1. Introduction

In general, the research on centrifugal pumps mainly focuses on four stages: design and development, manufacturing, performance testing, and optimization and improvement [

1]. This paper focuses on extracting feature information and predicting energy performance according to critical design and operation parameters of the centrifugal pump during the first stage only, with the goal of shortening the development period and reducing research costs. Current methods of centrifugal pump performance prediction (CPPP) mainly include the hydraulic loss method (HLM) [

2,

3,

4,

5], the computational fluid dynamic (CFD) [

6,

7,

8] numerical simulation method, and the artificial neural network (ANN) method [

9,

10,

11,

12].

Because it takes into consideration factors such as secondary flow, the HLM is widely used in the field of CPPP. Lin [

13] applied the enstrophy dissipation method to study hydraulic loss, and the results showed that the losses are controlled by the fluctuating and the wall enstrophy dissipation power. Naggar [

14] used Euler and energy equations to calculate the fluid slip and volute loss at the impeller outlet. However, due to the difference in hydraulic loss between the mathematical calculation models for different types of pumps, the application is subject to restrictions. The development of computer visualization technology has led to the CFD method being widely used in the research on various fluid machineries [

15,

16,

17,

18]. Kang [

19] used CFD to predict the variation rule of internal flow and performance parameters of the short blade centrifugal pump. Rehman [

20] used ANSYS soft to predict the cavitation phenomenon of the pump under different working conditions. However, CFD’s effectiveness in prediction accuracy depends to a certain extent on the engineers’ experience. In recent years, ANNs have been increasingly used to predict complex behavior in uncertain problems [

21,

22,

23]. Zhao [

24] combined the gray clustering method and a second curvelet neural network to predict the performance ratio of photovoltaic pumping systems. The simulation results showed that the second curvelet neural network had the highest prediction precision. Mrinal [

25] developed approximate models based on ANN to predict pump performance. These approximation models can eliminate the expensive testing to plot the performance curve of a pump. Park [

26] applied ANN to predict the seasonal heating performance of a large-scale ground-source heat pump system. The prediction model can be used as a baseline for the measurement and verification of future energy conservation measures and real-time performance monitoring to check for system malfunctions. Nie [

27] used a back-propagation neural network (BPNN) algorithm to predict centrifugal pump performance and found that the errors of head and efficiency were 7% and 8%, respectively. Deng [

28] used the least squares support vector regression (LSSVR) algorithm to predict pump performance from multiple impeller parameters but did not consider the influence of volute parameters. Although the above findings have achieved good results, they have one drawback: only one hidden layer was selected in the structure of the prediction model, and the features contained in the training data were not always completely extracted. The reason why only one hidden layer was selected is that, for these shallow networks, due to the particularity of the training algorithm, a large number of hidden layers might cause difficulty in the training process, and they are prone to problems such as overfitting, gradient disappearance, and falling into local minimum value [

29]. Therefore, an ANN with one hidden layer was unable to extract pump features efficiently, and the prediction accuracy of the pump needed to be further improved.

Later, with the rapid development of computer software and hardware technology, deep learning (DL) has been proven to alleviate the problems of training difficulties and gradient disappearance caused by the shallow neural network algorithm [

30]. Several researchers have introduced convolutional neural networks (CNNs) in DL to performance prediction in various fields [

31,

32,

33]. CNNs have been shown to outperform ANNs with one hidden layer and learn features automatically instead of requiring manual design [

34,

35]. Ye [

36] used a CNN to predict the pressure coefficient of a non-uniform cylindrical flow, and prediction accuracy was significantly improved. Harbola [

37] used a one-dimensional CNN to predict the dominant wind speed and direction of the wind field; these research results are beneficial for the installation of wind turbines. Haidar [

38] used a deep CNN to predict the monthly rainfall of a location in eastern Australia. Yong [

39] introduced DL to quantitatively predict changes in the heating capacity, power consumption, and performance coefficient of air source heat pumps. DíazeVico D [

40] used a CNN to predict wind energy and solar irradiance, based on input data from a numerical weather prediction system. These results attest to the powerful feature extraction ability of the CNN.

However, most researchers using deep neural networks for performance prediction only migrated the DL directly from other fields, including CPPP, without considering the embedding of physical laws between the design and performance parameters of centrifugal pumps for small datasets. In this paper, we did consider this correlation in exploring a new method suitable for CPPP and validated it by carrying out experiments. The novelty of this approach is that it predicts centrifugal pump performance based on HLM and CNN (HLCNN), rather than relying solely on a purely data-driven black box agent model to complete CPPP. In addition, for the centrifugal pump’s entire flow field, the performance prediction process considered hydraulic loss analysis, giving it the advantage of improving the interpretability and stability of the intelligent model.

Therefore, to improve the accuracy and interpretability of the CPPP model under small sample datasets, this paper proposes a HLCNN-based approach for predicting the energy performance of a centrifugal pump. This paper achieved the CPPP by using multiple alternately distributed convolutional layers to complete the adaptive learning of performance features and combine the fully connected layer (FCL). The main contributions are as follows: (1) a hybrid CPPP model considering the relationship between centrifugal pump hydraulic loss and energy performance is established; (2) considering the influence of network structure on the CPPP model, the feature learning speed of different convolutional layers is analyzed; and (3) compared with an experimental study and other methods (BPNN, LSSVR, CFD), the effectiveness of the proposed model is proved.

2. Methodology and model

2.1. Modeling of Hydraulic Loss and Energy Performance of Centrifugal Pump

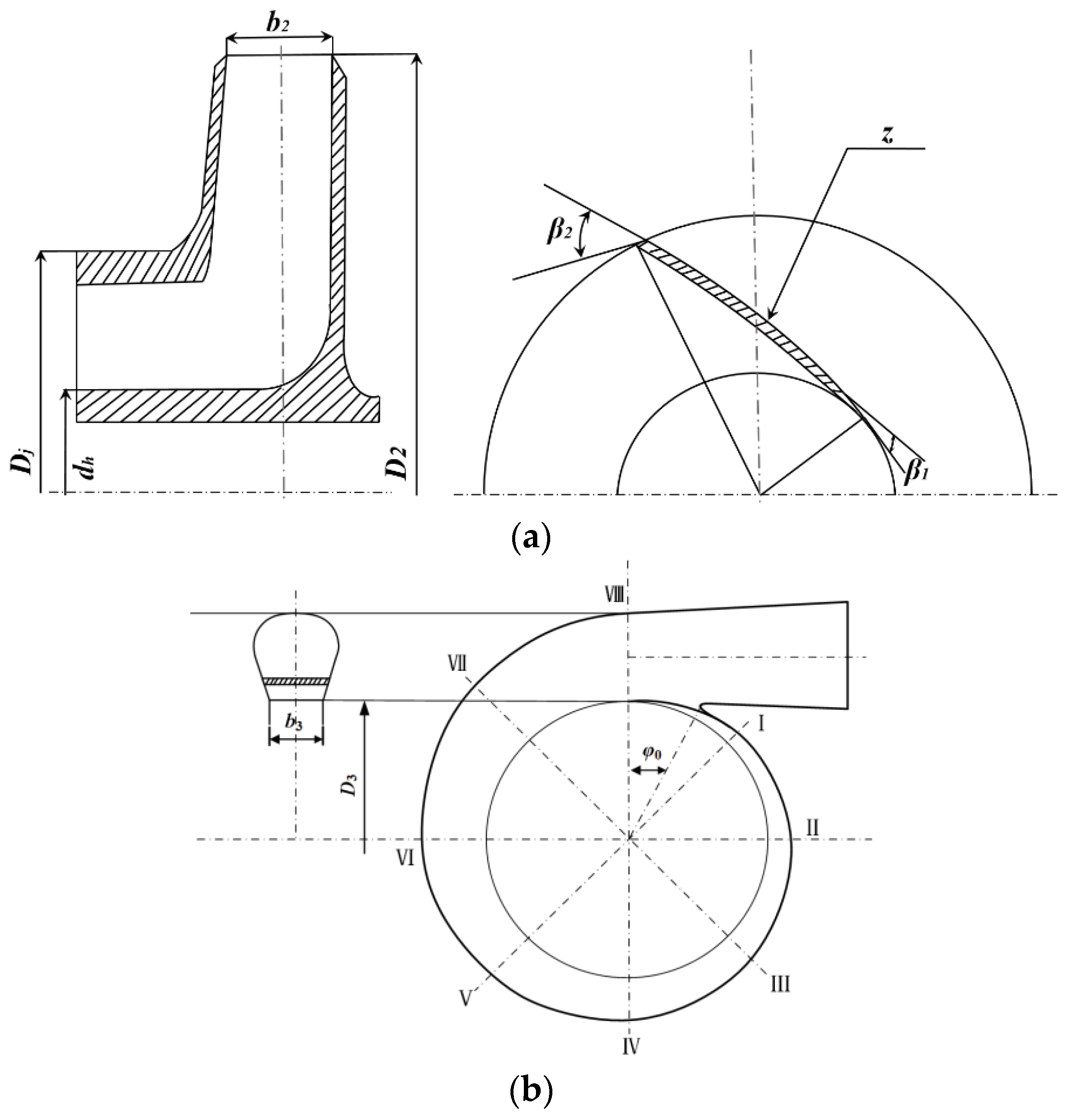

The common structure of a centrifugal pump consists of inlet, impeller, volute, and outlet. The impeller and volute play the crucial role in energy conversion in a centrifugal pump. The main design parameters of the impeller and volute are shown in

Figure 1, including the impeller inlet diameter (

Dj), impeller outlet diameter (

D2), blade outlet width (

b2), the number of blades (

z), blade outlet angle (

β2), hub diameter (

dh), blade inlet angle (

β1), volute base circle diameter (

D3), and volute inlet width (

b3), initial angle of volute tongue (

φ0), and throat area (

Ft). The specific speed (

ns), flow rate (

Q), and impeller rotational speed (

n) are significant operating parameters of the pump. The design and operating parameters affecting the centrifugal pump energy performance (head (

H) and efficiency (

ղ)) have been widely researched [

41,

42,

43].

Generally, there are many semi-theoretical and semi-empirical methods to calculate the hydraulic loss of a centrifugal pump. Hydraulic loss is mainly caused by the inlet, impeller, and three volute parts, and the inlet is usually ignored. In this section, the following hydraulic losses are taken into consideration: (a) impeller inlet shock loss (liis), (b) impeller surface friction loss (lisf), (c) impeller flow passage diffusion loss (lifd), (d) volute inlet shock loss (lvis), (e) volute friction loss (lvfri), and (f) volute diffusion loss (lvdif).

2.1.1. Impeller Inlet Shock Loss

When the centrifugal pump operates under off-design conditions, shock loss will occur at the blade inlet. The

liis depends on the relative velocity of the blade inlet, which is defined as:

where

fiis is the impeller inlet shock loss coefficient,

u1 is the circumferential velocity of the impeller inlet, and

Qd represents the flow rate of the centrifugal pump under design conditions.

2.1.2. Impeller Surface Friction Loss

The impeller surface friction loss follows that of the standard pipe friction model [

44], and the corrected

lisf is as follows:

The relationship between impeller circumferential velocity (

u), relative velocity (

w), and absolute velocity (

v) is obtained from the rules of vector addition, which can be illustrated as velocity triangles [

45]. The relevant parameters used in this work to calculate the

lisf are presented in

Table 1.

2.1.3. Impeller Flow Passage Diffusion Loss

When liquid flows through the centrifugal pump, it will cause flow separation on the impeller inner wall, which is defined as:

2.1.4. Volute Inlet Shock Loss

When the centrifugal pump operates under off-design conditions, the liquid that flows out of the impeller and enters the volute will have an impact due to the different velocity, which is shown as:

where

u2 and

vm2 are the circumferential and axial velocities at the impeller outlet, and ψ

2 is the extrusion coefficient of the blade outlet.

2.1.5. Volute Friction Loss

According to the theory of equivalent pipe flow loss [

46], the

lvfri can be estimated as:

The relevant parameters used in this work to calculate the

lvfri are presented in

Table 2.

2.1.6. Volute Diffusion Loss

As the volute flow passage is in a diffusion state, the diffusion loss of the liquid flow out of the impeller and entering the volute is calculated as follows:

Cv is the volute loss coefficient. v3d is the velocity component in a tangential direction to the impeller.

To sum up, the actual head (

H) and total efficiency (

ղ) of the centrifugal pump in this paper can be expressed as:

Here,

Ht,

ղh,

ղv, and

ղm are the theoretical head, hydraulic efficiency, volumetric efficiency, and mechanical efficiency of the centrifugal pump [

47]. The theoretical calculation of

Ht (as shown in

Appendix A) can be referred to the literature [

48].

2.2. Hydraulic Loss–Convolution Neural Network (HLCNN)

CNN is an end-to-end, supervised neural network, whose basic structure can be divided into input layer, alternately distributed convolutional layer, pooling layer, FCL, and output layer. In this paper, the basic architecture for predicting the hydraulic loss of the centrifugal pump applying the CNN is shown in

Figure 2. In addition, the nonlinear mathematical relation between centrifugal pump design, operation parameters, and hydraulic loss can be derived as follows.

First, suppose that the input layer neuron is

a (

aϵ

xi), which represents the design and operation parameters of the centrifugal pump. The expression of the centrifugal pump feature information

g(

z) extracted from the first convolution layer (Conv1) through

p channels is shown in Equation (21), where

is the convolution kernel and

bz is the bias of the Conv1.

After each channel completes the convolution computation, the nonlinear transformation is conducted by applying the rectified linear unit (ReLU) [

49], and the output of Conv1 is given by

Assuming that the CPPP model in this paper contains

n convolutional layers, the feature information extracted through the

n-th convolution layer (Conv

n) is presented in Equation (23). The output of Conv

n is shown in Equation (24).

Next, the centrifugal pump feature information extracted from

n convolutional layers is inputted to the first fully connected layer (FCL1), and the output of FCL1 is shown in Equation (25), where

f1 represent the number of neurons of FCL1. Similarly, the feature information of the (

n +

l)th layer is inputted to the regression layer, and the regression function is shown in Equation (26), where

wT and

b are regression coefficients.

Finally, all feature information of the centrifugal pump is outputted from the output layer, as shown in Equation (27), where

mpl represents all hydraulic loss of the centrifugal pump.

As can be seen in

Figure 3, the prediction process consisted of three parts. The first part was to calculate the hydraulic loss of the impeller and volute based on the design and operation parameters of the centrifugal pump.

The second part was to build a fully convolution neural network. To improve the stability of the network and avoid the gradient disappearance in the training process, all activation functions were set as ReLUs. The Adam algorithm [

50] was used to optimize and update each training parameter. To accelerate the learning speed of centrifugal pump feature information and ensure the correctness of the training direction, mapminmax normalization was used to initialize the training samples.

The third part was the evaluation of the HLCNN model. The test samples were inputted to the prediction model for testing, and the prediction model was evaluated by comparing the absolute relative error (ARE) between the predicted and the experimental values, as follows:

Other regression evaluation indicators [

51], including root mean square error (RMSE), the sum of squares due to error (SSE), and mean absolute error (MAE) are defined as follows:

where

yi and

ŷi represent the experimental and predicted values of the

i-th sample, and

n is the number of samples.

The HLCNN model framework used to predict the hydraulic loss of centrifugal pump is shown in

Figure 4.

3. Experimental Research and Data Sources

The centrifugal pump is an indispensable energy conversion machine on pump station systems. The prediction of its energy performance directly affects the energy-saving transformation and stable operation of the pump station system. In order to study the relationship between the energy performance and design parameters of the centrifugal pump, performance tests were carried out on an open test rig in Zhejiang, China. The test rig met the Chinese national standard of GB/T3216, and the test accuracy was Level I. The working medium was room temperature water. The experimental devices for the energy performance test are presented in

Figure 4. Two pressure sensors were installed at the inlet and outlet pipe of the centrifugal pump. The flow rate was controlled by an electric valve, and a photoelectric sensor was used for feedback on the impeller rotational speed. Finally, the obtained energy performance parameters were saved and processed in real time by the data acquisition system.

In this paper, the fourteen design parameters, namely Dj, D2, b2, z, β2, dh, β1, D3, b3, φ0, Ft, and ns, Q, and n are considered as the input variables of the HLCNN model. The six hydraulic losses, namely liis, lisf, lifd, lvis, lvfri and lvdif, were selected as output variables. In the design of the centrifugal pump, the variations in these parameters were related to each other along with the working condition and the regulation mode. In this paper, the HLCNN model is proposed to predict the head and efficiency of the centrifugal pump. Consequently, the modeling samples of the centrifugal pump can be represented as M = {X, Y}, where X = [x1, …, xN]T∈Rn×14, Y = [y1, …, yN]T∈Rn×6, and n is the number of the sampling set. The i-th sample set can be further described as mi = {(xi = [Dj (i), D2(i), b2(i), z(i), β2(i), dh(i), β1(i), D3(i), b3(i), φ0(i), Ft(i), ns(i), Q(i), n(i)]T, yi = [liis (i), lisf (i), lifd(i), lvis(i), lvfri(i), lvdif(i)]T)}.

In this paper, 390 groups of experimental data were collected from the centrifugal pump energy performance test rig. In terms of dataset division, we used 20% of the samples as the test set to evaluate the generalization ability of the HLCNN model. Similarly, 20% of the experimental data were used as the validation set to adjust and optimize the hyperparameters of the HLCNN model. The rest of the samples, except the test and validation set, were used as a training set to build a prediction model. Therefore, the numbers of samples in the training, validation, and test sets were 234, 78 and 78, respectively.

4. Results and Discussions

4.1. Influence of Convolutional Layer on Prediction Model

As discussed in

Section 2, we found that the convolutional layer was the main building block of the HLCNN model. Three parameters affected the structure of the convolutional layer: convolutional kernel size, feature maps, and neurons. Here, the convolution kernel was able to achieve the feature extraction of the input sample. The feature map refers to the number of convolution kernels. In this paper, the convolutional layer directly affected whether the prediction model could completely extract the feature information from the design and operation parameters of centrifugal pump. Therefore, the same sample set was used to train three (CNN3), four (CNN4), five (CNN5), and six (CNN6) convolution layers to determine the influence of the convolutional layers on the HLCNN model. The simulation environment was a MATLAB 2020a with a 2.3 GHz CPU and 16 GB RAM.

The variation trend of losses with different convolutional layers is shown in

Figure 5. From the curve comparison, it can be found that, except for CNN5, the training process of the other three networks was similar. In terms of model stability, the loss fluctuation of CNN5 was the largest compared with the other three networks under the same training epoch. The fluctuation was most obvious when the training epochs were 20 and 60. Therefore, CNN5 was not suitable for predicting the performance of the centrifugal pump. At the same time, CNN3 did not reach the convergence state for the feature learning speed of the model when the training epoch was 100. Finally, we selected a network with four convolution layers (CNN4) to predict the head and efficiency of the centrifugal pump after taking the impact of the training time into consideration. The hyperparameters of the selected network are listed in

Table 3.

The loss variation in the CNN4 model in the training and validation processes is shown in

Figure 6. The results show that the loss gradually decreases with the increase in the learning epoch, and finally keeps near zero. There was no fluctuation or overfitting in the whole feature learning process. It indicates that the CNN4 model has robustness and fitting ability, and it can be utilized in modeling analysis of centrifugal pump performance.

4.2. Performance Prediction for the Test Samples

We used 78 test samples to evaluate the prediction effect of the HLCNN model. The comparison curve between predicted and experimental values of head and efficiency is shown in

Figure 7. It shows that the values predicted by the HLCNN model were consistent with the change trend of the experimental values, and the difference was insignificant.

The ARE variations in the HLCNN model test samples are shown in

Figure 8. It can be found that the ARE

means of the head and efficiency were both less than 9%, which meets the requirements of theoretical research and engineering practice [

52]. The change in ARE indicates that it is feasible to use the HLCNN model to predict the energy performance of the centrifugal pump.

Once the head and efficiency predictions of the test samples are realized,

Figure 9 can further illustrate the correlation between the prediction and the experimental results. It can be seen that the coefficients of determination (R−Square) of head and efficiency were 0.9902 and 0.9663, indicating that the HLCNN model has better fitting performance.

4.3. Comparison with the Other Machine Learning Models

To further verify the nonlinear approximation ability of the proposed HLCNN model, we compared the prediction results of the HLCNN, the BPNN, and the LSSVR models. The same data set and running environment were adopted for the three models. The predicted results of the different models compared to the experimental results are shown in

Figure 10. It can be seen that the fitting ability of the HLCNN model was better than that of the other two models in terms of predicting the head and efficiency of the centrifugal pump (as marked with the blue rectangles). This indicates that the problems of training process difficulties and model instability are solved by the HLCNN model compared with the traditional machine learning models.

Table 4 and

Table 5 summarize the error distributions of the different models regarding head and efficiency, respectively. It can be seen that the HLCNN prediction model obtained better ARE

max, ARE

min, ARE

mean, RMSE, SSE, and MAE values than the BPNN and LSSVR models. This indicates that the predicted head and efficiency of the HLCNN model and the experimental values have a great agreement, which means that it is more suitable for approximating the nonlinear mapping relationship between design, operation parameters, and energy performance of the centrifugal pump. At the same time, it is worth noting that the HLCNN model reduces the complexity of the prediction model with its special structure of local weight sharing, which is embodied in the data reconstruction in the process of centrifugal pump feature extraction.

4.4. Comparison with the CFD Method

According to many previous studies, the CFD method, which analyzes the relationship between the internal flow field characteristics and the external performance parameters, is another way to predict the performance of centrifugal pumps. In order to verify the prediction ability of the HLCNN model, the CFD flow field numerical simulation method was compared in this section. The simulation environment of the CFD method was the same as that of the MATLAB.

In this section, a centrifugal pump was selected randomly to reflect the variation in performance parameters with the flow rate. The design and operation parameters of the centrifugal pump are given in

Table 6. The impeller and volute, as two important components of the centrifugal pump, were divided into grids as shown in

Figure 11.

The changes in performance parameters of the centrifugal pump are presented in

Figure 12. The research in

Figure 12 shows that when the centrifugal pump was operating under design conditions (as marked with the green circles), the predicted values of the two models were both close to the experimental values, and those the HLCNN model proposed are particularly obvious. The predicted values of the CFD model gradually deviated from the experimental values when it operated in off−design conditions. There may be three reasons for this phenomenon: (1) The accuracy of the CFD method is limited by the influence of computer performance and engineer experience. (2) The inside flow pattern of the centrifugal pump has a high turbulence value. At the same time, the numerical simulation process is affected by turbulence model selection, separated flow, reverse flow, and other factors under off−design conditions (see

Figure 13). (3) At present, the research of the interaction between the impeller and volute is not deep enough.

It can be found from

Figure 14 that the ARE

means of the head and efficiency obtained by the CFD model were 17.30% and 7.16%. On the contrary, the ARE

means of the HLCNN model were 4.36% and 4.00%, respectively, proving the strong generalization ability of the HLCNN model within a wide flow rate range.

In addition, compared with the CFD method, the HLCNN model has advantages in the prediction time of centrifugal pump performance. The whole prediction process of the HLCNN model took 6.48 min in this section. However, under the same operating environment, the CFD method required 27.5 h to complete the performance predictions at 11 operating points (Q = 30~80 m3/h). Therefore, the HLCNN model built in this paper can build a CPPP model to meet the needs of design, production, and operation quickly and accurately.

5. Conclusions

This paper proposes a HLCNN-based method for predicting centrifugal pump energy performance. The results demonstrate that the HLCNN method can improve prediction accuracy compared with other methods. The following conclusions can be drawn:

(1) The performance features of the centrifugal pump were extracted by the HLCNN model, and a nonlinear mathematical relationship was established between the hydraulic loss of the centrifugal pump and the design operating parameters.

(2) The influence of convolution layers on the HLCNN model training process was analyzed, and it was determined that the network with four convolution layers (CNN4) was feasible to build the performance prediction model for the centrifugal pump.

(3) The HLCNN model prediction results were compared with the experimental results, and it was found that the AREmeans of head and efficiency were both less than 9%, which is consistent with the error range required by both theoretical research and engineering practice.

(4) The AREmean of the HLCNN model was lower in predicting the head and efficiency compared with the BPNN and the LSSVR model.

(5) The AREmeans of the HLCNN model were lower than the CFD method in predicting head and efficiency, and the whole prediction process only took 6.48 min. It indicates that the HLCNN model can predict the energy performance of centrifugal pumps in a wide flow rate range quickly and efficiently.

In light of the above analysis, the energy performance prediction method proposed in this paper only studies the centrifugal pump without considering more types of pumps, such as mixed-flow pumps, axial-flow pumps, etc. Hence, the first effort in future work should be to validate this idea. The second effort should be to analyze the internal flow mechanism on the basis of energy performance prediction combined with advanced flow field visualization technology, such as particle image velocimetry (PIV).