Operation Performance and Seepage Flow of Impervious Body in Blast-Fill Dams Using Discrete Element Method and Measured Data

Abstract

:1. Introduction

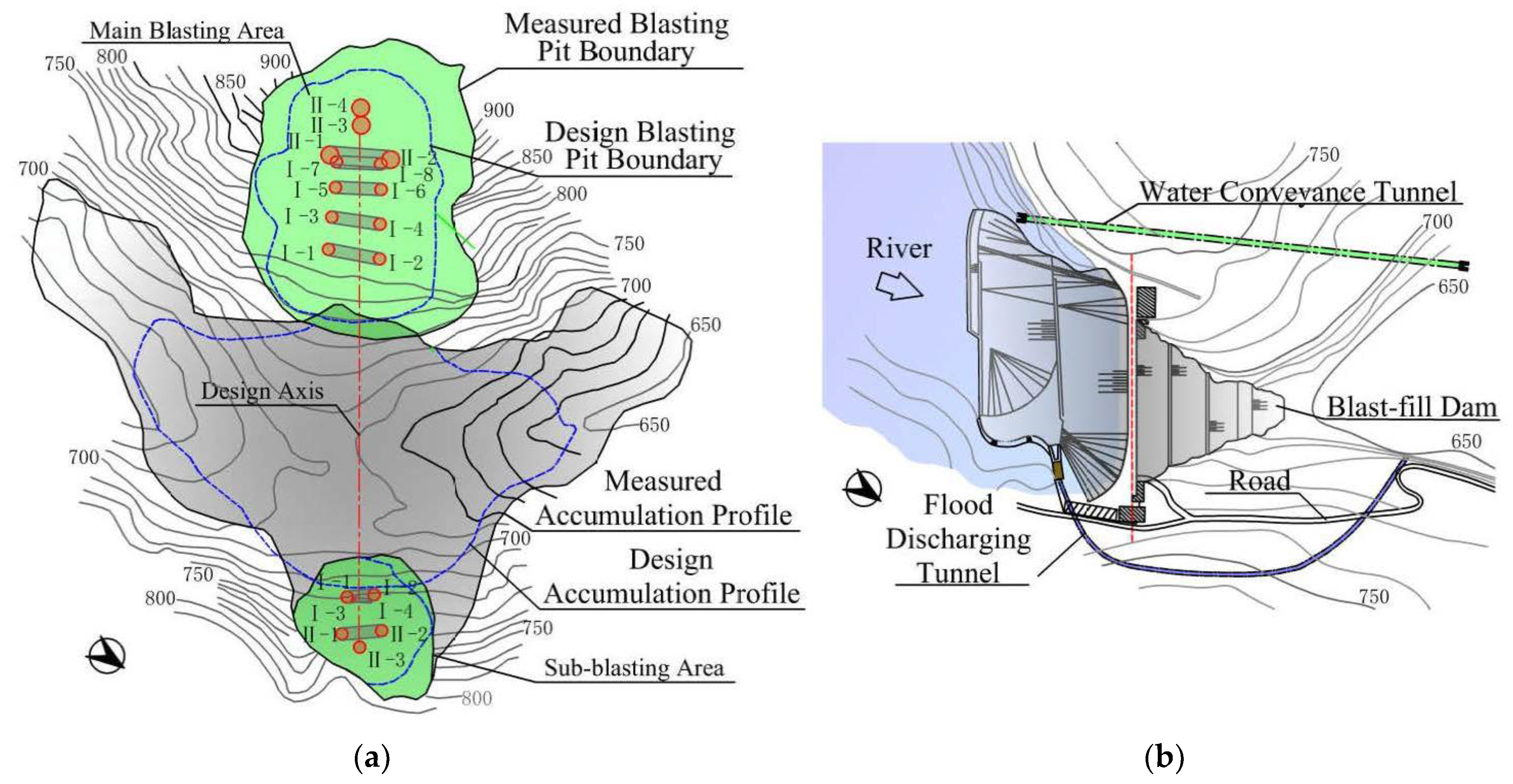

2. Statistics on Blast-Fill Dams

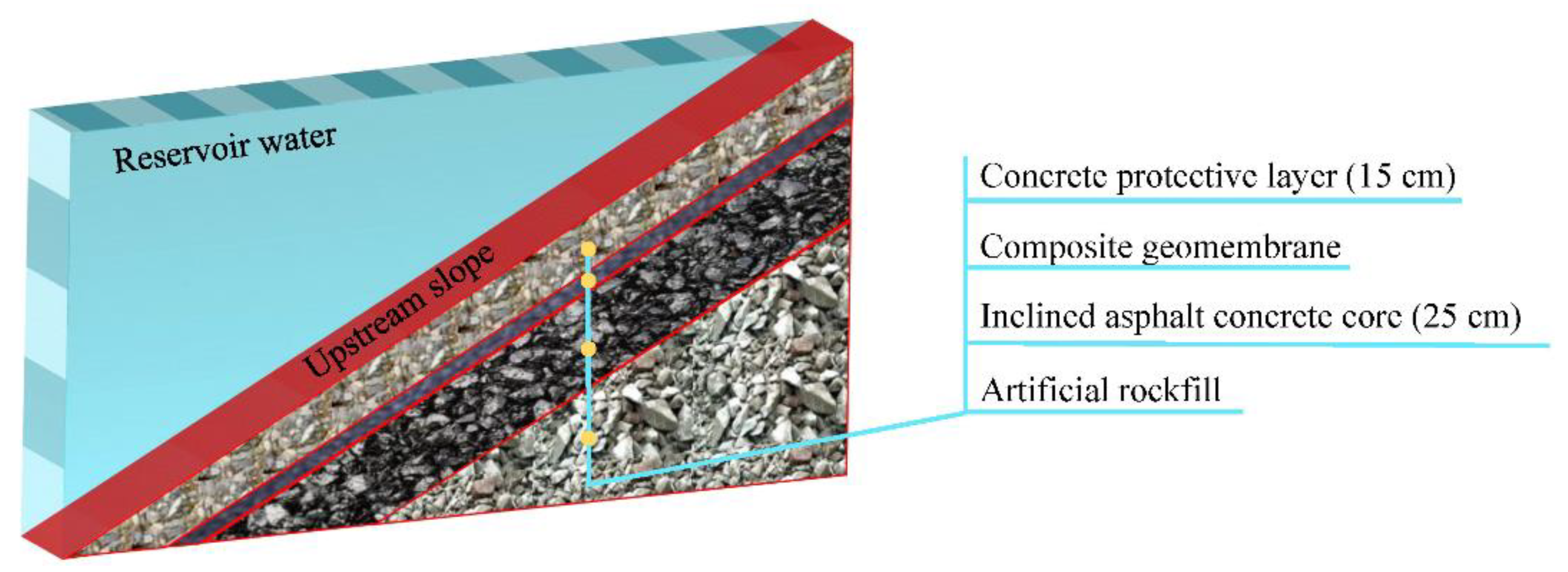

3. Design of the Impervious Body

3.1. Initial Design of the Impervious Body

- Seepage control around the dam. The rock mass in the dam abutment is the main material source for blast-fill dams. Meanwhile, the considerable explosion energy generated by the explosives is likely to inflict great vibration damage to mountain bodies surrounding the dam abutment, causing further fracture generation and expansion of the rock mass. If seepage control treatments are not performed around the dam, there is a high probability of seepage around the dam during its operation period. Therefore, in the process of site selection for blast-fill dams, the dam abutment is required to be thick overall, and the top must be steep. At the same time, to reduce the damage to the dam abutment, the blasting area must be a certain height above the dam crest. During construction, the dam abutment should be treated with seepage control measures, such as expanding seepage control in the dam body, setting concrete plugs and local grouting. For mountains with serious damage, a covering for the overall slope surface and grouting curtain can be used.

- Seepage control in the riverbed. In the early stage of blast-fill dam construction, the riverbed is usually not thoroughly and effectively cleaned before blasting, and the deep overburden layer is not effectively treated with seepage control measures. Consequently, the riverbed clearly becomes the main seepage path during the operation period. Therefore, the dam foundation should be cleaned before blasting, and a clay or concrete cutoff wall may be constructed for the deep overburden layer at an appropriate time.

- Seepage control in the dam body. On-site detection indicates that the density of the bottom blasting pile, whose porosity is less than that of the rockfill dam, is very high, but the density of the surface layer of the blasting pile is low [12]. In addition, after blasting, it is often necessary to heighten the dam body to the design elevation using artificial rockfill. However, in the early stage of artificial rockfill, large stones are used without rolling equipment, resulting in poor construction quality at the top of blast-fill dams. Therefore, in the design process, it is very important to select a reasonable seepage control measure in the dam body to accommodate the large, long-term and nonuniform deformation of blast-fill dams. At present, the most commonly used seepage control measure in dam bodies is an inclined core; inclined cores can be made of clay, asphalt concrete, composite geomembranes and other materials. Moreover, the support structures can be used to reduce the influence of deformation, such as concrete or stone protective layer, filter layer and transition layers. The seepage control measures in the dam body can also include curtain grouting, concrete cutoff wall construction and so on.

- Seepage control in the peripheral joint. To satisfy the blasting requirements, the natural rock mass of a dam abutment is usually steep, which will cause a large change in the dam thickness at the joint between the dam foundation and dam body. There is a great possibility that the dam deformation will be uncoordinated, resulting in cracking of the impervious body, and that a seepage channel will be formed on the bedrock surface, threatening the dam safety. Therefore, seepage control measures should be carried out for the joint between the dam foundation and dam body, such as expanding the scope of the seepage control used in the dam body, using multilayer anti-seepage structures and selecting a flexible impervious body.

3.2. Reinforcement of Impervious Body

4. Operation Performance and Seepage Flow in the Impervious Body of a Blast-Fill Dam

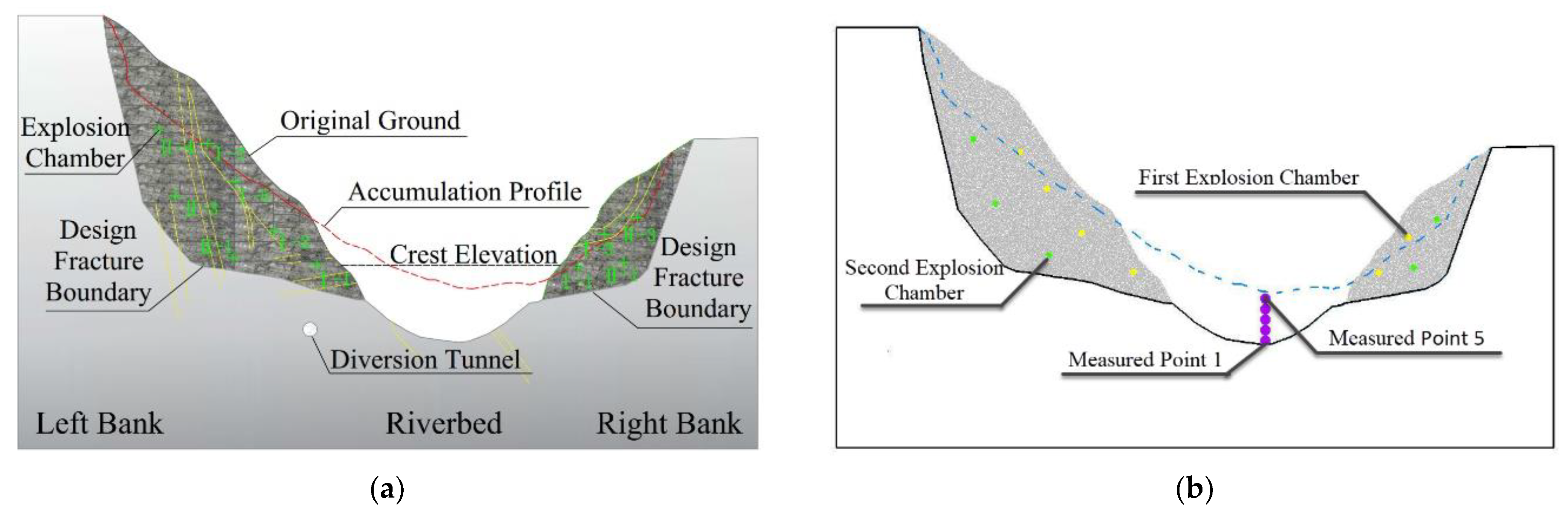

4.1. Structural Characteristic Analysis of Blast-Fill Dam Using the DEM

4.1.1. Discrete Element Simulation of Blasting Process

4.1.2. Structural Characteristic Analysis of the Blast-Fill Dam

4.2. Seepage Cause Analysis and Impervious Body before and after Reinforcement

- (1)

- Long-term, large and nonuniform deformation of the dam body. Although there is a favorable compactness in the bottom blasting pile, the surface layer of the blasting pile, talus material of the dam foundation and artificial rockfill are relatively soft, causing nonuniform deformation on the inclined core foundation. Under high water pressure, the asphalt concrete strain exceeds its allowable value, forming cracks and, consequently, a seepage path.

- (2)

- Seepage path expansion. The reservoir water infiltrates through the cracks in the inclined core, and the cushion under the inclined core is gradually emptied, resulting in a larger zone of the inclined core hanging in the air. Finally, under high water pressure, the IACC breaks. Therefore, the complementary effects of seepage and collapse pits are observed: the cracks expand into the collapse pit, resulting in a significant increase in the amount of seepage.

- (3)

- Blasting pile erosion. Due to the damage in the inclined core, the hydraulic gradient and seepage deformation change in the dam body, aggravating the particle corrosion in the dam. Then, the rock body that has been stabilized in the dam begins to slide, rearrange and collapse, which will cause collapse and damage to the inclined core and cushion.

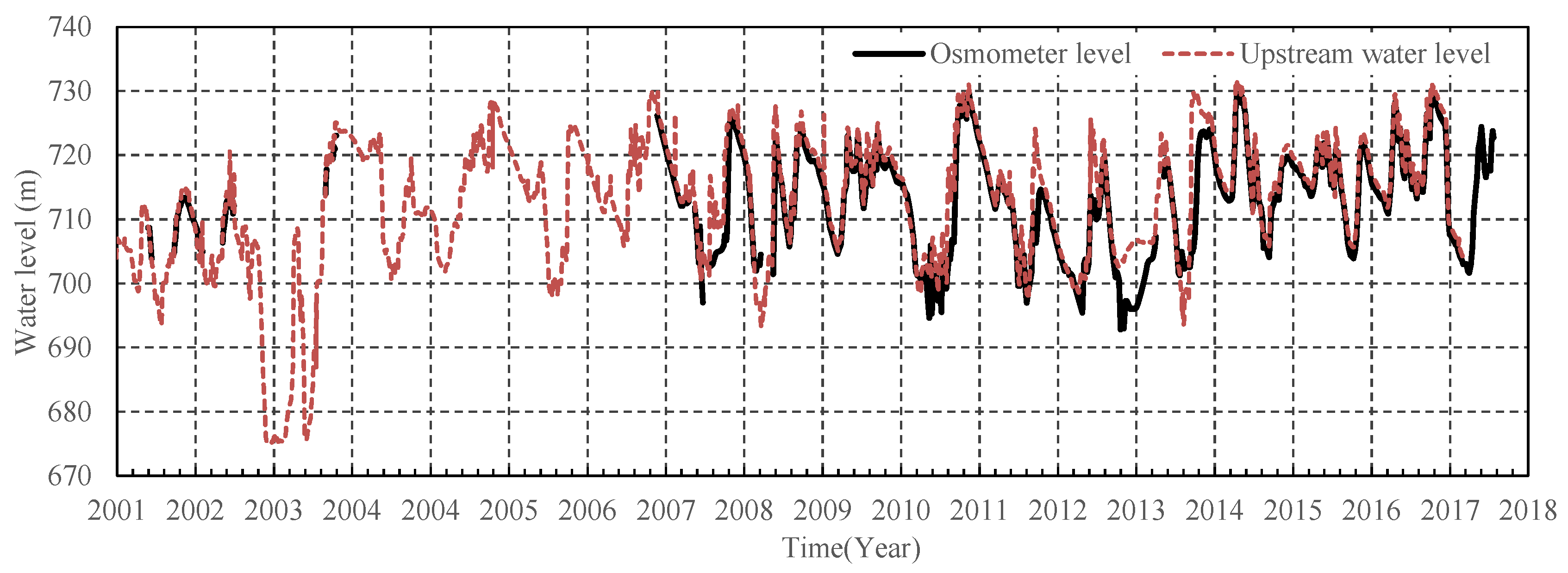

4.3. Operation Performance Analysis after Reinforcement Using Measured Data

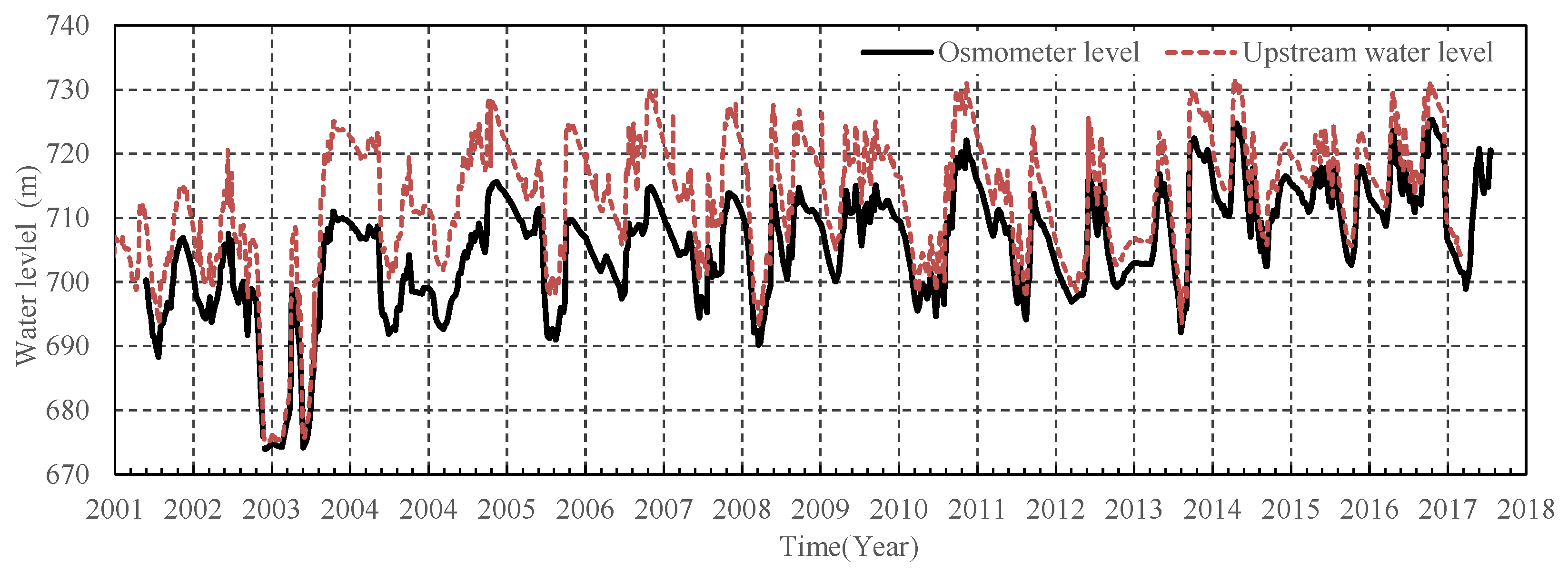

4.3.1. Seepage Control Effect of the Geomembrane

4.3.2. Seepage Control Effect of the IACC

4.3.3. Analysis of Phreatic Line

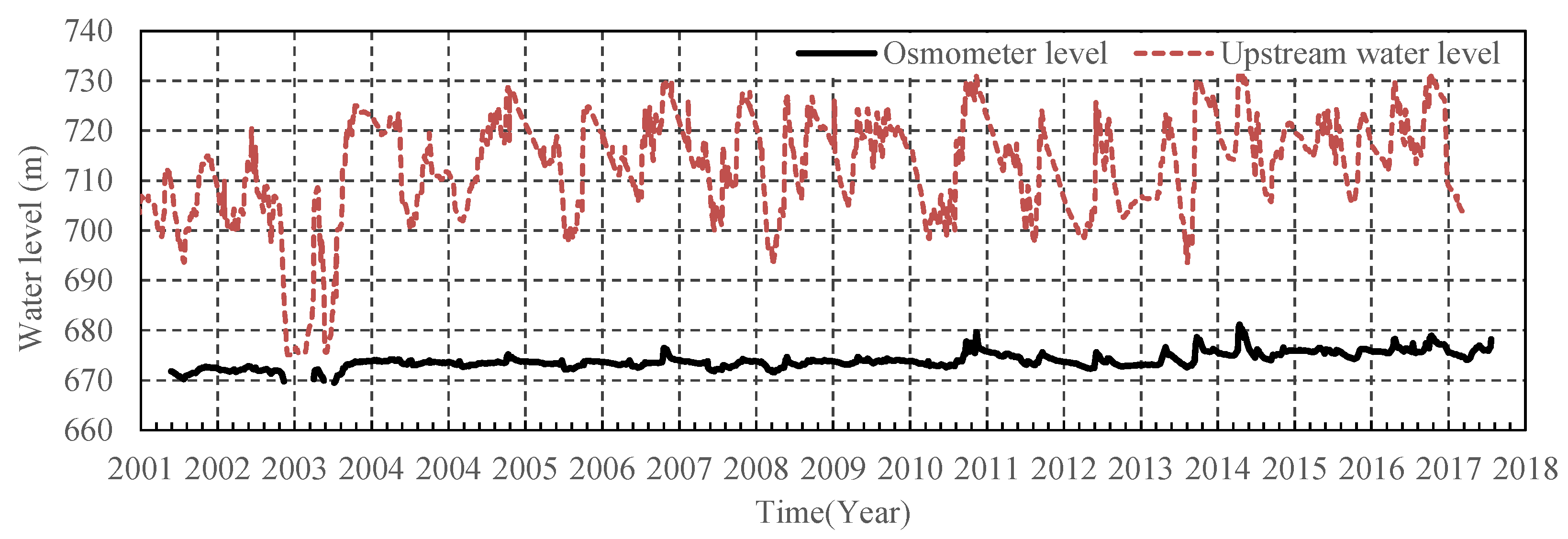

- (1)

- Due to this blast-fill dam having several large leaks, the fine particles were transported from upstream to downstream by seepage in the dam body. Hence, the rockfill pores in the downstream area of the dam are filled, and the permeability of this blast-fill dam is reduced, which is not conducive to the dissipation of seepage and pore water. Therefore, the phreatic line and overflow position of this blast-fill dam are raised.

- (2)

- According to the on-site detection of multiple blast-fill dams [12,37], the gradation of the bottom blasting pile is uniform, and its compactness exceeds or equals that of other rockfill dams [38,39]. On the one hand, during the blasting process, the rock mass experienced short-term high-speed impact, crushing, thrusting, collision and stacking, which had a considerable tamping effect on the dam foundation and blasting pile. On the other hand, the rock mass is mixed with surface soil in the bank slope and talus material and overburden in the dam foundation, so the rockfill pores are filled with fine materials, forming a dam with continuous gradation and high compactness. Therefore, the bottom of the blast-fill dam has certain impermeability due to the continuous gradation and high compactness, causing an obvious lifting effect on the phreatic line of blast-fill dams.

- (3)

- Because this dam once temporarily stored water before the impervious body was completed, it is possible that fine particles were transported from upstream to downstream. Then, the rockfill pores downstream were blocked by fine materials, and the phreatic line rose. According to the monitoring data, after reinforcement, the measured seepage flow was 0.00~0.20 m3/s. If the average seepage flow of this blast-fill dam is calculated as 0.04 m3/s, the annual seepage flow accounts for 6.54% of the total reservoir capacity, indicating that the overall seepage flow of this blast-fill dam is normal. Because of the large occlusal force between rockfill materials, a slightly higher phreatic line has a small impact on the slope stability of blast-fill dams, but osmometer monitoring should be further strengthened.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, X.G. Discussion on some problems observed in high earth-rockfill dams. Chin. J. Geotech. Eng. 2018, 40, 203–222. (In Chinese) [Google Scholar] [CrossRef]

- Ma, C.H.; Yang, J.; Zenz, G.; Staudacher, E.J.; Cheng, L. Calibration of the microparameters of the discrete element method using a relevance vector machine and its application to rockfill materials. Adv. Eng. Softw. 2020, 147, 102833. [Google Scholar] [CrossRef]

- Maranha, D.N.E. Advances in Rockfill Structures; NATO ASI Series E: Applied Science; Springer: Berlin/Heidelberg, Germany, 1991; pp. 13–16. [Google Scholar]

- Jiang, G.C. Review on development of geotechnical engineering research in the past 50 years. J. China Inst. Water Resour. Hydropower Res. 2008, 6, 16–26. (In Chinese) [Google Scholar] [CrossRef]

- Qlz, A.; Ygh, B.; Msl, B.; Dyl, A. Role of negative pressure in structural responses of gravity dams to underwater explosion loadings: The need to consider local cavitation. Eng. Fail. Analysis 2021, 122, 105270. [Google Scholar] [CrossRef]

- Meng, N.; Bai, J.; Chen, Y.; Wang, X.; Wu, B. Stability analysis of roadside backfill body at gob-side entry retaining under combined static and dynamic loading. Eng. Fail. Anal. 2021, 127, 105531. [Google Scholar] [CrossRef]

- Adushkin, V.V. Russian Experience with Blast-Fill Dam Construction. Natural and Artificial Rockslide Dams; Springer: Berlin/Heidelberg, Germany, 2011; pp. 104–106. [Google Scholar]

- Nedriga, V.P.; Pokrovskii, G.I.; Avdeev, F.A. Earth dams constructed by the directional blasting method. Hydrotech. Constr. 1986, 20, 61–66. [Google Scholar] [CrossRef]

- Pokrovskii, G.I.; Lushnov, N.P. Technology of constructing blast-filled dams and geotechnical properties of soils of such structures. Hydrotech. Constr. 1992, 26, 395–400. [Google Scholar] [CrossRef]

- Havenith, H.B.; Torgoev, I.; Torgoev, A.; Strom, A.; Xu, Y.; Fernandez-Steeger, T.M. The Kambarata 2 blast-fill dam, Kyrgyz Republic: Blast event, geophysical monitoring and dam structure modelling. Geoenvironmental Disasters 2015, 2, 11. [Google Scholar] [CrossRef] [Green Version]

- Torgoev, I.A.; Havenith, H.B.; Torgoev, A.D. Geophysical Monitoring of Artificial Landslide Dam of Kambarata Hydro Power Plant-2 (Kyrgyzstan); Springer: Berlin/Heidelberg, Germany, 2014; pp. 11–13. [Google Scholar]

- Chen, B.L.; Wang, B.Q.; Chen, Y.Z. Structural and seepage characteristics of rockfill dam by directional blasting. J. Hydraul. Eng. 1998, 29, 51–56. (In Chinese) [Google Scholar] [CrossRef]

- Xi, H.Z.; Pan, J.N.; Wang, C.Y. Soil clogging to seal the rockfill dam constructed by directional blasting. J. Hydraul. Eng. 1992, 4, 8–14. (In Chinese) [Google Scholar] [CrossRef]

- Adushkin, V.V. Explosive initiation of creative processes in nature. Combust. Explos. Shock Waves 2000, 36, 695–703. [Google Scholar] [CrossRef]

- Yan, Y.Z.; Yuan, J.G. New construction technology for gully harness key engineering soil conservation. J. Hydraul. Eng. 2002, 33, 78–81. (In Chinese) [Google Scholar] [CrossRef]

- Evans, S.G.; Delaney, K.B.; Hermanns, R.L.; Strom, A.; Scarascia-Mugnozza, G. The formation and behaviour of natural and artificial rockslide dams; implications for engineering performance and hazard management. Chin. Med. J. 2011, 66, 1046–1055. [Google Scholar] [CrossRef]

- Honkanadavar, N.P.; Sharma, K.G. Testing and Modeling the Behavior of Riverbed and Blasted Quarried Rockfill Materials. Int. J. Geomech. 2014, 14, 04014028. [Google Scholar] [CrossRef]

- Lu, J.H.; Tan, J.X.; Zhou, H.Q. Review of the illness characteristics and reinforcement technology of directed blasting rockfill dams. Hydropower New Energy 2017, 10, 10–12, 26. (In Chinese) [Google Scholar] [CrossRef]

- Sokolov, Y.F.; Shapovalov, G.I. Building a rockfill dam by directional blasting. Hydrotech. Constr. 1968, 2, 385–389. [Google Scholar] [CrossRef]

- Huo, Y.J. Research on high directional blasting dam technology. Water Power 1991, 9, 71–75. (In Chinese) [Google Scholar]

- Li, Z.; Wang, T.; Ge, W.; Wei, D.; Li, H. Risk analysis of earth-rock dam breach based on dynamic bayesian network. Water 2019, 11, 2305. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.G. Typical Blasting Engineering and Technology in China; Metallurgical Industry Press: Beijing, China, 2006; pp. 55–57. (In Chinese) [Google Scholar]

- Xie, L.A. Application of directional blasting in construction of rockfill dam. Water Power 1987, 4, 60–63. (In Chinese) [Google Scholar]

- Li, Z.X. The first scrapping demonstration of the blast-fill dam reservoir in Yunnan Province. China Water Resour. 2011, 4, 57–58. (In Chinese) [Google Scholar] [CrossRef]

- Yang, N.H.; Zhao, X.B. Preliminary study on soil erosion control with technology of building dam with directional blasting. Enigneering Blasting 1998, 4, 34–38. (In Chinese) [Google Scholar]

- Labra, C.; Onate, E.; Zarate, F.; Rojek, J.; Yaseen, Z.M. Modelling and Simulation of the Effect of Blast Loading on Structures Using an Adaptive Blending of Discrete and Finite Element Methods. In Proceedings of the 2nd International Conference on Particle-Based Methods—Fundamentals and Applications (Particles), Barcelona, Spain, 2 September 2011. [Google Scholar] [CrossRef] [Green Version]

- An, H.M.; Liu, H.Y.; Han, H.; Zheng, X.; Wang, X.G. Hybrid finite-discrete element modelling of dynamic fracture and resultant fragment casting and muck-piling by rock blast. Comput. Geotech. 2017, 81, 322–345. [Google Scholar] [CrossRef]

- Yan, C.Z.; Tong, Y.; Luo, Z.Q.; Ke, W.H.; Wang, G. A two-dimensional grouting model considering hydromechanical coupling and fracturing for fractured rock mass. Eng. Anal. Bound. Elem. 2021, 133, 385–397. [Google Scholar] [CrossRef]

- Ma, C.H.; Gao, Z.Y.; Yang, J.; Cheng, L.; Zhao, T.H. Calibration of Adjustment Coefficient of the Viscous Boundary in Particle Discrete Element Method Based on Water Cycle Algorithm. Water 2022, 14, 439. [Google Scholar] [CrossRef]

- Afrasiabian, B.; Ahangari, K.; Noorzad, A. Study on the effect of air deck on ground vibration and development of blast damage zone using 3D discrete element numerical method. Arab. J. Geosci. 2021, 14, 1267. [Google Scholar] [CrossRef]

- Masi, F.; Stefanou, I.; Maffi-Berthier, V.; Vannucci, P. A Discrete Element Method based-approach for arched masonry structures under blast loads. Eng. Struct. 2020, 216, 110721. [Google Scholar] [CrossRef]

- Gao, W.L.; Zhang, Z.H.; Li, B.J.; Li, K.P. Study on numerical simulation of geometric elements of blasting funnel based on pfc5.0. Shock Vib. 2021, 11, 8812964. [Google Scholar] [CrossRef]

- He, C.; Yang, J. Experimental and numerical investigations of dynamic failure process in rock under blast loading. Tunn. Undergr. Space Technol. 2019, 83, 552–564. [Google Scholar] [CrossRef]

- Saharan, M.R.; Mitri, H.S. Numerical procedure for dynamic simulation of discrete fractures due to blasting. Rock Mech. Rock Eng. 2008, 41, 641–670. [Google Scholar] [CrossRef]

- Babanouri, N.; Abdolahpour, M.; Dehghani, H. Modeling blast-induced fragmentation of jointed rock mass using voronoi discrete-element method. Int. J. Geomech. 2020, 20, 04020117. [Google Scholar] [CrossRef]

- Babanouri, N.; Mansouri, H.; Nasab, S.K.; Bahaadini, M. A coupled method to study blast wave propagation in fractured rock masses and estimate unknown properties. Comput. Geotech. 2013, 49, 134–142. [Google Scholar] [CrossRef]

- Huang, Y.Q. The development of directional blasting and dam construction in China. Blasting 1984, 2, 3–7. (In Chinese) [Google Scholar]

- Liu, D.H.; Sun, L.F.; Ma, H.Y.; Cui, W. Process simulation and mesoscopic analysis of rockfill dam compaction using discrete element method. Int. J. Geomech. 2020, 20, 04020047. [Google Scholar] [CrossRef]

- Ameen, A.; Ibrahim, Z.; Othman, F.; Al-Ansari, N.; Yaseen, Z.M. Minimizing the principle stresses of powerhoused rock-fill dams using control turbine running units: Application of finite element method. Water 2018, 10, 1138. [Google Scholar] [CrossRef] [Green Version]

| No. | Project | Location | Blasting Time | Dam Height | Dam Volume (×104 m3) | Impervious Body Type | Remarks |

|---|---|---|---|---|---|---|---|

| 1 | Chirchiq | Soviet Union | 1935 | - | First worldwide, river closure | ||

| 2 | Alma-Ata | Soviet Union (Kazakhstan) | 1966~ 1967 | 150.0 | 237.0 | None | Multiple blasting, controlled mudslides |

| 3 | Baipaza | Soviet Union (Tajikistan) | 1969 | 65.0 | 78.0 | Impervious body built by blasting | |

| 4 | Ak-Su | Soviet Union | 1971 | 91.0 | 25.0 | None | |

| 5 | Burlykia | Soviet Union (Kyrgyzstan) | 1975 | 50.0 | 54.0 | None | |

| 6 | Uch-Terek | Soviet Union (Kyrgyzstan) | 1989 | 42.0 | 87.0 | None | |

| 7 | Kambarata II | Kyrgyzstan | 2009 | 60.0 | Concrete face | ||

| 8 | Dong Huan | Hebei, China | 1959 | 33.5 | 8.5 | Inclined clay core | First in China, dam break |

| 9 | Shi Kuo I | Zhejiang, China | 1959 | 52.0 | 18.4 | Inclined clay core | |

| 10 | Nan Shui | Guangdong, China | 1960 | 81.8 | 100.0 | Inclined clay core | Maximum reservoir capacity in China |

| 11 | He Jiaping | Hebei, China | 1959 | 40.0 | 3.4 | None | |

| 12 | Fu Xi | Zhejiang, China | 1960 | 50.0 | 17.7 | Inclined clay core | |

| 13 | Nan Shan | Zhejiang, China | 1960 | 56.0 | 5.2 | ||

| 14 | Tao Shuping | Hebei, China | 1961 | 40.0 | 4.7 | None | Dam break |

| 15 | Shi Bianyu | Shaanxi, China | 1973 | 85.0 | 143.7 | IACC | |

| 16 | Li Ceyu | Shanxi, China | 1975 | 51.6 | 26.30 | IACC | |

| 17 | Hong Yan | Yunnan, China | 1976 | 55.0 | 54.0 | IACC | |

| 18 | Hu Jiashan | Yunnan, China | 1976 | 60.0 | 38.0 | IACC | |

| 19 | Shan Ba | Yunnan, China | 1977 | 40.0 | 13.2 | Hydraulic fill | |

| 20 | Ma Lucao | Yunnan, China | 1977 | 40.0 | 14.6 | Inclined clay core | |

| 21 | Yi Yi | Yunnan, China | 1977 | 90.0 | 120.0 | None | |

| 22 | Kang Jiahe | Yunnan, China | 1978 | 70.0 | 32.5 | Plastic film | |

| 23 | Bai Longhe | Yunnan, China | 1978 | 46.0 | 20.0 | Inclined clay core | |

| 24 | Tang Xian | Guangxi, China | 1999 | 70.0 | Geomemb-rane | Impervious body built after 5 years | |

| 25 | Shui Men | Hebei, China | 1960-03 | 42.0 | 6.2 | - | Tailings dam |

| 26 | E Kou | Shanxi, China | 1972 | 65.5 | 30.7 | - | Tailings dam |

| 27 | Liu Jiagou | Shaanxi, China | 2002 | 40.0 | 9.1 | - | Tailings dam |

| 28 | Sai Shentang | Qinghai, China | 2002 | 36.4 | 12.1 | - | Tailings dam |

| 29 | Mu Xingou | Shaanxi, China | 2006 | 62.0 | 42.2 | - | Tailings dam |

| 30 | Da Shibangou | Shaanxi, China | 2010 | 35.0 | 8.5 | - | Tailings dam |

| 31 | Xin Kang | Sichuang, China | 1985 | 50.0 | 20.0 | - | Soil and water conservation |

| 32 | Hu Donggo | Shanxi, China | 1992 | 19.3 | 2.5 | - | Soil and water conservation |

| 33 | Ma Dihao | Neimenggu, China | 1992 | 33.0 | 3.8 | - | Soil and water conservation |

| 34 | Qia Puqihai | Xinjiang, China | 2002 | 0.5 | River closure |

| No. | Project | Dam Height | Blasting Time | Initial Design | Reinforce-Ment Time | Reinforcement Design |

|---|---|---|---|---|---|---|

| 1 | Fu Xi | 50.0 | 1960 | Inclined clay core | 2009 | Concrete face |

| 2 | Shi Bianyu | 85.0 | 1973 | IACC | 1999 | Geomembrane |

| 3 | Li Ceyu | 51.6 | 1975 | IACC | Thickened face | |

| 4 | Yi Yi | 90.0 | 1977 | None | 2007 | Concrete diaphragm wall |

| 5 | Ma Lucao | 40.0 | 1977 | Inclined clay core | 2010 | Concrete diaphragm wall |

| 6 | Shan Ba | 40.0 | 1977 | Hydraulic fill | 2004 | Concrete diaphragm wall |

| 7 | Kang Jiahe | 70.0 | 1978 | Plastic film | 2010 | Curtain grouting |

| 8 | Hu Jiashan | 60.0 | 1976 | IACC | 2010 | New CFRD |

| 9 | Bai Longhe | 46.0 | 1978 | Inclined clay core | 1997 | Reinforcement failed, discard |

| Parameter | Unit | Value |

|---|---|---|

| Particle density | kg/m3 | 2500.0 |

| Friction coefficient (ball-ball) | - | 0.1 |

| Effective contact modulus | GPa | 50.0 |

| Normal-to-shear stiffness ratio | - | 2.0 |

| Bond effective modulus | GPa | 10.0 |

| Bond normal-to-shear stiffness ratio | - | 1.0 |

| Parallel-bond tensile strength | MPa | 37.0 |

| Parallel-bond cohesion | MPa | 37.0 |

| Parallel-bond friction angle | Degree | 10.0 |

| Time | Upstream Water Level | Points Behind Geomembrane | Point Behind IACC | ||||

|---|---|---|---|---|---|---|---|

| B2 | B9 | B3 | |||||

| Osmometer Level | Reduction Water Level | Osmometer Level | Reduction Water Level | Osmometer Level | Reduction Water Level | ||

| 23 October 2005 | 728.32 | 714.09 | 14.23 | 715.18 | 13.14 | 674.66 | 40.52 |

| 25 October 2006 | 724.78 | 707.73 | 17.05 | 709.78 | 15.00 | 673.9 | 35.88 |

| 27 October2007 | 729.78 | 713.63 | 16.15 | 714.52 | 15.26 | 675.63 | 38.89 |

| 30 November 2008 | 727.70 | 712.14 | 15.56 | 712.77 | 14.93 | 673.71 | 39.06 |

| 25 May 2009 | 727.58 | 713.47 | 14.11 | 714.88 | 12.70 | 674.71 | 40.17 |

| 12 September 2010 | 724.97 | 713.93 | 11.04 | 715.07 | 9.90 | 674.31 | 40.76 |

| 9 November 2011 | 731.08 | 721.50 | 9.58 | 722.08 | 9.00 | 679.46 | 42.62 |

| 16 September 2012 | 723.37 | 713.23 | 10.14 | 713.77 | 9.60 | 675.62 | 38.15 |

| 30 May 2013 | 725.66 | 717.03 | 8.63 | 717.44 | 8.22 | 675.63 | 41.81 |

| 4 October 2014 | 729.82 | 721.77 | 8.05 | 722.42 | 7.40 | 678.14 | 44.28 |

| 24 April 2015 | 731.21 | 723.28 | 7.93 | 724.02 | 7.19 | 676.49 | 47.53 |

| 18 April 2017 | 729.62 | 722.92 | 6.70 | 723.55 | 6.07 | 678.28 | 45.27 |

| 10 October 2017 | 730.91 | 724.25 | 6.66 | 725.21 | 5.70 | 678.72 | 46.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Gao, Z.; Yang, J.; Cheng, L.; Chen, L. Operation Performance and Seepage Flow of Impervious Body in Blast-Fill Dams Using Discrete Element Method and Measured Data. Water 2022, 14, 1443. https://doi.org/10.3390/w14091443

Ma C, Gao Z, Yang J, Cheng L, Chen L. Operation Performance and Seepage Flow of Impervious Body in Blast-Fill Dams Using Discrete Element Method and Measured Data. Water. 2022; 14(9):1443. https://doi.org/10.3390/w14091443

Chicago/Turabian StyleMa, Chunhui, Zhiyue Gao, Jie Yang, Lin Cheng, and Lei Chen. 2022. "Operation Performance and Seepage Flow of Impervious Body in Blast-Fill Dams Using Discrete Element Method and Measured Data" Water 14, no. 9: 1443. https://doi.org/10.3390/w14091443