Flume Experiments Evaluating the Efficacy of a Large Wood Trap Featuring Horizontal Rods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Outline

2.2. Experimental Equipment

2.3. Large Wood

2.4. Large Wood Supply

2.4.1. Constant Spacing Method (with Variable Numbers of LW Units)

2.4.2. Constant LW Unit Method (with Variable Spacing)

2.5. Experimental Conditions

3. Results

4. Discussion

5. Conclusions

- Relatively long LW was scooped up and captured by the trap that featured horizontal rods. However, a shorter LW slipped through the rods. These behaviors depended on the rod spacing (Sr), the LW number (n), and supply rate (rw).

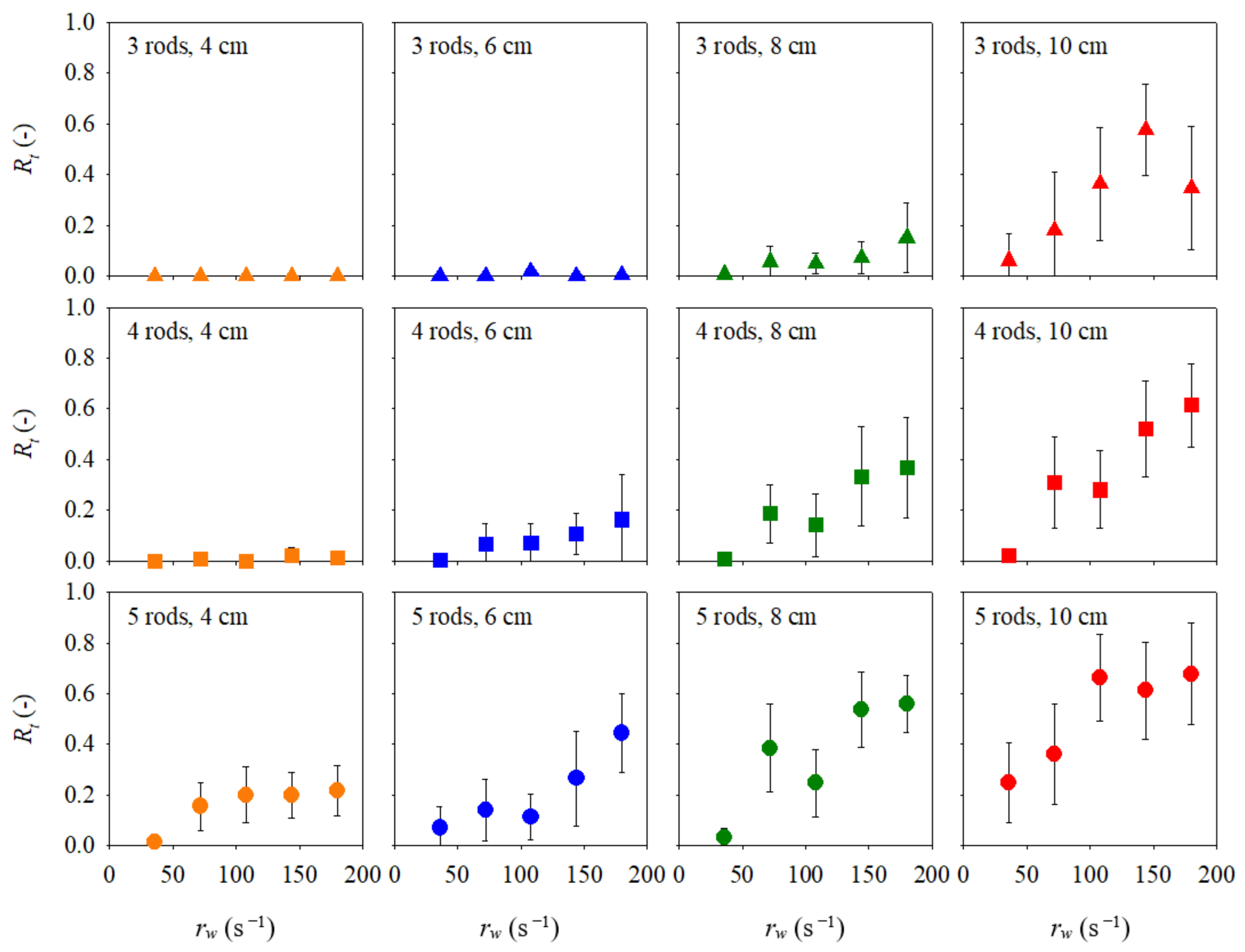

- The mean trapping rates (10 experiments) (Rt) confirmed that trapping tended to increase as the number of rods and the length of the LW (Lw) increased. The trapping rate (Rt) increased as the LW supply rate (rw) increased for all combinations of rod number and LW length (Lw).

- LW flowing in a congested regime was captured more efficiently than when LW transport was uncongested.

- A linear relationship was evident between the trapping rate (Rt) and the relative length of the LW with respect to rod spacing (Lw/Sr). The x-intercepts of the regression lines were around Lw/Sr = 1.5 for all LW supply rates, and the slopes of the regression lines increased as the LW supply rate (rw) increased.

- The relationship between the slope of the regression line and the LW supply rate differed depending on the supply method (thus the constant-number and the constant-spacing methods). Thus, even at the same LW supply rate (rw), the higher the LW number (n), the higher the trapping rate (Rt).

- Compared to the results of previous flume experiments for LW traps featuring vertical columns, our trapping rates were generally low because the prior experiments featured smaller Froude number, and LW captured by horizontal rods can be relocated by water flow or later-arriving LW and slip between the rods especially in an uncongested regime.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| lb | spacing on the conveyor belt on which the LW units were placed (cm) |

| Lw | length of LW (cm) |

| Lw/Sr | relative length of LW in terms of the rod spacing (-) |

| n | number of LW units fed to the flume (-) |

| nt | number of LW units captured by the trap (-) |

| rw | LW supply rate, rw = n/(lb/vb) (s−1) |

| Rt | LW trapping rate, Rt = nt/n (-) |

| Sr | rod spacing (cm) |

| vb | speed of the conveyor belt (cm s−1) |

| λ | scale factor |

References

- Wohl, E.; Jaeger, K. A conceptual model for the longitudinal distribution of wood in mountain streams. Earth Surf. Process. Landf. 2009, 34, 329–344. [Google Scholar] [CrossRef]

- Ruiz-Villanueva, V.; Piégay, H.; Gurnell, A.M.; Marston, R.A.; Stoffel1, M. Recent advances quantifying the large wood dynamics in river basins: New methods and remaining challenges. Rev. Geophys. 2016, 54, 611–652. [Google Scholar] [CrossRef] [Green Version]

- Schalko, I.; Schmocker, L.; Weitbrecht, V.; Boes, R.M. Backwater rise due to large wood accumulations. J. Hydraul. Eng. 2018, 144, 04018056. [Google Scholar] [CrossRef]

- Beltoldi, W.; Ruiz-Villanueva, V. Physical and numerical modelling of large wood and vegetation in rivers. In Gravel-Bed Rivers: Processes and Disasters; Tsutsumi, D., Laronne, J.B., Eds.; Wiley Blackwell: Hoboken, NJ, USA, 2017; pp. 729–753. [Google Scholar]

- Nagayama, S.; Nakamura, F. Fish habitat rehabilitation using wood in the world. Landsc. Ecol. Eng. 2010, 6, 289–305. [Google Scholar] [CrossRef]

- Ruiz-Villanueva, V.; Wyżga, B.; Mikuś, P.; Hajdukiewicz, M.; Stoffel, M. Large wood clogging during floods in a gravel-bed river: The Długopole bridge in the Czarny Dunajec River, Poland. Earth Surf. Process. Landf. 2017, 42, 516–530. [Google Scholar] [CrossRef]

- Ruiz-Villanueva, V.; Bodoque, J.M.; Díez-Herrero, A.; Bladé, E. Large wood transport as significant influence on flood risk in a mountain village. Nat. Hazards 2014, 74, 967–987. [Google Scholar] [CrossRef] [Green Version]

- Lucía, A.; Comiti, F.; Borga, M.; Cavalli, M.; Marchi, L. Dynamics of large wood during a flash flood in two mountain catchments. Nat. Hazards Earth Syst. Sci. Discuss. 2015, 3, 1643–1680. [Google Scholar]

- Schalko, I.; Schmocker, L.; Weitbrecht, V.; Boes, R.M. Hazards due to large wood accumulations: Local scour and backwater rise. In E3S Web of Conferences River Flow 2018—Ninth International Conference on Fluvial Hydraulics; EDP Sciences: Les Ulis, France, 2018; Volume 40, p. 02003. [Google Scholar]

- Marutani, T.; Kaibori, M.; Jitousono, T.; Mizuno, H.; Ohno, H.; Shimizu, O.; Kubota, T.; Ue, H.; Kanazawa, A.; Kawano, T.; et al. Sediment-related disasters by a heavy rainfall in the northern part of Kyushu-Island, Japan in July 2017. J. Jpn. Soc. Eros. Control Eng. 2017, 70, 31–42, (In Japanese with English abstract). [Google Scholar]

- Kaibori, M.; Hasegawa, Y.; Yamashita, Y.; Sakida, H.; Nakai, S.; Kuwada, S.; Hiramatsu, S.; Jitousono, T.; Irasawa, M.; Shimizu, O.; et al. Sediment related disaster due to heavy rainfall in Hiroshima Prefecture in July, 2018. J. Jpn. Soc. Eros. Control Eng. 2018, 71, 49–60, (In Japanese with English abstract). [Google Scholar]

- Furlan, P. Blocking Probability of Large Wood and Resulting Head Increase at Ogee Crest Spillways. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2019. [Google Scholar]

- Takada, S.; Sumi, T. Study on flood risk assessment caused by functional deterioration of dam flood cntrol gates. DPRI Annu. 2019, 62B, 671–678, (In Japanese with English abstract). [Google Scholar]

- Ishikawa, Y.; Mizuyama, T. An experimental study on permeable sediment control dams as a countermeasure against floating logs. In Proceedings of the Sixth Congress Asian and Pacific Division International Association for Hydraulic Research, Kyoto, Japan, 20–22 July 1988; pp. 723–730. [Google Scholar]

- Shibuya, H.; Katsuki, S.; Ohsumi, H.; Ishikawa, N.; Mizuyama, T. Experimental study on woody debris trap performance of drift wood capturing structure. J. Jpn. Soc. Eros. Control Eng. 2010, 63, 34–41, (In Japanese with English abstract). [Google Scholar]

- Matsumura, K.; Hashida, Y.; Kasai, S. Effect of trapping floodwood by grid type sabodam. J. Jpn. Soc. Eros. Control Eng. 1990, 43, 9–12, (In Japanese with English abstract). [Google Scholar]

- Horiguchi, T.; Katsuki, S.; Ishikawa, N.; Mizuyama, T. Method for evaluating the trapping effects of woody debris using a distinct element method. Int. J. Eros. Control Eng. 2019, 12, 1–12. [Google Scholar] [CrossRef]

- National Institute for Land and Infrastructure Management, Ministry of Land, Infrastructure and Transport, Japan. Manual of Technical Standard for designing Sabo facilities against debris flow and driftwood. Tech. Note Natl. Inst. Land Infrastruct. Manag. 2007, 365, 1–73. (In Japanese) [Google Scholar]

- Kokuryo, H.; Sasaki, T.; Tamura, K.; Hiroi, K.; Shima, J. A proposal for driftwood countermeasures to be added to the existing closed-type sabo dam. Proc. Jpn. Soc. Eros. Control Eng. 2018, 67, 113–114, (In Japanese with English abstract). [Google Scholar]

- Yoshida, K.; Matsumoto, S.; Satofuka, Y.; Takayama, S.; Sakamoto, R.; Shima, J.; Mizuyama, T. Experimental study on adding driftwood capture function to existing concrete dams. Proc. Jpn. Soc. Eros. Control Eng. 2018, 67, 119–120, (In Japanese with English abstract). [Google Scholar]

- Schalko, I. Wood retention at inclined racks: Effects on flow and local bedload processes. Earth Surf. Process. Landf. 2020, 45, 2036–2047. [Google Scholar] [CrossRef]

- Braudrick, C.A.; Grant, G.E.; Ishikawa, Y.; Ikeda, H. Dynamics of wood transport in streams: A flume experiment. Earth Surf. Process. Landf. 1997, 22, 669–683. [Google Scholar] [CrossRef]

- Ruiz-Villanueva, V.; Mazzorana, B.; Bladé, E.; Bürkli, L.; Iribarren-Anacona, P.; Mao, L.; Nakamura, F.; Ravazzolo, D.; Rickenmann, D.; Sanz-Ramos, M.; et al. Characterization of wood-laden flows in rivers. Earth Surf. Process. Landf. 2019, 44, 1694–1709. [Google Scholar] [CrossRef]

- Schalko, I.; Schmocker, L.; Weitbrecht, V.; Boes, R.M. Laboratory study on wood accumulation probability at bridge piers. J. Hydraul. Res. 2020, 58, 566–581. [Google Scholar] [CrossRef]

| Number of Rods | Rod Spacing Sr (cm) | Length of LW Lw (cm) | Relative Length Lw/Sr |

|---|---|---|---|

| 3 | 3.3 | 4 | 1.2 |

| 6 | 1.8 | ||

| 8 | 2.4 | ||

| 10 | 3.0 | ||

| 4 | 2.5 | 4 | 1.6 |

| 6 | 2.4 | ||

| 8 | 3.2 | ||

| 10 | 4.0 | ||

| 5 | 2.0 | 4 | 2.0 |

| 6 | 3.0 | ||

| 8 | 4.0 | ||

| 10 | 5.0 |

| LW Supply Method | |||||

|---|---|---|---|---|---|

| Spacing Constant Method (Variable LW Number) | Number Constant Method (Variable Spacing) | ||||

| n (-) | lb (cm) | rw (s−1) | n (-) | lb (cm) | rw (s−1) |

| 10 | 10 | 36 | 50 | 50 | 36 |

| 20 | 10 | 72 | 50 | 40 | 45 |

| 30 | 10 | 108 | 50 | 30 | 60 |

| 40 | 10 | 144 | 50 | 20 | 90 |

| 50 | 10 | 180 | 50 | 10 | 180 |

| Present Study | Shibuya et al., 2010 [15] | Matsumura et al., 1990 [16] | |

|---|---|---|---|

| Width of flume | 0.1 m | 0.3 m | 0.3 m |

| Slope of flume | 0.087 | 0.052 | 0.020 |

| Discharge per unit width | 18 L/s/m | 9.0 L/s/m | 5.0 L/s/m |

| LW trap | Horizontal rod | Vertical column | Vertical grid |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Furukawa, M.; Tsutsumi, D.; Muto, H.; Uchida, T.; Suzuki, T.; Horiguchi, T. Flume Experiments Evaluating the Efficacy of a Large Wood Trap Featuring Horizontal Rods. Water 2021, 13, 1837. https://doi.org/10.3390/w13131837

Furukawa M, Tsutsumi D, Muto H, Uchida T, Suzuki T, Horiguchi T. Flume Experiments Evaluating the Efficacy of a Large Wood Trap Featuring Horizontal Rods. Water. 2021; 13(13):1837. https://doi.org/10.3390/w13131837

Chicago/Turabian StyleFurukawa, Mayuko, Daizo Tsutsumi, Hironori Muto, Taro Uchida, Takuro Suzuki, and Toshiyuki Horiguchi. 2021. "Flume Experiments Evaluating the Efficacy of a Large Wood Trap Featuring Horizontal Rods" Water 13, no. 13: 1837. https://doi.org/10.3390/w13131837

APA StyleFurukawa, M., Tsutsumi, D., Muto, H., Uchida, T., Suzuki, T., & Horiguchi, T. (2021). Flume Experiments Evaluating the Efficacy of a Large Wood Trap Featuring Horizontal Rods. Water, 13(13), 1837. https://doi.org/10.3390/w13131837