1. Introduction

Water heating corresponds to one of the main forms of energy consumption in households in several countries [

1], and its performance is mainly influenced by the climatic conditions, the energy source used, and the type and arrangement of the system [

2]. In Brazil, the electric shower is the third most common equipment, with the largest share in electricity consumption in the residential sector, accounting for about 15% of the sector’s consumption [

3]. According to [

4], 37.5% of Brazilian households use electricity to heat water for showers, while less than 2.0% use gas or solar energy.

To reduce electricity consumption and promote clean energy, several policies worldwide encourage the use of more efficient systems and renewable energy sources for water heating, such as financial subsidy policies, tax credits, and even mandatory policies [

5]. In Brazil, some cities [

6] and states [

7] already have laws making it mandatory to use solar heating to meet a minimum proportion of hot water demand. Solar heating systems can reduce the maximum peak demand compared to electric showers, which highly represent the peak demand in Brazil. A study showed that solar heating systems would provide more than a 60% reduction in the peak demand if these systems were applied in new housing developments in Brazil, improving the national electric power generation system [

8]. In addition, several authors have indicated solar energy as an alternative to reduce primary energy consumption for hot water generation [

9,

10]. However, using solar systems in multi-family buildings may not be as efficient as for single-family homes. In tall buildings, the greater that the number of floors is, the higher that the ratio is between the total hot water demand and the perimeter of the building. In such cases, the roof area may not be sufficient for the collectors needed to meet the demand [

11]. Especially in climates with significant variations in solar radiation, solar heating systems may not be suitable all year. A backup system, such as gas, should be considered in these cases. In turn, the efficiency of the backup system depends on the temperature difference between the cold and the hot water [

12].

Furthermore, not only hot water generation should be considered in water heating system performance and efficiency analyses. Several authors have shown that thermal losses in hot water storage and distribution and electricity consumption for water circulation influence the system performance and the water and energy consumption [

1]. According to Gu [

13] and Bøhm [

14], many studies and standards focus on the efficiency of hot water generation but do not consider the thermal losses in the pipes. These losses must be considered to avoid wasting water and energy and to increase the efficiency of the system as a whole. Thermal losses can be reduced by insulating the pipes and reducing the temperature difference between the water and the environment [

15]. According to Atienza-Márquez et al. [

16], poor thermal insulation and deterioration over time can be responsible for significant thermal loss throughout hot water distribution pipes. Lutz [

17] estimated that 20% of household hot water is wasted. After a hot water shower, the hot water in the pipes loses heat, so the water temperature decreases. When the system is activated again, the water in the pipe is at a lower temperature than expected and is discarded until the water reaches the desired temperature [

18]. In addition to the waste of energy to reheat a quantity of water that had already been previously heated, there is the waste of drinking water. These previous works raised questions about the efficiency of water heating systems with significant distribution losses compared to electric systems, with which no distribution losses occur [

19].

It is important to note that the energy lost through heat transfer in the pipes can significantly increase energy consumption for hot water generation, but it is not a rule. As shown in the NAHB study [

20], the reduction in heat losses due to thermal insulation will not necessarily reduce energy consumption because the efficiency of the distribution system is influenced by the temperature of the hot water and the environment. In addition, even with insulation, there will be some heat losses. In addition, the time between uses of the shower impacts the thermal losses of the system because, if the shower is used twice in a row, the remaining hot water in the pipes is used again before its temperature decreases.

The distance between the heater and the shower also influences energy losses because the longer that the pipes are, the greater that the volume of water is that will cool in the pipes when the system is being used. Furthermore, it takes longer for the heated water to reach the point of use. Therefore, cold water is wasted until hot water arrives [

21]. In this context, works such as Wendt et al. [

22] and Bøhm [

14] recommended that hot water pipes be as short as possible. Ioris and Ghisi [

23] suggested installing an automated system to save cold water in one or two showers per flat in a multi-family building. The authors found that these systems could save 2.13 litres and 4.14 litres of water per shower in cases of one and two systems per flat, respectively. In addition, intelligent techniques (e.g., artificial neural networks and vector machines) can be used to predict heaters’ performance [

24].

The performance of alternative water heaters has been investigated in the literature, e.g., photovoltaic-powered electric water heaters [

25], photovoltaic panels combined with thermal collectors [

26], solar-assisted heat pump water heaters [

27], biogas from building waste [

28], biomass and geothermal energy heaters [

29], and other cogeneration systems [

30]. However, studies analysing the thermal performance of these alternative systems compared to those using only electricity have been limited. In addition, in some works, the electric systems had water storage [

31], which is a system different from the electric showers (with instantaneous heating) widely used in Brazil. Thus, studies evaluating the efficiency of alternative systems compared to electric showers in different climatic and building conditions are still needed. Furthermore, Brazilian laws and regulations present systems that use clean energy for water heating, such as solar energy, as more energy-efficient alternatives. However, Brazil has an extensive territory and a great variety of climates. The north and northeast regions have hot climates and less need for hot water compared to the south and southeast, which have milder climates. Thus, performance evaluations must consider climate characteristics and thermal losses in the pipes, as they can influence the efficiency of these systems. This study aims to compare the primary energy consumption and thermal losses of different water heating systems for showering during the operation phase in multi-family residential buildings, considering three different climatic contexts.

2. Methodology

2.1. Climatic Conditions

As the climatic conditions of the building location influence the performance of the water heating system, the study was carried out for three Brazilian cities with different climates: Curitiba, Brasília, and Belém.

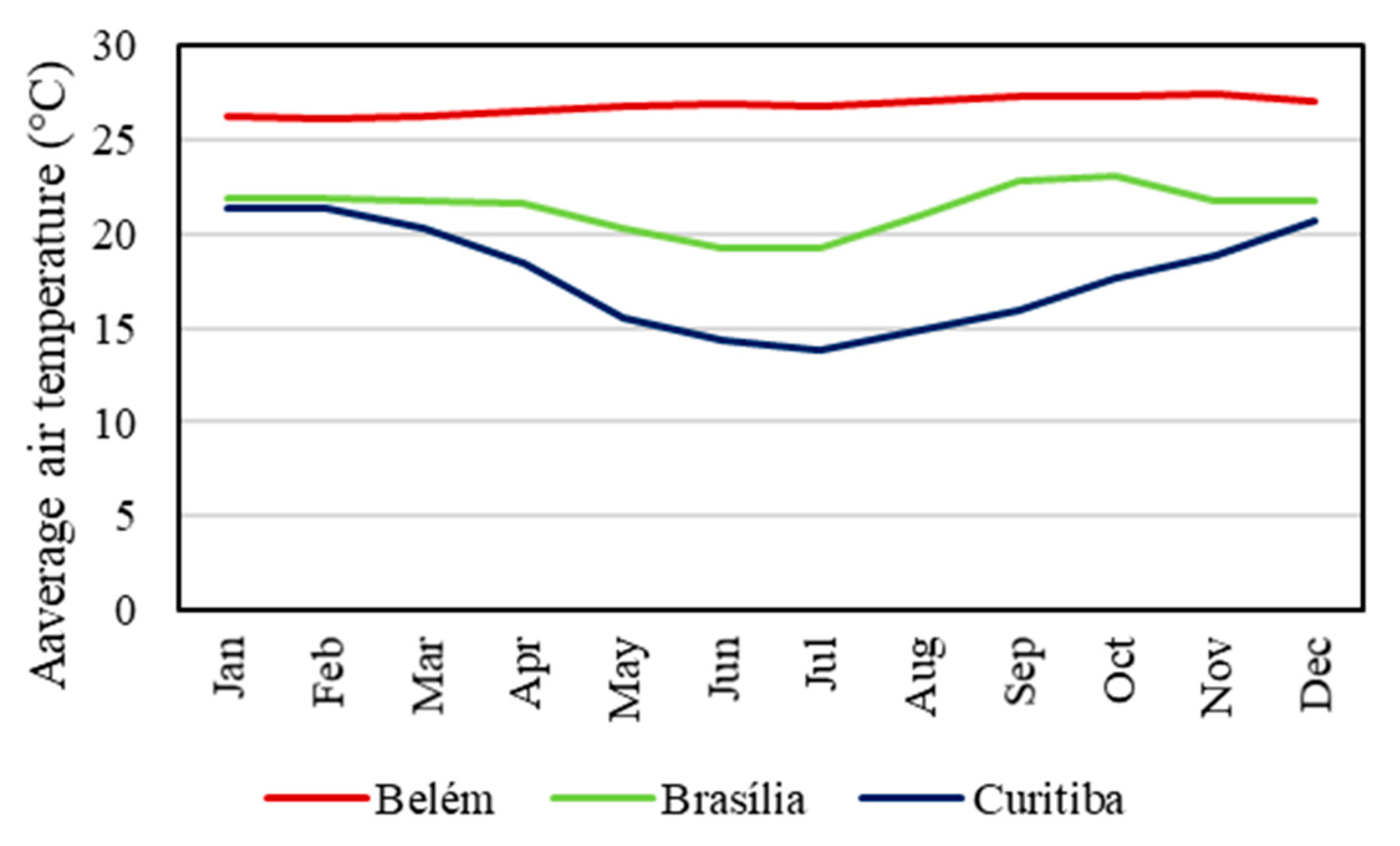

Figure 1 shows the average monthly temperatures of the cities analysed throughout the year.

Curitiba is the coldest city, with an annual average of 17.8 °C, and Belém is the hottest city, with an annual average of 26.8 °C. In Brasília, the annual average temperature is 21.4 °C. Curitiba has a latitude of −25°25′, Brasília’s is −15°46′, and Belém’s is −01°27′.

2.2. Characterisation of the Building and Water Heating Systems

Two multi-family buildings with four flats per floor were considered, one with four floors and another with 12 floors (

Figure A1 in

Appendix A). The envelope of the buildings consists of ceramic masonry walls with a mortar coating. Concrete slabs were used for the floors and roofs. In models with solar heating, the collectors are installed on the roof. The windows are composed of ordinary glass. Natural ventilation was modelled according to [

33]. Both have the same floor plan with one bathroom, two bedrooms, and an area of approximately 60 m

2. It was considered that each flat has three residents, and hot water is used only in showers. Thus, hot water was not analysed at other points, such as kitchen and bathroom taps, hygienic showers, or washing machines.

The water heating systems analysed were the most commonly used in multi-family dwellings in Brazil: an electric shower, an instantaneous gas heater in each flat, a central solar heating system with electric backup, and a central solar heating system with gas backup (

Table 1). The influence of thermal insulation was investigated in the centralised systems with instantaneous gas heaters and solar heating with gas backup. The sizing of the systems aimed to meet the determinations of the Technical Regulation of the Quality for the Energy Efficiency Level of Residential Buildings [

33] and Brazilian technical standards and was described in [

34]. For electric showers, a flow rate of 3 L/min was considered, according to existing models of electric showers. For the solar and gas heating systems, the type of shower used has a flow rate of 12 L/min, according to Brazilian Standard NBR 5626 [

35].

Table A1 in

Appendix A shows the characteristics of the instantaneous individual systems (one heater per flat). These systems operate without a hot water tank.

Solar heating was considered a collective system that serves all flats, sized to meet 70% of the annual demand, which is the minimum solar fraction to obtain a high-efficiency level according to [

33]. For solar heaters with electric backup, an electric heating element was considered inside the hot water tank, the power of which corresponds to the boiler’s available power. For the solar heater with gas backup, the solar heating and the collective gas heaters were sized independently. The gas system was sized to meet 100% of the demand, as it is required to provide sufficient hot water on cloudy days.

Table A2 in

Appendix A presents the characteristics of the gas central heating system adopted.

Table A3 in

Appendix A shows the characteristics of the solar heating system of the four-storey building. For the system with electric heating element in the water tank, the power of the tank model adopted is 10,000 W.

The data used in the design for the 12-storey building is shown in

Table A4 (

Appendix A). Although the number of inhabitants is three times greater than in the four-storey building, the calculated collector area is approximately 2.3 times greater because the occupancy factor for calculating daily hot water consumption varies according to the number of flats. The electric heating element of the tank models adopted is 15,000 W.

2.3. Computer Simulations

Computer simulations over one year were carried out in EnergyPlus software, version 8.2, to analyse the energy consumption of the systems. The showers were modelled with the WaterUse:Equipment object. The inputs included shower temperatures, pattern schedules, and the shower flow rate. The showers were inserted into the model circuit using the WaterUse:Connections object for each floor, with each set containing four showers.

The desired hot water temperatures at the consumption points are shown in

Table 2. Shower temperatures (hot water) were lower in summer and higher in winter. The monthly cold water temperature was considered equal to the average monthly air temperature minus 2 °C, according to [

33]. Regarding the use pattern of showers, one shower per day per resident lasting 10 min was considered. In instantaneous individual heating systems, the cold and hot water temperatures are fixed since the shower time does not influence consumption. Thus, three showers were considered during the morning period for the gas heater and electric shower systems. For central solar heating, the showers were distributed among the flats, considering some flats with a shower in the morning and others in the evening so that, on all floors, showers occur in all periods.

To simulate the instantaneous devices (electric showers and instantaneous gas heaters), the WaterHeater:Mixed object was used. The tank volume field was considered the internal volume of the heater, as there is no storage. The heater control type was modulated, in which the power of the heaters varies between the maximum and minimum capacities.

The solar heating system simulation model consists of solar collectors, hot water tanks, and an auxiliary heating system. The objects

SolarCollector:FlatPlate:Water and

SolarCollectorPerformance:FlatPlate were used to define the collectors. Collector models available in EnergyPlus with an optical efficiency factor and overall loss coefficient close to those of the collectors sized (obtained from [

36]) were used.

Table A5 in

Appendix A shows the coefficients of the efficiency equation. The collectors’ area, position, inclination, and orientation were modelled as a shading element.

In these systems, the storage volume was divided into two tanks. The second tank has supplementary heating (a tank with an electric heating element or connected to the gas heaters). The tank for hot water storage was designed as a vertical tank, providing higher efficiency through stratification. The setpoint temperatures of the tanks are described in

Table 3. Since the thermal losses in collective systems are more significant than for individual systems, the adopted setpoint temperatures are higher than the shower temperatures to meet the desired temperature on all floors.

For electric showers, the Pipe:Adiabatic object was used to model the pipes since there are no hot water pipes (i.e., the water is heated directly in the shower). In central systems, the Pipe:Indoor object was used. This object simulates the heat transfer between the pipes and the thermal zone in which each section of pipe is located.

Adaptations of the water heating systems geometry were carried out to make them compatible with the EnergyPlus resources since the programme version used does not allow for the design of complex water heating systems with identical configurations to those of the actual buildings. The systems were sized as open circuits. However, the programme simulates only systems with closed circuits.

2.4. Primary Energy Consumption

The annual primary energy consumption was used to compare the efficiency of systems using different energy sources. The primary energy consumption is given by multiplying the annual final energy consumption (obtained from the simulations) by the conversion factor from final to primary energy for the energy source analysed, according to Equation (1). For liquefied petroleum gas, a conversion factor of 1.10 was adopted [

37]. A factor of 1.46 was considered for electricity, calculated using the same method as [

37] but using data published by [

38]:

where PE is the annual primary energy consumption (kWh), FE is the annual final energy consumption (kWh), and CF is the primary energy conversion factor (dimensionless).

2.5. Thermal Losses in the Pipes

The influence of thermal insulation in the piping for hot water distribution was analysed through simulations considering piping with and without insulation for the instantaneous gas system and the central solar system with gas backup. For the systems with an instantaneous gas heater, for each flat, the simulation model considers the pipes from the heater (located in the laundry) to the shower (in the bathroom). For the solar system, the collectors and tanks are installed on the roof. In these cases, the pipes between the tank and the shower were considered, i.e., the vertical pipe that distributes water from the tank to the floors and the horizontal pipes in each flat.

For hot water distribution, polypropylene random copolymer (PP-R) pipes with and without thermal insulation were considered. The insulating material used was expanded polyethylene with 1-cm thickness and thermal conductivity of 0.035 W/mK, meeting the requirements of [

33]. It was considered that the pipes and heaters exchange heat with the thermal zones of the simulation model. The piping of the primary solar heating circuit (between the collectors and the tank) is made of copper with the same thermal insulation used in the secondary system. The insulation of these pipes was kept in all simulated cases due to the high thermal conductivity of copper and because these pipes are located in an external environment.

Water temperatures at various points in the circuit were obtained in the simulations to analyse the influence of thermal insulation on the performance of the system. The temperatures at the pipe outlet of the systems with and without insulation were compared, and for the central system, the temperatures at the pipe outlet on the first and last floors were analysed.

For the system with an instantaneous gas heater, the variation in the water temperature at the end point of the pipe throughout the day was checked to determine whether the insulation was sufficient to maintain the water at the desired temperature and avoid the disposal of cold water until the arrival of hot water when the shower is turned on. Temperatures at the time of showering were also compared to verify the reduction in shower water temperature caused by thermal losses in the pipes and the impact of thermal insulation.