Fixed-Bed Studies of Landfill Leachate Treatment Using Chitosan-Coated Carbon Composite

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

2.2. Characterization of the Composite

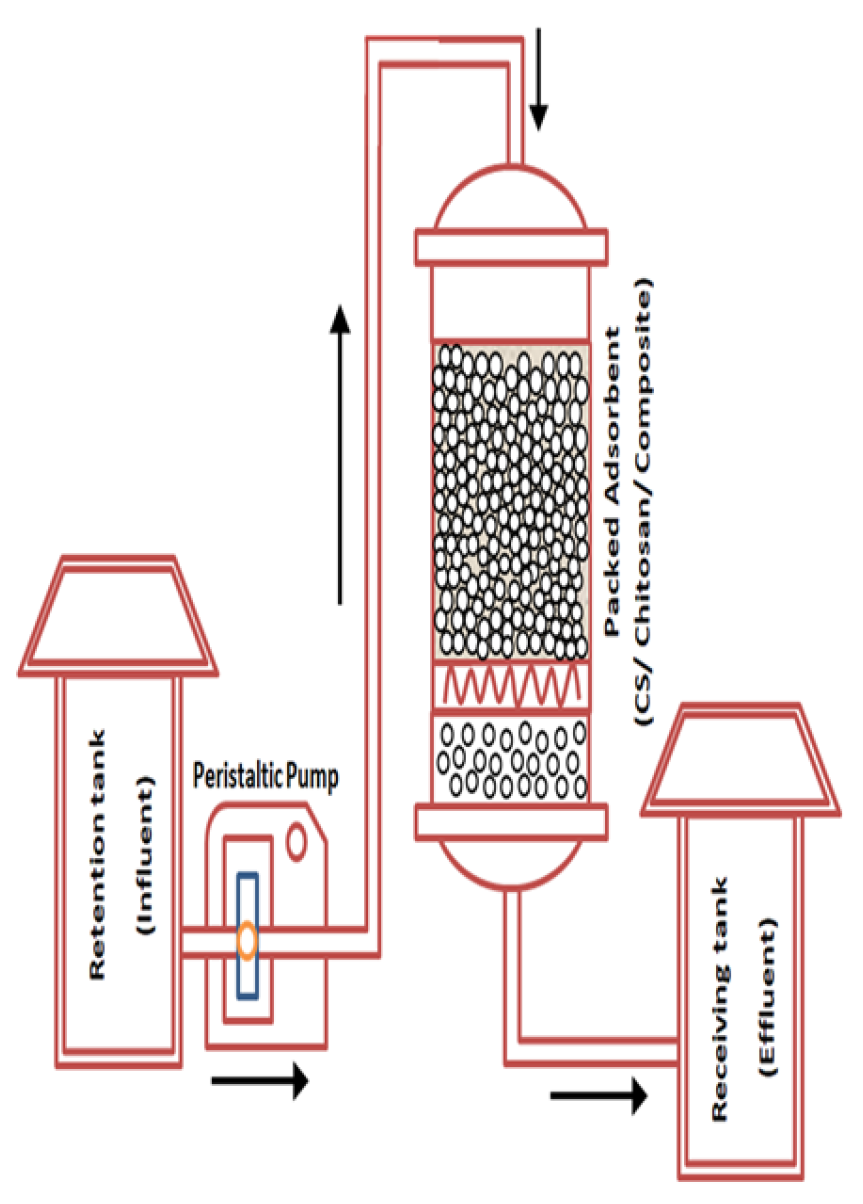

2.3. Fixed-Bed Studies

2.4. Regeneration Tests

2.5. Statistical Analysis

3. Results and Discussion

3.1. Properties of Leachate Samples

3.2. Characterization of the Composite

3.3. Fixed-Bed Studies

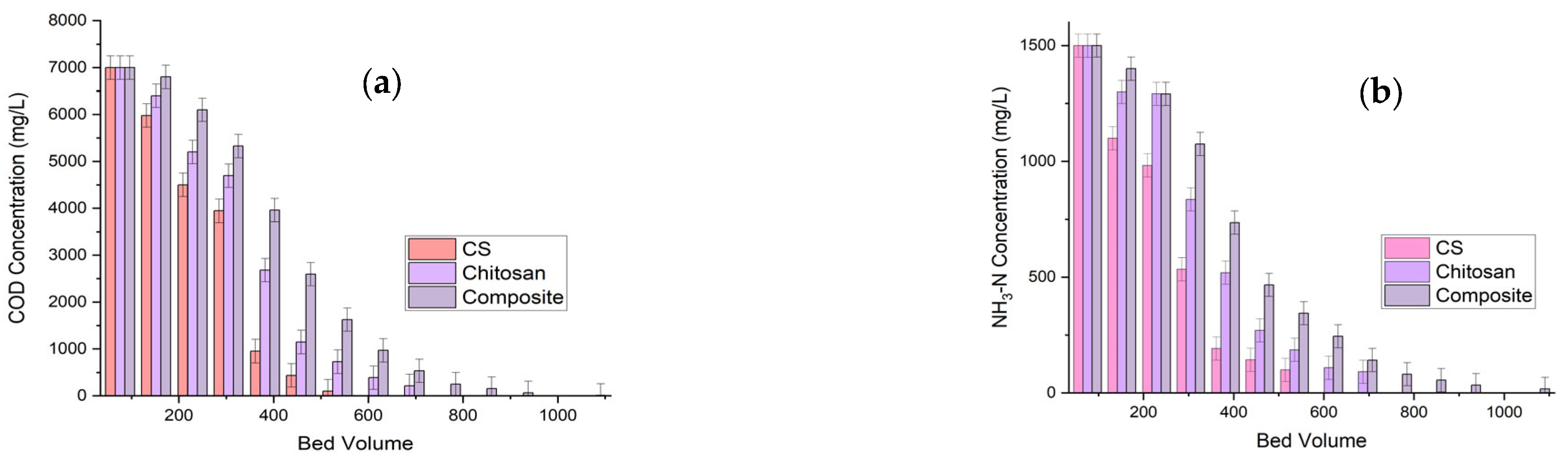

3.3.1. Breakthrough

3.3.2. Effects of Flow Rate

3.3.3. Effects of Bed Depth

3.4. Regeneration

3.5. Thomas Model

4. Comparison of This Work with Other Studies

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mengting, Z.; Kurniawan, T.A.; Duan, L.; Song, Y.; Hermanowicz, S.W.; Othman, M.H.D. Advances in BiOX-based ternary photocatalysts for water technology and energy storage applications: Research trends, challenges, solutions, and ways forward. Rev. Environ. Sci. Bio/Technol. 2022, 21, 331–370. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Sillanpää, M.E.T.; Sillanpää, M. Nanoadsorbents for remediation of aquatic environment: Local and practical solutions for global water pollution problems. Crit. Rev. Environ. Sci. Technol. 2012, 42, 1233–1295. [Google Scholar] [CrossRef]

- Liang, X.; Kurniawan, T.A.; Goh, H.H.; Zhang, D.; Dai, W.; Liu, H.; Goh, K.C.; Othman, M.H.D. Conversion of landfilled waste-to-electricity (WTE) for energy efficiency improvement in Shenzhen (China): A strategy to contribute to resource recovery of unused methane for generating renewable energy on-site. J. Clean. Prod. 2022, 369, 133078. [Google Scholar] [CrossRef]

- Liang, X.; Goh, H.H.; Kurniawan, T.A.; Zhang, D.; Dai, W.; Liu, H.; Liu, J.; Goh, K.C. Utilizing landfill gas (LFG) to electrify digital data centers in China for accelerating energy transition in Industry 4.0 era. J. Clean. Prod. 2022, 369, 133297. [Google Scholar] [CrossRef]

- Sniatala, B.; Kurniawan, T.A.; Sobotka, D.; Makinia, J.; Othman, M.H.D. Macro-nutrients recovery from liquid waste as a sustainable resource for production of recovered mineral fertilizer: Uncovering alternative options to sustain global food security cost-effectively. Sci. Total Environ. 2023, 856, 159283. [Google Scholar] [CrossRef] [PubMed]

- Maiurova, A.; Kurniawan, T.A.; Kustikova, M.; Bykovskaia, E.; Othman, M.H.D.; Singh, D.; Goh, H.H. Promoting digital transformation in waste collection service and waste recycling in Moscow (Russia): Applying a circular economy paradigm to mitigate climate change impacts on the environment. J. Clean. Prod. 2022, 354, 131604. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Liang, X.; O’callaghan, E.; Goh, H.; Othman, M.H.D.; Avtar, R.; Kusworo, T.D. Transformation of solid waste management in China: Moving towards sustainability through digitalization-based circular economy. Sustainability 2022, 14, 2374. [Google Scholar] [CrossRef]

- Fu, D.; Kurniawan, T.A.; Lin, L.; Li, Y.; Avtar, R.; Othman, M.H.D. Arsenic removal from aqueous solution by FeS2. J. Environ. Manag. 2021, 286, 112246. [Google Scholar] [CrossRef]

- Babel, S.; Kurniawan, T.A. Low-cost adsorbents for heavy metals uptake from contaminated water: A review. J. Hazard. Mater. 2003, 97, 219–243. [Google Scholar] [CrossRef]

- Babel, S.; Kurniawan, T.A. A Research Study on Cr(VI) removal from contaminated wastewater using natural zeolite. J. Ion Exch. 2003, 14, 289–292. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Avtar, R.; Singh, D.; Xue, W.; Dzarfan Othman, M.H.; Hwang, G.H.; Iswanto, I.; Albadarin, A.B.; Kern, A.O. Reforming MSWM in Sukunan (Yogjakarta, Indonesia): A case-study of applying a zero-waste approach based on circular economy paradigm. J. Clean. Prod. 2021, 284, 124775. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, T.A.; Chan, G.Y.S.; Lo, W.-H.; Babel, S. Physico-chemical treatment techniques for wastewater laden with heavy metals. Chem. Eng. J. 2006, 118, 83–98. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Chan, G.Y.S.; Lo, W.-H.; Babel, S. Comparisons of low-cost adsorbents for treating wastewaters laden with heavy metals. Sci. Total Environ. 2006, 366, 409–426. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, T.A.; Lo, W.-H.; Chan, G.Y.S. Physico-chemical treatments for removal of recalcitrant contaminants from landfill leachate. J. Hazard. Mater. 2006, 129, 80–100. [Google Scholar] [CrossRef]

- Dun, F.; Kurniawan, T.A.; Gui, H.; Li, H.; Feng, S.; Li, Q.; Wang, Y. Role of CuxO-anchored pyrolyzed hydrochars on H2O2-activated degradation of tetracycline: Effects of pyrolysis temperature and pH. Ind. Eng. Chem. Res. 2022, 61, 8847–8857. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Singh, D.; Avtar, R.; Dzarfan Othman, M.H.; Hwang, G.H.; Albadarin, A.B.; Rezakazemi, M.; Setiadi, T.; Shirazian, S. Resource recovery from landfill leachate: An experimental investigation and perspectives. Chemosphere 2021, 274, 129986. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Liang, X.; Singh, D.; Othman, M.H.D.; Goh, H.H.; Gikas, P.; Kern, A.O.; Kusworo, T.D.; Shoqeir, J.A. Harnessing landfill gas (LFG) for electricity: A strategy to mitigate greenhouse gas emissions in Jakarta (Indonesia). J. Environ. Manag. 2022, 301, 113882. [Google Scholar] [CrossRef]

- Fu, D.; Kurniawan, T.A.; Gui, H.; Feng, S.; Li, Q.; Othman, M.H.D. Treatment of As(III)-contaminated water using iron-coated carbon fiber. Maters 2022, 15, 4365. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Singh, D.; Avtar, R.; Goh, H.H.; Setiadi, T.; Lo, W.-H. Technological solutions for long-term management of partially used nuclear fuel: A review. Ann. Nucl. Energy 2022, 166, 108736. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Hwang, G.H.; Gikas, P. Unlocking digital technology in waste recycling industry in Industry 4.0 era: A transformation towards digitalization-based circular economy in Indonesia. J. Clean. Prod. 2022, 357, 131911. [Google Scholar] [CrossRef]

- Huuha, T.S.; Kurniawan, T.A.; Sillanpää, M.E.T. Removal of silicon from pulping whitewater using integrated treatment of chemical precipitation and evaporation. Chem. Eng. J. 2010, 158, 584–592. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Adam, M.R.; Goh, H.H.; Mohyudin, A.; Avtar, R.; Kusworo, T.D. Treatment of whitewater from pulp and paper industry using membrane filtrations. Chem. Papers 2022, 76, 5001–5010. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Maiurova, A.; Kustikova, M.; Bykovskaia, E.; Othman, M.H.D.; Goh, H.H. Accelerating sustainability transition in St. Petersburg (Russia) through digitalization-based circular economy in waste recycling industry: A strategy to promote carbon neutrality in era of Industry 4.0. J. Clean. Prod. 2022, 363, 132452. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Singh, D.; Xue, W.; Avtar, R.; Othman, M.H.D.; Hwang, G.H.; Setiadi, T.; Albadarin, A.B.; Shirazian, S. Resource recovery toward sustainability through nutrient removal from landfill leachate. J. Environ. Manag. 2021, 287, 112265. [Google Scholar] [CrossRef]

- Premakumara, D.G.J.; Canete, A.M.L.; Nagaishi, M.; Kurniawan, T.A. Policy implementation of the Republic Act (RA) No. 9003 in the Philippines: A case study of Cebu City. Waste Manag. 2014, 34, 971–979. [Google Scholar] [CrossRef]

- Ulfat, W.; Mohyuddin, A.; Amjad, M.; Kurniawan, T.A.; Mujahid, B.; Nadeem, S.; Javed, M.; Amjad, A.; Ashraf, A.Q.; Othman, M.H.D.; et al. Reuse of buffing dust-laden tanning waste hybridized with polystyrene for fabrication of thermal insulation materials. Sustainability 2023, 15, 1958. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Lo, W.; Chan, G.; Sillanpää, M.E.T. Biological processes for treatment of landfill leachate. J. Environ. Monit. 2010, 12, 2032–2047. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Liang, X.; Ayub, M.; Goh, H.H.; Kusworo, T.D.; Mohyuddin, A.; Chew, K.W. Microbial fuel cells: A potential game changer in renewable energy development. Sustainability 2022, 14, 16847. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Liang, X.; Goh, H.H.; Chew, K.W. From liquid waste to mineral fertilizer: Recovery, recycle and reuse of high-value macro-nutrients from landfill leachate to contribute to circular economy, food security, and carbon neutrality. Process Saf. Environ. Prot. 2023, 170, 791–807. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Meidiana, C.; Othman, M.H.D.; Goh, H.H.; Chew, K.W. Strengthening waste recycling industry in Malang (Indonesia): Lessons from waste management in the era of Industry 4. 0. J. Clean. Prod. 2023, 382, 135296. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Lo, W.; Liang, X.; Goh, H.H.; Othman, M.H.D.; Chong, K.-K.; Chew, K.W. Remediation technologies for contaminated groundwater due to arsenic (As), mercury (Hg), and/or fluoride (F): A critical review and ways forward to contribute to carbon neutrality. Sep. Purif. Technol. 2023, 314, 123474. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Lo, W.H.; Liang, X.; Goh, H.H.; Othman, M.H.D.; Chong, K.K.; Mohyuddin, A.; Kern, A.O.; Chew, K.W. Heavy Metal Removal from Aqueous Solutions Using Biomaterials and/or Functional Composites: Recent Advances and the Way Forward in Wastewater Treatment Using Digitalization. J. Compos. Sci. 2023, 7, 84. [Google Scholar] [CrossRef]

- Lo, H.M.; Liu, M.H.; Pai, T.Y.; Liu, W.H.; Lin, C.Y.; Wang, S.C.; Banks, C.J.; Hung, C.H.; Chiang, C.F.; Lin, K.C.; et al. Biostabilization assessment of MSW co-disposed with MSWI fly ash in anaerobic bioreactors. J. Hazard. Mater. 2009, 162, 1233–1242. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Liang, X.; Goh, H.H.; Gikas, P.; Chong, K.-K.; Chew, K.W. Challenges and opportunities for biochar management to promote circular economy and carbon neutrality. J. Environ. Manag. 2023, 332, 117429. [Google Scholar] [CrossRef]

- Lo, H.M.; Chiang, C.; Tsao, H.; Pai, T.; Liu, M.; Kurniawan, T.; Chao, K.; Liou, C.; Lin, K.; Chang, C.; et al. Effects of spiked metals on MSW anaerobic digestion. Waste Manag. Res. 2012, 30, 32–48. [Google Scholar] [CrossRef] [PubMed]

- Al-Daghistani, H.I.; Mohammad, B.T.; Kurniawan, T.A.; Singh, D.; Rabadi, A.D.; Xue, W.; Avtar, R.; Othman, M.H.D.; Shirazian, S. Characterization and applications of Thermomonas hydrothermalis isolated from Jordan’s hot springs for biotechnological and medical purposes. Process Biochem. 2021, 104, 171–181. [Google Scholar] [CrossRef]

- Mohyuddin, A.; Kurniawan, T.A.; Khan, Z.-U.; Nadeem, S.; Javed, M.; Dera, A.A.; Iqbal, S.; Awwad, N.S.; Ibrahium, H.A.; Abourehab, M.A.S.; et al. Comparative insights into the antimicrobial, antioxidant, and nutritional potential of the Solanum Nigrum complex. Processes 2022, 10, 1455. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Haider, A.; Ahmad, H.M.; Mohyuddin, A.; Aslam, H.M.U.; Nadeem, S.; Javed, M.; Othman, M.H.D.; Goh, H.H.; Chew, K.W. Source, occurrence, distribution, fate, and implications of microplastic pollutants in freshwater on environment: A critical review and way forward. Chemosphere 2023, 325, 138367. [Google Scholar] [CrossRef]

- Kurniawan, T.A. Removal of Toxic Chromium from Wastewater; Nova Science Publisher: New York, NY, USA, 2012; ISBN 978-1-60876-340-5. [Google Scholar]

- Fu, D.; Kurniawan, T.A.; Li, H.; Wang, H.; Wang, Y.; Li, Q. Co-oxidative removal of arsenite and tetracycline based on a heterogeneous Fenton-like reaction using iron nanoparticles-impregnated biochar. Environ. Pollut. 2021, 290, 118062. [Google Scholar] [CrossRef]

- Fu, D.; Kurniawan, T.A.; Avtar, R.; Xu, P.; Othman, M.H.D. Recovering heavy metals from electroplating wastewater and their conversion into Zn2Cr-layered double hydroxide (LDH) for pyrophosphate removal from industrial wastewater. Chemosphere 2021, 271, 129861. [Google Scholar] [CrossRef]

- Babel, S.; Kurniawan, T.A. Cr(VI) removal from synthetic wastewater using coconut shell charcoal and commercial activated carbon modified with oxidizing agents and/or chitosan. Chemosphere 2004, 54, 951–967. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, T.A.; Lo, W.; Othman, M.H.D.; Liang, X.; Goh, H.H.; Chew, K.W. Influence of Fe2O3 and bacterial biofilms on Cu(II) distribution in a simulated aqueous solution: A feasibility study to sediments in the Pearl River Estuary (PR China). J. Environ. Manag. 2023, 329, 117047. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Lo, W.; Othman, M.H.D.; Goh, H.H.; Chong, K.-K. Biosorption of heavy metals from aqueous solutions using activated sludge, Aeromasss hydrophyla, and Branhamella spp based on modeling with GEOCHEM. Environ. Res. 2022, 214, 114070. [Google Scholar] [CrossRef]

- Song, S.; Song, H.; Li, L.; Wang, S.; Chu, W.; Peng, K.; Meng, X.; Wang, Q.; Deng, B.; Liu, Q.; et al. A selective Au-ZnO/TiO2 hybrid photocatalyst for oxidative coupling of methane to ethane with dioxygen. Nat. Catal. 2021, 4, 1032–1042. [Google Scholar] [CrossRef]

- Chan, G.Y.; Chang, J.; Kurniawan, T.A.; Fu, C.-X.; Jiang, H.; Je, Y. Removal of non-biodegradable compounds from stabilized leachate using VSEPRO membrane filtration. Desalination 2007, 202, 310–317. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Lo, W.-H. Removal of refractory compounds from stabilized landfill leachate using an integrated H2O2 oxidation and granular activated carbon adsorption treatment. Water Res. 2009, 43, 4079–4091. [Google Scholar] [CrossRef]

- Standard Methods for the Examination of Water and Wastewater 20th; American Public Health Association (APHA): Washington, DC, USA, 2018.

- Kurniawan, T.A.; Lo, W.-H.; Chan, G. Radicals-catalyzed oxidation reactions for degradation of recalcitrant compounds from landfill leachate. Chem. Eng. J. 2006, 125, 35–57. [Google Scholar] [CrossRef]

- Samuel, O.; Othman, M.H.D.; Kamaludin, R.; Dzinun, H.; Imtiaz, H.; Li, T.; El-badawi, T.; Khan, A.U.; Puteh, M.H.; Yuliwati, E.; et al. Photocatalytic degradation of recalcitrant aromatic hydrocarbon compounds in oilfield-produced water: A critical review. J. Cleaner. Prod. 2023, 414, 137567. [Google Scholar] [CrossRef]

- Bandala, E.R.; Liu, A.; Wijesiri, B.; Zeidman, A.B.; Goonetilelke, A. Emerging materials and technologies for landfill leachate treatment: A critical review. Environ. Pollut. 2021, 291, 118133. [Google Scholar] [CrossRef] [PubMed]

- El-Saadony, M.T.; Saad, A.M.; El-Wafai, N.A.; Abou-Aly, H.E.; Salem, H.M.; Solman, S.M.; El-Mageed, T.A.A.; Elrys, A.S.; Selim, S.; El-Hack, M.E.A.; et al. Hazardous wastes and management strategies of landfill leachates: A comprehensive review. Environ. Technol. Innov. 2023, 31, 103150. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Adam, M.R.; Liang, X.; Goh, H.; Anouzla, A.; Sillanpää, M.; Mohyuddin, A.; Chew, K.W. Cr removal from aqueous solution using natural clinoptilolite. Water 2023, 15, 1667. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Othman, M.H.D.; Liang, X.; Goh, H.H.; Gikas, P.; Kusworo, T.D.; Anouzla, A.; Chew, K.W. Decarbonization in waste recycling industry using digitalization to promote net-zero emissions and its implications on sustainability. J. Environ. Manag. 2023, 338, 117765. [Google Scholar] [CrossRef]

- Yanyan, L.; Kurniawan, T.A.; Zhu, M.; Ouyang, T.; Avtar, R.; Othman, M.H.D.; Mohammad, B.T.; Albadarin, A.B. Removal of acetaminophen from synthetic wastewater in a fixed-bed column adsorption using low-cost coconut shell waste pretreated with NaOH, HNO3, ozone, and/or chitosan. J. Environ. Manag. 2018, 226, 365–376. [Google Scholar] [CrossRef]

- Xu, L.; Wang, S.; Zhou, J.; Deng, H.; Frost, R.L. Column adsorption of 2-naphthol from aqueous solution using carbon nanotube-based composite adsorbent. Chem. Eng. J. 2018, 335, 450–457. [Google Scholar] [CrossRef]

- Golie, W.M.; Upadhyayula, S. Continuous fixed-bed column study for the removal of nitrate from water using chitosan/alumina composite. J. Water Process Eng. 2016, 12, 58–65. [Google Scholar] [CrossRef]

- Belat, B.; Veli, S.; Isgoren, M. Modeling of linear alkyl benzene sulphonic acid removal from aqueous solution with fixed bed adsorption column: Thomas and Yoon–Nelson methods. J. Chem. Tech. Biotech. 2022, 97, 1771–1780. [Google Scholar] [CrossRef]

- Oyekanmi, A.A.; Alshammari, M.B.; Ibrahim, M.N.M.; Hanafiah, M.M.; Elnaggar, A.Y.; Ahmad, A.; Oyediran, A.T.; Rosli, M.A.; Setapar, S.H.M.; Daud, N.N.N.; et al. Highly effective cow bone based biocomposite for the sequestration of organic pollutant parameter from palm oil mill effluent in a fixed bed column adsorption system. Polymers 2021, 14, 86. [Google Scholar] [CrossRef] [PubMed]

- Halim, A.A.; Aziz, H.A.; Johari, M.A.M.; Ariffin, K.S.; Adlan, M.N. Ammoniacal nitrogen and COD removal from semi-aerobic landfill leachate using a composite adsorbent: Fixed bed column adsorption performance. J. Hazard. Mater. 2010, 175, 960–964. [Google Scholar] [CrossRef]

- Borna, M.O.; Pirsaheb, M.; Niri, M.V.; Mashizie, R.K.; Kakavandi, B.; Zare, M.R.; Asadi, A. Batch and column studies for the adsorption of chromium (VI) on low-cost Hibiscus cannabinus kenaf, a green adsorbent. J. Taiwan Inst. Chem. Eng. 2016, 68, 80–89. [Google Scholar] [CrossRef]

- Ouachtak, H.; Akhouairi, S.; Haounati, R.; Addi, A.A.; Jada, A.; Taha, M.L.; Douch, J. 3,4-Dihydroxybenzoic acid removal from water by goethite modified natural sand column fixed-bed: Experimental study and mathematical modeling. Desalination Water Treat. 2020, 194, 439–449. [Google Scholar] [CrossRef]

- Alardhi, S.M.; Albayati, T.M.; Alrubaye, J.M. Adsorption of the methyl green dye pollutant from aqueous solution using mesoporous materials MCM-41 in a fixed-bed column. Heliyon 2020, 6, e03253. [Google Scholar] [CrossRef] [PubMed]

- Zakmout, A.; Sadi, F.; Velizarov, S.; Crespo, J.G.; Portugal, C.A.M. Recovery of Cr(III) from tannery effluents by diafiltration using chitosan modified membranes. Water 2021, 13, 2598. [Google Scholar] [CrossRef]

- Zeng, H.; Hu, Z.; Peng, C.; Deng, L.; Liu, S. Effective Adsorption and sensitive detection of Cr(VI) by chitosan/cellulose nanocrystals grafted with carbon dots composite hydrogel. Polymers 2021, 13, 3788. [Google Scholar] [CrossRef] [PubMed]

- da Silva Alves, D.C.; Healy, B.; Pinto, L.A.d.A.; Cadaval, T.R.S., Jr.; Breslin, C.B. Recent developments in chitosan-based adsorbents for the removal of pollutants from aqueous environments. Molecules 2021, 26, 594. [Google Scholar] [CrossRef]

- Ullah, R.; Ahmad, W.; Yaseen, M.; Khan, M.; Iqbal Khattak, M.; Mohamed Jan, B.; Ikram, R.; Kenanakis, G. Fabrication of MNPs/rGO/PMMA composite for the removal of hazardous Cr(VI) from tannery wastewater through batch and continuous mode adsorption. Materials 2021, 14, 6923. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, L.; Ma, X.; Han, X.; Xing, C.; Qi, X.; He, R.; Arbiol, J.; Pan, H.; Zhao, J.; et al. Selective ethylene glycol oxidation to formate on nickel selenide with simultaneous evolution of hydrogen. Adv. Sci. 2023, 10, 2300841. [Google Scholar] [CrossRef] [PubMed]

- Akri, M.; Zhao, S.; Li, X.; Zang, K.; Lee, A.F.; Isaacs, M.A.; Xi, W.; Gangarajula, Y.; Luo, J.; Ren, Y.; et al. Atomically dispersed nickel as coke-resistant active sites for methane dry reforming. Nat. Commun. 2019, 10, 5181. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Deng, J.; Lan, T.; Shen, Y.; Zhong, Q.; Ren, W.; Zhang, D. Promoting methane dry reforming over Ni catalysts via modulating surface electronic structures of BN supports by doping carbon. ACS Catal. 2022, 12, 14152–14161. [Google Scholar] [CrossRef]

| Property | |

|---|---|

| Packing density (g/cm3) | 0.65 |

| Total surface area (m2/g) | 15 |

| Solid density (g/cm3) | 0.57 |

| Particle size (mm) | 0.35 |

| Pore volume (mL/g) | 0.04 |

| Parameter | Value |

|---|---|

| pH | 7.8 |

| BOD5 (mg/L) | 500 |

| COD (mg/L) | 7000 |

| BOD5/COD | 0.07 |

| TOC (mg/L) | 2100 |

| Cr3+ (mg/L) | 21.l2 |

| Na+ (mg/L) | 11.01 |

| Ca2+ (mg/L) | 12.51 |

| NH3-N (mg/L) | 1500 |

| Conductivity (mS/cm) | 11.5 |

| Alkalinity (as CaCO3) (mg/L) | 10,500 |

| Pollutant | Concentration (mg/L) | Breakthrough Point (h) | BV at Breakthrough Point | Saturated Point (h) | BV at Saturated Point | Volume of Treated Influent (L) | |

|---|---|---|---|---|---|---|---|

| Adsorbent | |||||||

| CS | COD | 7000 | 10 | 76.4 | 50 | 458.5 | 10.8 |

| Chitosan | 7000 | 25 | 200 | 80 | 611 | 14.4 | |

| Composite | 7000 | 40 | 305.7 | 120 | 917 | 21.6 | |

| CS | NH3-N | 1500 | 9 | 68.7 | 49 | 374 | 8.8 |

| Chitosan | 1500 | 24 | 183.4 | 79 | 603 | 14.2 | |

| Composite | 1500 | 39 | 298 | 119 | 909 | 21.4 |

| Adsorbents | Q (mL/min) | m (g) | COD | NH3-N | ||||

|---|---|---|---|---|---|---|---|---|

| A | qtotal (mg) | qexp (mg/g) | A | qtotal (mg) | qexp (mg/g) | |||

| CS | 3 | 10 | 1807.1 | 5.421 | 0.542 | 1958.9 | 5.8767 | 0.587 |

| Chitosan | 3 | 10 | 3107.02 | 9.321 | 0.932 | 3178.01 | 9.5340 | 0.953 |

| Composite | 3 | 10 | 5041.09 | 15.12 | 1.512 | 5106.1 | 15.318 | 1.531 |

| COD | NH3-N | |||||||

|---|---|---|---|---|---|---|---|---|

| Types of Adsorbents | Before First Regeneration (mg/g) | After First Regeneration (mg/g) | RE (%) | LAC (%) | Before First Regeneration (mg/g) | After First Regeneration (mg/g) | RE (%) | LAC (%) |

| CS | 0.542 | 0.480 | 88 | 12 | 0.587 | 0.501 | 85 | 15 |

| Chitosan | 0.932 | 0.850 | 91 | 9 | 0.953 | 0.863 | 90 | 10 |

| Composite | 1.512 | 1.460 | 96 | 4 | 1.531 | 1.465 | 95 | 5 |

| Pollutant | Type of Adsorbent | Co (mg/L) | Flow Rate (mL /min) | Bed Depth (cm) | qo,cal (mg/g) | qo,exp (mg/g) | Kth (×103) (L/h ·mg) | R2 |

|---|---|---|---|---|---|---|---|---|

| NH3-N | Composite | 1500 | 3 | 5 | 1.338 | 1.531 | −0.4035 | 0.9845 |

| Chitosan | 1500 | 3 | 5 | 0.854 | 0.953 | −0.5571 | 0.9784 | |

| CS | 1500 | 3 | 5 | 0.488 | 0.587 | −0.8419 | 0.9180 | |

| COD | Composite | 7000 | 3 | 5 | 1.317 | 1.512 | −0.1097 | 0.982 |

| Chitosan | 7000 | 3 | 5 | 0.875 | 0.932 | −0.1412 | 0.975 | |

| CS | 7000 | 3 | 5 | 0.432 | 0.542 | −0.2302 | 0.922 |

| Type of Adsorbent | Target Pollutant | pH | Influent Concentration (mg/L) | Flow Rate (mL/min) | Bed Depth (cm) | Breakthrough Point (min) | Satu-rated Point (min) | Adsorption Capacity (mg/g) | References |

|---|---|---|---|---|---|---|---|---|---|

| Chitosan-coated carbon composite | COD NH3-N | 7.8 | 7000 1500 | 3 3 | 5 5 | 40 | 120 | 1.51 1.53 | This study |

| Granular activated carbon | Acetaminophen | 9 | 40 | 2 | 45 | 5300 | 10,800 | 38.20 | [55] |

| Alkyl benzene sulfonic acid | Detergent and COD | NA | 30 | 10 | 7.5 | 60 | 180 | 216 | [58] |

| Cow-bone-based biocomposite | COD | 7 | NA | 1.4 | 30 | 309 | 600 | NA | [59] |

| Carbon-mineral composite | NH3-N COD | NA | 1640 2257 | 8 | 36 | 150 | 500 500 | 4.46 3.23 | [60] |

| Hibiscus cannabinus kenaf. | Cr(VI) | 7 | 0.5 | 2 | 15 | 22.5 | 90 | 21.48 | [61] |

| Goethite-modified natural sand | 3,4-dihydroxy-benzoic acid | 5 | 60 | 1 | 9.8 | 93 | 263 | 35.66 | [62] |

| MCM-41 | Methyl green | 6 | 20 | 0.8 | 6 | 250 | 1400 | 20.97 | [63] |

| Chitosan/alumina | Nitrate | 6.8 | 100 | 8 | 40 | 510 | 600 | 25.52 | [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batool, F.; Kurniawan, T.A.; Mohyuddin, A.; Othman, M.H.D.; Anouzla, A.; Meidiana, C.; Goh, H.H.; Chew, K.W. Fixed-Bed Studies of Landfill Leachate Treatment Using Chitosan-Coated Carbon Composite. Water 2023, 15, 2263. https://doi.org/10.3390/w15122263

Batool F, Kurniawan TA, Mohyuddin A, Othman MHD, Anouzla A, Meidiana C, Goh HH, Chew KW. Fixed-Bed Studies of Landfill Leachate Treatment Using Chitosan-Coated Carbon Composite. Water. 2023; 15(12):2263. https://doi.org/10.3390/w15122263

Chicago/Turabian StyleBatool, Fatima, Tonni Agustiono Kurniawan, Ayesha Mohyuddin, Mohd Hafiz Dzarfan Othman, Abdelkader Anouzla, Christia Meidiana, Hui Hwang Goh, and Kit Wayne Chew. 2023. "Fixed-Bed Studies of Landfill Leachate Treatment Using Chitosan-Coated Carbon Composite" Water 15, no. 12: 2263. https://doi.org/10.3390/w15122263

APA StyleBatool, F., Kurniawan, T. A., Mohyuddin, A., Othman, M. H. D., Anouzla, A., Meidiana, C., Goh, H. H., & Chew, K. W. (2023). Fixed-Bed Studies of Landfill Leachate Treatment Using Chitosan-Coated Carbon Composite. Water, 15(12), 2263. https://doi.org/10.3390/w15122263