Experimental Investigation of Breach Mechanism for Overtopped Cohesive and Non-Cohesive Embankments

Abstract

:1. Introduction

- The breach mechanism was recorded and analyzed to describe the behavior of the embankment during and after breaching;

- The breach evolution was described in terms of three different stages;

- A detailed study of the different breach shapes formed after the breaching process was carried out;

- The effect of moisture content was described by analyzing the results of three experiments.

2. Review of Literature

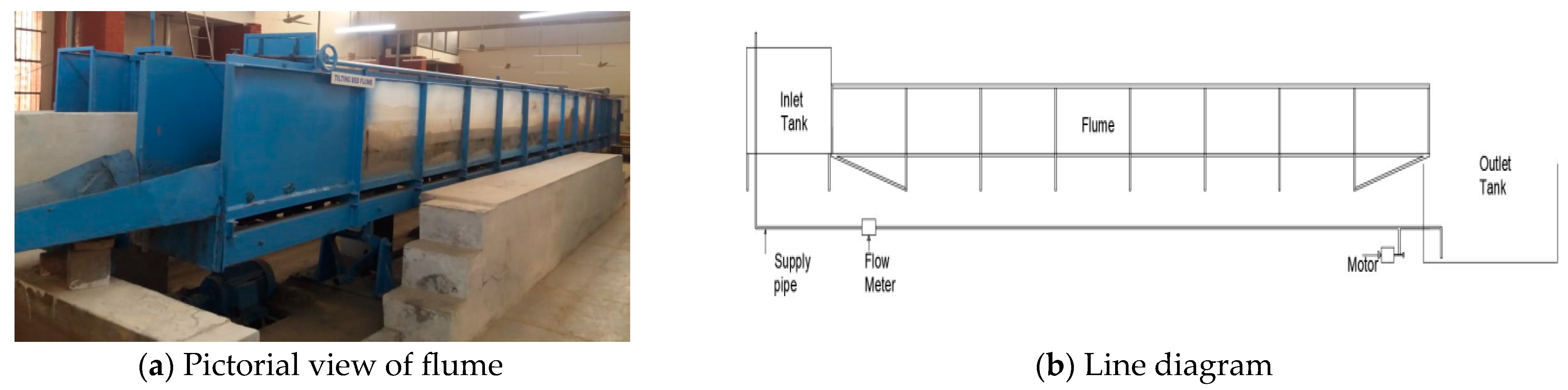

3. Experimental Facility

3.1. Layout of Hydraulic Channel

3.2. Material Characteristics

3.3. Experimental Procedure

4. Design of Embankment Models

4.1. Hydraulic and Material Homogeneity

4.2. Overtopping and Breaching of Embankment Models

4.3. Flow Parameters

4.4. Experimental Observations

5. Results and Discussion

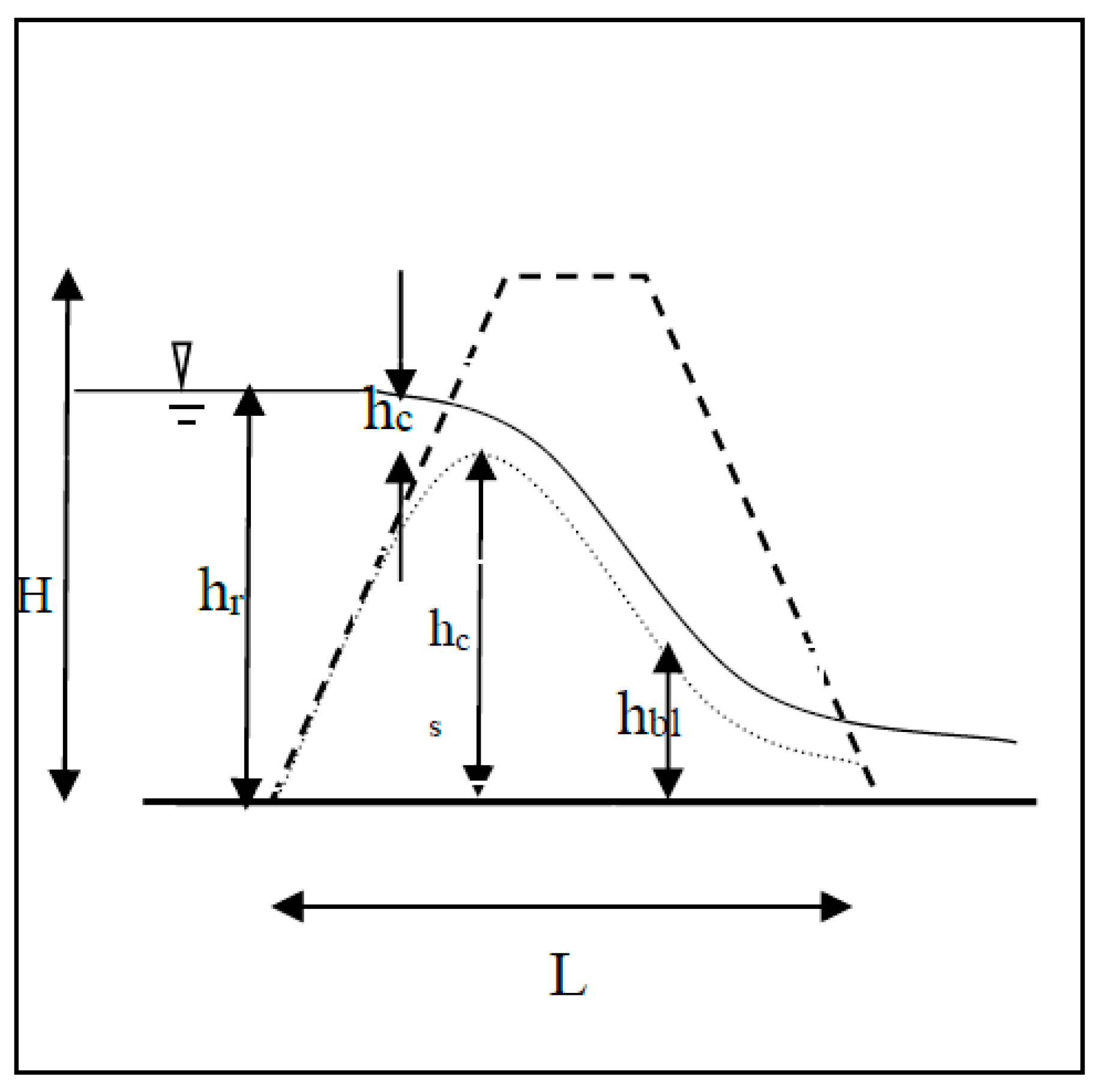

5.1. Breach Evolution

5.1.1. Stage I: Initial Erosion

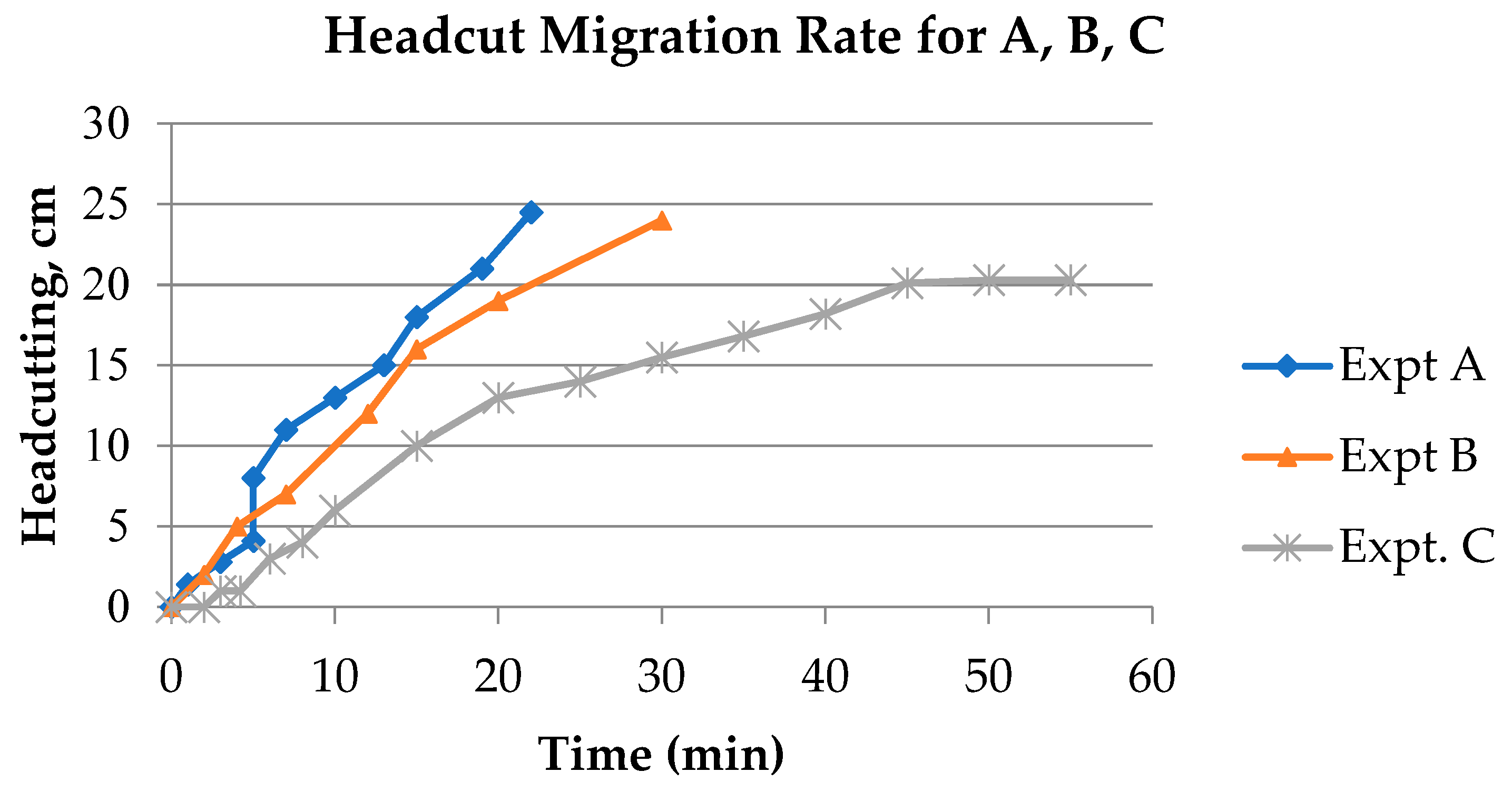

5.1.2. Stage II: Head Cut Erosion

5.1.3. Stage III: Lateral Erosion

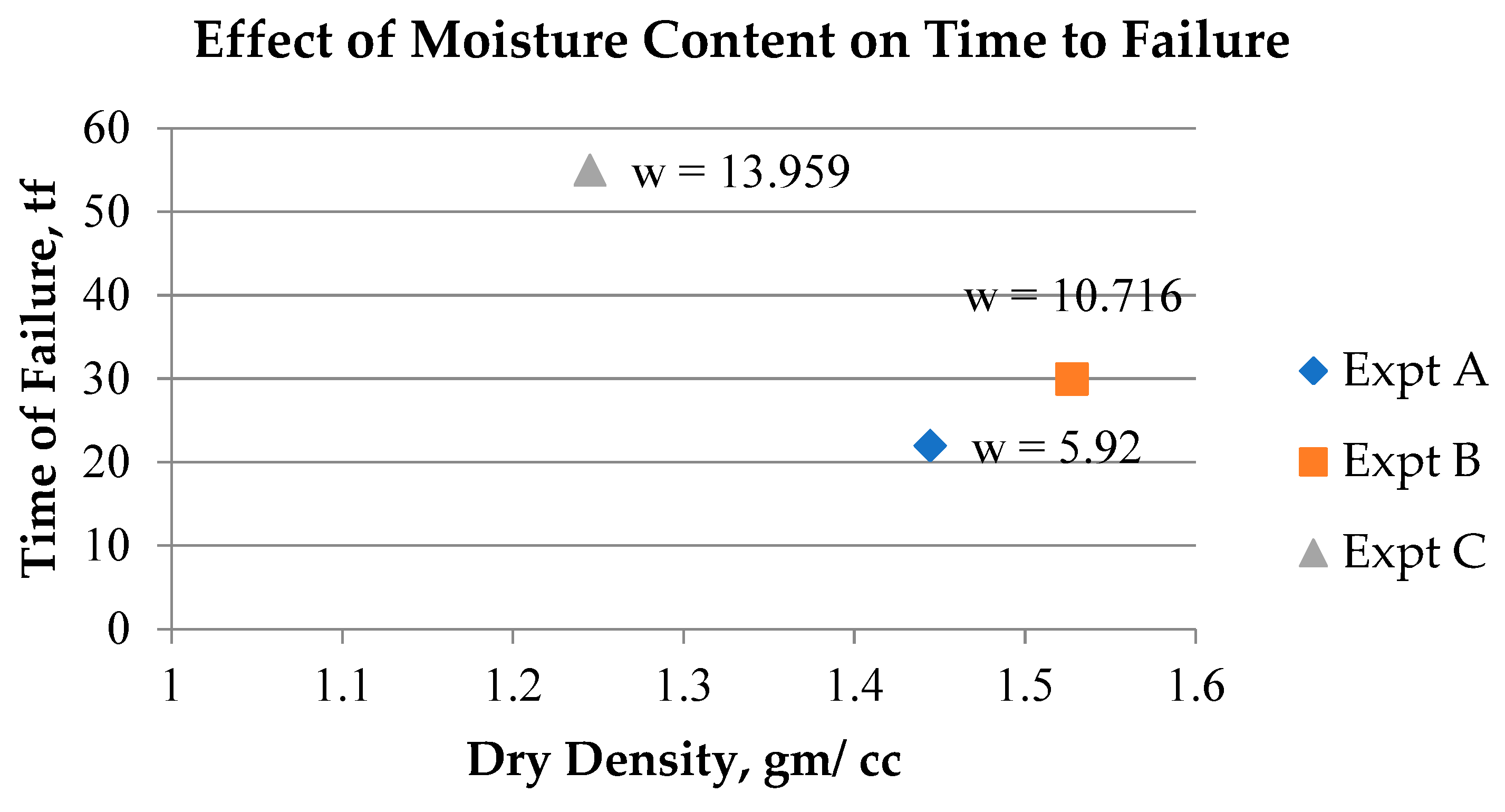

5.1.4. Effect of Water Content

5.1.5. Breach Shape

5.1.6. Comparison with Other Researchers

6. Conclusions

- Initial erosion;

- Headcut erosion;

- Lateral erosion.

- A drop of about 50% in moisture content causes an approximately 20% decrease in time to failure. Hence, moisture content directly affects the breach widening;

- Variation in water content affected the dry density of soil.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Psomiadis, E.; Tomanis, L.; Kavvadias, A.; Soulis, K.; Charizopoulos, N.; Michas, S. Potential Dam Breach Analysis and Flood Wave Risk Assessment Using HEC-RAS and Remote Sensing Data: A Multicriteria Approach. Water 2021, 13, 364. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Xuan, G.; Wang, X.; Li, J. Overtopping breaching of cohesive homogeneous earth dam with different cohesive strength. Sci. China Ser. E Technol. Sci. 2009, 52, 3024–3029. [Google Scholar] [CrossRef]

- Loukola, E.; Reiter, P.; Shen, C.; Pan, S. Embankment dams and their foundations, evaluation of erosion. In Proceedings of the International Workshop on Dam Safety Evaluation, Grindelwald, Switzerland, 26–28 April 1993; Volume 4. [Google Scholar]

- Foster, M.; Fell, R.; Spannagle, M. A Method for Assessing the Relative Likelihood of Failure of Embankment Dams by Piping. Can. Geotech. J. 2000, 37, 1025–1061. [Google Scholar] [CrossRef]

- Zhang, L.M.; Xu, Y.; Jia, J.S. Analysis of earth dam failures—A database approach. In Proceedings of the 1st International Symposium on Geotechnical Safety & Risk, ISGSR2007, Shanghai Tongji University, Shanghai, China, 18–19 October 2007; pp. 293–302. [Google Scholar]

- Singh, V.P. Dam Breach Modeling Technology; Kluwer Academic Publisher: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Wahl, T.L. Prediction of Embankment Dam Breach Parameters: A Literature Review and Needs Assessment; Dam Safety Rep. No. DSO-98-004; U.S. Department of the Interior, Bureau of Reclamation: Denver, CO, USA, 1998.

- Wahl, T.L. Predicting of Embankment Dam Breach Parameters: A Needs Assessment; PAP-735; USBR, Water Resources Research Laboratory: Denver, CO, USA, 2007. [Google Scholar]

- Rahman, A.; Mohamed, N. The Effect of Flowing Water on Cohesive Beds. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 1963. [Google Scholar] [CrossRef]

- Das, P.K. Breach Erosion Process of Homogeneous Earthfill Dams and Fuse Pugs Due to Overtopping Flow. Ph.D. Thesis, IIT Kanpur, Kanpur, India, 1997. [Google Scholar]

- Kumar, J.; Kouzer, K.M. Vertical uplift capacity of horizontal anchors using upper bound limit analysis and finite elements. Can. Geotech. J. 2008, 45, 698–704. [Google Scholar] [CrossRef]

- Aydan, O.; Ohta, Y.; Hamada, M. Geotechnical evaluation of slope and ground failures during the 8 October 2005 Muzaffarabad earthquake. Pakistan. J. Seismol. 2009, 13, 399–413. [Google Scholar] [CrossRef]

- Trivedi, A. Strength and dilatancy of jointed rocks with granular fill. Acta Geotech. 2010, 5, 15–31. [Google Scholar] [CrossRef]

- Gaagai, A.; Aouissi, H.A.; Krauklis, A.E.; Burlakovs, J.; Athamena, A.; Zekker, I.; Boudoukha, A.; Benaabidate, L.; Chenchouni, H. Modeling and Risk Analysis of Dam-Break Flooding in a Semi-Arid Montane Watershed: A Case Study of the Yabous Dam, Northeastern Algeria. Water 2022, 14, 767. [Google Scholar] [CrossRef]

- Wu, W. Earthen Embankment Breaching. J. Hydraul. Eng. 2011, 137, 1549–1564. [Google Scholar] [CrossRef]

- Verma, D.; Berwal, P.; Khan, M.A.; Alharbi, R.S.; Alfaisal, F.M.; Rathnayake, U. Design for the Prediction of Peak Outflow of Embankment Breaching due to Overtopping by Regression Technique and Modelling. Water 2023, 15, 1224. [Google Scholar] [CrossRef]

- Verma, D.; Setia, B.; Arora, V.K. Effect of Functional Parameters on Embankment Breaching. In Proceedings of the 3rd International Conference on Natural Hazards and Infrastructure, ICONHIC, Athens, Greece, 5–7 July 2022. [Google Scholar]

- Cristofano, E.A. Method of Computing Erosion Rate for Failure of Earthfill Dams; U.S. Bureau of Reclamation: Denver, CO, USA, 1965.

- Ashraf, M.; Soliman, A.H.; El-Ghorab, E.; El Zawahry, A. Assessment of embankment dams breaching using large scale physical modeling and statistical methods. Water Sci. 2018, 32, 362–379. [Google Scholar] [CrossRef]

- Weiming, W. Simplified Physically Based Model of Earthen Embankment Breaching. J. Hydraul. Eng. 2013, 139, 837–851. [Google Scholar]

- Tingsanchali, T.; Chinnarasri, C. Numerical modelling of dam failure due to flow overtopping. Hydrol. Sci. J. 2001, 46, 113–130. [Google Scholar] [CrossRef]

- Wang, P.; Kahawita, R. Modeling the hydraulics and erosion process in breach formation due to overtopping. In Sedimentation and Sediment Transport; Springer: Dordrecht, The Netherlands, 2003; pp. 211–220. [Google Scholar]

- MacDonald, T.C.; Langridge-Monopolis, J. Breaching characteristics of dam failures. J. Hydraul. Eng. 1984, 110, 567–586. [Google Scholar] [CrossRef]

- Powledge, G.R.; Ralston, D.C.; Miller, P.; Chen, Y.H.; Clopper, P.E.; Temple, D.M. Mechanics of overflow erosion on embankments. I: Research activities. J. Hydraul. Eng. 1989, 115, 1040–1055. [Google Scholar] [CrossRef]

- Singh, V.P.; Scarlatos, C.A. Analysis of gradual earth-dam failure. J. Hydraul. Eng. 1988, 114, 21–42. [Google Scholar] [CrossRef]

- Zhong, Q.M.; Chen, S.S.; Deng, Z.; Mei, S.A. Prediction of overtopping-induced breach process of cohesive dams. J. Geotech. Geoenvironmental Eng. 2019, 145, 04019012. [Google Scholar] [CrossRef]

- Wang, Z.; Bowles, D.S. Dam breach simulations with multiple breach locations under wind and wave actions. Adv. Water Resour. 2006, 29, 1222–1237. [Google Scholar] [CrossRef]

- Mohamed, A.A.A.; Samuels, P.G.; Morris, M.W.; Ghataora, G.S. Improving the accuracy of prediction of breach formation through embankment dams and flood embankments. In Proceedings of the International Conference on Fluvial Hydraulics, Louvain-la-Neuve, Belgium, 4–6 September 2002. [Google Scholar]

- Faeh, R. Numerical modeling of breach erosion of river embankments. J. Hydraul. Eng. 2007, 133, 1000–1009. [Google Scholar] [CrossRef]

- Wahl, T.L. Dam breach modeling-an overview of analysis methods. In Proceedings of the Joint Federal Interagency Conference on Sedimentation and Hydrologic Modeling, Las Vegas, NV, USA, 27 June–1 July 2010. [Google Scholar]

- Verma, D.K.; Setia, B.; Arora, V.K. Breach behaviour of earth embankments during overtopping. In Proceedings of the 2nd International Conference on Natural Hazards and Infrastructure, ICONHIC 2019, Chania, Greece, 23–26 June 2019. [Google Scholar]

- Alhasan, Z.; Jandora, J.; Říha, J. Study of dam-break due to overtopping of four small dams in the Czech Republic. Acta Univ. Agric. Silvic. Mendel. Brun. 2015, 63, 717–729. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Visser, P.J.; Vrijling, J.K.; Wang, G.Q. Experimental investigation on breaching of embankments. Sci. China Technol. Sci. 2011, 54, 148–155. [Google Scholar] [CrossRef]

- Verma, D.K.; Setia, B.; Arora, V.K. Experimental Study of Breaching of an Earthen Dam using a Fuse Plug Model. Int. J. Eng. Trans. A Basics 2017, 30, 479–485. [Google Scholar]

- Pugh, C.A. Hydraulic Model Studies of Fuse Plug Embankment; Rep. No. REC-ERC-85-7; Bureau of Reclamation, U.S. Department of the Interior: Denver, CO, USA, 1985; Volume 34.

- Schmocker, L.; Höck, E.; Mayor, P.A.; Weitbrecht, V. Hydraulic model study of the fuse plug spillway at Hagneck canal, Switzerland. J. Hydraul. Eng. 2013, 139, 894–904. [Google Scholar] [CrossRef]

- Verma, D.; Setia, B.; Arora, V.K. Mechanism of embankment dam breach. In Proceedings of the International Conference on Fluvial Hydraulics, Lausanne, Switzerland, 3–5 September 2014; pp. 1655–1659. [Google Scholar]

- Verma, D.; Setia, B.; Arora, V.K. Experimental study on breaching of embankments. In Proceedings of the 9th International Conference on Scour and Erosion, ICSE, 2018, Taipei, Taiwan, 5–8 November 2018; pp. 255–261. [Google Scholar]

- Verma, D.K.; Setia, B. Two-dimensional unsteady dam breach analysis using fuse plug models. Disaster Adv. 2021, 14, 74–82. [Google Scholar]

- Aamir, M.; Ahmad, Z.; Pandey, M.; Khan, M.A.; Aldrees, A.; Mohamed, A. The Effect of Rough Rigid Apron on Scour Downstream of Sluice Gates. Water 2022, 14, 2223. [Google Scholar] [CrossRef]

- Wu, M.; Ge, W.; Li, Z.; Wu, Z.; Zhang, H.; Li, J.; Pan, Y. Improved Set Pair Analysis and Its Application to Environmental Impact Evaluation of Dam Break. Water 2019, 11, 821. [Google Scholar] [CrossRef]

- Kruse, E.; Eslamian, S.; Ostad-Ali-Askari, K.; Hosseini-Teshnizi, S.H. Borehole Investigations. In Encyclopedia of Engineering Geology, Encyclopedia of Earth Sciences Series; Bobrowsky, P., Marker, B., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Dhiman, S.; Patra, K.C. Studies of dam disaster in India and equations for breach parameter. Nat. Hazards 2019, 98, 783–807. [Google Scholar] [CrossRef]

- Visser, P.J. Breach growth in sand-dikes. In Communications on Hydraulic and Geotechnical Engineering; Delft University of Technology: Delft, The Netherlands, 1998; Volume 172. [Google Scholar]

- Zhu, Y.; Visser, P.J.; Vrijling, J.K. Laboratory observations of embankment breaching. In Proceedings of the 7th ICHE Congress, Philadelphia, PA, USA, 10–13 September 2006. [Google Scholar]

- Chang, D.S.; Zhang, L.M. Simulation of the erosion process of landslide dams due to overtopping considering variations in soil erodibility along depth. Nat. Hazards Earth Syst. Sci. 2010, 10, 933–946. [Google Scholar] [CrossRef]

- Zhao, G. Breach Growth in Cohesive Embankments due to Overtopping. Ph.D. Thesis, Delft Academic Press, Delft, The Netherlands, 2016. [Google Scholar]

- Hanson, G.J.; Morris, M.; Vaskinn, K.; Temple, D.M.; Hunt, S.; Hassan, M. Research activities on the erosion mechanics of overtopped embankment dams. ASDSO J. Dam Saf. 2005, 3, 4–16. [Google Scholar]

- Hanson, G.J.; Temple, D.M.; Morris, M.; Hassan, M.; Cook, K. Simplified Breach Analysis Model for Homogeneous Embankments: Part II, Parameter Inputs and Variable Scale Model Comparisons; The United State Society on Dams: Salt Lake City, UT, USA, 2005; pp. 163–174. [Google Scholar]

- Hunt, S.L.; Hanson, G.J.; Cook, K.R.; Kadavy, K.C. Breach widening observations from earthen embankment tests. Trans. ASAE 2005, 48, 1115–1120. [Google Scholar] [CrossRef]

| Soil Type | Median Size (D50) mm | Dry Density (gm/cc) | Cohesion (Kg/cm2) | Moisture Content (%) | Soil Classification |

|---|---|---|---|---|---|

| A | 0.25 | 1.82 | 0.055 | 24 | SW (Non-cohesive) |

| B | 0.09 | 1.66 | 0.35 | 18 | CL (Cohesive) |

| Model No. | Soil Type | Embankment Model Parameters | ||||||

|---|---|---|---|---|---|---|---|---|

| Dam Length (cm) | Dam Height (cm) | Crest Width (cm) | Bottom Width (cm) | Upstream Slope | Downstream Slope | Flume Bed Thickness (cm) | ||

| M1 | Soil A | 60 | 25 | 20 | 92.5 | 1:1 | 1:1.5 | 10 |

| M2 | Soil B | 60 | 25 | 20 | 92.5 | 1:1 | 1:1.5 | 10 |

| M3 | Soil A | 60 | 25 | 20 | 120 | 1:1 | 1:2 | 10 |

| M4 | Soil B | 60 | 25 | 20 | 120 | 1:1 | 1:2 | 10 |

| M5 | Soil A | 60 | 35 | 20 | 142.5 | 1:1 | 1:1.5 | 10 |

| M6 | Soil B | 60 | 35 | 20 | 142.5 | 1:1 | 1:1.5 | 10 |

| Model No. | Breach Initiation Time (s) | Time to Failure (s) | Breach Width (cm) | Breach Depth (cm) | |

|---|---|---|---|---|---|

| Top | Bottom Width | ||||

| M1 | 4 | 99 | 50 | 40 | 19 |

| M2 | 20 | 132 | 42 | 48 | 20 |

| M3 | 3 | 120 | 42 | 48 | 25 |

| M4 | 55 | 181 | 44 | 48 | 15 |

| M5 | 8 | 98 | 46 | 44 | 32 |

| M6 | 35 | 208 | 48 | 47 | 30 |

| Expt. | Water Content, w | Dry Density, γ | w/w0 | γ/γd | Time to Failure, tf |

|---|---|---|---|---|---|

| A | 5.922 | 1.4442 | 0.42 | 0.87 | 22 |

| B | 10.716 | 1.5272 | 0.76 | 0.92 | 30 |

| C | 13.959 | 1.245 | 0.99 | 0.75 | 55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verma, D.; Berwal, P.; Gupta, N.; Alfaisal, F.M.; Khan, M.A.; Alam, S.; Qadri, J. Experimental Investigation of Breach Mechanism for Overtopped Cohesive and Non-Cohesive Embankments. Water 2023, 15, 3030. https://doi.org/10.3390/w15173030

Verma D, Berwal P, Gupta N, Alfaisal FM, Khan MA, Alam S, Qadri J. Experimental Investigation of Breach Mechanism for Overtopped Cohesive and Non-Cohesive Embankments. Water. 2023; 15(17):3030. https://doi.org/10.3390/w15173030

Chicago/Turabian StyleVerma, Deepak, Parveen Berwal, Nakul Gupta, Faisal M. Alfaisal, Mohammad Amir Khan, Shamshad Alam, and Jibran Qadri. 2023. "Experimental Investigation of Breach Mechanism for Overtopped Cohesive and Non-Cohesive Embankments" Water 15, no. 17: 3030. https://doi.org/10.3390/w15173030

APA StyleVerma, D., Berwal, P., Gupta, N., Alfaisal, F. M., Khan, M. A., Alam, S., & Qadri, J. (2023). Experimental Investigation of Breach Mechanism for Overtopped Cohesive and Non-Cohesive Embankments. Water, 15(17), 3030. https://doi.org/10.3390/w15173030