Characteristics of Microstructural Changes of Malan Loess in Yan’an Area during Creep Test

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

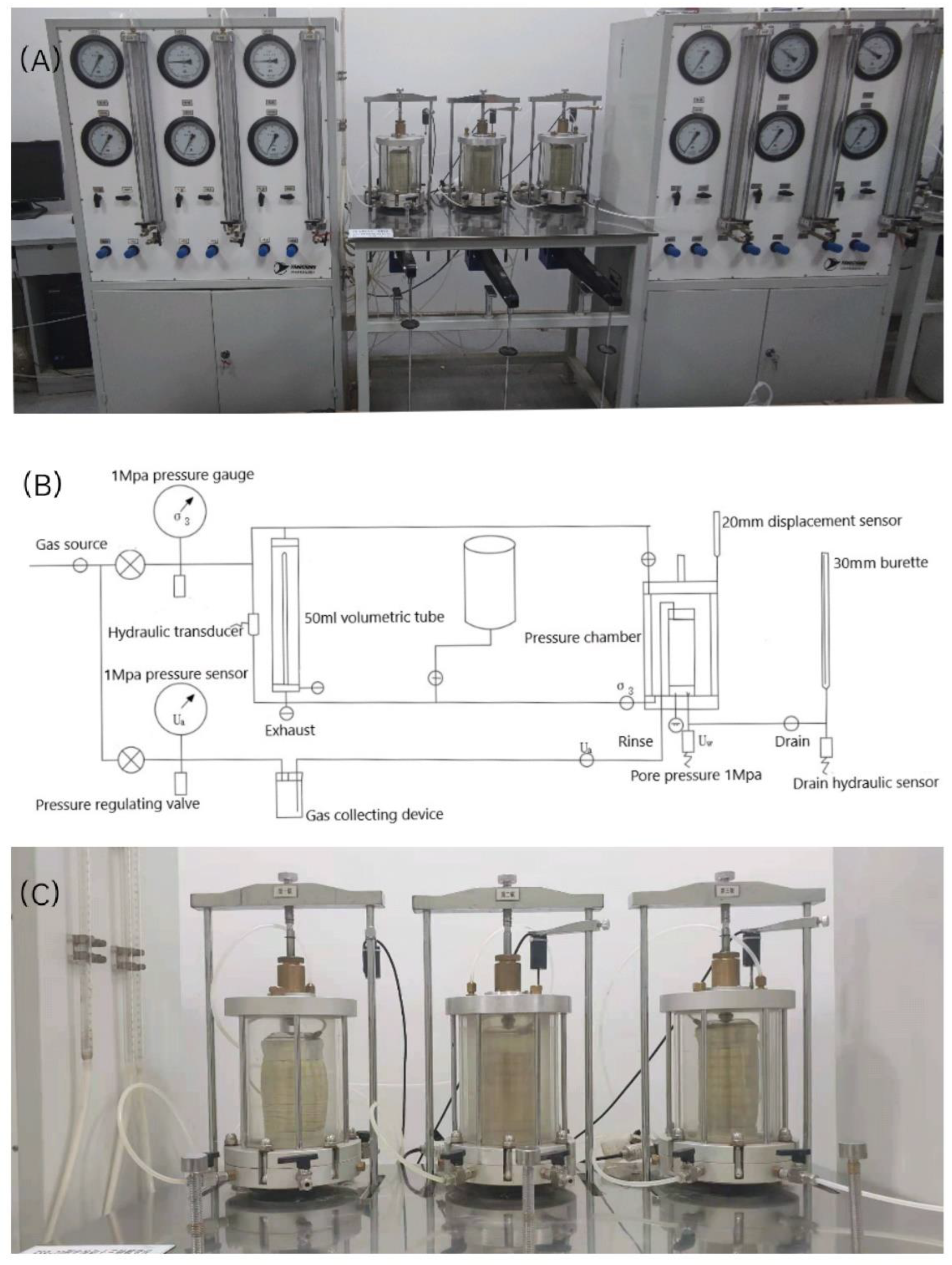

2.2. Testing Programs

2.3. Testing Method

- (1)

- Pore diameter means the average diameter value through the geometric center. According to the method of the loess hole classification [34], the loess pore is divided into a macropore (radius more significant than 16 μm), mesopore (radius between 4–16 μm), small pore (radius between 1–4 μm) and micropore (radius less than 1 μm).

- (2)

- Number of pores N refers to the number of loess pores in different pore size intervals.

- (3)

- Pore area S refers to the area of loess pore space in different pore size intervals.

- (4)

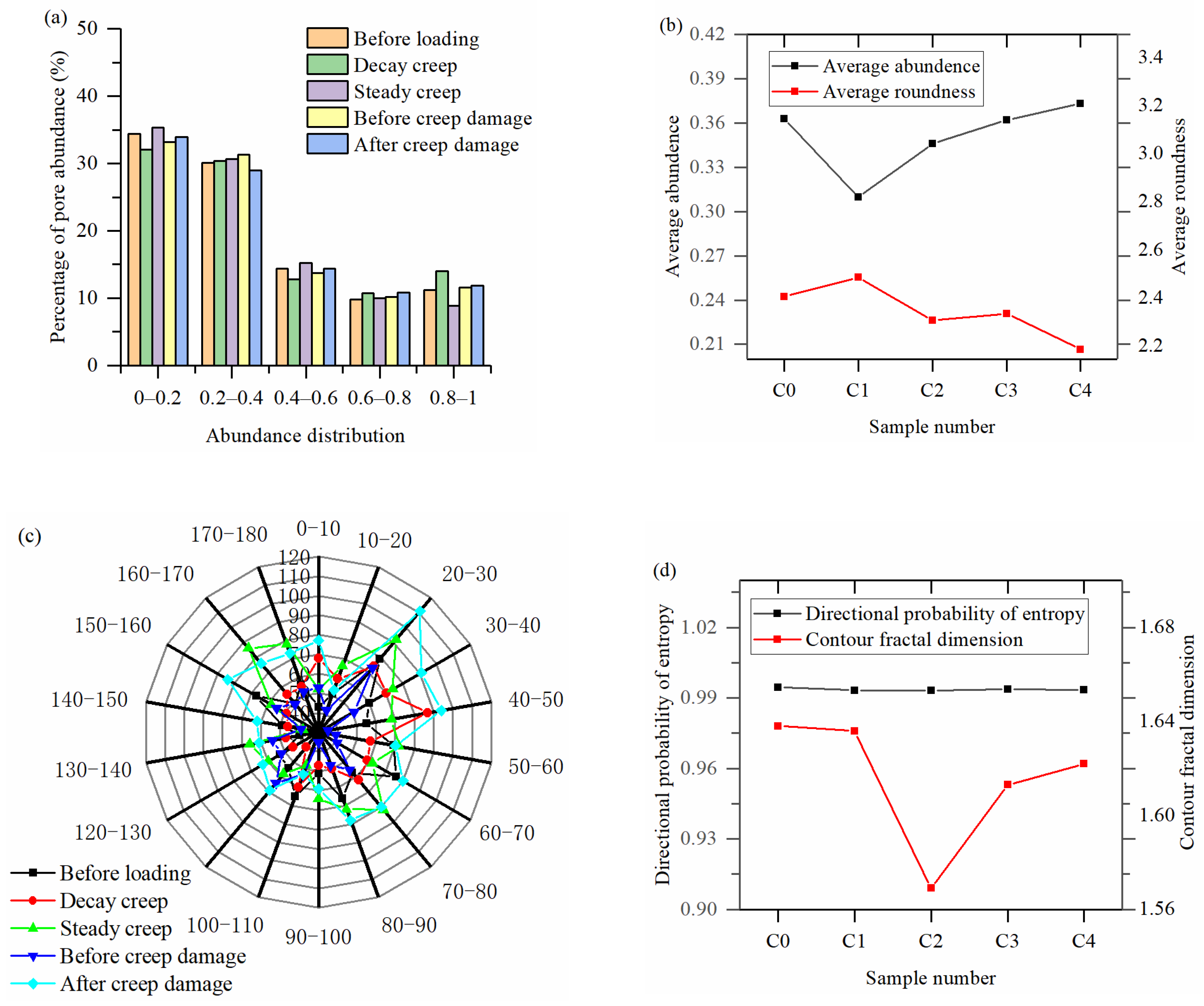

- Pore abundance C is the ratio of long-axis pore radius and short-axis pore radius.

- (5)

- Pore roundness R can be expressed as:A is the perimeter of the pore, S is the pore area.

- (6)

- Pore outline fractal dimension Dc is used to describe the complexity of the pore profile. It reflects the irregularity of the interface between the pore and the particles surrounding it. The fractal dimension can be used to describe the pore edge roughness, which can be expressed as:where P refers to the perimeter of the soil pore (particle), A refers to the area of the soil pore and C is a constant.The area of the soil pore is the horizontal coordinate and the perimeter is the vertical coordinate to obtain the corresponding double logarithmic relationship. The fractal dimension can be found by linearly fitting the slope of the line:

- (7)

- Directional frequency Fi(α) indicates the degree of distinctness of the pole arrangement in a given direction, which can be expressed as:where is the number of holes in the long axis direction in part i. M is the total number of poles. For this paper, = 10° and ranges from 1 to n.

- (8)

- Directional probability of entropy Hm refers to the index of orderliness of unit arrangement:where the value of ranges from 0 to 1. = 0 means that all the pores in this range are oriented in the same direction and feature the highest order state. = 1 means that the pores are entirely randomly distributed; ranges from 1 to n.

3. Testing Results

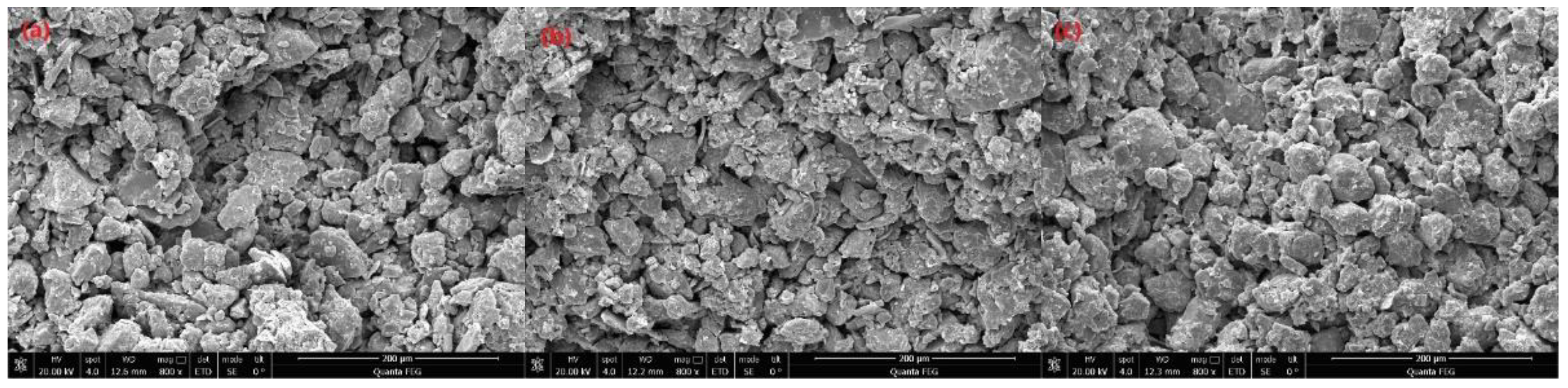

3.1. Microstructure Characteristics of Intact Loess

3.2. Qualitative Analysis of the Microstructure of Intact and Remolded Samples under Triaxial Creep Condition

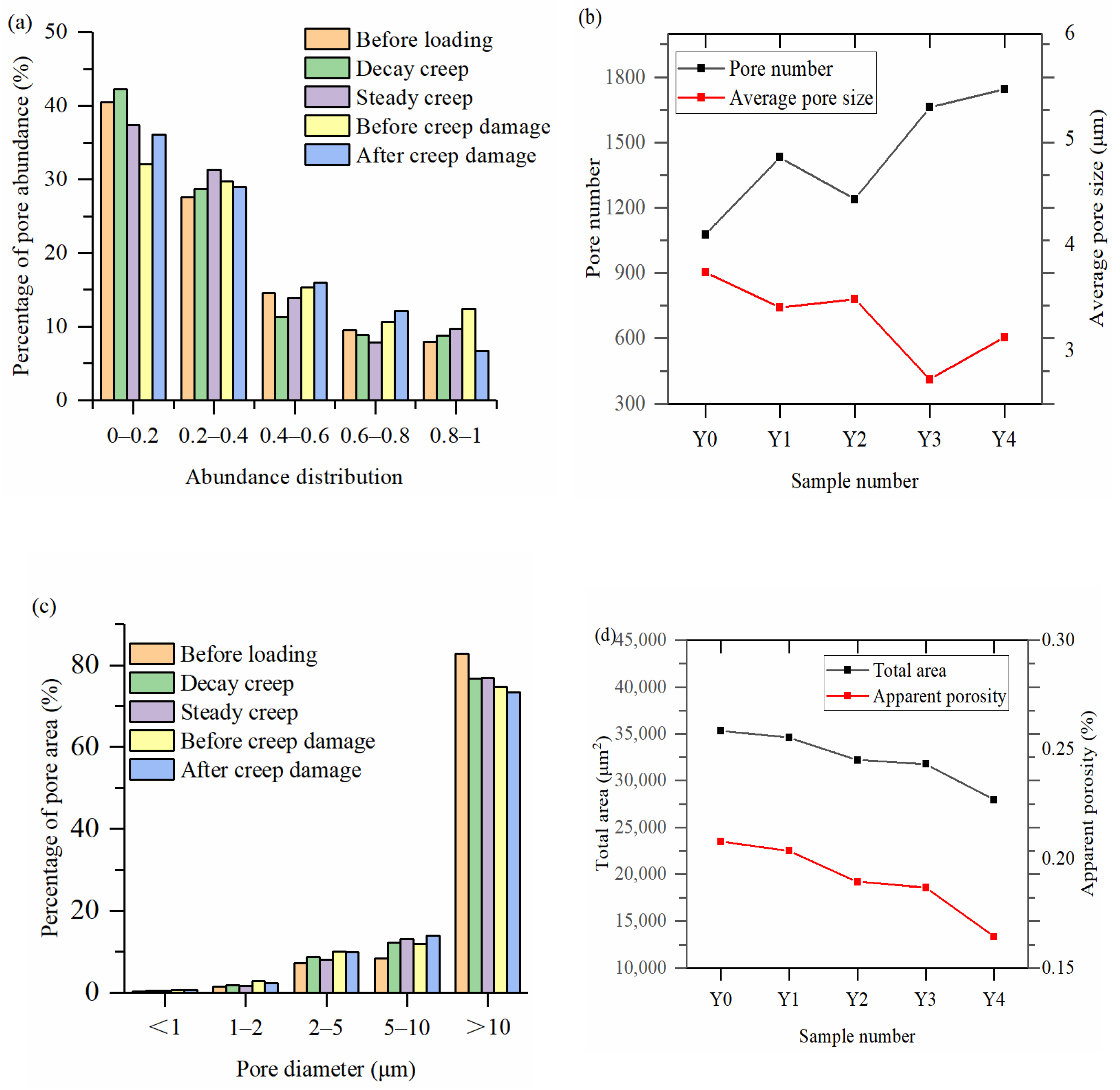

3.2.1. Analysis of Intact Loess Pore Characteristics

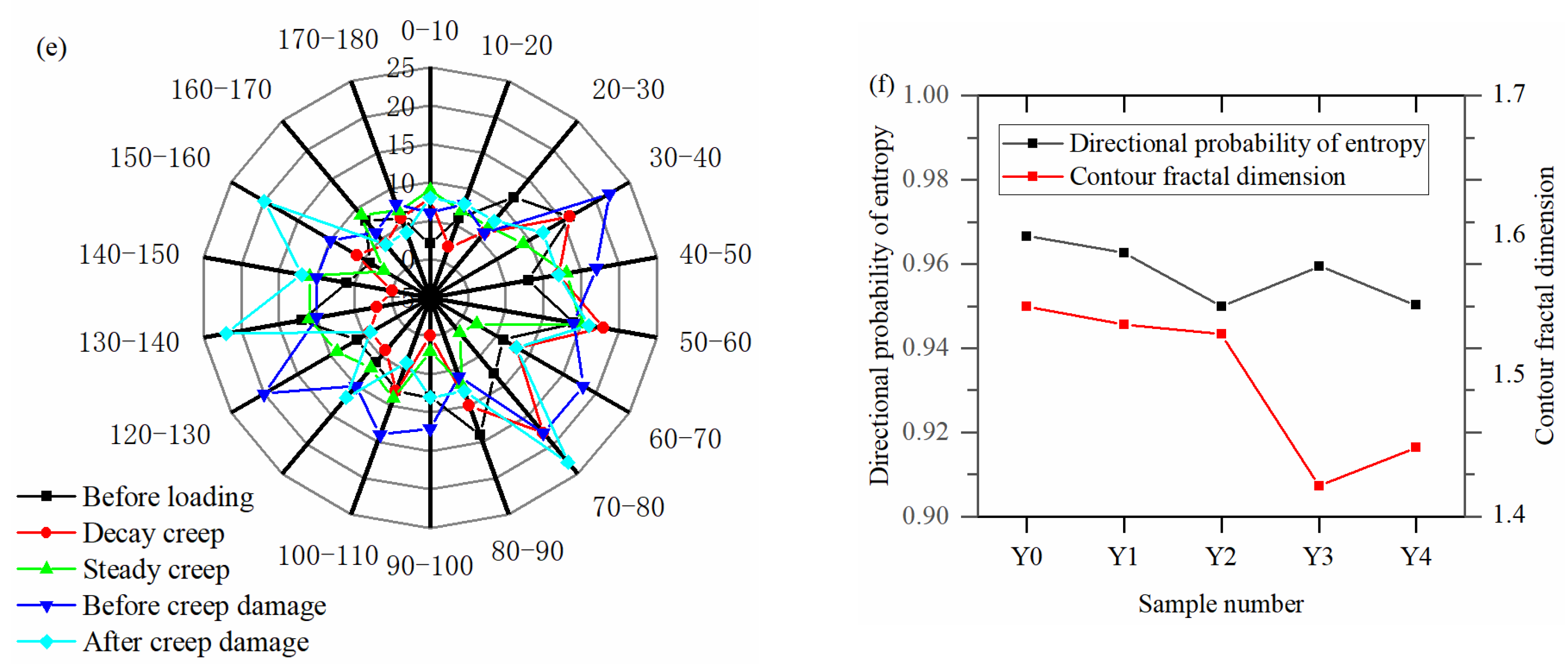

3.2.2. Quantitative Analysis of Intact Loess Particles

3.2.3. Analysis of Remolded Loess Pore Characteristics

3.2.4. Quantitative Analysis of Remolded Loess Particles

3.3. Analysis of Influence Degree of Micro-Parameters

4. Discussion

- (1)

- When the external load is less than the long-term strength of the soil, at the early stage of creep, the free water and gas between the soil particles are preferentially excluded; at this time, the internal forces in the soil are borne by the soil particles in the form of contact points, causing the soil particles to indicate the combined water film to produce extrusion elastic deformation, forming a resistance to an external load. The overall performance is dominated by structural hardening, the deformation rate gradually decreases until it tends to 0 and the soil creep deformation is small.

- (2)

- When the external load gradually approaches the long-term strength of the loess, under the action of the external load, the weaker linkage between the soil particles will preferentially fracture, the soil particles will slip and rotate, some of the soil particles will break and the softening of the soil structure will prevail. Under the action of this external force with the continuation of time, the loess deformation increases, forming more particle contact points; broken particles form new aggregates to adapt to the changes in the external forces, manifested as structural hardening.

- (3)

- When the external load is greater than the long-term strength of the loess, the growth of the structural hardening under the external load is not sufficient to compensate for the softening of the structure. At this time, the misalignment and slip between the particles are the main cause of deformation and, with the increase in the deformation rate, the soil is damaged.

5. Conclusions

- Quantitative analysis shows that in the process of the triaxial creep test, the soil structure of the intact loess gradually becomes compact, the debris material and viscous material on the surface of the particles increase, the soil particles gradually change from mainly granular and massive to mainly agglomerated, the overhead pores in the soil pores decrease and the intergranular pores increase. This is because the intact loess structure is loose and, under the action of external load, soil particles gradually gather into larger aggregates; and under the action of confining pressure and deviator stress, the large pores in the loess collapse, tiny pores and micro-pores increase, leading to the macroscopic expression of axial compression and volume compression. Due to thorough disturbance, the initial orientation of the soil particles is poor for remodeled loess. Under the action of confining pressure and deviator stress, the direction of soil particles gradually deviates to the direction of combined force (deviator stress). Hence, the qualitative development of remodeled loess in the creep process is obvious compared with intact loess.

- The microstructural characteristics of loess can be described by size index (pore diameter, number of pores, pore area), shape index (abundance), complexity index (roundness, contour fractal dimension) and directionality index (directional frequency, directional probability of entropy). During the creep process, the microstructural parameters of soil change, among which the change in pore and particle size (pore diameter, particle size) and shape (abundance) are the most obvious. By contrast, the complexity of other microstructural parameters (roundness, contour fractal dimension) and orientation (probability of entropy direction) exert little effect.

- During the creep process of loess, the soil skeleton changes continuously, but the soil microstructure experiences different changes at different levels of deviator stress. Before the loess enters the accelerated creep phase (the external force is less than the structural yield stress), the structural strength generated by the association between soil particles is greater than the external force, the degree of rotation and transposition of soil particles is small and the degree of microstructural change is small. When the loess enters the accelerated creep phase (the external force is greater than the structural yield stress), the linkage between soil particles is broken under the action of external force and the soil particles slip and rotate. Under the action of this external force with the continuation of time, the loess deformation increases, more particle contact points are formed and broken particles form new and stable aggregates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rogers, C.D.F.; Dijkstra, T.A.; Smalley, I.J. Hydroconsolidation and Subsidence of Loess: Studies from China, Russia, North America and Europe: In Memory of Jan Sajgalik. Eng. Geol. 1994, 37, 83–113. [Google Scholar] [CrossRef]

- Romero, E.; Simms, P.H. Microstructure Investigation in Unsaturated Soils: A Review with Special Attention to Contribution of Mercury Intrusion Porosimetry and Environmental Scanning Electron Microscopy. Geotech. Geol. Eng. 2008, 26, 705–727. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Hall, M.R.; Augarde, C.E. Macrostructural Changes in Compacted Earthen Construction Materials under Loading. Acta Geotech. 2013, 8, 423–438. [Google Scholar] [CrossRef] [Green Version]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural Characterization of Natural Loess and Remolded Loess under Triaxial Tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, T.; Zhang, Y.; Xu, Q. Geometrical Appearance and Spatial Arrangement of Structural Blocks of the Malan Loess in NW China: Implications for the Formation of Loess Columns. J. Asian Earth Sci. 2018, 158, 18–28. [Google Scholar] [CrossRef]

- Pusch, R.; Weston, R. Microstructural Stability Controls the Hydraulic Conductivity of Smectitic Buffer Clay. Appl. Clay Sci. 2003, 23, 35–41. [Google Scholar] [CrossRef]

- Wen, B.-P.; Yan, Y.-J. Influence of Structure on Shear Characteristics of the Unsaturated Loess in Lanzhou, China. Eng. Geol. 2014, 168, 46–58. [Google Scholar] [CrossRef]

- Li, P.; Vanapalli, S.; Li, T. Review of Collapse Triggering Mechanism of Collapsible Soils Due to Wetting. J. Rock Mech. Geotech. Eng. 2016, 8, 256–274. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.R. Influence of Structure on the Behavior of a Saturated Clayey Loess. Can. Geotech. J. 2016, 53, 1026–1037. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Mu, Q.Y.; Zhou, C. Effects of Soil Structure on the Shear Behaviour of an Unsaturated Loess at Different Suctions and Temperatures. Can. Geotech. J. 2017, 54, 270–279. [Google Scholar] [CrossRef]

- Wang, J.; Li, P.; Gu, Q.; Xu, Y.; Gu, T. Changes in Tensile Strength and Microstructure of Loess Due to Vibration. J. Asian Earth Sci. 2019, 169, 298–307. [Google Scholar] [CrossRef]

- Li, D.-W.; Fan, J.-H.; Wang, R.-H. Research on Visco-Elastic-Plastic Creep Model of Artificially Frozen Soil under High Confining Pressures. Cold Reg. Sci. Technol. 2011, 65, 219–225. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, Q.; Peng, D.; Fan, X.; Ouyang, C.; Zhao, K.; Li, H.; Zhu, X. Quantitative Spatial Distribution Model of Site-Specific Loess Landslides on the Heifangtai Terrace, China. Landslides 2021, 18, 1163–1176. [Google Scholar] [CrossRef]

- Romero, E. A Microstructural Insight into Compacted Clayey Soils and Their Hydraulic Properties. Eng. Geol. 2013, 165, 3–19. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Khattab, S.; Alcover, J.-F. Microstructure and Geotechnical Properties of Lime-Treated Expansive Clayey Soil. Eng. Geol. 2012, 139–140, 17–27. [Google Scholar] [CrossRef]

- Casini, F.; Vaunat, J.; Romero, E.; Desideri, A. Consequences on Water Retention Properties of Double-Porosity Features in a Compacted Silt. Acta Geotech. 2012, 7, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Cuisinier, O.; Masrouri, F.; Pelletier, M.; Villieras, F.; Mosser-Ruck, R. Microstructure of a Compacted Soil Submitted to an Alkaline PLUME. Appl. Clay Sci. 2008, 40, 159–170. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, L.M.; Li, X. Soil-Water Characteristic Curve and Permeability Function for Unsaturated Cracked Soil. Can. Geotech. J. 2011, 48, 1010–1031. [Google Scholar] [CrossRef]

- Mansour, M.F.; Morgenstern, N.R.; Martin, C.D. Expected Damage from Displacement of Slow-Moving Slides. Landslides 2011, 8, 117–131. [Google Scholar] [CrossRef]

- Di Maio, C.; Vassallo, R.; Vallario, M. Plastic and Viscous Shear Displacements of a Deep and Very Slow Landslide in Stiff Clay Formation. Eng. Geol. 2013, 162, 53–66. [Google Scholar] [CrossRef]

- Wen, B.-P.; Jiang, X.-Z. Effect of Gravel Content on Creep Behavior of Clayey Soil at Residual State: Implication for Its Role in Slow-Moving Landslides. Landslides 2017, 14, 559–576. [Google Scholar] [CrossRef]

- Di Maio, C.; Scaringi, G.; Vassallo, R. Residual Strength and Creep Behaviour on the Slip Surface of Specimens of a Landslide in Marine Origin Clay Shales: Influence of Pore Fluid Composition. Landslides 2015, 12, 657–667. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zhang, D. Creep Behavior of Intact Loess Followed Unloading Paths. Front. Earth Sci. 2021, 9, 812. [Google Scholar] [CrossRef]

- Sun, M.; Tang, H.; Wang, M.; Shan, Z.; Hu, X. Creep Behavior of Slip Zone Soil of the Majiagou Landslide in the Three Gorges Area. Env. Earth Sci 2016, 75, 1199. [Google Scholar] [CrossRef]

- Palmer, J. Creeping Earth Could Hold Secret to Deadly Landslides. Nature 2017, 548, 384–386. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, D.; Wang, N.; Gu, T. Mechanisms of Wetting-Induced Loess Slope Failures. Landslides 2019, 16, 937–953. [Google Scholar] [CrossRef]

- Yates, K.; Fenton, C.H.; Bell, D.H. A Review of the Geotechnical Characteristics of Loess and Loess-Derived Soils from Canterbury, South Island, New Zealand. Eng. Geol. 2018, 236, 11–21. [Google Scholar] [CrossRef]

- Tan, R.Y.; Yang, C.H. Structural Responses of Underground Pipelines to Dynamic Loadings. Mech. Struct. Mach. 1988, 16, 103–122. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, G.; Kamai, T.; Chen, W. Effect of Pore-Water Chemistry on Undrained Shear Behaviour of Saturated Loess. Q. J. Eng. Geol. Hydrogeol. 2014, 47, 201–210. [Google Scholar] [CrossRef]

- Peng, J.; Fan, Z.; Wu, D.; Zhuang, J.; Dai, F.; Chen, W.; Zhao, C. Heavy Rainfall Triggered Loess–Mudstone Landslide and Subsequent Debris Flow in Tianshui, China. Eng. Geol. 2015, 186, 79–90. [Google Scholar] [CrossRef]

- Zhou, Y.F.; Tham, L.G.; Yan, R.W.M.; Xu, L. The Mechanism of Soil Failures along Cracks Subjected to Water Infiltration. Comput. Geotech. 2014, 55, 330–341. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Zhan, H.; Li, P.; Qiu, H.; Hu, S. Moisture Content Effect on the Creep Behavior of Loess for the Catastrophic Baqiao Landslide. Catena 2020, 187, 104371. [Google Scholar] [CrossRef]

- Wang, J.-D.; Li, P.; Ma, Y.; Vanapalli, S.K. Evolution of Pore-Size Distribution of Intact Loess and Remolded Loess Due to Consolidation. J. Soils Sediments 2019, 19, 1226–1238. [Google Scholar] [CrossRef]

- IUSS Working Group WRB. World Reference Base for Soil Resources 2014, update 2015 International soil classification system for naming soils and creating legends for soil maps. In World Soil Resources Reports No. 106; FAO: Rome, Italy, 2015. [Google Scholar]

- Soil Taxonomy, Keys to Soil Taxonomy, 12th ed.; USDA-Natural Resources Conservation Service: Washington, DC, USA, 2014.

| Water Content ω % | Density ρ g/cm3 | Liquid Limit ωL % | Plastic Limit ωP % | Cohesion c kPa | Internal Friction Angle φ ° | Specific Gravity Gs | Grain Composition | ||

|---|---|---|---|---|---|---|---|---|---|

| Viscous Particles % | Silt Particles % | Sand Particles % | |||||||

| 14.7 | 1.54 | 27.9 | 18.9 | 28.87 | 18.99 | 2.69 | 16.3 | 71.6 | 12.1 |

| Sample | Number | Initial Confining Pressure kPa | Matrix Suction kPa | Deviator Stress kPa | Creeping Status |

|---|---|---|---|---|---|

| Remolded Samples | RC-0 | - | - | Not loaded | Before loading |

| RC-1 | 400 | 100 | 200 | Decay creep | |

| RC-2 | 400 | 100 | 200–400 | Steady creep | |

| RC-3 | 400 | 100 | 200–400–500–600 | Before creep failure | |

| RC-4 | 400 | 100 | 200–400–500–600–700 | Creep failure | |

| Intact Samples | UC-0 | - | - | Not loaded | Before loading |

| UC-1 | 400 | 100 | 200 | Decay creep | |

| UC-2 | 400 | 100 | 200–400 | Steady creep | |

| UC-3 | 400 | 100 | 200–400–500 | Before creep failure | |

| UC-4 | 400 | 100 | 200–400–500–600 | Creep failure |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Wang, J.; Yang, S.; Liu, S.; Li, Y. Characteristics of Microstructural Changes of Malan Loess in Yan’an Area during Creep Test. Water 2022, 14, 438. https://doi.org/10.3390/w14030438

Li Z, Wang J, Yang S, Liu S, Li Y. Characteristics of Microstructural Changes of Malan Loess in Yan’an Area during Creep Test. Water. 2022; 14(3):438. https://doi.org/10.3390/w14030438

Chicago/Turabian StyleLi, Zhenxiao, Jiading Wang, Shuai Yang, Shehu Liu, and Yongwei Li. 2022. "Characteristics of Microstructural Changes of Malan Loess in Yan’an Area during Creep Test" Water 14, no. 3: 438. https://doi.org/10.3390/w14030438

APA StyleLi, Z., Wang, J., Yang, S., Liu, S., & Li, Y. (2022). Characteristics of Microstructural Changes of Malan Loess in Yan’an Area during Creep Test. Water, 14(3), 438. https://doi.org/10.3390/w14030438