The Effect of Flocculants and Water Content on the Separation of Water from Dredged Sediment

Abstract

:1. Introduction

2. Materials and Methods

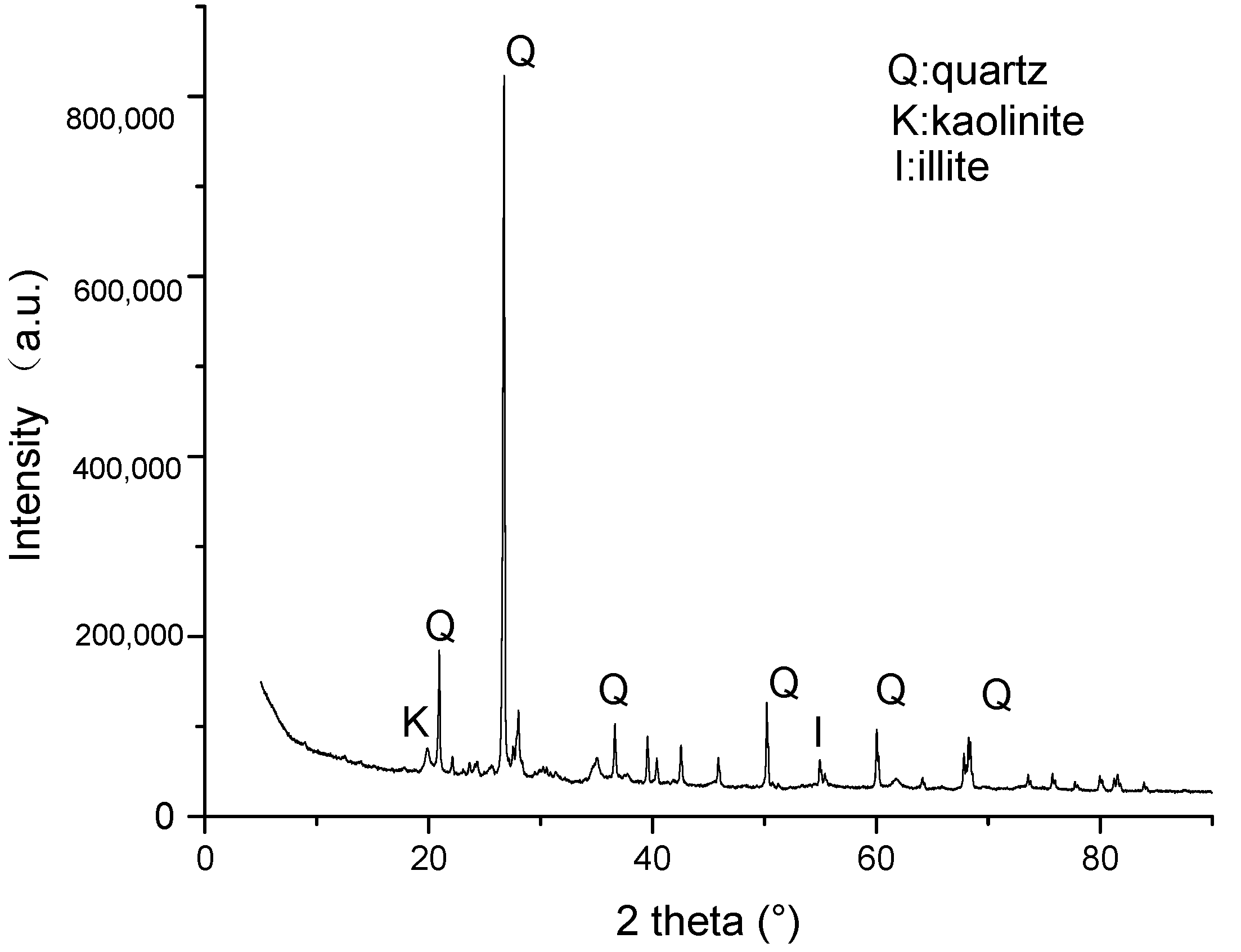

2.1. Materials

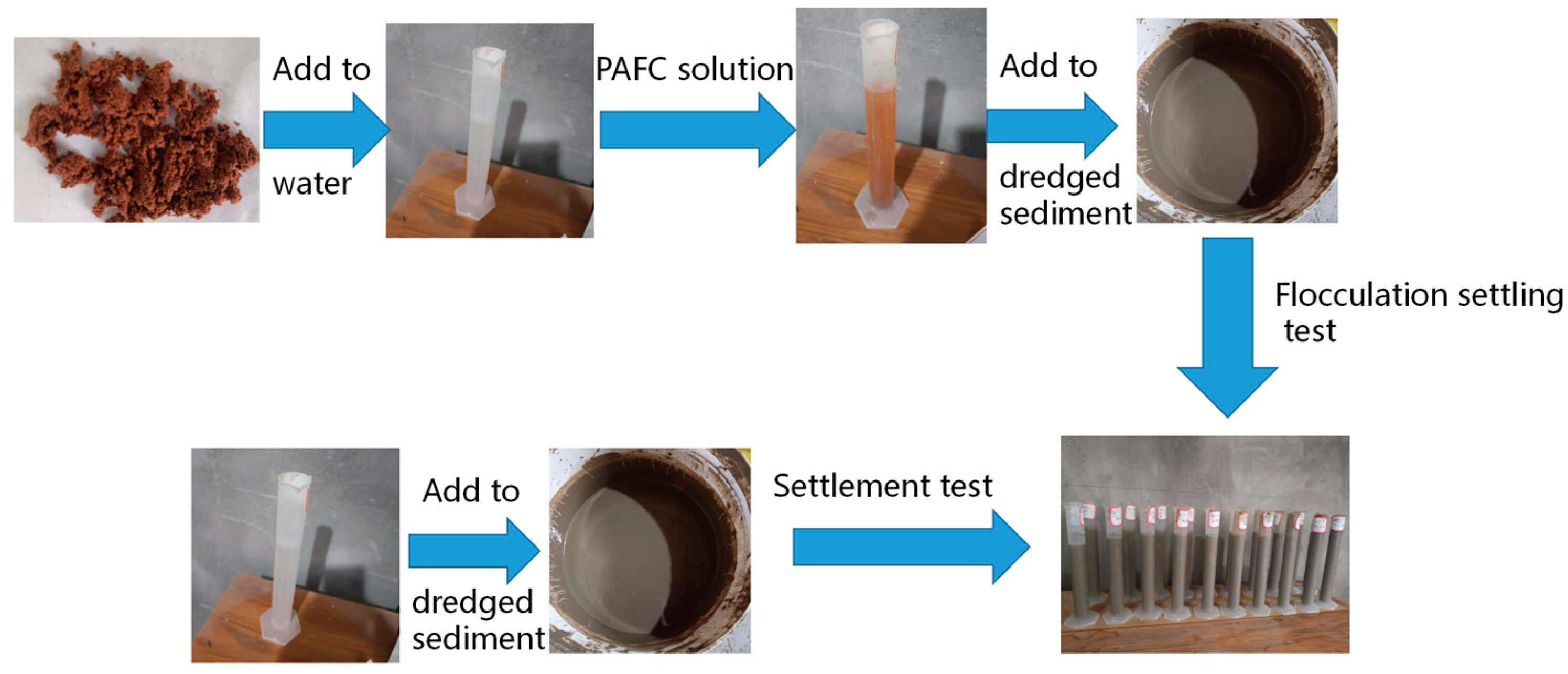

2.2. Test Methods

- (1)

- We first removed the supernatant after settling the dredged sediment and then removed 1000 mL of the dredged sediment, placing 50 mL into each of 7 measuring cylinders (100 mL). Then, we added 50 mL of water to each measuring cylinder and evenly stirred the contents. PAFC (2, 3, 4, 5, 6, 7, or 8 g) was placed into the 7 beakers containing 100 mL river water; after mixing until even, 2 mL of mixed PAFC solution was added into the diluted dredged sediment measuring cylinder, 2 mL of clean water was added to the natural control group, and the flocculation effects were observed.

- (2)

- We added 10, 20, 30, 40, 50, 60, 70, 80, 90, or 100 mL of the bottom dredged sediment to the measuring cylinder, and then we injected water into the measuring cylinder. The total volume of the dredged sediment with injected water was 100 mL. We added 5 g of PAFC into 100 mL of river water to prepare the PAFC solution, and then we added 2 mL of the PAFC solution to each measuring cylinder to observe the flocculation precipitation effect. The flowchart for the study is shown in Figure 3.

3. Results

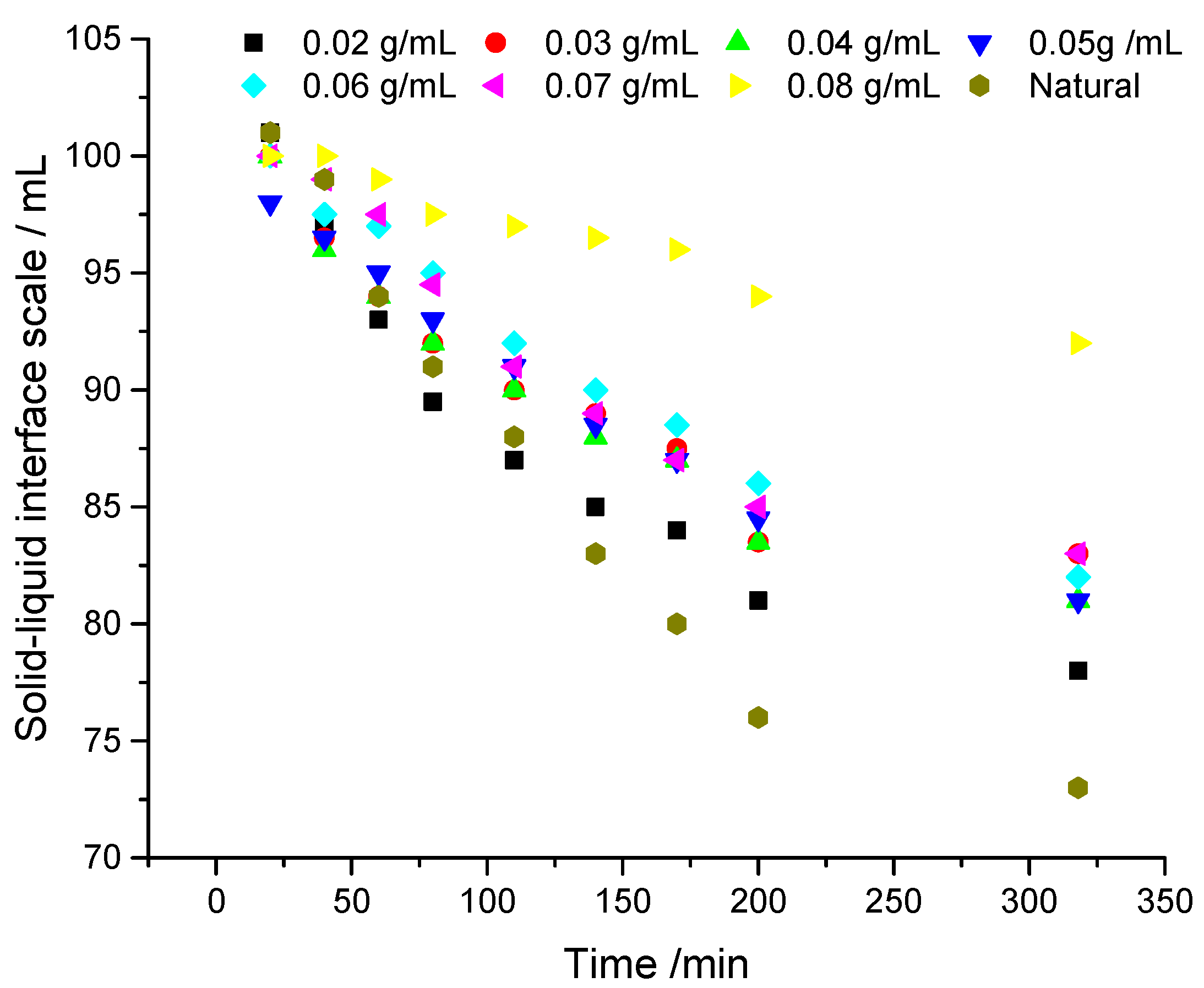

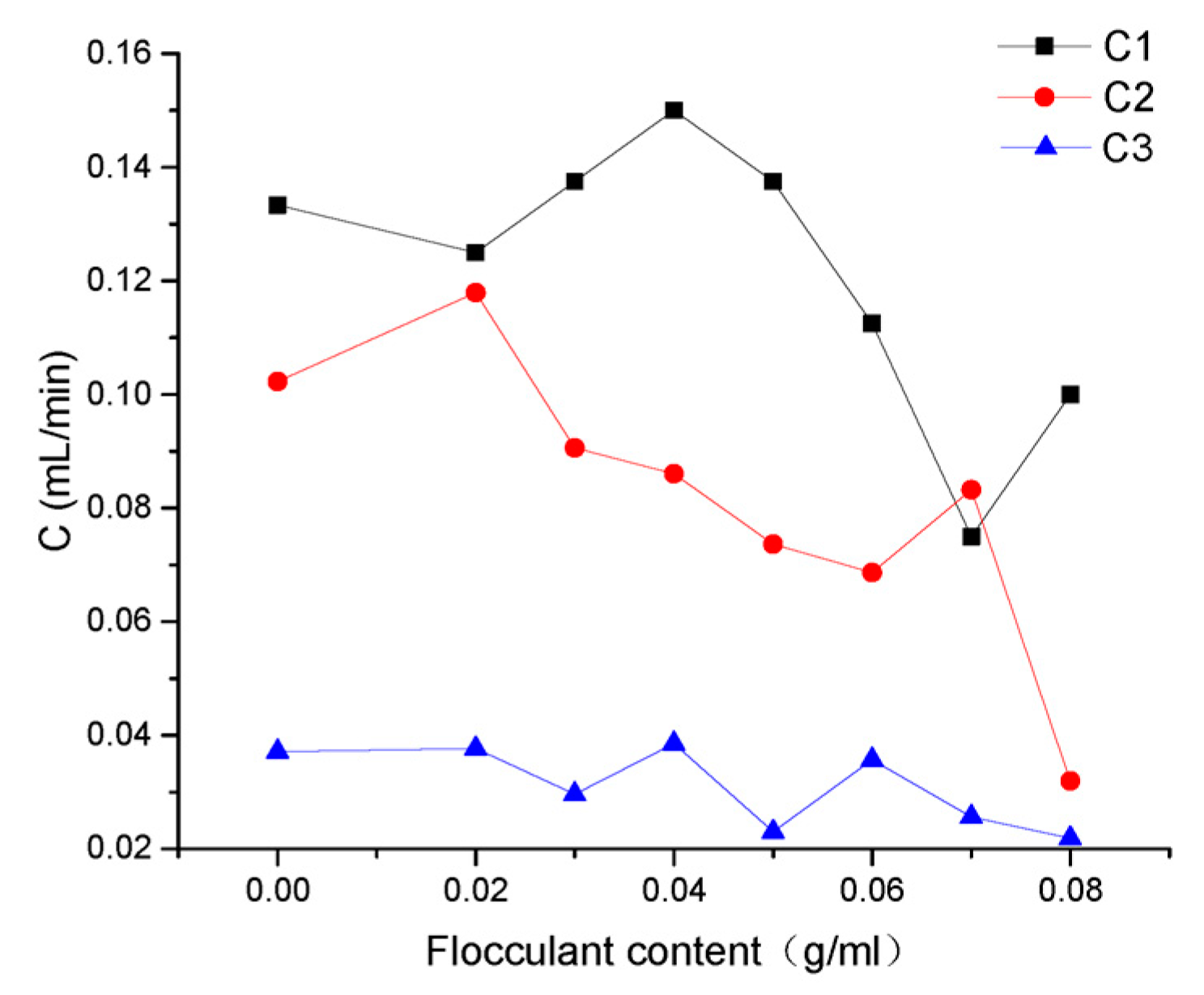

3.1. Effect of Flocculant Dosage

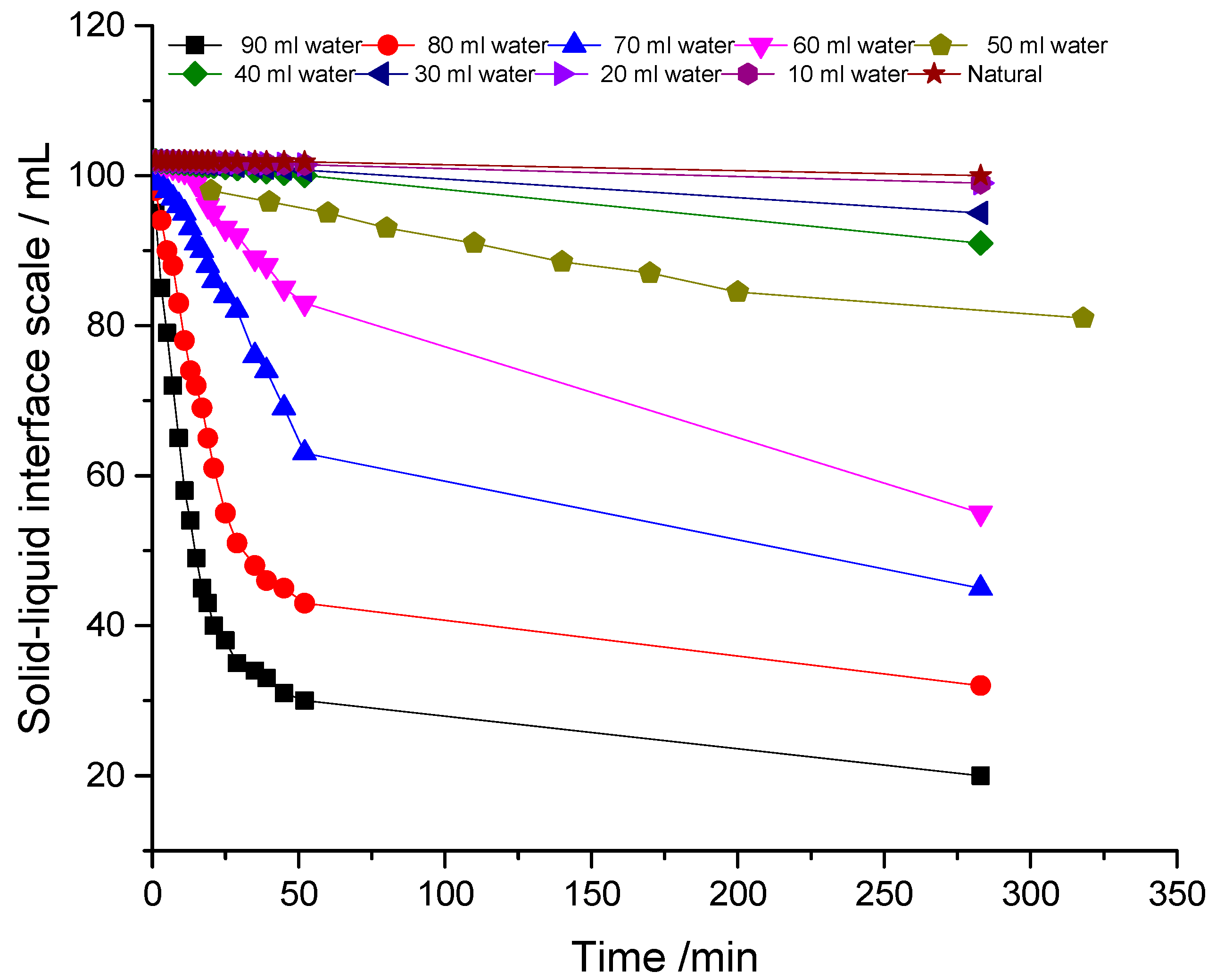

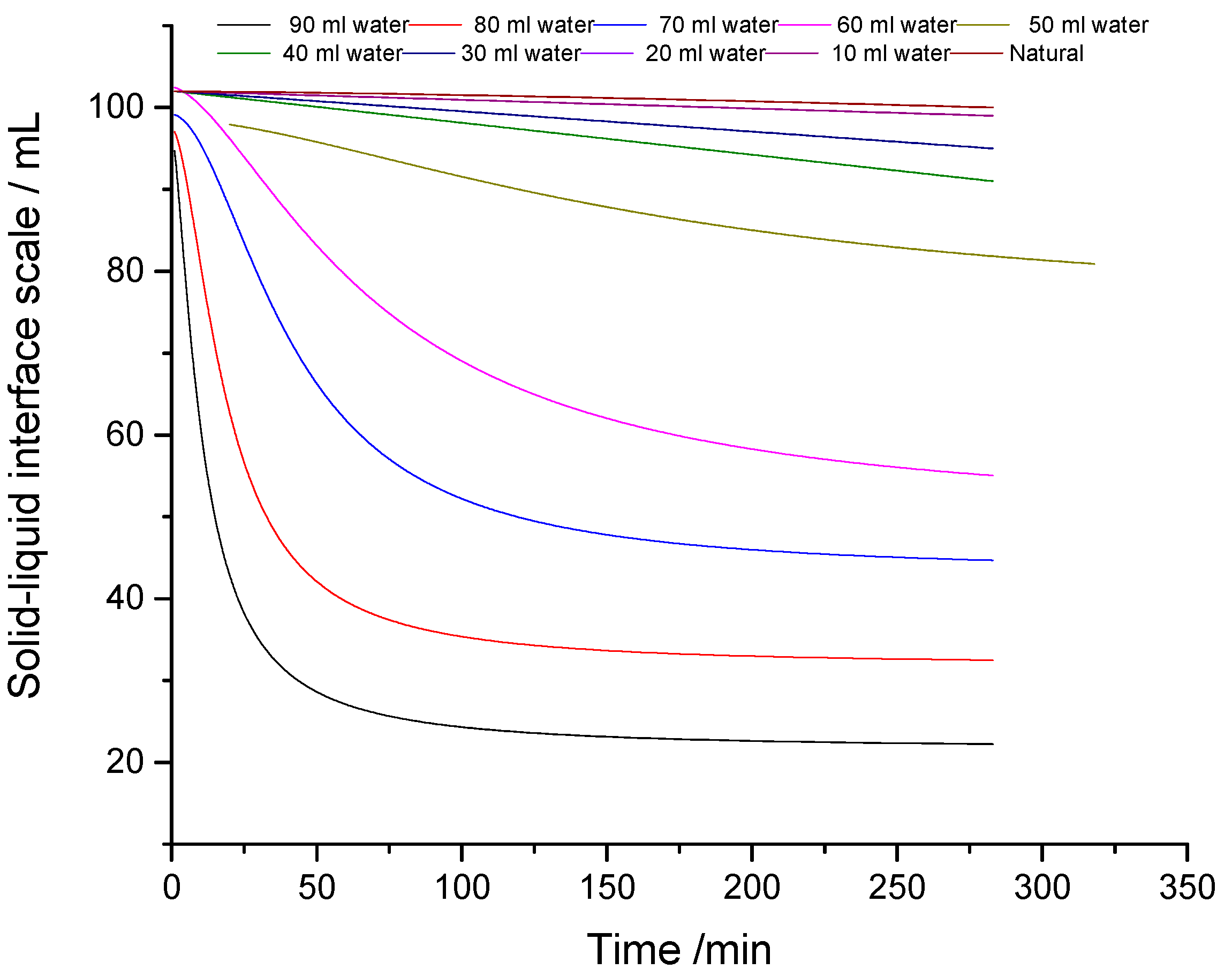

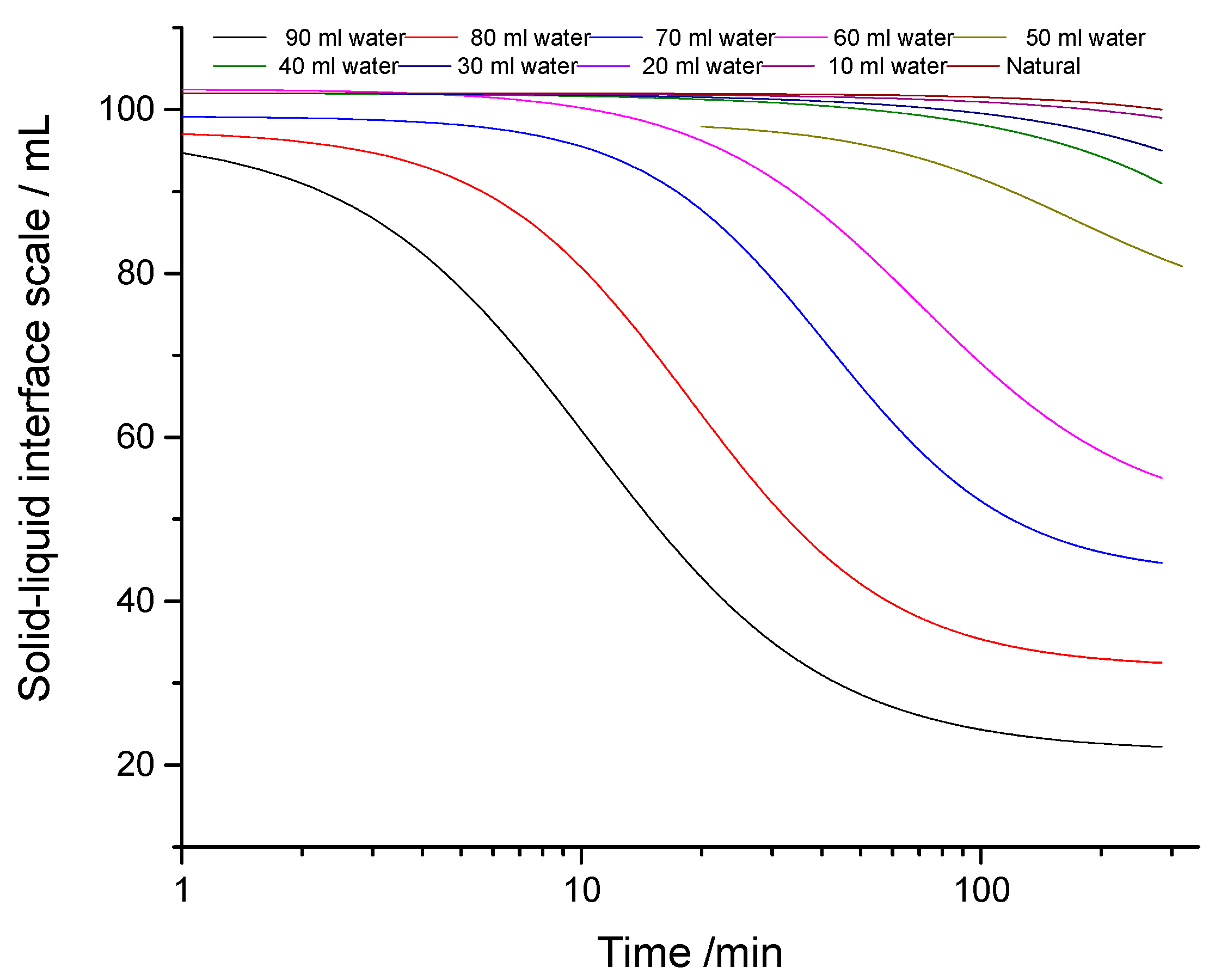

3.2. Effect of Water Content on Flocculation Effect

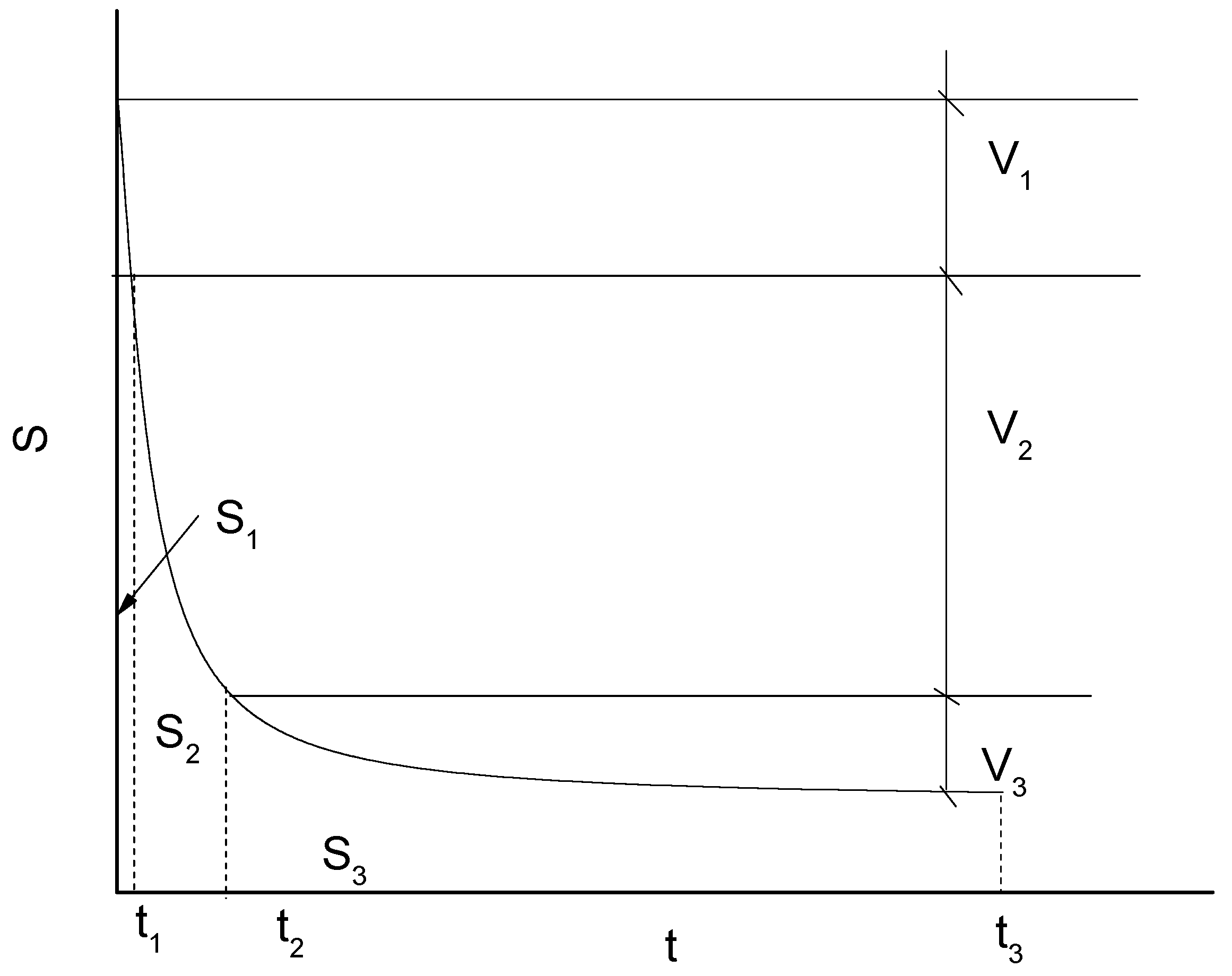

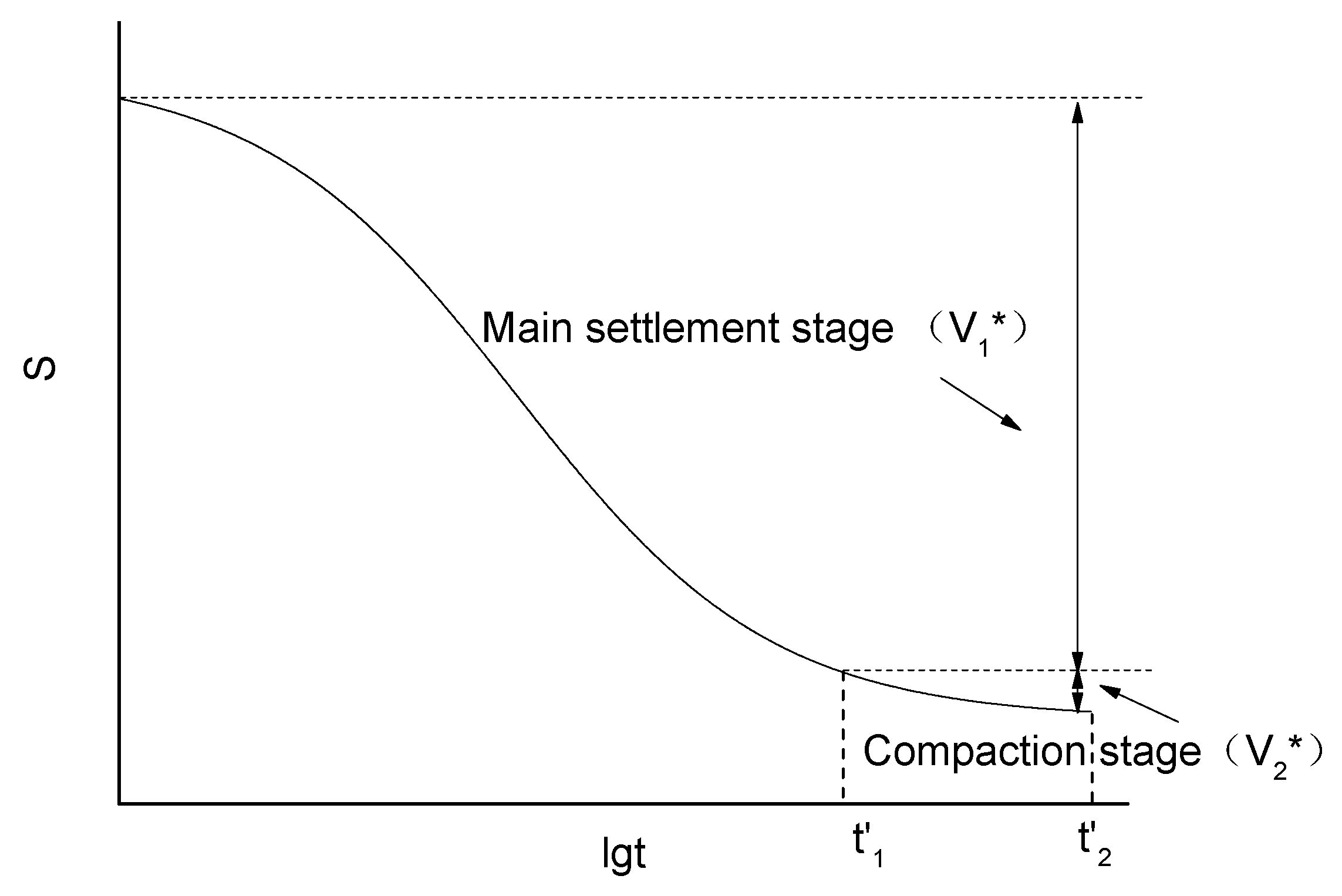

3.3. Settlement Stages of Dredged Sediment

3.4. Flocculation Dehydration Process and Flocculation Precipitation Mechanism

3.4.1. Flocculation Dehydration Process

3.4.2. Flocculation Precipitation Mechanism

4. Discussion

5. Conclusions

- The flocculation effect of dredged sediment is related to the flocculant dosage, water content, and flocculation time. The optimal dosage of PAFC changed with time, the optimal dosage of PAFC has the best flocculation effect, the flocculation effect decreased when the PAFC content exceeded the optimal dosage, and the dilution of the dredged sediment was conducive to flocculation precipitation. The flocculation precipitation of dredged sediment had an optimal flocculation precipitation time, after which the flocculation effect substantially decreased and was even lower than that of the free sedimentation dredged sediment.

- The higher the water content, the stronger the flocculation precipitation effect. In the initial stage, the flocculant can markedly increase the flocculation precipitation rate, but over time, flocculation hindered the sedimentation and compression processes; the higher the solid content, the stronger the effect.

- The settlement coefficient and compaction settlement index can reflect the settling performance of dredged sediment at different settling stages and can provide reference for selecting flocculant.

- In the PAFC flocculation process, the solid–liquid equilibrium system of the sediment was first broken, and then the particles precipitated through the synergistic flocculation of aluminum and iron salts. The appropriate amount of PAFC should be added: too little does not produce the desired effect, and too many lead to sediment particle restabilization.

- In engineering applications, the flocculant content should be adjusted according to the solid content. For dredged sediment with a high solid content, dilution is required before flocculation dehydration.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; He, X.; Gong, S.; Cai, G.; Lang, L.; Ma, H.; Niu, Z.; Zhou, F. Influence Mechanism of Fulvic Acid on the Strength of Cement-Solidified Dredged Sludge. Water 2022, 14, 2616. [Google Scholar] [CrossRef]

- Li, L.; Song, Z.; Zhang, W.; Wu, H.; Liu, W.; Yu, J.; Wang, D. Performance and mechanisms of dredged sludge dewaterability enhancement with slag-based polymeric titanium aluminum coagulant. Colloids Surf. A 2021, 630, 127514. [Google Scholar] [CrossRef]

- He, X.; Chen, Y.; Wan, Y.; Liu, L.; Xue, Q. Effect of Curing Stress on Compression Behaviorof Cement-Treated Dredged Sediment. Int. J. Geomech. 2020, 20, 04020201–04020211. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Y.; Wang, C. Study on mechanical properties of dredged silt stabilized with cement and reinforced with alginate fibers. Case Stud. Constr. Mat. 2023, 18, e01977. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, R.; Cai, Y.; Fu, H.; Li, X.; Hu, X. Vacuum preloading and electro-osmosis consolidation of dredged slurry pre-treated with flocculants. Eng. Geol. 2018, 246, 123–130. [Google Scholar] [CrossRef]

- Wu, P.; Shi, Y.; Wang, Z.; Xiong, Z.; Liu, D.; Gerson, A.R.; Pi, K. Effect of electric field strength on electro-dewatering efficiency for river sediments by horizontal electric field. Sci. Total Environ. 2019, 647, 1333–1343. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ni, J.; Cai, Y.; Fu, H.; Wang, P. Combination of vacuum preloading and lime treatment for improvement of dredged fill. Eng. Geol. 2017, 227, 149–158. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Ni, J.; Geng, X.; Xu, F. Effect of sand on the vacuum consolidation of dredged slurry. Mar. Georesour. Geotechnol. 2017, 36, 238–244. [Google Scholar] [CrossRef] [Green Version]

- Karadoğan, Ü.; Korkut, S.; Çevikbilen, G.; Teymur, B.; Koyuncu, İ. Evaluation of beneficial of polyacrylamide use dewatering of dredged sludge obtained from golden horn. Mar. Georesour. Geotechnol. 2020, 39, 919–928. [Google Scholar] [CrossRef]

- Wang, D.; Tang, Y.; Wu, L. Evaluation on deep dewatering performance of dredged sludge treated by chemical flocculation-vacuum preloading. Rock Soil Mech. 2020, 41, 3929–3938. [Google Scholar]

- Tang, L.; Song, J.; Chen, H.; Wang, Y.; Yin, J.; Ye, J. Impacts of organic content and pH on consolidation of clayey dredger fill by vacuum preloading method. Geosci. J. 2017, 21, 765–778. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Xu, B.; Ruan, X.; Wei, Z. The use of urban river sediments as a primary raw material in the production of highly insulating brick. Ceram. Int. 2014, 40, 8833–8840. [Google Scholar] [CrossRef]

- Dubois, V.; Abriak, N.E.; Zentar, R.; Ballivy, G. The use of marine sediments as a pavement base material. Waste Manag. 2009, 29, 774–782. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-F.; Hu, H.; Wang, H.-J.; Zeng, R.J. Combined use of inorganic coagulants and cationic polyacrylamide for enhancing dewaterability of sewage sludge. J. Clean. Prod. 2019, 211, 387–395. [Google Scholar] [CrossRef]

- Costine, A.; Cox, J.; Travaglini, S.; Lubansky, A.; Fawell, P.; Misslitz, H. Variations in the molecular weight response of anionic polyacrylamides under different flocculation conditions. Chem. Eng. Sci. 2018, 176, 127–138. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, A.; Wang, H.; Liu, S.; Zhou, B. Influence mechanism of flocculant dosage on tailings thickening. J. Beijing Univ. Sci. Technol. 2013, 35, 1419–1423. [Google Scholar]

- Wang, D.; Di, S.; Wu, L.; Tan, Y.; Tang, Y. Sedimentation Behavior of Organic, Inorganic, and Composite Flocculant-Treated Waste Slurry from Construction Works. J. Mater. Civ. Eng. 2021, 33, 04021134. [Google Scholar] [CrossRef]

- Wang, J.; Shi, W.; Wu, W.; Liu, F.; Fu, H.; Cai, Y.; Hai, J.; Hu, X.; Zhu, X. Influence of composite flocculant FeCl3–APAM on vacuum drainage of river-dredged sludge. Can. Geotech. J. 2019, 56, 868–875. [Google Scholar] [CrossRef]

- Lin, W.; Zhan, X.; Zhan, T.L.; Chen, Y.; Jin, Y.; Jiang, J. Effect of FeCl3-conditioning on consolidation property of sewage sludge and vacuum preloading test with integrated PVDs at the Changan landfill, China. Geotext. Geomembr. 2014, 42, 181–190. [Google Scholar] [CrossRef]

- Gao, B.; Yue, Q.; Miao, J. Evaluation of polyaluminium ferric chloride (PAFC) as a composite coagulant for water and wastewater treatment.pdf. Water Sci. Technol. 2003, 1, 127–132. [Google Scholar] [CrossRef]

- Gao, J.-Y.; Gao, F.-Z.; Zhu, F.; Luo, X.-H.; Jiang, J.; Feng, L. Synergistic coagulation of bauxite residue-based polyaluminum ferric chloride for dyeing wastewater treatment. J. Cent. South Univ. 2019, 26, 449–457. [Google Scholar] [CrossRef]

- Malíková, P.; Chromíková, J.; Čablík, V.; Thomas, J. Flotation tailings—Intensification of the dewatering process by the aluminium prehydrolysed coagulants. Inżynieria Miner. 2015, 36, 73–78. [Google Scholar]

- Hou, H.Z.; Li, C.P.; Wang, S.Y.; Yan, B.H. Settling velocity variation of mud layer and particle settling characteristics in thickening of tailings. J. Cent. South Univ. 2019, 50, 1428–1436. [Google Scholar]

- Kong, D.; Zhou, Z.; Song, S.; Feng, S.; Lian, M.; Jiang, R. Preparation of Poly Aluminum-Ferric Chloride (PAFC) Coagulant by Extracting Aluminum and Iron Ions from High Iron Content Coal Gangue. Materials 2022, 15, 2253. [Google Scholar] [CrossRef]

- Liu, X.; Graham, N.; Liu, T.; Cheng, S.; Yu, W. A comparison of the coagulation performance of PAFC and FeSO4 for the treatment of leach liquor from Stevia processing. Sep. Purif. Technol. 2021, 255, 117680. [Google Scholar] [CrossRef]

- Wang, D.X.; Wu, L.F.; Tang, Y.K.; Xu, X.Y. Mud-water separation process and performance evaluation of waste slurry from construction engineering. J. Zhejiang Univ. Sci. 2020, 54, 1049–1057. [Google Scholar]

- Gjaltema, A.; Vinke, J.L.; Loosdrecht, M.C.M.V.; Heijnen, J.J. Abrasion of suspended biofilm pellets in airlift reactors Importance of shape, structure, and particle concentrations. Biotechnol. Bioeng. 1997, 53, 88–99. [Google Scholar] [CrossRef]

- Hu, Y.; Gu, G. The Coagulatin Mechanisms and Characteristics of Polymeric Aluminum Ferric Chloride. J. Tongji Univ. 1993, 21, 343–348. [Google Scholar]

- Russel, W.B. Brownian Motion of Small Particles Suspended in Liquids. Ann. Rev. Fluid Mech. 1981, 13, 425–455. [Google Scholar] [CrossRef]

- Blazejewski, R. Apparent viscosity and settling velocity of suspensions of rigid monosized spheres in Stokes flow. Int. J. Multiph. Flow 2012, 39, 179–185. [Google Scholar] [CrossRef]

- Davis, R.H.; Birdsell, K.H. Hindered settling of semidilute monodisperse and polydisperse suspensions. AIChE J. 1988, 34, 123–129. [Google Scholar] [CrossRef]

- Zhang, N.; Zhu, W.; Wang, L.; Lü, Y.-y.; Zhou, X. Study of sedimentation and consolidation of soil particles in dredged slurry. Rock Soil Mech. 2013, 34, 1681–1686. [Google Scholar]

- Kumar, S.; Mandre, N.R.; Bhattacharya, S. Flocculation Studies of Coal Tailings and the Development of a Settling Index. Int. J. Coal Prep. Util. 2015, 36, 293–305. [Google Scholar] [CrossRef]

| Element | Si | Al | Fe | K | Ca | Ti | Mg |

|---|---|---|---|---|---|---|---|

| Content (%) | 59.95 | 14.18 | 13.20 | 5.82 | 3.09 | 1.52 | 1.30 |

| Characteristics | PAFC |

|---|---|

| pH (1% water solution) | 4.5 |

| Al2O3 (%) | 29.5 |

| Fe2O3 (%) | 3.8 |

| Basicity (%) | 75.5 |

| Insoluble matter (%) | 0.8 |

| As (mg/L) | 0.002 |

| Mn (mg/L) | 0.0068 |

| Pb (mg/L) | 0.0026 |

| Hg (mg/L) | 0.0002 |

| SO2−4 (%) | 8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, L.; Yao, D. The Effect of Flocculants and Water Content on the Separation of Water from Dredged Sediment. Water 2023, 15, 2462. https://doi.org/10.3390/w15132462

Wen L, Yao D. The Effect of Flocculants and Water Content on the Separation of Water from Dredged Sediment. Water. 2023; 15(13):2462. https://doi.org/10.3390/w15132462

Chicago/Turabian StyleWen, Liang, and Duoxi Yao. 2023. "The Effect of Flocculants and Water Content on the Separation of Water from Dredged Sediment" Water 15, no. 13: 2462. https://doi.org/10.3390/w15132462

APA StyleWen, L., & Yao, D. (2023). The Effect of Flocculants and Water Content on the Separation of Water from Dredged Sediment. Water, 15(13), 2462. https://doi.org/10.3390/w15132462