Abstract

Ensuring the uninterrupted flow of the complex piped water distribution networks to combat the COVID-19 pandemic in Taiwan’s hospitals has become a priority. The process involved in the no-shutdown pipe fixing freezing method depends on the water supply system design and the conditions of the environment. Before carrying out repair works onsite, two experiments were undertaken to estimate the liquid nitrogen supply rate and make sure of its adequacy in relation to the fixing system’s heat transfer performance. Using an iron exhaust pipe and galvanized steel inlet pipe with jacket for a 50-mm-diameter water pipe, temperature variations and timelapse were recorded and analyzed. The results showed that the frost length on the water pipe surface at either side of the jacket was 1.2–1.8 times of the pipe diameter. The ice length (~45 cm) was longer than the jacket (~34 cm), and the water pressure at the jacket inlet side was 1 kg/cm2 greater than at the exit. Injecting the right amount of liquid nitrogen into the inlet and at a proper speed between 0.7 and 0.8 kg/min will ensure a safe and smooth completion of the ice plug formation process. The design and processes have been used successfully in hospital water supply system fixing works.

1. Introduction

On 19 May 2021, Taiwan entered a nationwide level 3 COVID-19 pandemic emergency. Domestic transmission of the virus increased exponentially in a short period of time. The island recorded more than 1200 local infections in five days, a sharp reversal from 253 days straight without any local infections the previous year [1]. The government required people to wear masks outside their homes, urging them to leave their homes only if necessary.

COVID-19 lockdown emergency measures in Taiwan and around the world had a direct impact on the water supply and distribution systems. Even though the environment was cleaner in big cities [2], water consumption increased [3], and water supply inequalities also increased [3]. The water sector in general underwent some changes. Those changes were documented [4,5,6]. However, the interplay of several factors, such as global warming and access to clean water, probably influenced the COVID-19 measures. Yet, hospitals are often confronted with pipe breakdowns and water shortages, which do not help the simple hygienic practice of washing hands and tools that facilitate the infection and spread of COVID-19. The main problem is to find a way to fix water pipes without shutting down the whole supply system. Therefore, our efficient no-shutdown pipe-fixing freezing approach is designed to provide a fast and reliable solution to this problem.

Preventing or containing the COVID-19 pandemic requires increased water availability in homes for personal hygiene and for institutions such as healthcare facilities [7]. Unreliable and unsafe water supplies can create conditions to facilitate infections [8]. With the lockdown restrictions and the increased number of domestic infections, hospitals in Taiwan have been overwhelmed. Ensuring the uninterrupted flow of their complex piped water distribution networks to combat this pandemic has become a priority. Piped water is one of the main improved water sources that plays an important role in achieving safely managed drinking water services [9], especially during global emergency cases such as the COVID-19 pandemic.

To help hospitals solve this problem, we have implemented an efficient pipe-fixing freezing method using the mechanism of heat transfer and ice plug formation that does not require water shutdown and tools that can be quickly moved to multiple pipeline failure points in narrow-spaced hospital locations.

The pipe-fixing freezing method uses bypass pipes to make it possible to work on a faulty area, while leaving the water supply system running. The heat transfer mechanism and ice plug formation have been widely used to fix water pipes. A two-pronged approach looked at the phase changes and convection phenomena in the ice formation process [10]. Habeebullah [11] used cooled copper tubes to examine the external characteristics of ice formation. Natural convection was shown to have some effect on the formation of ice in isothermally cooled horizontal cylinders [12,13]. The ice frost outside of a tube was measured [14]. The distribution of natural convection heat flux on isothermal circumferential fins attached to a horizontal cooled tubed was recorded [15].

The challenge encountered during the heat transfer and ice plug formation process is usually related to using different pipe sizes, monitoring temperatures, recording the freezing time, and choosing appropriate freezing liquids. More importantly, a major difficulty is to accurately determine when the ice has successfully blocked the pipe. Another difficulty is to control the steady flow, because it is very important to ensure completion of the freezing process. So, experiments have been carried out to understand the procedural steps. Tests were done on vertical pipes from 100 to 250 mm to monitor the shape of the ice plug, freezing time, and temperature variations [16,17,18]. All the studies mentioned above have been very important in understanding the parameters involved in the ice plug formation process. However, those studies were mostly conducted in laboratory with no specific methods to gauge if and when the ice had already formed. A traditional method was to wait for a long time to make sure that the process was completed. Our experiments, on the other hand, were not only carried out in the laboratory but also onsite under real and complex working conditions. In the wake of our experiments, we proposed two methods to gauge the completion of the ice formation process in real time.

More recent studies showed that using liquid nitrogen freezing was better than using other freezing liquids like brine freezing, because it was faster, safer, and more effective [19]. However, the literature review showed that liquid nitrogen freezing has not yet been used to fix water pipes in hospitals. Hu et al. [19] examined how the LN2 freezing method helped recover a collapsed shield tunnel. Choi et al. [20] used liquid nitrogen on ground freezing to study the rate and mechanical properties of coastal clayey silt. Sudisman et al. [21] investigated the vertically buried freezing pipe to look into the effects of the water flow to freezing sand. A testing model to evaluate the LN2 freezing temperature and plastic freezing pipe was developed [22].

The correlation between a freezing jacket’s length and a pipe diameter is important. Jackets should usually be longer than pipe diameters. However, short pipes with less freezing lengths require the use of shorter jackets less than twice the pipe diameters. Such a problem could have dire consequences if it is to be applied in hospitals where the freezing length, space, and time are considerably reduced. The size of the jacket is related to the size of the ice: increasing the jacket size requires the increase of the contact area (A), which leads to the increase of the size of the ice. Moreover, increasing the jacket size also requires using more liquid nitrogen and spending more time forming the ice. Therefore, there is a pressing need to design a proper size of the jacket.

From the literature, it is clear that there is not enough data on the use of heat transfer and ice plug formation to fix water pipes in hospitals. It is also clear that there is lack of studies on the technique designed to estimate the adequate liquid nitrogen supply rate, develop the proper size of the jacket, and reduce the time during the ice plug formation process. This paper aims to fill this gap. As mentioned earlier, the traditional method used to fix water pipes was to shut down the entire water supply system. Our major preoccupation in this study was to figure out how to fix complex water pipe systems in hospitals without shutting down the entire system. In order to answer this question, we set a couple of objectives, which were to develop a noninvasive water pipe fixing method that can help us isolate the faulty pipes while leaving the rest of the supply system up and running and to design a proper ice plugging jacket that can be flexible and adaptable. The following sections will focus on the setup of ice plug formation easily deployable equipment, the experiments involved in the process, the case study in the hospitals, and a discussion.

2. Materials and Methods

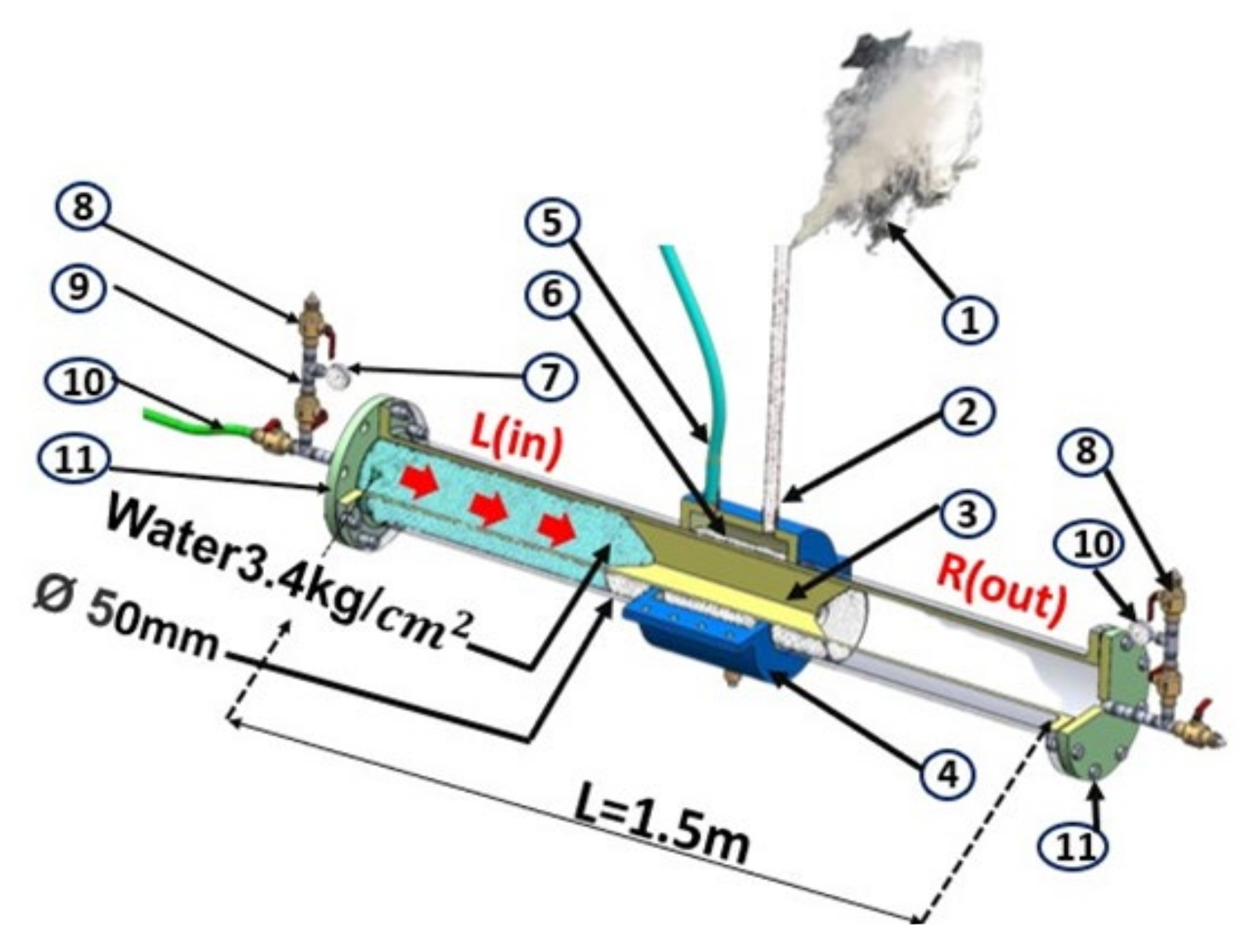

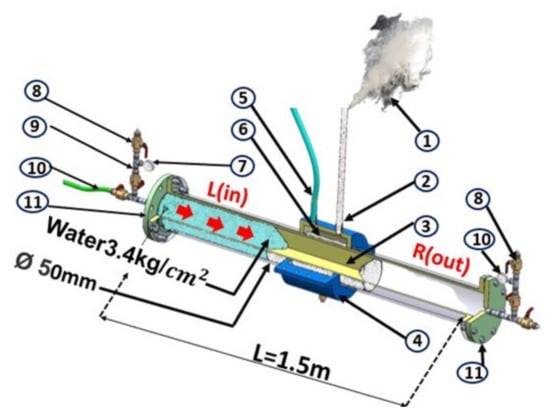

Considering the reduced space in hospitals and the risks of COVID-19 infection, repairing and maintaining water pipes required the use of equipment that is portable, malleable, fast, and safe. We conduct experiments and test our equipment first before doing maintenance work onsite. Figure 1 and Figure 2 below show the basic material and equipment required in the process of freezing pipes and stopping water to perform repairs and maintenance in narrow spaces.

Figure 1.

Detailed ice plug freezing mobile module.

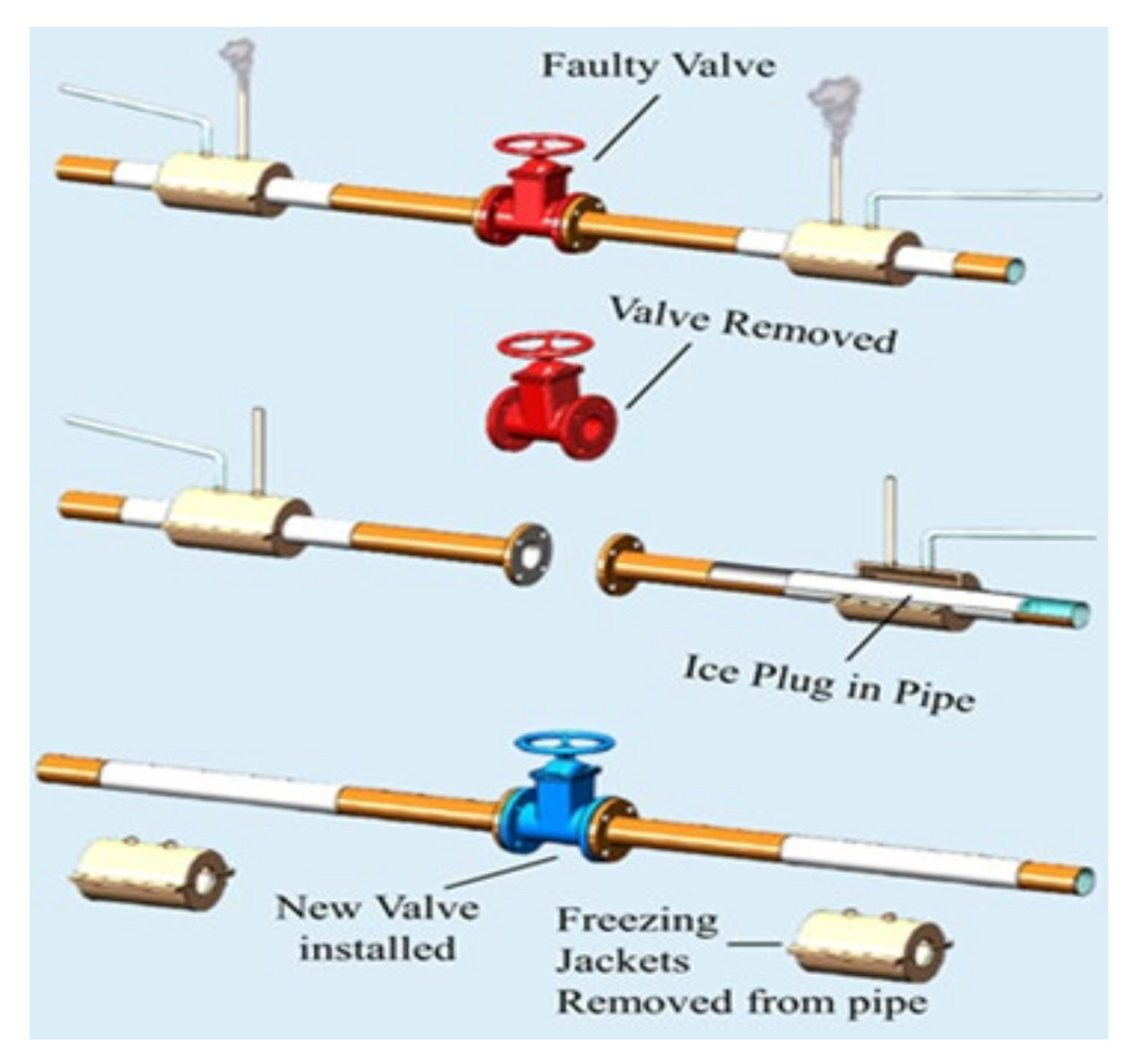

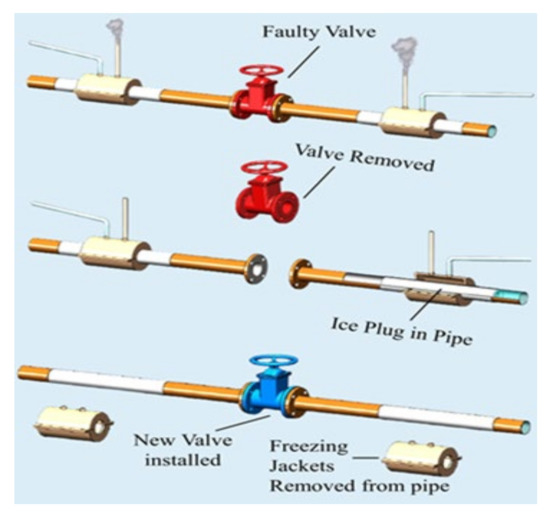

Figure 2.

Replacement of a faulty valve.

As we developed our methodology, we faced a couple of uncertainties. First, we needed to control the steady flow, because any flow in the isolated pipe would render the freezing method obsolete. Fellow researchers who may want to replicate this study should monitor the water flow and make sure it is steady before carrying out the freezing method. Then, we needed to pay attention to the thermal conductivity of the pipe wall, because with a low conductivity, the freezing method may not be successful. To avoid this, researchers should check the pipe properties and if there is any surface coating. Finally, we also considered the liquid nitrogen mass flow rate, because when it is too slow, it cannot take away enough heat to form an ice plug. Therefore, replicating this study requires using pipes with the same sizes utilized here and inject the right amount of liquid nitrogen into the inlet and at a proper speed between 0.7 and 0.8 kg/min to ensure a safe and smooth completion of the ice plug formation process.

Figure 1 illustrates a (1) nitrogen vapor exit, (2) vapor nitrogen exhaust pipe, (3) ice plug, (4) freezing jacket, (5) liquid nitrogen injection, (6) inside the freezing jacket, (7) pressure meter, (8) ball valve, (9) tee water pipe, (10) inlet pipe, and (11) blind. Figure 1 describes the process of turning water into an ice plug. The water pressure was maintained at about 1 kg/cm2 for about 30 min. The two ends of the pipe covered by the frozen saddle belt produced about 5–7 cm of frost, respectively, allowing to fix the faulty section of the pipe. During the ice formation process, we checked the freezing time, control freezing temperatures, and measured the flow rate. The experiment was implemented at the maximum water pressure, and the temperature, time and flow rate data were recorded. A hydrostatic test was utilized to check the ice formation and the movement of the ice plug in the pipes. Figure 2 shows that, at the end of the freezing process, we can safely replace the faulty valve.

3. Data Analysis and Case Study

3.1. Experimental Data Analysis

The process involved in the no-shutdown pipe-fixing freezing method depends on the water supply system design and the conditions of the environment. In order to perform onsite repair works in hospital water supply systems, two preliminary experiments are carried out. In this study, the authors estimated the liquid nitrogen supply rate to make sure of its adequacy in relation to the fixing system’s heat transfer performance. To ensure an efficient functioning of the equipment, a proper jacket needs to be designed considering the thermal property of the pipe material, thickness of pipe wall, and water temperature inside the pipe.

In general, when we slowly injected liquid nitrogen into the jacket, water also slowly turned into ice. This process is not harmful to the environment, since the liquid nitrogen concentration completely vaporizes into the ambient air at the exit area. However, when we injected liquid nitrogen into the jacket very fast, the two-phase heat transfer process accelerated. Partial nitrogen droplets were then carried by the vapor stream into the environment and could be detected at the exit area. Although these droplets could vaporize quickly into the environment at the exit, some large droplets caused cold burns to the staff onsite and might have been harmful to any surrounding tools or equipment. If there is too much nitrogen concentration in the air, ventilation may be needed to facilitate the vaporization of the droplets and regulate the proper circulation of breathable air. This is why doing some preliminary experiments and testing the appropriateness, safety, and efficiency of the equipment before carrying out repair works is important, because they help to measure the nitrogen stream temperature above the exit area to understand the conditions of the vaporized liquid nitrogen. An equally interesting future research could focus on developing a nitrogen concentration detection sensor.

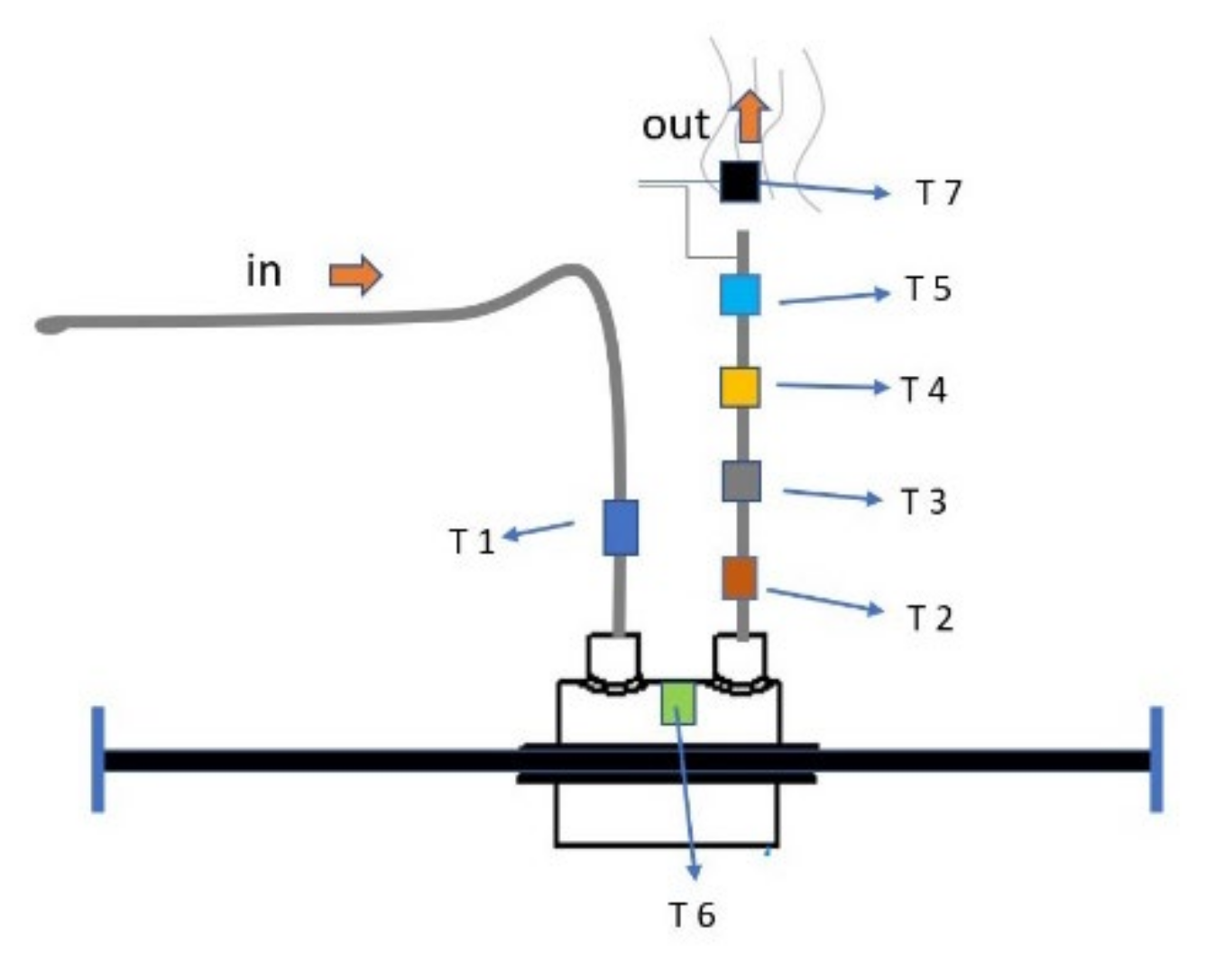

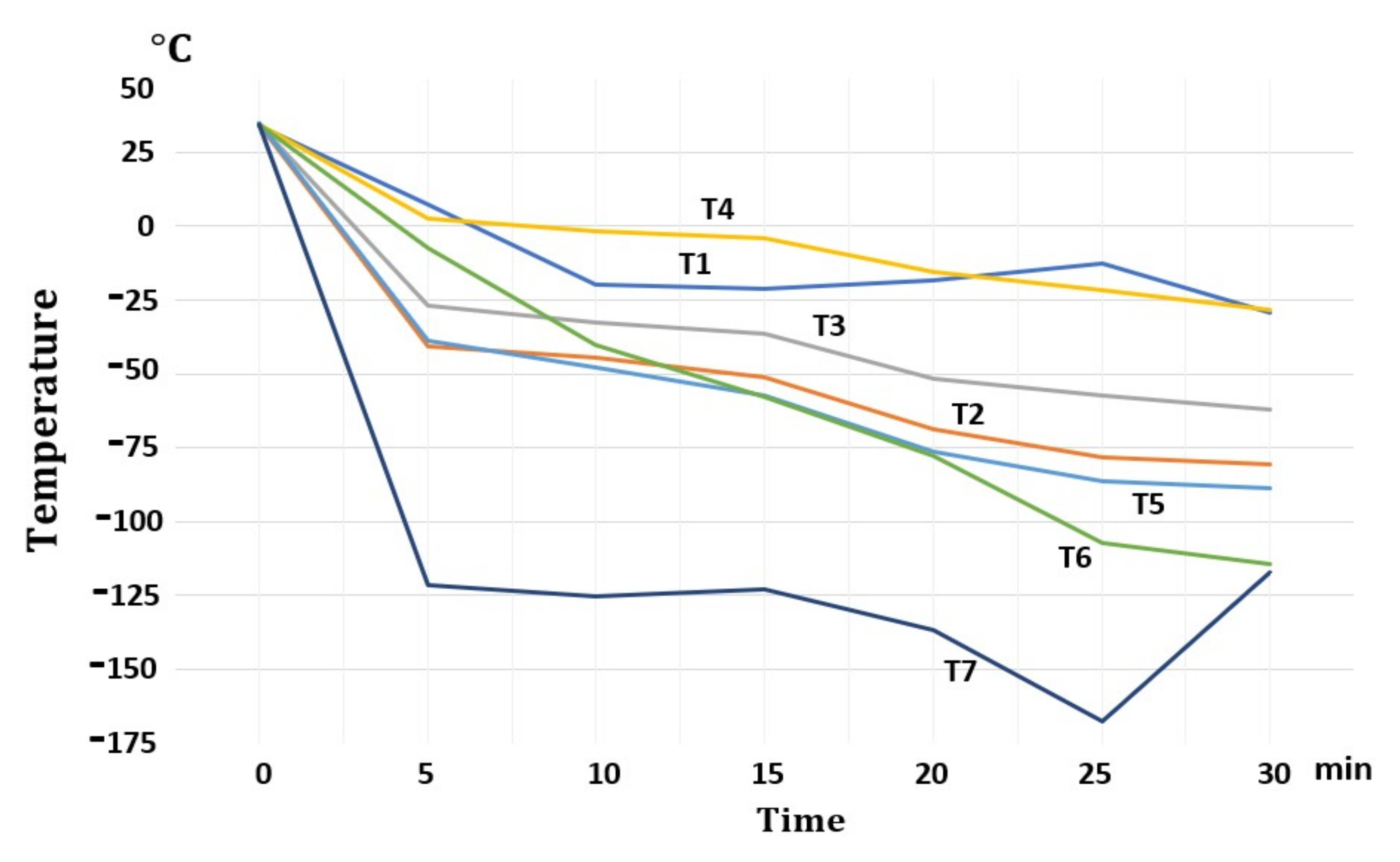

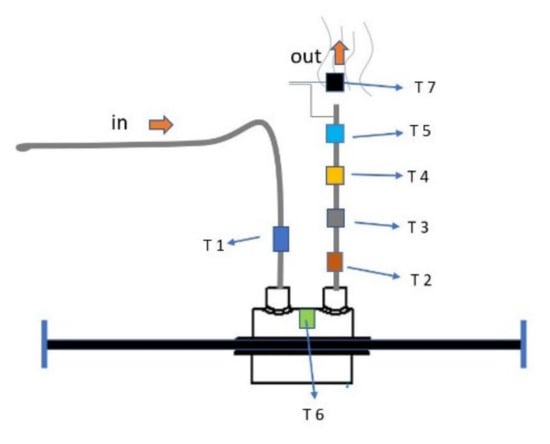

The first preliminary experiment conducted before the onsite fixing work was carried out is to install temperature sensors and record and analyze the temperature variations. In Figure 3, the experiment shows temperature sensor T1 on the surface of the inlet steel pipe, four sensors at the exhaust iron pipe, T6 on the surface of the jacket, and T7 at 8 cm above the exit. The exact locations of the sensors arranged from the water pipe centerline can be seen in Table 1. Figure 4 is the recorded temperature variations during the experiment. The environment temperature was 34.2 °C, and LN2 was injected at about −196 °C. The data showed that the temperature on the surface of the inlet pipe wall was not nearly as low as the temperature of the liquid nitrogen, because the poor thermal conductivity of steel reduced the environment air energy conduction to the inlet pipe wall.

Figure 3.

Locations of the temperature sensors.

Table 1.

Locations of the sensors.

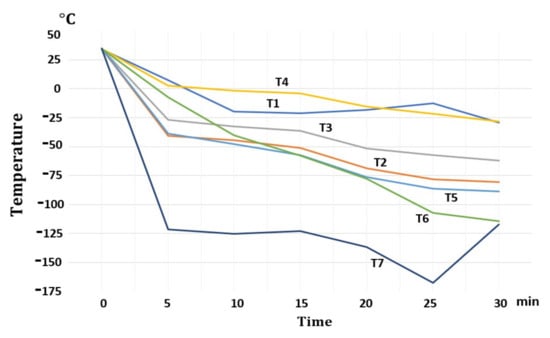

Figure 4.

Temperature variations.

After a violent heat transfer inside the jacket, the two-phase nitrogen process flows toward the exit. Sensors T2, T3, and T4 recorded similar temperatures change. As the two-phase nitrogen flowed through the small diameter exhaust pipe, the nitrogen droplets near the wall vaporized and heated up by the air in the environment. For about 15 min during the experiment, T4 recorded temperatures higher than inlet pipe T1, because the iron pipe had higher thermal conductivity than the steel pipe; and in this case, the environment air supply energy easily vaporized the liquid nitrogen droplets. Interestingly, the temperatures of T5 and T7 were lower than the others at the exhaust pipe. T7 was just above the exit area, so it was directly in contact with the nitrogen flow. T5 was attached to the exhaust pipe’s surface near the exit area and recorded the lowest temperature of all the surface sensors, because when the nitrogen flowed out of the pipe, there was a flow area contraction effect at the exit area.

The flow area contraction condition depends on the thickness and machine-shaped rim of the pipe exit wall, so that the flow rate coefficient is smaller than 1. This flow area contraction will increase the boundary layer thickness at the wall near the exit, the lower flow velocity will accumulate lots of nitrogen droplets on this wall, which will lower the temperature of the pipe outside the wall so that the recorded temperature of T5 is the lowest. T6 records the jacket surface temperature. A two-phase flow of nitrogen inside the jacket shows that the liquid and vapor nitrogen have the same temperature. However, the jacket is designed much thicker than the pipe wall to keep the temperature higher than LN2.

To summarize, dividing the nitrogen mass by the freezing time yields a range from 0.7 to 0.8 kg/min (see Table 2). These are the normal feeding rates. If we inject liquid nitrogen too fast (more than the above range) into the jacket, the vaporization process may not be completed, and the recorded temperatures may be very close to the temperature of the liquid nitrogen. If we inject liquid nitrogen slowly into the jacket, the vaporization process may be completed, and after mixing with the air in the environment, the recorded temperatures may be higher.

Table 2.

Freezing time for different water temperatures inside the pipe.

The second preliminary experiment conducted before the onsite fixing work was carried out to estimate the time needed for freezing and the liquid nitrogen consumption. For this experiment, a galvanized steel pipe diameter of 50 mm was used, which is the same as the one used in hospital water supply systems, and the water pressure inside the pipe was 3.3 kg/cm2. Usually, the challenge was to verify whether the water completely turned into ice inside the pipe. There are generally two ways to make sure: one is to measure the frost characteristics outside the pipe [23]. When water inside has completely turned into ice, the jacket and part of the pipe surface will be covered with frost. The patent acquired for such an experiment showed that the frost length on the pipe surface at either side of the jacket is 1.2–1.8 times the pipe diameter. This is a good way to judge the ice condition for onsite fixing work.

The other way is to measure the water pressure at both sides of the jacket. During the process of turning water into ice, the expansion volume increases the water pressure on both sides. At the end of the experiment, when it is verified that the ice has successfully blocked the water flow, the pipe is opened, and the ice is taken out. The immediate observation is that the ice length is longer than the jacket. The ice length is also asymmetrical to the jacket, as the left side by the inlet, where liquid nitrogen is injected, is longer than the right side, where the nitrogen vapor exits, so that, if the water pressure at the inlet side is 1 kg/cm2 greater than at the exit side, the ice freezing process is complete. This method is suitable for the preliminary experiment before carrying out the fixing work onsite, because the experiment pipe total length is short and limited. Table 1 shows the time needed and liquid nitrogen consumption of the freezing experiment results. When the water temperature is low, the freezing time and liquid nitrogen consumption decrease. When the water temperature is high, there is a need to get rid of sensible heat energy. However, the sensible heat effect is minor, because natural convection is alleviated at a lower temperature.

3.2. Case Study

The COVID-19 lockdown restrictions in Taiwan and the increased number of domestic infections have overwhelmed hospitals. Ensuring the uninterrupted flow of their complex piped water distribution networks to combat this pandemic has become a priority. Emergency repair works require the mobility and flexibility of pipe-fixing equipment because of the pressure of the growing number of cases, the multiple pipe defects, and the limitation of space at sites. Below are examples of pipes fixing using the liquid nitrogen method at two reference hospitals in Southern and Northern Taiwan.

Figure 5 below shows that the water pipe is located too close to the wall with not enough space to deploy heavy equipment. In this case, even with a complete shutdown of the system, a mechanical operation is hard to perform. Therefore, the authors designed small mobile equipment to freeze the pipe and fix the faulty point.

Figure 5.

Horizontal pipe in a narrow space location.

In some cases, facilities have several faulty pipes that need to be fixed in a short period of time. In traditional water shutdown mechanical fixing, there would need to be either a total shutdown of the entire system or at least a partial shutdown of a large area before repairing the pipe. However, with the flexible freezing jacket designs shown in Figure 6 below, we can operate in multiple locations and apply simultaneous freezing to as many pipes as possible.

Figure 6.

Fast-deployable equipment.

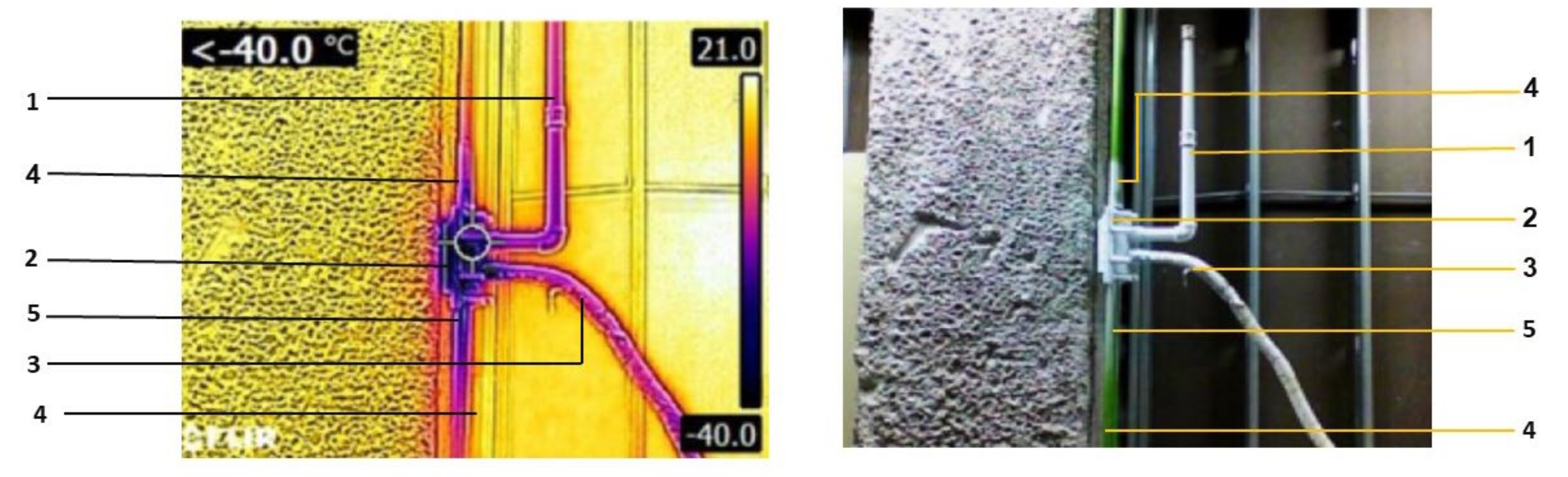

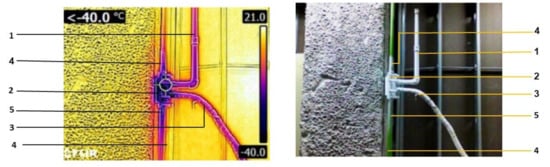

Figure 7 is used to actively monitor ice formation, allowing to trace downflow issues during a freeze and ensure the safety of every freeze. It helps us see through the pipe what we cannot see with our naked eyes. With this, we can control the temperature and quality of the ice plug. The scale bar shows that the highest temperature is about 21 °C, which is the surrounding temperature near the frozen location. The lowest temperature is −40 °C on the surface of the jacket. With this tool, we can see when water inside the jacket has transformed into an ice block.

Figure 7.

Infrared thermal imaging and onsite freezing jacket.

Figure 7 illustrates the (1) nitrogen exhaust pipe, (2) freezing jacket, (3) liquid nitrogen injection, (4) water pipe, and (5) low-temperature ring frost.

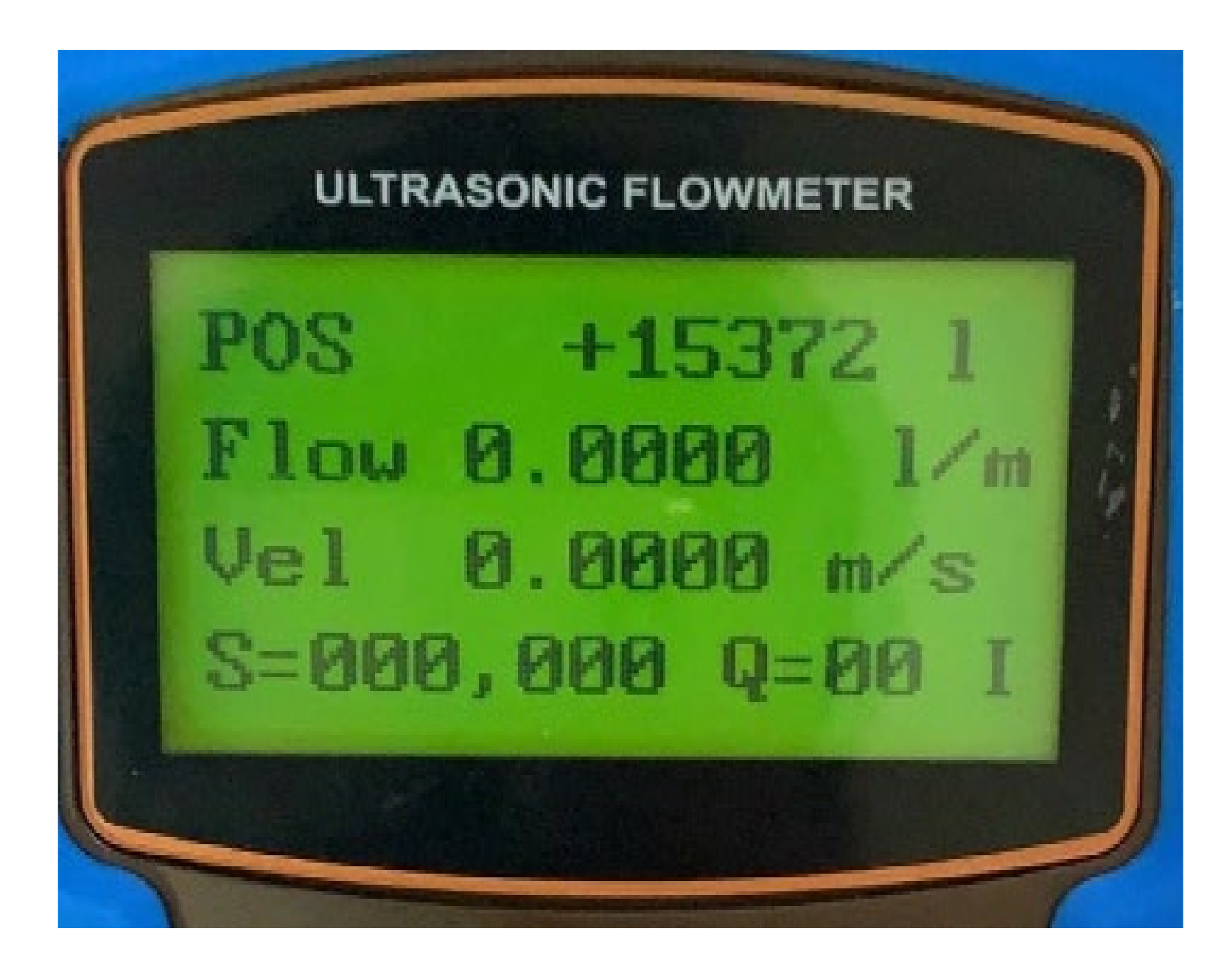

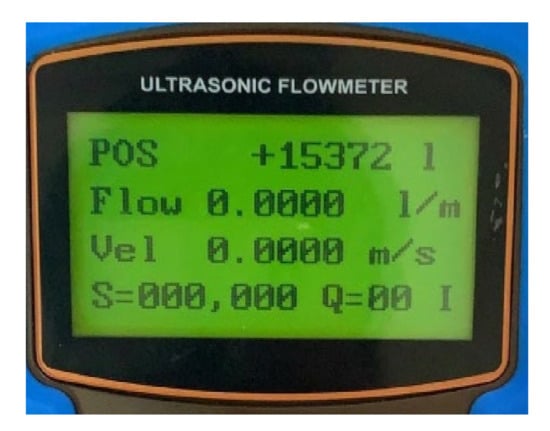

Figure 8 is used to measure the steady flow. A small flow rate will affect the heat transfer inside the jacket. Part of the nitrogen latent heat will be carried out by the water flow. The time needed to transform water into ice will be much longer. Under a higher critical flow rate reading condition, it is not possible to freeze water into ice inside the jacket. The zero flow rate reading can ensure better conditions for fixing water pipes successfully.

Figure 8.

Ultrasonic flowmeter.

4. Conclusions and Discussion

The COVID-19 pandemic has pushed humanity to adjust to the new reality and develop new methods to solve problems. One of those problems is to ensure a permanent water flow in hospitals and avoid more infections. The current study is concerned with undertaking two preliminary experiments before carrying out repair works at hospital complex water supply systems. The first experiment focuses on installing temperature sensors on iron and steel pipes, recording and analyzing the temperature variations. The results of this experiment showed that iron pipes have a higher thermal conductivity than steel pipes. The second preliminary experiment is two-fold and regards the estimation of the time needed during the freezing process and LN2 consumption. The first leg measures the frost characteristics to ascertain the completion of the ice plug formation process. The results show that, for the process to be deemed complete, the frost length on the pipe surface at either side of the jacket should be 1.2–1.8 times of the pipe diameter. The second leg of this experiment is to measure the water pressure at both sides of the jacket. The result showed that the ice length (~45 cm) was longer than the jacket (~34 cm), and when the water pressure at the liquid nitrogen injection inlet left side was 1 kg/cm2 greater than at the exit right side and the ice length was asymmetrically longer than the jacket at that left side, the ice freezing process was complete. However, a couple limitations of this study are the fact that it is still difficult to apply the heat transfer method to large diameter water pipes, and water with antifreeze cannot use water pipe freezing technology.

The overall aim of this study is to estimate the liquid nitrogen supply rate to make sure of its adequacy in relation to the fixing system’s heat transfer performance. During the experiments, it was shown that a fast injection of liquid nitrogen into the inlet accelerated the two-phase heat transfer process. Even though nitrogen droplets can vaporize quickly into the environment at the exit, partial large droplets are carried by the vapor stream into the environment, may cause cold burns to the staff onsite, and may be harmful to any surrounding tools or equipment. If there is too much nitrogen concentration in the air, ventilation may be needed to facilitate the vaporization of the droplets and regulate the safe and proper circulation of the air. Interesting future research could focus on developing nitrogen concentration detection sensors to monitor the safety of the environment. Research on artificial intelligence in freezing technology may also be a direction to explore.

Injecting the right amount of liquid nitrogen into the inlet and at a proper speed between 0.7 and 0.8 kg/min will ensure a safe and smooth completion of the ice plug formation process. If liquid nitrogen is injected too fast into the jacket, the vaporization process may not be completed, and the recorded temperatures may be very close to the temperature of the liquid nitrogen. If liquid nitrogen is injected slowly into the jacket, the vaporization process may be complete, and after mixing with the air in the environment, the recorded temperatures may be higher.

Once all the experiments and tests have been successfully carried out, proper equipment can be designed to fix faulty pipes in narrow space environments like hospitals. In the case study, the use of an ultrasonic flowmeter helped to measure the steady flow accurately and to keep away from the pump outlet and half-open valve. Ten straight unobstructed pipe outer diameters (10D) upstream and five diameters (5D) downstream is the minimum recommended distance for proper operation. The thermal imaging helps to see through the pipe what cannot be seen with naked eyes. These devices help to control the temperature and quality of the ice plug. The flexible and easily deployable equipment allows the engineers to operate and perform multiple and simultaneous freezing in narrow spaces.

Finally, our main research question was to figure out a way to fix complex water pipe systems in hospital buildings without shutting down the entire system. Our experiments, both in the laboratory and onsite led us to design the proper ice plugging jacket that can be flexible and adaptable and to develop a noninvasive water pipe-fixing method using LN2 to form ice plugs that can help us isolate the faulty pipes while leaving the rest of the supply system up and running. This study contributed to the improvement of the field of pipe fixing and thermal design methods and to understand the challenges involved in the freezing method and how to overcome them.

5. Patents

Liu, F.L and Chiang, T.Y. Chiang. Application of a frozen ice blocked pipe water method to non-shutdown repairing work of a water supply system. Patent No. TW201938923A.

Author Contributions

Conceptualization, F.-L.L. and S.-K.S.F.; methodology, F.-L.L. and S.-K.S.F.; formal analysis, F.-L.L. and S.-K.S.F.; investigation, F.-L.L. and E.N.; resources, F.-L.L. and J.-F.T.; data curation, F.-L.L.; writing—original draft preparation, E.N.; writing—review and editing, E.N.; project administration, F.-L.L.; supervision, F.-L.L.; funding acquisition, F.-L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by ST Water Company (Grant No. 2021001).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Special thanks to all those who supported the authors in this research.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| A | area |

| kg | Kilogram (basic unit of mass) |

| cm | centimeter (unit of displacement) |

| T | temperature (degree of heat present in a substance or object) |

| °C | degree Celsius (unit used to measure temperature) |

| min | minute |

| t | time |

| cm2 | square centimeter |

| mm | millimeter |

| ~ | approximately |

| D | diameter |

| LN2 | liquid nitrogen |

References

- Tan, Y. COVID-19: What Went Wrong in Singapore and Taiwan? Available online: https://www.bbc.com/news/world-asia-57153195 (accessed on 20 May 2021).

- Das, S.; Kaur, S.; Jutla, A. Earth Observations Based Assessment of Impact of COVID-19 Lockdown on Surface Water Quality of Buddha Nala, Punjab, India. Water 2021, 13, 1363. [Google Scholar] [CrossRef]

- Paudel, S.; Kumar, P.; Dasgupta, R.; Johnson, B.A.; Avtar, R.; Shaw, R.; Mishra, B.K.; Kanbara, S. Nexus between Water Security Framework and Public Health: A Comprehensive Scientific Review. Water 2021, 13, 1365. [Google Scholar] [CrossRef]

- Kalbusch, A.; Henning, E.; Brikalski, M.P.; Luca, F.V.D.; Konrath, A.C. Impact of coronavirus (COVID-19) spread-prevention actions on urban water consumption. Resour. Conserv. Recycl. 2020, 163, 105098. [Google Scholar] [CrossRef] [PubMed]

- Balacco, G.; Totaro, V.; Iacobellis, V.; Manni, A.; Spagnoletta, M.; Piccinni, A.F. Influence of COVID-19 Spread on Water Drinking Demand: The Case of Puglia Region (Southern Italy). Sustainability 2020, 12, 5919. [Google Scholar] [CrossRef]

- WatEner. Wasserverbrauch und Bedarfsprognose während der COVID-19-Krise. Available online: http://watener.com/index.php/wasserverbrauch-und-bedarfsprognose-wahrend-der-COVID-19-krise/?lang=de (accessed on 30 November 2020).

- Cooper, R. Water Security Beyond COVID-19; Unversity of Brimingham: Brimingham, UK, 2020. [Google Scholar]

- Howard, G.; Bartram, J.; Brocklehurst, C. COVID-19: Urgent actions, critical reflections and future relevance of ‘WaSH’: Lessons for the current and future pandemics. J. Water Sanit. Hyg. Dev. 2020, 18. [Google Scholar] [CrossRef]

- World Bank Group. Reducing Inequalities in Water Supply, Sanitation, and Hygiene in the Era of the Sustainable Development Goals; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Intemann, P.A.; Kazmierczak, M. Heat Transfer and Ice Formations Deposited upon Cold Tube Bundles Immersed in Flowing Water—I. Convective analysis. Int. J. Heat Mass Transf. 1997, 40, 557–572. [Google Scholar] [CrossRef]

- Habeebullah, B.A. An Experimental Study on Ice Formation around Horizontal Long Tubes. Int. J. Refrig. 2007, 30, 789–797. [Google Scholar] [CrossRef]

- Cheng, K.C.; Inaba, H.; Gilpin, R.R. Effects of Natural Convection on Ice Formation around an Isothermally Cooled Horizontal Cylinder. J. Heat Transf. 1988, 110, 931–937. [Google Scholar] [CrossRef]

- Hirata, T.; Matsui, H. Ice Formation and Heat Transfer with Water Flow around Isothermally Cooled Cylinders Arranged in a Line. J. Heat Transf. 1990, 112, 707–713. [Google Scholar] [CrossRef]

- Stampa, C.S.; Nieckele, A.O. Numerical Study of Ice Layer Growth around a Vertical Tube. Therm. Eng. 2005, 4, 138–144. [Google Scholar] [CrossRef]

- Sparrow, E.M.; Bahrami, P.A. Experiments on Natural Convection Heat Transfer on the Fins of a Finned Horizontal Tube. Int. J. Heat Mass Transf. 1980, 23, 1555–1560. [Google Scholar] [CrossRef]

- Burton, M.J. An experimental and Numerical Study of Plug Formation in Vertical Pipes during Pipe Freezing. Ph.D. Thesis, University of Southampton, Southampton, UK, 1986. [Google Scholar]

- Tavner, A.C.R. An Experimental Study of Ice Formation and Convection during Cryogenic Pipe Freezing. Ph.D. Thesis, University of Southampton, Southampton, UK, 1992. [Google Scholar]

- Bowen, R.J.; Burton, M.J.; Smith, G.S. The effect of pipe diameter and pressure drop on the formation of ice plugs in pipelines. In Proceedings of the Ninth International Heat Transfer Conference, Jerusalem, Israel, 19–24 August 1990. [Google Scholar]

- Hu, X.; Guo, W.; Zhang, L.; Wang, J. Application of Liquid Nitrogen Freezing to Recovery of a Collapsed Shield Tunnel. J. Perform. Constr. Facil. 2014, 28, 04014002. [Google Scholar] [CrossRef]

- Choi, H.J.; Won, J.; Lee, D.; Lee, H. Effect of Ground Freezing with Liquid Nitrogen on Freezing Rate and Mechanical Properties of Coastal Clayey Silt. J. Eng. Mech. 2021, 147, 04021057. [Google Scholar] [CrossRef]

- Sudisman, R.A.; Osada, M.; Yamabe, T. Experimental Investigation on Effects of Water Flow to Freezing Sand around Vertically Buried Freezing Pipe. J. Cold Reg. Eng. 2019, 33, 04019004. [Google Scholar] [CrossRef] [Green Version]

- Cai, H.; Li, P.; Wu, Z. Model Test of Liquid Nitrogen Freezing-Temperature Field of Improved Plastic Freezing Pipe. J. Cold Reg. Eng. 2020, 34, 04020001. [Google Scholar] [CrossRef]

- Liu, F.L.; Chiang, T.Y. Application of a Frozen Ice Blocked Pipe Water Method to Non-Shutdown Repairing Work of Water Supply System. Patent No. TW201938923A, 1 October 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).