Environmental and Economic Performance of Sludge Composting Optimization Alternatives: A Case Study for Thermally Hydrolyzed Anaerobically Digested Sludge

Abstract

1. Introduction

- Analyze the existing ADS management processes and identify problems and their causes;

- Experiment on ADS composting to find the optimal mixing ratios of ADS and other biodegradable waste (BDW) and determine the possibilities for optimization using microbial inoculants in the production of a product with a higher added value (compost–soil improver);

- Propose alternatives for optimizing the composting process and conduct a feasibility analysis.

2. Materials and Methods

2.1. Analysis of the Current Situation and Evaluation of Gaseous Emissions

- EI (environmental indicator)—consumption of a certain input (e.g., sludge or ADS, chemical materials, energy, additional water consumption, etc.) and amount of output (e.g., air emissions, wastewater, waste, etc.), expressed in absolute values, units per year;

- D (main raw material)—amount of sludge in tonnes of dry matter (DM) per year;

- EIr—consumption of a certain input and amount of output per unit of processed sludge (D), units per tonne of sludge DM.

- Ep—GHGs (CO2, CH4, N2O), tonnes CO2e year−1;

- FCT—the energy value of the fuel used, TJ year−1;

- FCM—mass of consumed fuel, tonnes year−1;

- Q—lower heating value of fuel, TJ tonne−1;

- EF—emission factor, kg TJ−1.

- In the case of using diesel fuel: EFCO2—72,800 kg CO2e per TJ; Q—0.04286 TJ per tonne of diesel fuel;

- In the case of using natural gas: EFCO2—55,590 kg CO2e per TJ; Q—0.033696 TJ per thousand m3 of natural gas;

- In the case of using biogas: EFCO2—58,450 kg CO2e per TJ; Q—0.02 TJ per thousand m3 of biogas.

- Ep—GHGs, tonnes CO2e year−1;

- Mi—amount of biologically treated organic waste, tonnes year−1;

- EF—emission factor, kg per tonne of processed organic waste. For example, according to Maulini-Duran et al., (2013), composting anaerobically digested sludge (ADS) together with green waste (GW) generates only 0.73 to 0.83 kg of CH4 per tonne of compostable BDW and from 0.49 to 0.56 kg of N2O per tonne of BDW [21];

- η—reduction efficiency, e.g., in the case of a biofilter, CH4 is reduced by a minimum of 50%; N2O—up to 90% [22].

2.2. Sampling and Laboratory Analysis of Processed Sludge and Produced Compost

- Contamination with heavy metals: cadmium (Cd), lead (Pb), mercury (Hg), chromium (Cr), zinc (Zn), copper (Cu), nickel (Ni), arsenic (As), and mg kg−1 (DM);

- Contamination with organic pollution (Polycyclic Aromatic Hydrocarbons: PAH16 and PCB7), mg kg−1 (DM));

- Microbiological contamination (Escherichia coli (E. coli)) and intestinal enterococci, CFU g−1; anaerobic Clostridia, CFU g−1; Helminth eggs and larvae, pcs. kg−1; and Salmonella bacteria, pcs. kg−1);

- Contamination with undesirable impurities (glasses, metals, plastics (>2 mm), % in DM; germinated plant seeds, pcs. L−1; stones (>10 mm), % in DM).

2.3. Composting Experiment and Measurement of Air and Odor Emissions

2.4. ADS Composting Alternatives and Their Feasibility Analysis (Environmental and Economic Evaluation)

- PBP—payback period, years;

- I—investments, EUR;

- S—savings due to project implementation, EUR year−1.

3. Results and Discussion

3.1. Results of the Analysis of the Current Situation, and Problem Identification

- Dewatered ADS (on average, up to 30.43% of DM)—12,020 tonnes;

- Dried ADS (on average, to 98.02% of DM)—5300 tonnes.

| Energy Flows | Energy Consumption in the Sludge Treatment Processes, GWh Year−1 | 1 Relative Indicators in the Fuel/Energy Balance | |||

|---|---|---|---|---|---|

| EI (Total) | EI (for ADS Drying) | EI (for Sludge Processing before Drying) | EIr, MWh t−1 of Sludge in DM | % of Dried ADS | |

| Energy used: | |||||

| Electricity (from networks) | 2.93 | 1.09 | 1.84 | 0.151 | 37.26 |

| Electricity (from CHP) | 3.28 | 1.22 | 2.06 | 0.170 | 37.26 |

| Thermal energy (from CHP) | 11.74 | 11.74 | 0 | 0.606 | 100.00 |

| Exceed biogas (only for boiler) | 3.57 | 1.49 | 2.08 | 0.184 | 41.76 |

| Natural gas | 16.51 | 3.24 | 13.27 | 0.853 | 19.60 |

| Diesel | 0.03 | 0.03 | 0 | 0.002 | 100.00 |

| SUM: | 38.06 | 18.81 | 19.25 | 1.966 | 49.42 |

| Excess energy generation in sludge treatment: | |||||

| Excess electrical energy from CHP | 9.01 | 0 | 9.01 | 0.465 | 0 |

| Excess thermal energy from CHP | 0.97 | 0 | 0.97 | 0.050 | 0 |

| SUM: | 9.98 | 0 | 9.98 | 0.515 | 0 |

| Final energy consumption for sludge treatment: | 28.08 | 18.81 | 9.27 | 1.450 | 66.99 |

| Amount of purchased energy in GWh (% of the cost of the final energy consumption) | 19.48 (69.37) | 4.36 (23.18) | 15.12 (163.11) | 1.004 | 22.27 |

- -

- Digestate after anaerobic treatment of sewage sludge (before dewatering) (ADS—no. 1) (one sample);

- -

- Dewatered digestate after anaerobic treatment of sewage sludge (ADSD—no. 2) (three samples);

- -

- Dewatered and dried digestate after anaerobic treatment of sewage sludge (ADSDR—no. 3) (three samples);

- -

- Compost produced from dewatered digestate, GW, and peat in another company during the research (C—no. 4) (one sample).

| Quality and Contamination Parameters | 1 Values for Quality indication [1,24] | 2 Requirements for Compost [25] | Digestate from Methane Tank | Manufactured Product (Current Situation) | Quality Assessment of Produced Ddr and C | ||

|---|---|---|---|---|---|---|---|

| ADS No. 1 | ADSD No. 2 | ADSDR No. 3 | C No. 4 | ||||

| Quality Parameters [1,25] | |||||||

| DM, % | <21.00 → >50.00 | info | 4.00 | 30.53–33.00 | 93.87–97.00 | 53.61 | Very high |

| OM, % DM | <16.00 → >45.00 | >25 | 61.64 | 49.31–56.68 | 57.63–57.92 | 37.87 | High and very high |

| C, % DM | <5.5 → >50 | - | 23.26 | 25.20–26.00 | 22.27–32.20 | 17.60 | Medium |

| TN, % DM | <0.5 → >2.0 | TN + P2O5 + K2O > 2.50 | 8.71 | 4.30–4.59 | 4.01–4.33 | 2.19 | Very high |

| TP, % DM (P2O5) | <0.21 → >0.8 (0.48 → >1.83) | 2.94 | 2.36–2.80 | 2.58–2.80 | 1.03 | Very high | |

| TK, % SM (K2O) | <0.6 → >2.5 (0.72 → >3.00) | 1.10 | 0.36–0.46 | 0.22–0.36 | 0.26 | Very low | |

| Conductivity, mS cm−1 | <0.6 → >2.0 | info | - | 137.00 | 77.00 | - | Very high |

| Water-soluble N, ppm | <51.00 → >200.00 | info | - | 839.00–2660.00 | 380.00–708.00 | 1767.00 | Very high |

| Water-soluble P, ppm | <26.00 → >100.00 | info | - | 91.50–295.00 | 355.00–1954.00 | 72.00 | Very high |

| Water-soluble K, ppm | <91.00 → >300.00 | info | - | 175.00–901.00 | 200.00–746.00 | 1147.0 | Very high |

| Water-soluble Ca, ppm | <101.00 → >500.00 | - | - | 58.00 | 41.00 | - | Very low |

| Water-soluble Mg, ppm | <31.00 → >120.00 | - | - | 28.00 | 39.00 | - | Very low |

| SO4, ppm | <51.00 → >300.00 | - | 154.00 | 1775.00–9807.00 | 684.00 | - | Very high |

| Cl, ppm | <51.00 → >300.00 | - | 77.10 | 22.20–2718.00 | 26.60 | - | Very low |

| C:N | <11.00 → >25.00 | - | 2.67 | 5.66–5.86 | 5.55–7.46 | 8.04 | Very low |

| pHKCl | <5.6 → >8.5 | info | 7.90 | 7.8–7.9 | 6.7 | - | Medium |

| pHH2O | <6.1 → >9.0 | info | 8.0 | 8.0–8.3 | 6.4–7.1 | 8.3 | Medium |

| Humic acids, % DM | - | - | - | 1.94 | 3.61 | 1.71 | Medium |

| DOC, mg kg−1 | ≤4000 | - | - | 273.00–5850.00 | 5400 | 2580 | DDR unstable |

| Contamination parameters [24,25]: | |||||||

| Cd, mg kg−1, DM | <1.5–≤5.0 | ≤2.00 | 1.83 | 2.06–4.44 | 1.99–3.85 | 2.19 | Exceeds limit value for a product |

| Pb, mg kg−1, DM | <140.00–≤150.00 | ≤120.00 | 40.90 | 43.00–50.80 | 44.30–60.30 | 41.3 | meets the requirements |

| Hg, mg kg−1, DM | <1.00–≤1.50 | ≤1.00 | 0.019 | 0.052–0.353 | 0.003–0.017 | 0.061 | meets the requirements |

| Cr, mg kg−1, DM | <140.00–≤170.00 | ≤70.00 | 55.9 | 40.10–58.50 | 39.60–57.60 | 37.5 | meets the requirements |

| Zn, mg kg−1, DM | <800.00–≤2500.00 | ≤800.00 | 1387.00 | 1580.00–1873.00 | 1357.00–1533.00 | 1330.00 | Exceeds limit value for a product |

| Cu, mg kg−1, DM | <300.00–≤1000.00 | ≤300.00 | 256.00 | 270.00–329.00 | 271.00–299.00 | 253.00 | DD exceeds limit value |

| Ni, mg kg−1, DM | <50.00–≤70.00 | ≤50.00 | 65.90 | 40.00–58.90 | 30.50–66.60 | 28.50 | DDR exceeds limit value for a product |

| As, mg kg−1, DM | - | ≤1.00 | 0.32 | 0.46–0.47 | 0.45–0.46 | 0.26 | Meets the requirements |

| PAH16, mg kg−1, DM | <4.00 | ≤6.00 | - | - | 0.452 | 3.08 | Meets the requirements |

| PCB7, mg kg−1, DM | <0.20 | ≤0.20 | - | - | 0.007–0.03 | 0.009 | Meets the requirements |

| E. coli, CFU g−1 | ≤1000–≤100,000 | <1000 | - | 330.00–410.00 | 10.00–20.00 | 10.00 | Meets the requirements |

| Clostridium perfringens, CFU g−1 | ≤100,000–≤10,000,000 | - | - | 6000–7100 | 10.00 | 40.00 | Meets the requirements |

| Helminth eggs and larvae, units kg−1 | 0.00 | 0.00 | - | 0.00 | 0.00 | 0.00 | Meets the requirements |

| Salmonella bacteria, units kg−1 in 25 g of sample | 0.00 | 0.00 | - | found in one sample | 0.00 | 0.00 | DD does not meet the requirements |

| Glass, metals, and plastic, when their particle size >2 mm, % DM | ≤0.50 | ≤3.00 | - | 0.00 | 0.00 | - | Meets the requirements |

| Germinated plant seeds, incl. viable weeds, units l−1 | ≤2.00 | ≤2.00 | - | 0.00 | 0.00 | 0.30 | Meets the requirements |

| Stones >10 mm, % DM | ≤5.00 | ≤5.00 | - | 0.00 | 0.00 | - | Meets the requirements |

3.2. Results of ADS Composting Experiment

- -

- Cd concertation in DM decreased from an average of 2.92 to 1.36 mg kg−1 (from 1.46 LV to 0.68 LV, where LV = 2 mg kg−1);

- -

- Zn concertation in DM decreased from an average of 1445 to 699 mg kg−1 (from 1.81 LV to 0.87 LV, where LV = 800 mg kg−1);

- -

- Cu concertation in DM decreased from an average of 285 to 133.75 mg kg−1 (from 0.95 LV to 0.45 LV, where LV = 300 mg kg−1);

- -

- Ni concertation in DM decreased from an average of 48.58 to 23.03 mg kg−1 (from 0.97 LV to 0.46 LV, where LV = 50 mg kg−1).

3.3. Suggestion of Alternatives and Results of Their Feasibility Analysis

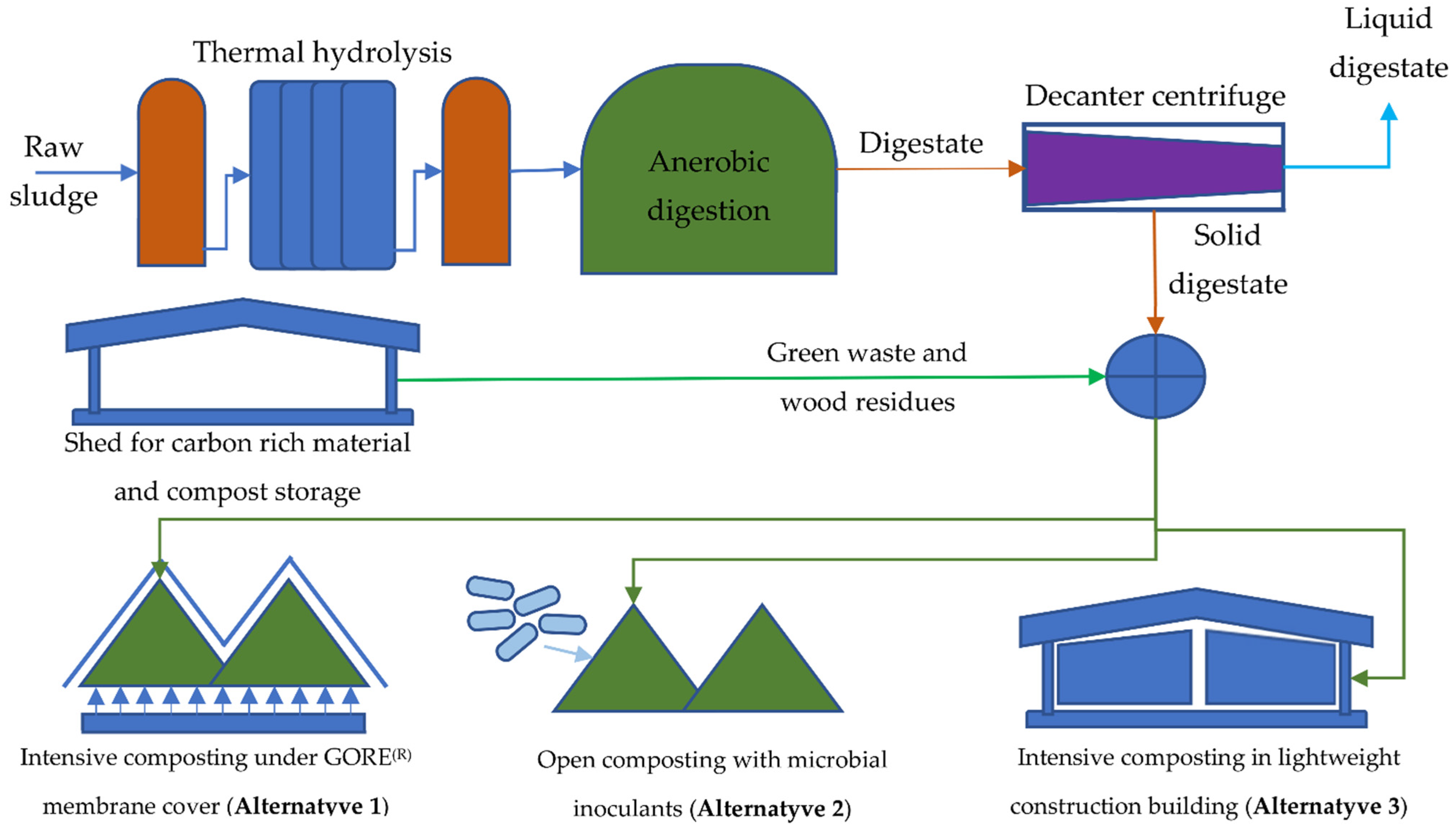

- (1)

- Intensive composting under GORE(R) membrane cover with forced air supply and compost turning; maturation of the primary compost, storage of raw materials (GW, shredded wood waste, etc.); and produced compost under a newly built shed (S is ≈2050 m2) (Alternative 1—intensive composting under GORE(R) membrane).

- (2)

- Open composting with the use of microbial inoculants (up to 0.324 L per tonne of dewatered ADS, as determined in the experiment) to optimize the process, reduce the environmental impact and increase the value of the product produced (another solution regarding the implementation of a shed corresponds to alternative 1) (Alternative 2—open composting with the use of microbial inoculants).

- (3)

- Intensive composting in a new lightweight construction building (S is ≈5000 m2) with sliding walls and doors, a forced-air exhaust system, and a biofilter to minimize the concentration of air emissions and odors during the composting process (Alternative 3—intensive composting in new lightweight construction building).

4. Conclusions

- Reduces energy costs for sludge treatment from 1.966 to 0.996 MWh tonne−1 sludge DM;

- Increases the use of excess energy in other technological processes of the WWTP from 0.515 to 1.008 GWh tonne−1 sludge DM;

- Directs part of the excess thermal energy (about 10 GWh year−1) to city networks, thereby realizing industrial symbiosis (savings due to the realization of excess energy were not evaluated);

- Reduces the direct costs of sludge treatment by 1.7 times (from 216.75 to 129.27 EUR tonne−1 sludge DM);

- Produces a product with added value (up to 33,600 tonne year−1), which can be used for fertilization without increasing the impact on the environment due to possible pollution with heavy metals and microbiological−parasitological contamination;

- Safely returns nutrients to the soil (up to 345 tonnes year−1 of TN, 202 tonnes year−1 of TP, and 60 tonnes year−1 of TK) and thus contributes to the realization of circular economy principles in the country.

- Reduces the total fuel costs for composting by 1.3 times and simultaneously reduces the direct and indirect costs associated with the operation and wear and tear of the turner;

- Preventively reduces the impact on ambient air quality: (a) emissions from stationary sources of pollution are reduced: NH3 by 1.37 times (from 0.214 to 0.157 kg tonne−1 BDW), NMVOC by 1.12 times (from 0.046 to 0.041 kg tonne−1 BDW), and (b) emissions from mobile sources decrease since the frequency of turning is reduced 3 times;

- Does not increase the impact on climate change due to GHG (CH4 and N2O);

- Does not exceed the limit values of air pollutants and odors that are set by hygiene standards;

- Produces a product of higher added value, compost, which is characterized by a higher amount of nutrients. Compared to compost produced from identical raw material but without the addition of microbial inoculants, TN increased by over 20%, TP increased by over 30%, TK increased by over 50%, and humic acids increased by 63.37%;

- When analyzing the costs of all sludge treatment processes, reduces the costs by approx. 13% when comparing the open composting of ADS with the addition of microbial inoculants to intensive composting of ADS under cover or in a building.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lithuanian Ministry of Environment. Arrangement of Requirements (Criterions) for Products Made of Biodegradable Waste; Agrochemical Research Laboratory and UAB “EcoIri Solutions”, 2016; p. 131. Available online: https://am.lrv.lt/uploads/am/documents/files/TYRIMAI%20IR%20ANALIZES/0_184367001489675205.pdf (accessed on 10 August 2022). (In Lithuanian).

- EurEau. Waste Water Treatment—Sludge Management. Available online: https://www.eureau.org/resources/briefing-notes/5629-briefing-note-on-sludge-management/file (accessed on 10 August 2022).

- Wu, S.; Zhang, Z.; Li, J.; Wu, T.; Jiao, X. An Experimental Study of Paddy Drainage Treatment by Zeolite and Effective Microorganisms (EM). Sustainability 2022, 14, 6992. [Google Scholar] [CrossRef]

- Zhang, C.; Li, X.; Zhao, X.; Yang, J.; Li, S.; Dang, Q.; Tan, X. Recognize and Assessment of Key Host Humic-Reducing Microorganisms of Antibiotic Resistance Genes in Different Biowastes Composts. Sci. Total Environ. 2022, 806, 150736. [Google Scholar] [CrossRef] [PubMed]

- Henry, A.B.; Maung, C.E.H.; Kim, K.Y. Metagenomic Analysis Reveals Enhanced Biodiversity and Composting Efficiency of Lignocellulosic Waste by Thermoacidophilic Effective Microorganism (TEM). J. Environ. Manag. 2020, 276, 111252. [Google Scholar] [CrossRef]

- Ansari, K.; Khandeshwar, S.; Waghmare, C.; Mehboob, H.; Gupta, T.; Shrikhande, A.N.; Abbas, M. Experimental Evaluation of Industrial Mushroom Waste Substrate Using Hybrid Mechanism of Vermicomposting and Effective Microorganisms. Materials 2022, 15, 2963. [Google Scholar] [CrossRef]

- Zainudin, M.H.; Zulkarnain, A.; Azmi, A.S.; Muniandy, S.; Sakai, K.; Shirai, Y.; Hassan, M.A. Enhancement of Agro-Industrial Waste Composting Process via the Microbial Inoculation: A Brief Review. Agronomy 2022, 12, 198. [Google Scholar] [CrossRef]

- Yang, L.; Jie, G.; She-Qi, Z.; Long-Xiang, S.; Wei, S.; Xun, Q.; Man-Li, D.; Ya-Nan, Y.; Xiao-Juan, W. Effects of Adding Compound Microbial Inoculum on Microbial Community Diversity and Enzymatic Activity During Co-Composting. Environ. Eng. Sci. 2018, 35, 270–278. [Google Scholar] [CrossRef]

- Niu, J.; Li, X. Effects of Microbial Inoculation with Different Indigenous Bacillus Species on Physicochemical Characteristics and Bacterial Succession during Short-Term Composting. Fermentation 2022, 8, 152. [Google Scholar] [CrossRef]

- Wu, D.; Xia, T.; Zhang, Y.; Wei, Z.; Qu, F.; Zheng, G.; Song, C.; Zhao, Y.; Kang, K.; Yang, H. Identifying Driving Factors of Humic Acid Formation during Rice Straw Composting Based on Fenton Pretreatment with Bacterial Inoculation. Bioresour. Technol. 2021, 337, 125403. [Google Scholar] [CrossRef]

- El Hayany, B.; Rumpel, C.; Hafidi, M.; El Fels, L. Occurrence, Analysis of Microplastics in Sewage Sludge and Their Fate during Composting: A Literature Review. J. Environ. Manag. 2022, 317, 115364. [Google Scholar] [CrossRef]

- Xu, M.; Yang, M.; Sun, H.; Meng, J.; Li, Y.; Gao, M.; Wang, Q.; Wu, C. Role of Multistage Inoculation on the Co-Composting of Food Waste and Biogas Residue. Bioresour. Technol. 2022, 361, 127681. [Google Scholar] [CrossRef]

- Ballardo, C.; Vargas-García, M.d.C.; Sánchez, A.; Barrena, R.; Artola, A. Adding Value to Home Compost: Biopesticide Properties through Bacillus Thuringiensis Inoculation. Waste Manag. 2020, 106, 32–43. [Google Scholar] [CrossRef] [PubMed]

- Jeffrey, G. Simultaneous Aerobic and Anaerobic Composting Process. U.S. Patent 2,867,521, 6 January 1955. [Google Scholar]

- Cambi. How Does Thermal Hydrolysis Work. Available online: https://www.cambi.com/what-we-do/thermal-hydrolysis/how-does-thermal-hydrolysis-work/ (accessed on 10 August 2022).

- Barber, W.P.F. Thermal Hydrolysis for Sewage Treatment: A Critical Review. Water Res. 2016, 104, 53–71. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Qi, F.; Li, R.; Wang, H.; Sun, D. Health Impact of Odor from On-Situ Sewage Sludge Aerobic Composting throughout Different Seasons and during Anaerobic Digestion with Hydrolysis Pretreatment. Chemosphere 2020, 249, 126077. [Google Scholar] [CrossRef] [PubMed]

- Ngo, P.L.; Udugama, I.A.; Gernaey, K.V.; Young, B.R.; Baroutian, S. Mechanisms, Status, and Challenges of Thermal Hydrolysis and Advanced Thermal Hydrolysis Processes in Sewage Sludge Treatment. Chemosphere 2021, 281, 130890. [Google Scholar] [CrossRef]

- Staniškis, J.K.; Stasiškienė, Ž.; Kliopova, I.; Varžinskas, V. Innovations in Lithuania Industry Development and Implementation; Technologija: Kaunas, Lithuania, 2010; 458p. [Google Scholar]

- Eggleston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006; Volume 5. [Google Scholar]

- Maulini-Duran, C.; Artola, A.; Font, X.; Sánchez, A. A Systematic Study of the Gaseous Emissions from Biosolids Composting: Raw Sludge versus Anaerobically Digested Sludge. Bioresour. Technol. 2013, 147, 43–51. [Google Scholar] [CrossRef]

- Baky, A.; Eriksson, O. Systems Analysis of Organic Waste Management in Denmark: Environmental Project No. 822 2003 Miljøprojekt; Danish Environmental Protection Agency: Odense, Denmark, 2003. [Google Scholar]

- EMEP/EEA. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 15 July 2021).

- Ministry of Environment of the Republic of Lithuania. Normative Document LAND 20-2005 “Requirements for the Use of Sewage Sludge for Fertilization and Restoration”; Final Revision—2022; Ministry of Environment of the Republic of Lithuania: Vilnius, Lithuania, 2001. [Google Scholar]

- Parliament of the Republic of Lithuania. Description of the Procedure for Inclusion and Removal of Fertilizing Products Placed in the Identification List and Supplied in the Market of the Republic of Lithuania; Final Revision—2022; Parliament of the Republic of Lithuania: Vilnius, Lithuania, 2019. [Google Scholar]

- Kliopova, I. Integrated Waste Management System for Resort Town. Environ. Res. Eng. Manag. 2016, 72, 31–55. [Google Scholar] [CrossRef]

- Đurđević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Study of Croatia. Energies 2019, 12, 927. [Google Scholar] [CrossRef]

- Siedlecka, E.; Siedlecki, J. Influence of Valorization of Sewage Sludge on Energy Consumption in the Drying Process. Energies 2021, 14, 4511. [Google Scholar] [CrossRef]

- Tańczuk, M.; Kostowski, W. Technical, Energetic and Economic Optimization Analysis of Selection of Heat Source for Municipal Sewage Sludge Dryer. Energies 2021, 14, 316. [Google Scholar] [CrossRef]

- Jin, X.; Ai, W.; Zhang, Y.; Dong, W. Application of Functional Microbial Agent in Aerobic Composting of Wheat Straw for Waste Recycling. Life Sci. Space Res. 2022, 33, 13–20. [Google Scholar] [CrossRef]

- Tan, W.; Liu, P.; Zhang, X.; Xi, B. Effect of Matured Compost and Exogenous Microbial Inoculants on the Composting Process of Digestate Eluted from Dry Anaerobic Digestion. In Proceedings of the Third International Workshop on Environment and Geoscience, Chengdu, China, 18–20 July 2020. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, X.; Liao, X.; Wu, Y.; Mi, J.; Wang, Y. Effect of Different Proportions of Three Microbial Agents on Ammonia Mitigation during the Composting of Layer Manure. Molecules 2019, 24, 2513. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wu, M.; Peng, C.; Yan, F.; Jia, Y.; Li, X.; Li, M.; Wu, B.; Xu, H.; Qiu, Z. Bacterial Dynamics and Functions Driven by a Novel Microbial Agent to Promote Kitchen Waste Composting and Reduce Environmental Burden. J. Clean. Prod. 2022, 337, 130491. [Google Scholar] [CrossRef]

- Ruiz-Barrera, O.; Rivera-Sida, J.; Arzola-Alvarez, C.; Itza-Ortiz, M.; Ontiveros-Magadan, M.; Murillo-Ortiz, M.; Angulo-Montoya, C.; Corral-Luna, A.; Castillo-Castillo, Y. Composting of Laying Hen Manure with the Addition of a Yeast Probiotic. Ital. J. Anim. Sci. 2018, 17, 1054–1058. [Google Scholar] [CrossRef]

- Greff, B.; Szigeti, J.; Nagy, Á.; Lakatos, E.; Varga, L. Influence of Microbial Inoculants on Co-Composting of Lignocellulosic Crop Residues with Farm Animal Manure: A Review. J. Environ. Manag. 2022, 302, 114088. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, X.; Shaheen, S.M.; Rinklebe, J.; Bolan, N.S.; Ali, E.F.; Li, G.; Tsang, D.C.W. Effects of Microorganism-Mediated Inoculants on Humification Processes and Phosphorus Dynamics during the Aerobic Composting of Swine Manure. J. Hazard. Mater. 2021, 416, 125738. [Google Scholar] [CrossRef]

- Manu, M.K.; Kumar, R.; Garg, A. Performance Assessment of Improved Composting System for Food Waste with Varying Aeration and Use of Microbial Inoculum. Bioresour. Technol. 2017, 234, 167–177. [Google Scholar] [CrossRef]

- Van Fan, Y.; Lee, C.T.; Klemeš, J.J.; Chua, L.S.; Sarmidi, M.R.; Leow, C.W. Evaluation of Effective Microorganisms on Home Scale Organic Waste Composting. J. Environ. Manag. 2018, 216, 41–48. [Google Scholar] [CrossRef]

- Stunžėnas, E.; Kliopova, I.; Kliaugaitė, D.; Budrys, R.P. Industrial Symbiosis for Optimal Bio-Waste Management and Production of a Higher Value-Added Product. Processes 2021, 9, 2228. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Olsson, G. Energy Issues in Sustainable Urban Wastewater Management: Use, Demand Reduction and Recovery in the Urban Water Cycle. Sustainability 2020, 12, 266. [Google Scholar] [CrossRef]

- Amann, A.; Weber, N.; Krampe, J.; Rechberger, H.; Zoboli, O.; Zessner, M. Operation and Performance of Austrian Wastewater and Sewage Sludge Treatment as a Basis for Resource Optimization. Water 2021, 13, 2998. [Google Scholar] [CrossRef]

| No. | Analyzed Parameters | 1st Pile (Composting with Microbial Inoculants) | 2nd Pile (Composting in the Classic Way) |

|---|---|---|---|

| 1 | Amount of compostable BDW | 7.4 tonnes | 7.4 tonnes |

| 1.1 | dewatered ADS (50% by mass) | 3.7 tonnes | 3.7 tonnes |

| 1.2 | GW (leaves, grass) (29.73% by mass) | 2.2 tonnes | 2.2 tonnes |

| 1.3 | GW (waste pruning trees, shrubs) (20.27% by mass) | 1.5 tonnes | 1.5 tonnes |

| 2 | Amount of used microbial inoculants (0.324 L for 1 tonne of dewatered ADS) | 1.2 L | 0 |

| 3 | Amount of used water for dilution (1:50) | 60 L | 0 |

| 4 | Duration of primary compost production | 40 days | 40 days |

| 5 | Number of turns during the composting period | 4 | 12 |

| 6 | Maintenance of conditions | Simultaneous aerobic and anaerobic composting | Aerobic |

| 7 | Temperature reached during composting:after 7 days | 50 °C | 45 °C |

| after 10 days | 58 °C | 55 °C | |

| after 21 days | 60 °C | 63 °C | |

| after 30 days | 63 °C | 54 °C | |

| after 39 days | 38 °C | 35 °C | |

| 8 | Results of odor measurement on the fifth day of composting: within each m2 in the composting site | 0.776 OUE s−1 21.728 OUE s−1 | 1.840 OUE s−1 51.52 OUE s−1 |

| 9 | Results of odor modeling within the plot boundaries of the composting site | 0.012 OUE m−3 | 0.037 OUE m−3 |

| 10 | NH3 emissions (average of 3 measurements) on the seventh day of composting: | ||

| within each m2 | 1.20 × 10−5 g s−1 | 1.64 × 10−5 g s−1 | |

| in the composting site | 33.6 × 10−5 g s−1 | 45.92 × 10−5 g s−1 | |

| per 1 tonne of BDW | 0.157 kg tonne−1 | 0.214 kg tonne−1 | |

| 11 | NMVOC (average of 3 measurements) on the seventh day of composting: | ||

| within each m2 | 3.16 × 10−6 g s−1 | 3.54 × 10−6 g s−1 | |

| in the composting site | 88.48 × 10−6 g s−1 | 99.12 × 10−6 g s−1 | |

| per 1 tonne of BDW | 0.041 kg tonne−1 | 0.046 kg tonne−1 |

| Quality and Contamination Parameters | Values for Quality Indication and LV for Contamination [1,25,39] | Produced Primary Composts | Quality Assessment of Produced C1 and C2 | |

|---|---|---|---|---|

| C1 (Produced Using Microbial Inoculants) | C2 (Produced by a Classical Method) | |||

| 1 Analyzed quality parameters | ||||

| DM, % | <21.00 → >50.00 | 38.53–39.93 | 42.00–44.32 | High and very high |

| OM, % DM | <16.00 → >45.00 | 41.00–45.49 | 39.95–40.39 | Very high and high |

| TN, % DM | <0.5 → >2.0 | 2.45–2.57 | 2.03–2.09 | Very high |

| TP, % DM (P2O5) | <0.21 → >0.8 (0.48 → >1.83) | (3.22–3.44) | (2.43–2.55) | Very high |

| TK, % SM (K2O) | <0.6 → >2.5 (0.72 → >3.00) | (0.51–0.53) | (0.31–0.37) | Very low |

| Conductivity, mS/m | <60 → >200 | 94.1 | 72.6 | Low |

| Water-soluble N, ppm | <51 → >200 | 433 | 171 | Very high |

| Water-soluble P, ppm | <26 → >100 | 125 | 104 | Very high |

| Cl, ppm | <51.00 → >300.00 | 140 | n | Medium |

| pH KCl | <5.6 → >8.5 | 7.8–8.1 | 7.1 | High and medium |

| Humic acids, % DM | - | 1.55–1.75 | 0.97–1.05 | Medium and low |

| Fulvo acids, % DM | - | 1.10–1.17 | 0.90–0.99 | Medium and low |

| 1 Analyzed contamination parameters | ||||

| Cd, mg kg−1, DM | <2.00 | 1.35–1.42 | 1.27–1.38 | Meets the requirements |

| Zn, mg kg−1, DM | <800.00 | 655.00–758.00 | 627.00–756.00 | Meets the requirements |

| Cu, mg kg−1, DM | <300.00 | 125.00–160.00 | 117.00–133.00 | Meets the requirements |

| Ni, mg kg−1, DM | <50.00 | 23.00–27.00 | 19.10–23.00 | Meets the requirements |

| E. coli, CFU g−1 | <1000 | <110 | <110 | Meets the requirements |

| Clostridium perfringens, CFU g−1 | <100,000 | 0–10.00 | 0–10.00 | Meets the requirements |

| Salmonella bacteria, units kg−1 in 25 g of sample | 0.00 | 0 | 0 | Meets the requirements |

| Analysis of Key Inputs and Outputs | Units Per Tonne of DM | Current Situation | 3 Alternative 1 | 3 Alternative 2 | 3 Alternative 3 |

|---|---|---|---|---|---|

| Inputs | |||||

| 2 Sludge (main raw materials) | tonne | 1 | 1 | 1 | 1 |

| NPK (nitrogen, phosphorus, potassium) fertilizers for biological biogas purification | liters | 0.132 | 0.132 | 0.132 | 0.132 |

| Flocculants for sludge thickening and dewatering | kg | 5.287 | 5.287 | 5.287 | 5.287 |

| Chemicals (for cleaning air pollutants in biofilters, scrubbers, etc.) | kg | 10.747 | 1.346 | 1.346 | 1.346 |

| Microbial inoculant | litres | 0.000 | 0.000 | 0.489 | 0.000 |

| Diesel fuel | kg | 0.141 | 1.700 | 1.867 | 2.283 |

| Lubricants | liters | 0.129 | 0.130 | 0.130 | 0.130 |

| Hydraulic oil | litres | 0.000 | 0.009 | 0.009 | 0.009 |

| Big bags for dried compost | units | 0.202 | 0 | 0 | 0 |

| Water | m3 | 4.309 | 4.309 | 4.333 | 4.309 |

| Electricity (from grid) | kWh | 151.483 | 34.579 | 31.862 | 31.997 |

| Electricity (from CHP) | kWh | 169.580 | 169.580 | 169.580 | 169.580 |

| Thermal energy (from CHP) | kWh | 606.076 | 113.596 | 113.596 | 113.596 |

| Biogas (from anaerobic digestion) | m3 | 33.783 | 33.783 | 33.783 | 33.783 |

| Natural gas (from grid) | m3 | 89.551 | 49.869 | 49.869 | 49.869 |

| GW (leaves, grass, etc.) | tonnes | 0.000 | 0.906 | 0.906 | 0.906 |

| Other carbon-rich BDW (e.g., wood residues) | tonnes | 0.000 | 0.302 | 0.302 | 0.302 |

| Outputs | |||||

| Dewatered ADS (30.43% DM) | tonnes | 0.621 | 0.000 | 0.000 | 0.000 |

| Dried ADS (98.02% DM) | tonnes | 0.273 | 0.000 | 0.000 | 0.000 |

| Organic fertilizer (compost) | tonnes | 0.000 | 1.700 | 1.700 | 1.700 |

| Excess electricity from CHP | kWh | 465.234 | 465.234 | 465.234 | 465.234 |

| Excess thermal energy from CHP | kWh | 50.257 | 542.737 | 542.737 | 542.737 |

| Wastewater/evaporation | m3 | 51.235 | 51.552 | 51.552 | 51.552 |

| Air pollution (from stationary sources without analyzing composting) | kg | 13.524 | 12.914 | 12.914 | 12.914 |

| 4 Air pollution from composting (NH3; NMVOC) | kg | 4 0.242 | 0.121 | 0.538 | 0.092 |

| 4 Air pollution (from mobile sources) | kg | 0.007 | 0.083 | 0.091 | 0.112 |

| 4 GHGs from the combustion of natural gas, diesel | tonnes of CO2e | 0.169 | 0.099 | 0.100 | 0.101 |

| 4 GHGs from biogas combustion | tonnes of CO2e | 0.001 | 0.001 | 0.001 | 0.001 |

| 4 GHGs from composting BDW | tonnes of CO2e | 0.175 | 0.074 | 0.446 | 0.074 |

| 4 GHGs due to electricity from grid (indirect impact) | tonnes of CO2e | 0.064 | 0.015 | 0.013 | 0.013 |

| Waste from air treatment plant | kg | 0.508 | 0.162 | 0.162 | 0.777 |

| Analysis of Key Inputs and Outputs | Units | Current Situation | Alternative 1 | Alternative 2 | Alternative 3 |

|---|---|---|---|---|---|

| Direct costs of sludge management, incl. salary of employees, all related taxes | thousand EUR year−1 | 4197.71 | 2427.65 | 2503.56 | 2433.67 |

| EUR tonne−1 of sludge DM | 216.75 | 125.35 | 129.27 | 125.66 | |

| 2 Savings through reduced direct process costs (S) | thousand EUR year−1 | - | 1770.06 | 1694.14 | 1764.04 |

| Investments: | thousand EUR | - | 3008.15 | 1128.15 | 4269.75 |

| Buildings and design | thousand EUR | - | 293.15 | 293.15 | 3434.75 |

| Composting equipment | thousand EUR | - | 545.00 | 795.00 | 795.00 |

| Automation (instrumentation, control) | thousand EUR | - | 0.00 | 40.00 | 40.00 |

| Equipment (for intensive composting) | thousand EUR | - | 2170.00 | 0.00 | |

| 3 Payback period (PBP) | years | - | 1.70 | 0.67 | 2.42 |

| Income that reduces direct costs: | thousand EUR | 2676.30 | 3524.01 | 3524.01 | 3524.01 |

| Due to GW (e.g., leaves, grass) management service | thousand EUR | 0 | 175.45 | 175.45 | 175.45 |

| Due to excess electricity from CHP | thousand EUR | 2588.70 | 2588.70 | 2588.70 | 2588.70 |

| Due to excess thermal energy from CHP | thousand EUR | 87.60 | 87.60 | 87.60 | 87.60 |

| Due to compost production and sale | thousand EUR | 0 | 672.26 | 672.26 | 672.26 |

| Direct costs, after taking into account reductions due to incomes | EUR tonne−1 of sludge DM | 78.55 | −56.61 | −52.69 | −56.30 |

| Depreciation and amortization (existing equipment) (company’s data) | EUR tonne−1 of sludge DM | 97.00 | 97.00 | 97.00 | 97.00 |

| 4 Depreciation and amortization (new equipment and constructions) | EUR tonne−1 of sludge DM | 0.00 | 20.64 | 8.66 | 19.48 |

| Cost price of sludge management | EUR tonne−1 of sludge DM | 175.55 | 61.03 | 52.97 | 60.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kliopova, I.; Stunžėnas, E.; Kruopienė, J.; Budrys, R.P. Environmental and Economic Performance of Sludge Composting Optimization Alternatives: A Case Study for Thermally Hydrolyzed Anaerobically Digested Sludge. Water 2022, 14, 4102. https://doi.org/10.3390/w14244102

Kliopova I, Stunžėnas E, Kruopienė J, Budrys RP. Environmental and Economic Performance of Sludge Composting Optimization Alternatives: A Case Study for Thermally Hydrolyzed Anaerobically Digested Sludge. Water. 2022; 14(24):4102. https://doi.org/10.3390/w14244102

Chicago/Turabian StyleKliopova, Irina, Edgaras Stunžėnas, Jolita Kruopienė, and Rimas Pranas Budrys. 2022. "Environmental and Economic Performance of Sludge Composting Optimization Alternatives: A Case Study for Thermally Hydrolyzed Anaerobically Digested Sludge" Water 14, no. 24: 4102. https://doi.org/10.3390/w14244102

APA StyleKliopova, I., Stunžėnas, E., Kruopienė, J., & Budrys, R. P. (2022). Environmental and Economic Performance of Sludge Composting Optimization Alternatives: A Case Study for Thermally Hydrolyzed Anaerobically Digested Sludge. Water, 14(24), 4102. https://doi.org/10.3390/w14244102