Temperature Effect on Crack Evolution of Red Clay in Guilin

Abstract

:1. Introduction

2. Experimental Investigation

2.1. Test Materials

2.2. Test Instrument

2.3. Testing Procedure

3. Crack Image Processing Steps and Analysis

4. Water Evaporation Process of Red Clay at Different Temperatures

5. Development Process and Quantitative Analysis of Cracks at Different Temperatures

6. Analysis of Crack Evolution Mechanism of Guilin Red Clay

7. Conclusions

- (1)

- The water evaporation process of red clay is mainly divided into three stages: constant rate stage (I), variable deceleration rate stage (II), and residual stable stage (III).

- (2)

- The development and morphology of cracks in the drying process of red clay have a certain regularity. In the fissure network initially formed during the development of fissures, the small area of the fissure block more easily reaches a stable state of water content. Surface fissures are mainly divided into grade I, II, and III fissures.

- (3)

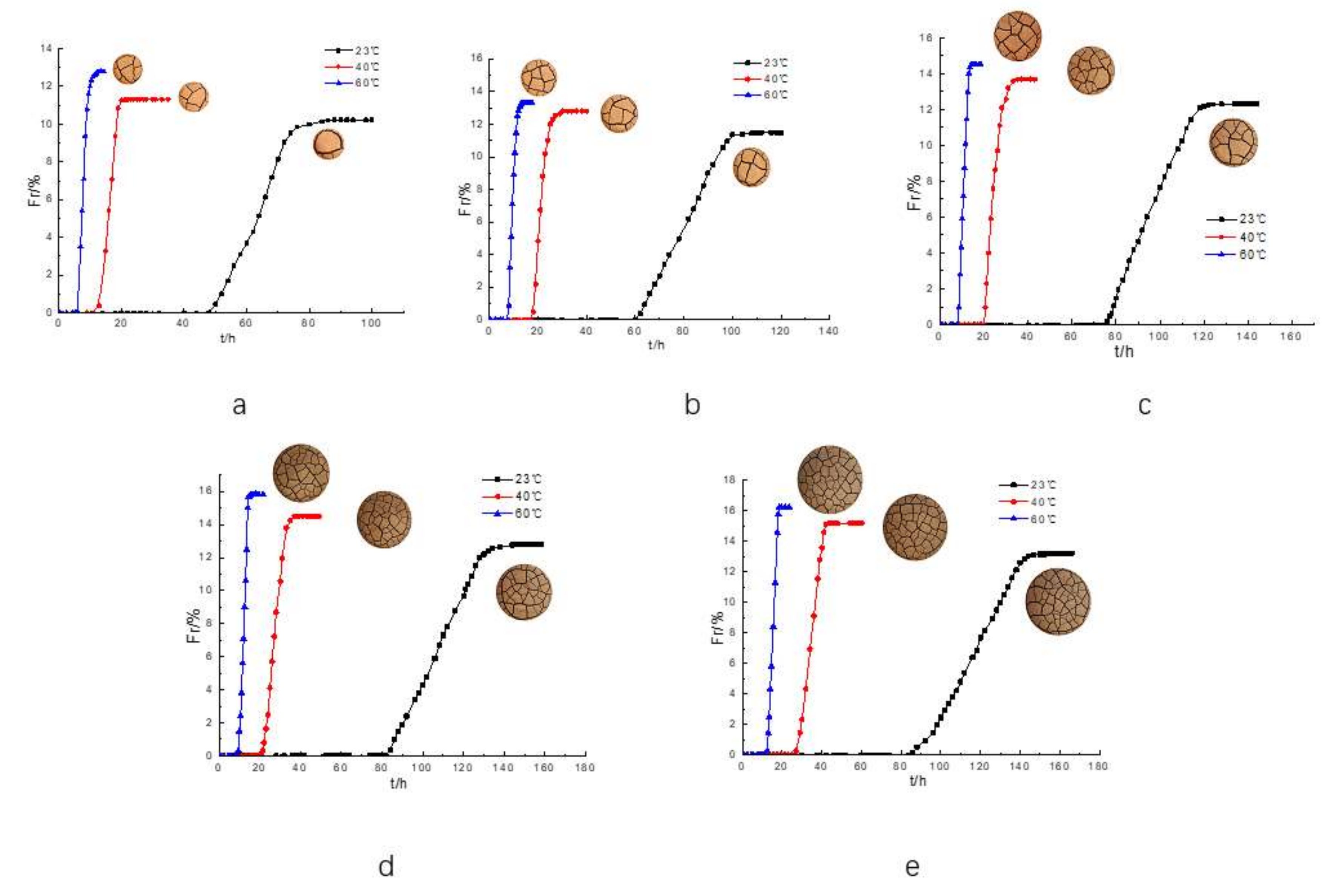

- The temperature effect of the fracture evolution of Guilin red clay is more obvious. With the increase of temperature, the time for the appearance of initial cracks in red clay becomes shorter, and the growth rate of cracks is significantly accelerated. The three stages of crack evolution in red clay are correspondingly shorter, and the number of final blocks of cracks is significantly reduced. The final surface crack rate of red clay increases with the increase of temperature.

- (4)

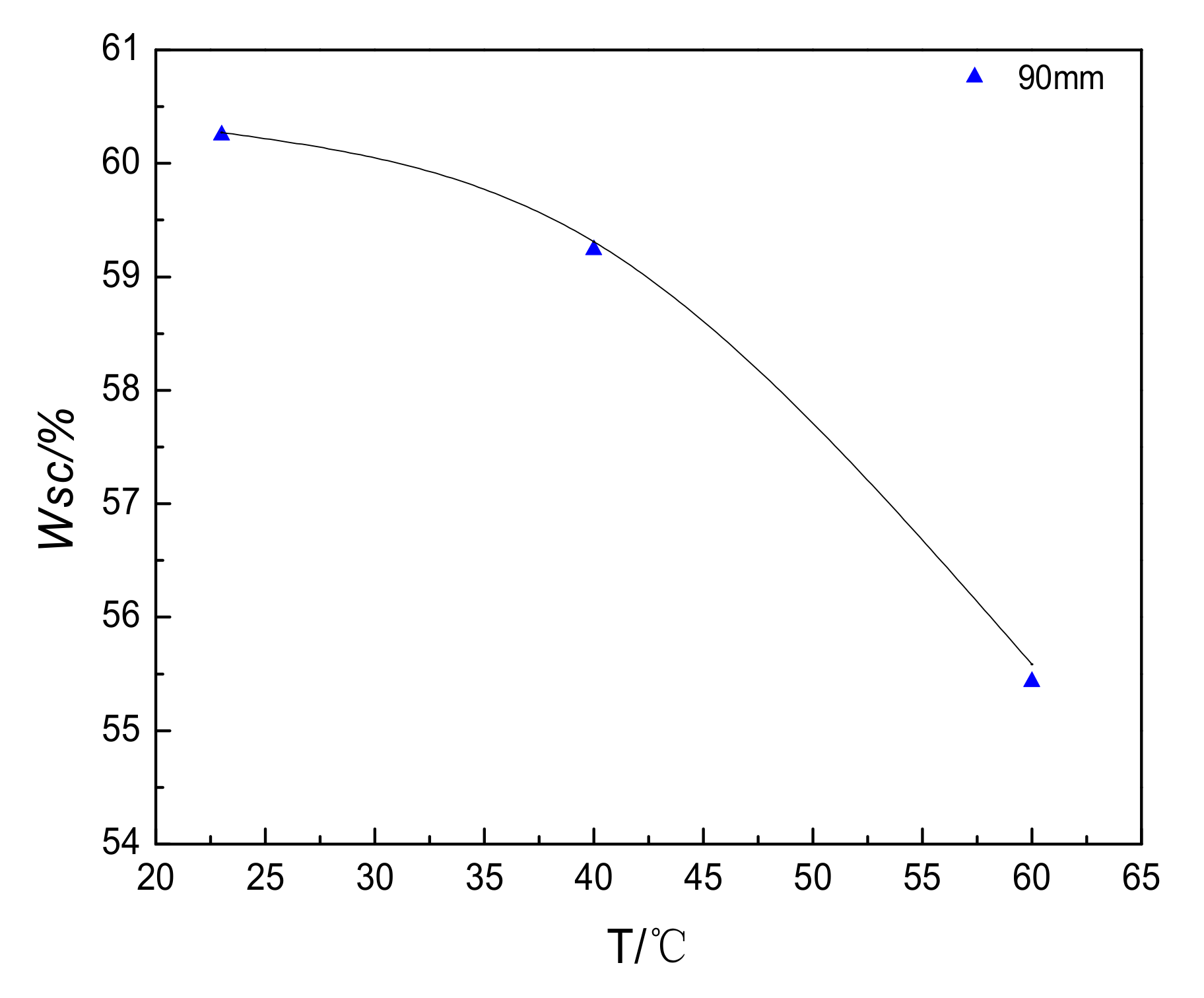

- With the increase of temperature, the total time required for the soil sample to lose water to the stability of the fissure gradually decreases. In addition, temperature has a greater influence on the critical moisture content of initial cracking. The higher the temperature, the lower the critical moisture content of initial cracking. The change in the air–liquid interfacial tension (surface tension) between soil particles is an important reason for the shrinkage and cracking of red clay. In the process of water loss and cracking of clay soil, the interior of the soil has experienced three states: saturated, unsaturated (water-air-grain interface), and dry states.

8. Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abuhejleh, A.N.; Znidarcic, D. Desiccation Theory for Soft Cohesive Soils. J. Geotech. Eng. 1995, 121, 493–502. [Google Scholar] [CrossRef]

- Peron, H.; Hueckel, T.; Laloui, L.; Hu, L. Fundamentals of desiccation cracking of fine-grained soils: Experimental characterisation and mechanisms identification. Can. Geotech. J. 2009, 46, 1177–1201. [Google Scholar] [CrossRef]

- Yao, J. Drought survey in Yunnan: Weak Water Conservancy Foundation and Prominent Engineering Water Shortage. Available online: http://news.sina.com.cn/c/sd/2013-05-08/055927056174.shtml (accessed on 8 March 2013).

- Kong, L.W.; Chen, J.B.; Guo, A.G.; Zhao, Y.L.; Lü, H.B. Field response tests on expansive soil slopes under atmosphere. Chin. J. Geotech. Eng. 2007, 29, 1065–1073. (In Chinese) [Google Scholar]

- Yin, Z.Z.; Yuan, J.P.; Wei, J.; Cao, X.S.; Liu, H.Q.; Xu, B. Influences of fissures on slope stability of expansive soil. Chin. J. Geotech. Eng. 2012, 34, 2155–2161. (In Chinese) [Google Scholar]

- Wang, S.J.; Wang, X.Q.; Li, D.; Li, X.; Liang, G. Evolution of fissures and bivariate—bimodal soil—water characteristic curves of expansive soil under drying—wetting cycles. Chin. J. Geotech. Eng. 2021, 43, 58–63. (In Chinese) [Google Scholar]

- Wang, Y.G. Theoretical Analysis and Experimental Study on the Mechanism of Bank Collapse in Alluvial River; China Institute of Water Resources and Hydropower Research: Beijing, China, 2003. (In Chinese) [Google Scholar]

- Sun, P.; Peng, J.B.; Wu, S.R. An experimental study on mechanical properties of fractured loess. J. Cent. South Univ. (Sci. Technol.) 2015, 46, 2188–2195. (In Chinese) [Google Scholar]

- Lloyd-Hughes, B. The Long Range Predictability of European Drought; University of London: London, UK, 2002. [Google Scholar]

- Tong-Lu, L.; Hong, W.; Yu-Kai, F.; Yan, L. Test Simulation on the Forming Mechanism of Loess Vertical Joints. J. Earth Environ. 2014, 36, 127–134. (In Chinese) [Google Scholar]

- Rayhani, M.H.; Yanful, E.K.; Fakher, A. Desiccation-induced cracking and its effect on the hydraulic conductivity of clayey soils from Iran. Can. Geotech. J. 2007, 44, 276–283. [Google Scholar] [CrossRef]

- Chang, L.-C.; Wang, H.-Y.; Xue, K.-X. Study on the laws of changes of cracks and shear strength in unsaturated red clay under different drying temperature. J. Eng. Geol. 2020. (In Chinese) [Google Scholar] [CrossRef]

- Liao, Y.L.; Bi, Q.T.; Jiang, G.P.; Zhao, K. Karst and red clay on the surface of carbonate terrane. Earth Environ. 2005, 33, 13–19. (In Chinese) [Google Scholar]

- Liao, Y.L.; He, J.; Qing, G. The Changing Law of Engineering Characteristics of Red Clay in South China. Guizhou Sci. 2008, 26, 53–58. (In Chinese) [Google Scholar]

- Jiang, H.-T. The origin of red clay and its influence on engineering properties. Hydrogeol. Eng. Geol. 2000, 27, 33–37. (In Chinese) [Google Scholar]

- Yao, H.L.; Zheng, S.H.; Chen, S.Y. Analysis on the slope stability of expansive soils considering cracks and infiltration of rain. Chin. J. Geotech. Eng. 2001, 23, 606–609. (In Chinese) [Google Scholar]

- Song, L.; Li, J.; Garg, A.; Mei, G. Experimental study on water exchange between crack and clay. J. Harbin Inst. Technol. 2017, 49, 146–151. (In Chinese) [Google Scholar]

- Cai, W.; Ling, D.; Xu, Z.; Chen, Y. Influence of preferential flow induced by a single crack on anti-seepage performance of clay barrier. Rock Soil Mech. 2014, 35, 2838–2844. (In Chinese) [Google Scholar]

- Jun, H.; Juan, W.; Yu, W. Desiccation Cracks and Hydraulic Performance of Compacted Clay Liner via Laboratory Wet-Dry Cycling. J. Eng. Geol. 2012, 20, 397–402. (In Chinese) [Google Scholar]

- Abedine AZ, E.; Robinson, G.H. A study on cracking in some Vertisols of the Sudan. Geoderma 1971, 5, 241. [Google Scholar]

- Ringrose-Voase, A.J.; Sanidad, W.B. A method for measuring the development of surface cracks in soils: Application to crack development after lowland rice. Geofis. Int. 1996, 71, 261. [Google Scholar] [CrossRef]

- Chen, K.-S. Evolution of cracks in red clay under wetting-drying cycles and its influence on shear strength. Hydrogeol. Eng. Geol. 2018, 45, 89–95. (In Chinese) [Google Scholar]

- Tang, C.S.; Shi, B.; Liu, C.; Wang, B.J.; Gao, W. Developing law and morphological analysis of shrinkage cracks of clayey soil under different temperatures. Chin. J. Geotech. Eng. 2007, 29, 743–749. (In Chinese) [Google Scholar]

- Shen, K.; Zhu, X.-Y.; Zhang, Y.-Y. Study on Crack Evolution Law of Expansive Soil under Different Temperatures. Water Resour. Power 2017, 35, 116–118. [Google Scholar]

- Zhang, H.; He, L.L.; Liu, H.Y. Research on the shrinkage and cracking characteristics of compacted red clay in Hohhot. J. Eng. Geol. 2019, 27, 1311–1319. [Google Scholar]

- Sima, J.; Jiang, M.; Zhou, C. Numerical simulation of desiccation cracking in a thin clay layer using 3D discrete element modeling. Comput. Geotech. 2014, 56, 168–180. [Google Scholar] [CrossRef]

- Kodikara, J.; Costa, W. Desiccation cracking in clayey soils: Mechanisms and modelling. In Multiphysical Testing of Soils and Shales; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Costa, W.D.S.M. Study of Desiccation Cracking and Fracture Properties of Clay Soils. Ph.D. Thesis, Monash University, Melbourne, Australia, 2010. [Google Scholar]

- Zhang, H.; He, L.L. Fracture characteristics of compacted red clay based on image processing. J. Jiang Su Univ. (Nat. Sci. Ed.) 2020, 41, 387–391. [Google Scholar]

- Tang, C.S.; Cui, Y.J.; Shi, B.; Tang, A.M.; Liu, C. Desiccation and cracking behavior of clay layer from slurry state under wetting–drying cycles. Geoderma 2011, 166, 111–118. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Tang, C.; Sun, K.; Li, H.; Xu, S.; Leng, T. Review on the mechanism and theoretical model of desiccattion cracking in clay soil. J. Eng. Geol. 2018, 26, 296–308. [Google Scholar]

- DeCarlo, K.F.; Shokri, N. Effects of substrate on cracking patterns and dynamics in desiccating clay layers. Water Resour. Res. 2014, 50, 3039–3051. [Google Scholar] [CrossRef]

- Murray, R.S.; Quirk, J.P. Intrinsic Failure and Cracking of Clay. Soil Sci. Soc. Am. J. 1990, 54, 1179. [Google Scholar] [CrossRef]

| Physical Properties | Value |

|---|---|

| Specific gravity | 2.73 |

| Liquid limit | 69.7% |

| Plastic limit | 44.6% |

| Natural moisture content | 34.91% |

| Optimum moisture content | 26.5% |

| Void ratio | 1.070 |

| Compression elastic modulus | 8.50 |

| Plasticity index | 23.7 |

| Maximum dry density | 1.56 ρd/g·cm−3 |

| Chemical Composition (%) | ||||||

|---|---|---|---|---|---|---|

| Material | SiO2 | Al2O3 | Fe2O3 | TiO2 | MgO | K2O |

| Red Clay | 34.5 | 41.32 | 16.72 | 2.48 | 1.2 | 1.9 |

| Particle Fraction | Clay | Silt | Gravel |

|---|---|---|---|

| grain size | <0.005 mm | 0.005–0.075 mm | 0.075–2 mm |

| Content | 32.0% | 66.40% | 1.60% |

| Temperature/°C | Diameter/mm | Number of Parallel Groups |

|---|---|---|

| 23 | 90 | 3 |

| 40 | 90 | 3 |

| 60 | 90 | 3 |

| Temperature/°C | Diameters/mm | Total Duration/h | Initial Cracking Time/h | Cracking Stability Time/h | Critical Humidity of Initial Cracking WSC/% | Number of Sample | Fissure Ratio/% |

|---|---|---|---|---|---|---|---|

| 23 | 90 | 168 | 76 | 136 | 60.25 | 32 | 12.32 |

| 40 | 90 | 47 | 20 | 35 | 59.24 | 31 | 13.69 |

| 60 | 90 | 21.5 | 8.5 | 16.5 | 55.43 | 29 | 14.53 |

| Temperature/°C | Diameter/mm | Initial Moisture Rate/% | Final Moisture Rate% |

|---|---|---|---|

| 23 | 90 | 60.25 | 2.23 |

| 40 | 90 | 59.24 | 1.64 |

| 60 | 90 | 55.43 | 0.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, G.; Ye, Z.; Xu, G.; Zeng, J.; Zhang, L. Temperature Effect on Crack Evolution of Red Clay in Guilin. Water 2021, 13, 3025. https://doi.org/10.3390/w13213025

Xiao G, Ye Z, Xu G, Zeng J, Zhang L. Temperature Effect on Crack Evolution of Red Clay in Guilin. Water. 2021; 13(21):3025. https://doi.org/10.3390/w13213025

Chicago/Turabian StyleXiao, Guiyuan, Ziming Ye, Guangli Xu, Jian Zeng, and Lu Zhang. 2021. "Temperature Effect on Crack Evolution of Red Clay in Guilin" Water 13, no. 21: 3025. https://doi.org/10.3390/w13213025

APA StyleXiao, G., Ye, Z., Xu, G., Zeng, J., & Zhang, L. (2021). Temperature Effect on Crack Evolution of Red Clay in Guilin. Water, 13(21), 3025. https://doi.org/10.3390/w13213025