Permeability and Porosity Changes in Sandstone Reservoir by Geothermal Fluid Reinjection: Insights from a Laboratory Study

Abstract

1. Introduction

2. Methods

2.1. Sample Preparation

2.2. Experimental Design

2.3. Major Elements and Mineral Analysis of Water and Ground Sandstone Specimens

2.4. Calculation of Mineral Volume and Porosity Changes

2.5. Inversion Simulation of Water-Rock Interaction

3. Results

3.1. Pressures Variation

3.2. Mineral and Element Changes during the Displacement Process

3.2.1. Major Elements Composition in Water and Ground Sandstone Specimens

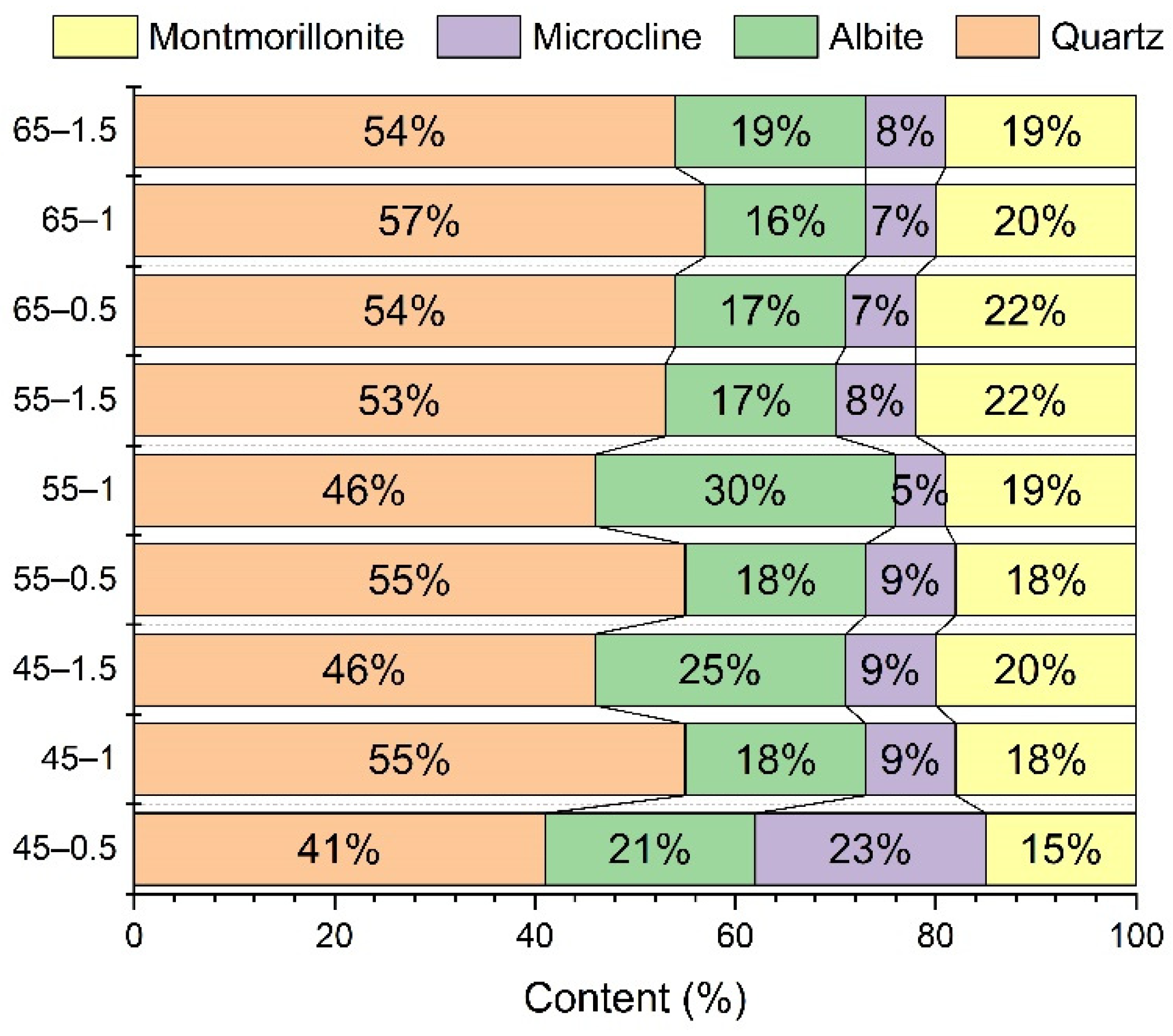

3.2.2. Mineral Composition Changes of Ground Sandstone Specimens

3.3. Permeability and Porosity Changes during the Displacement Process

3.3.1. Permeability Changes

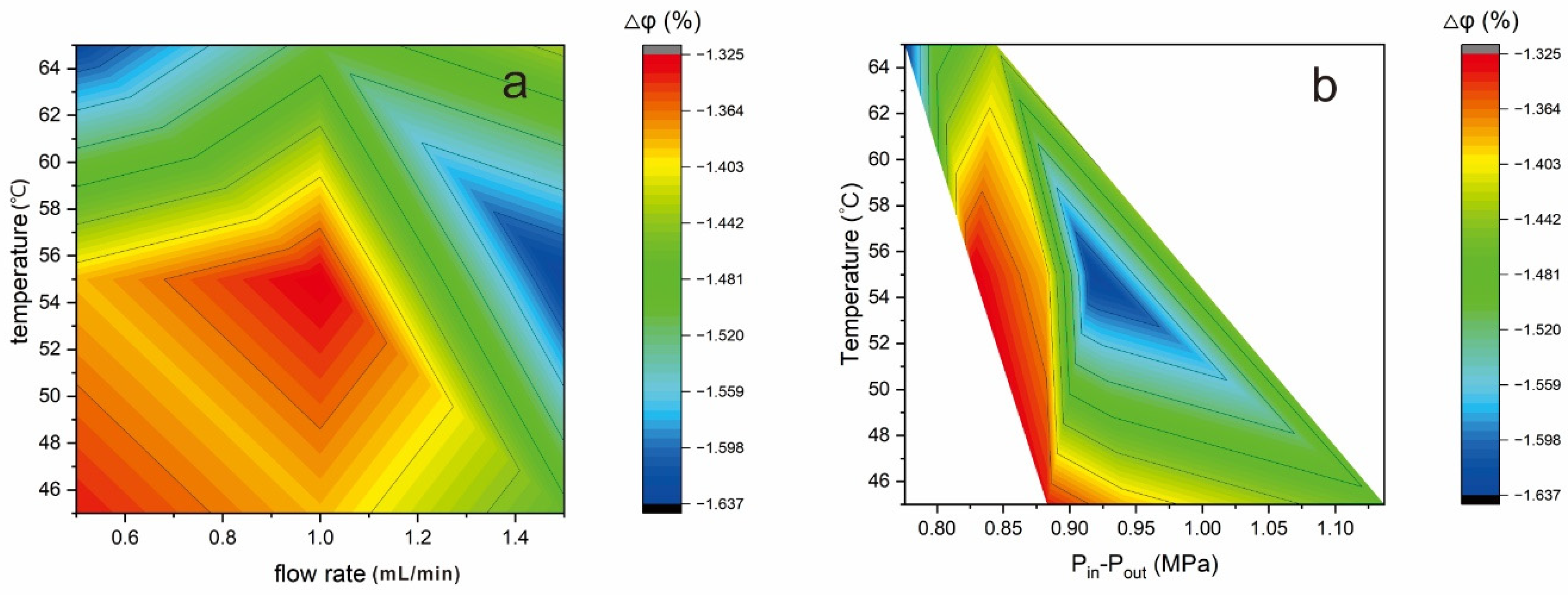

3.3.2. Porosity Changes

3.4. Water–Rock Interaction Simulation

- Halite: NaCl = Cl− + Na+

- Gypsum: CaSO4·2H2O = Ca2+ + + 2H2O

- Calcite: CaCO3 = + Ca2+

- Albite: NaAlSi3O8 + 8H2O = Na+ + + 3H4SiO4

- Quartz: SiO2 + 2H2O = H4SiO4

- Ca-montmorillonite: Ca0.165Al2.33Si3.67O10(OH)2 + 12H2O = 0.165Ca2+ + 2.33 + 3.67H4SiO4 + 2H+

4. Discussion

4.1. Analysis of the Causes of Permeability and Porosity Changes

4.1.1. Hydrochemistry Characteristics

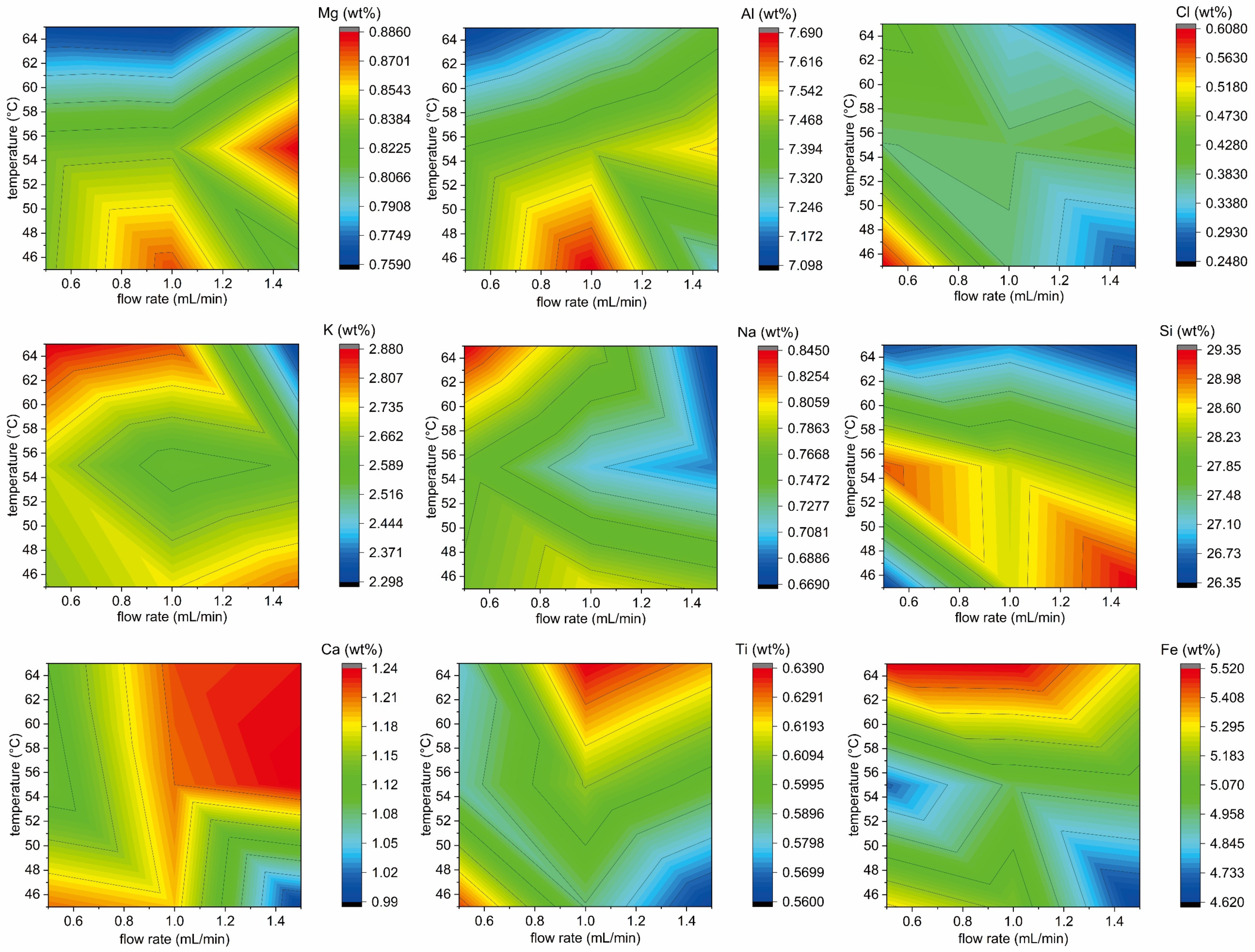

4.1.2. Comparison of Major Elements in Water Samples under Different Temperature and Flow Rate Conditions

4.1.3. Comparison of Major Elements in Ground Sandstone Specimens under Different Temperature and Flow Rate Conditions

4.1.4. Comparison of the Major Elemental Composition between Water and Ground Sandstone Specimens

4.1.5. Possible Reasons for Permeability and Porosity Changes

4.2. Implications for Sandstone Reinjection Blockage Reduction

5. Conclusions

- The high temperature with low flow rate exhibited the minimum displacement pressure. Flow rate is the main factor controlling permeability, while temperature has a relatively minor effect. Displacement at 45 °C—1.0 mL/min showed a minimal influence on permeability. Furthermore, 55 °C—1.0 mL/min and 45 °C—0.5 mL/min conditions showed a minimal amount of porosity decrease.

- During the experiments, quartz precipitated, albite and microcline dissolved, and montmorillonite was newly formed. A high temperature or high flow rate both led to an increase in the total volume change of minerals.

- The inversion simulation shows that albite is the main dissolved mineral and quartz, montmorillonite, and calcite are the main precipitated minerals. The injection process of geothermal fluids at 55 °C may have dissolved more minerals. However, the permeability reduction at 55 °C is greater than that at 45 °C. Therefore, the integrated blockage leading to permeability reduction contains multiple causes.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stefansson, V. Geothermal Reinjection Experience. Geothermics 1997, 26, 99–139. [Google Scholar] [CrossRef]

- Kaya, E.; Zarrouk, S.J.; O’Sullivan, M. Reinjection in Geothermal Fields: A Review of Worldwide Experience. Renew. Sustain. Energy Rev. 2011, 15, 47–68. [Google Scholar] [CrossRef]

- Wang, G.; Lin, W. Main Hydro-Geothermal Systems and Their Genetic Models in China. Acta Geol. Sin. 2020, 94, 1923–1937. (In Chinese) [Google Scholar]

- Long, X.; Xie, H.; Deng, X.; Wen, X.; Ou, J.; Ou, R.; Wang, J.; Fei, L.; Hu, D. Geological and Geochemical Characteristics of the Geothermal Resources in Rucheng, China. Lithosphere 2021, 2021, 1357568. [Google Scholar] [CrossRef]

- Lund, J.W.; Huttrer, G.W.; Toth, A.N. Characteristics and Trends in Geothermal Development and Use, 1995 to 2020. Geothermics 2022, 105, 102522. [Google Scholar] [CrossRef]

- Chen, Z. Modeling Water-Rock Interaction of Geothermal Reinjection in the Tanggu Low-Temperature Field, Tianjin. Earth Sci. J. China Univ. Geosci. 1998, 23, 513–518. (In Chinese) [Google Scholar]

- Xu, G.; Ma, Z.; Zhou, X.; Xi, L.; Sun, C. Study on the Mechanism of Chemical Clog for the Recharging of Geopressured Thermal Water—Taking the Recharging Well No. 1 In Xianyang as the Example. Geotechnol. Investig. Surv. 2013, 7, 40–44. (In Chinese) [Google Scholar]

- Zhao, Z.; Qin, G.; Luo, Y.; Yao, J.; Geng, S.; Zhang, L. Characteristics of Geothermal Water in the Xining Basin and Risk of Reinjection Scaling. Hydrogeol. Eng. Geol. 2021, 48, 193–204. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, R.; Zhang, W.; Gan, H.; Liu, F.; Wei, S.; Liu, L. Hydrochemical Characteristics and the Genetic Mechanism of Low–Medium Temperature Geothermal Water in the Northwestern Songliao Basin. Water 2022, 14, 2235. [Google Scholar] [CrossRef]

- Hou, J.; Cao, M.; Liu, P. Development and Utilization of Geothermal Energy in China: Current Practices and Future Strategies. Renew. Energy 2018, 125, 401–412. [Google Scholar] [CrossRef]

- Ullah, J.; Luo, M.; Ashraf, U.; Pan, H.; Anees, A.; Li, D.; Ali, M.; Ali, J. Evaluation of the Geothermal Parameters to Decipher the Thermal Structure of the Upper Crust of the Longmenshan Fault Zone Derived from Borehole Data. Geothermics 2021, 98, 102268. [Google Scholar] [CrossRef]

- Liu, J. The Status of Geothermal Reinjection. Hydrogeol. Eng. Geol. 2003, 30, 100–104. (In Chinese) [Google Scholar]

- Ma, Z.; Hou, C.; Xi, L.; Yun, H.; Sun, C. Reinjection Clogging Mechanism of Used Geothermal Water in a Super-Deep-Porous Reservoir. Hydrogeol. Eng. Geol. 2013, 40, 133–139. (In Chinese) [Google Scholar]

- Zheng, L.; Ma, Z.; Zheng, H.; He, D.; Li, Y. Comparison of Clogging Mechanism of Pore-Type Heat Storage Tail Water Recharge in Xi’an and Xianyang. Water Resour. Prot. 2015, 31, 40–45. (In Chinese) [Google Scholar]

- Zhang, L.; Geng, S.; Yang, L.; Wen, R.; He, C.; Zhao, Z.; Qin, G. Formation Blockage Risk Analysis of Geothermal Water Reinjection: Rock Property Analysis, Pumping and Reinjection Tests, and Long-Term Reinjection Prediction. Geosci. Front. 2021, 13, 101299. [Google Scholar] [CrossRef]

- Rybach, L. Geothermal Energy: Sustainability and the Environment. Geothermics 2003, 32, 463–470. [Google Scholar] [CrossRef]

- Song, W.; Liu, X.; Zheng, T.; Yang, J. A Review of Recharge and Clogging in Sandstone Aquifer. Geothermics 2020, 87, 101857. [Google Scholar] [CrossRef]

- Kamila, Z.; Kaya, E.; Zarrouk, S.J. Reinjection in Geothermal Fields: An Updated Worldwide Review 2020. Geothermics 2020, 89, 101970. [Google Scholar] [CrossRef]

- Seibt, P.; Kellner, T. Practical Experience in the Reinjection of Cooled Thermal Waters Back into Sandstone Reservoirs. Geothermics 2003, 32, 733–741. [Google Scholar] [CrossRef]

- Rosenbrand, E.; Haugwitz, C.; Jacobsen, P.S.M.; Kjøller, C.; Fabricius, I.L. The Effect of Hot Water Injection on Sandstone Permeability. Geothermics 2014, 50, 155–166. [Google Scholar] [CrossRef]

- Lin, J.; Zhao, S. An Analysis of the Reinjection Attenuation of the Guantao Group Geothermal Reservoir in the Tianjin Area. Hydrogeol. Eng. Geol. 2010, 37, 133–136. (In Chinese) [Google Scholar]

- Wu, J.; Zhang, J.; Li, X.; Shi, F.; Zhang, P.; Bai, M. Experiment on Artificial Pressure Reinjection of Geothermal Water in Xian Suburb. J. Water Resour. Water Eng. 2014, 25, 215–218. (In Chinese) [Google Scholar]

- Su, Y.; Yang, F.; Wang, B.; Jia, Z.; Duan, Z. Reinjection of Cooled Water into Sandstone Geothermal Reservoirs in China: A Review. Geosci. J. 2017, 22, 199–207. [Google Scholar] [CrossRef]

- Gao, B.; Zeng, M. Causes and Prevention Measures of Clogging in the Reinjection Well of a Geothermal Double-Well System. Hydrogeol. Eng. Geol. 2007, 34, 75–80. (In Chinese) [Google Scholar]

- Liu, X.; Zhu, J. A study of Clogging in Geothermal Reinjection Wells in the Neogene Sandstone Aquifer. Hydrogeol. Eng. Geol. 2009, 5, 138–141. (In Chinese) [Google Scholar]

- Bouwer, H. Artificial Recharge of Groundwater: Hydrogeology and Engineering. Hydrogeol. J. 2002, 10, 121–142. [Google Scholar] [CrossRef]

- Rinck-Pfeiffer, S.; Ragusa, S.; Sztajnbok, P.; Vandevelde, T. Interrelationships Between Biological, Chemical, and Physical Processes as an Analog to Clogging in Aquifer Storage and Recovery (ASR) wells. Water Res. 2000, 34, 2110–2118. [Google Scholar] [CrossRef]

- Fetzer, J.; Holzner, M.; Plötze, M.; Furrer, G. Clogging of an Alpine Streambed by Silt-Sized Particles–Insights from Laboratory and Field Experiments. Water Res. 2017, 126, 60–69. [Google Scholar] [CrossRef]

- Yuhara, K.; Maruyama, H. Model Experiment of Effects of Air Bubbles on the Decrease of the Ability of the Reinjection Well. J. Geotherm. Res. Soc. Jpn. 1996, 8, 201–217. [Google Scholar] [CrossRef]

- Pan, J.; Song, J.; Ye, M. Experimental Study on Influencing Factors of Chemical Plugging of Iron and Manganese in Groundwater Source Heat Pump. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2017, 33, 953–960. [Google Scholar]

- Li, Y.; Pang, Z.; Yang, F. CO2-EATER Model on Guantao Formation of Beitang Sag. Sci. Technol. Rev. 2013, 31, 15–20. (In Chinese) [Google Scholar]

- Tutolo, B.M.; Luhmann, A.J.; Kong, X.-Z.; Saar, M.O.; Seyfried, W.E. CO2 Sequestration in Feldspar-Rich Sandstone: Coupled Evolution of Fluid Chemistry, Mineral Reaction Rates, and Hydrogeochemical Properties. Geochim. Cosmochim. Acta 2015, 160, 132–154. [Google Scholar] [CrossRef]

- Wigand, M.; Carey, J.; Schütt, H.; Spangenberg, E.; Erzinger, J. Geochemical Effects of CO2 Sequestration in Sandstones Under Simulated in Situ Conditions of Deep Saline Aquifers. Appl. Geochem. 2008, 23, 2735–2745. [Google Scholar] [CrossRef]

- Safaei-Farouji, M.; Thanh, H.V.; Dashtgoli, D.S.; Yasin, Q.; Radwan, A.E.; Ashraf, U.; Lee, K.-K. Application of Robust Intelligent Schemes for Accurate Modelling Interfacial Tension of CO2 Brine Systems: Implications for Structural CO2 Trapping. Fuel 2022, 319, 123821. [Google Scholar] [CrossRef]

- Alalimi, A.; AlRassas, A.M.; Thanh, H.V.; Al-Qaness, M.A.A.; Pan, L.; Ashraf, U.; Al-Alimi, D.; Moharam, S. Developing the Efficiency-Modeling Framework to Explore the Potential of CO2 Storage Capacity of S3 Reservoir, Tahe Oilfield, China. Géoméch. Geophys. Geo-Energy Geo-Resour. 2022, 8, 1–23. [Google Scholar] [CrossRef]

- Safaei-Farouji, M.; Thanh, H.V.; Dai, Z.; Mehbodniya, A.; Rahimi, M.; Ashraf, U.; Radwan, A.E. Exploring the Power of Machine Learning to Predict Carbon Dioxide Trapping Efficiency in Saline Aquifers for Carbon Geological Storage Project. J. Clean. Prod. 2022, 372, 133778. [Google Scholar] [CrossRef]

- Medici, G.; West, L.J.; Mountney, N.P. Characterization of a Fluvial Aquifer at a Range of Depths and Scales: The Triassic St Bees Sandstone Formation, Cumbria, UK. Appl. Hydrogeol. 2017, 26, 565–591. [Google Scholar] [CrossRef]

- Medici, G.; West, L.J.; Mountney, N.P.; Welch, M. Permeability of Rock Discontinuities and Faults in the Triassic Sherwood Sandstone Group (UK): Insights for Management of Fluvio-Aeolian Aquifers Worldwide. Appl. Hydrogeol. 2019, 27, 2835–2855. [Google Scholar] [CrossRef]

- Weibel, R.; Olivarius, M.; Vosgerau, H.; Mathiesen, A.; Kristensen, L.; Nielsen, C.M.; Nielsen, L.H. Overview of Potential Geothermal Reservoirs in Denmark. Neth. J. Geosci. 2020, 99, e3. [Google Scholar] [CrossRef]

- Weibel, R.; Kristensen, L.; Olivarius, M.; Hjuler, M.L.; Mathiesen, A.; Nielsen, L.H. Investigating Deviations from Overall Porosity–Permeability Trends. In Proceedings of the 36th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 30 January–1 February 2012; Volume 16. [Google Scholar]

- Stumm, W.; Morgan, J.J. Aquatic Chemistry-Chemical Equilibria and Rates in Natural Waters, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Orywall, P.; Drüppel, K.; Kuhn, D.; Kohl, T.; Zimmermann, M.; Eiche, E. Flow-Through Experiments on the Interaction of Sandstone with Ba-Rich Fluids at Geothermal Conditions. Geotherm. Energy 2017, 5, 1–24. [Google Scholar] [CrossRef]

- Dávila, G.; Dalton, L.; Crandall, D.M.; Garing, C.; Werth, C.J.; Druhan, J.L. Reactive Alteration of a Mt. Simon Sandstone Due to CO2-Rich Brine Displacement. Geochim. Cosmochim. Acta 2020, 271, 227–247. [Google Scholar] [CrossRef]

- Shandong Provincial Territorial Spatial Ecological Restoration Center. Report on the Project of Geothermal Tailwater Reinjection to Sandstone Geothermal Reservoir, Huimin County, Shandong, China. 2022; unpublished work. [Google Scholar]

- Gan, H.; Liu, Z.; Wang, X.; Zhang, Y.; Liao, Y.; Zhao, G.; Zhao, J.; Liu, Z. Effect of Temperature and Acidification on Reinjection of Geothermal Water into Sandstone Geothermal Reservoirs: Laboratory Study. Water 2022, 14, 2955. [Google Scholar] [CrossRef]

- Parkhurst, D.L.; Appelo, C.A.J. Description of Input and Examples for PHREEQC Version 3—A Computer Program for Speciation, Batch-Reaction, One-Dimensional Transport, and Inverse Geochemical Calculations; USGS Techniques and Methods: Denver, CO, USA, 2013. [Google Scholar]

- Liu, Z. Study on the Groundwater Circulation and the Hydrogeological Environment Evolution in the Southern Junggar Basin. Ph.D. Thesis, Nanjing University, Nanjing, China, 2007. [Google Scholar]

- Shen, Z. Hydrogeochemistry; Geological Publishing House: Beijing, China, 1984. (In Chinese) [Google Scholar]

- Ashraf, U.; Zhang, H.; Anees, A.; Ali, M.; Zhang, X.; Shakeel Abbasi, S.; Nasir Mangi, H. Controls on Reservoir Heterogeneity of a Shallow-Marine Reservoir in Sawan Gas Field, SE Pakistan: Implications for Reservoir Quality Prediction Using Acoustic Impedance Inversion. Water 2020, 12, 2972. [Google Scholar] [CrossRef]

- Le, C. Petrology; Geological Publishing House: Beijing, China, 1984. (In Chinese) [Google Scholar]

- Feng, B.; Song, D.; Fu, L.; Zhang, S.; Chen, M.; Jiang, Z. Formation Laws of Hydrothermal Alteration Minerals and the Genesis of Travertine in the Zhacang Geothermal Field, Guide Basin. Natur. Gas Ind. 2019, 39, 133–142. (In Chinese) [Google Scholar]

- Li, J.; Yang, G.; Sagoe, G.; Li, Y. Major Hydrogeochemical Processes Controlling the Composition of Geothermal Waters in the Kangding Geothermal Field, Western Sichuan Province. Geothermics 2018, 75, 154–163. [Google Scholar] [CrossRef]

- Lin, W.; Wang, G.; Gan, H.; Zhang, S.; Zhao, Z.; Yue, G.; Long, X. Heat Source Model for Enhanced Geothermal Systems (EGS) under Different Geological Conditions in China. Gondwana Res. 2022. [Google Scholar] [CrossRef]

- Rivera Diaz, A.; Kaya, E.; Zarrouk, S.J. Reinjection in Geothermal Fields−A Worldwide Review Update. Renew. Sustain. Energy Rev. 2016, 53, 105–162. [Google Scholar] [CrossRef]

- He, M.; Zhang, L.; Yuan, Y.; Zhang, J.; Gao, Y. Study on the Relationship between Re-injection Volume and Temperature of Sandstone Geothermal Reservoir in Nanzhan Area of Dongying City. Shandong Land Resour. 2018, 34, 44–48. (In Chinese) [Google Scholar]

| Temperature (°C) | Flow Rate (mL/min) | Length of Core Sample (cm) | Displacement Fluid |

|---|---|---|---|

| 45 | 0.5 | 6 | in situ geothermal fluid |

| 45 | 1.0 | 6 | in situ geothermal fluid |

| 45 | 1.5 | 6 | in situ geothermal fluid |

| 55 | 0.5 | 6 | in situ geothermal fluid |

| 55 | 1.0 | 6 | in situ geothermal fluid |

| 55 | 1.5 | 6 | in situ geothermal fluid |

| 65 | 0.5 | 6 | in situ geothermal fluid |

| 65 | 1.0 | 6 | in situ geothermal fluid |

| 65 | 1.5 | 6 | in situ geothermal fluid |

| Parameter | Value |

|---|---|

| core length (cm) | 6 |

| core diameter (cm) | 1.6 |

| fluid viscosity (mPa. s) | 0.595 |

| fluid density (g/cm3) | 0.991 |

| Sample ID | Type | pH | K | Na | Ca | Mg | Cl | SO4 | HCO3 | Si |

|---|---|---|---|---|---|---|---|---|---|---|

| mg/L | ||||||||||

| yuan-1 (water) a | Na-Cl-SO4 | 7.73 | 38.8 | 4030 | 351 | 70.1 | 4210 | 2720 | 139 | 21.88 |

| 45—0.5 b | Na-Cl | 7.89 | 29.8 | 2900 | 331 | 65.4 | 4670 | 1010 | 115 | 7.22 |

| 45—1 | Na-Cl | 7.44 | 30.8 | 3220 | 393 | 80.2 | 5290 | 1140 | 120 | 12.29 |

| 45—1.5 | Na-Cl | 7.48 | 29.8 | 3130 | 365 | 80.7 | 5100 | 1130 | 125 | 15.67 |

| 55—0.5 | Na-Cl | 7.45 | 28.8 | 2720 | 345 | 67.5 | 5340 | 1220 | 120 | 11.15 |

| 55—1 | Na-Cl | 7.3 | 35.1 | 3310 | 398 | 86.7 | 5340 | 1210 | 110 | 12.53 |

| 55—1.5 | Na-Cl | 7.24 | 29.5 | 3010 | 378 | 77.8 | 5360 | 1300 | 110 | 15.69 |

| 65—0.5 | Na-Cl | 7.26 | 31.5 | 2990 | 354 | 68.5 | 4980 | 1140 | 110 | 12.03 |

| 65—1 | Na-Cl | 7.18 | 26.6 | 2740 | 299 | 63.4 | 4890 | 1100 | 99 | 13.45 |

| 65—1.5 | Na-Cl | 7.17 | 27.1 | 2980 | 343 | 70.6 | 5410 | 1270 | 104 | 16.62 |

| Sample ID | Si | Al | Fe | K | Ca | Mg | Ti | Na | Cl |

|---|---|---|---|---|---|---|---|---|---|

| yuan-1 (rock) a | 26.65 | 10.91 | 2.87 | 2.07 | 10.91 | 0.552 | 0.441 | 0.751 | 0.0895 |

| 45—0.5 b | 26.43 | 7.43 | 5.31 | 2.66 | 1.21 | 0.835 | 0.633 | 0.769 | 0.608 |

| 45—1 | 28.48 | 7.69 | 5.15 | 2.73 | 1.19 | 0.876 | 0.589 | 0.8 | 0.377 |

| 45—1.5 | 29.35 | 7.26 | 4.62 | 2.81 | 0.999 | 0.81 | 0.56 | 0.782 | 0.273 |

| 55—0.5 | 29.07 | 7.4 | 4.72 | 2.7 | 1.1 | 0.832 | 0.585 | 0.762 | 0.382 |

| 55—1 | 28.46 | 7.48 | 4.98 | 2.55 | 1.21 | 0.835 | 0.61 | 0.71 | 0.39 |

| 55—1.5 | 27.98 | 7.56 | 5.03 | 2.6 | 1.24 | 0.886 | 0.595 | 0.692 | 0.409 |

| 65—0.5 | 26.59 | 7.1 | 5.51 | 2.88 | 1.12 | 0.763 | 0.581 | 0.845 | 0.44 |

| 65—1 | 26.87 | 7.22 | 5.52 | 2.83 | 1.22 | 0.759 | 0.639 | 0.778 | 0.337 |

| 65—1.5 | 26.35 | 7.36 | 5.27 | 2.3 | 1.23 | 0.807 | 0.625 | 0.669 | 0.248 |

| Sample ID | Quartz | Albite | Microcline | Montmorillonite | Calcite | Muscovite |

|---|---|---|---|---|---|---|

| yuan-1 (rock) a | 0.66 | 0.11 | 0.07 | 0 | 0.1 | 0.06 |

| 45—0.5 b | 0.41 | 0.21 | 0.23 | 0.15 | 0 | 0 |

| 45—1 | 0.55 | 0.18 | 0.09 | 0.18 | 0 | 0 |

| 45—1.5 | 0.46 | 0.25 | 0.09 | 0.2 | 0 | 0 |

| 55—0.5 | 0.55 | 0.18 | 0.09 | 0.18 | 0 | 0 |

| 55—1 | 0.46 | 0.3 | 0.05 | 0.19 | 0 | 0 |

| 55—1.5 | 0.53 | 0.17 | 0.08 | 0.22 | 0 | 0 |

| 65—0.5 | 0.54 | 0.17 | 0.07 | 0.22 | 0 | 0 |

| 65—1 | 0.57 | 0.16 | 0.07 | 0.2 | 0 | 0 |

| 65—1.5 | 0.54 | 0.19 | 0.08 | 0.19 | 0 | 0 |

| Sample ID | Mineral Volume Change (cm3/100 g) | Total Volume Change (cm3/100 g) | Porosity Change (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Quartz | Albite | Microcline | Muscovite | Montmorillonite | Calcite | |||

| 45—0.5 a | −9.43 | 3.724 | 6.178 | −2.151 | −3.690 | 6.383 | 1.01 | 4.52 |

| 45—1 | −4.151 | 2.607 | 0.772 | −2.151 | −3.690 | 7.660 | 1.047 | 4.69 |

| 45—1.5 | −7.547 | 5.214 | 0.772 | −2.151 | −3.690 | 8.511 | 1.109 | 4.96 |

| 55—0.5 | −4.151 | 2.607 | 0.772 | −2.151 | −3.690 | 7.660 | 1.047 | 4.69 |

| 55—1 | −7.547 | 7.076 | −0.772 | −2.151 | −3.690 | 8.085 | 1.001 | 4.48 |

| 55—1.5 | −4.906 | 2.235 | 0.386 | −2.151 | −3.690 | 9.362 | 1.236 | 5.53 |

| 65—0.5 | −4.528 | 2.235 | 0 | −2.151 | −3.690 | 9.362 | 1.228 | 5.50 |

| 65—1 | −3.396 | 1.862 | 0 | −2.151 | −3.690 | 8.511 | 1.136 | 5.08 |

| 65—1.5 | −4.528 | 2.98 | 0.386 | −2.151 | −3.690 | 8.085 | 1.082 | 4.84 |

| Density a | 2.65 g/cm3 | average 2.685 g/cm3 | average 2.59 g/cm3 | average 2.79 g/cm3 | average 2.35 g/cm3 | 2.71 g/cm3 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, H.; Liu, Z.; Wang, G.; Liao, Y.; Wang, X.; Zhang, Y.; Zhao, J.; Liu, Z. Permeability and Porosity Changes in Sandstone Reservoir by Geothermal Fluid Reinjection: Insights from a Laboratory Study. Water 2022, 14, 3131. https://doi.org/10.3390/w14193131

Gan H, Liu Z, Wang G, Liao Y, Wang X, Zhang Y, Zhao J, Liu Z. Permeability and Porosity Changes in Sandstone Reservoir by Geothermal Fluid Reinjection: Insights from a Laboratory Study. Water. 2022; 14(19):3131. https://doi.org/10.3390/w14193131

Chicago/Turabian StyleGan, Haonan, Zhiming Liu, Guiling Wang, Yuzhong Liao, Xiao Wang, Yu Zhang, Jichu Zhao, and Zhitao Liu. 2022. "Permeability and Porosity Changes in Sandstone Reservoir by Geothermal Fluid Reinjection: Insights from a Laboratory Study" Water 14, no. 19: 3131. https://doi.org/10.3390/w14193131

APA StyleGan, H., Liu, Z., Wang, G., Liao, Y., Wang, X., Zhang, Y., Zhao, J., & Liu, Z. (2022). Permeability and Porosity Changes in Sandstone Reservoir by Geothermal Fluid Reinjection: Insights from a Laboratory Study. Water, 14(19), 3131. https://doi.org/10.3390/w14193131