Effect of Gradation Characteristics and Particle Morphology on Internal Erosion of Sandy Gravels: A Large-Scale Experimental Study

Abstract

:1. Introduction

2. Methodology

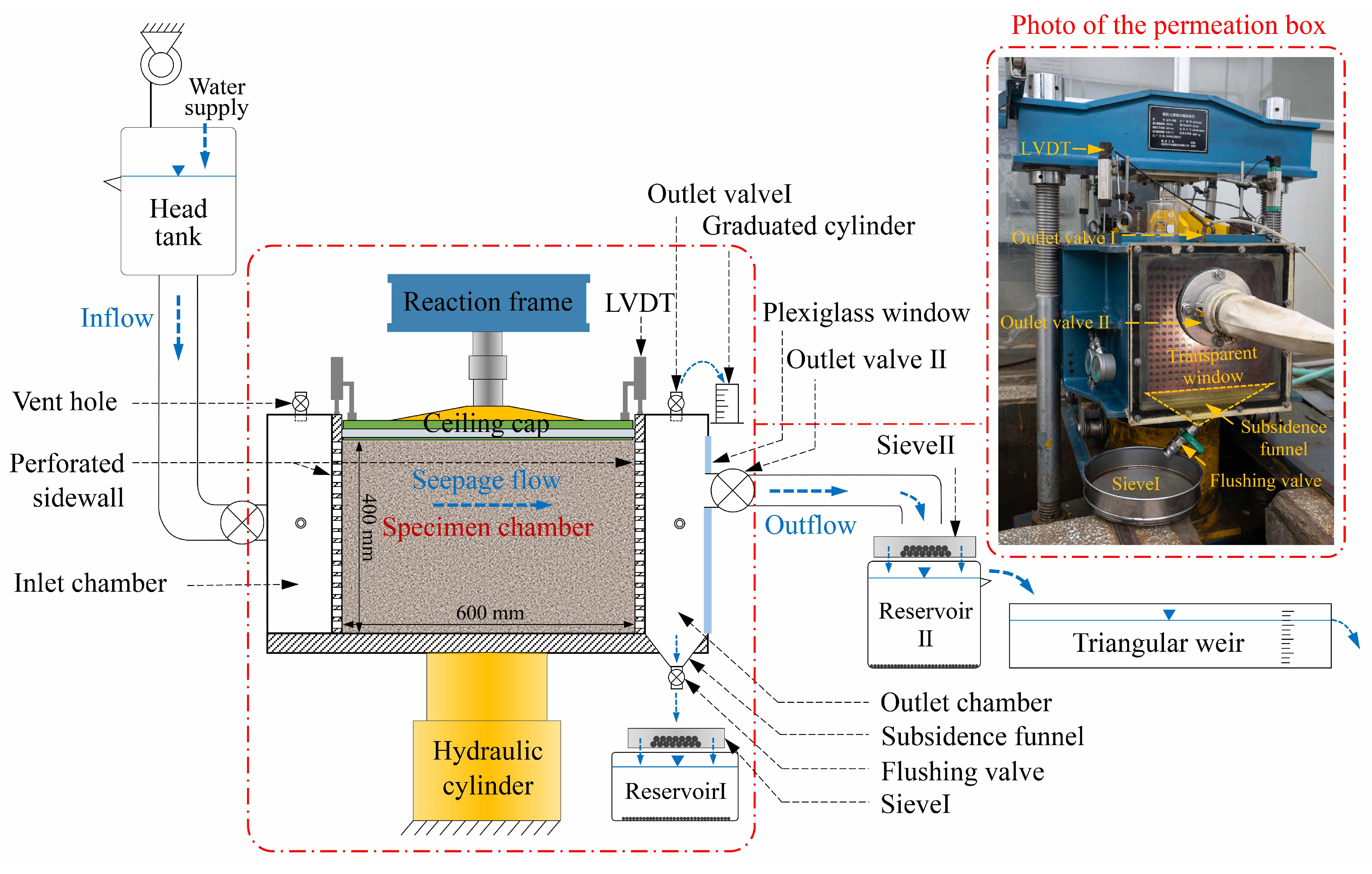

2.1. Test Apparatus

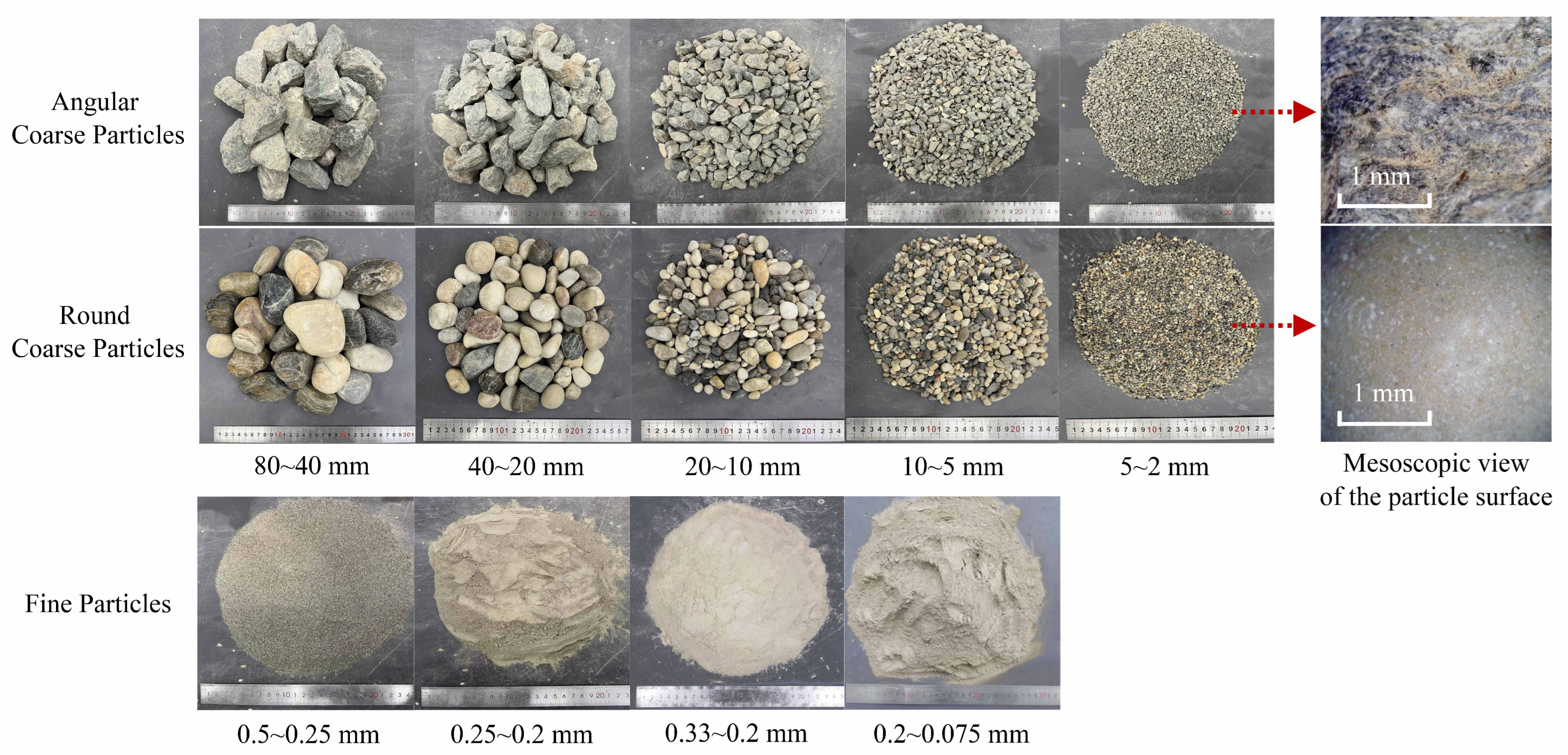

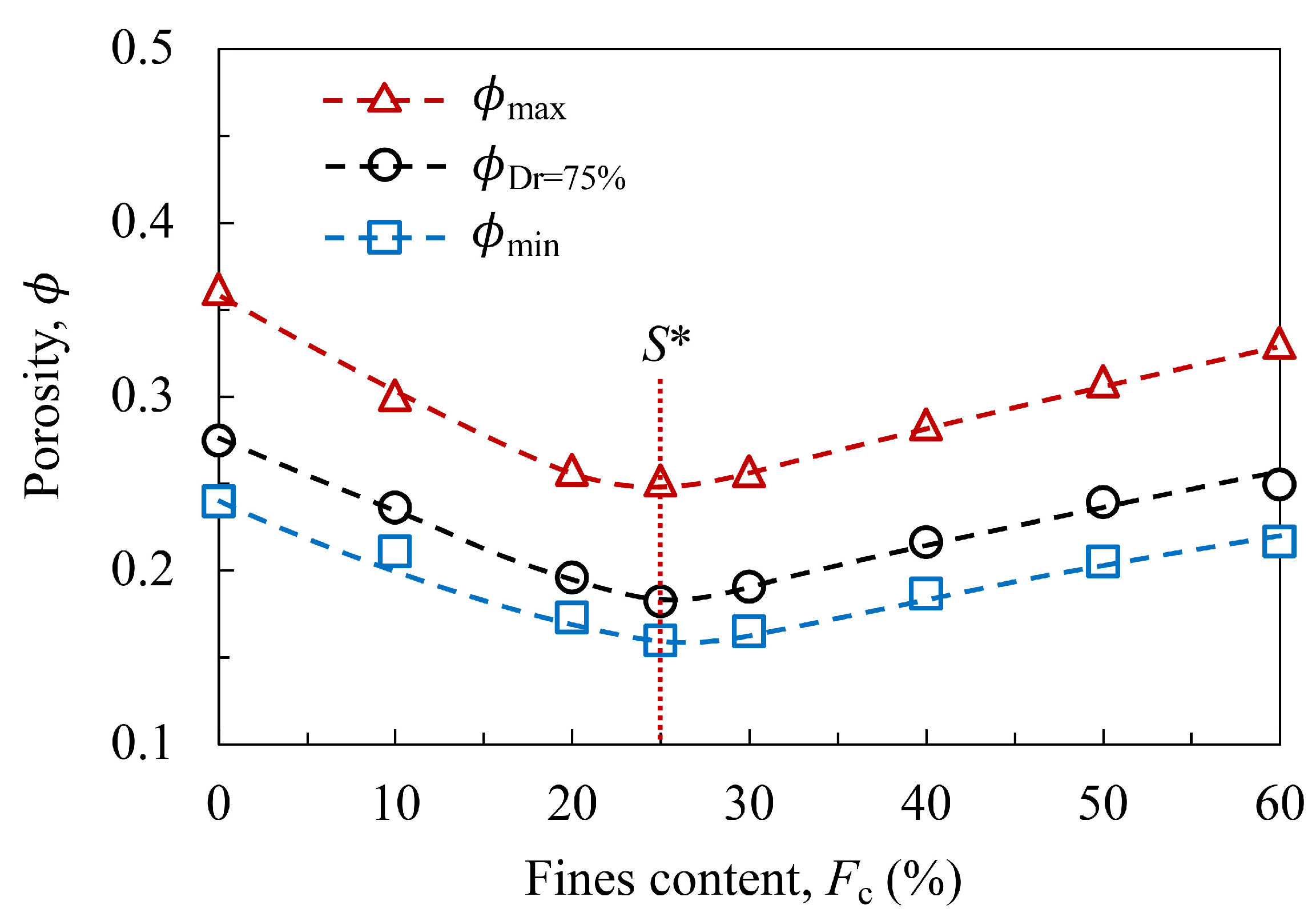

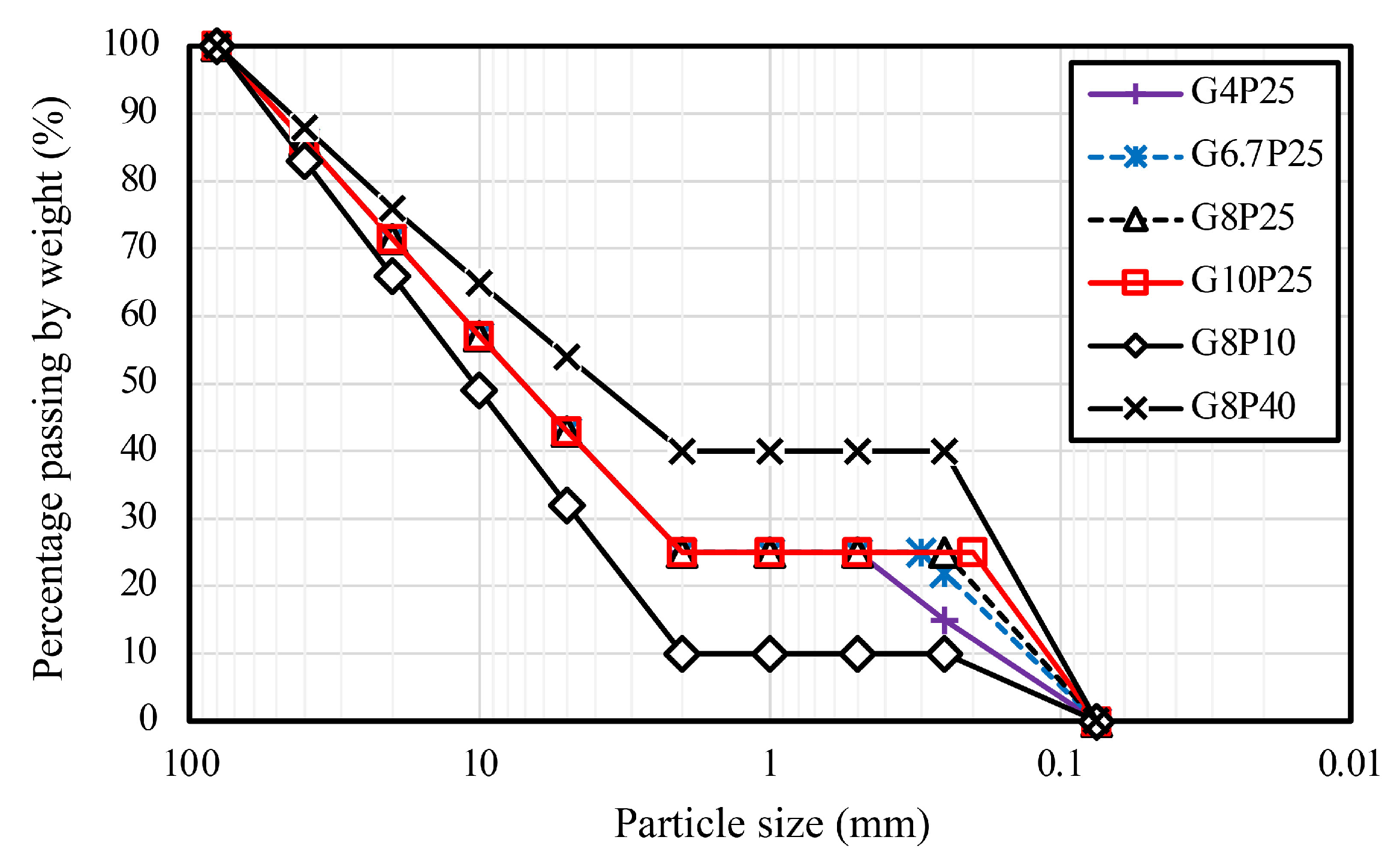

2.2. Test Materials

2.3. Specimen Preparation

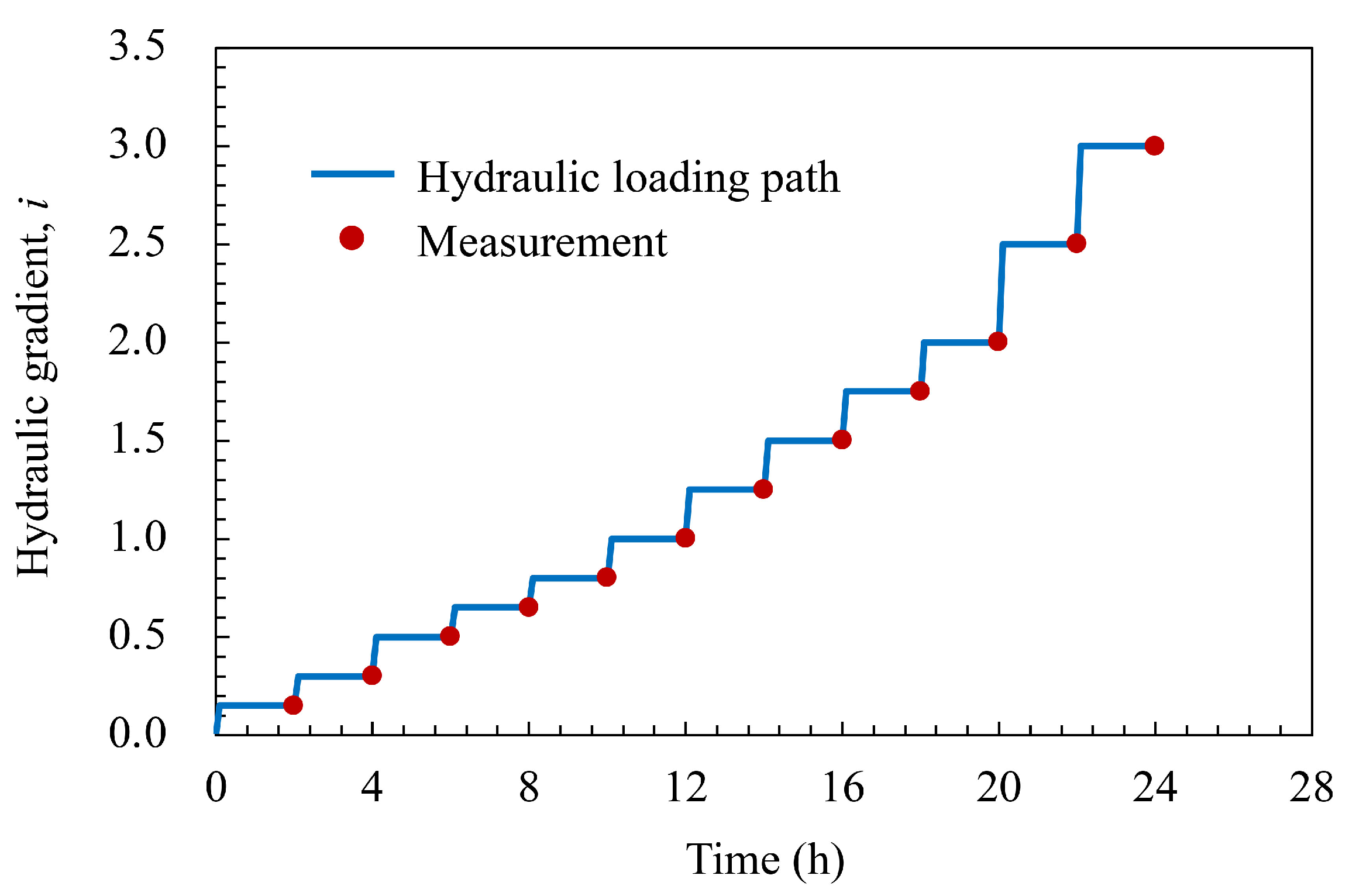

2.4. Test Scheme

3. Test Results

3.1. Test Repeatability

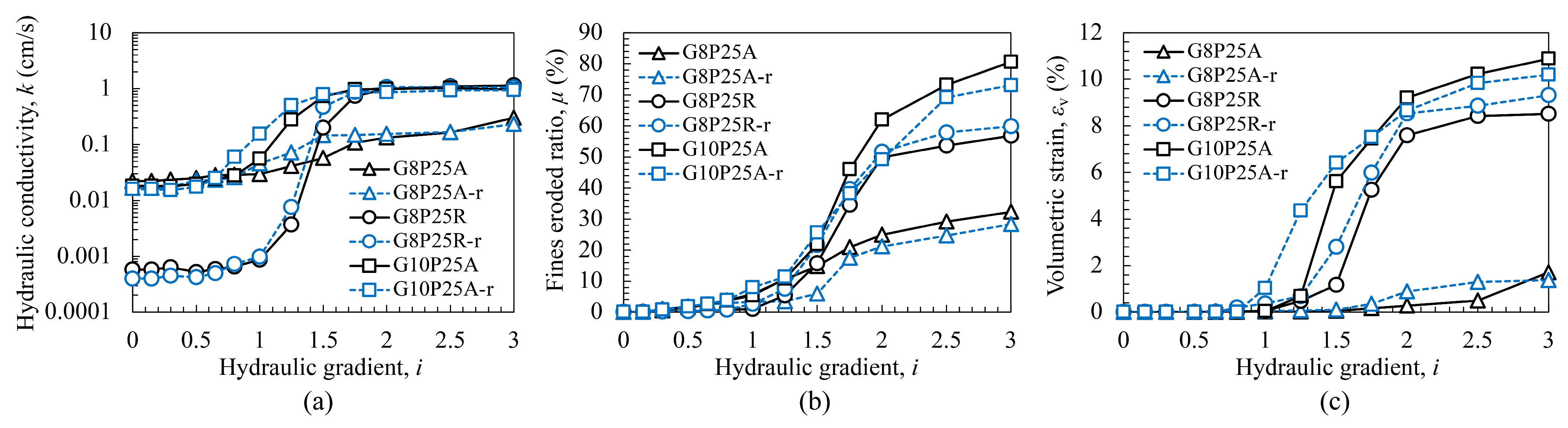

3.2. Effect of Gap Ratio

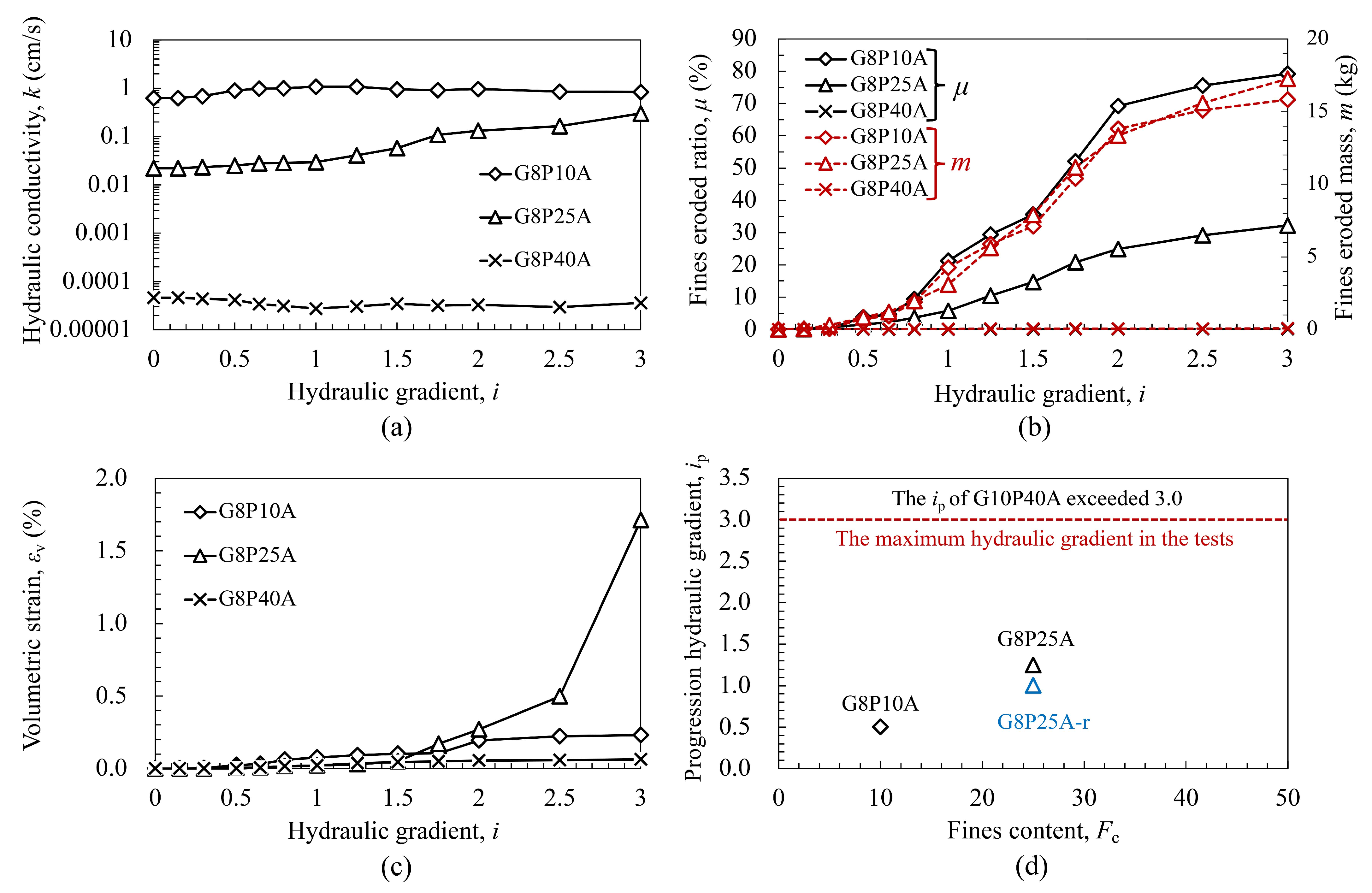

3.3. Effect of Fines Content

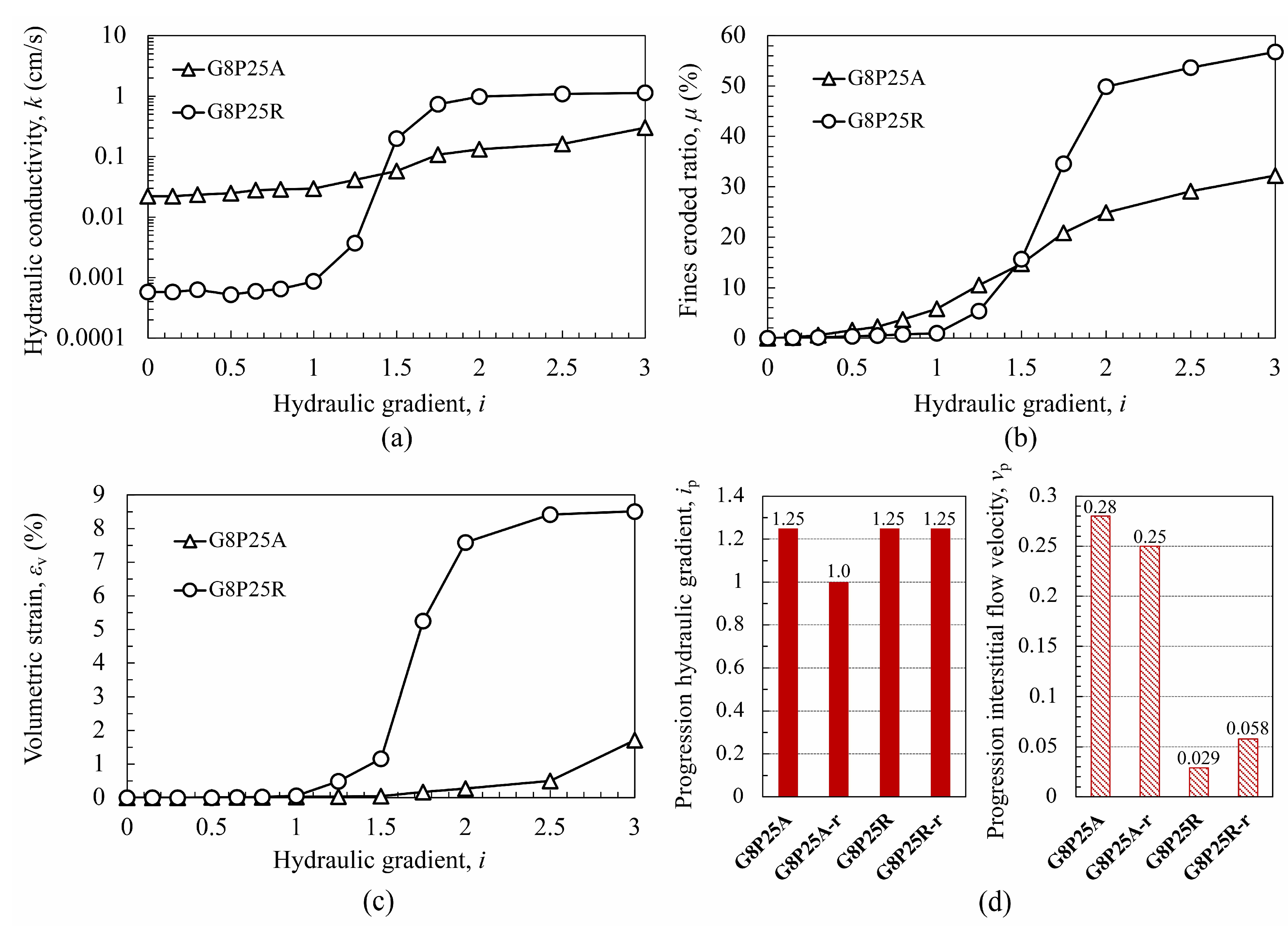

3.4. Effect of Coarse Particle Morphology

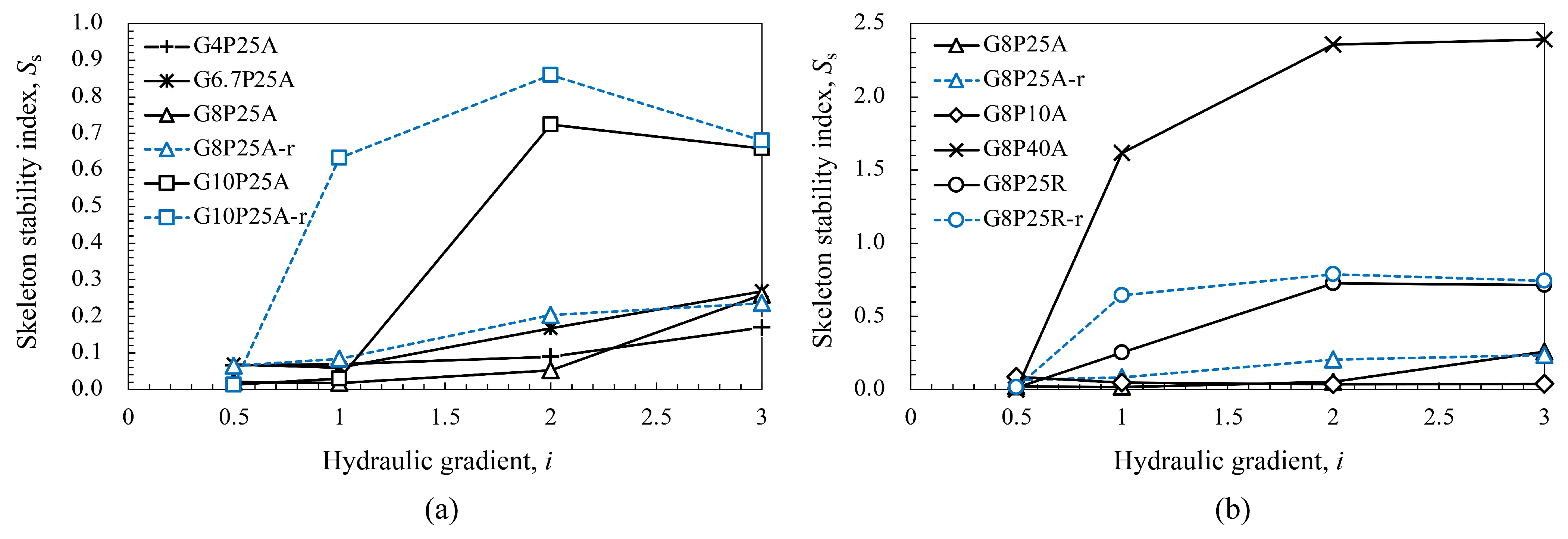

3.5. Skeleton Stability Analysis

4. Conclusions

- (1)

- The gap ratio can impact both the internal stability and mechanical stability of the soil. The increase in gap ratio not only reduced the progression hydraulic gradient, but also promoted the fine particle erosion process and the consequent permeability increase and volumetric strain. Moreover, a positive correlation was shown between the gap ratio and the skeleton stability index, indicating that soil with a higher gap ratio is more likely to suffer mechanical instability during the erosion process.

- (2)

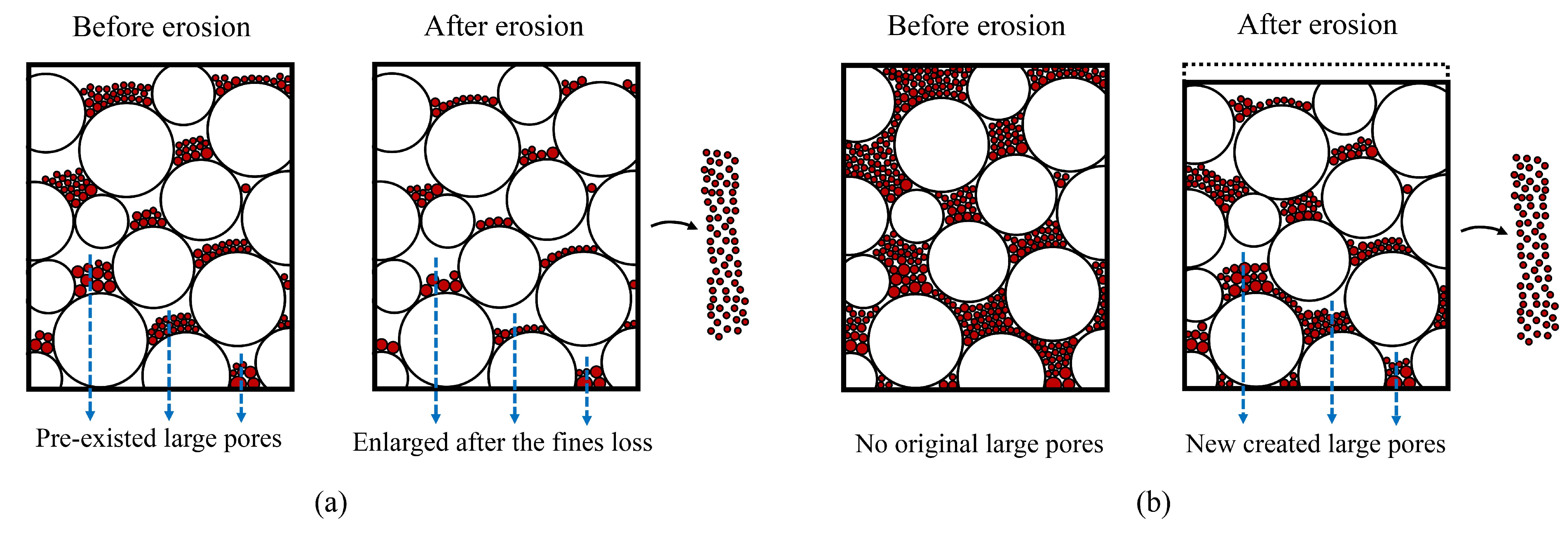

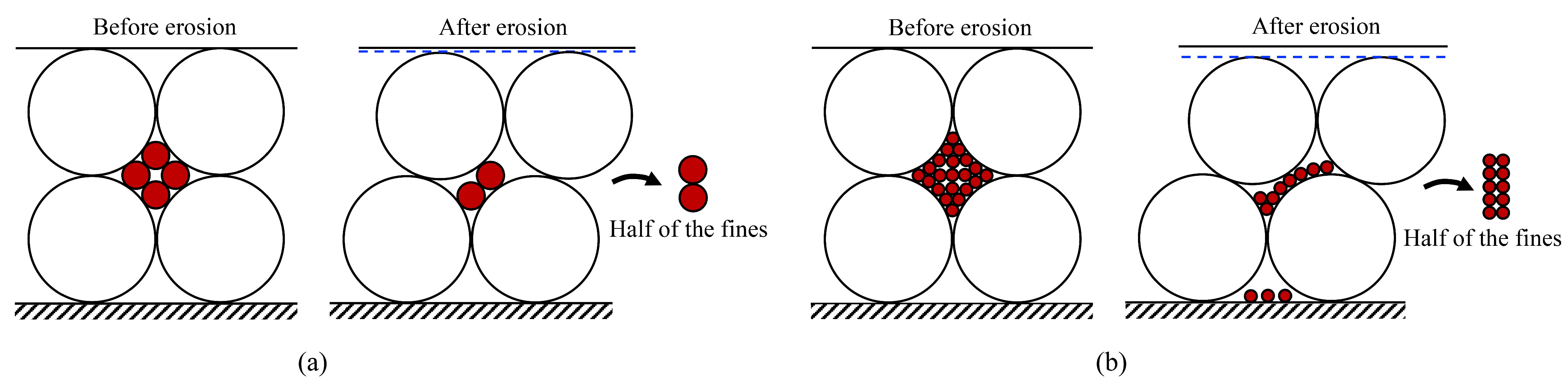

- The fines content influences the filling state of inter-granular pores and the transfer of effective stress on fine particles, thereby affecting the permeability and internal stability of the soil. The soil showed a decreasing trend in the hydraulic conductivity while an increasing trend in the progression hydraulic gradient with the increase of fines content. Additionally, it was found that the increase in permeability was not directly related to the increase in porosity but might be highly related to the change in the pore channels morphology.

- (3)

- The morphology of coarse particles is an influential factor in determining the internal erosion characteristics. The increase in roundness, sphericity, and smoothness can reduce the interlocking effect within coarse particles, which results in two consequences. First, it facilitates the movement of fine particles. The specimens with round coarse particles showed a lower progression interstitial flow velocity and a higher fines eroded ratio compared with the specimens with granular coarse particles. Second, it prompts the soil matrix to reach a denser packing state. The specimens with round coarse particles not only showed a lower porosity and permeability after the specimen preparation, but also showed a higher skeleton stability index during the erosion process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shire, T.; O’Sullivan, C.; Hanley, K.J.; Fannin, R.J. Fabric and effective stress distribution in internally unstable soils. J. Geotech. Geoenviron. Eng. 2014, 140, 04014072. [Google Scholar] [CrossRef] [Green Version]

- Kenney, T.C.; Lau, D. Internal stability of granular filters. Can. Geotech. J. 1985, 22, 215–225. [Google Scholar] [CrossRef]

- Fell, R.; Fry, J.J. State of the art on the likelihood of internal erosion of dams and levees by means of testing. In Erosion in Geomechanics Applied to Dams and Levees; Bonelli, S., Ed.; Wiley: London, UK, 2013; pp. 1–99. [Google Scholar] [CrossRef]

- Skempton, A.W.; Brogan, J.M. Experiments on piping in sandy gravels. Géotechnique 1994, 44, 449–460. [Google Scholar] [CrossRef]

- Hicher, P.Y. Modelling the Impact of Particle Removal on Granular Material Behaviour. Géotechnique 2013, 63, 118–128. [Google Scholar] [CrossRef] [Green Version]

- Benamar, A.; Correia dos Santos, R.N.; Bennabi, A.; Karoui, T. Suffusion evaluation of coarse-graded soils from Rhine dikes. Acta Geotech. 2019, 14, 815–823. [Google Scholar] [CrossRef]

- Prasomsri, J.; Takahashi, A. Experimental study on suffusion under multiple seepages and its impact on undrained mechanical responses of gap-graded soil. Soils Found. 2021, 61, 1660–1680. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, G.; Jin, W. Mesostructural mechanism of hydraulic gradient fluctuations affecting internal instability using transparent soil. Geotech. Test. J. 2022, 45, 1054–1069. [Google Scholar] [CrossRef]

- Foster, M.; Fell, R.; Spannagle, M. The statistics of embankment dam failures and accidents. Can. Geotech. J. 2000, 37, 1000–1024. [Google Scholar] [CrossRef]

- Lade, P.V.; Liggio, C.D.; Yamamuro, J.A. Effects of Non-plastic Fines on Minimum and Maximum Void Ratios of Sand. Geotech. Test. J. 1998, 21, 336–347. [Google Scholar] [CrossRef]

- Chang, D.S.; Zhang, L.M. Extended internal stability criteria for soils under seepage. Soils Found. 2013, 53, 569–583. [Google Scholar] [CrossRef] [Green Version]

- Kezdi, A. Soil Physics: Selected Topics; Elsevier Scientific: Essex, UK, 1979. [Google Scholar]

- Richards, K.S.; Reddy, K.R. Experimental investigation of initiation of backward erosion piping in soils. Géotechnique 2012, 62, 933–942. [Google Scholar] [CrossRef] [Green Version]

- Cubrinovski, M.; Ishihara, K. Maximum and Minimum Void Ratio Characteristics of Sands. Soils Found. 2002, 42, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Sufian, A.; Artigaut, M.; Shire, T.; O’Sullivan, C. Influence of Fabric on Stress Distribution in Gap-Graded Soil. J. Geotech. Geoenviron. Eng. 2021, 147, 04021016. [Google Scholar] [CrossRef]

- Göktepe, B.; Sezer, A. Effect of particle shape on density and permeability of sands. Proc. Inst. Civil Eng.-Geotechn. Eng. 2010, 163, 307–320. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Akbulut, N. Effects of the particle shape and size of sands on the hydraulic conductivity. Acta Geotech. Slov. 2016, 13, 83–93. [Google Scholar]

- Taiba, A.C.; Mahmoudi, Y.; Belkhatir, M.; Schanz, T. Experimental Investigation into the Influence of Roundness and Sphericity on the Undrained Shear Response of Silty Sand Soils. Geotech. Test. J. 2018, 41, 619–633. [Google Scholar] [CrossRef]

- Cherif Taiba, A.; Mahmoudi, Y.; Hazout, L.; Belkhatir, M.; Baille, W. Evaluation of hydraulic conductivity through particle shape and packing density characteristics of sand–silt mixtures. Mar. Georesour. Geotech. 2019, 37, 1175–1187. [Google Scholar] [CrossRef]

- Cho, G.C.; Dodds, J.; Santamarina, J.C. Particle Shape Effects on Packing Density, Stiffness, and Strength: Natural and Crushed Sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef] [Green Version]

- Nie, Z.; Zhu, Y.; Zou, J.; Gong, J.; Liu, S. DEM study of the microscopic characteristics and internal stability of binary mixtures. Powder Technol. 2019, 352, 314–324. [Google Scholar] [CrossRef]

- Ke, L.; Takahashi, A. Experimental Investigations on Suffusion Characteristics and Its Mechanical Consequences on Saturated Cohesionless Soil. Soils Found. 2014, 54, 713–730. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.; Yeh, T.C.J.; Zha, Y.; Wang, J.; Liu, M.; Hao, Y. Onset of suffusion in gap-graded soils under upward seepage. Soils Found. 2017, 57, 849–860. [Google Scholar] [CrossRef]

- Cao, Z.; Sun, W.; Xie, Q.; Wu, Z.; Fu, X.; Fumagalli, A.; Tian, D.; Liang, L. Fluid–solid coupled model for the internal erosion of gap-graded soil–rock mixtures with different fines contents: Its verification and application. Hydrol. Processes 2022, 36, 14677. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, Y.; Yu, X. Influence of particle shape on the erodibility of non-cohesive soil: Insights from coupled CFD–DEM simulations. Particuology 2018, 39, 21–24. [Google Scholar] [CrossRef]

- Nie, Z.; Fang, C.; Gong, J.; Yin. Z. Exploring the effect of particle shape caused by erosion on the shear behaviour of granular materials via the DEM. Int. J. Solids Struct. 2020, 202, 1–11. [Google Scholar] [CrossRef]

- Xiong, H.; Wu, H.; Bao, X.; Fei, J. Investigating effect of particle shape on suffusion by CFD-DEM modeling. Constr. Build Mater. 2021, 289, 123043. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, F.; Zheng, W. Suffusion of Gap-Graded Soil with Realistically Shaped Coarse Grains: A DEM–DFM Numerical Study. Int. J. Geomech. 2023, 23, 04022247. [Google Scholar] [CrossRef]

- Cho, S.E.; Lee, S.R. Instability of unsaturated soil slopes due to infiltration. Comput. Geotech. 2001, 28, 185–208. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, F.; Zhang, H.; Zhang, L.; Zhang, J. Influences of internal erosion on infiltration and slope stability. Bull. Eng. Geol. Environ. 2017, 78, 1–13. [Google Scholar] [CrossRef]

- Sterpi, D. Effects of the erosion and transport of fine particles due to seepage flow. Int. J. Geomech. 2003, 3, 111–122. [Google Scholar] [CrossRef]

- Elekes, F.; Parteli, E.J.R. An expression for the angle of repose of dry cohesive granular materials on Earth and in planetary environments. Proc. Natl. Acad. Sci. USA 2021, 118, e2107965118. [Google Scholar] [CrossRef]

- Torfs, H.; Mitchener, H.; Huysentruyt, H.; Toorman, E. Settling and consolidation of mud/sand mixtures. Coast. Eng. 1996, 29, 27–45. [Google Scholar] [CrossRef]

- Zhang, J.F.; Ding, P.Z.; Zhang, W.; Hu, Z.J. Studies of permeability and seepage deformation characteristics of cushion material for Shuibuya concrete faced rockfill dam. Rock Soil Mech. 2009, 30, 3145–3150. [Google Scholar] [CrossRef]

- Zhong, C.H.; Le, V.T.; Bendahmane, F.; Marot, D.; Yin, Z.Y. Investigation of spatial scale effects on suffusion susceptibility. J. Geotech. Geoenviron. Eng. 2018, 144, 10. [Google Scholar] [CrossRef]

- Pachideh, V.; Hosseini, S. A new physical model for studying flow direction and other influencing parameters on the internal erosion of soils. Geotech. Test. J. 2019, 42, 1431–1456. [Google Scholar] [CrossRef]

- Chang, D.S.; Zhang, L.M. Critical Hydraulic Gradients of Internal Erosion under Complex Stress States. J. Geotech. Geoenviron. Eng. 2013, 139, 1454–1467. [Google Scholar] [CrossRef]

- Jin, W.; Deng, Z.; Wang, G.; Zhang, D.; Wei, L. Internal Erosion Experiments on Sandy Gravel Alluvium in an Embankment Dam Foundation Emphasizing Horizontal Seepage and High Surcharge Pressure. Water 2022, 14, 3285. [Google Scholar] [CrossRef]

- Wang, G.; Deng, Z.Z.; Yang, J.; Chen, X.S.; Jin, W. A large-scale high-pressure erosion apparatus for studying internal erosion in gravelly soils under horizontal seepage flow. Geotech. Test. J. 2022, 45, 1037–1053. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, G.; Jin, W.; Tang, N.; Ren, H.; Chen, X. Characteristics and quantification of fine particle loss in internally unstable sandy gravels induced by seepage flow. Eng. Geol. 2023, 321, 107150. [Google Scholar] [CrossRef]

- Wautier, A.; Bonelli, S.; Nicot, F. DEM investigations of internal erosion: Grain transport in the light of micromechanics. Int. J. Numer. Anal. Met. 2019, 43, 339–352. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.J.; Wang, L.Z.; Yin, Z.Y.; Hong, Y. A coupled CFD-DEM investigation into suffusion of gap-graded soil considering anisotropic stress conditions and flow directions. Acta Geotech. 2022, 18, 3111–3132. [Google Scholar] [CrossRef]

- Fannin, R.J.; Slangen. P. On the Distinct Phenomena of Suffusion and Suffosion. Geotech. Lett. 2014, 4, 289–294. [Google Scholar] [CrossRef]

- Ahmadi, M.; Shire, T.; Mehdizadeh, A.; Disfani, M.M. DEM modelling to assess internal stability of gap-graded assemblies of spherical particles under various relative densities, fine contents and gap ratios. Comput. Geotech. 2020, 126, 103710. [Google Scholar] [CrossRef]

- Shire, T.; O’Sullivan, C. Micromechanical assessment of an internal stability criterion. Acta Geotech. 2013, 8, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Tian, D.; Xie, Q.; Fu, X.; Zhang, J. Experimental study on the effect of fine contents on internal erosion in natural soil deposits. Bull. Eng. Geol. Environ. 2020, 79, 4135–4150. [Google Scholar] [CrossRef]

- Maroof, A.; Mahboubi, A.; Noorzad, A. Particle Shape Effect on Internal Instability of Cohesionless Soils. In Proceedings of the 10th International Conference on Scour and Erosion (ICSE-10), Arlington, VA, USA, 18–21 October 2021. [Google Scholar]

- Wautier, A.; Bonelli, S.; Nicot, F. Rattlers’ contribution to granular plasticity and mechanical stability. Int. J. Plast. 2019, 112, 172–193. [Google Scholar] [CrossRef] [Green Version]

- Shinohara, K.; Oida, M.; Golman, B. Effect of Particle Shape on Angle of Internal Friction by Triaxial Compression Test. Powder Technol. 2000, 107, 131–136. [Google Scholar] [CrossRef]

- Santamarina, J.; Cascante, G. Effect of surface roughness on wave propagation parameters. Géotechnique 1998, 48, 129–136. [Google Scholar] [CrossRef]

| Particle Size Fraction (mm) | Angular Coarse Particles | Round Coarse Particles | ||

|---|---|---|---|---|

| Sphericity | Roundness | Sphericity | Roundness | |

| 80~40 | 0.59 | 0.69 | 0.71 | 0.89 |

| 40~20 | 0.63 | 0.78 | 0.72 | 0.89 |

| 20~10 | 0.58 | 0.84 | 0.76 | 0.96 |

| 10~5 | 0.54 | 0.89 | 0.71 | 0.97 |

| 5~2 | 0.55 | 0.92 | 0.63 | 0.96 |

| Specimen | Gap Ratio | Fines Content (%) | Coarse Particle Morphology | Cu | Initial Porosity |

|---|---|---|---|---|---|

| G4P25A | 4 | 25 | granular | 63.1 | 18.7 |

| G6.7P25A | 6.7 | 25 | granular | 84.2 | 18.5 |

| G8P25A | 8 | 25 | granular | 87.8 | 18.1 |

| G10P25A | 10 | 25 | granular | 93.5 | 18.0 |

| G8P10A | 8 | 10 | granular | 60 | 23.6 |

| G8P40A | 8 | 40 | granular | 72 | 22.1 |

| G8P25R | 8 | 25 | round | 87.8 | 16.1 |

| Specimen | (cm/s) | (cm/s) | (%) | (%) | ||

|---|---|---|---|---|---|---|

| G4P25A | 2.55 × 10−2 | 5.43 × 10−2 | 12.42 | 0.43 | 1.5 | 0.170 |

| G6.7P25A | 1.69 × 10−2 | 0.18 | 29.78 | 1.93 | 1.5 | 0.268 |

| G8P25A | 2.22 × 10−2 | 0.30 | 32.25 | 1.71 | 1.25 | 0.259 |

| G8P25A-r | 1.65 × 10−2 | 0.23 | 28.34 | 1.37 | 1.0 | 0.236 |

| G10P25A | 1.83 × 10−2 | 0.95 | 80.60 | 10.88 | 1.0 | 0.658 |

| G10P25A-r | 1.58 × 10−2 | 0.94 | 73.08 | 10.19 | 0.8 | 0.680 |

| G8P10A | 0.63 | 0.84 | 79.23 | 0.23 | 0.5 | 0.038 |

| G8P40A | 4.63 × 10−5 | 3.64 × 10−5 | 0.08 | 0.06 | >3.0 | 2.391 |

| G8P25R | 5.78 × 10−4 | 1.13 | 56.8 | 8.51 | 1.25 | 0.715 |

| G8P25R-r | 3.99 × 10−4 | 1.05 | 59.9 | 9.31 | 1.25 | 0.741 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; Chen, X.; Jin, W.; Wang, G. Effect of Gradation Characteristics and Particle Morphology on Internal Erosion of Sandy Gravels: A Large-Scale Experimental Study. Water 2023, 15, 2660. https://doi.org/10.3390/w15142660

Deng Z, Chen X, Jin W, Wang G. Effect of Gradation Characteristics and Particle Morphology on Internal Erosion of Sandy Gravels: A Large-Scale Experimental Study. Water. 2023; 15(14):2660. https://doi.org/10.3390/w15142660

Chicago/Turabian StyleDeng, Zezhi, Xiangshan Chen, Wei Jin, and Gang Wang. 2023. "Effect of Gradation Characteristics and Particle Morphology on Internal Erosion of Sandy Gravels: A Large-Scale Experimental Study" Water 15, no. 14: 2660. https://doi.org/10.3390/w15142660

APA StyleDeng, Z., Chen, X., Jin, W., & Wang, G. (2023). Effect of Gradation Characteristics and Particle Morphology on Internal Erosion of Sandy Gravels: A Large-Scale Experimental Study. Water, 15(14), 2660. https://doi.org/10.3390/w15142660