Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru

Abstract

:1. Introduction

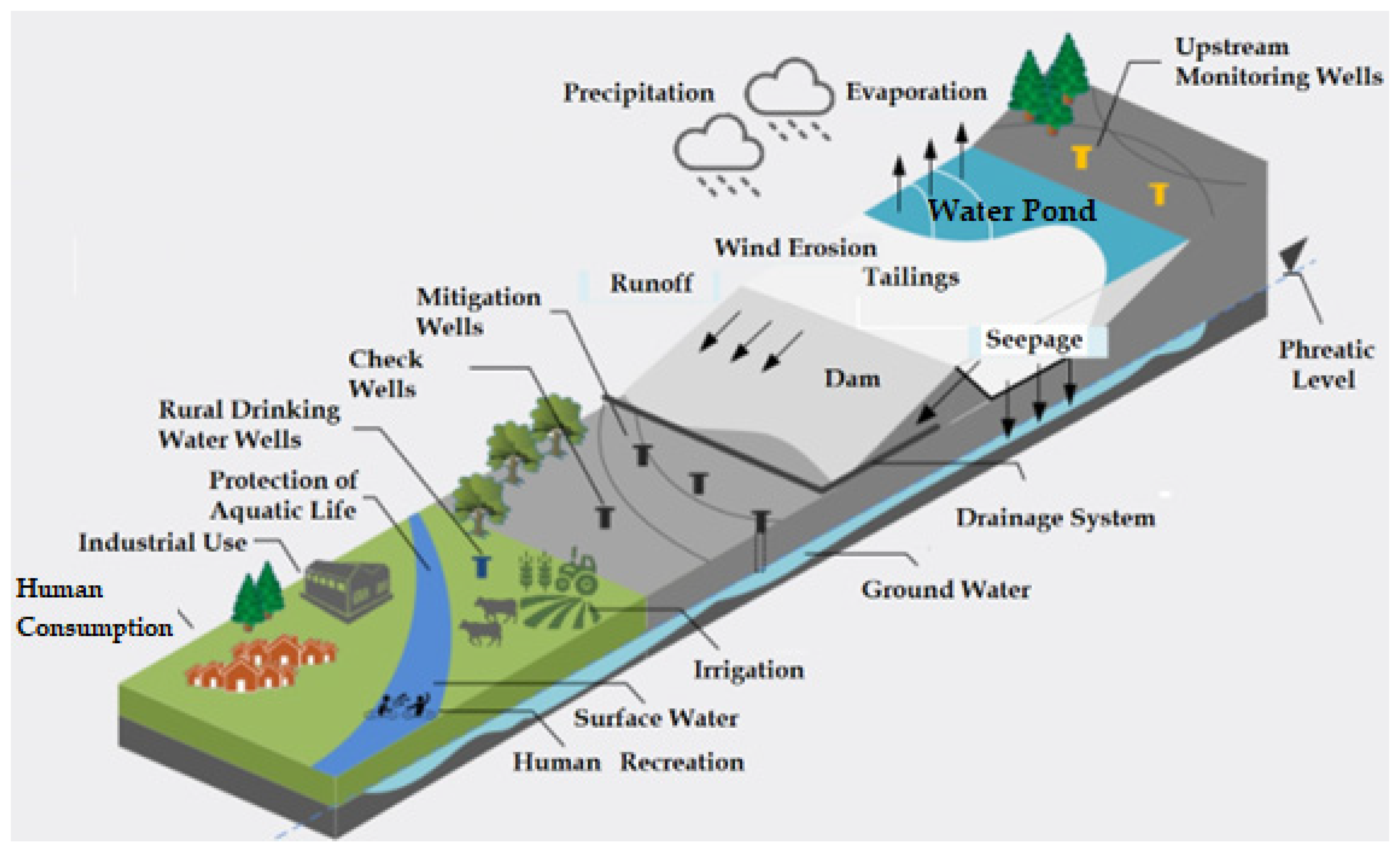

1.1. Environmental Issues Related to Tailings Storage Facilities

- Safe storage of mine tailings, process water, and rainfall water;

- Mitigating leakage from the TSF through the dam and adjacent zones, for environmental care of soils, and ground water;

- Controlling internal dam erosion (piping issues);

- Providing filter and drainage capacity of the dam;

- Improving the long-term physical and geochemical stability of the TSF (operation closure and post closure), considering severe seismic activity and potential extreme floods.

1.2. Aim of the Article

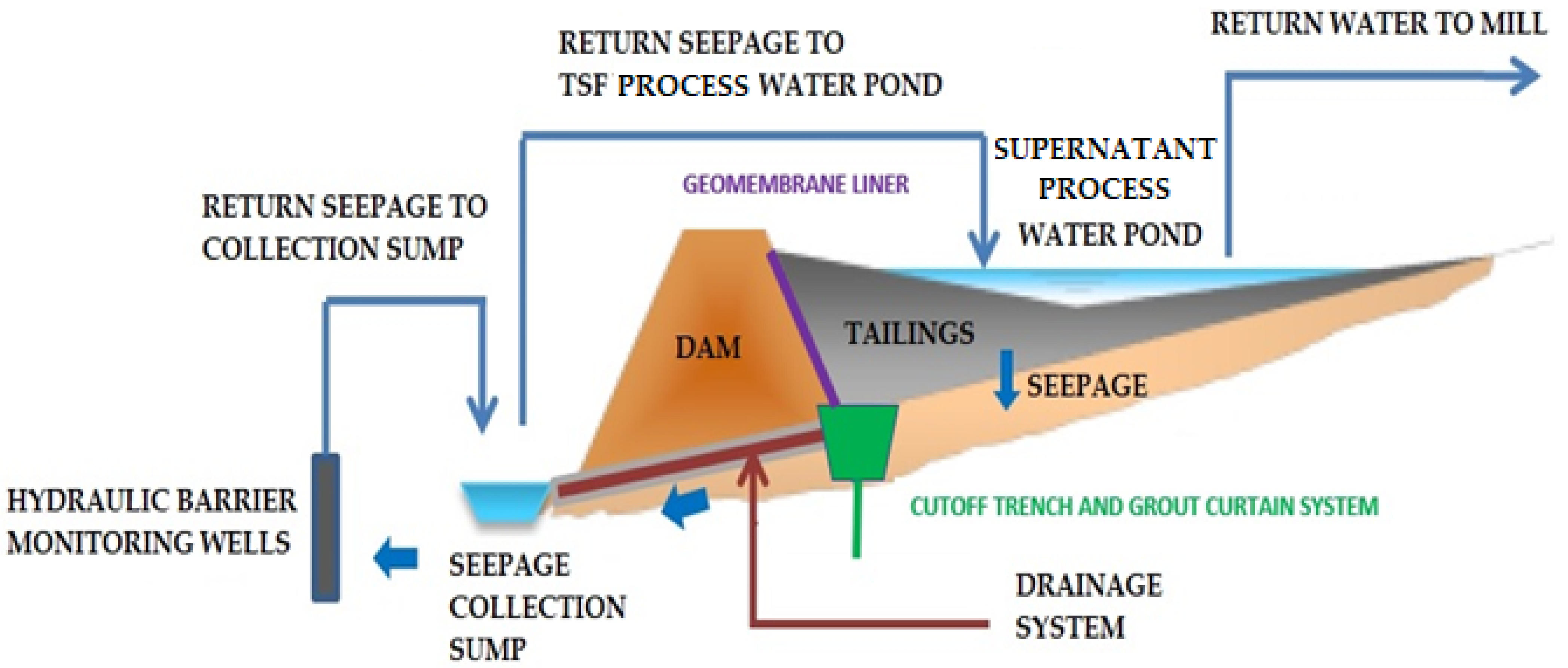

2. Process Water Management and Seepage Control in Tailings Storage Facilities

2.1. Seepages in Tailings Storage Facilities

2.2. Seepage Control

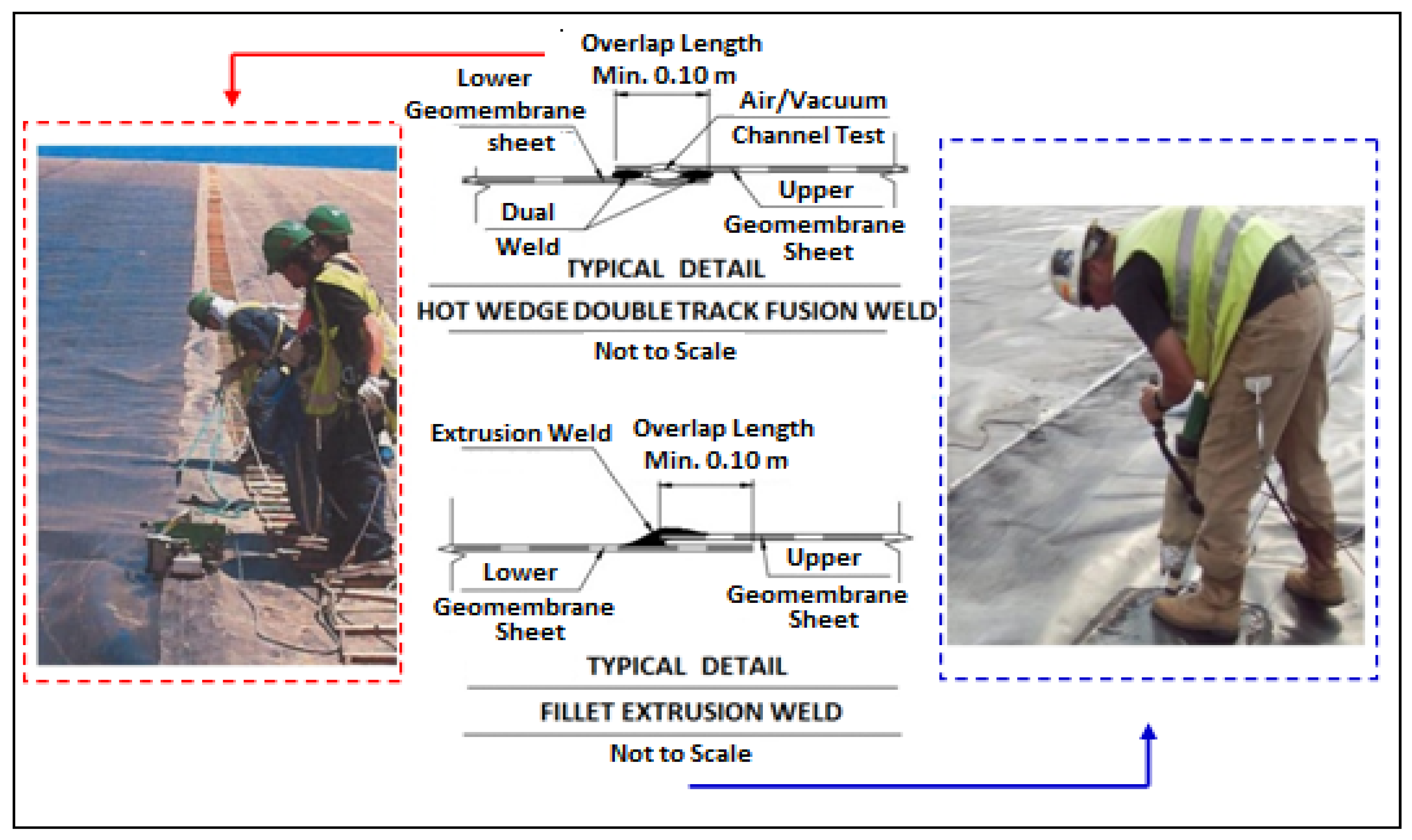

2.2.1. Geomembrane Liners

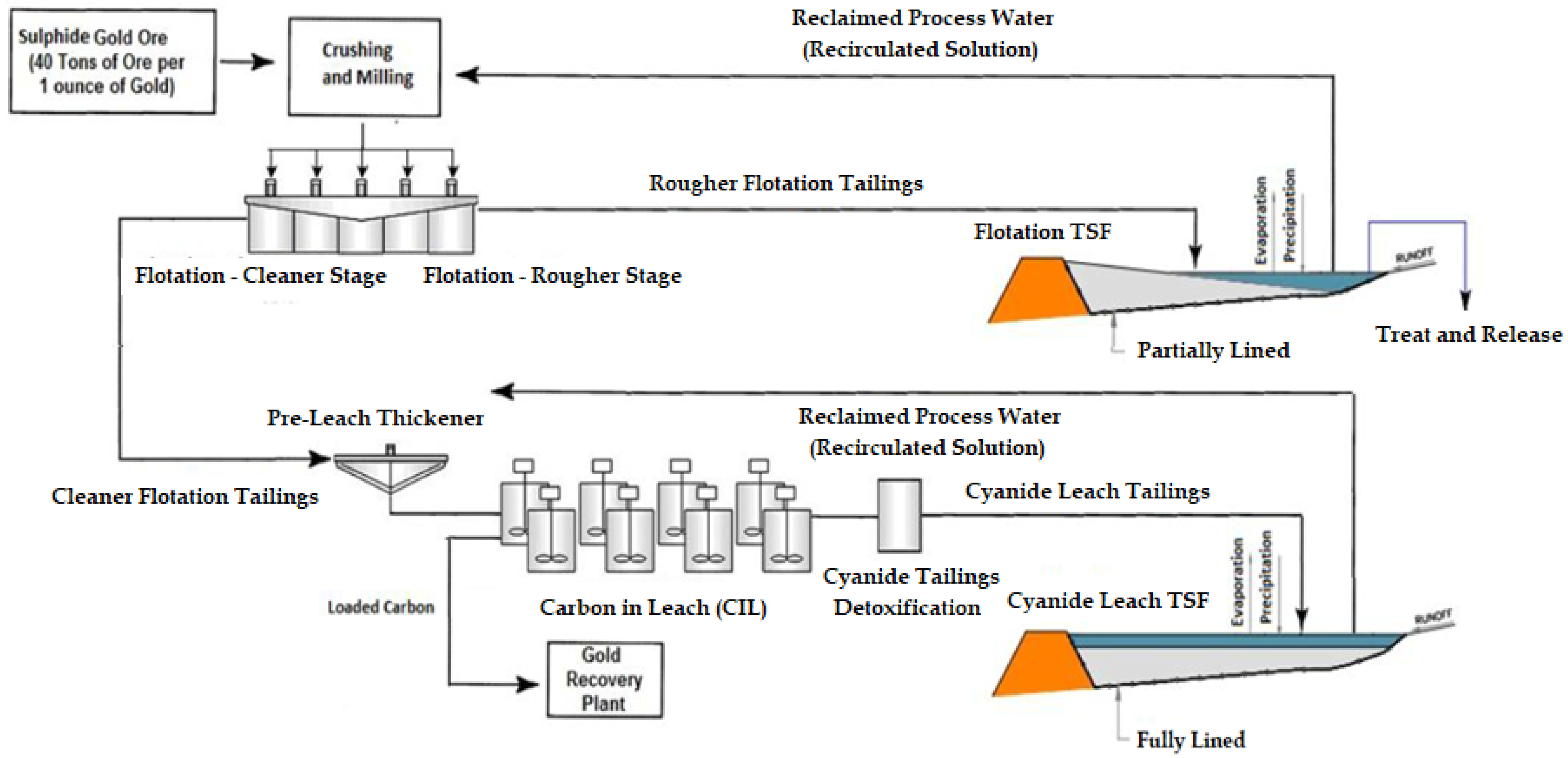

- Management of Gold Tailings Storage Facilities

- Management of Copper Tailings Storage Facilities

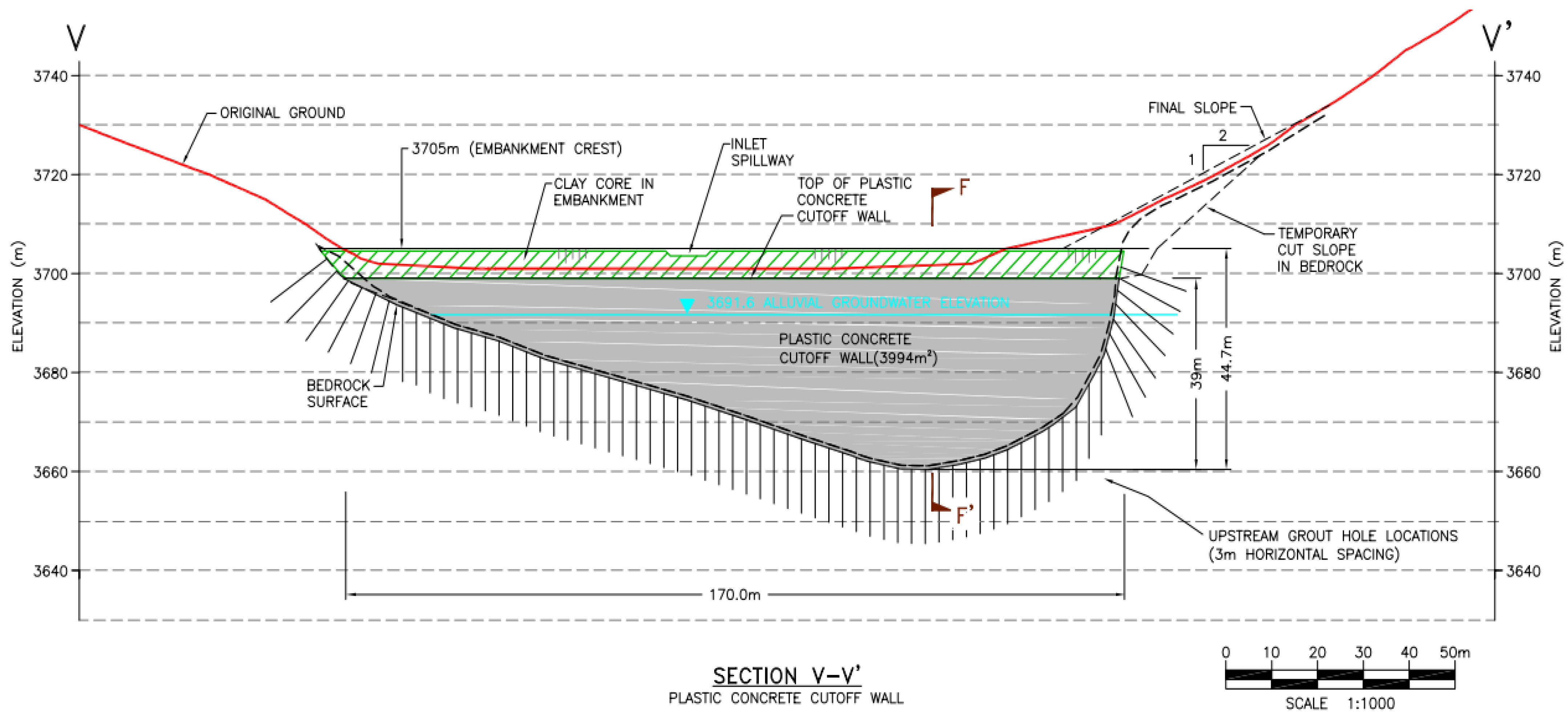

2.2.2. Cutoff Trench, Slurry Walls, and Grout Curtain Systems

- Perforations: The perforations for the injection curtain will be made with rotary-percussion equipment or rotary probes, in the places established in the project, always using clear water as a lubricating and dragging fluid. Its minimum diameter in rock will be 50 mm for rotary percussion and HQ3 for rotation with core extraction. To cross the fluvial fill, the drilling must consider the placement of casing pipes to the rock and thus ensure a controlled injection process;

- Water: The water used in the injection works, which may be available in the area or brought from another place, must be clean, with a pH close to neutral and comply with the standard established for mixing water for cement mortars and Portland concrete;

- Cement: The cement used in injections must be pozzolanic in order to guarantee its resistance to the aggression of contact waters, have a Blaine specific surface of the order of 5000, must not present lumps or foreign matter, and have a manufacturing age of less than three months;

- Bentonite: The bentonite to be used must be sodium and have a liquid limit greater than 250% and a plasticity index greater than 200%.

2.2.3. Slimes (Fine Fraction of Mine Tailings)

3. Types of Geotextile and Geomembrane Used in Tailings Storage Facility Dams

3.1. Geosynthetic Base Layer—Geotextiles

3.2. Geosynthetic Liner Layer—Geomembranes

3.3. Geomembrane Liner Leakage Rates

4. Geosynthetic Solution Applications in Tailings Storage Facility Dams

4.1. Geosynthetic Constructability Issues

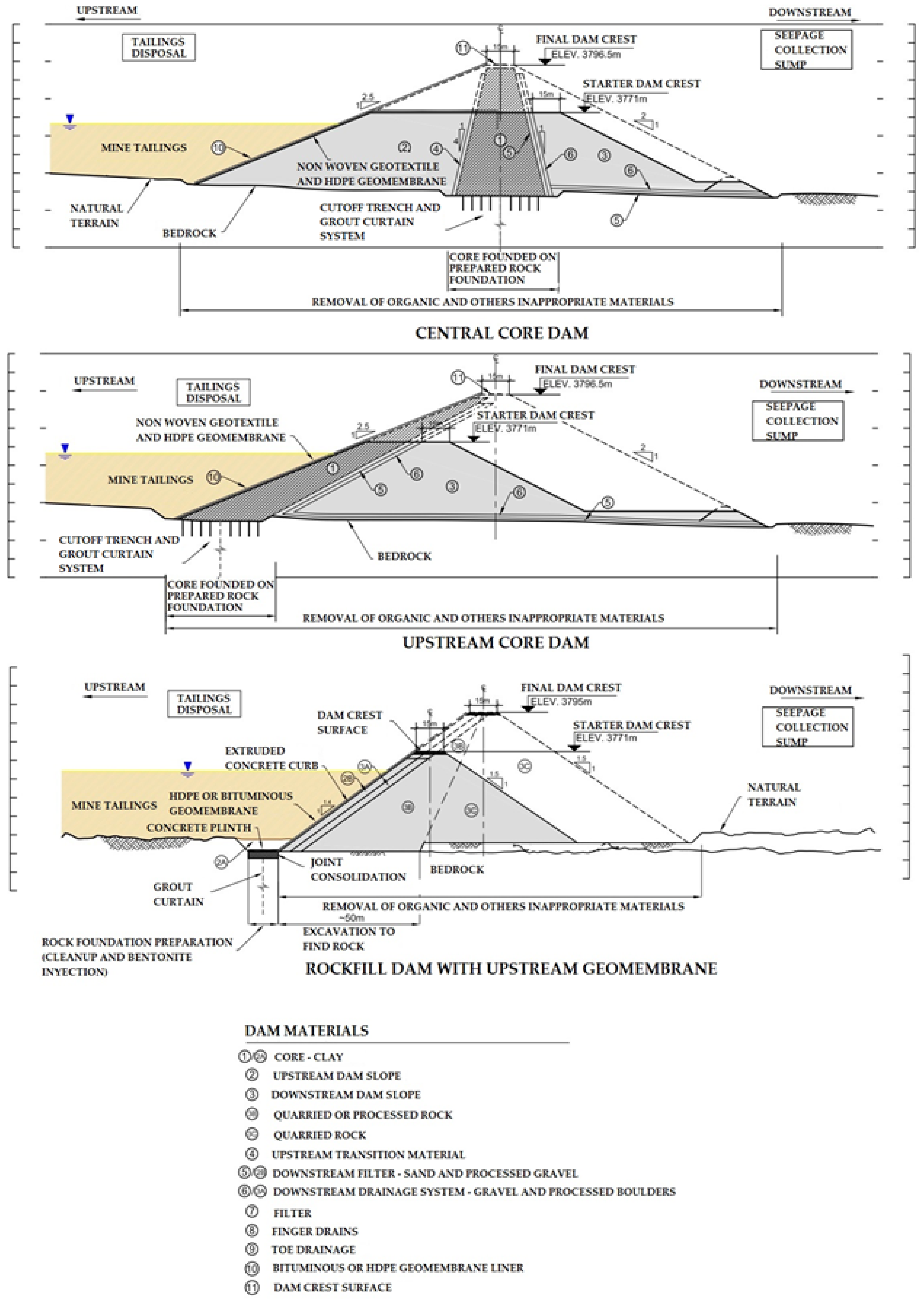

4.2. Starter Dams of TSF Built with Borrow Materials

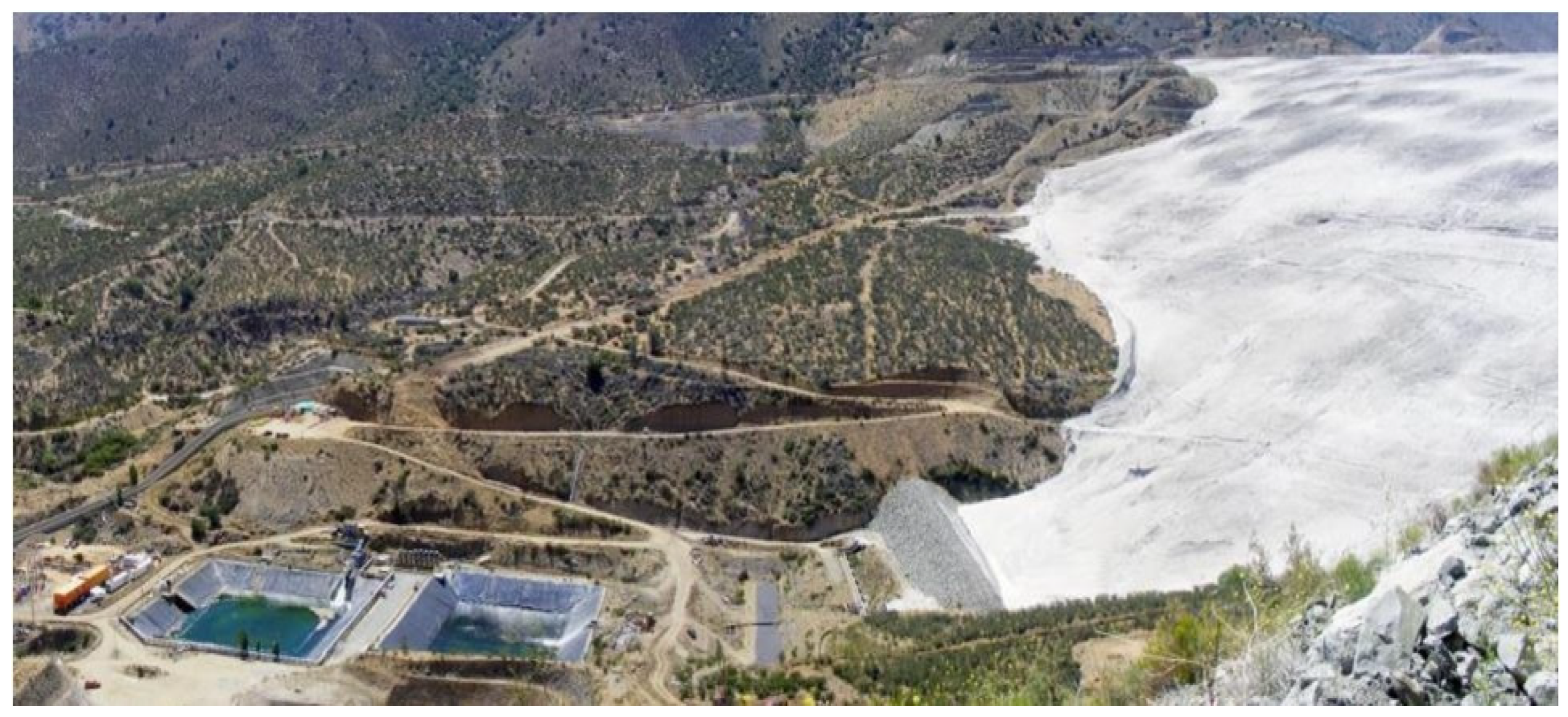

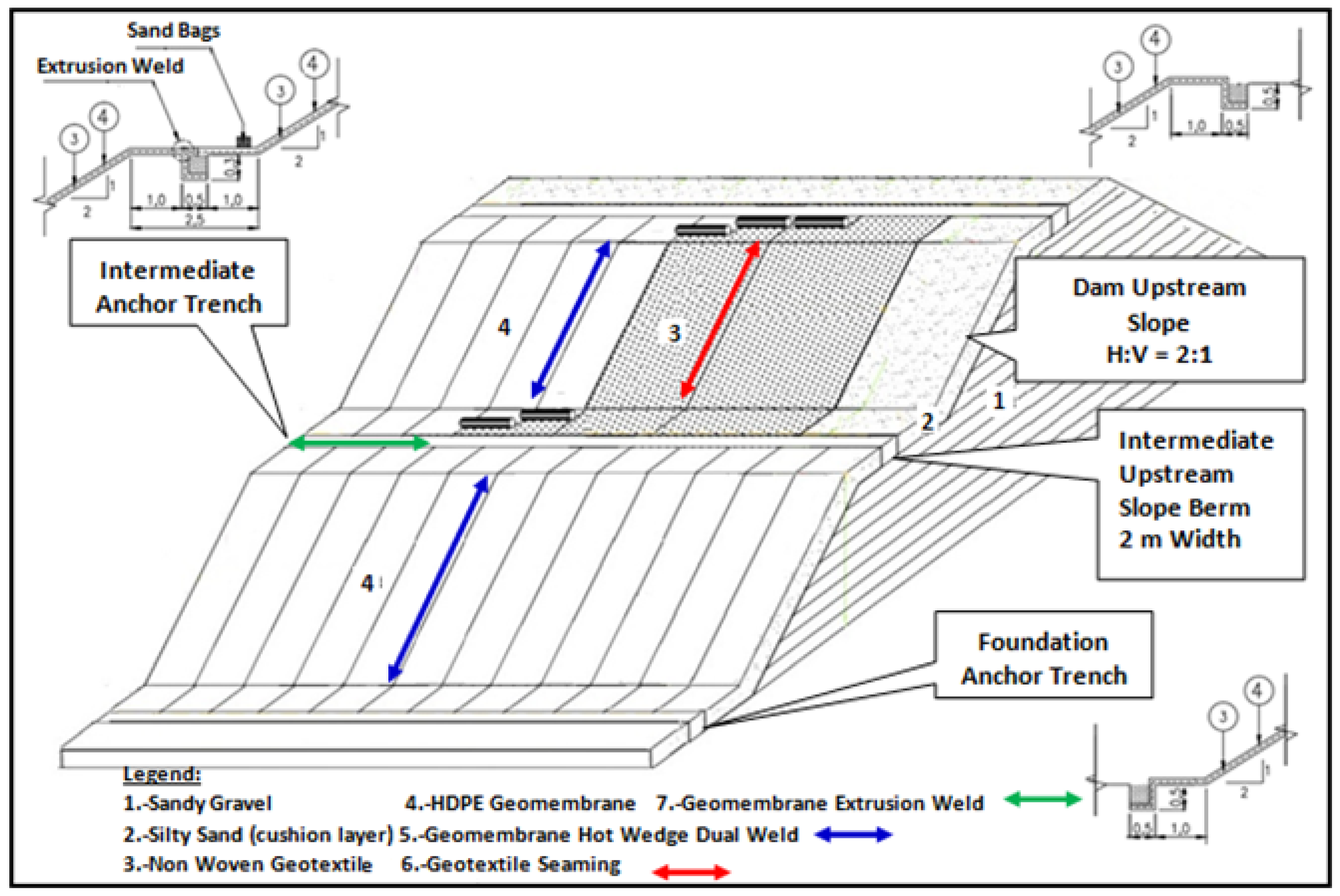

4.3. Cycloned Tailings Sand Dams

- Dispose of hydrocyclone underflow materials (cycloned tailings sand) in a loose 0.5 m thick layer;

- Allow the deposited hydrocyclone underflow materials to drain;

- Compact the underflow materials with smooth vibratory rollers;

- Construct the geometry of the dam (slopes and crest width, providing adequate freeboard);

- Install the waterproofing liner at the upstream face of the dam.

- Is necessary to install a new wooden structure to assemble the sand transport pipes;

- The louver discharge pipe must be relocated;

- An anchor trench for the geosynthetic materials must be built along the entire crest of the dam;

- A new roll of geotextile and geomembrane needs to be installed on the slope upstream of the dam.

- A typical cycloned tailings sand dam crest with wooden trestles for tailings sand pipelines, slimes pipeline with spigots, and geosynthetic liner (Figure 20);

- A geosynthetic installation schematic view of a cycloned tailings sand dam using the downstream construction method (Figure 21);

- A construction procedure in cycloned tailings sand dam crest (Figure 22).

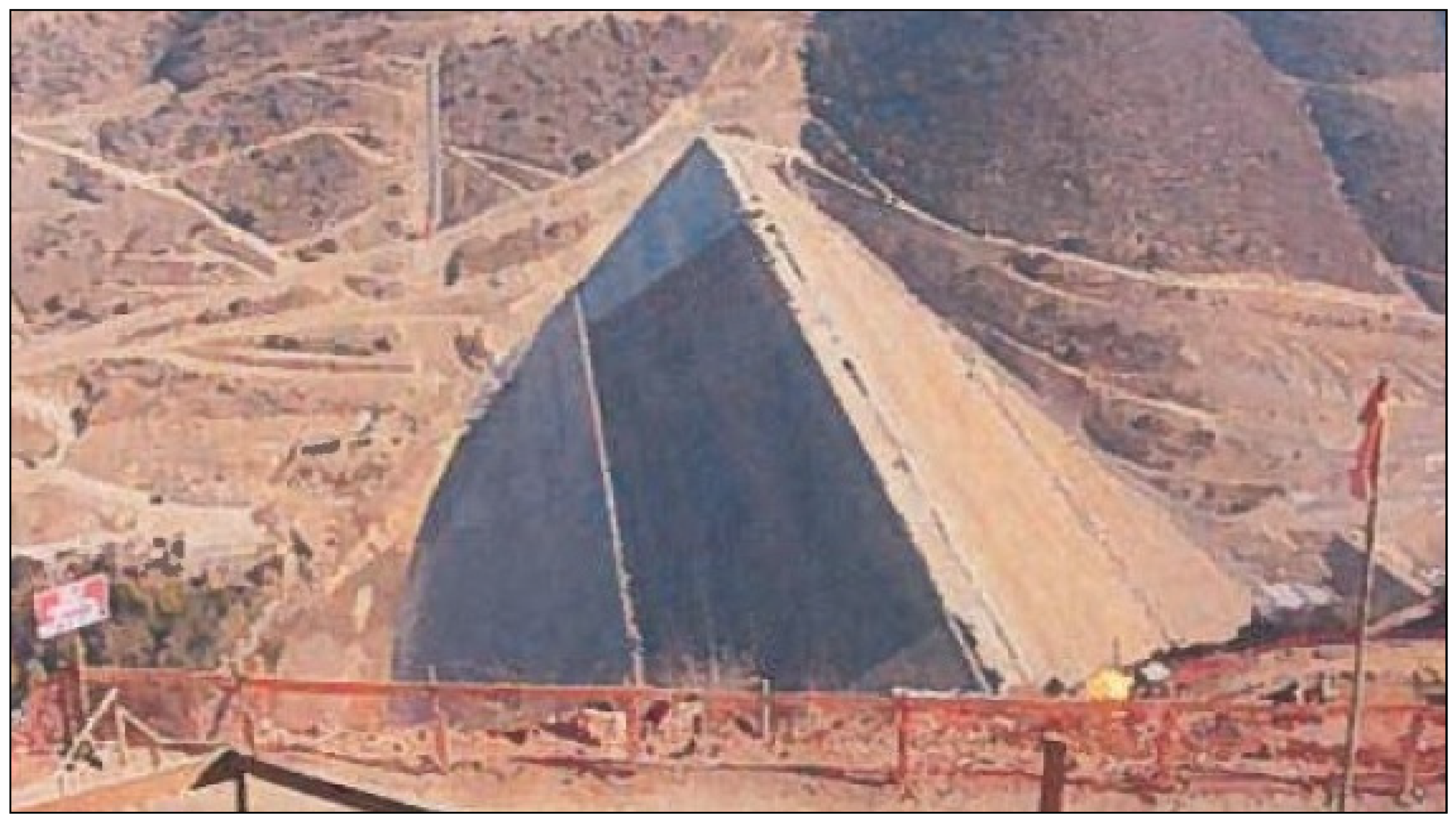

4.4. Mine Waste Rock (Rockfill) Dams

- The mining waste rock materials have no potential to generate AMD (acid mine drainage);

- There is a lack of borrow material availability and high waste rock/ore ratios;

- There are short hauling distances between the waste rock sources and the TSF site;

- There are flatter terrains, such as in the Atacama Desert areas, where mines need to build TSFs with a ring-dike configuration with large dams (more than 4 km long). This presents difficulties regarding transport and construction of cycloned tailings sand dams.

5. Discussion

5.1. Lessons Learned Considering Experience

5.1.1. Advantages

- No use of clay layers: geotextiles and geomembranes allow a chance to minimize the use of costly clay soil filter materials in the dam. The geomembrane lining system is adequate, because it is flexible and resists differential settlement, allowing control of the hydraulic gradients, and providing both physical and environmental containment of tailings [46,47,48];

5.1.2. Disadvantages

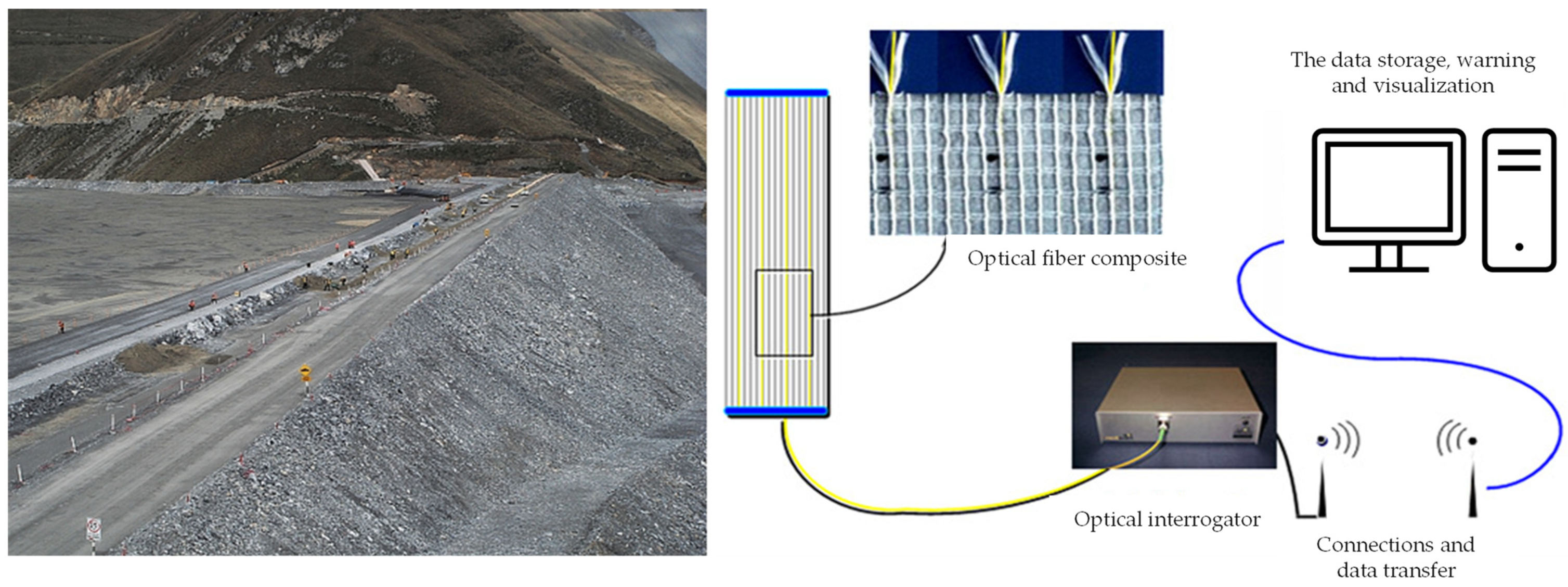

5.2. New Trends

- Resistance to aggressive environments even without adding an anti-puncture geotextile;

- Compatible with all subgrades and covering material (hot-mix, asphalt, concrete, stone, gravel);

- Excellent resistance to ageing (UV, weather, biological agents and oxidation);

- Suitable for extreme weather conditions (rain, wind, extreme cold (–40 °C));

- Remarkable dimensional stability and flexibility guaranteeing permanent support with the supporting ground;

- Durability under real conditions exceeding 40 years;

- Friction angle up to 34°, greater than any other geomembrane;

- Figure 26 shows an example of application of BGM in the Toromocho TSF project in Peru.

5.3. Hydrogeological Aspects to Note

5.4. Final Remarks

- Types of geosynthetic materials: many types of geomembranes have been used in TSFs, including: polyvinyl chloride (PVC), high-density polyethylene (HDPE), and linear-low-density polyethylene (LLDPE). The criteria for the selection of the geosynthetics are based on technical environmental and cost issues;

- Thickness and performance of geosynthetics: the current state-of-the-art practices to prevent leakage, to provide durability, and to enhance resistance to UV rays;

- Types of cushion layers for geosynthetic materials: the criteria used to choose materials on which to place geomembranes, with a focus on limiting damage by puncturing;

- Constructability: a key aspect is the installation of the geosynthetics on the upstream face slope of the tailings dams, taking into consideration the mine tailings discharges (spigots), wind, and rainfall conditions;

- QA/QC: quality assurance and quality control—the geosynthetic quality is monitored at all stages of design, manufacturing, construction, and operation;

- Sustainability: the application of geosynthetics is environmentally friendly because (i) they minimize the environmental impacts of borrow material pits and quarry operations by providing filters, grading the materials in the dam, and (ii) they mitigate tailings dam seepage.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TSF | Tailings storage facility |

| BATs | Best available technologies |

| AMD | Acid mine drainage |

| Cw | Slurry tailings solids content by weight |

| mtpd | Metric tonnes per day |

| HDPE | High density polyethylene |

| LLDPE | Linear low-density polyethylene |

| PVC | Polyvinyl chloride |

| BGM | Bituminous geomembrane |

| GCL | Geosynthetic clay liner |

| masl | Meters above sea level |

| UV rays | Ultraviolet rays |

| QA/QC | Quality assurance and quality control |

| MQA/MQC | Manufacturing quality assurance/control |

| CQA/CQC | Construction quality assurance/control |

| lphd | Liter per hectare per day |

| lpd | Liter per day |

References

- Cacciuttolo, C.; Valenzuela, F. Efficient Use of Water in Tailings Management: New Technologies and Environmental Strategies for the Future of Mining. Water 2022, 14, 1741. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E. An Alternative Technology to Obtain Dewatered Mine Tailings: Safe and Control Environmental Management of Filtered and Thickened Copper Mine Tailings in Chile. Minerals 2022, 12, 1334. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E. Past, Present, and Future of Copper Mine Tailings Governance in Chile (1905–2022): A Review in One of the Leading Mining Countries in the World. Int. J. Environ. Res. Public Health 2022, 19, 13060. [Google Scholar] [CrossRef] [PubMed]

- Cacciuttolo, C.; Cano, D. Environmental Impact Assessment of Mine Tailings Spill Considering Metallurgical Processes of Gold and Copper Mining: Case Studies in the Andean Countries of Chile and Peru. Water 2022, 14, 3057. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Franks, D.M.; Boger, D.V.; Côte, C.M.; Mulligan, D.R. Sustainable development principles for the disposal of mining and mineral processing wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Cacciuttolo Vargas, C.; Pérez Campomanes, G. Practical Experience of Filtered Tailings Technology in Chile and Peru: An Environmentally Friendly Solution. Minerals 2022, 12, 889. [Google Scholar] [CrossRef]

- East, D.; Fernandez, R. Managing Water to Minimize Risk in Tailings Storage Facility Design, Construction, and Operation. Mine Water Environ. 2021, 40, 36–41. [Google Scholar] [CrossRef]

- Oberle, B.; Brereton, D.; Mihaylova, A. Towards Zero Harm: A Compendium of Papers; Global Tailings Review: St. Gallen, Switzerland, 2020. [Google Scholar]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- US EPA. The Feasibility of Lining Tailings Ponds; U.S. Environmental Protection Agency, Office of Solid Waste: Washington, DC, USA, 1997.

- U.S. Environmental Protection Agency, Office of Solid Waste, Special Waste Branch. Design and Evaluation of Tailings Dams: Technical Report; U.S. Environmental Protection Agency, Office of Solid Waste: Washington, DC, USA, 1994; pp. 5–14.

- Fourie, A.B.; Bouazza, A.; Lupo, J.; Abrão, P. Improving the Performance of Mining Infrastructure through the Judicious Use of Geosynthetics. In Proceedings of the 9th International Conference on Geosynthetics, Guarujá, Brazil, 23–27 May 2010. [Google Scholar]

- Davies, M.P.; Lightall, C.; Rice, S.; Martin, T.E. Design of Tailings Dams and Impoundments. In Proceedings of the Processing Plant Design, Practice, and Control Conference, Phoenix, AZ, USA, 25–27 February 2002. [Google Scholar]

- Caldwell, J.; Smith, A. Material Considerations in the Design of Downstream Embankments for Tailings Impoundments. Min. Sci. Technol. 1985, 3, 35–49. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Marinovic, A. Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance. Sustainability 2022, 14, 10901. [Google Scholar] [CrossRef]

- Adams, M. Approaches to Cyanide Code Compliance Tailings Storage Facil. In Gold Ore Processing: Project Development and Operations; Elsevier: Amsterdam, The Netherlands, 2016; Volume 13. [Google Scholar]

- Dobry, R.; Alvarez, L. Seismic Failures of Chilean Tailings Dams. J. Soil Mech. Found. Div. ASCE 1967, SM6, 237–259. [Google Scholar] [CrossRef]

- Alva-Hurtado, J.E. Causas, Conclusiones y Remediación de Presas de Relave Colapsadas por Eventos Sísmicos. In Proceedings of the Primer Simposio Nacional de Medio Ambiente y Seguridad Minera, Colegio de Ingenieros del Peru (CIP), Lima, Peru, 18–21 May 1997. [Google Scholar]

- USACE General Design and Construction Considerations for Earth and Rock-Fill Dams. Eng. Des.-U.S. Army Corps Eng. 1994, EM 1110-2, 78. Available online: http://www.usace.army.mil/inet/usace-docs/ (accessed on 23 December 2022).

- USACE Seepage Analysis and Control for Dams. Eng. Des.-U.S. Army Corps Eng. 2005, EM 1110-2, 392. Available online: https://books.google.co.jp/books/about/Seepage_Analysis_and_Control_for_Dams.html?id=ggVSAAAAMAAJ&redir_esc=y: (accessed on 23 December 2022).

- McLeod, H.; Murray, L. Tailings Dam Versus a Water Dam, what is the Design Difference. In Proceedings of the ICOLD Symposium on Major Challenges in Tailings Dams, Montreal, QC, Canada, 15 June 2003. [Google Scholar]

- Barrera, S.; Lagas, R. Evolution in the Use of Geomembranes in Tailings Dams. In Proceedings of the 3rd Pan-American Geosynthetic Conference GeoAmericas, Lima, Peru, 6–9 May 2012. [Google Scholar]

- Barrera, S. Deposition Densities of Tailings in Chilean Deposits. In Proceedings of the 5th International Conference on Tailings and Mine Waste, Fort Collins, CO, USA, 26–28 January 1998; pp. 109–116. [Google Scholar]

- Cacciuttolo, C.; Tabra, K. Water Management in the Closure of Tailings Storage Facilities. Available online: https://www.imwa.info/docs/imwa_2015/IMWA2015_Cacciuttolo_138.pdf (accessed on 23 December 2022).

- Lavoie, F.L.; Kobelnik, M.; Valentin, C.A.; da Silva Tirelli, É.F.; de Lurdes Lopes, M.; Lins da Silva, J. Environmental Protection with HDPE Geomembranes in Mining Facility Constructions. Constr. Mater. 2021, 1, 122–133. [Google Scholar] [CrossRef]

- Tuomela, A.; Ronkanen, A.K.; Rossi, P.M.; Rauhala, A.; Haapasalo, H.; Kujala, K. Using geomembrane liners to reduce seepage through the base of tailings ponds—A review and a framework for design guidelines. Geosciences 2021, 11, 93. [Google Scholar] [CrossRef]

- Spagnoli, G.; Clement, F.; Zeleke Dilnesa, B.; Cao, F.; Feng, P. A new waterproofing membrane for tailings ponds. In Proceedings of the 22nd International Conference on Paste, Thickened and Filtered Tailings, Cape Town, South Africa, 8–10 May 2019; pp. 153–164. [Google Scholar] [CrossRef] [Green Version]

- ASTM D 698; Standard Methods for Laboratory Compaction Characteristics of Soil using Standard Effort. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- ASTM D 751; Standard Test Methods for Coated Fabrics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ASTM D 4595; Tensile Properties of Geotextiles by the Wide Width Strip Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D 4632; Tensile Properties of Geotextiles by Grab Tensile Test Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- ASTM D 4884; Standard Test Method for Seam Strength Sewn Geotextiles. American Society for Testing and Materials: West Conshohocken, PA, USA, 2009.

- ASTM D 6392; Standard Test Method for Determining the Integrity of Nonreinforced Geomembrane Seams Produced Using Thermo-Fusion Methods. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- ASTM D 5820; Standard Practice for Pressurized Air Channel Evaluation of Dual Seamed Geomembranes. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ASTM D 5641; Standard Practice for Geomembrane Seam Evaluation by Vacuum Chamber. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ASTM D 6365; Standard Practice for the Nondestructive Testing of Geomembrane Seams Using the Spark Test. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- Lupo, J.F.; Morrison, K.F. Geosynthetic Design and Construction Approaches in the Mining Industry. Geotext. Geomembr. 2005, 25, 96–108. [Google Scholar] [CrossRef]

- Giroud, J.P.; Bonaparte, R. Leakage through Liners Constructed with Geomembranes, Part I: Geomembrane Liners. Geotext. Geomembr. 1989, 8, 27–67. [Google Scholar] [CrossRef]

- Giroud, J.P.; Bonaparte, R. Leakage through Liners Constructed with Geomembranes, Part II: Composite Liners. Geotext. Geomembr. 1989, 8, 71–111. [Google Scholar] [CrossRef]

- Koerner, R.M. Designing with Geosynthetics, 5th ed.; Hall, P.P., Ed.; Pearson Prentice Hall: Hoboken, NJ, USA, 2005; ISBN 0-13-145415-3. [Google Scholar]

- Belfi Obras Chile. Available online: http://www.belfi.cl/obra-belfi.php?idTipoObra=10&idObra=116 (accessed on 31 October 2022).

- Incolour Chile. Available online: http://www.incolur.cl/servicios-tierra.php (accessed on 31 October 2022).

- Barrientos, S. Design, Operation and Control of the Mauro Tailings Dam. In Proceedings of the Plenary Presentation at 1st International Seminar on Tailings Management, Santiago, Chile, 1–3 September 2013. [Google Scholar]

- Mafra, J.M.Q.; Mello, J.; Eldridge, T.; Breu, B. Two Case Histories of Dams Waterproofing with Bituminous Geomembrane. In Proceedings of the First Pan American Geosynthetics Conference & Exhibition, Cancun, Mexico, 2–5 March 2008. [Google Scholar]

- Cacciuttolo, C.; Barrera, S. Variation of Tailings Density in Depth—A Model. In Proceedings of the 16th International Conference on Tailings and Mine Waste, Keystone, CO, USA, 14–17 October 2012; pp. 151–162.

- ICOLD. Geomembrane Sealing Systems for Dams—Design Principles and Review of Experience. Bulletin No. 135. 2008. Available online: https://www.infona.pl/resource/bwmeta1.element.springer-doi-10_1007-S41062-017-0089-0 (accessed on 23 December 2022).

- Giroud, J.P. Leakage Control using Geomembrane Liners. Soils Rocks 2016, 39, 213–235. [Google Scholar] [CrossRef]

- Dijcker, R.; Van Der Wijk, M.; Artieres, O.; Dortland, G.; Lostumbo, J. Geotextile Enabled Smart Monitoring Solutions for Safe and Effective Management of Tailings and Waste Sites. In Proceedings of the 15th International Conference on Tailings and Mine Waste, Vancouver, BC, Canada, 6–9 November 2011. [Google Scholar]

- Strachan, C.; Caldwel, J. New Directions in Tailings Management. In Proceedings of the 14th International Conference on Tailings and Mine Waste, Vail, CO, USA, 17–20 October 2010. [Google Scholar]

- Brixel, B.; Caldwell, J. Thirty Years of Tailings Seepage History from Tailings & Mine Waste. Available online: https://open.library.ubc.ca/cIRcle/collections/59368/items/1.0107754 (accessed on 21 December 2022).

- Klohn, E. Seepage Control for Tailings Dams. 1979. Available online: https://www.imwa.info/docs/imds_1979/IMDS1979_Klohn_671.pdf (accessed on 23 December 2022).

- Schwank, S. Cut-off systems for dikes and tailings dams in mining. In Proceedings of the 17th African Regional Conference on Soil Mechanics and Geotechnical Engineering, Cape Town, South Africa, 7–9 October 2019. [Google Scholar]

- Yang, J.; Hu, J.; Wu, Y.; Zhang, B. Numerical Simulation of Seepage and Stability of Tailing Dams: A Case Study in Ledong, China. Sustainability 2022, 14, 12393. [Google Scholar] [CrossRef]

| Tailings Storage Facility Name | Mine Name | Country | Tailings Production Rate (mtpd) | Dam Construction Material | Projected Dam Height (m) |

|---|---|---|---|---|---|

| Los Leones | Andina | Chile | Closure Phase | Borrow material | 160 |

| Pampa Pabellon | Collahuasi | Chile | 170,000 | Mine waste rock | 90 |

| Talabre | Chuquicamata | Chile | 200,000 | Mine waste rock | 50 |

| Los Quillayes | Los Pelambres | Chile | Closure Phase | Cycloned tailings sand | 198 |

| El Mauro | Los Pelambres | Chile | 205,000 | Cycloned tailings sand | 237 |

| Ovejeria | Andina | Chile | 75,000 | Cycloned tailings sand | 130 |

| Las Tortolas | Los Bronces | Chile | 125,000 | Cycloned tailings sand | 150 |

| Pampa Austral | Salvador | Chile | 35,000 | Borrow material | 36 |

| Caren | El Teniente | Chile | 180,000 | Borrow material | 70 |

| Quebrada Blanca | Quebrada Blanca Phase II | Chile | 140,000 | Cycloned tailings sand | 310 |

| La Brea | Caserones | Chile | 50,000 | Borrow material | 248 |

| Candelaria | Candelaria | Chile | Closure Phase | Mine waste rock | 160 |

| Los Diques | Candelaria | Chile | 75,000 | Mine waste rock | 156 |

| Andacollo | Carmen de Andacollo | Chile | 55,000 | Mine waste rock | 150 |

| Quebrada Linga | Cerro Verde | Peru | 240,000 | Cycloned tailings sand | 305 |

| Quebrada Enlozada | Cerro Verde | Peru | Closure Phase | Cycloned tailings sand | 200 |

| Quebrada Ayash | Antamina | Peru | 145,000 | Mine waste rock | 265 |

| Las Bambas | Las Bambas | Peru | 140,000 | Mine waste rock | 220 |

| Constancia | Constancia | Peru | 90,000 | Mine waste rock | 170 |

| Quebrada Honda | Cuajone and Toquepala | Peru | 150,000 | Cycloned tailings sand | 180 |

| Quebrada Cortadera | Quellaveco | Peru | 127,500 | Cycloned tailings sand | 300 |

| QuebradaTunshuruco | Toromocho | Peru | 140,000 | Mine waste rock | 245 |

| Properties of Material | Test Method | Unit of Measure | Required Value | Required Value |

|---|---|---|---|---|

| Weight Per Area Unit | ASTM D5261 | g/m2 (oz/yd2) | ≥335 (10) | ≥180 (6) |

| Apparent Opening Size, Sieve No. | ASTM D4751 | mm | ≤0.15 | ≤0.21 |

| Grab Tensile Strength | ASTM D4632 | N | ≥1110 | ≥600 |

| Grab Elongation | ASTM D4632 | % | ≥50 | ≥50 |

| Puncture Strength | ASTM D4833 | N | ≥665 | ≥350 |

| Trapezoidal Tear | ASTM D4533 | N | ≥445 | ≥240 |

| Permittivity | ASTM D4491 | 1/s | ≤1.2 | ≤1.4 |

| Flow Rate | ASTM D4491 | l/min/m2 | ≤3100 | ≤4500 |

| UV Resistance (after 500 h) | ASTM D4355 | % | ≥70 | ≥70 |

| Properties of Material | Test Method | Unit of Measure | Required Value |

|---|---|---|---|

| Thickness | ASTM D5199 | mm (mil) | ≥1.5 (60) |

| Density | ASTM D1505 | g/cm3 | ≥0.94 |

| Strength at Yield | ASTM D6693 | N/mm | ≥22 |

| Strength at Break | ASTM D6693 | N/mm | ≥40 |

| Elongation at Yield | ASTM D6693 | % | ≥12 |

| Elongation at Break | ASTM D6693 | % | ≥700 |

| Tear Resistance | ASTM D1004 | N | ≥186 |

| Puncture-Resistance | ASTM D4833 | N | ≥480 |

| Oxidative Induction Time | ASTM D3895 | Min | ≥100 |

| Carbon Black Content | ASTM D1603 | % | 2.0–3.0 |

| Foundation Conditions (α) | Liner Bedding Soil (β) | Overliner Material (γ) | Effective Normal Stress (MPa) (σ) | ||

|---|---|---|---|---|---|

| σ < 0.5 | 0.5 < σ < 1.2 | σ > 1.2 | |||

| Firm or High Stiffness | Coarse grained | Coarse grained Fine grained | 2.0 mm HDPE 1.5 mm HDPE | 2.0 mm HDPE 2.0 mm HDPE | 2.5 mm HDPE 2.5 mm HDPE |

| Fine grained | Coarse grained Fine grained | 1.5 mm HDPE 1.0 mm HDPE | 1.5 mm HDPE 1.5 mm HDPE | 2.0 mm HDPE 2.0 mm HDPE | |

| Soft or Low Stiffness | Coarse grained | Coarse grained Fine grained | 2.0 mm LLDPE 1.5 mm LLDPE | 2.0 mm LLDPE 2.0 mm LLDPE | 2.5 mm LLDPE 2.5 mm LLDPE |

| Fine grained | Coarse grained Fine grained | 2.0 mm LLDPE 1.5 mm LLDPE | 2.0 mm LLDPE 2.0 mm LLDPE | 2.5 mm LLDPE 2.5 mm LLDPE | |

| Water Depth on Top of the Geomembrane, hw | ||||||

|---|---|---|---|---|---|---|

| 0 m (0 ft) | 0.003 m (0.01 ft) | 0.03 m (0.1 ft) | 0.3 m (1 ft) | 3 m (10 ft) | >10 m (>30 ft) | |

| Coefficient of Migration, mg (m2/s) | 0 | 9 × 10−20 | 9 × 10−18 | 9 × 10−16 | 9 × 10−14 | 3 × 10−13 |

| Unitized leakage rate, qg | - | - | - | - | - | - |

| (m/s) | 0 | 9 × 10−17 | 9 × 10−15 | 9 × 10−13 | 9 × 10−11 | 3 × 10−10 |

| (lphd) | 0 | 8 × 10−5 | 0.008 | 0.8 | 80 | 260 |

| (gpad) | 0 | 8 × 10−6 | 0.0008 | 0.08 | 8 | 28 |

| Water Depth on Top of the Geomembrane, hw | ||||||

|---|---|---|---|---|---|---|

| Defect Diameter | 0.003 m (0.01 ft) | 0.03 m (0.1 ft) | 0.3 m (1 ft) | 3 m (10 ft) | 30 m (100 ft) | |

| Pinholes | 1 mm | 0.006 | 0.06 | 0.6 | 6 | 60 |

| (0.004 in) | (0.0015) | (0.015) | (0.15) | (1.5) | (15) | |

| 0.3 mm | 0.5 | 5 | 50 | 500 | 5000 | |

| (0.012 in) | (0.1) | (1) | (13) | (130) | (1300) | |

| Holes | 2 mm | 40 | 130 | 400 | 1300 | 4000 |

| (0.08 in) | (10) | (30) | (100) | (300) | (1000) | |

| 11.3 mm | 1300 | 4000 | 13,000 | 40,000 | 130,000 | |

| 0.445 in) | (300) | (1000) | (3000) | (10,000) | (30,000) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cacciuttolo, C.; Pastor, A.; Valderrama, P.; Atencio, E. Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru. Water 2023, 15, 196. https://doi.org/10.3390/w15010196

Cacciuttolo C, Pastor A, Valderrama P, Atencio E. Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru. Water. 2023; 15(1):196. https://doi.org/10.3390/w15010196

Chicago/Turabian StyleCacciuttolo, Carlos, Alvar Pastor, Patricio Valderrama, and Edison Atencio. 2023. "Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru" Water 15, no. 1: 196. https://doi.org/10.3390/w15010196

APA StyleCacciuttolo, C., Pastor, A., Valderrama, P., & Atencio, E. (2023). Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru. Water, 15(1), 196. https://doi.org/10.3390/w15010196