Internal Erosion Stabilization of Cohesionless Soil Using Lime

Abstract

:1. Introduction

2. Research Significance

3. Experimental Program and Methodology

3.1. Material Properties

3.2. Specimen Preparation

3.3. Specimen Testing Process

3.4. Process for Analysing the Data

4. Results and Discussion

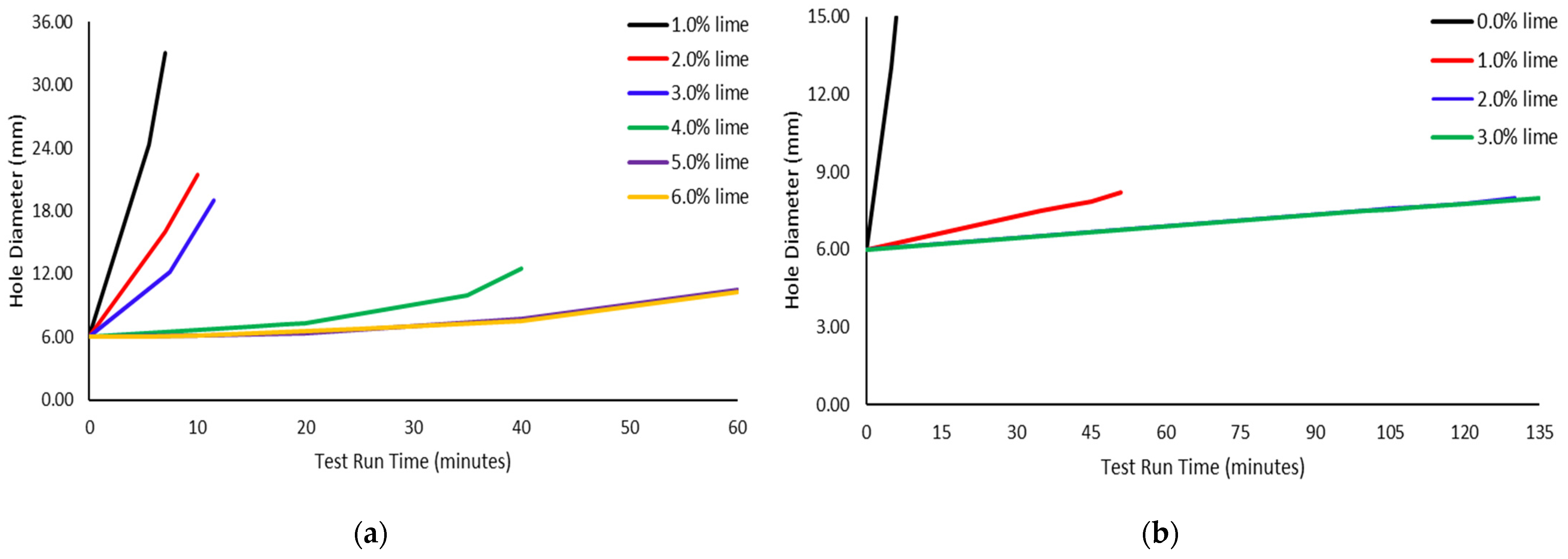

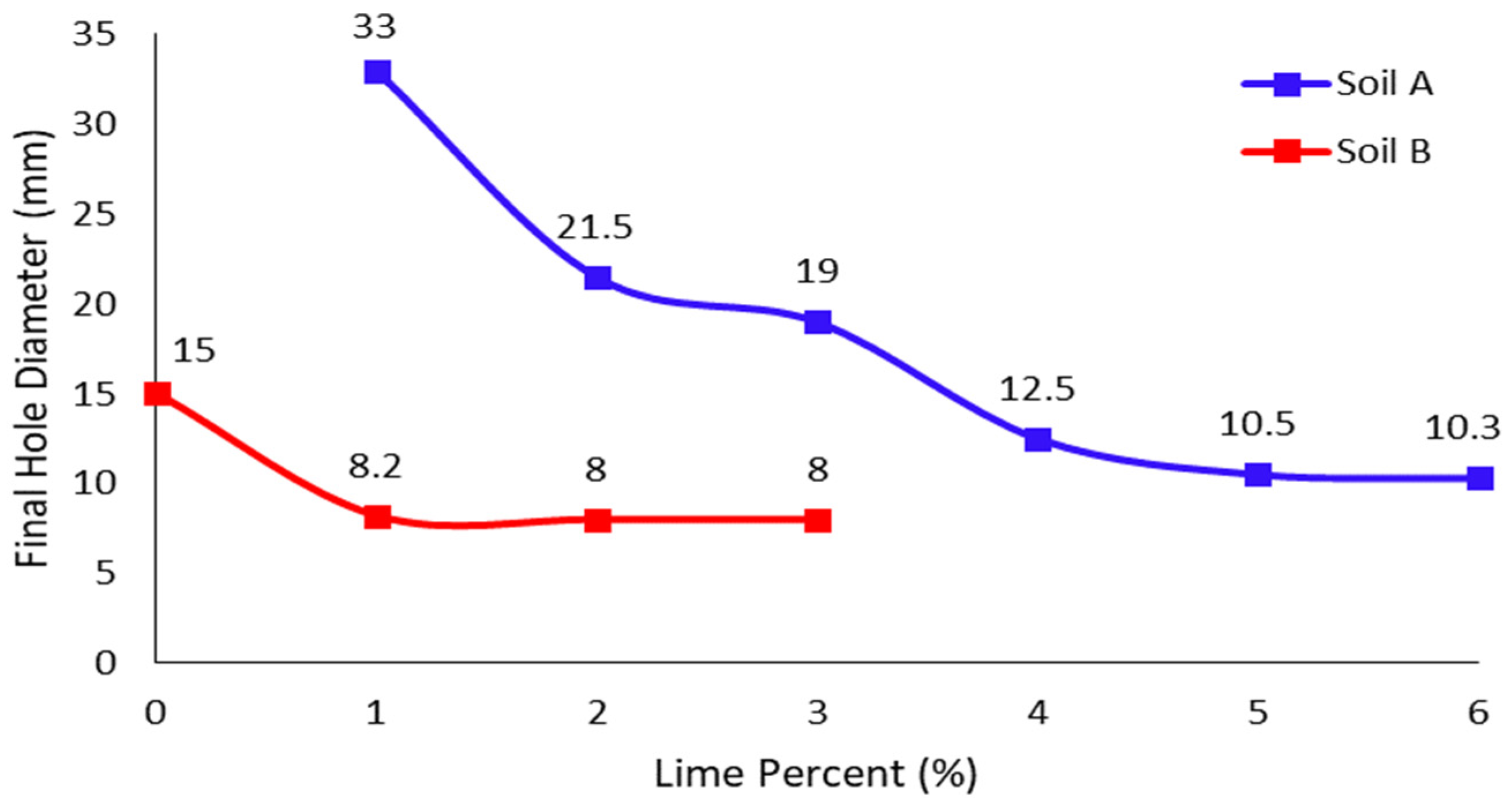

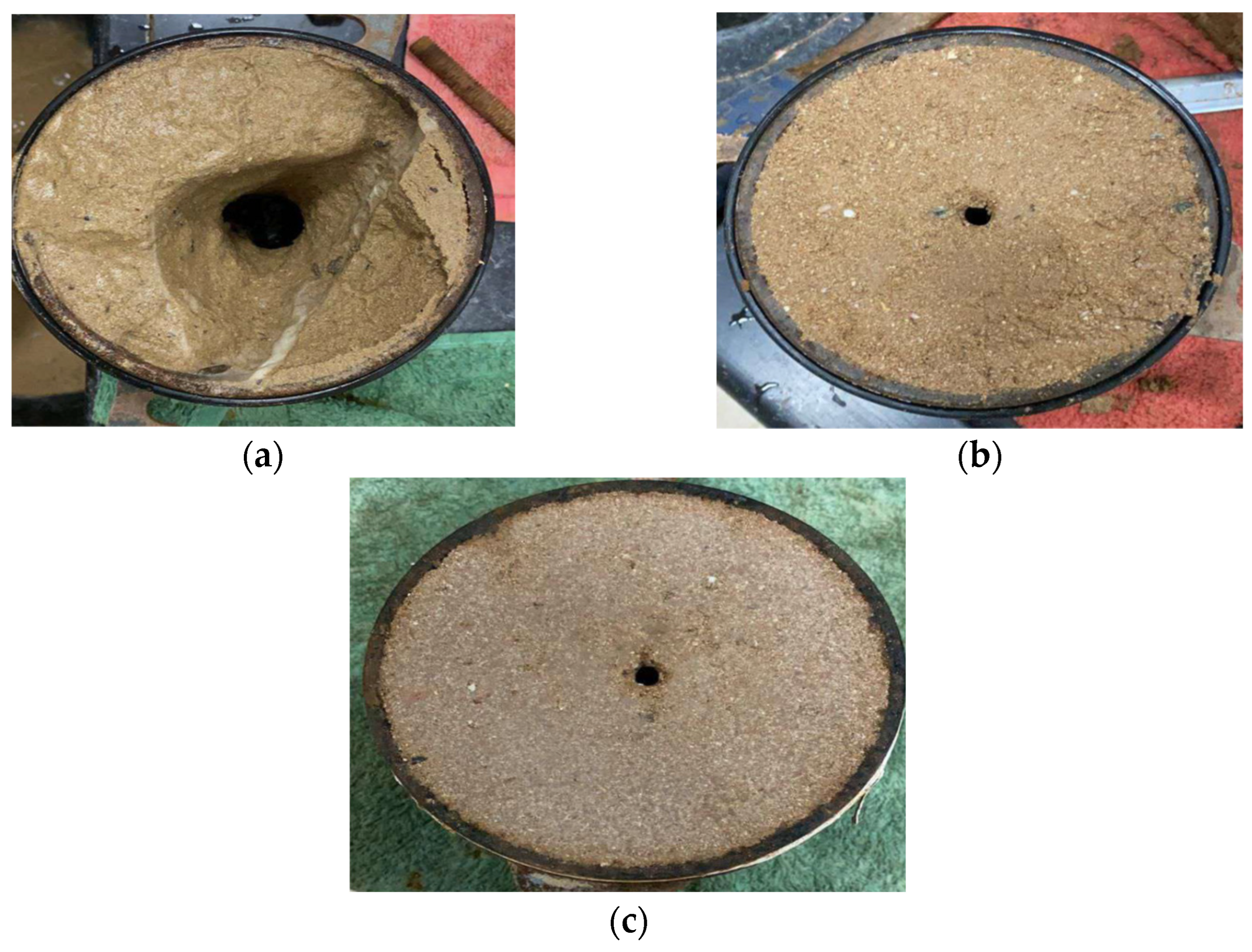

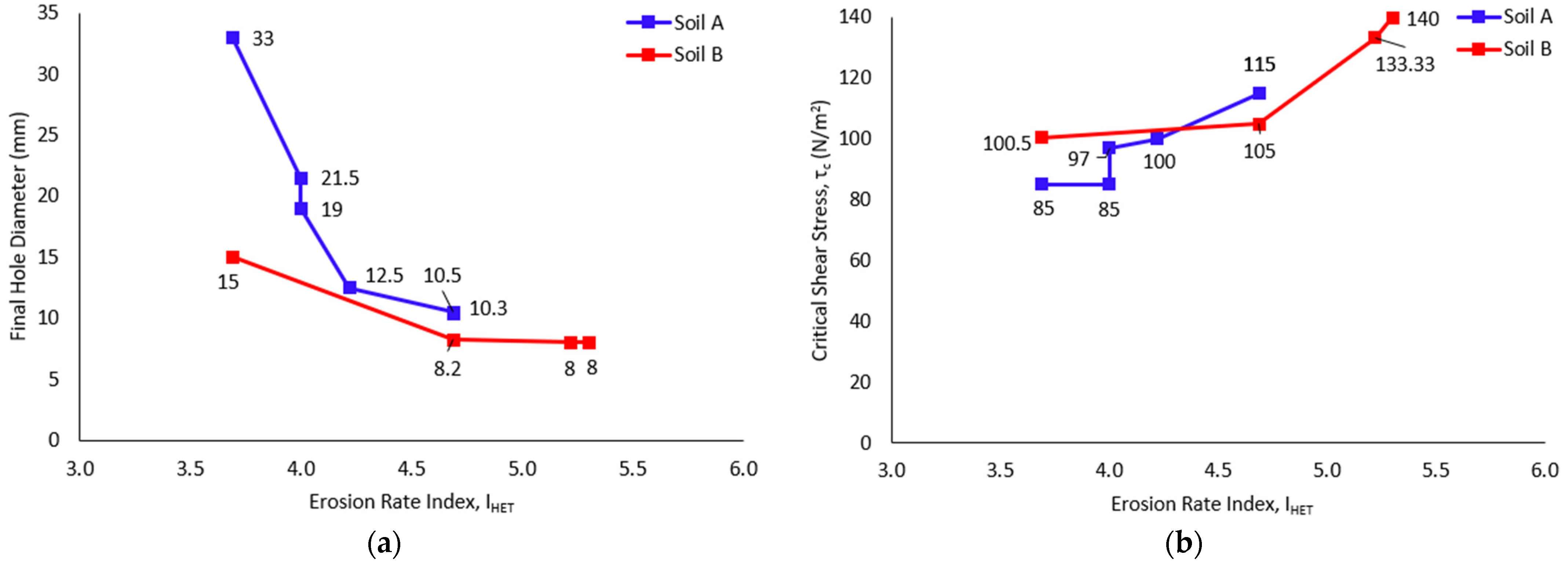

4.1. Addition of Lime Effect on Water Flow Path

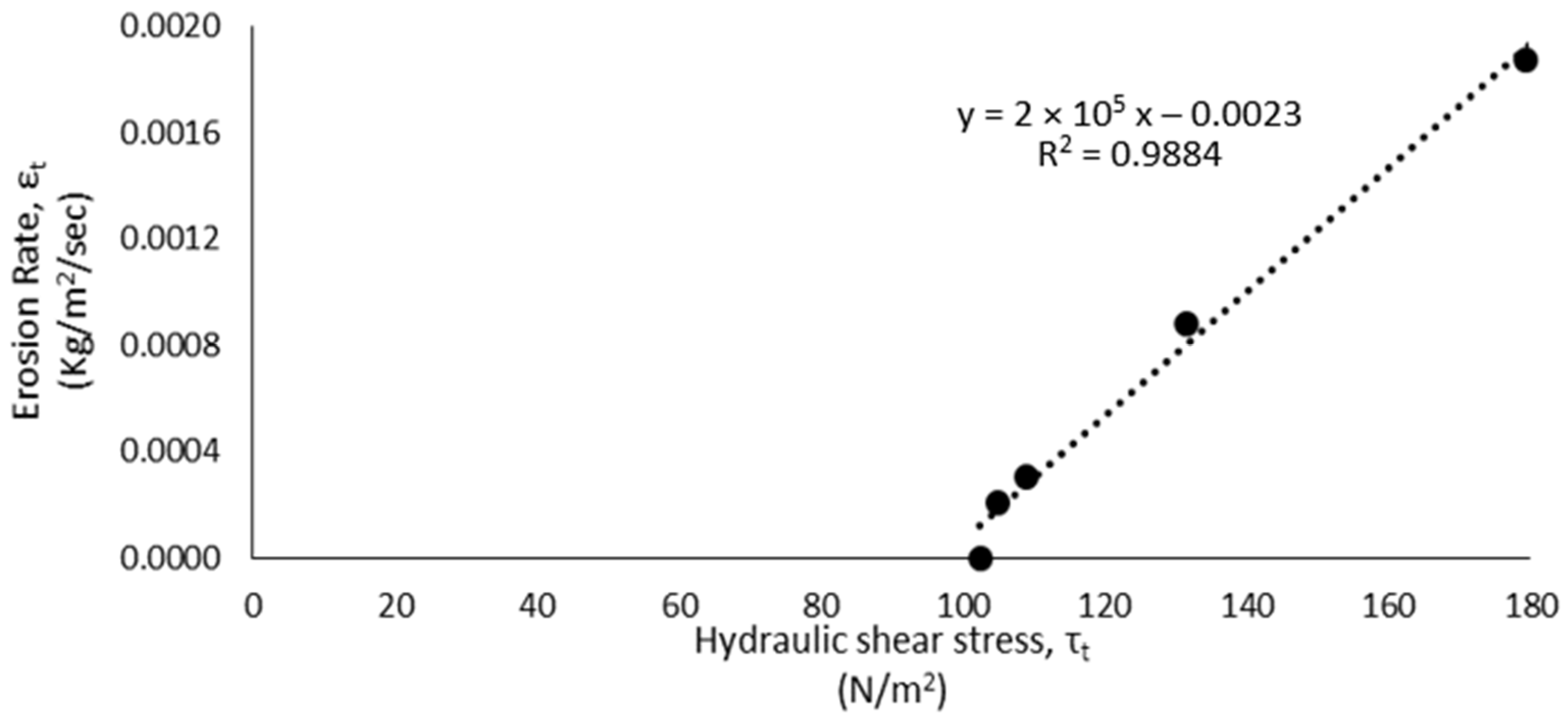

4.2. Addition of Lime Effect on Critical Shear Stress

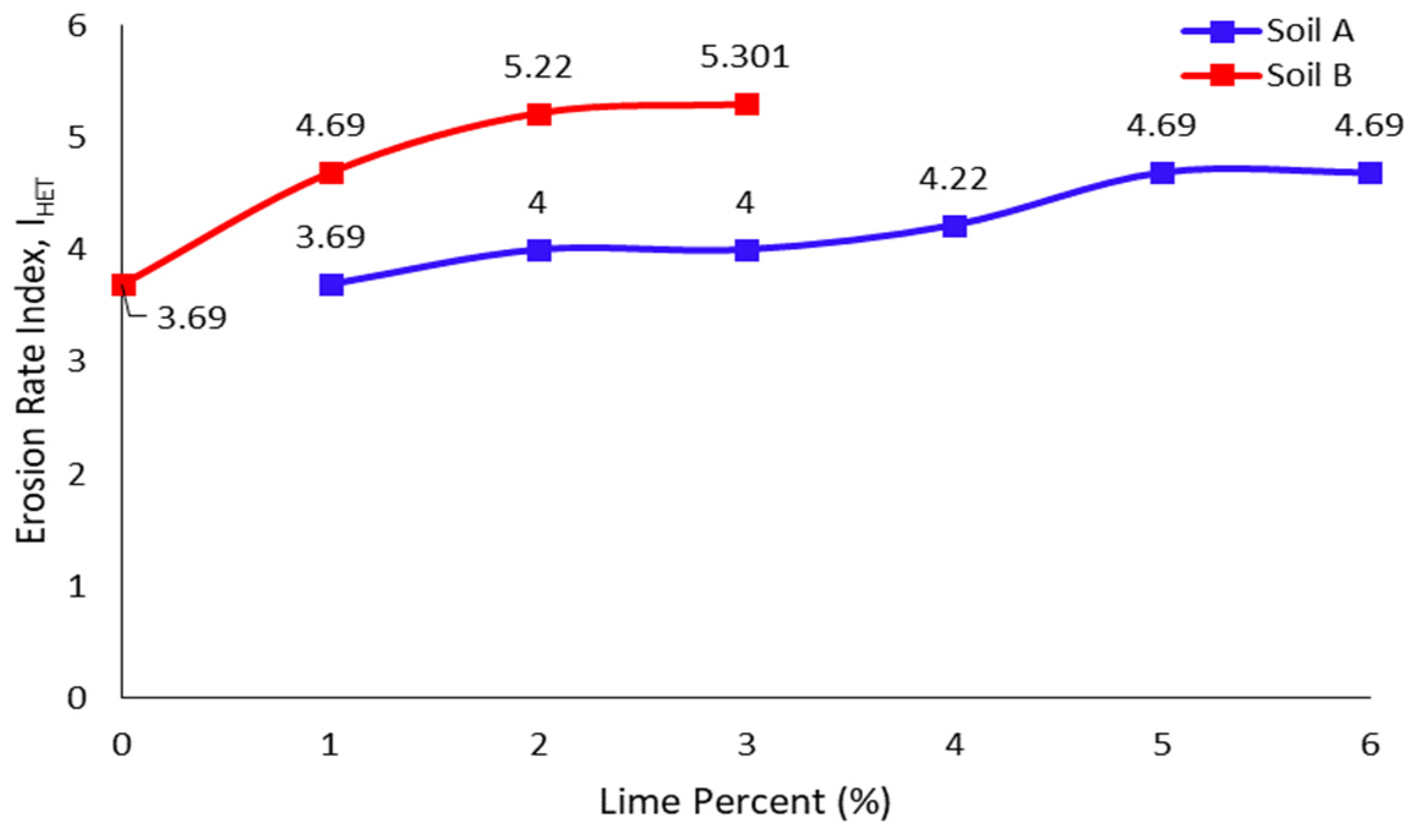

4.3. Addition of Lime Effect on Erosion Rate Index (IHET)

4.4. Internal Erosion Types of Soil A and Soil B

5. Conclusions

- Quick lime is an adequate internal erosion stabilizer for cohesionless soils;

- The water flow path diameter can be reduced and controlled with a higher amount of lime for both types of cohesionless soil;

- An increase in lime content leads to stronger critical shear stress (τc) and higher erosion rate index (IHET) values for cohesionless soil;

- The inclusion of 5.0% lime in poorly graded soil resulted in a 68.2% lower final hole diameter, 35.3% higher critical shear stress (τc), and 27.1% higher erosion rate index (IHET) value. In contrast, for Soil B, the addition of only 3.0% lime resulted in a 46.7% lower final hole diameter, 39.3% higher τc, and 43.7% higher IHET value;

- For poorly graded cohesionless soil, with 5.0% optimum lime content, the internal erosion improved from a moderately rapid erosion type to a moderately slow erosion type, and for well-graded soil, with only 3.0% of lime, the internal soil erosion improved from a moderately rapid to a very slow erosion type;

- Lower lime is required to stabilize well-graded cohesionless soil as opposed to poorly graded soil. Moreover, stabilized well-graded soil demonstrated comparatively better erosion parameters than stabilized poorly graded soil. This is related to the clay and silt (binding materials) present in well-graded soil, which gives higher strength and better supports the lime reaction. Hence, well-graded soil is preferred in construction compared to poorly graded cohesionless soil.

6. Recommendations for Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Notations

| AUS | American University of Sharjah |

| CBR | California Bearing Ratio |

| Cc | Coefficient of Curvature |

| Soil Erosion Coefficient | |

| Cu | Coefficient of Uniformity |

| Laminar Friction Factors at any time, t | |

| Turbulent Friction Factors at any time, t | |

| Gravitational Acceleration (m/s2) | |

| GGBS | Ground Granulated Blast-furnace Slag |

| Gs | Specific Gravity of Soil |

| HET | Hole Erosion Test |

| Soil Erosion Rate Index | |

| IHET | Erosion Rate Index determined using Hole Erosion Test |

| JET | Jet Erosion Test |

| OAP | Open Access Program |

| Qt | Flow Rate at time, t (m3/s) |

| R | Reynold’s Number |

| SET | Slot Erosion Test |

| Soil Sample Hydraulic Gradient | |

| Average Water Flow Velocity at time, t (m/s) | |

| Erosion Rate per Unit Surface Area at time, t (kg/m2/s) | |

| Absolute Water Viscosity (Pa·s) | |

| Soil Dry Density (kg/m3) | |

| dmax | Maximum Dry Density (kg/m3) |

| Water Density (kg/m3) | |

| Critical Shear Stress (N/m2) | |

| Hydraulic Shear Stress at time, t (N/m2) | |

| φf | Final hole (water flow path) diameter |

| Water Flow Path (Hole) Diameter at time t (m) | |

| Rate of Diameter Change with Time (m/s) | |

| ωop | Optimum Moisture (or Water) Content |

References

- Chen, S.H. Introduction. In Hydraulic Structures; Springer: Berlin/Heidelberg, Germany; Wuhan, China, 2015; pp. 1–39. [Google Scholar]

- Kuriqi, A.; Ardiçlioglu, M.; Muceku, Y. Investigation of seepage effect on river dike’s stability under steady state and transient conditions. Pollack Period. 2016, 11, 87–104. [Google Scholar] [CrossRef]

- Lüthi, M. A Modified Hole Erosion Test (HET-P) to Study Erosion Characteristics of Soil. Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Hanneman, D. Recent examples of backward erosion piping, internal erosion along a conduit, and embankment cracking at Bureau of Reclamation dams. In Proceedings of the Internal Erosion in Embankment Dams and Their Foundations, Brno, Czech Republic, 26–29 April 2011. [Google Scholar]

- Foster, M.; Fell, R.; Spannagle, M. A method for assessing the relative likelihood of failure of embankment dams by piping. Can. Geotech. J. 2000, 37, 1025–1038. [Google Scholar] [CrossRef]

- Robbins, B.; Griffiths, D. Internal Erosion of Embankments: A review and Appraisal. In Proceedings of the Rocky Mountain Geo-Conference 2018, Golden, CO, USA, 2 November 2018; ASCE Library: Reston, VA, USA, 2018. [Google Scholar]

- Klipalo, E.; Besharat, M.; Kuriqi, A. Full-Scale Interface Friction Testing of Geotextile-Based Flood Defense Structures. Buildings 2022, 12, 990. [Google Scholar] [CrossRef]

- Kuriqi, A.; Hysa, A. Multidimensional Aspects of Floods: Nature-Based Mitigation Measures from Basin to River Reach Scale. In Nature-Based Solutions for Flood Mitigation; Springer: Cham, Switzerland, 2021; Volume 107, pp. 11–33. [Google Scholar]

- Cao, Y.; Wang, J.L.; Chen, H.C.; Li, Y.; Nurtjahyo, P. EFA tests and the influence of various factors on the erodibility of cohesive soils. In Proceedings of the 1st International Conference on Scour of Foundations, College Station, TX, USA, 17–20 November 2002. [Google Scholar]

- Hanson, G.I.; Tejral, S.H.; Temple, D. Internal Erosion and Impact of Erosion Resistance USDA Small Watershed Program. Collab. Manag. Integr. Watersheds Trans. ASABE 2007, 5, 773–784. [Google Scholar]

- Briaud, J.-L. Case Histories in Soil and Rock Erosion: Woodrow Wilson Bridge, Brazos River Meander, Normandy Cliffs, and New Orleans Levees. J. Geotech. Geoenviron. Eng. 2008, 134, 1425–1447. [Google Scholar] [CrossRef]

- Sherard, J.L.; Richard, S.D.; Woodward, J.; Stanley, N.S.; Gizenski, F.; Willaim, M.S.; Clevenger, B.S. Earth and Earth Rock Dams; Chapter 2; John Wiley and Sons: New York, NY, USA, 1963. [Google Scholar]

- Wan, C.F.; Fell, R. Investigation of Rate of Erosion of Soils in Embankment Dams. J. Geotech. Geoenviron. Eng. 2004, 130, 373–380. [Google Scholar] [CrossRef]

- Yamin, M.; Attom, M.F.; Atabay, S.; Vandanapu, R. The Effect of Compaction Effort on Shear Strength Parameters of Low/High Plasticity Clay Soils. Geotech. Eng. J. SEAGS AGSSEA 2021, 52, 1–8. [Google Scholar]

- Attom, M.F.; Khan, Z.; Vandanapu, R. Efficacy of sand columns to increase the sub-soil moisture content of clay. SN Appl. Sci. 2020, 2, 1–6. [Google Scholar] [CrossRef]

- Vandanapu, R.; Omer, J.R.; Attom, M.F. Laboratory simulation of the influence of groundwater rise and drip irrigation on the settlement of a sample of collapsible desert soil. Int. J. Geotech. Eng. 2018, 15, 760–766. [Google Scholar] [CrossRef]

- Negi, A.S.; Faizan, M.; Siddharth, D.P.; Singh, R. Soil stabilization using lime. International Journal of Innovative Research in Science. Eng. Technol. 2013, 2, 1–6. [Google Scholar]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physicochemical, microstructural and mechanical characteristics of a plastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Karimi, M.; Ghorbani, A.; Daghigh, Y.; Kia, S. Stabilization of Silty Sand Soils with lime and Microsilica Admixture in presence of Sulfates. In Proceedings of the 2011 Pan-Ame CGS Geotechnical Conference–14th Pan-American Conference on Soil Mechanics and Geotechnical Engineering, Toronto, ON, Canada, 2–6 October 2011. [Google Scholar]

- Khemissa, M.; Mahamedi, A. Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl. Clay Sci. 2014, 95, 104–110. [Google Scholar] [CrossRef]

- Al-Aghbari, M.; Mohamedzein, Y.E.A.; Taha, R. Stabilisation of desert sands using cement and cement dust. Proc. Inst. Civ. Eng. Ground Improv. 2009, 162, 145–151. [Google Scholar] [CrossRef]

- Mohamedzein, Y.E.-A.; Al-Aghbari, M.Y.; Taha, R.A. Stabilization of desert sands using municipal solid waste incinerator ash. Geotech. Geol. Eng. 2006, 24, 1767–1780. [Google Scholar] [CrossRef]

- Soundarya, N. Effect of fly ash and GGBS on lime stabilized mud block. Mater. Today Proc. 2021, 47, 4636–4640. [Google Scholar] [CrossRef]

- Malkanthi, S.; Balthazaar, N.; Perera, A. Lime stabilization for compressed stabilized earth blocks with reduced clay and silt. Case Stud. Constr. Mater. 2019, 12, e00326. [Google Scholar] [CrossRef]

- Vinod, J.S.; Indraratna, B.; Al Mahamud, M.A. Stabilisation of an erodible soil using a chemical admixture. Proc. Inst. Civ. Eng. Ground Improv. 2010, 163, 43–51. [Google Scholar] [CrossRef]

- Vakili, A.H.; Ghasemi, J.; bin Selamat, M.R.; Salimi, M.; Farhadi, M.S. Internal erosional behaviour of dispersive clay stabilized with lignosulfonate and reinforced with polypropylene fiber. Constr. Build. Mater. 2018, 193, 405–415. [Google Scholar] [CrossRef]

- Indraratna, B.; Mahamud, M.; Vinod, J.S.; Wijeyakulasuriya, V. Stabilization of an erodible soil using a chemical admixtures. In Proceedings of the 2nd International Conference on Geotechnical Engineering, Hammamet City, Tunisia, 25–27 October 2010. [Google Scholar]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Kolias, S.; Kasselouri-Rigpoulou, V.; Karahalios, A. Stabilization of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- Attom, M.; Shatnawi, M.Y. Stabilization of clayey soils using hay material. J. Solid Waste Technol. Manag. 2005, 31, 84–92. [Google Scholar]

- Baldovino, J.d.J.A.; Izzo, R.L.d.S.; Moreira, E.B.; Rose, J.L. Optimizing the evolution of strength for lime-stabilized rammed soil. J. Rock Mech. Geotech. Eng. 2019, 11, 882–891. [Google Scholar] [CrossRef]

- Nagaraj, H.; Sravan, M.; Arun, T.; Jagadish, K. Role of lime with cement in long-term strength of Compressed Stabilized Earth Blocks. Int. J. Sustain. Built Environ. 2014, 3, 54–61. [Google Scholar] [CrossRef]

- Burns, B.; Barker, R.; Ghataora, G.S. Investigating internal erosion using a miniature resistivity array. NDT E Int. 2006, 39, 169–174. [Google Scholar] [CrossRef]

- Herrier, G.; Chevalier, C.; Froumentin, M.; Cuisinier, O.; Bonelli, S.; Fry, J. Lime treated soil as an erosion-resistant material for hydraulic earthen structures. In Proceedings of the 6th International Conference on Scour and Erosion, Paris, France, 27 August–1 September 2012. [Google Scholar]

- Rahman, M.; Rashiduzzaman, M.; Akhand, F.Z.; Kabir, K.B. Compressed Stabilized Earth Block: A Green Alternative for Non-load Bearing Building Block in Developing Countries like Bangladesh. Am. Chem. Sci. J. 2016, 12, 1–10. [Google Scholar] [CrossRef]

- Estabragh, A.; Soltannajad, K.; Javadi, A. Improving piping resistance using randomly distributed fibers. Geotext. Geomembr. 2014, 42, 15–24. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Silva Lopes, L., Jr.; Prietto, P.D.M.; Festugato, L.; Cruz, R.C. Variables Controlling Stiffness and Strength of Lime-Stabilized Soils. J. Geotech. Geoenviron. Eng. 2011, 137, 628–632. [Google Scholar] [CrossRef]

- Consoli, N.C.; Bittar Marin, E.J.; Quiñónez Samaniego, R.A.; Heineck, K.S.; Johann, A.D.R. Use of Sustainable Binders in Soil Stabilization. J. Mater. Civ. Eng. 2019, 31, 06018023. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Silva Lopes, L., Jr.; Heineck, K.S. Key Parameters for the Strength Control of Lime Stabilized Soils. J. Mater. Civ. Eng. 2009, 21, 210–216. [Google Scholar] [CrossRef]

- Banu, S.A.; Attom, M.F. Effect of Curing Time on Lime-Stabilized Sandy Soil against Internal Erosion. Geosciences 2023, 13, 102. [Google Scholar] [CrossRef]

- Elandaloussi, R.; Bennabi, A.; Dupla, J.C.; Canou, J.; Benamar, A.; Gotteland, P. Effectiveness of Lime Treatment of Coarse Soils Against Internal Erosion. Geotech. Geol. Eng. 2018, 37, 139–154. [Google Scholar] [CrossRef]

- Benaissa, K.; Angel, P.V.M.; Dolores, R.; Larbi, E.; Abdellatif, K.; Bezzazi, M.; Dubujet, P. Effect of Wall Roughness and Con-centration of Clay on Erosion in the Hole Erosion Test. Am. J. Eng. Appl. Sci. 2010, 3, 734–739. [Google Scholar]

- Marine Propellers and Propulsion, “Reynolds’ Number”, Science Direct. 2019. Available online: https://www.sciencedirect.com/topics/engineering/reynolds-number (accessed on 1 June 2020).

- Baecque, M.D.; Chevalier, C.; Lopes, S.P.; Feuvre, M.L.; Reiffsteck, P.; Charles, I.; Herrier, G. Resistance to erosion of lime treated soils and perspectives for coastal dikes. In Proceedings of the 25th Meeting of the European Working Group on Internal Erosion, Delft, The Netherlands, 4–7 September 2017; pp. 133–142. [Google Scholar]

- Bonelli, S.; Benahmed, N. Piping flow erosion in water retaining structures. Int. J. Hydropower Dams 2011, 18, 94–98. [Google Scholar]

| Property | Soil A | Soil B |

|---|---|---|

| Specific Gravity, Gs of soil | 2.60 | 2.67 |

| Amount of Clay (%) | 0.00 | 4.00 |

| Amount of Silt (%) | 0.60 | 8.00 |

| Amount of Sand (%) | 99.40 | 88.00 |

| Coefficient of Uniformity, Cu | 1.60 | 11.05 |

| Coefficient of Curvature, Cc | 0.90 | 2.26 |

| Optimum Moisture (or Water) Content, ωop (%) | 11.95 | 13.00 |

| Maximum Dry Density, dmax (kg/m3) | 1690.00 | 1908.00 |

| Classification | Poorly Graded | Well Graded |

| Group Number | Erosion Rate | Description |

|---|---|---|

| 1 | Less than 2 | Extremely Rapid Erosion |

| 2 | 2 to 3 | Very Rapid Erosion |

| 3 | 3 to 4 | Moderately Rapid Erosion |

| 4 | 4 to 5 | Moderately Slow Erosion |

| 5 | 5 to 6 | Very Slow Erosion |

| 6 | Greater than 6 | Extremely Slow Erosion |

| Lime Percentage | Erosion Parameters | Soil A | Soil B |

|---|---|---|---|

| 0.0% | Final Hole Diameter, φf (mm) | - | 15 |

| Critical Shear Stress, τc (N/m2) | - | 100.5 | |

| Erosion Rate Index, IHET | - | 3.69 | |

| Soil Erosion Type | Failed Instantly | Moderately Rapid | |

| 1.0% | Final Hole Diameter, φf (mm) | 33 | 8.2 |

| Critical Shear Stress, τc (N/m2) | 85 | 105 | |

| Erosion Rate Index, IHET | 3.69 | 4.69 | |

| Soil Erosion Type | Moderately Rapid | Moderately Slow | |

| 2.0% | Final Hole Diameter, φf (mm) | 21.5 | 8 |

| Critical Shear Stress, τc (N/m2) | 85 | 133.33 | |

| Erosion Rate Index, IHET | 4 | 5.22 | |

| Soil Erosion Type | Moderately Slow | Very Slow | |

| 3.0% | Final Hole Diameter, φf (mm) | 19 | 8 |

| Critical Shear Stress, τc (N/m2) | 97 | 140 | |

| Erosion Rate Index, IHET | 4 | 5.301 | |

| Soil Erosion Type | Moderately Slow | Very Slow | |

| 4.0% | Final Hole Diameter, φf (mm) | 12.5 | - |

| Critical Shear Stress, τc (N/m2) | 100 | - | |

| Erosion Rate Index, IHET | 4.22 | - | |

| Soil Erosion Type | Moderately Slow | - | |

| 5.0% | Final Hole Diameter, φf (mm) | 10.5 | - |

| Critical Shear Stress, τc (N/m2) | 115 | - | |

| Erosion Rate Index, IHET | 4.69 | - | |

| Soil Erosion Type | Moderately Slow | - | |

| 6.0% | Final Hole Diameter, φf (mm) | 10.3 | - |

| Critical Shear Stress, τc (N/m2) | 115 | - | |

| Erosion Rate Index, IHET | 4.69 | - | |

| Soil Erosion Type | Moderately Slow | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banu, S.; Attom, M. Internal Erosion Stabilization of Cohesionless Soil Using Lime. Water 2023, 15, 1992. https://doi.org/10.3390/w15111992

Banu S, Attom M. Internal Erosion Stabilization of Cohesionless Soil Using Lime. Water. 2023; 15(11):1992. https://doi.org/10.3390/w15111992

Chicago/Turabian StyleBanu, Shaziya, and Mousa Attom. 2023. "Internal Erosion Stabilization of Cohesionless Soil Using Lime" Water 15, no. 11: 1992. https://doi.org/10.3390/w15111992