Generation of Tequila Vinasses, Characterization, Current Disposal Practices and Study Cases of Disposal Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Collecting Information on Tequila Factories

2.2. Vinasse Characterizations

2.3. Analysis of Current Disposal Practices for Treated and Untreated Vinasses

2.4. Case Studies to Assess the Impact of Current Vinasse Disposal Practices

- (a)

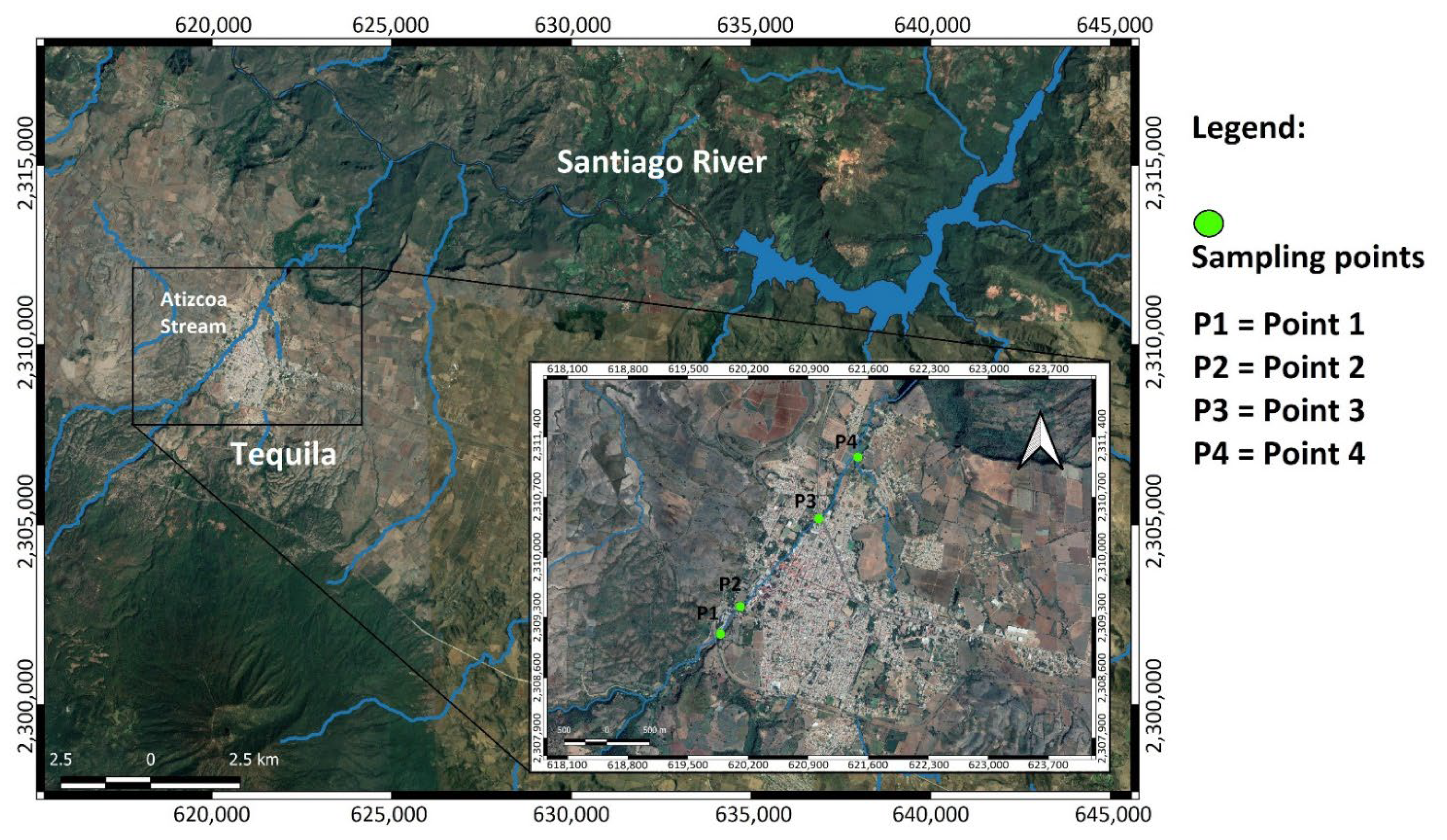

- Monitoring of surface water in Tequila, Jalisco;

- (b)

- Characterization of a soil irrigated with vinasse for 14 years;

- (c)

- Monitoring of groundwater in a well located near soils used for vinasse disposal

3. Results and Discussion

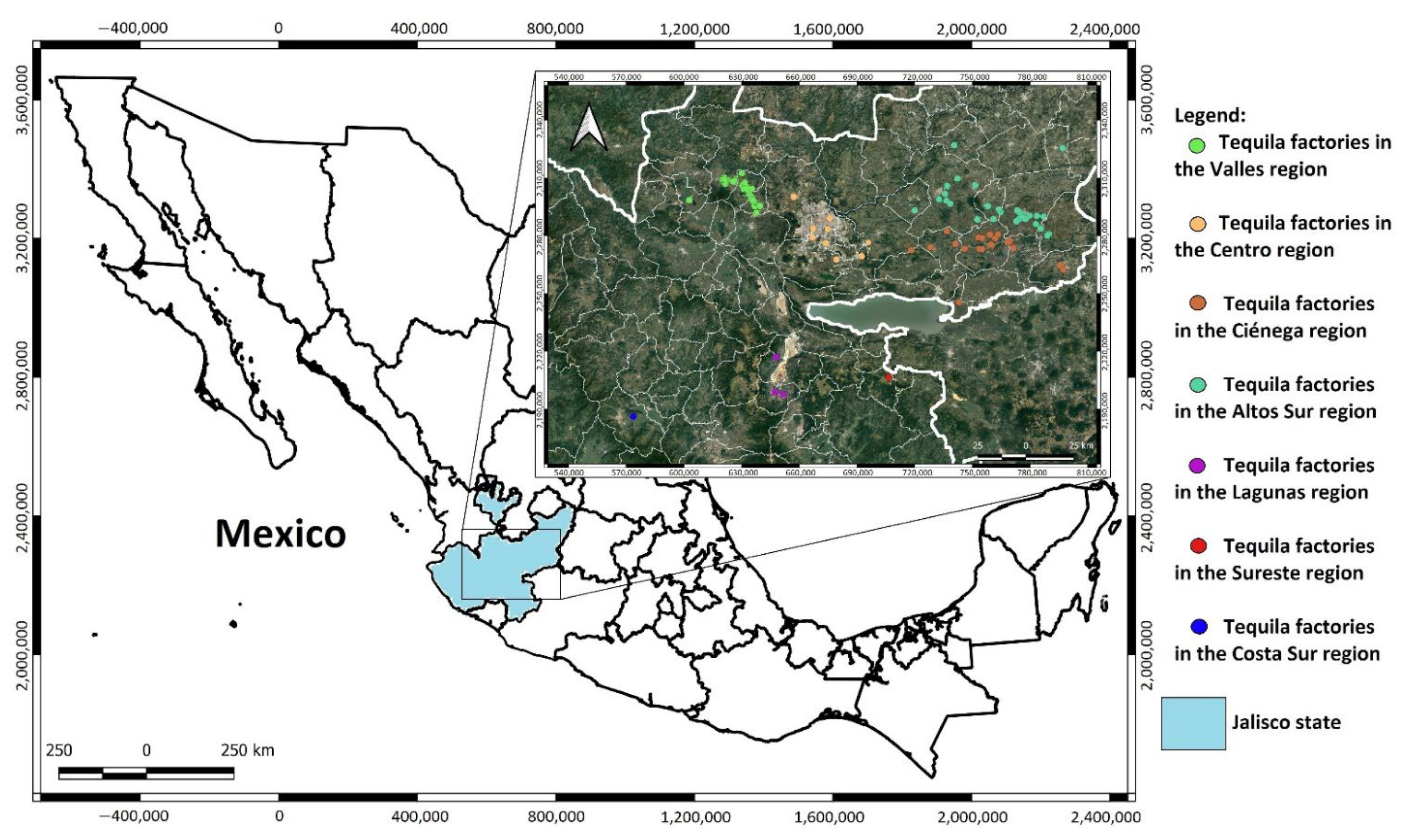

3.1. Distribution of Tequila Factories in the State of Jalisco

3.2. Distribution of Tequila Factories in the State of Jalisco

3.3. Current Disposal Practices and Treatments of Tequila Vinasse

| Disposal in Surface Waters (m3/año) | Disposal in Soils (m3/año) | Use of Vinasse for Irrigation m3/año) | Treated by an External Company (m3/año) | Disposal into Municipal Sewer Systems (m3/año) | |

|---|---|---|---|---|---|

| No treatment | 32–48 | 5000–7500 | 6000–9000 | 27,395 | - |

| Incomplete treatment | 400–600 | 180,100–270,150 | 180,319–270,748 | 8000–12,000 | 300–450 |

| Full treatment | 594,400–981,600, | 14,000–21,000 | 404,044–606,067 | - | - |

3.4. Evaluation of the Impact of Vinasse Disposal in Atizcoa Stream

3.5. Evaluation of a Soil Irrigated with Vinasse for 14 Years

| Parameter | Value |

|---|---|

| Textural classification | Clay |

| Sand (%) | 23.51 ± 3.12 |

| Clay (%) | 45.13 ± 5.42 |

| Silt (%) | 31.36 ± 5.47 |

| pH | 7.90 ± 0.20 |

| Electrical conductivity (µs/cm) | 425.08 ± 52.34 |

| Moisture (%) | 19.81 ± 0.13 |

| Water retention capacity (%) | 64.94 ± 1.98 |

| Cation exchange capacity (meq/100 g) | 46.80 ± 2.26 |

| Density (g/cm3) | 1.29 ± 0.014 |

| Organic carbon (%) | 9.38 ± 0.626 |

| Chloride (ppm Cl−) | 93.33 ± 7.64 |

| Total phosphorus (ppm P) | 44.66 ± 11.01 |

| Phosphorus available to plants (ppm P) | 14.89 ± 1.95 |

| Total Nitrogen (ppm) | 2688.06 ± 195.08 |

| Total Kjeldahl Nitrogen: N-org. y NH3 (ppm) | 2674.56 ± 200.90 |

| Nitrate (NO3− ppm) | 18.50 ± 5.89 |

| Potassium (ppm K) | 690.50 ± 12.02 |

| Ca2+ (ppm Ca) | 6247.50 ± 212.84 |

| Magnesium (ppm Mg) | 1593.00 ± 135.76 |

| Sulfur (SO4− ppm) | 28.00 ± 0.00 |

| Boron (B ppm) | 1.20 ± 0.141 |

| Copper (Cu ppm) | 5.60 ± 0.424 |

| Iron (Fe ppm) | 100.00 ± 11.31 |

| Manganese (Mn ppm) | 304.00 ± 21.21 |

| Zinc (Zn ppm) | 2.95 ± 0.495 |

| Sodium (Na ppm) | 120.50 ± 6.36 |

| Fats and oils (g/kg soil) | 21.71 ± 3.55 |

3.6. Physicochemical Characterization of Groundwater near to Soils Used for Vinasse Disposal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CRT. Producción Total de Tequila y Tequila 100% en 2021. Available online: https://www.crt.org.mx/EstadisticasCRTweb/ (accessed on 1 March 2021).

- INEGI; CAJ. Coleccion de Estudios Regionales y Sectoriales. Conociendo la Industria del Tequila y el Mezcal; Instituto Nacional de Estadistica y Geografía: Mexico City, Mexico, 2019; Volume 1. [Google Scholar]

- Lopez-Lopez, A.; Davila-Vazquez, G.; León-Becerril, E.; Villegas, E.; Gallardo-Valdez, J. Tequila Vinasses: Generation and full scale treatment processes. Rev. Environ. Sci. Bio/Technol. 2010, 9, 109–116. [Google Scholar] [CrossRef]

- CRT. Manual del Tecnico Tequilero; Consejo Regulador del Tequila: Guadalajara, Mexico, 2019; Volume 1. [Google Scholar]

- Díaz-Vázquez, D.; Carrillo-Nieves, D.; Orozco-Nunnelly, D.A.; Senés-Guerrero, C.; Gradilla-Hernández, M.S. An Integrated Approach for the Assessment of Environmental Sustainability in Agro-Industrial Waste Management Practices: The Case of the Tequila Industry. Front. Environ. Sci. 2021, 9, 682093. [Google Scholar] [CrossRef]

- Kharayat, Y. Distillery wastewater: Bioremediation approaches. J. Integr. Environ. Sci. 2012, 9, 69–91. [Google Scholar] [CrossRef]

- APHA; AWWA; WEF. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- DOF. Especificaciones de Fertilidad, Salinidad y Clasificación de Suelos. Estudios, Muestreo y Analisis; NOM-021-RECNAT-2000. Diario Oficial de la Federación: Mexico City, Mexico, 2000.

- Margesin, R.; Schinner, F. Manual for Soil Analysis-Monitoring and Assessing Soil Bioremediation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005; Volume 5. [Google Scholar]

- Bremner, J.M. Nitrogen-Total. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1996; pp. 1085–1121. [Google Scholar]

- DOF. NMX-AA-026-SCFI-2010. Analisis de Agua- Medición de Nitrógeno Total Kjeldahl en Aguas Naturales, Residuales y Residuales Tratadas—Metodo de Prueba; Diario Oficial de la Federacion: Mexico City, Mexico, 2010.

- Miller, R.; Sonon, L. Nitrate-Nitrogen. In Soil Test Methods From the Southeastern United States; Southern Cooperative Series Bulletin No.419; Southern Extension and Research Activity Information Exchange Group-6 (SERA-IEG-6): Fayetteville, AR, USA, 2014; Volume 1. [Google Scholar]

- Andersen, J.M. An ignition method for determination of total phosphorus in lake sediments. Water Res. 1976, 10, 329–331. [Google Scholar] [CrossRef]

- Murphy, J.; Riley, J.P. A modified single solution method for the determination of phosphate in natural waters. Anal. Chim. Acta 1962, 27, 31–36. [Google Scholar] [CrossRef]

- Huluka, G.; Miller, R. Particle Size Determination by Hidrometer Method. In Soil Test Methods From the Southeastern United States; Southern Cooperative Series Bulletin No.419; Southern Extension and Research Activity Information Exchange Group-6 (SERA-IEG-6): Fayetteville, AR, USA, 2014; Volume 1. [Google Scholar]

- DOF. NMX-AA-134-SFCI-2006. Norma Oficial Mexicana para Suelos-Hidrocarburos Fraccion Pesada por Extraccion y Gravimetria-Mtodo Prueba; Diario Oficial de la Federación: Mexico City, Mexico, 2006.

- Baker, D.E.; Amacher, M.C. Nickel, Copper, Zinc, and Cadmium. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 323–336. [Google Scholar]

- Bingham, F.T. Boron. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 431–447. [Google Scholar]

- Blake, G.R.; Hartge, K.H. Bulk Density. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1986; pp. 363–375. [Google Scholar]

- Gambrell, R.P.; Patrick, W.H., Jr. Manganese. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 313–322. [Google Scholar]

- Gardner, W.H. Water Content. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1986; pp. 493–544. [Google Scholar]

- Klute, A. Water Retention: Laboratory Methods. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1986; pp. 635–662. [Google Scholar]

- Knudsen, D.; Peterson, G.A.; Pratt, P.F. Lithium, Sodium, and Potassium. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 225–246. [Google Scholar]

- Lanyon, L.E.; Heald, W.R. Magnesium, Calcium, Strontium, and Barium. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 247–262. [Google Scholar]

- Nelson, D.W.; Sommers, L.E. Total Carbon, Organic Carbon, and Organic Matter. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 539–579. [Google Scholar]

- Olson, R.V.; Ellis, R., Jr. Iron. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 301–312. [Google Scholar]

- Rhoades, J.D. Cation Exchange Capacity. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 149–157. [Google Scholar]

- Rhoades, J.D. Soluble Salts. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 167–179. [Google Scholar]

- Tabatabai, M.A. Sulfur. In Methods of Soil Analysis; American Society of Agronomy, Inc.: Madison, WI, USA; Soil Science Society of America, Inc.: Madison, WI, USA, 1983; pp. 501–538. [Google Scholar]

- SEMADET. Listado de Cedulas de Operación Anual. 2019. Available online: https://semadet.jalisco.gob.mx/medio-ambiente/calidad-del-aire/listados-delas (accessed on 16 March 2021).

- Toure, A.; Wenbiao, D.; Keita, Z.; Dembele, A. Investigation of the water quality of daily used surface-sources for drinking and irrigation by the population of Segou in the center of Mali. J. Water Health 2018, 17, 338–349. [Google Scholar] [CrossRef] [PubMed]

- Thai-Hoang, L.; Thong, T.; Loc, H.T.; Van, P.T.T.; Thuy, P.T.P.; Thuoc, T.L. Influences of anthropogenic activities on water quality in the Saigon River, Ho Chi Minh City. J. Water Health 2022, 20, 491–504. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Lopez, A.; Contreras-Ramos, S. Tratamiento de Efluentes y Aprovechamiento de Residuos; CIATEJ: Guadalajara, Mexico, 2015; pp. 343–378. [Google Scholar]

- CONAGUA. Estadisticas del Agua en México; Comision Nacional del Agua: Mexico City, Mexico, 2018. [Google Scholar]

- Sandoval, L.; Marín-Muñíz, J.L.; Adame-García, J.; Fernández-Lambert, G.; Zurita, F. Effect of Spathiphyllum blandum on the removal of ibuprofen and conventional pollutants from polluted river water, in fully saturated constructed wetlands at mesocosm level. J. Water Health 2020, 18, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Casillas-García, L.F.; de Anda, J.; Yebra-Montes, C.; Shear, H.; Díaz-Vázquez, D.; Gradilla-Hernández, M.S. Development of a specific water quality index for the protection of aquatic life of a highly polluted urban river. Ecol. Indic. 2021, 129, 107899. [Google Scholar] [CrossRef]

- Rizo-Decelis, L.D.; Pardo-Igúzquiza, E.; Andreo, B. Spatial prediction of water quality variables along a main river channel, in presence of pollution hotspots. Sci. Total Environ. 2017, 605–606, 276–290. [Google Scholar] [CrossRef] [PubMed]

- Hansen, A.M.; González-Márquez, L.C. Scenarios of metal concentrations in the Arcediano Dam (State of Jalisco, Mexico). J. Environ. Sci. Health Part A 2010, 45, 99–106. [Google Scholar] [CrossRef] [PubMed]

- Mobilian, C.; Craft, C.B. Wetland Soils: Physical and Chemical Properties and Biogeochemical Processes. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Upadhyay, S.; Raghubanshi, A.S. Chapter 16—Determinants of soil carbon dynamics in urban ecosystems. In Urban Ecology; Verma, P., Singh, P., Singh, R., Raghubanshi, A.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Lozano-Trejo, S.; Olazo-Aquino, J.; Pérez-León, M.I.; Castañeda-Hidalgo, E.; Díaz-Zorrilla, G.O.; Santiago-Martínez, G.M. Infiltración y escurrimiento de agua en suelos de una cuenca en el sur de México. Terra Latinoam. 2020, 38, 57–66. [Google Scholar] [CrossRef] [Green Version]

- Fuess, L.T.; Altoé, M.E.; Felipe, M.C.; Garcia, M.L. Pros and cons of fertirrigation with in natura sugarcane vinasse: Do improvements in soil fertility offset environmental and bioenergy losses? J. Clean. Prod. 2021, 319, 128684. [Google Scholar] [CrossRef]

- Dlamini, P.; Chivenge, P.; Chaplot, V. Overgrazing decreases soil organic carbon stocks the most under dry climates and low soil pH: A meta-analysis shows. Agric. Ecosyst. Environ. 2016, 221, 258–269. [Google Scholar] [CrossRef]

- Moran-Salazar, R.G.; Sanchez-Lizarraga, A.L.; Rodriguez-Campos, J.; Davila-Vazquez, G.; Marino-Marmolejo, E.N.; Dendooven, L.; Contreras-Ramos, S.M. Utilization of vinasses as soil amendment: Consequences and perspectives. SpringerPlus 2016, 5, 1007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Christofoletti, C.A.; Escher, J.P.; Correia, J.E.; Marinho, J.F.U.; Fontanetti, C.S. Sugarcane vinasse: Environmental implications of its use. Waste Manag. 2013, 33, 2752–2761. [Google Scholar] [CrossRef] [PubMed]

- Maradiaga-Rodriguez, W.D.; Pêgo-Evangelista, A.W.; Alves Júnior, J.; Costa, R.B.-d. Effects of vinasse and lithothanmium application on the initial growth of sugar cane (Saccharum sp. cv. RB 86-7515) irrigated and not irrigated. Acta Agron. 2018, 67, 252–257. [Google Scholar] [CrossRef] [Green Version]

- DOF. NOM-127-SSA1-1994. Salud Ambiental, Agua Para Uso y Consumo Humano-Limites Permisibles de Calidad y Tratamientos a que debe Someterse el Agua Para su Potabilización; Diario Oficial de la Federación: Mexico City, Mexico, 1994. [Google Scholar]

- Peinado-Guevara, H.J.; Green-Ruìz, C.R.; Delgado-Rodríguez, O.; Herrera-Barrientos, J.; Belmonte Jiménez, S.; Ladrón de Guevara Torres, M.d.l.Á.; Shevnin, V. Estimación de la conductividad hidráulica y contenido de finos a partir de leyes experimentales que relacionan parámetros hidráulicos y eléctricos. Ra Ximhai 2010, 6, 469–478. [Google Scholar] [CrossRef]

- Osuna Ceja, E.S.; Padilla Ramirez, J.S. Estimación de la sorbilidad e infiltración usando datos de simulación de lluvia para tres tipos de suelos de la zona semiárida de México. Terra Latinoam. 1998, 16, 293–302. [Google Scholar]

- Ortegón, G.P.; Arboleda, F.M.; Candela, L.; Tamoh, K.; Valdes-Abellan, J. Vinasse application to sugar cane fields. Effect on the unsaturated zone and groundwater at Valle del Cauca (Colombia). Sci. Total Environ. 2016, 539, 410–419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Municipality | Region | Tequila Factories |

|---|---|---|

| Tequila | Valles | 22 |

| Arandas | Altos Sur | 15 |

| Amatitán | Valles | 13 |

| Atotonilco el Alto | Ciénega | 12 |

| El Arenal | Valles | 9 |

| Tepatitlán | Altos Sur | 7 |

| Jesús María | Altos Sur | 3 |

| Tototlán | Ciénega | 3 |

| Parameter | This Study | Lopez-Lopez et al. 2010 | Parameter | This Study | Lopez-Lopez et al. 2010 |

|---|---|---|---|---|---|

| Total BOD5 (mg/L) | 23,254 ± 7924 (3718–35,516) | 35,000–60,000 | Ammonia | (<0.40–15.8) | 15–40 |

| Total COD (mg/L) | 45,381 ± 17,369 (7565–73,690) | 60,000–100,000 | Nitrite | <0.00199 | --- |

| TSS (mg/L) | 7127 ± 7294 (190–24,800) | 2000–8000 | Nitrate | <0.100 | --- |

| VSS (mg/L) | 6418 ± 6451 (185–23,000) | 1990–7500 | Ca2+ | 516.4 ± 292.1 (123–1287) | 200–1100 |

| SetS (ml/L) | 235.6 ± 306.1 (0.1–900) | 10–900 | Cu | 1.22 ± 2.5 (<0.05–12.5) | <3.0 |

| TP (mg/L) | <0.3 | 32–228 | Fe | 18.5 ± 15.8 (0.24–61.5) | <45 |

| Fats and Oils (mg/L) | 119 ± 109 (6–423) | 10–100 | Mg2+ | 168 ± 92 (10.4–382.0) | 100–300 |

| Total Phenols | <0.0103 | --- | K | 297.5 ± 212.5 (3.68–961.8) | 150–650 |

| TDS (mg/L) | 19816 ± 8550 (2055–33,970) | 23,000–42,000 | Na | 45.1 ± 37.7 (9.2–161.9) | --- |

| Conductivity | 3044 ± 1007 (523–5385) | --- | Ni | <.0.1–0.54 | <0.02 |

| pH | 3.6 ± 0.2 (3.4–3.9) | 3.4–4.5 | Zn | 1.03 ± 0.76 (<0.1–3.0) | <1.0 |

| Org-N | 254 ± 127 (24–574) | 5.0–10 |

| Parameter | Average Value | ||

|---|---|---|---|

| Large | Medium | Micro | |

| Total BOD5 (mg/L) | 19,587 | 21,084 | 24,856 |

| Total COD (mg/L) | 47,776 | 49151 | 43,394 |

| TSS (mg/L) | 9472 | 8242 | 6211 |

| VSS (mg/L) | 8675 | 7524 | 5524 |

| TDS (mg/L) | 22,624 | 22,536 | 18,168 |

| Conductivity | 3321 | 3158 | 2943 |

| pH | 3.5 | 3.7 | 3.6 |

| Fats and Oils (mg/L) | 130 | 87 | 130 |

| Org-N | 262 | 335 | 219 |

| Size | Micro | Small | Medium | Large | Total |

|---|---|---|---|---|---|

| Data collected in a survey (m3/year) | 27,278 (3.8%) | 13,250 (1.8%) | 127,164 (17.6%) | 556,000 (76.8%) | 723,692 |

| Estimate for Jalisco State(m3/year) | 55,000–82,501 | 26,053–39,079 | 254,740–382,109 | 1,111,591–1,667,386 | 1,447,384–2,171,076 |

| Type of Treatment | Number of Tequila Factories | Size of Tequila Factories |

|---|---|---|

| Retention lagoon and pH adjustment | 20 | Micro (16), Small (1) Medium(2) Large(1) |

| Sedimentation pond | 2 | Medium (2) |

| Full biological treatment | 6 | Micro (3), Medium (2) Large (1) |

| Full physicochemical treatment (coagulation-floculation) | 2 | Large (2) |

| No treatment | 12 | Micro (8), Small (2) Medium (2) |

| Disposal in Surface Waters (m3/year) | Disposal in Soils (m3/year) | Use of Vinasse for Irrigation (m3/year) | Treated by an External Company (m3/year) | Disposal into Municipal Sewer Systems (m3/year) | Total (m3/year) | |

|---|---|---|---|---|---|---|

| No treatment | 16 | 2500 | 3000 | 27,395 | - | 32,911 |

| Incomplete treatment | 200 | 90,050 | 90,159 | 4000 | 150 | 184,559 |

| Full treatment | 297,200 | 7000 | 202,022 | - | - | 506,222 |

| Parameter | Point 1 | Point 2 | Point 3 | Point 4 |

|---|---|---|---|---|

| Temperature | 24 ± 1.8 | 35.8 ± 1.6 | 27.1 ± 1.0 | 26.0 ± 1.7 |

| pH | 6.9 ± 0.5 | 5.4 ± 1.0 | 5.7 ± 1.1 | 4.7 ± 0.4 |

| DO | 6.3 ± 0.2 | 3.2 ± 0.3 | 0.5 ± 0.3 | 0.4 ± 0.0 |

| Conductivity | 82.1 ± 0.9 | 155.7 ± 56.2 | 712.0 ± 145.9 | 1384.7 ± 63.5 |

| Parameter | Excellent Quality | Good Quality | Acceptable Quality | Polluted | Highly Polluted |

|---|---|---|---|---|---|

| BOD5 (mg/L) | ≤ 3 | >3 ≤6 | >6 ≤30 | >30 ≤120 | >120 |

| COD (mg/L) | ≤10 mg/L | >10 ≤20 | >20 ≤40 | >40 ≤200 | >200 |

| TSS (mg/L) | ≤25 mg/L | >25 ≤75 | >75 ≤150 | >150 ≤400 | >400 |

| Fecal Colifoms (MPN/100 mL) | ≤100 | >100 ≤200 | >200 ≤1000 | >1000 ≤10,000 | >10,000 |

| Parameter | Value on This Study | Mexican Standards |

|---|---|---|

| Nitrate (mg/L) | 9.366 ± 2.484 | 10 |

| Nitrite (mg/L) | 0.058 ± 0.041 | 1 |

| Total Fe (mg/L) | 0.026 ± 0.0115 | 0.30 |

| Mn (mg/L) | 0.9 ± 0.1 | 0.15 |

| Cl− (mg/L) | 17.0 ± 4.334 | 250 |

| F− (mg/L) | 0.306 ± 0.4 | 1.5 |

| Hardness (mg/L CaCO3) | 376.66 ± 2.88 | 500 |

| Alkalinity (mg/L CaCO3) | 327.10 ± 16.07 | N.R. |

| N-NH4+ (mg/L) | 0.0 ± 0.0 | 0.5 |

| Turbidity (NTU) | 0.296 ± 0.513 | 5 NTU |

| Sulfate SO42−(mg/L) | 60.6 ± 1.154 | 400 |

| pH | 8.083 ± 0.155 | 6.5–8.5 |

| Conductivity (μs/cm) | 722.67 ± 214.13 | N.R. |

| Color (Units of Pt-Co) | 3.0 ± 2.0 | 20 |

| Reactive phosphorus (mg/L) | 0.054 ± 0.0188 | N.R. |

| Total Phenols (mg/L) | <0.0101 | 0.3 |

| Fats and oils (mg/L) | <5.00 | N.R. |

| Ca2+ (mg/L) | 82.40 ± 5.234 | N.R. |

| Copper (mg/L) | <0.020 | 2 |

| K+ (mg/L) | 3.298 ± 0.240 | N.R. |

| Mg+2 (mg/L) | 41.60 ± 2.515 | N.R. |

| Na+ (mg/L) | 18.50 ± 2.656 | 200 |

| Nickel (mg/L) | <0.020 | N.R. |

| Zinc (mg/L) | <0.020 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zurita, F.; Tejeda, A.; Montoya, A.; Carrillo, I.; Sulbarán-Rangel, B.; Carreón-Álvarez, A. Generation of Tequila Vinasses, Characterization, Current Disposal Practices and Study Cases of Disposal Methods. Water 2022, 14, 1395. https://doi.org/10.3390/w14091395

Zurita F, Tejeda A, Montoya A, Carrillo I, Sulbarán-Rangel B, Carreón-Álvarez A. Generation of Tequila Vinasses, Characterization, Current Disposal Practices and Study Cases of Disposal Methods. Water. 2022; 14(9):1395. https://doi.org/10.3390/w14091395

Chicago/Turabian StyleZurita, Florentina, Allan Tejeda, Arturo Montoya, Isaías Carrillo, Belkis Sulbarán-Rangel, and Alejandra Carreón-Álvarez. 2022. "Generation of Tequila Vinasses, Characterization, Current Disposal Practices and Study Cases of Disposal Methods" Water 14, no. 9: 1395. https://doi.org/10.3390/w14091395