1. Introduction

Excess sediment in watercourses is the most common contaminant on the planet. Economic and social losses and the growing reduction in productive land and navigable watercourses exceed losses caused by the release of pollutants and toxic waste. This problem is exacerbated as we move downstream towards coasts and population centers [

1].

Soil erosion caused by water is the most representative type of erosion and has become an important research topic [

2]. This type of erosion is one of the main threats to soils, negatively impacting ecosystem services, agricultural production, drinking water, and carbon stocks. Besides, it is responsible for the most significant soil loss in regions such as Europe compared to other erosion processes (for example, wind erosion) [

3]. Erosion is a problem that can cause damage to civil infrastructure and the silting up of natural and artificial reservoirs for water supply and hydroelectric power generation. Therefore, it is crucial to prevent and control erosion, minimizing its consequences [

4]. Controlling erosion entails curbing, reducing, or restricting (not stopping completely) the gradual or sudden wear and tear of the soil. Soil loss (erosion) is a process that occurs continuously in natural ecosystems, as well as in recovered sites [

1], caused by natural or human-made processes. The most common and natural element used to control erosion is vegetation, which helps absorb water that the soil cannot handle and protects the soil from the direct incidence of wind, thereby preventing erosion [

5]. Vegetation significantly controls erosion rates, which decrease exponentially with increasing vegetation cover [

6,

7].

Although vegetation is the most used element for erosion control, it takes several seasons (time) to establish itself fully. Therefore, during the initial stages of growth (when the exposure of erosion processes is high), geosynthetics are presented as auxiliaries of vegetation to control erosion processes [

5]. Geosynthetics can be used in the short and long term, as they are made of durable polymeric materials with specific formulations. They can last for many years depending on their application; when used in critical applications, they have a service life of 300 years or even more [

6,

8]. The durability of the material in terms of its service life is essential as it will be exposed to several environmental factors.

Geosynthetics have been gaining ground as erosion control elements since 1958 when a ‘plastic cloth’ was used in place of a granular filter to prevent sand from escaping behind concrete blocks used for coastal protection [

1]. They are used in interventions to prevent erosion of slopes or channels where energy demands are not particularly strong. The application of recycled polymeric materials (geosynthetics) and fibers mixed with local soil to control erosion processes has also gained prominence in recent years, as in the work of Broda et al. [

9]. They used these techniques to protect a steep slope exposed to intensive rill erosion in a region of Poland. There are also options for more environmentally friendly geosynthetics, such as jute geotextile, treated with antimicrobial chemicals and used as a substitute for traditional geosynthetics [

10]. Furthermore, geosynthetics from biodegradable polyester are used in specific seasonal or temporary applications [

11]. Geosynthetics have brought many benefits in erosion control applications. However, it is essential to consider the long-term environmental impacts caused by their use [

12], as geosynthetics are generally made from non-biodegradable polymers.

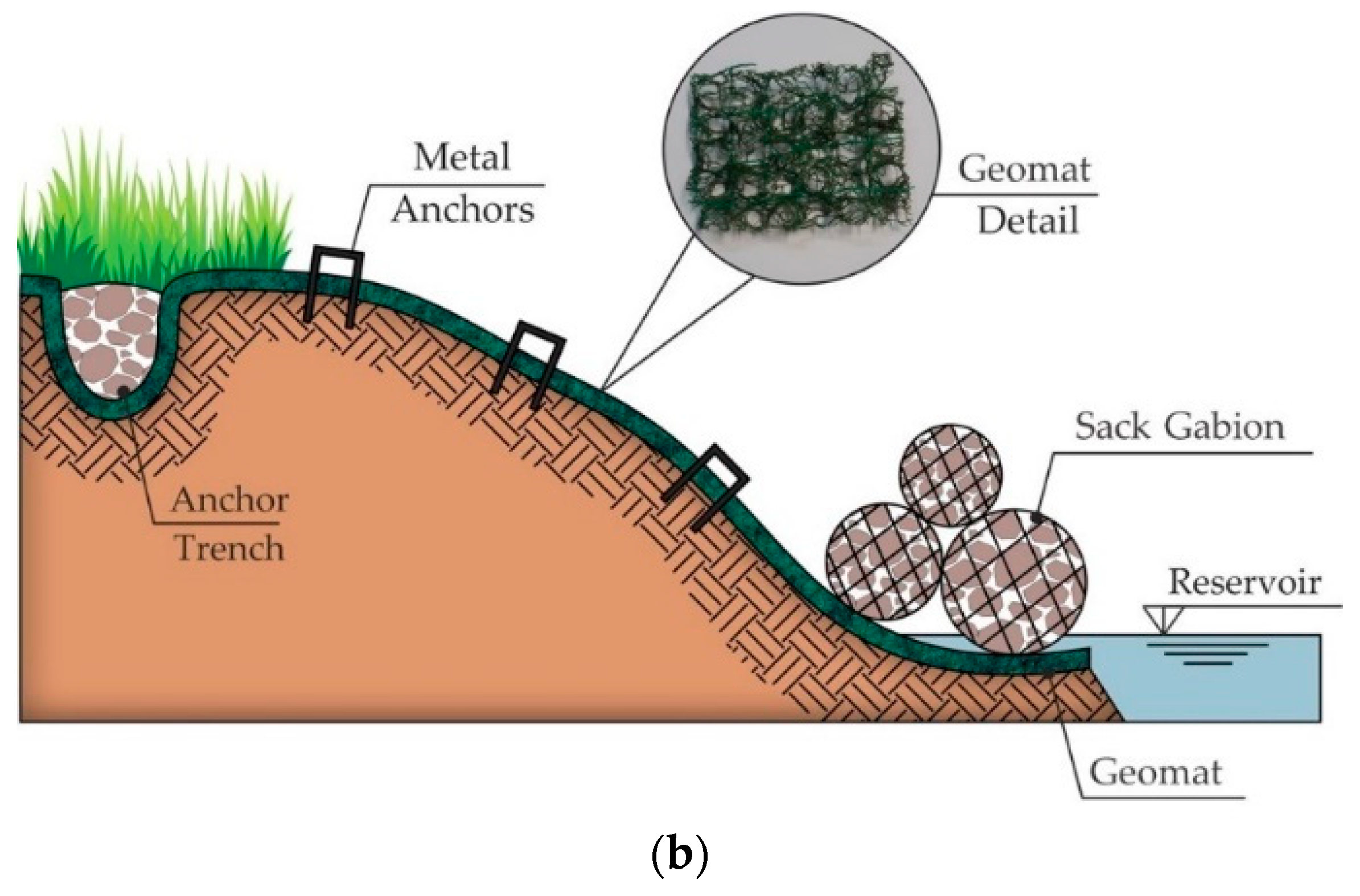

One of the most widespread erosion control techniques entails placing natural materials (biomats) or geosynthetic erosion mats (geomats) [

13]. These techniques can be considered bioengineering techniques. Bioengineering is a technique that combines the use of vegetation with other materials and has gained high popularity in the world in recent decades due to its low environmental impact [

14].

Geomats are biotechnical composites manufactured with non-degradable materials that provide temporary passive protection against erosion before vegetation growth (short term). Finally, they become synergistically entangled with the vegetation, reinforcing vegetation performance (long term). The faster the vegetation is established, the better results the erosion control technique presents [

1,

13]. Research conducted in the laboratory has confirmed that shear strength and cohesion of the geomat–soil interface can be significantly improved by reinforcement combined with roots [

15]. Lejcus et al. [

16] carried out studies with other types of geocomposites (water-absorbing geocomposites), different from geomats. The study indicated increases in shear resistance of soil covered by roots in different vegetation types (66.7% for shrubs and 20.1% for grasses). A study carried out by Xu et al. [

17] on an earthen levee subjected to different scenarios indicated that geomats could significantly improve the stability of the levee during hurricane overtopping conditions involving storm surge and wind-generated wave action. Geomats exercise reliable control of topsoil erosion for slopes of different lengths and gradients [

18]. In practice, the efficiency of bioengineering methods can be improved by controlling the variation in root cohesion [

19].

Geomats have been increasingly used as an environmental protection material for slopes and margins due to their low cost and simple, rapid construction [

20]. Nowadays, when time and economy are the most important criteria to find a solution, decision-makers and designers must select a quick installation technique that ensures reliability in its performance and, most importantly, is inexpensive and does not require specialized labor. Laboratory and field research has confirmed the effectiveness of geomats in protecting against erosive processes in general [

4,

5,

15,

20]. However, there is still little research carried out in the field that has conducted constant monitoring of the techniques, as is the case of the present work, which has been monitoring the performance of geomats over a 4-year study period.

Erosion is a process common in tropical regions such as Brazil. Problems caused by soil erosion both on reservoir margins and hydroelectric power plant (HPP) slopes have been commonly faced by Eletrobras Furnas, which is a mixed Brazilian economy private power generation company [

4]. Eletrobras Furnas has carried out several studies on its HPPs, including that of Vianna et al. [

12], who analyzed plant development in different bioengineering techniques applied on slopes, and that of Aparicio Ardila et al. [

21], who analyzed the performance of semi-rigid erosion control techniques (gabion/gabion mattress and geogrid mattress) on the reservoir margins of the HPPs. In addition to field research, laboratory research, such as that performed by Melo et al. [

4], who evaluated the performance of geosynthetics in erosive processes caused by high-intensity rainfall, is of great importance. It is also essential to consider other erosion control techniques, such as biological restoring, studied by Hashim et al. [

22]. They evaluated the impact of biological soil crusts (Cyanobacteria and Chlorophyte on the behavior of soil sample erodability parameters collected on the bank of the Tigris River in Iraq.

Due to the importance of erosion in environmental and economic terms, the main objective of this study was to investigate the performance of geomats and geomats with sack gabion used in erosion control in different sections of three experimental units located on the reservoir margins of the HPPs called Porto Colômbia and Volta Grande. This work is a continuation of the research developed by Aparicio Ardila et al. [

21]. They evaluated the performance of erosion control techniques different from those analyzed in the present study, only implemented in the same HPPs (Porto Colombia and Volta Grande). Moreover, they evaluated the degradation of the geotextile used in the techniques through thermal analysis (thermogravimetry (TG) and differential scanning calorimetry (DSC) analyses). In the present work, thermal analysis was performed on geomats exposed to UV radiation in the field and aged in the laboratory, using DSC.

4. Conclusions

The present contribution, considering the geomat performance over four years of monitoring, through a qualitative evaluation matrix and differential bathymetry, enabled us to confirm the long-term efficiency of the examined geomats after a real service. Moreover, the effect of UV radiation on the degradation of geomats installed under natural conditions, as well as under accelerated conditions, was observed using differential scanning calorimetry (DSC).

In general, the results indicated that there was no significant difference in performance between using the erosion control technique consisting only of geomat and the technique consisting of geomat and sack gabion. However, a difference in the complexity and costs of the erosion control techniques is evident, as they increase when the sack gabion technique is added.

Although the VG experimental unit was the one with the best qualitative performance, it was the one with the highest sediment disposition at the margin, which makes it clear that the specific conditions of the place, such as the effect of wind and wave incidence, are of great importance when an erosive process on the reservoir margins needs to be controlled.

The sample in section VG2 was the one that most showed variations in the DSC analyses and was also one of the sections with a more significant sediment arrangement on its margins, which indicates that the sediments had chemical characteristics that allowed their incorporation into the geomat polymer material.

For future work, we highlight the need to carry out hydrodynamic studies to improve the knowledge about the lithodynamic and morphodynamic processes to which the reservoir margins are exposed.