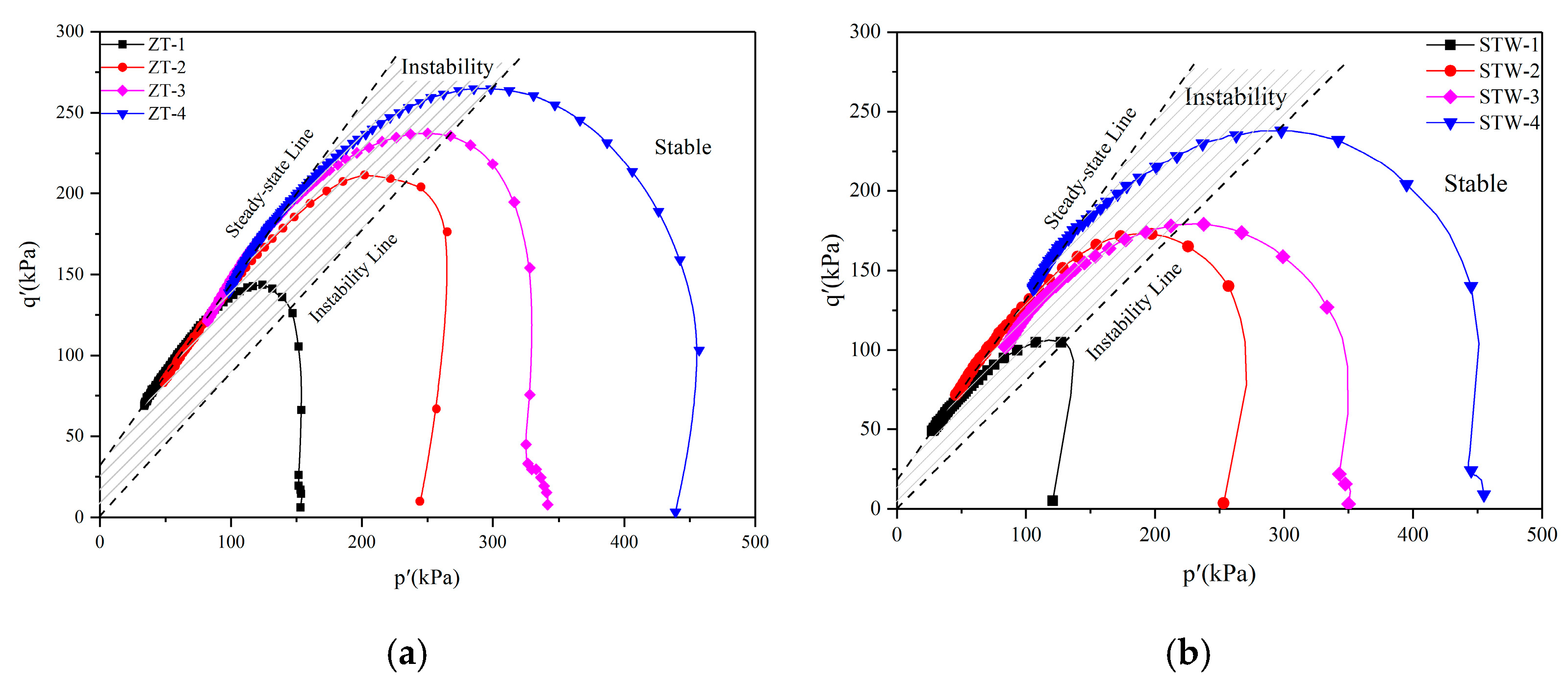

5.1.2. Analysis of the Stress Path Evolution

5.2. Correlation Analysis of the Macro and Micro Characteristics of Static Liquefaction

- (1)

- Average pore diameter (μm): it is the average length of diameters (brown lines in Figure 12) measured at 2degree intervals and passing through the centroid of pore.

- (2)

- Shape ratio: it is the ratio of the long axis to the short axis of ellipse equivalent to the pore, and the long axis and short axis are showed in Figure 12. The larger the shape ratio is, the more the pore shape resembles a long strip; the smaller the shape ratio, the more equiaxed the pore is. When the shape ratio is 1, the pore is square-shaped or circular [54].

- (3)

- Roundness: R = 4πA/P2, where P is the perimeter of the pore and A is the pore area. The perimeter is the length of the red contour, and the pore area is the white area inside the red contour (Figure 12). This index can better reflect the plane shape characteristics of the pore; the larger the roundness value is, the closer the pore is to the circle [55].

- (4)

- Fractal dimension: it is used to describe the fractal characteristics of the pores, and it reflects the irregularity of the contact boundary between the pores and the solid particles in loess [56]. The calculation of the pore contour (blue contour in Figure 12) fractal dimension is based on the “silt-island” method, proposed by Mandelbrot [57]: lgP = D/2 × lgA + C where P is the perimeter of the pore; A is the pore area; and C is a constant. The pore contour fractal dimension can be determined by plotting the scatter map in the lgP − lgA double logarithmic coordinate and performing a linear regression analysis. The larger the pore contour fractal dimension, the more complex the pore contour.

6. Conclusions

- (1)

- The stress-strain curves of the ZT and STW loess show the characteristics of the strong strain softening under the different confining pressures, and there were stages of rapid strain hardening, rapid strain softening, and stable strain softening. The pore water pressure under the different confining pressures increased rapidly to the effective confining pressure level after a small axial strain (εa < 3%). By having a continuous shear, it was always near this level; hence, its change also presents phased characteristics: a sharp rise stage and a stable stage. The effective confining pressure decreased with an increase in the pore water pressure and then it remained stable. Afterwards, it reached a lower value (20–100 kPa) at the end of the shear.

- (2)

- The LPI of the ZT and STW loess shows a trend of first increasing and then stabilizing with the increase in the confining pressure. The larger LPI was, the smaller ψ was, which reflected that the loess in different layers and buried depths had the ability of static liquefaction. The steady-state points of the saturated loess were the instability region. However, the steady-state strength was not zero, which indicates that there was a certain residual strength and it belonged to the incomplete static liquefaction.

- (3)

- After the ICU tests, the average pore diameter of the ZT and STW loess decreased, and the shape ratio essentially remained unchanged. The pore contour fractal dimension and the roundness show two different trends. The change in the proportion of the different pores is as follows: the macropore and mesopore decreased, the small pore increased slightly, and the micropore increased significantly. However, most of the above pore structure quantitative parameters did not show a monotonous change rule with the increase in the confining pressures.

- (4)

- When εa < 3%, the compression of the spaced pore structure in the loess resulted in full contact and the formation of a force chain, and it compressed the pore water transport channel. The macroscopic mechanical behavior shows rapid strain hardening. When εa = 1–3%, the deformation of the spaced pore structure occurred significantly, that is, the process of particle arrangement and recombination. At the beginning of this process, fine aggregates could enter the original pore throat channel, which caused the water transport channel formed by the spaced pore to be blocked to a certain extent. The macroscopic mechanical behavior shows rapid strain softening. When εa = 10–15%, the gradually stable rearrangement and reorganization of the particles and the migration and agglomeration of finer grains under the effect of the pore water pressure caused agglomeration blocking of the reconstructed pore throat. The macroscopic mechanical behavior indicates stable strain softening.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Terzaghi, K.; Peck, R.B. Soil Mechanics in Engineering Practice, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1967; Chapter 2; p. 108. ISBN 0471852732. [Google Scholar]

- Castro, G. Liquefaction of Sands; Harvard Soil Mechanics Series No. 81; Harvard University: Cambridge, MA, USA, 1969. [Google Scholar]

- Kramer Steven, L.; Seed, H.B. Initiation of soil liquefaction under static loading conditions. J. Geotech. Eng. 1988, 114, 412–430. [Google Scholar] [CrossRef]

- Mróz, Z.; Boukpeti, N.; Drescher, A. Constitutive model for static liquefaction. Int. J. Geomech. 2003, 3, 133–144. [Google Scholar] [CrossRef]

- Konrad, J.M.; Watts, B.D. Undrained shear strength for liquefaction flow failure analysis. Can. Geotech. J. 1995, 32, 783–794. [Google Scholar] [CrossRef]

- McKenna, G.; Luternauer, J.; Kostaschuk, R. Large-scale mass-wasting events on the Fraser River delta front near Sand Heads, British Columbia. Can. Geotech. J. 1992, 29, 151–156. [Google Scholar] [CrossRef]

- Olson Scott, M.; Stark Timothy, D.; Walton William, H.; Castro, G. 1907 static liquefaction flow failure of the North Dike of Wachusett Dam. J. Geotech. Geoenviron. Eng. 2000, 126, 1184–1193. [Google Scholar] [CrossRef]

- Leng, Y.; Peng, J.; Wang, Q.; Meng, Z.; Huang, W. A fluidized landslide occurred in the Loess Plateau: A study on loess landslide in South Jingyang tableland. Eng. Geol. 2018, 236, 129–136. [Google Scholar] [CrossRef]

- Peng, J.; Zhuang, J.; Wang, G.; Dai, F.; Zhang, F.; Huang, W.; Xu, Q. Liquefaction of loess landslides as a consequence of irrigation. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 330–337. [Google Scholar] [CrossRef]

- Xu, L.; Dai, F.-C.; Min, H.; Kwong, A.K.L. Loess landslide types and topographic features at South Jingyang Plateau, China. Diqiu Kexue-Zhongguo Dizhi Daxue Xuebao/Earth Sci.-J. China Univ. Geosci. 2010, 35, 155–160. [Google Scholar]

- Li, T.; Wang, P.; Xi, Y. The Mechanisms for Initiation and Motion of Chinese Loess Landslides; Springer: Berlin/Heidelberg, Germany, 2013; pp. 105–122. [Google Scholar]

- Ma, P.; Peng, J.; Wang, Q.; Zhuang, J.; Zhang, F. The mechanisms of a loess landslide triggered by diversion-based irrigation: A case study of the South Jingyang Platform, China. Bull. Eng. Geol. Environ. 2019, 78, 4945–4963. [Google Scholar] [CrossRef]

- Zhuang, J.; Peng, J.; Wang, G.; Javed, I.; Wang, Y.; Li, W. Distribution and characteristics of landslide in Loess Plateau: A case study in Shaanxi province. Eng. Geol. 2018, 236, 89–96. [Google Scholar] [CrossRef]

- Yan, R.-X.; Peng, J.-B.; Huang, Q.-B.; Chen, L.-J.; Kang, C.-Y.; Shen, Y.-J. Triggering Influence of Seasonal Agricultural Irrigation on Shallow Loess Landslides on the South Jingyang Plateau, China. Water 2019, 11, 1474. [Google Scholar] [CrossRef] [Green Version]

- Li, H.J.; Jin, Y.L. Initiation analysis of an irrigation-induced loess landslide. Appl. Mech. Mater. 2012, 170–173, 574–580. [Google Scholar] [CrossRef]

- Liu, W.; Chen, W.; Wang, Q.; Wang, J.; Lin, G. Effect of pre-dynamic loading on static liquefaction of undisturbed loess. Soil Dyn. Earthq. Eng. 2020, 130, 105915. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Furuya, G.; Yang, J. Pore-pressure generation and fluidization in a loess landslide triggered by the 1920 Haiyuan earthquake, China: A case study. Eng. Geol. 2014, 174, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Pei, X.; Zhang, X.; Guo, B.; Wang, G.; Zhang, F. Experimental case study of seismically induced loess liquefaction and landslide. Eng. Geol. 2017, 223, 23–30. [Google Scholar] [CrossRef]

- Xu, L.; Dai, F.C.; Tham, L.G.; Tu, X.B.; Min, H.; Zhou, Y.F.; Wu, C.X.; Xu, K. Field testing of irrigation effects on the stability of a cliff edge in loess, North-West China. Eng. Geol. 2011, 120, 10–17. [Google Scholar] [CrossRef]

- Xu, L.; Dai, F.C.; Gong, Q.M.; Tham, L.G.; Min, H. Irrigation-induced loess flow failure in Heifangtai platform, North-West China. Environ. Earth Sci. 2012, 66, 1707–1713. [Google Scholar] [CrossRef]

- Peng, J.; Qiao, J.; Leng, Y.; Wang, F.; Xue, S. Distribution and mechanism of the ground fissures in Wei River Basin, the origin of the Silk Road. Environ. Earth Sci. 2016, 75, 718. [Google Scholar] [CrossRef]

- Peng, J.; Wang, G.; Wang, Q.; Zhang, F. Shear wave velocity imaging of landslide debris deposited on an erodible bed and possible movement mechanism for a loess landslide in Jingyang, Xi’an, China. Landslides 2017, 14, 1503–1512. [Google Scholar] [CrossRef]

- Peng, J.; Ma, P.; Wang, Q.; Zhu, X.; Zhang, F.; Tong, X.; Huang, W. Interaction between landsliding materials and the underlying erodible bed in a loess flowslide. Eng. Geol. 2018, 234, 38–49. [Google Scholar] [CrossRef]

- Zhuang, J.-Q.; Peng, J.-B. A coupled slope cutting—A prolonged rainfall-induced loess landslide: A 17 october 2011 case study. Bull. Eng. Geol. Environ. 2014, 73, 997–1011. [Google Scholar] [CrossRef]

- Tu, X.B.; Kwong, A.K.L.; Dai, F.C.; Tham, L.G.; Min, H. Field monitoring of rainfall infiltration in a loess slope and analysis of failure mechanism of rainfall-induced landslides. Eng. Geol. 2009, 105, 134–150. [Google Scholar] [CrossRef]

- Derbyshire, E.; Dijkstra, T.A.; Smalley, I.J.; Li, Y. Failure mechanisms in loess and the effects of moisture content changes on remoulded strength. Quat. Int. 1994, 24, 5–15. [Google Scholar] [CrossRef]

- Xu, L.; Dai, F.C.; Tu, X.B.; Javed, I.; Woodard, M.J.; Jin, Y.L.; Tham, L.G. Occurrence of landsliding on slopes where flowsliding had previously occurred: An investigation in a loess platform, North-West China. Catena 2013, 104, 195–209. [Google Scholar] [CrossRef]

- GB/T50123-1999. Standard for Soil Test Method; China Planning Press: Beijing, China, 1999. [Google Scholar]

- Wang, H.N.; Ni, W.K.; Liu, G.Y. Ct images analysis of damage process in loess under triaxial conditions. Adv. Mater. Res. 2011, 243–249, 3175–3181. [Google Scholar] [CrossRef]

- Jiang, M.; Hu, H.; Peng, J.; Leroueil, S. Experimental study of two saturated natural soils and their saturated remoulded soils under three consolidated undrained stress paths. Front. Archit. Civ. Eng. China 2011, 5, 225–238. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Passoja, D.E.; Paullay, A.J. Fractal character of fracture surfaces of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Poulos, S.J. Steady state of deformation. J. Geotech. Eng. Div. 1981, 107, 553–562. [Google Scholar]

- Wang, Y.; Xie, W.; Gao, G. Effect of different moisture content and triaxial test methods on shear strength characteristics of loess. E3S Web Conf. 2019, 92, 07007. [Google Scholar] [CrossRef]

- GAO, G.-R. Classification of microstructures of loess in China and their collapsibility. Sci. Sin. 1981, 24, 962. [Google Scholar]

- Li, P.; Vanapalli, S.; Li, T. Review of collapse triggering mechanism of collapsible soils due to wetting. J. Rock Mech. Geotech. Eng. 2016, 8, 256–274. [Google Scholar] [CrossRef]

- Fang, X.; Shen, C.; Li, C.; Wang, L.; Chen, Z. Quantitative analysis of microstructure characteristics of Pucheng loess in Shaanxi Province. Yanshilixue Yu Gongcheng Xuebao Chin. J. Rock Mech. Eng. 2013, 32, 1917–1925. [Google Scholar]

- Wang, F.W.; Sassa, K.; Wang, G. Mechanism of a long-runout landslide triggered by the August 1998 heavy rainfall in Fukushima Prefecture, Japan. Eng. Geol. 2002, 63, 169–185. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Fung, W.; Cheuk, C.Y.; Zhang, L. Influence of stress ratio and stress path on behavior of loose decomposed granite. J. Geotech. Geoenviron. Eng. 2004, 130. [Google Scholar] [CrossRef]

- Bishop, A.W. Progressive failure with special reference to the mechanism causing it. In Proceedings of the Geotechnical Conference; Norwegian Geotechnical Institute: Oslo, Norway, 1968; pp. 142–150. [Google Scholar]

- Been, K.; Jefferies, M.G. A state parameter for sands. Géotechnique 1985, 35, 99–112. [Google Scholar] [CrossRef]

- Sladen, J.; D’Hollander, R.; Krahn, J.; Mitchell, D. Back analysis of the nerlerk berm liquefaction slides. Can. Geotech. J. 1985, 22, 579–588. [Google Scholar] [CrossRef]

- Been, K.; Conlin, B.; Crooks, J.; Fitzpatrick, S.; Jefferies, M.; Rogers, B.; Shinde, S. Back analysis of the Nerlerk berm liquefaction slides: Discussion. Can. Geotech. J. 2011, 24, 170–179. [Google Scholar] [CrossRef]

- Vaid, Y.P.; Chung, E.K.F.; Kuerbis, R.H. Stress path and steady state. Can. Geotech. J. 1990, 27, 1–7. [Google Scholar] [CrossRef]

- Lade, P.; Yamamuro, J. Effects of nonplastic fines on static liquefaction of sands. Can. Geotech. J. 1997, 34, 918–928. [Google Scholar] [CrossRef]

- Sladen, J.; D’Hollander, R.; Krahn, J. The liquefaction of sands, a collapse surface approach. Can. Geotech. J. 1985, 22, 564–578. [Google Scholar] [CrossRef]

- Lade, P.V.; Yamamuro, J.A. Evaluation of static liquefaction potential of silty sand slopes. Can. Geotech. J. 2011, 48, 247–264. [Google Scholar] [CrossRef]

- Zhou, Y.-X.; Zhang, D.-X.; Luo, C.-Y.; Chen, J. Experimental research on steady strength of saturated loess. Yantu Lixue/Rock Soil Mech. 2010, 31, 1486–1490. [Google Scholar]

- Ishihara, K. Liquefaction and flow failure during earthquakes. Géotechnique 1993, 43, 351–451. [Google Scholar] [CrossRef]

- Konrad, J.M. Undrained response of loosely compacted sands during monotonic and cyclic compression tests. Géotechnique 1993, 43, 69–89. [Google Scholar] [CrossRef]

- Tian, K.-L.; Wang, P.; Zhang, H.-L. Discussion on stress-strain relation of intact loess considering soil structure. Yantu Lixue Rock Soil Mech. 2013, 34, 1893–1898. [Google Scholar]

- Shen, Y.; Yang, H.; Xi, J.; Yang, Y.; Wang, Y.; Wei, X. A novel shearing fracture morphology method to assess the influence of freeze–thaw actions on concrete–granite interface. Cold Reg. Sci. Technol. 2020, 169, 102900. [Google Scholar] [CrossRef]

- Hu, R.L.; Yeung, M.R.; Lee, C.F.; Wang, S.J. Mechanical behavior and microstructural variation of loess under dynamic compaction. Eng. Geol. 2001, 59, 203–217. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, L.M.; Wang, J.; Ma, H.P.; Zhong, X.M.; Wang, N.; Wang, J. Laboratory study on the liquefaction properties of the saturation structural loess. Appl. Mech. Mater. 2012, 170–173, 1339–1343. [Google Scholar] [CrossRef]

- Xie, X.; Qi, S.; Zhao, F.; Wang, D. Creep behavior and the microstructural evolution of loess-like soil from Xi’an area, China. Eng. Geol. 2018, 236, 43–59. [Google Scholar] [CrossRef]

- Li, X.A.; Hong, B.; Wang, L.; Li, L.; Sun, J. Microanisotropy and preferred orientation of grains and aggregates (POGA) of the Malan loess in Yan’an, China: A profile study. Bull. Eng. Geol. Environ. 2020, 79, 1893–1907. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, Y.; Wu, J. Quantitative analysis of soil pores under natural vegetation successions on the Loess Plateau. Sci. China Earth Sci. 2010, 53, 617–625. [Google Scholar] [CrossRef]

- Zhang, X.-C.; Huang, R.-Q.; Xu, M.; Pei, X.-J.; Han, X.-S.; Song, L.-J.; Zhang, F.-Y. Loess liquefaction characteristics and its influential factors of Shibeiyuan landslide. Yantu Lixue Rock Soil Mech. 2014, 35, 801–810. [Google Scholar]

- Li, P.; Xie, W.; Pak, R.Y.S.; Vanapalli, S.K. Microstructural evolution of loess soils from the Loess Plateau of China. Catena 2019, 173, 276–288. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, F.; Ma, F.; Wang, M.; Bai, X.; Zheng, Y.; Yin, H.; Zhang, G. Collapsibility, composition, and microstructure of loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef] [Green Version]

- Lei, X.-Y. Pore type of loess in China and collapsibility. Sci. China Ser. B 1987, 17, 1309–1316. [Google Scholar]

| Samples | Water Content (%) | Dry Density (g/cm3) | Void Ratio | Specific Gravity (g·cm−3) | Liquid Limit (%) | Plastic Limit (%) | Liquid Index | Plastic Index |

|---|---|---|---|---|---|---|---|---|

| ZT | 17 | 1.44 | 0.88 | 2.71 | 25.3 | 19.61 | −0.46 | 5.73 |

| STW | 9.8 | 1.43 | 0.89 | 2.72 | 24.4 | 20.35 | −2.59 | 4.08 |

| Samples | Particle Size(%) | Mineral Composition(%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Clay (≤5 μm) | Silt (5–75 μm) | Fine Sand (75–250 μm) | Quartz | Carbonate | Illite | Kaolinite | Chlorite | Others | |

| ZT | 22.6 | 74.1 | 3.3 | 29 | 23 | 20 | 5 | 14 | 9 |

| STW | 10.6 | 82.2 | 7.2 | 31 | 20 | 19 | 3 | 17 | 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, R.-X.; Peng, J.-B.; Zhang, J.-Y.; Wang, S.-k. Static Liquefaction Capacity of Saturated Undisturbed Loess in South Jingyang Platform. Water 2020, 12, 2298. https://doi.org/10.3390/w12082298

Yan R-X, Peng J-B, Zhang J-Y, Wang S-k. Static Liquefaction Capacity of Saturated Undisturbed Loess in South Jingyang Platform. Water. 2020; 12(8):2298. https://doi.org/10.3390/w12082298

Chicago/Turabian StyleYan, Rui-Xin, Jian-Bing Peng, Jin-Yuan Zhang, and Shao-kai Wang. 2020. "Static Liquefaction Capacity of Saturated Undisturbed Loess in South Jingyang Platform" Water 12, no. 8: 2298. https://doi.org/10.3390/w12082298

APA StyleYan, R.-X., Peng, J.-B., Zhang, J.-Y., & Wang, S.-k. (2020). Static Liquefaction Capacity of Saturated Undisturbed Loess in South Jingyang Platform. Water, 12(8), 2298. https://doi.org/10.3390/w12082298