Carbon Nanotube-Supported FeCo2O4 as a Catalyst for an Enhanced PMS Activation of Phenol Removal

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Preparation of FeCo2O4/CNT

2.3. Characterization

2.4. Experimental Section

2.5. Analysis

3. Results and Discussion

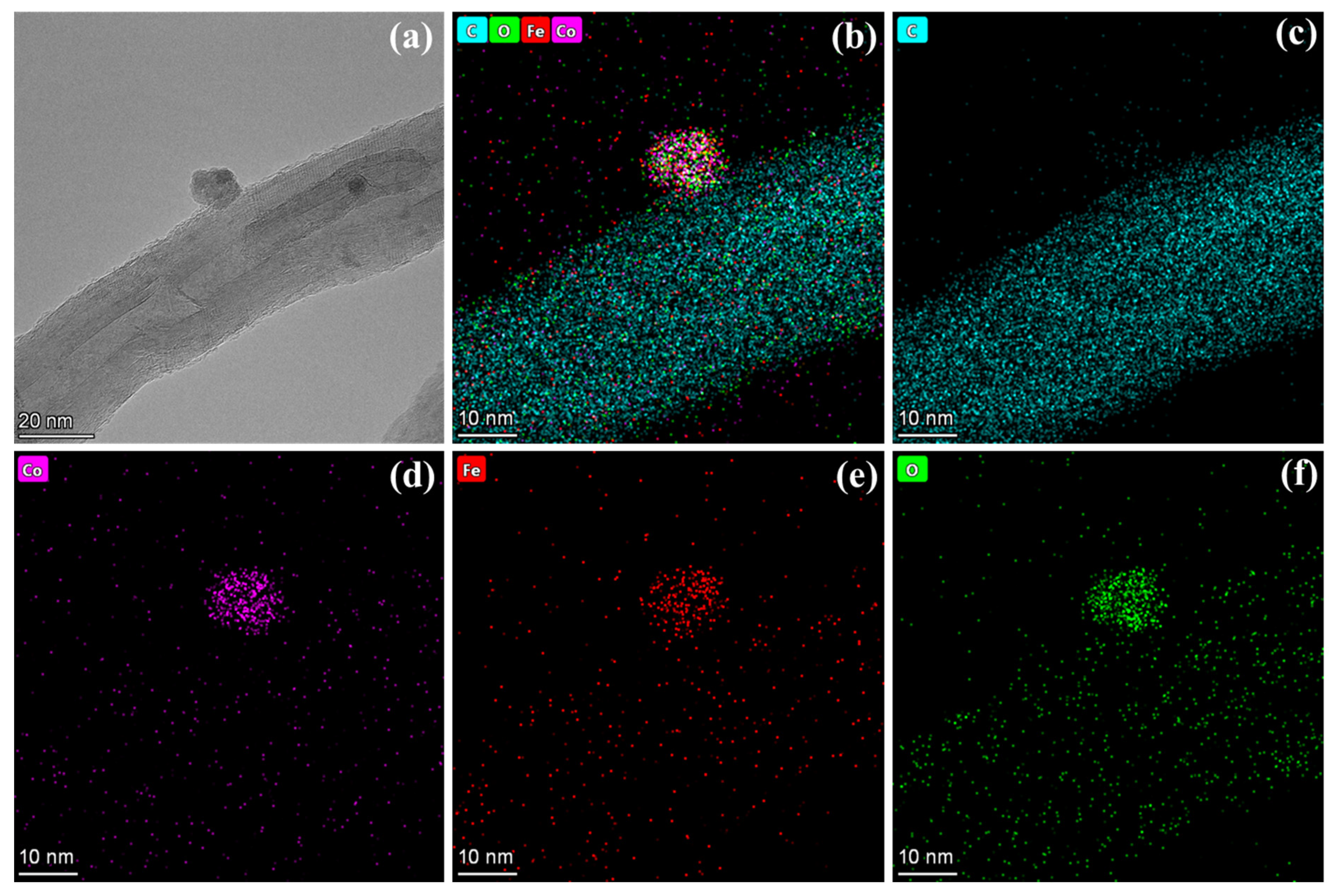

3.1. Characterization of Catalysts

3.2. Performance of FeCo2O4/CNT for Phenol Removal

3.3. Catalytic Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stasinakis, A.S. Use of selected advanced oxidation processes (AOPs) for wastewater treatment—A mini review. Glob. Nest J. 2008, 10, 376–385. [Google Scholar]

- Deng, Y.; Zhao, R. Advanced Oxidation Processes (AOPs) in Wastewater Treatment. Curr. Pollut. Rep. 2015, 1, 167–176. [Google Scholar] [CrossRef]

- Andreozzi, R.; Caprio, V.; Insola, A.; Marotta, R. Advanced oxidation processes (AOP) for water purification and recovery. Catal. Today 1999, 53, 51–59. [Google Scholar] [CrossRef]

- Kohantorabi, M.; Moussavi, G.; Giannakis, S. A review of the innovations in metal- and carbon-based catalysts explored for heterogeneous peroxymonosulfate (PMS) activation, with focus on radical vs. non-radical degradation pathways of organic contaminants. Chem. Eng. J. 2021, 411, 127957. [Google Scholar] [CrossRef]

- Ghanbari, F.; Moradi, M. Application of peroxymonosulfate and its activation methods for degradation of environmental organic pollutants: Review. Chem. Eng. J. 2017, 310, 41–62. [Google Scholar] [CrossRef]

- Medford, A.J.; Vojvodic, A.; Hummelshøj, J.S.; Voss, J.; Abild-Pedersen, F.; Studt, F.; Bligaard, T.; Nilsson, A.; Nørskov, J.K. From the Sabatier principle to a predictive theory of transition-metal heterogeneous catalysis. J. Catal. 2015, 328, 36–42. [Google Scholar] [CrossRef]

- Zheng, S.S.; Li, X.R.; Yan, B.Y.; Hu, Q.; Xu, Y.X.; Xiao, X.; Xue, H.G.; Pang, H. Transition-Metal (Fe, Co, Ni) Based Metal-Organic Frameworks for Electrochemical Energy Storage. Adv. Energy Mater. 2017, 7, 1602733. [Google Scholar] [CrossRef]

- Wang, Q.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotech. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.X.; Indrawirawan, S.; Duan, X.G.; Sun, H.G.; Ang, H.M.; Tadé, M.O.; Wang, S.B. New insights into heterogeneous generation and evolution processes of sulfate radicals for phenol degradation over one-dimensional α-MnO2 nanostructures. Chem. Eng. J. 2015, 266, 12–20. [Google Scholar] [CrossRef]

- Xiao, S.; Cheng, M.; Zhong, H.; Liu, Z.F.; Liu, Y.; Yang, X.; Liang, Q.H. Iron-mediated activation of persulfate and peroxymonosulfate in both homogeneous and heterogeneous ways: A review. Chem. Eng. J. 2020, 384, 123265. [Google Scholar] [CrossRef]

- Zhao, L.L.; Zhang, J.M.; Zhang, Z.P.; Feng, J.; Wei, T.; Ren, Y.M.; Zhu, Y.J.; Ma, J. CuO with (001)-plane exposure efficiently induces peroxymonosulfate to form ≡Cu-OOSO3-intermediates directly oxidizing organic contaminants in water. Chem. Eng. J. 2022, 441, 136100. [Google Scholar] [CrossRef]

- Hu, P.D.; Long, M.C. Cobalt-catalyzed sulfate radical-based advanced oxidation: A review on heterogeneous catalysts and applications. Appl. Catal. B Environ. 2016, 181, 103–117. [Google Scholar] [CrossRef]

- Mao, S.; Zhao, P.; Wu, Y.; Liu, C.; Xia, M.Z.; Wang, F.Y. Promoting charge migration of Co(OH)2/g-C3N4 by hydroxylation for improved PMS activation: Catalyst design, DFT calculation and mechanism analysis. Chem. Eng. J. 2023, 451, 138503. [Google Scholar] [CrossRef]

- Li, J.L.; Zhu, W.H.; Gao, Y.; Lin, P.; Liu, J.W.; Zhang, J.F.; Huang, T.L. The catalyst derived from the sulfurized Co-doped metal-organic framework (MOF) for peroxymonosulfate (PMS) activation and its application to pollutant removal. Sep. Purif. Technol. 2022, 285, 120362. [Google Scholar] [CrossRef]

- Ding, C.; Lei, J.; Cai, Z.; Gao, M.Y.; Zou, Z.Z.; Li, Y.F.; Deng, J. Catalytic oxidation activation of peroxymonosulfate over Fe-Co bimetallic oxides for flurbiprofen degradation. Environ. Sci. Pollut. Res. 2023, 30, 53355–53369. [Google Scholar] [CrossRef]

- Zhang, T.; Li, W.; Croué, J.P. Catalytic ozonation of oxalate with a cerium supported palladium oxide: An efficient degradation not relying on hydroxyl radical oxidation. Environ. Sci. Technol. 2011, 45, 9339–9346. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.M.; Lin, L.Q.; Ma, J.; Yang, J.; Feng, J.; Fan, Z.J. Sulfate radicals induced from peroxymonosulfate by magnetic ferrospinel MFe2O4 (M=Co, Cu, Mn, and Zn) as heterogeneous catalysts in the water. Appl. Catal. B Environ. 2015, 165, 572–578. [Google Scholar] [CrossRef]

- Zhang, H.; An, Q.; Su, Y.; Quan, X.; Chen, S. Co3O4 with upshifted d-band center and enlarged specific surface area by single-atom Zr doping for enhanced PMS activation. J. Hazard. Mater. 2023, 448, 130987. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Zhao, J.; Shen, N.; Ma, T.; Su, Y.U.; Ren, H. Efficient degradation of 2,4-dichlorophenol in aqueous solution by peroxymonosulfate activated with magnetic spinel FeCo2O4 nanoparticles. Chemosphere 2018, 197, 670–679. [Google Scholar] [CrossRef]

- Zhang, T.; Zhu, H.B.; Croué, J.P. Production of Sulfate Radical from Peroxymonosulfate Induced by a Magnetically Separable CuFe2O4 Spinel in Water: Efficiency, Stability, and Mechanism. Environ. Sci. Technol. 2013, 47, 2784–2791. [Google Scholar] [CrossRef]

- Yamashita, T.; Hayes, P. Analysis of XPS spectra of Fe2+ and Fe3+ ions in oxide materials. Appl. Surf. Sci. 2008, 254, 2441–2449. [Google Scholar] [CrossRef]

- Liang, J.; Fan, Z.Y.; Chen, S.; Ding, S.J.; Yang, G. Hierarchical NiCo2O4 nanosheets @ halloysite nanotubes with ultrahigh capacitance and long cycle stability as electrochemical pseudocapacitor materials. Chem. Mater. 2014, 26, 4354–4360. [Google Scholar] [CrossRef]

- Das, T.N.; Huie, R.E.; Neta, P. Reduction Potentials of SO3•−, SO5•−, and S4O6•3− Radicals in Aqueous Solution. J. Phys. Chem. A 1999, 103, 3581–3588. [Google Scholar] [CrossRef]

- Stumm, W. Chemistry of the Solid-Water Interface: Process at the Mineral-Water and Particle-Water Interface in Natural Systems; John Wiley & Sons: New York, NY, USA, 1992. [Google Scholar]

- Wang, A.; Zhu, B.Z.; Huang, C.H.; Zhang, W.X.; Wang, M.Y.; Li, X.C.; Ling, L.; Ma, J.; Fang, J.Y. Generation mechanism of singlet oxygen from the interaction of peroxymonosulfate and chloride in aqueous systems. Water Res. 2023, 235, 119904. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Liu, L.; Li, Y.; Li, W.; Zhou, L.; Lan, Y.; Li, Y. Insight into heterogeneous catalytic degradation of sulfamethazine by peroxymonosulfate activated with CuCo2O4 derived from bimetallic oxalate. Chem. Eng. J. 2020, 384, 123257. [Google Scholar] [CrossRef]

- Fu, H.; Ma, S.; Zhao, P.; Xu, S.; Zhan, S. Activation of peroxymonosulfate by graphitized hierarchical porous biochar and MnFe2O4 magnetic nanoarchitecture for organic pollutants degradation: Structure dependence and mechanism. Chem. Eng. J. 2019, 360, 157–170. [Google Scholar] [CrossRef]

- Pang, Y.; Zhou, J.; Yang, X.; Lan, Y.; Chen, C. Rationally designed Co3O4-SnO2 activated peroxymonosulfate for the elimination of chloramphenicol. Chem. Eng. J. 2021, 418, 129401. [Google Scholar] [CrossRef]

- Ding, H.; Zhu, Y.; Wu, Y.; Zhang, J.; Deng, H.; Zheng, H.; Liu, Z.; Zhao, C. In situ regeneration of phenol-saturated activated carbon fiber by an electro peroxymonosulfate process. Environ. Sci. Technol. 2020, 54, 10944–10953. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, H.G.; Zhang, Y.L.; Tang, W.H.; Cheng, X.; Li, W. Heterogeneous activation of peroxymonosulfate by sillenite Bi25FeO40: Singlet oxygen generation and degradation for aquatic levofloxacin. Chem. Eng. J. 2018, 343, 128–137. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhou, H.; Ma, L.; Wang, Q.; Sun, D.; Jin, L.; Zeng, G.; Zhao, J. Carbon Nanotube-Supported FeCo2O4 as a Catalyst for an Enhanced PMS Activation of Phenol Removal. Water 2023, 15, 2856. https://doi.org/10.3390/w15152856

Wang J, Zhou H, Ma L, Wang Q, Sun D, Jin L, Zeng G, Zhao J. Carbon Nanotube-Supported FeCo2O4 as a Catalyst for an Enhanced PMS Activation of Phenol Removal. Water. 2023; 15(15):2856. https://doi.org/10.3390/w15152856

Chicago/Turabian StyleWang, Jing, Huanyu Zhou, Li Ma, Quanfeng Wang, Da Sun, Libo Jin, Guoming Zeng, and Jujiao Zhao. 2023. "Carbon Nanotube-Supported FeCo2O4 as a Catalyst for an Enhanced PMS Activation of Phenol Removal" Water 15, no. 15: 2856. https://doi.org/10.3390/w15152856

APA StyleWang, J., Zhou, H., Ma, L., Wang, Q., Sun, D., Jin, L., Zeng, G., & Zhao, J. (2023). Carbon Nanotube-Supported FeCo2O4 as a Catalyst for an Enhanced PMS Activation of Phenol Removal. Water, 15(15), 2856. https://doi.org/10.3390/w15152856