Comprehensive Evaluation Method for the Safety State of RCC Dams Based on Interval Number Theory

Abstract

1. Introduction

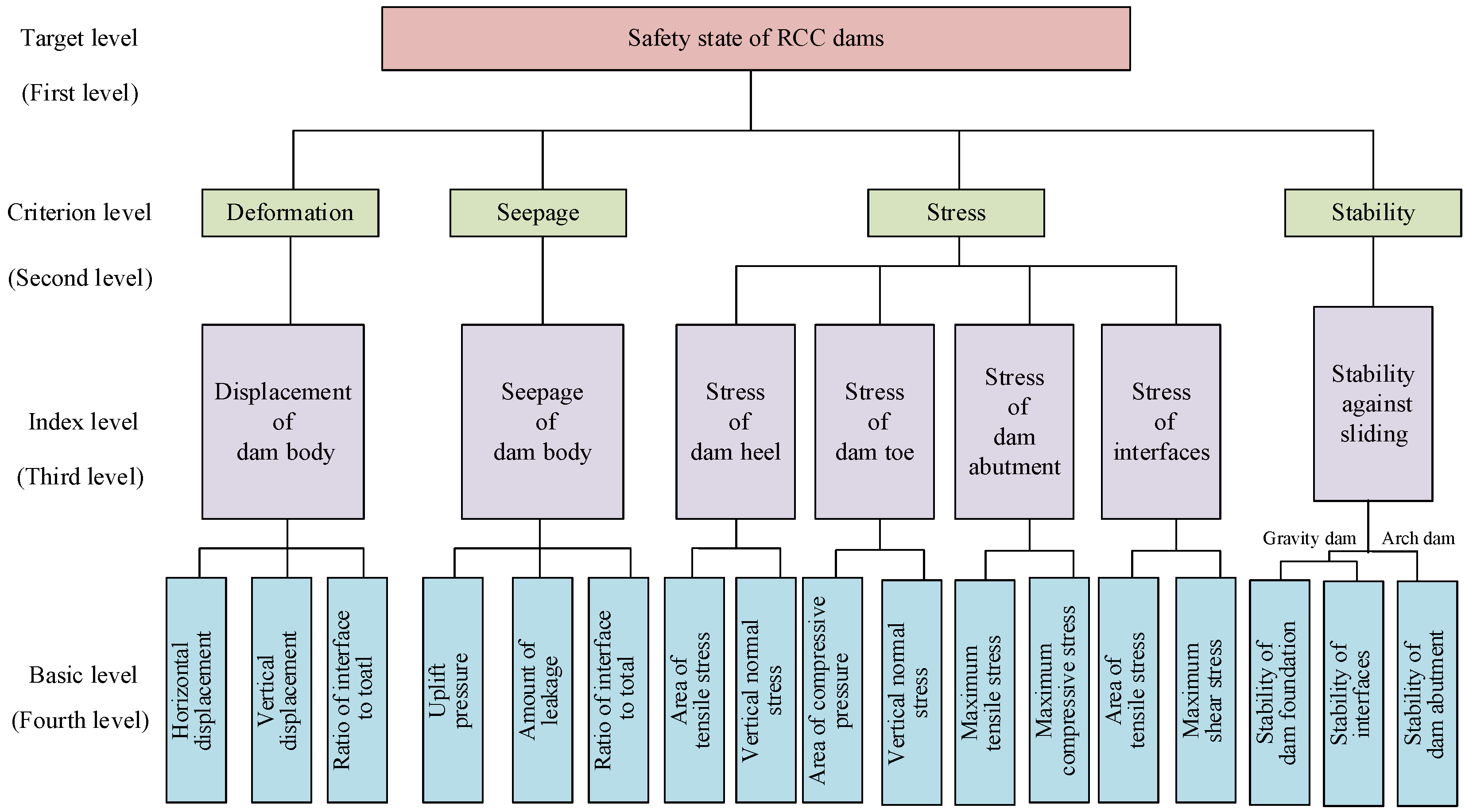

2. Comprehensive Evaluation Indicators

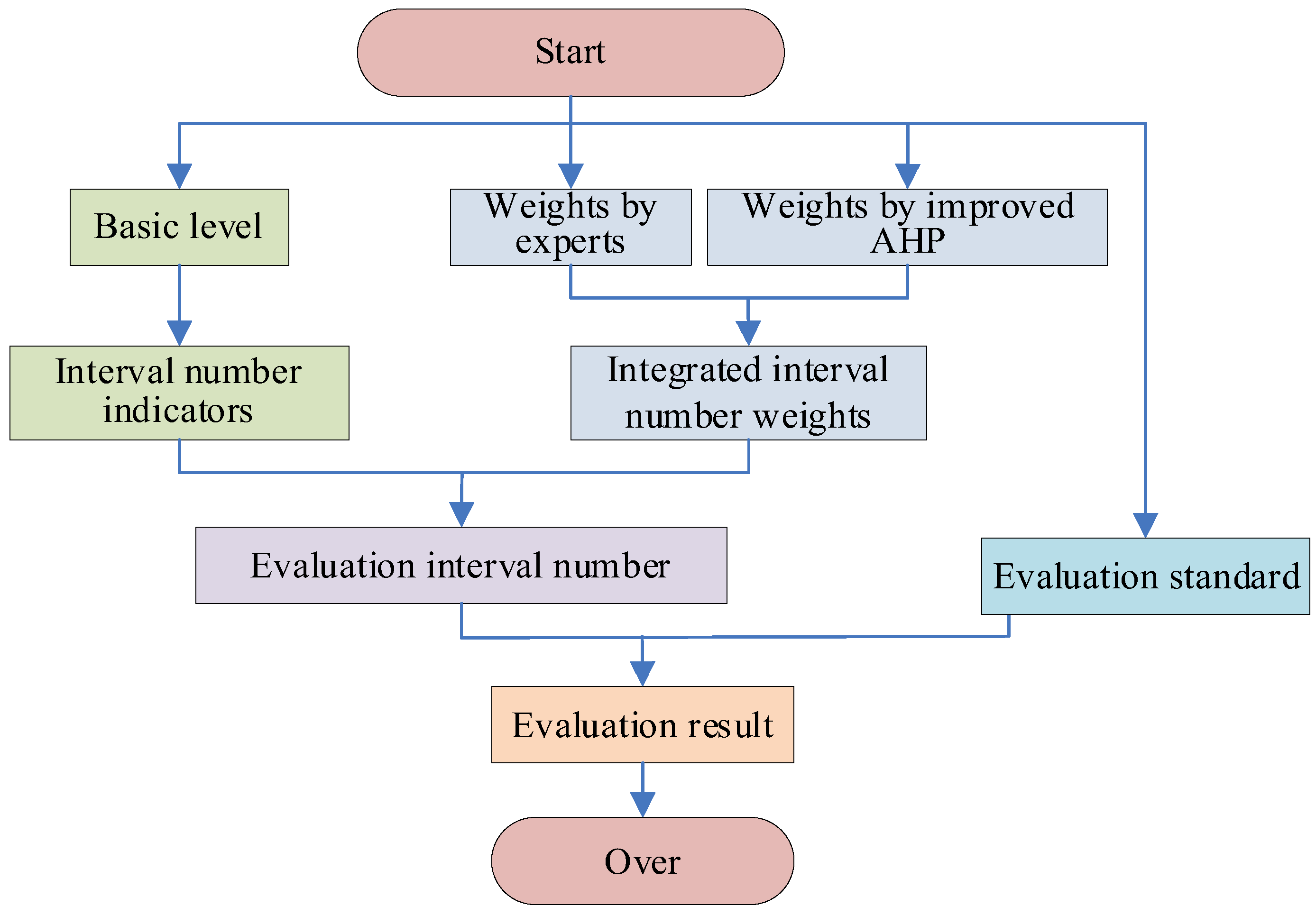

2.1. Comprehensive Evaluation Indicator System

2.2. Grades of Evaluation Indicators

2.2.1. Grades of Qualitative Evaluation Indicators

2.2.2. Grading Standards for Quantitative Evaluation Indicators

2.3. Interval Number Expressions of Evaluation Indicators

2.3.1. Interval Number Expressions of Qualitative Evaluation Indicators

2.3.2. Interval Number Expressions of Quantitative Evaluation Indicators

- (1)

- Interval number expressions of the deformation indicators

- (2)

- Interval number expressions of the seepage indicators

- (3)

- Interval number expressions of the stress indicators

- (4)

- Interval number expression of the stability indicators

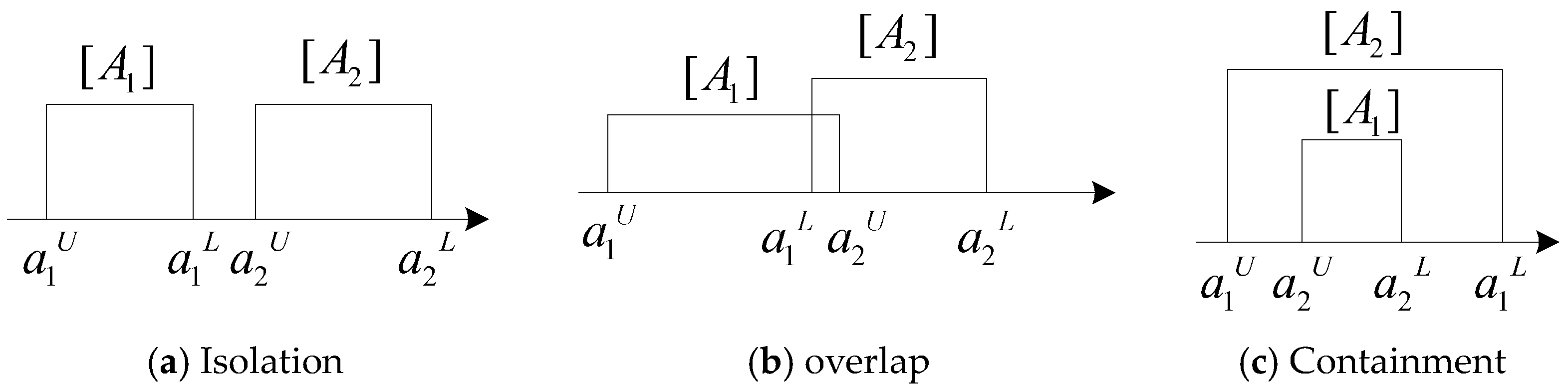

2.4. Normalization Method of the Interval Number Indicators

3. Interval Number Weights of the Comprehensive Evaluation Indicators

3.1. Interval Number Weights Obtained by Expert Evaluation

3.2. Interval Number Weights Obtained by the Improved Analytical Hierarchy Process

3.3. Integrated Interval Number Weights Obtained by Combined Methods

4. Comprehensive Evaluation Models with Interval Number Indicators and Weights

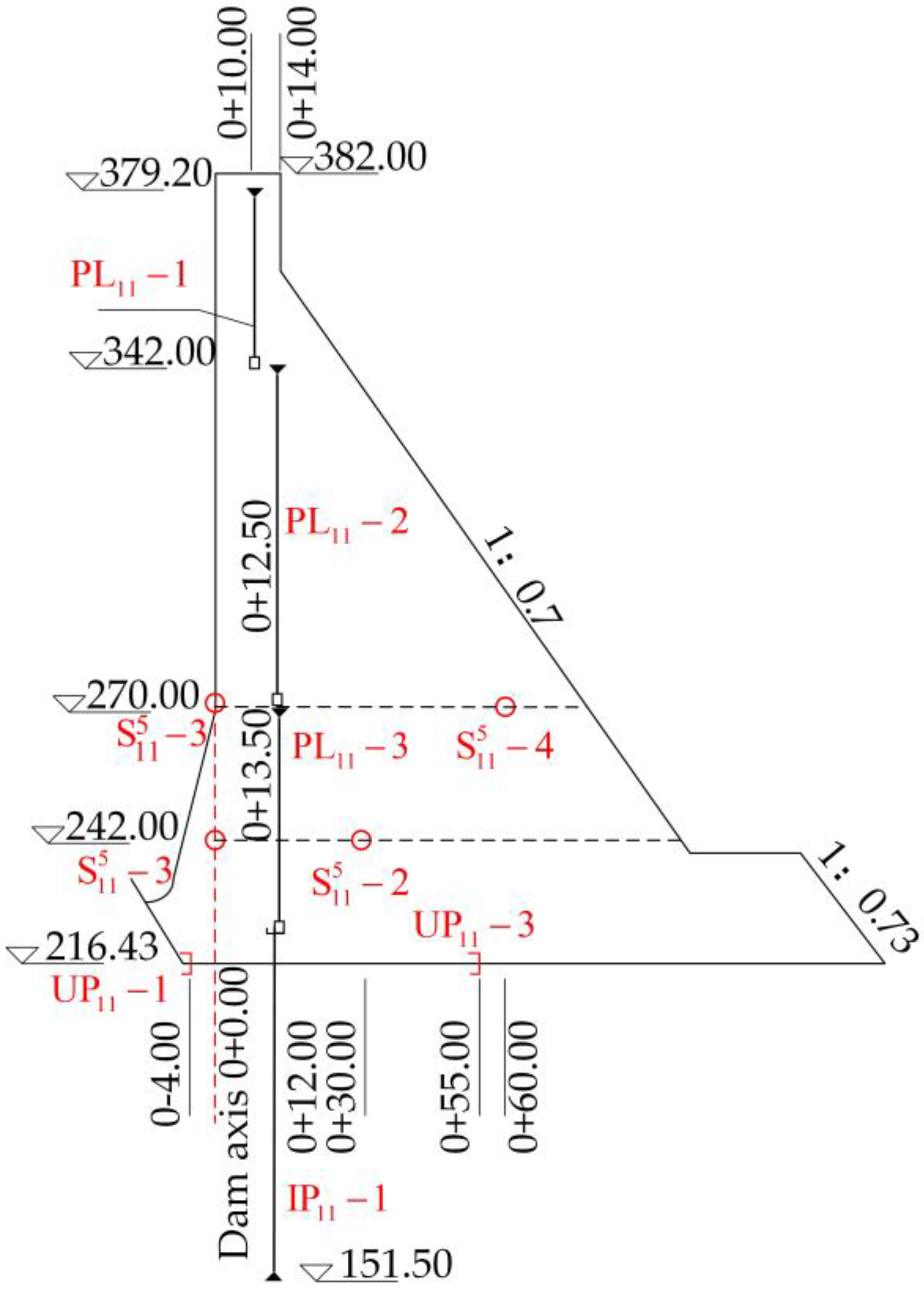

5. Case Study

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raphael, J.M. The Optimum Gravity Dam, Rapid Construction of Concrete Dams; American Society of Civil Engineers: New York, NY, USA, 1970. [Google Scholar]

- Wang, T.; Chen, J.S.; Wang, T.; Wang, S. Entropy weight-set pair analysis based on tracer techniques for dam leakage investigation. Nat. Hazards 2015, 76, 747–767. [Google Scholar] [CrossRef]

- Chelidze, T.; Matcharashvili, T.; Abashidze, V.; Kalabegishvili, M.; Zhukova, N. Real time monitoring for analysis of dam stability: Potential of nonlinear elasticity and nonlinear dynamics approaches. Front. Struct. Civ. Eng. 2013, 7, 188–205. [Google Scholar] [CrossRef]

- Li, Z.; Gu, C.; Wang, Z.; Wu, Z. On-line diagnosis method of crack behavior abnormality in concrete dams based on fluctuation of sequential parameter estimates. Sci. China Technol. Sci. 2015, 58, 415–424. [Google Scholar] [CrossRef]

- Haralampos, G.; Christos, O. Determination of factors affecting compressive strength of lean RCC mixtures: The experience of Filiatrinos Dam. Geotech. Geol. Eng. 2014, 32, 1317–1327. [Google Scholar]

- Chen, H.Q. Seismic safety of high concrete dams. Earthq. Eng. Eng. Vib. 2014, 13, 1–16. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Z.; Liu, Y.; Yang, S. Evaluation Standard for Safety Coefficient of Roller Compacted Concrete Dam Based on Finite Element Method. Math. Probl. Eng. 2014, 2014, 601418. [Google Scholar] [CrossRef]

- Xi, W.; Yang, J.; Song, J.; Qu, X. Deep learning model of concrete dam deformation prediction based on CNN. IOP Conf. Ser. Earth Environ. Sci. 2020, 580, 012042. [Google Scholar] [CrossRef]

- Chen, S.; Gu, C.; Lin, C.; Zhao, E.; Song, J. Safety monitoring model of a Super-high concrete dam by using RBF neural network coupled with kernel principal component analysis. Math. Probl. Eng. 2018, 2018, 1712653. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Lv, P.; Wang, C.; Zhang, J.; Yu, J. Seepage safety assessment of concrete gravity dam based on matter-element extension model and FDA. Energies 2019, 12, 502. [Google Scholar] [CrossRef]

- He, Y.; Zhao, M.; Wang, K.; Liu, P. Fuzzy comprehensive evaluation of earth rockfill dam seepage security risk based on cloud model. Water Resour. Power 2018, 36, 83–86. [Google Scholar]

- Yang, C.; Yang, J.; Li, Y.; Han, L.; Chen, S. 3D laser scanning point cloud analysis method for dam deformation monitoring. Bull. Surv. Mapp. 2021, 10, 54–59. [Google Scholar]

- Panvalkar, G.A.; Chunade, A.D. Tracing dam seepage using nuclear logging and tracer techniques—A case study. ISH J. Hydraul. Eng. 2018, 24, 311–316. [Google Scholar] [CrossRef]

- Mirzabozorg, H.; Hariri-Ardebili, M.; Heshmati, M.; Seyed-Kolbadi, S. Structural safety evaluation of Karun III Dam and calibration of its finite element model using instrumentation and site observation. Case Stud. Struct. Eng. 2014, 1, 6–12. [Google Scholar] [CrossRef]

- Mata, J.; Leitão, N.S.; de Castro, A.T.; da Costa, J.S. Construction of decision rules for early detection of a developing concrete arch dam failure scenario, a discriminant approach. Comput. Struct. 2014, 142, 45–53. [Google Scholar] [CrossRef]

- Lokke, A.; Chopra, A.K. Response spectrum analysis of concrete gravity dams including dam-water-foundation interaction. J. Struct. Eng. 2015, 141, 1–9. [Google Scholar] [CrossRef]

- Chiganne, F.; Marche, C.; Mahdi, T.F. Evaluation of the overflow failure scenario and hydrograph of an embankment dam with a concrete upstream slope protection. Nat. Hazards 2014, 71, 21–39. [Google Scholar] [CrossRef]

- Bretas, E.M.; Lemos, J.V.; Lourenco, P.B. A DEM based tool for the safety analysis of masonry gravity dams. Eng. Struct. 2014, 59, 248–260. [Google Scholar] [CrossRef]

- Li, H.; Ouyang, J.; Li, F.; Xie, X. Study on safety evaluation model of small and medium-sized earth-rock dam based on BP-AdaBoost algorithm. IOP Conf. Ser. Mater. Sci. Eng. 2019, 490, 032024. [Google Scholar] [CrossRef]

- Han, L.; Liu, M.; Zhang, H.; Yao, L.; Ge, W. Safety assessment model of Earth-rock dam based on ideal point-cloud theory. J. Eng. Sci. Technol. Rev. 2019, 12, 38–50. [Google Scholar]

- Wen, L.; Yang, Y.; Li, Y.; Liu, Y.; Zhou, H. Comprehensive evaluation method for the concrete-face rockfill dams behavior based on the fuzzy recognition model. J. Perform. Constr. Facil. 2022, 36, 04022021. [Google Scholar] [CrossRef]

- Shu, X.; Bao, T.; Li, Y.; Zhang, K.; Wu, B. Dam Safety Evaluation Based on Interval-Valued Intuitionistic Fuzzy Sets and Evidence Theory. Sensors 2020, 20, 2648. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Si, W.; Ren, Q.; Song, L.; Liu, H. An integrated method for evaluating and predicting long-term operation safety of concrete dams considering lag effect. Eng. Comput. 2020, 37, 2505–2519. [Google Scholar] [CrossRef]

- Sang, L.; Wang, J.; Sui, J.; Dziedzic, M. A new approach for dam safety assessment using the extended cloud model. Water Resour. Manag. 2022, 36, 5785–5798. [Google Scholar] [CrossRef]

- Su, H.; Hu, J.; Yang, M.; Wen, Z. Assessment and prediction for service life of water resources and hydropower engineering. Nat. Hazards 2015, 75, 3005–3019. [Google Scholar] [CrossRef]

- Zheng, G.; Jing, Y.; Huang, H.; Zhang, X.; Gao, Y. Application of life cycle assessment (LCA) and extenics theory for building energy conservation assessment. Energy 2009, 34, 1870–1879. [Google Scholar] [CrossRef]

- Pawlak, Z. Rough Sets: Theoretical Aspects of Reasoning about Data; Springer Science & Business Media: Dordrecht, The Netherland, 1991. [Google Scholar]

- Greco, S.; Matarazzo, B.; Slowinski, R. Rough sets theory for multicriteria decision analysis. Eur. J. Oper. Res. 2001, 129, 1–47. [Google Scholar] [CrossRef]

- Deng, J.L. Courses of Grey System Theory; Huazhong University of Science and Technology Press: Wuhan, China, 1990. [Google Scholar]

- Harris, J. Fuzzy Logic Applications in Engineering Science; Springer Science & Business Media: Dordrecht, The Netherland, 2005. [Google Scholar]

- Miller, R.L.; Brickman, P.; Bolen, D. Attribution versus persuasion as a means for modifying behavior. J. Personal. Soc. Psychol. 1975, 31, 430–470. [Google Scholar] [CrossRef]

- Zhao, K.Q. Set pair analysis and its preliminary application. Explor. Nat. 1994, 13, 67–72. [Google Scholar]

- Sevastianov, P. Numerical methods for interval and fuzzy number comparison based on the probabilistic approach and dempster-shafer theory. Inf. Sci. 2007, 177, 4645–4661. [Google Scholar] [CrossRef]

- Chen, L. Gradual Change Characteristics and Safety Monitoring Models of RCC Dams. Ph.D. Dissertation, University of Hohai, Nanjing, China, 2006. [Google Scholar]

- Li, B. Gradual Change Laws of Mechanical Parameters and Comprehensive Analysis Methods of Interfaces for RCC Dams. Ph.D. Dissertation, University of Hohai, Nanjing, China, 2010. [Google Scholar]

- Yu, X.H.; Xu, Z.S.; Chen, Q. A method based on preference degrees for handling hybrid multiple attribute decision making problems. Expert Syst. Appl. 2011, 38, 3147–3154. [Google Scholar] [CrossRef]

| Grade | Site Management | Design Recheck | Construction Review |

|---|---|---|---|

| I | Structural integrity with no obvious damage and leakage | Strength and seepage meet the regulation requirement | Construction quality meets the design requirement fully |

| II | Local damage with a few cracks or little leakage | Strength and seepage mainly meet the regulation requirement | Construction quality mainly meets the design requirement |

| III | Obvious cracks or a few educts with hidden damage | Some strength and seepage do not meet the regulation requirement, but the stability is good | Some construction quality does not meet the design requirements |

| IV | Local deep cracks, serious leakage, obvious educts | Some strengths and seepage severely do not meet the regulation requirement, and no measures are taken | Construction quality cannot meet the design requirement |

| V | Large area with cracks, increased leakage | Extreme flood or earthquake, stability fails | _ |

| Grade | I | II | III | IV | V |

|---|---|---|---|---|---|

| Interval number |

| Indicator | 1 | 2 | ||

|---|---|---|---|---|

| Expert 1 | ||||

| Expert 2 | ||||

| Expert | ||||

| Expert group |

| Scale | 1 | 3 | 5 | 7 | 9 | 2, 4, 6, 8 |

|---|---|---|---|---|---|---|

| Description degree | equally | slightly | obviously | seriously | extremely | in between |

| Safety State | Normal | Almost Normal | Mildly Abnormal | Abnormal | Dangerous |

|---|---|---|---|---|---|

| Grade | Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ |

| Standard |

| Item | Deformation | Seepage | Stress | Stability | |||

|---|---|---|---|---|---|---|---|

| Basic level | |||||||

| Interval number | |||||||

| Grade | I | I | I | II | I | III~I | III~I |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Xu, P.; Liu, X.; Su, C. Comprehensive Evaluation Method for the Safety State of RCC Dams Based on Interval Number Theory. Water 2023, 15, 2089. https://doi.org/10.3390/w15112089

Chen X, Xu P, Liu X, Su C. Comprehensive Evaluation Method for the Safety State of RCC Dams Based on Interval Number Theory. Water. 2023; 15(11):2089. https://doi.org/10.3390/w15112089

Chicago/Turabian StyleChen, Xudong, Peng Xu, Xinyi Liu, and Chen Su. 2023. "Comprehensive Evaluation Method for the Safety State of RCC Dams Based on Interval Number Theory" Water 15, no. 11: 2089. https://doi.org/10.3390/w15112089

APA StyleChen, X., Xu, P., Liu, X., & Su, C. (2023). Comprehensive Evaluation Method for the Safety State of RCC Dams Based on Interval Number Theory. Water, 15(11), 2089. https://doi.org/10.3390/w15112089