Abstract

With the exploitation of the lower coal seams of the Taiyuan Formation, the Ordovician limestone water inrush in the floor became more serious. This paper considers the 162 and 163 mining areas of the Jiangzhuang Coal Mine, in Shandong Province, China. A comprehensive analysis of the geological and hydrogeological conditions of the mining area revealed the following: water pressure and water richness provide the water source and power for the floor water inrush; the thickness of the effective aquifer and the ratio of brittle rock can restrain floor water inrush; fault structures provide water inrush channels; and mining damage is an artificial interference and increases the probability of water inrush. Therefore, six factors: the water pressure of the Ordovician limestone aquifer, water abundance of the Ordovician limestone aquifer, equivalent thickness of effective aquifuge, brittle rock ratio, fracture structure, and mining destruction were selected as the influencing factors on water penetration of the bottom plate, and drawing software was used to establish a mining area map of related factors. The improved fuzzy hierarchical analysis method is more suitable for analyzing multi-objective decisions than the traditional hierarchical analysis method, but the weighting of results is influenced by expert experience. The entropy weight method is data-driven, and the empowerment results are objective. The improved fuzzy analytic hierarchy process and entropy weight method were coupled together, to determine the weight of each factor. The new method is not only data driven, but also takes empirical experience into consideration, making the empowerment results more reasonable. An evaluation of coal floor water inrush was established using MapGIS10.6, which is a general tool-type geographic information system software developed by the China University of Geosciences; and the risk of Ordovician limestone water inrush in the floor of the study area was classified into four levels: dangerous, relatively dangerous, relatively safe, and safe. The whole evaluation process is simple, but the evaluation results have practical importance and are very efficient, providing theoretical support for coal mine water prevention and control engineering.

1. Introduction

Coal is the most important energy source in China for the medium and long term. With the rapid development of the economy, the demand for coal has also greatly increased, resulting in accelerated coal mining. With the gradual depletion of the resource reserves of shallow coal seams with relatively good mining conditions, the proportion of deep coal seam mining has increased. The old mining area has developed into deep mining. Mining the lower coal seams of the Taiyuan Formation in the coal-bearing area of North China encroaches on the underlying karst aquifer of the basal Ordovician limestone. The water-holding and water-conducting properties are strong in the Ordovician limestone, and floor water inrush disasters are prone to occur in the mining process. Therefore, it is very important to study the threat of water inrush in the Taiyuan coal seam mining process. In recent years, domestic and foreign scholars have conducted in-depth research on water inrushing from coal seam floors. Regarding the development of prediction methods, the most commonly used methods are mainly statistical methods, such as trend analysis and the extrapolation method [1], which are too specific. Liu D.W [2] used the water system method to evaluate the risk of ash water in a slope-bottom coal mine. Shi L.Q [3] et al. used the probability index method to predict the water in a stope. Multi-information comprehensive prediction can reflect the degree of influence more objectively than a single information point. This was the first method widely used for medium-and long-term prediction. The geographic information system-based plate water prediction model is the most commonly used [4,5]. Wu Q. et al. [6,7,8] proposed the vulnerability index method and developed a new practical method based on a geographic information system: an artificial neural network vulnerability index method, based on a geographic information system and an analytic hierarchy process vulnerability index method based on a geographic information system. The theory of fuzzy systems is based on fuzzy sets. Fuzzy inference is conducted using fuzzy rules that are defined in the fuzzy set [9]. Theoretically, this can approximate any nonlinear map. This is the theoretical basis for fuzzy techniques to solve nonlinear and complex problems [10]. Li J.X [11] used fuzzy mathematics to predict the water burst in a bottom plate. Li Z.J [12] et al. used the dimensionless information fusion method to evaluate water burst risk. A neural network is an artificial network modeled on the nervous system of the human brain [13]. They can accomplish impressive feats, and are more effective compared to traditional computers in pattern recognition, combinatorial optimization, and decision making [14,15]. Yin H.Y [16] et al., in order to accurately predict the water risk of a bottom plate, first optimized the initial weight and the threshold of the network was randomly assigned by a genetic algorithm, and then selected the sparrow search algorithm, with a good search ability and stability, to twice optimize the weight and threshold; so as to establish a water prediction model of the SSA-GA-BP neural network. Liu W.T [17] et al. used the principal component-entropy weight method to establish an evaluation model for the risk of water outburst. Pan G.Y [18] et al. used the improved fuzzy level analysis method to evaluate water outbursts on a bottom plate. Yao H [19] et al. divided the mining area into four grades, using the weighted rank-sum ratio method based on combination weighting. The evaluation results were consistent with the actual situation. Zhang C.X [20] et al. divided the mining area into five grades, according to a natural classification method based on surfer application software and the vulnerability index method of the analytic hierarchy process.

Many theoretical and practical problems require thorough study and a further improvement in their ease of use. Therefore, the water prediction methods of a coal seam bottom plate require further exploration. Since the water inrush from the coal floor is caused by multiple factors, the selection of water inrush factors and the determination of the weight of each factor are extremely important for a risk evaluation. The analytic hierarchy process (AHP) is a practical multi-criteria decision-making method [21,22]. However, since there is no unified quantitative unit for many evaluation objects, data need to be normalized, so many scholars combine fuzzy theory [23,24] and grey theory [25]. Grey comprehensive evaluation cannot reflect the absolute level, so the allocation of index and weight is also a key issue when applying this method to the object for evaluation; and the appropriateness of selection directly affects the final evaluation results. The fuzzy comprehensive evaluation method can, not only evaluate and sort the evaluation objects according to their comprehensive score, but also evaluate their grade according to the maximum membership principle, according to the values of the fuzzy evaluation set. This overcomes the defect of the single result of traditional mathematical methods, and the results contain rich information. Although this method uses fuzzy mathematics theory, it is not overly sophisticated and complicated, so it is easy for people to master and use. The shortcoming of the fuzzy evaluation method is that it applies subjective judgment in the evaluation process. At the same time, it is still necessary to check the consistency of the judgment matrix in the calculation process. Some scholars [26] have improved the fuzzy analytic hierarchy process, changing the reciprocal judgment matrix into the fuzzy consistency judgment matrix, and combining the sum row normalization method or square root method with the eigenvector method. The improved fuzzy analytic hierarchy process not only solves the consistency problem of the judgment matrix, but also improves the convergence speed and accuracy of evaluation, so as to obtain a ranking vector consistent with reality. Nevertheless, because the determination of the weight of each factor is subjective, the improved fuzzy analytic hierarchy process is an evaluation method based on subjective information. The entropy weight method is a decision method that objectively quantifies and synthesizes multi-factor information, assigns values to each factor, and determines the degree of influence of each factor on the target. With its strong objectivity and relatively simple calculation, many scholars [27,28] have adopted this method for evaluations.

In this paper, the two most common methods (analytic hierarchy process and entropy weight method) are used to improve the final coupling, to establish a more functional and accurate prediction model. Finally, the improved fuzzy analytic hierarchy process (IFAHP) and entropy weight method (EW) are coupled to evaluate and predict the risk of Ordovician limestone water inrush, in the lower coal seam of the Taiyuan Formation in the Jiangzhuang Coal Mine of Tengzhou Mining Area, in Shandong Province, China. The new method provides a reliable theoretical basis for the prevention and control of water disasters in mining areas.

2. Materials and Methods

2.1. General Situation of the Mine

Jiangzhuang Coal Mine is located in the Tengnan mining area of the Tengxian coalfield of southwestern Shandong Province, China. The Jiangzhuang minefield is affected by the Gaomiao fault, Liuxianzhuang fault, and Yinjiawa fault. The overall structural line is distributed in a NNE direction, forming a wide and gentle fold area with a developed fault structure, and main the characteristics of a graben and barrier. There are many faults in the field. Coal bearing strata change along the strike and tendency, and magmatic intrusion occurs in some sections. The Jiangzhuang Mine is in the middle of the Tengnan Coalfield.

The coalfield strata comprise North China type sedimentary rock, with coal seams in the Carboniferous–Permian formations. The strata’s ages, from old to new, are Cambrian, Ordovician, Carboniferous, Permian, Jurassic, and Quaternary. The Cambrian strata are underlain by Quaternary sediments, except for sporadic outcrops outside the coalfield.

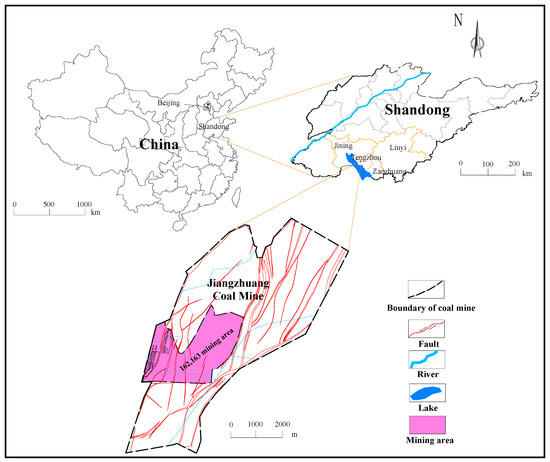

With the depletion of the upper coal resources in the Jiangzhuang Coal Mine, the mine will gradually start the mining of lower coal seams. The Taiyuan Group #16 coal will be the main mining object in the future. The 162 and 163 mining areas of the #16 coal seam are the initially developed and mined areas of the lower coal group in the mine. The burial depth of the 162 and 163 mining areas increases gradually from west to east, and the threat of floor water inrush increases gradually. In particular, the potentiometric pressure of the underlying Ordovician limestone confined aquifer increases, and the water inrush risk from the Ordovician limestone aquifer increases. Therefore, the study of the water inrush risk of the floor of the #16 coal seam has importance for the future prevention and control of water in the mine. The 162 and 163 mining areas are the research object of this paper, and their location is shown in Figure 1.

Figure 1.

162 and 163 mining area location diagram.

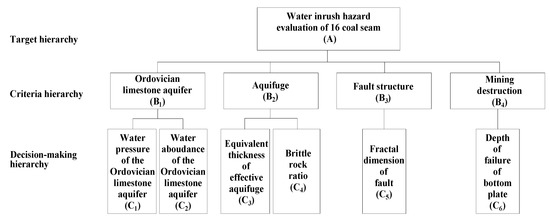

2.2. Analysis of Influencing Factors on Floor Water Inrush

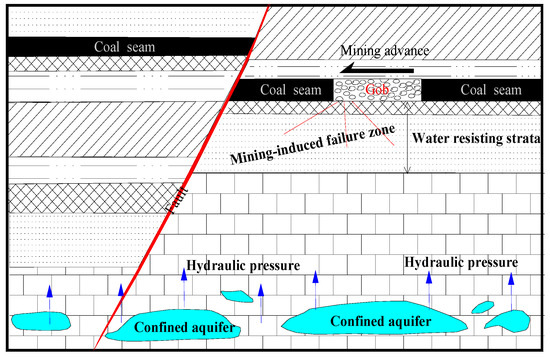

The proper selection of main control factors is conducive to establishing a hierarchical structure model, which plays a key role in the water inrush risk assessment of a coal seam floor. The water of a coal bed is affected by various factors, such as the geological structure, hydrogeology, and mining conditions [29]. As shown in Figure 2, the existence of a confined aquifer under a coal seam is the material basis of a water outburst, hydraulic pressure and mine pressure are the source of forces, and the water isolation formation is the inhibitory condition. The inhibitory capacity depends on the thickness, strength, and the combination of the water separator [30]. A fault is controlled when the water pressure, mine pressure, and stability of the isolation strata are in relative equilibrium. Through the study of the existing hydrological, geological, and production experience data of the Jiangzhuang Coal Mine and the analysis of water inrush factors, it was determined that the Ordovician limestone aquifer underlying the coal in the mine field is the main aquifer threatening the mining of the lower coal group. Coal seam #16 is seriously threatened by the Ordovician limestone water, because the seam is close to the Ordovician limestone, and the potentiometric pressure in the Ordovician limestone is high. Therefore, the water pressure of the Ordovician limestone aquifer, water richness of the Ordovician limestone aquifer, equivalent thickness of the effective water barrier, brittle rock ratio, fracture structure, and depth of failure of the bottom plate were selected as the main control factors for the water inrush prediction of the coal seam floor.

Figure 2.

Influencing factors of water inrush from coal floor.

2.2.1. Water Pressure of the Ordovician Limestone Aquifer

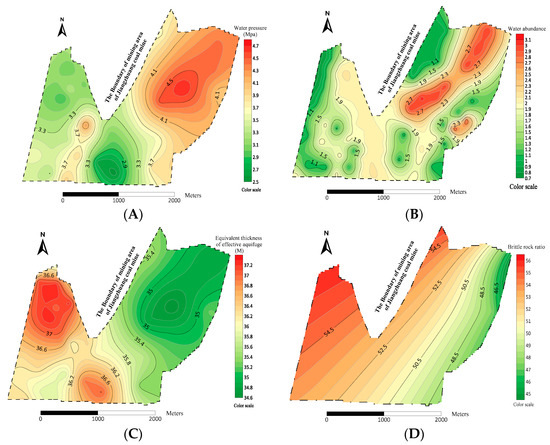

The water pressure of the Ordovician limestone aquifer is the source of the power of the floor water inrush. The greater the water pressure, the greater the possibility of water inrush. According to the mine’s 2006-1 hydrological drilling, the Ordovician limestone is 57.0 m above the #16 coal floor. The Ordovician limestone water head is −130.0 m below mean sea level, resulting in a water pressure of 4.564 MPa. The Ordovician limestone water pressure of the #16 coal seam floor in the 162 and 163 mining areas is between 2.5 and 4.7 MPa (Figure 3A). It can be seen from the figure that the water pressure in the northeastern mining area is the largest.

Figure 3.

Schematic map of water inrush influencing factors of the coal seam floor isoline in the 162 and 163 mining areas. (A) Water pressure of the Ordovician limestone aquifer isoline, (B)Water abundance of the Ordovician limestone aquifer isoline, (C) Equivalent thickness of effective aquifuge isoline, (D) Brittle rock ratio isoline, (E) Fracture structure dimension isoline, (F) Floor Failure Depth Isoline.

2.2.2. Water Abundance of the Ordovician Limestone Aquifer

The water abundance of the Ordovician limestone aquifer is the material basis for the floor water inrush. Its water abundance and supply conditions determine the water quantity of the floor water inrush and whether the water inrush point is sustained. Its water-richness is affected by its lithology, structure, hydrodynamic circulation conditions, burial depth, and other factors. The water-richness of the Ordovician limestone can be divided into three levels: weak, medium, and rich (Figure 3B). The water-richness of the Ordovician limestone aquifer in the mining area is weak to medium. It can be seen from the figure that the water abundance in the mining area increases from southwest to northeast.

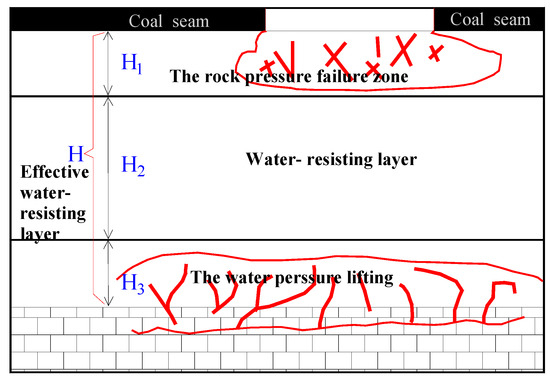

2.2.3. Equivalent Thickness of the Effective Aquifuge

The aquifuge has an inhibitory effect on the water inrush of the coal seam floor. According to the “lower three zones” (Figure 4) of water inrush from the coal seam floor [31], the effective water-resisting layer plays a important role in water blocking, and the thickness of the effective water-resisting layer is equal to the total thickness of the water-resisting layer, minus the depth of the rock pressure failure zone and the height of the water pressure lifting, which is expressed as Equation (1). The equivalent thickness of the effective water-resisting layer between coal seam #16 and the Ordovician limestone gradually becomes thinner from west to east, between 34.62 m and 37.32 m (Figure 3C).

Figure 4.

Schematic of the “lower three zones”.

According to the empirical formula of the depth of the bottom plate, and considering the mining depth, the inclination angle and slope length of the working face can be calculated according to Equation (2).

In this formula, H2—the thickness of the effective water-resisting layer, m; H—the total thickness of the water-resisting layer, m; H1—the depth of the rock pressure failure zone, m; H3—the height of the water pressure lifting, m; L—mining depth, m; α-Mining coal seam inclination; l—length of the mining work face, m.

2.2.4. Brittle Rock Ratio

Brittle rock plays a key role in preventing floor water inrush. Due to the heterogeneity of the rock strata, the ratio of brittle rock in different regions is different, and therefore the water insulation ability is also very different. Figure 3D shows the brittle rock ratio isoline in the 162 and 163 mining areas. The brittle rock ratio gradually increases from southeast to northwest.

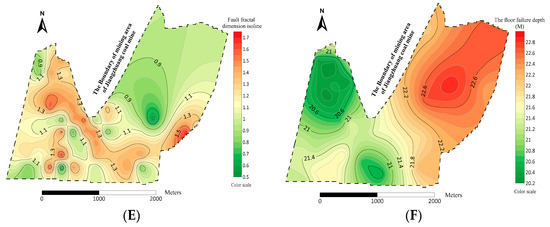

2.2.5. Fracture Structure

The fracture structure not only destroys the rock integrity, but also increases water conductivity. The greater the degree of fracture structure development, the higher the risk of water inrush. Therefore, the fracture structure is one of the important factors affecting the floor water inrush. The fractal dimension method [32] is used to synthesize many fault-related influencing factors, and the fault fractal dimension value is used to represent the influence of fault-related factors, so as to improve the accuracy of evaluation. First, the unit grids are established according to the size (), when the fault scale index is established. Then, each tectonic unit grid is divided into three levels, according to the continuation, and the number of grids containing faults in each cell is counted step by step, when the edge length of each grid is different. Through calculation, four groups of lgr and lgN (r) values (r is the cell edge length and N is the number of lattices with faults) were obtained. The point (lgr, lgN (r)) was plotted in a two-dimensional coordinate system, and a double logarithmic linear regression analysis was carried out. The slope k of the linear function is the fractal value, and a fault fractal dimension contour map of the mining area was drawn (Figure 3E).

2.2.6. Mining Damage

Mining damage refers to the stope space after coal seam mining, which causes the original stress change of the surrounding rock. When the stress borne by the surrounding rock exceeds its ultimate strength, displacement, cracking, fracture, and breakage will occur. When overburden deformation or displacement changes the water conductivity and water isolation performance of the rock strata, this results in mine damage effects. According to the degree and form of damage, mining damage causes caving and cracking. The damage to a coal seam floor can be expressed by the depth of the floor damage zone. Unlike the roof mining cracks, the floor damage depth of the floor mining cracks makes the effective protective thickness of the water-resisting layer smaller, resulting in a greater risk of water inrush from the floor of coal seam 16, which, in turn, has a great influence on the water filling of coal seam 16. The greater the floor damage depth, the higher the risk of water inrush from coal seam 16. The lower the floor failure depth, the lower the risk of Ordovician limestone water inrush from coal seam 16. The northeast of the mining area is seriously damaged (Figure 3F).

2.3. Determination of Influence Weight

2.3.1. Steps of IFAHP

IFAHP not only conforms to human mental logic, but also has a simple and accurate form. It is more suitable for multi-objective decision-making analyses than traditional AHP [33,34]. The improved fuzzy analytic hierarchy process not only solves the consistency problem of the judgment matrix, but also solves the accuracy problem and convergence speed problem of the solution; so as to obtain the sorting vector with a higher calculation accuracy and greater consistency with the actual situation.

- (1)

- Appropriate selection of the evaluation index system is a key step, which directly affects the evaluation results. Many scholars [35,36,37] have established new evaluation index systems based on the relevant factors of the evaluation object. Chen, J. [38] et al. established a mixed grey decision-making model based on grey analysis and used a hierarchical process and grey clustering method to evaluate the construction level of green mines. The evaluation index system included 24 indexes, which were divided into four groups and constructed according to the conditions of a green coal mine. Zhou, Y. [39] et al. established a green surface mining evaluation index system based on green grade theory. The evaluation model consisted of three attributes (safety, efficiency, and environment), with nine standards and 35 indicators. Using the fuzzy comprehensive evaluation method, the weight of the index was determined by considering the degree of centrality, proximity centrality, and intermediate centrality. Izhar Mithal Jiskani et al. [40] adopted a three-stage system research method and developed a decision support system. In the first stage, nine approaches were identified by combining extensive literature review and a Fuzzy Delphi method. The second stage involved a comprehensive fuzzy decision analysis method; ranking all challenges, exploring the relationship between them, and prioritizing the paths. Finally, a sensitivity analysis of path priority for the five challenges was carried out. Chen, J. [41] et al. studied and evaluated the current situation of green mine construction in China, and put forward a future framework. First, based on the driver pressure state influence response model, an evaluation index system composed of 20 indexes was established. The principal component analysis method was used to analyze data from Yongcheng mine in China. Based on an analysis of the factors of floor water inrush of the 16 coal seam, a hierarchical structure model of floor water inrush risk assessment was established in this paper (Figure 5).

Figure 5. The proposed water inrush of the coal seam floor safety evaluation index.

Figure 5. The proposed water inrush of the coal seam floor safety evaluation index. - (2)

- A complementary fuzzy judgment matrix (priority judgment matrix) was established using the three-scale method with element values of 0, 0.5, and 1. In order to accurately describe the relative importance of any two factors for a certain criterion, this paper used the 0.1~0.9 scale method to determine the element value (Table 1), and establish a priority judgment matrix .

Table 1. Quantitative scale 0.1–0.9.

Table 1. Quantitative scale 0.1–0.9. - (3)

- Find the sum of the row , use the transformation formula to transform fuzzy judgment matrix into a fuzzy consistency judgment matrix .

- (4)

- Use and line normalization method , obtaining an Order Vector.

- (5)

- Using conversion formula , transform the complementary judgment matrix into a reciprocal matrix .

- (6)

- Taking the sorting vector as the initial value of the eigenvalue method, the sorting vector with higher accuracy is further obtained, namely:

- ①

- Taking as the initial value of iteration, the eigenvector is obtained using the iteration formula , and the infinite norm of is obtained.

- ②

- Judgment: if , then is the maximum eigenvalue , is normalized after , and the obtained vector is the scheme sorting vector, and the iteration ends.

- ③

- Otherwise, take as the new initial value, reiterate.

- (7)

The priority judgment matrix of A-B is

The priority judgment matrix of B1-C is

The priority judgment matrix of B2-C is

Through a MATLAB calculation, the weight of each factor was obtained using IFAHP, see Table 2.

Table 2.

Comparison of IFAHP and AHP methods to determine the weight of each main control factor.

The results calculated using IFAHP and AHP are shown in Table 2. The weight ranking of each index obtained by the two methods is different. IFAHP increased the weight of aquifer influencing factors, and the weight of fracture structure and mining failure influencing factors was the largest in AHP. In reality, the water pressure and water yield of an aquifer often play a key role in the factors causing water inrush from a coal seam floor. Compared with the weight distribution method of IFAHP, it is more reasonable and highlights the contribution of the main factors.

2.3.2. Determination of Weight by Entropy Weight Method

The entropy weight method is a decision-making method used to objectively quantify and synthesize multi-factor information, assign values to each factor, and determine the degree of influence of each factor on the target. In information theory, entropy is a measure of uncertainty. The greater the amount of information, the smaller the uncertainty and the smaller the entropy. The smaller the amount of information, the greater the uncertainty and the greater the entropy [42]. The smaller the entropy value of the evaluation index, the greater the information provided, and the greater the role played in the comprehensive judgment of the evaluation results. In recent years, the entropy weight method has been widely used in aquifer evaluation, ecological vulnerability, and economic development investigations [43,44,45].

Taking the standardized matrix R as the research object, with one evaluation object and b evaluation indexes, there is a matrix R = (Xij)a×b, ei as the entropy value of the ith factor in i influencing factors, which is expressed in Equation (3):

In this expression, Pij is the weight of the jth evaluation index value under the ith index, which is expressed as Equation (4):

On this basis, all the influencing factors are weighted, and a more objective comparison result can be obtained. The entropy weight of the ith index can be expressed as Equation (5):

Through this calculation, the weight of each factor can be obtained using the entropy weight method (Table 3).

Table 3.

Entropy Weight Method to Determine the Weight Results of the Main Controlling Factors.

2.3.3. Determination of Comprehensive Weight using IFAHP-EW Coupling

The subjective weight obtained using the improved fuzzy analytic hierarchy process and the objective weight obtained with the entropy weight method are combined to obtain the comprehensive weight W (Table 4), which is expressed as in Equation (6):

Table 4.

Entropy Weight Method to Determine Weight Results of the Main Controlling Factors.

2.4. Evaluation of Water Inrush

2.4.1. Data Standardization

In order to eliminate the influence of different dimensions on the superposition calculation, the quantitative data of related factors should be standardized. In this paper, the range standardization Equation (7) is used to standardize the original data.

where is the original data of a factor, and (or )is the maximum (or minimum) value in the original data for the same factor.

2.4.2. Establishing the Prediction Model

The linear weighting method is used to evaluate each factor, and the results are obtained using Equation (8):

where is the water inrush index; , , , , , are the standardized data of various factors; and is the standardized weight in different ranges.

3. Results

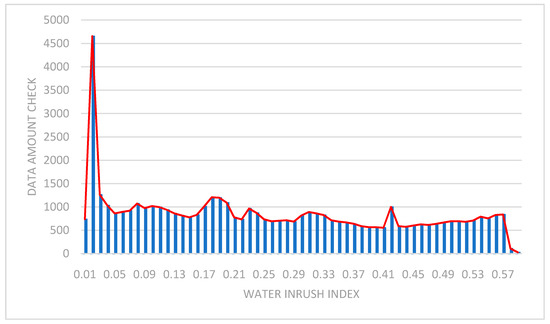

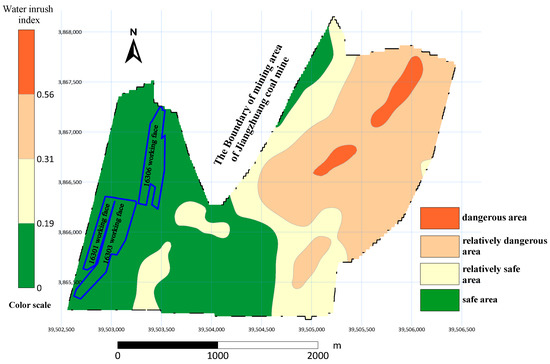

The assessment of water inrush risk consisted of the calculation of the mathematical model, obtainment of the water inrush index, determination of the partition threshold of the water inrush index, and the evaluation of the water inrush risk of the Ordovician limestone floor. The normalized data of the #16 coal seam were substituted into the prediction model to obtain the water inrush index. A total of 49,490 data points were extracted from the contour map of the water inrush index at an interval of 50 m (Table 5). Through an Excel analysis, the distribution of the water inrush index was determined, and a frequency histogram of the water inrush index was established (Figure 6). According to the distribution law of the frequency histogram, it suddenly decreased at 0.19, 0.31, and 0.56; gradually decreased after 0.46, and the changes of other parts were relatively gentle. The partition threshold of the Ordovician limestone water inrush index of the 16 coal seam floor was determined using the natural breakpoint method, which were 0.19, 0.31, and 0.56. According to this threshold, the mine field was divided into four areas: safe area (<0.19), safer area (0.19–0.31), more dangerous area (0.31–0.56), and dangerous area (>0.56). Figure 7 shows the water inrush risk zoning map.

Table 5.

Partial water inrush index data (standardization).

Figure 6.

Frequency histogram of water inrush index.

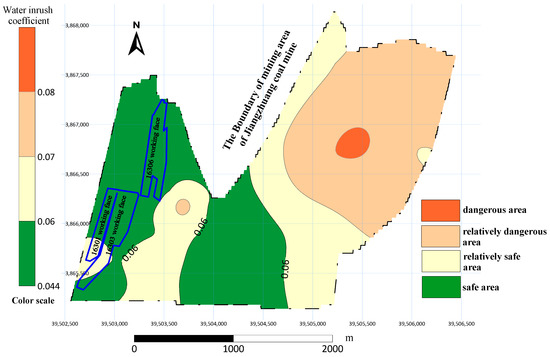

Figure 7.

Subjective and objective multi-source information coupling evaluation of water inrush risk zoning map.

The Chinese geodetic coordinate system 2000 was used in both Figure 7 and Figure 8. It can be seen from Figure 7 that the safety zone in the mining area is relatively large, mainly distributed in the west and southwest, and accounting for about 45% of the mining area. The relatively safe areas are mainly distributed in the central and southeast, accounting for about 20% of the mining area. The dangerous area is relatively large, mainly distributed in the east and northeast, and accounting for about 30% of the mining area. The dangerous area is the smallest, and is distributed in the northeast, accounting for about 5% of the mining area. From the evaluation model, it can be seen that the northeast and the east of the mining area have a greater possibility of water inrush. By analyzing the factors of water inrush from the coal floor, it can be seen that the northeast and east of the mining area have the largest water abundance and water pressure, which provide the source power for the water inrush from the coal floor. Moreover, the maximum mining damage leads to an increase of cracks in the coal floor, which provides a channel for water inrush. At the same time, the thickness of the waterproof layer in this area is the smallest, which further increases the probability of water inrush. The risk of water inrush is the greatest in the northeast and east of the 162 and 163 mining areas. It is suggested that the workers in this mining area need to increase their awareness and be effective in preventing water inrush.

Figure 8.

Risk zoning map of the water inrush coefficient method.

4. Discussion

The model needed to be tested. In this paper, the evaluation model established based on the water inrush coefficient method [46] (Figure 8) and the actual working situation of the mine were used to test the evaluation results. Chinese scholars first put forward the concept of the water inrush coefficient method during the Jiaozuo Mining Area hydrogeology Conference in 1964, and its expression is in Equation (9):

In the formula: Ts—water inrush coefficient, MPa/m; P—aquifer water pressure, MPa; M—thickness of the aquifer from mining coal seam to the floor, M.

It can be seen from the figure that the evaluation results of the model based on the combination weighting method and the results of the model based on the water inrush coefficient method are basically similar. By comparison, the water inrush coefficient method takes too few factors into account, and the range of zoning results obtained is fuzzy, so it cannot accurately reflect the actual situation of the mining area. At the same time, the 16301, 16303, and 16306 working faces in the mining area were mined safely, and no water inrush occurred during the mining period. These working faces are also located in the safety zone of the evaluation results, which further shows that the evaluation results are consistent with the actual situation. Multi-factor evaluation of mining areas, under the coupling of subjective and objective weights, can more specifically reflect the actual situation of a mining area, and the evaluation results are more accurate and scientific, which gives them a guiding role in the risk evaluation of coal seam water inrush.

At present, as mining has not commenced in the northeast of the mining area, it is impossible to verify the accuracy of the evaluation results in the northeast. If this can be accurately verified in the future, it can be used in future mine safety procedures.

5. Conclusions

- (1)

- Based on an analysis of the water inrush factors of the #16 coal seam floor in the Jiangzhuang Coal Mine, six main control factors affecting the water inrush of the Ordovician limestone confined water in the floor were determined, including the water pressure of the Ordovician limestone aquifer, water abundance of the Ordovician limestone aquifer, equivalent thickness of effective aquifuge, brittle rock ratio, fragile structure, and depth of failure of the bottom plate. These factors interact with each other, to jointly affect and control the dynamic process of the floor water inrush.

- (2)

- IFAHP was introduced to weight the main control factors of water inrush, which not only avoided the cumbersome consistency test of traditional AHP, but also highlighted the advantageous factors in determining the weight and determined the weight of each index more effectively, which provides a new method for the evaluation and prediction of water inrush from a floor.

- (3)

- In the calculation process of AHP, the determination of weight depends on expert experience, and the results are easily affected by the subjective factors of experts or evaluators. The entropy weight method determines the weight based on historical water inrush data. The calculation results are relatively objective and can avoid the influence of an evaluator’s subjective factors on the weight. However, the weight of the entropy weight method only represents the relative importance of each influencing factor, rather than the actual importance.

- (4)

- The IFAHP-EW method combines the entropy weight method and the fuzzy analytic hierarchy process (FAHP), utilizing the respective advantages of the FAHP and the entropy weight methods in determining the weight. This not only uses the actual water inrush data as the basis for calculation, but also reduces the influence of human factors. It effectively combines the subjective and objective, making the evaluation results closer to the actual situation. At the same time, a water inrush risk zoning model was established in combination with MapGIS10.6 software, to more directly and clearly represent the water inrush risk in the mining area.

- (5)

- The risk of the Ordovician limestone water inrush in the study area was divided into four grades: dangerous, relatively dangerous, relatively safe, and safe. The evaluation model predicted that the northeast and east of the mining area have the greatest probability of water inrush, and water prevention and control measures should be taken in future coal mining. It was verified that the prediction was in line with the actual situation. Compared with the prediction results of the water inrush coefficient method, it was more detailed and specific, and can be used to guide the prevention and control of mine water.

Author Contributions

Conceptualization, G.X.; methodology, H.Y.; validation, X.L.; investigation, Z.W.; data curation, G.X.; writing—original draft preparation, H.Y. and G.X.; writing—review and editing, P.Z.; visualization, Q.G.; supervision, H.Y.; project administration, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hingley, P.; Nicolas, M. Methods for forecasting numbers of patent applications at the European patent office. World Pat. Inf. 2004, 26, 191–204. [Google Scholar] [CrossRef]

- Liu, D.W. The study on the water inrush risk assessment of Ordovician limestone using water inrush coefficient method and its application in the Huipodi Coal Mine. China Coal 2016, 42, 118–120. [Google Scholar]

- Shi, L.Q.; Han, J.; Song, Y. Forecast of Water Inrush from Mining Floor with Probability Indexes. J. China Univ. Min. Technol. 1999, 28, 442–446. [Google Scholar]

- Marquinez, T. Predictive GIS-based model of rock fall activity in Mountain Cliffs. Nat. Hazards 2003, 30, 341–360. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, Y.; Liu, D.; Zhou, W. Prediction of floor water inrush: The application of GIS-based AHP vulnerable index method to Donghuantuo coal mine, China. Rock Mech. Rock Eng. 2011, 44, 591–600. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, S.Q.; Jia, G.K. Application of vulnerable index method in the assessment of water outbursts from coal seam floor. China Coal 2010, 36, 15–19. [Google Scholar]

- Wu, Q.; Jie, S.H.; Pei, Z.J. A new practical methodology of the coal floor water bursting evaluating III: The application of ANN vulnerable index method based on GIS. J. China Coal Soc. 2007, 12, 1301–1306. [Google Scholar]

- Wu, Q.; Wang, J.H.; Liu, D.H. A new practical methodology of the coal floor water bursting evaluating IV: The application of AHP vulnerable index method based on GIS. J. China Coal Soc. 2009, 34, 233–238. [Google Scholar]

- Abonyi, J.; Nagy, L.; Szeifert, F. Fuzzy model-based predictive control by instantaneous linearization. Fuzzy Sets Syst. 2001, 120, 109–122. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Li, M.; Liu, X. Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. Sci. 2012, 52, 50–55. [Google Scholar] [CrossRef]

- Li, J.X. Prediction of water irruption from coal floor using fuzzy mathematics. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 1990, 9, 11–18. [Google Scholar]

- Li, Z.J.; Wei, J.C.; Yin, H.Y. Dimensionless information fusion-A new method to evaluation of factors affecting water inrush from floor. China Min. Mag. 2010, 19, 95–103. [Google Scholar]

- Tawfiq, A.S.; Ibrahim, E.A. Artificial neural networks as applied to long-term demand forecasting. Artif. Intell. Eng. 1999, 13, 189–197. [Google Scholar]

- Taherdangkoo, R.; Taherdangkoo, M. Modified stem cells algorithm-based neural network applied to bottom hole circulating pressure in underbalanced drilling. Int. J. Pet. Eng. 2015, 1, 178–188. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Taherdangkoo, M. Application of hybrid neural particle swarm optimization algorithm to predict solubility of carbon dioxide in blended aqueous amine-based solvents. Int. J. Softw. Eng. Technol. Appl. 2015, 1, 290–307. [Google Scholar]

- Yin, H.Y.; Zhou, X.L.; Lang, N.; Zhang, L.F.; Wang, M.L.; Wu, T.; Li, X. Prediction model and application of GA-BP neural network based on SSA optimization. Geol. Explor. 2021, 49, 175–185. [Google Scholar]

- Liu, W.T.; Sun, Q.; Xu, B.C. Risk Evaluation of Water Inrush from Coal Seam Floor Based on GIS and Principal Component Analysis-Entropy Weight Method. Min. Res. Dev. 2020, 40, 83–88. [Google Scholar]

- Pan, G.Y.; Qin, Y.T.; Ma, Y.F. Risk Evaluation of Coal Floor Water Inrush Based on Improved Fuzzy Analytic Hierarchy Process. Saf. Coal Mines 2016, 47, 194–197. [Google Scholar]

- Yao, H.; Yin, S.X.; Xu, W.; Zhang, R.Q.; Jiang, Z.T. Risk assessment of floor water inrush based on weighted rank sum ratio method. Coal Geol. Explor. 2022, 1–6. Available online: http://kns.cnki.net/kcms/detail/61.1155.P.20220224.1721.002.html (accessed on 12 May 2022).

- Zhang, C.X.; Zheng, J.M.; Zhang, Y.Z.; Xu, Z.M. Coal seam floor water inrush evaluation method based on Surfer and its application. Min. Saf. Environ. Prot. 2020, 47, 60–64. [Google Scholar]

- Feng, B.S.; Yin, W.C. Research on Accessibility Evaluation Method of Urban Transportation Network Based on Analytic Hierarchy Process. Mod. Urban Rail Transit 2022, 4, 66–71. [Google Scholar]

- Zhao, H.; Zhao, X.M. Research on comprehensive evaluation of science and innovation enterprises based on AHP Method. Dev. Financ. Res. 2021, 6, 63–75. [Google Scholar]

- Liu, T.J.; Song, H.Q.; Zhang, J.; Luo, X.T.; Peng, R.Y.; Zhang, X.G. Application of fuzzy analytic Hierarchy Process in deep space exploration program optimization in China. J. Eng. Sci. 2022, 1–13. Available online: http://kns.cnki.net/kcms/detail/10.1297.TF.20220422.1329.002.html (accessed on 12 May 2022).

- Shu, W.T.; Zhou, S.W.; Liu, K.L.; Wang, X.N.; Tang, C.Y. Study on the Applicability of full section Method of Grade Surrounding rock section of single railway Tunnel based on fuzzy analytic Hierarchy Process. Railw. Constr. Technol. 2022, 1–6. Available online: http://kns.cnki.net/kcms/detail/11.3368.TU.20220406.0918.002.html (accessed on 12 May 2022).

- Tang, L.Y.; Zhang, C.M.; Yang, X.Y.; Liu, J.J.; Peng, X.; Li, D.X.; Du, X.Y. Research on establishment of comprehensive evaluation and screening system of TCM unknown prescription based on AHP-Grey Weighted Relational Analysis. Pharmacol. Clin. Tradit. Chin. Med. 2022, 1–22. [Google Scholar] [CrossRef]

- Li, Y.; Hu, X.H.; Qiao, J. An improved fuzzy AHP method. J. Northwest Univ. (Nat. Sci. Ed.) 2005, 35, 11–12. [Google Scholar]

- Liu, G.D.; Ji, Y.X.; Teng, R.; Liang, S.W.; Wang, Z.X.; Li, C.R. Control strategy of louvred exterior shading based on entropy weight method. Acta Energy Sol. Sin. 2022, 43, 236–241. [Google Scholar]

- Liu, H.Y.; Liu, Y.C.; Meng, L.H.; Jiao, K.Q.; Zhu, M.Y.; Chen, Y.K.; Zhang, P.F. Research progress of entropy weight method in water resources and water environment assessment. J. Glaciol. Geocryol. 2022, 44, 299–306. [Google Scholar]

- Wang, Y.; Jin, D.; Zeng, Y. Primary analysis on nonlinear characteristics of water in rush system through the seam floor in kaprst mines. Carsol. Sin. 1998, 17, 331–341. [Google Scholar]

- Ma, D.; Cai, X.; Li, Q.; Duan, H. In-Situ and Numerical Investigation of Groundwater Inrush Hazard from Grouted Karst Collapse Pillar in Longwall Mining. Water 2018, 10, 1187. [Google Scholar] [CrossRef] [Green Version]

- Li, B.Y. “Down Three Zones” in the Prediction of the water inrush from Coalbed Floor Aquifer theory, Development and Application. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 1999, 4, 11–18. [Google Scholar]

- Shi, L.Q.; Liu, L.; Zhou, J. Fault Fractal Information Dimension and Its Application in Floor Water Burst. J. Min. Strat. Control Eng. 2014, 19, 12. [Google Scholar]

- Wang, C.; Li, B.X.; Jiang, T.; Chen, H.H. AC fault screening and sequencing of AC/DC receiving power grid based on Improved Fuzzy Analytic Hierarchy Process. Power Grid Technol. 2021, 45, 4047–4056. [Google Scholar]

- Jiskani, I.M.; Shah, S.A.A.; Cai, Q.X.; Zhou, W.; Lu, X. A multi-criteria based SWOT analysis of sustainable planning for mining and mineral industry in Pakistan. Arab. J. Geosci. 2020, 13, 1108. [Google Scholar] [CrossRef]

- Suo, T.T. Influence factors and risk assessment of water inrush from coal seam floor. Shandong Coal Sci. Technol. 2021, 39, 156–159. [Google Scholar]

- Zhang, J.C.; Liu, T.Q. Analysis and research on influencing factors of water inrush from coal seam floor. Coal Min. 1993, 4, 35–39. [Google Scholar]

- Tian, L.G.; Jin, C.C.; Ba, C. Application of improved fuzzy AHP to safty evaluation of seawall engineering. Eng. J. Wuhan Univ. 2013, 46, 317–320. [Google Scholar]

- Chen, J.; Jiskani, I.M.; Lin, A.; Zhao, C.; Jing, P.; Liu, F.; Lu, M. A hybrid decision model and case study for comprehensive evaluation of green mine construction level. Environ. Dev. Sustain. 2022, 1–20. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, W.; Lu, X.; Jiskani, I.M.; Cai, Q.; Liu, P.; Li, L. Evaluation Index System of Green Surface Mining in China. Min. Metall. Explor. 2020, 37, 1093–1103. [Google Scholar] [CrossRef]

- Jiskani, I.M.; Cai, Q.X.; Zhou, W.; Lu, X.; Shah, S.A.A. An integrated fuzzy decision support system for analyzing challenges and pathways to promote green and climate smart mining. Expert Syst. Appl. 2022, 188, 116062. [Google Scholar] [CrossRef]

- Chen, J.; Jiskani, I.M.; Chen, J.; Yan, H. Evaluation and future framework of green mine construction in China based on the DPSIR model. Sustain. Environ. Res. 2020, 30, 13. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Pan, X.H. Entropy method for major hazards emergency rescue. J. Nanjing Technol. Univ. (Nat. Sci. Ed.) 2011, 33, 87–92. [Google Scholar]

- Ma, R.; Shi, J.S.; Liu, J.C. Application of Entropy Weight and Stochastic Theory to Study the Heterogeneity Synthetic Index of Aquifer. J. Jilin Univ. (Earth Sci. Ed.) 2011, 41, 1520–1528. [Google Scholar]

- Liu, P.G. Ecological Vulnerability Assessment Based on Entropy Weight Method-Taking Jinan City as an Example. Environ. Impact Assess. 2021, 43, 70–73. [Google Scholar]

- Luo, H.T. The Evaluation Model of “the Belt & Road” Economy Development and Suggestions-Analysis Based on AHP and Entropy Method. Spec. Zone Econ. 2021, 2, 64–68. [Google Scholar]

- Ministry of Coal Industry of People’s Republic of China. Regulations of Coal Mine Water Prevention and Control; China Coal Industry Press: Beijing, China, 1986. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).